Patents

Literature

49results about How to "Guaranteed passivation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

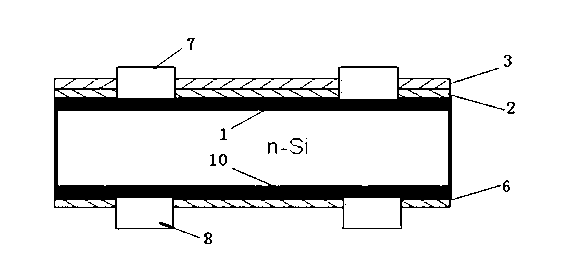

Low-cost n-type dual-side solar battery and preparation method thereof

ActiveCN103077975AReduce compound rateSimple manufacturing processFinal product manufactureSemiconductor devicesManufacturing cost reductionBack surface field

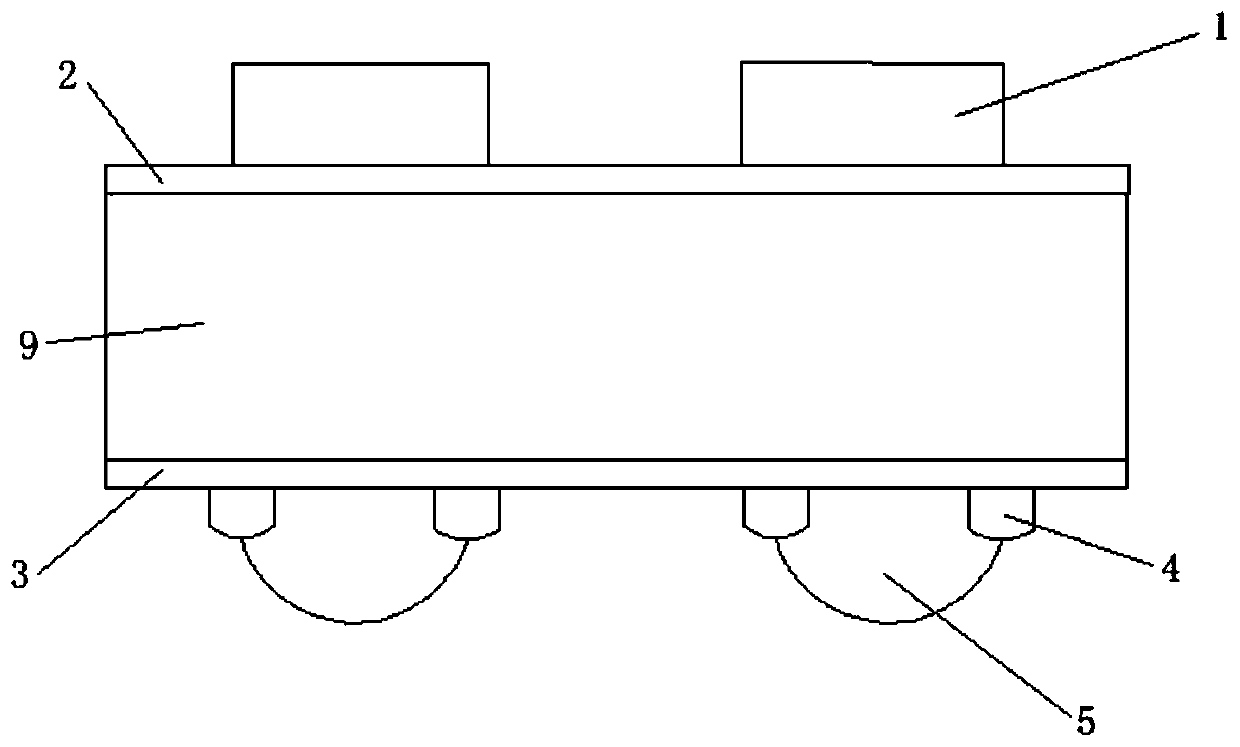

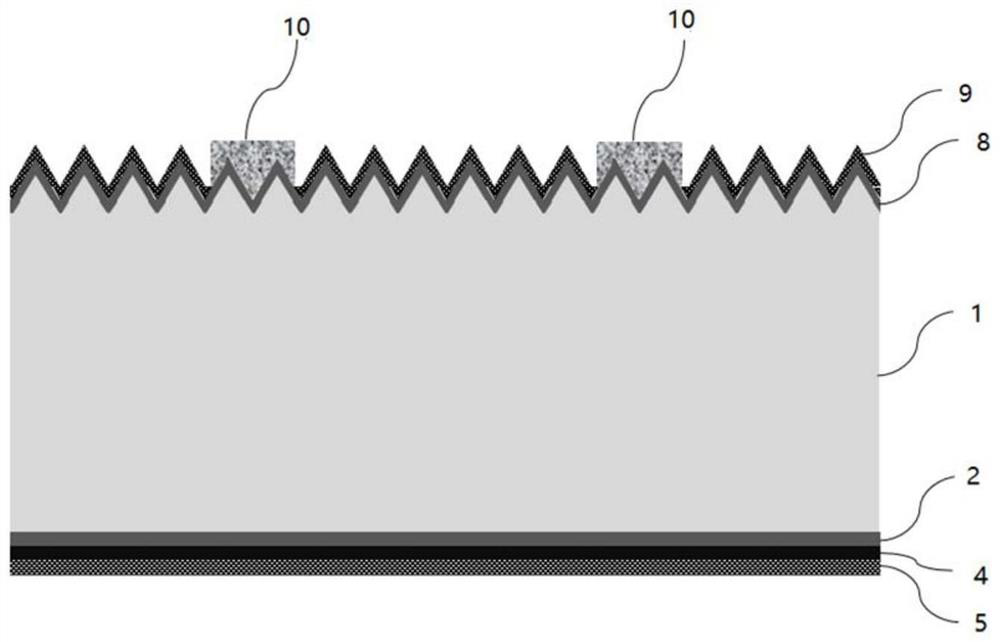

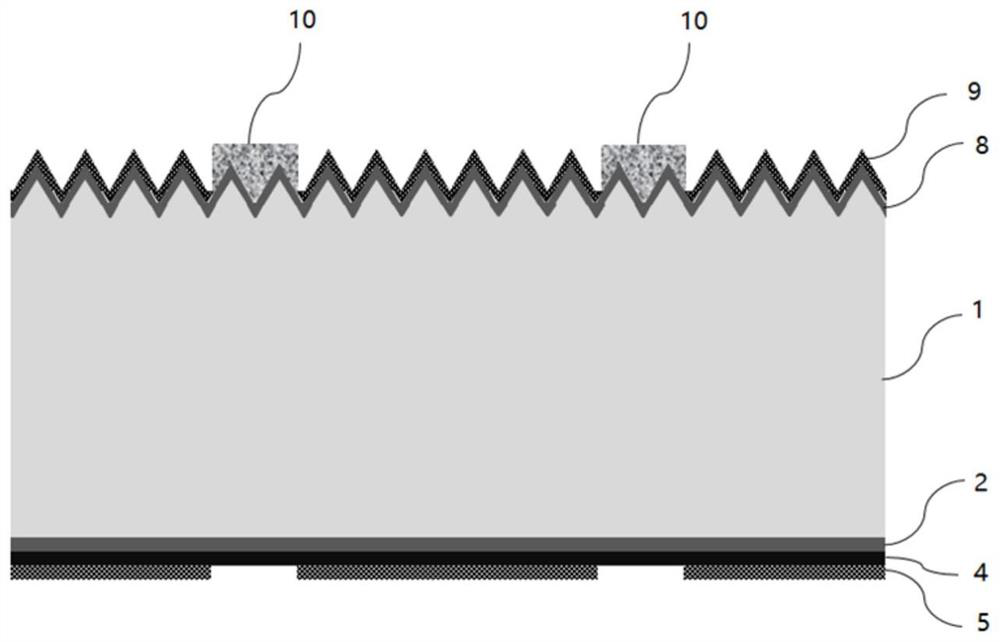

The invention discloses a low-cost n-type dual-side solar battery. The front surface of the solar battery is provided with a boron emitter formed by diffusing boron; a passivation layer and an antireflection layer are deposited on the boron emitter; a back electrode contact position on the back surface of the solar battery is a local phosphorus back surface field, and the rest is a non-doped area; a passivation layer is deposited on the non-doped area; the front surface of the non-doped area is provided with a metal front electrode; and the back surface of the non-doped area is provided with a metal back electrode. The invention further discloses a preparation method of the low-cost n-type dual-side solar battery. Compared with the prior art, the low-cost n-type dual-side solar battery has the beneficial effects that a local n<+>-doped area is formed by using a laser-doped phosphorus-containing film or a coated phosphorus source; and meanwhile, a passivation effect is kept, a front surface field and a back surface field can be formed simultaneously without secondary high-temperature phosphorus diffusion or other masking processes, the manufacturing process of the dual-size n-type solar battery is simplified, and the manufacturing cost is lowered.

Owner:江苏润阳光伏科技有限公司

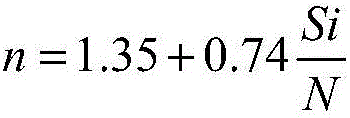

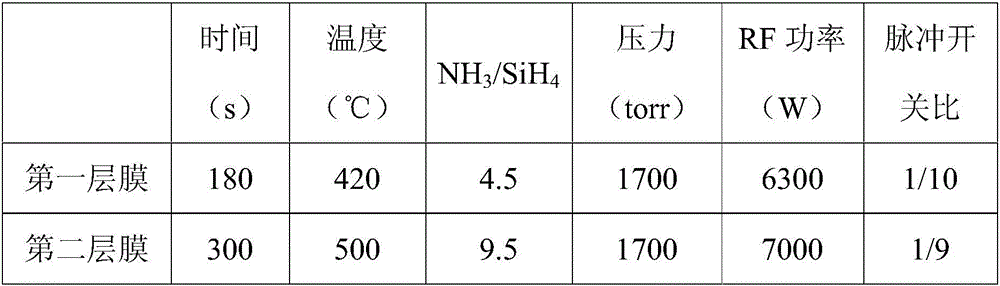

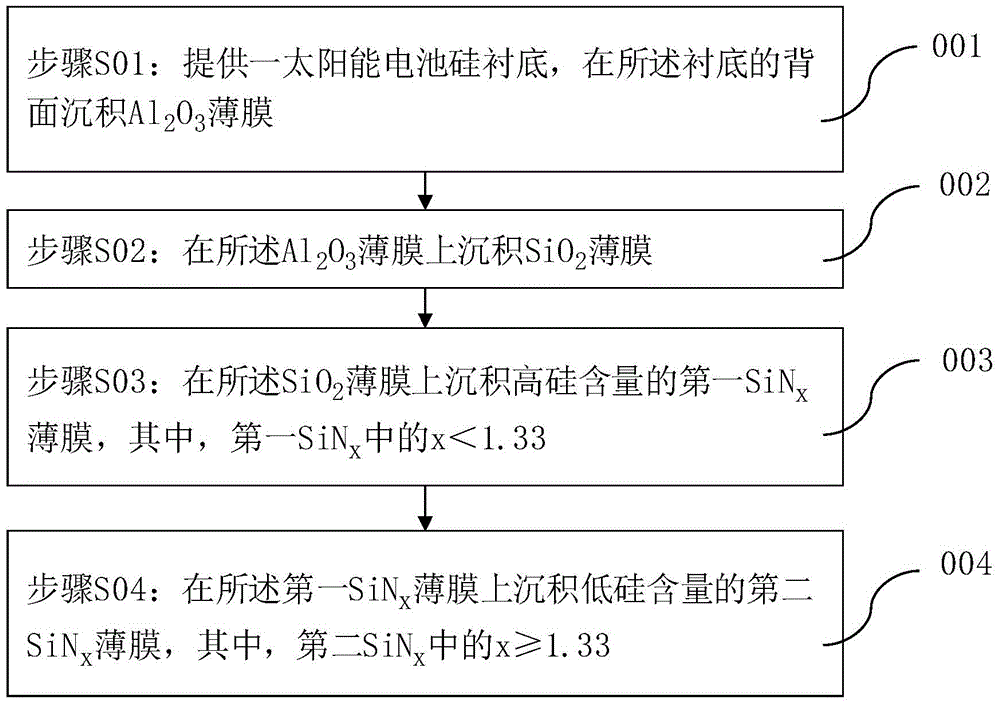

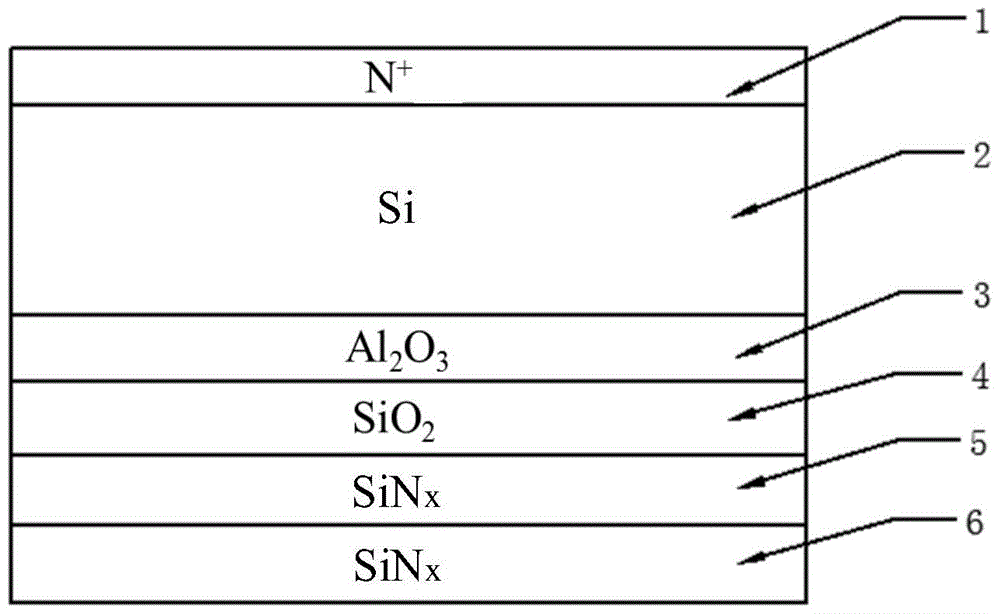

Tubular type silicon nitride PECVD technology

InactiveCN106299025AReduce deposition rateGood film qualityFinal product manufactureSemiconductor/solid-state device manufacturingSilicon nitrideSolar battery

The invention discloses a tubular type silicon nitride PECVD technology. Film plating is carried out twice, the temperature used for plating a first film is lower than the temperature used for plating a second film. The deposition technology provided by the invention improves the passivation anti-reflection effect of a tubular type PECVD silicon nitride film for a crystal silicon solar battery and reduces technology time.

Owner:成都富捷科技有限公司

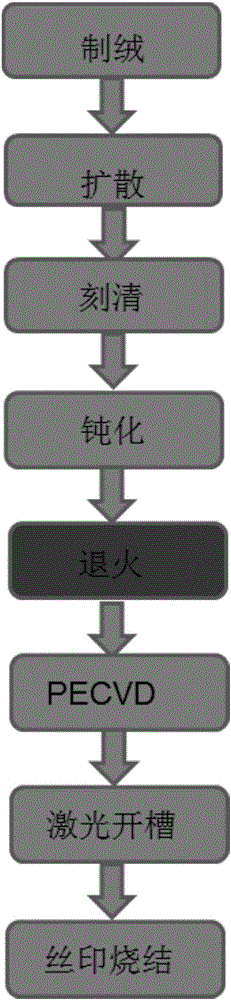

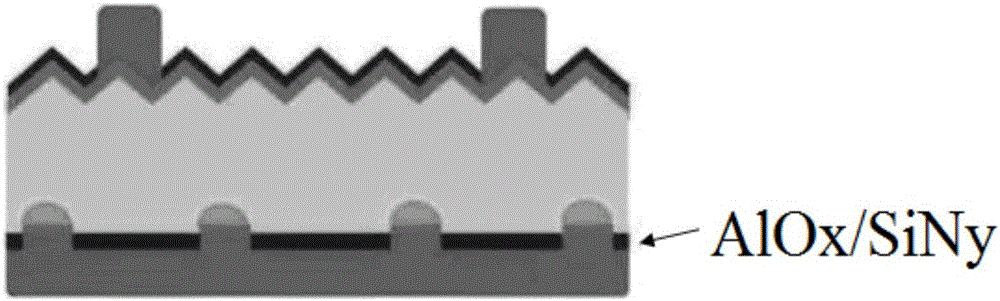

Annealing treatment process for PERC battery

InactiveCN106486568AGuaranteed passivation effectExtend your lifeFinal product manufacturePhotovoltaic energy generationAdverse effectAluminium oxide

The invention discloses an annealing treatment process for a PERC battery. The annealing treatment process comprises the following steps of preparing an aluminium oxide thin film on the back surface of a silicon wafer, and performing annealing treatment on the silicon wafer. By performing the annealing treatment on the aluminium oxide thin film in the PERC battery, the interface recombination is lowered, the minority carrier lifetime of the silicon wafer is prolonged, and the adverse effect on the passivation effect of the aluminium oxide thin film in the existing PERC battery preparation process is overcome; and meanwhile, the annealed silicon wafer is prepared into the PERC battery, and the average value of the photoelectric conversion efficiency reaches 21.0%; and compared with the conventional preparation process (without annealing treatment), the photoelectric conversion efficiency is improved by 0.2%, and relatively good electrical performance is achieved.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

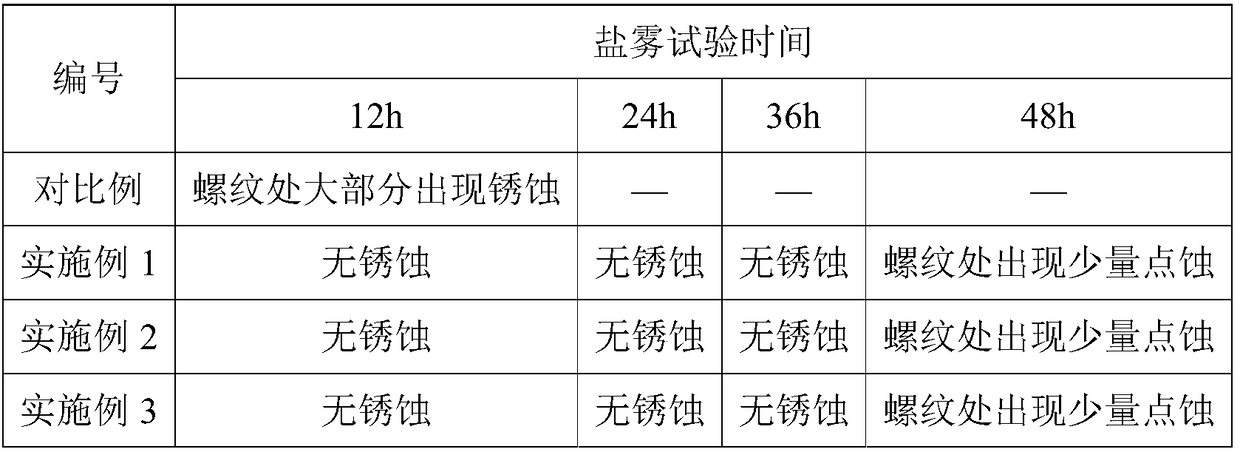

Method for improving corrosion resistance of 1Cr17Ni2 martensitic stainless steel fastener

InactiveCN109487326AHigh surface finishImprove uniform densityMetallic material coating processesMartensitic stainless steelFastener

The invention relates to a method for improving corrosion resistance of a 1Cr17Ni2 martensitic stainless steel fastener. The method comprises the following steps that 1) electric polishing is conducted, the 1Cr17Ni2 martensitic stainless steel fastener is immersed in an electric polishing solution for electric polishing treatment, and cleaning is conducted for later use after the treatment; 2) passivation is conducted, the fastener after the electric polishing treatment is immersed into a passivation solution for passivation treatment, and cleaning and drying are conducted for later use afterthe treatment; and 3) sealing is conducted, the fastener after the passivation treatment is immersed in a sealed liquid for sealing treatment. According to the method, the 1Cr17Ni2 martensitic stainless steel fastener is subjected to the electric polishing treatment, the passivation treatment and the sealing treatment, so that the surface smoothness of the fastener is effectively improved, the uniformity and compactness of a passivation film layer are improved, the defects of a traditional process are eliminated, the salt mist resistance test time of the fastener reaches 48 hours or above, andthe corrosion resistance of the corresponding fastener is remarkably improved.

Owner:河南航天精工制造有限公司

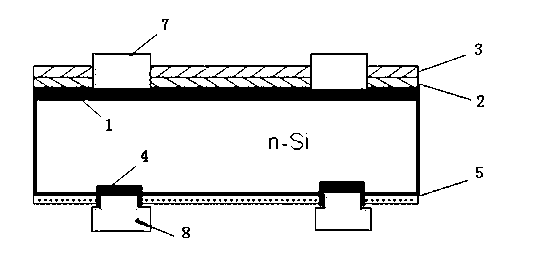

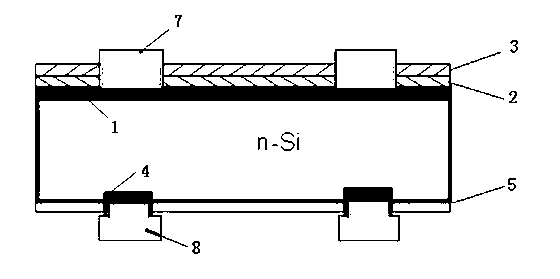

Preparation method for back-contact crystalline silicon solar cell based on plasma etching technology

InactiveCN102593248AIncrease productivityEase of industrial productionFinal product manufactureSemiconductor devicesMature technologyBack surface field

The invention discloses a preparation method for a back-contact crystalline silicon solar cell based on plasma etching technology, which comprises the steps of forming a silicon dioxide layer and a silicon nitride layer on a silicon wafer substrate by heat oxidation, thereby forming a double-layer passivating composite membrane; on a back screen mesh of the silicon wafer substrate, printing an aluminum slurry layer which is providing with hollow array patterns and no frit and sintering; placing a silicon wafer to a plasma etching device, and removing silicon nitride on the hollow patterns on the back surface of the silicon wafer substrate by plasmas; printing an aluminum slurry layer with frit on a back screen mesh of the silicon wafer; and sintering and burning through the thin silicon dioxide layer on the back surface by drying so as to form a point contact electrode, or a line contact electrode on the back surface and a local aluminum back-surface-field. The method adopts the mature technology of screen mesh printing, plasma etching and the like, the preparation of high-efficiency back-contact cell is completed, the investment cost is low, the market prospect is wide; and the cell can be produced in an industrialization way.

Owner:SUN YAT SEN UNIV

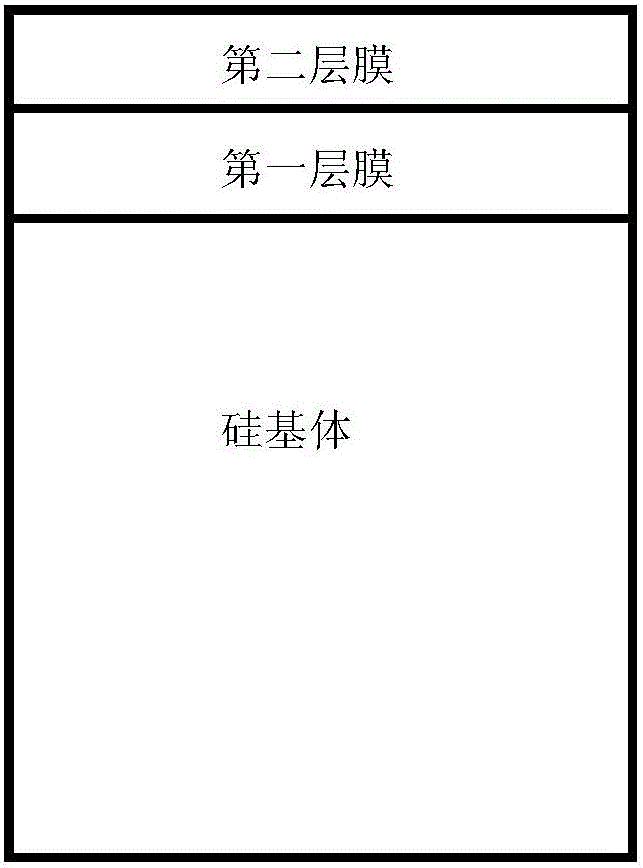

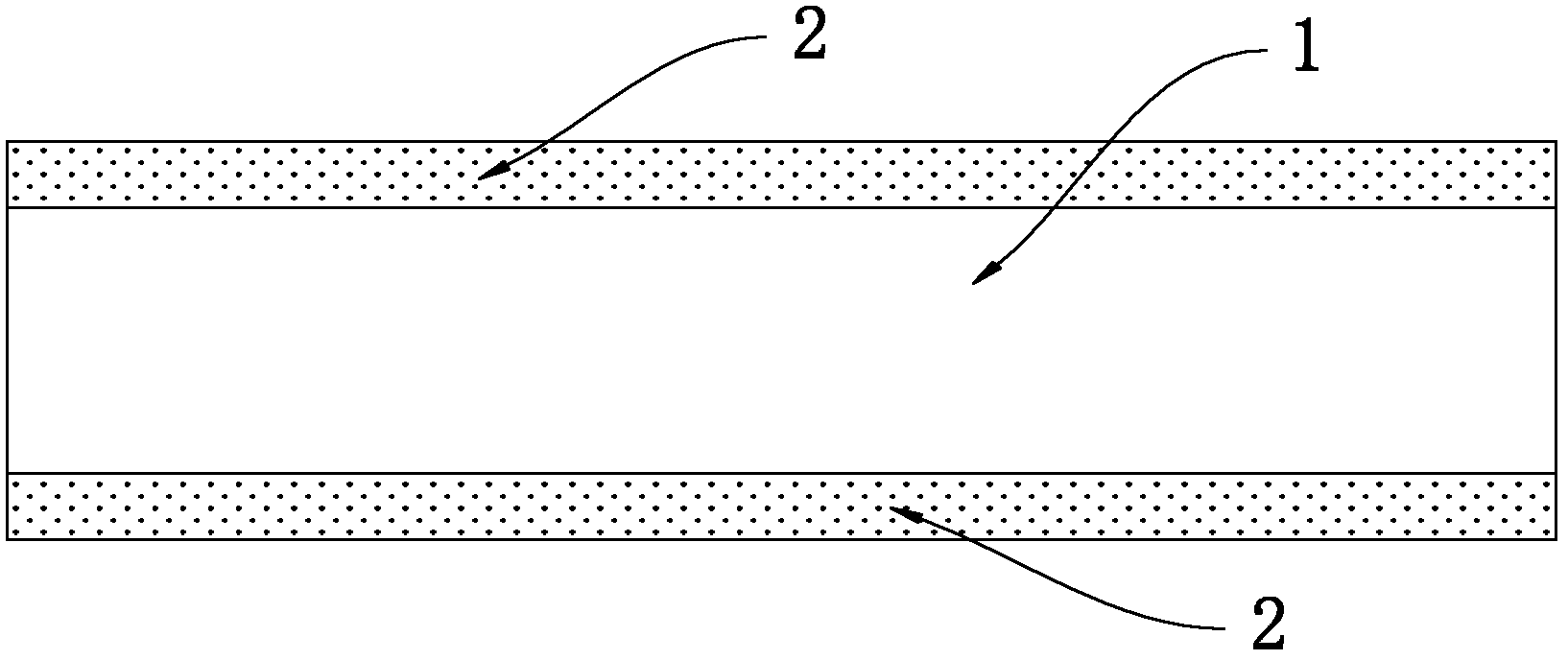

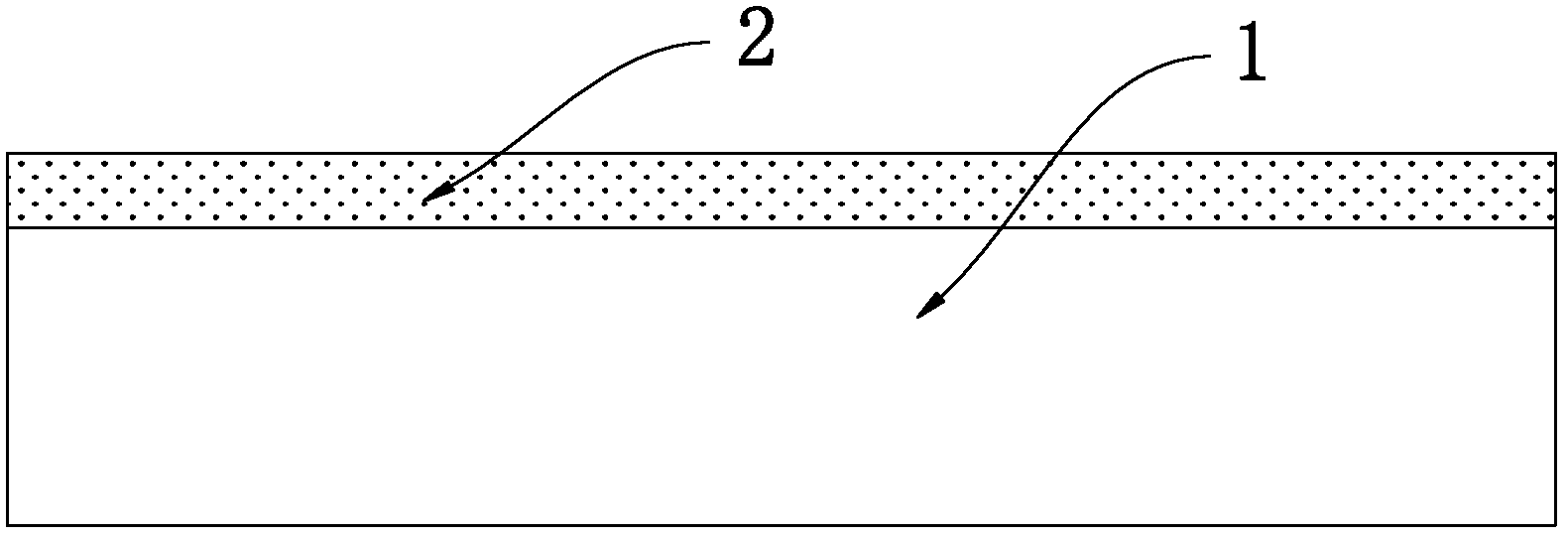

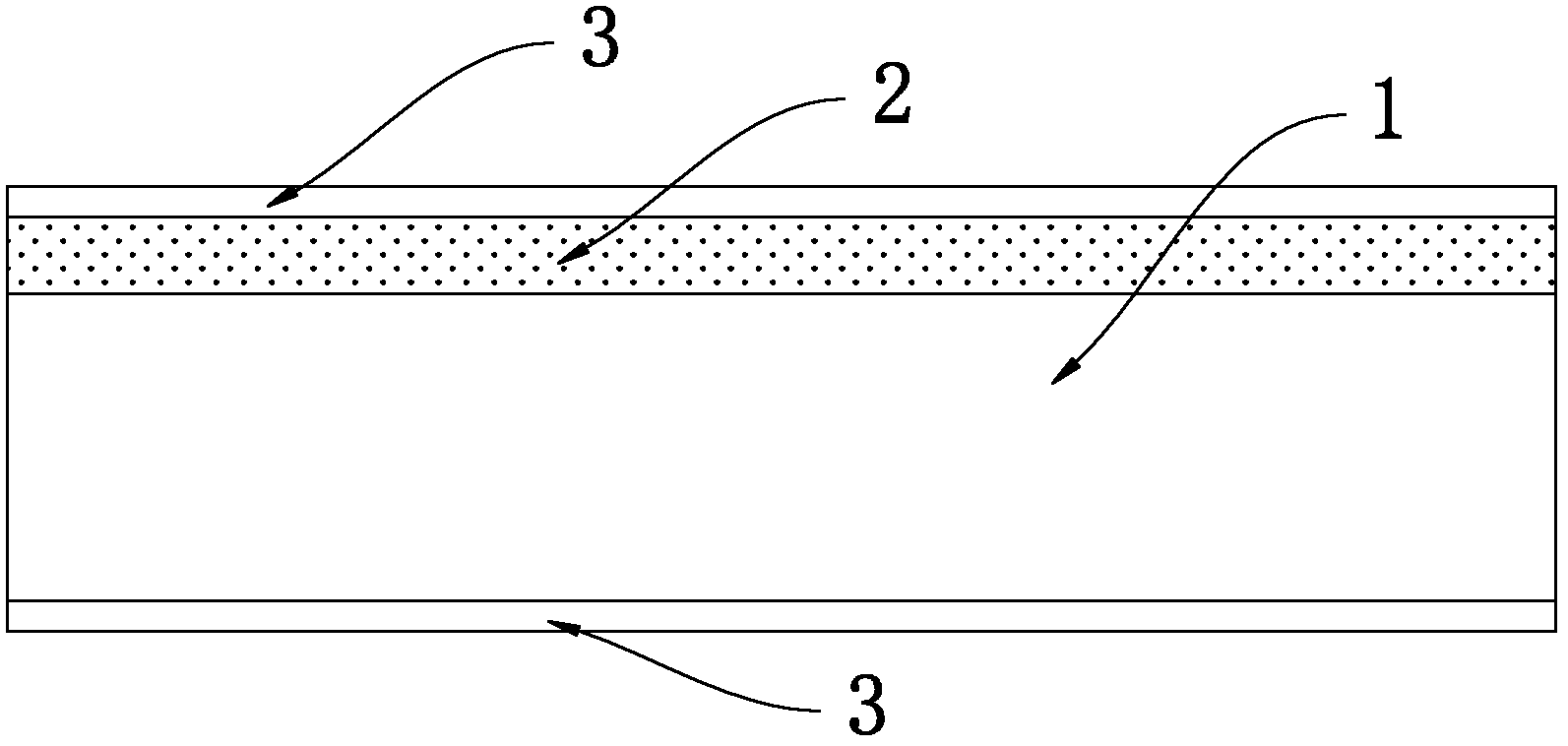

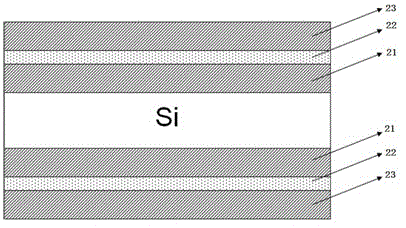

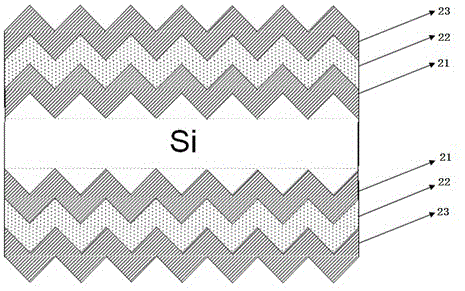

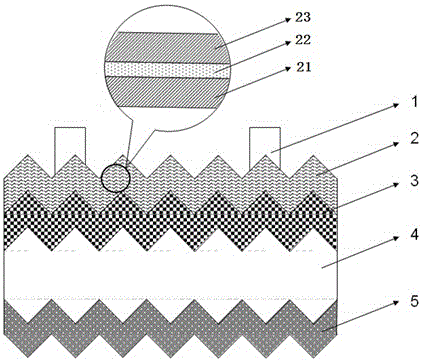

Crystalline silicon solar cell surface passivation layer having good conductive performance and passivation method

ActiveCN104992988ALow resistivityIncrease the carrier concentrationFinal product manufacturePhotovoltaic energy generationCrystallographyComposite film

The invention discloses a crystalline silicon solar cell surface passivation layer having good conductive performance. The surface passivation layer is a composite film lamination passivation layer which is disposed on the front surface and / or the back surface of a crystalline silicon solar cell and which has a dielectric-metal-dielectric structure, and the composite film lamination passivation layer comprises a first-layer medium film, a second-layer medium film and a metal film intermediate layer disposed between the first-layer medium film and the second-layer medium film. The surface passivation layer has the dielectric-metal-dielectric laminated structure and can achieve injection of current carriers into dielectrics, and the surface passivation layer has the good passivation effect and achieves a current transmission function of a surface passivation structure at the same time. The invention further discloses a method for achieving crystalline silicon solar cell surface passivation by utilizing the surface passivation layer enhancing conductivity.

Owner:江苏润阳世纪光伏科技有限公司

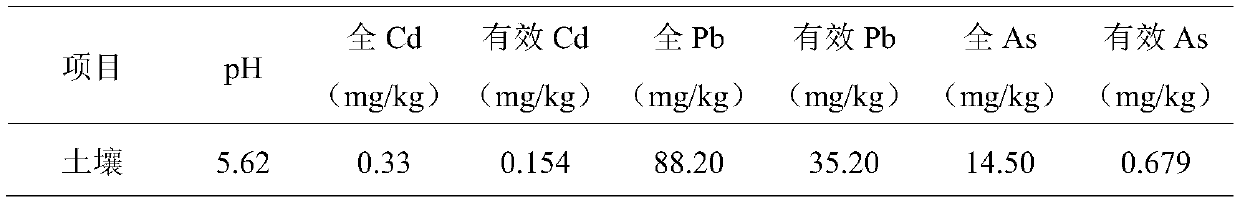

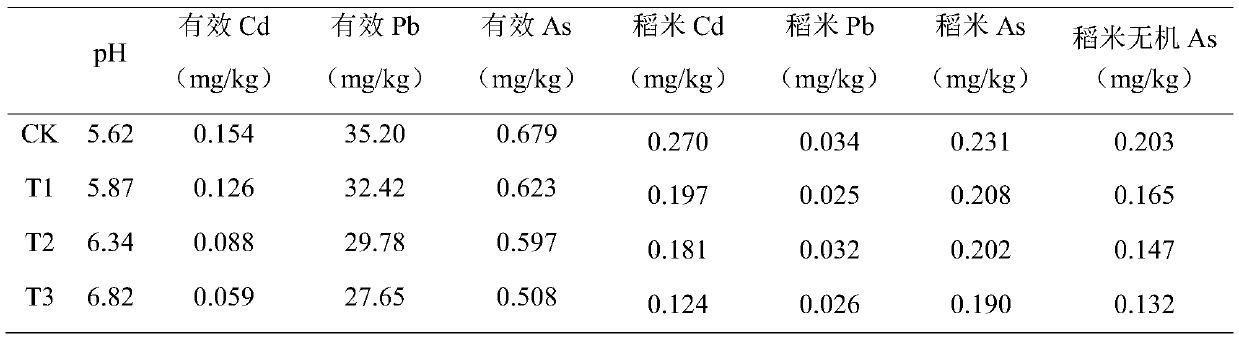

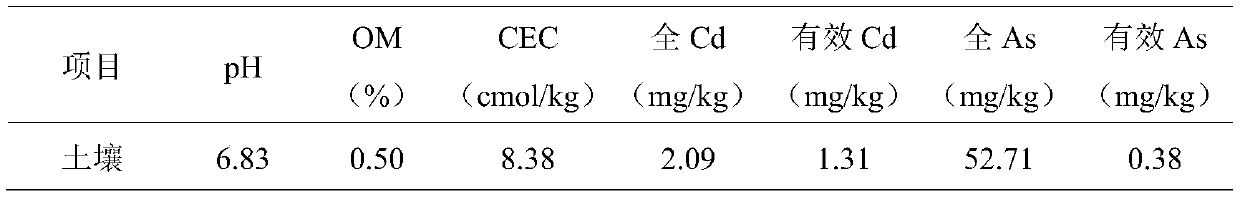

Slow-release repairing agent for treating cadmium-arsenic composite polluted rice field soil and preparation method thereof

ActiveCN111269722AImplement synchronous passivationOptimizing the ratio parametersAgriculture tools and machinesOther chemical processesSilicic acidPotassium silicate

The invention discloses a slow-release repairing agent for treating cadmium-arsenic combined pollution rice field soil and a preparation method thereof. The preparation method comprises the followingsteps: (1) fully and uniformly stirring calcium carbonate and calcium magnesium phosphate fertilizer and calcining under nitrogen protection, and obtaining a compound A after the calcined mixture is ground and smashed; (2) adding potassium silicate into water, fully stirring to dissolve potassium silicate, uniformly spraying the dissolved potassium silicate solution onto the surface of the iron powder, and then granulating on a granulator to obtain mixture granules B; (3) putting the compound A and the mixture granules B into the granulator, and gradually spraying pure water until the surfacelayers of the mixture granules B are uniformly coated with the compound A to form granules with the diameter of 3-5 mm; and (4) drying the particles obtained in the step (3) until the water content isless than or equal to 5% to obtain the slow-release repairing agent. The slow-release repairing agent can implement cadmium-arsenic synchronous passivation resistance control in the key growth periodof rice and is small in dosage and effectively reduces the cadmium-arsenic content of the rice and is remarkable and stable in effect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

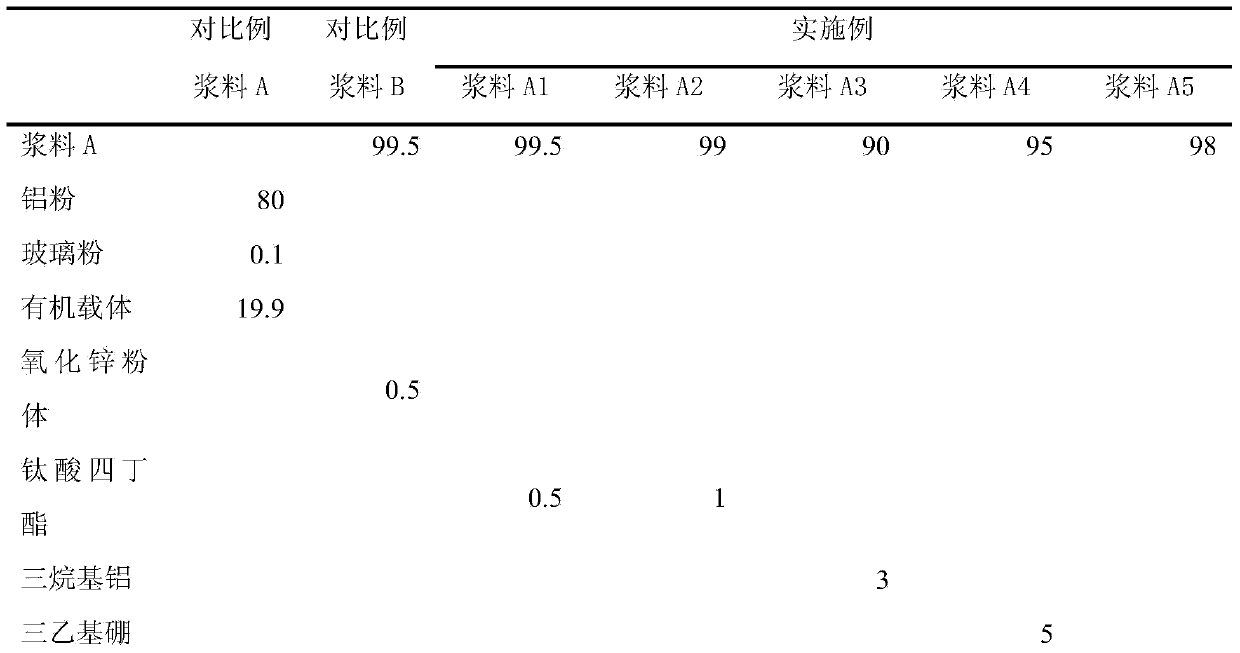

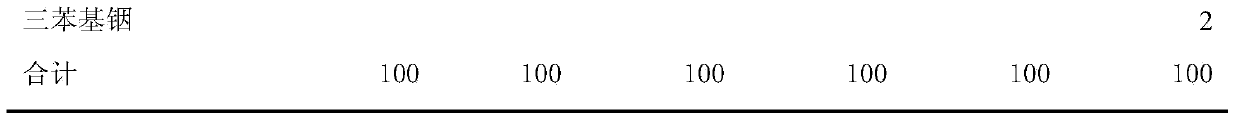

High-adhesion low-warpage crystalline silicon cell back side aluminum slurry

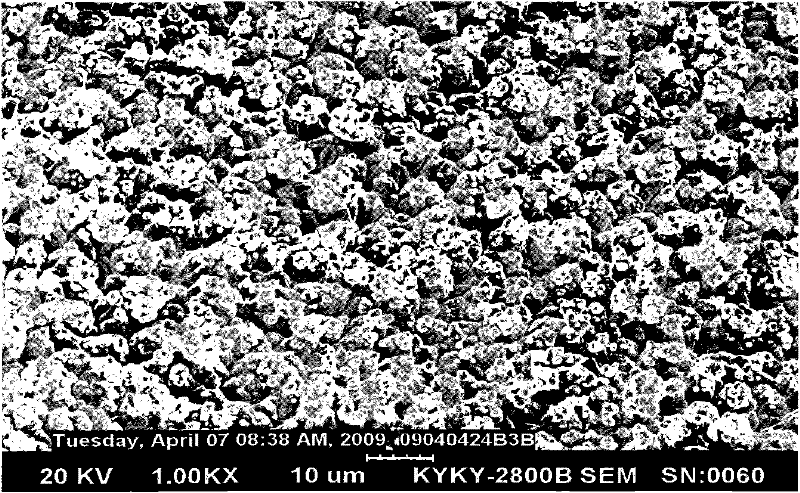

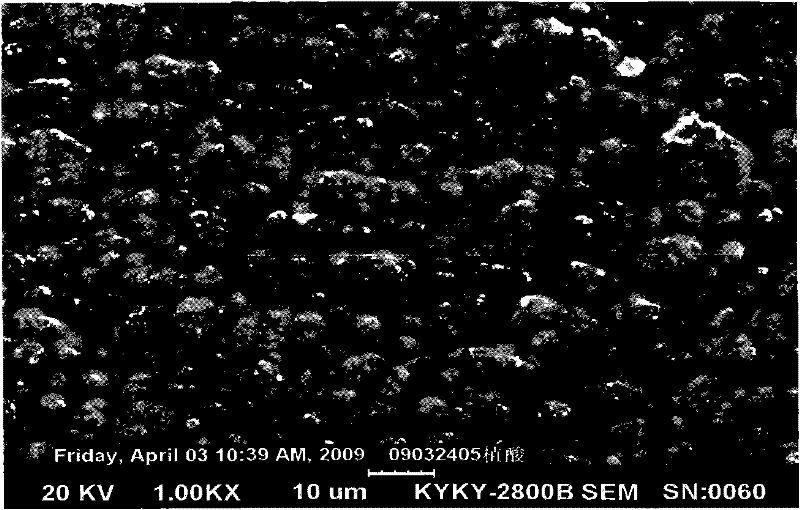

InactiveCN103745765ALow warpageGuaranteed back field adhesionNon-conductive material with dispersed conductive materialSemiconductor devicesDecompositionSlurry

The invention discloses a high-adhesion low-warpage crystalline silicon cell back side aluminum slurry. The aluminum slurry comprises, in percentage by weight, 60-80% of aluminum powder, 0.1-6% of glass powder, 15-35% of an organic carrier and 0.1 to 5% of an additive, wherein the additive is an organic matter containing a metal source. The additive, during a slurry processing or sintering process, is subjected to volatilization, decomposition and a reaction to generate metal oxides, nitrides and carbide particles which are in nanometer forms, have expansion coefficients smaller than 10*10-6 K, and have heat expansion coefficients close to the heat expansion coefficient of silicon, and nanometer particles are inlaid among aluminum powder particles in the aluminum slurry so that while back field adhesion and back field passivation are guaranteed, the low warpage of a solar cell back side aluminum slurry is realized.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

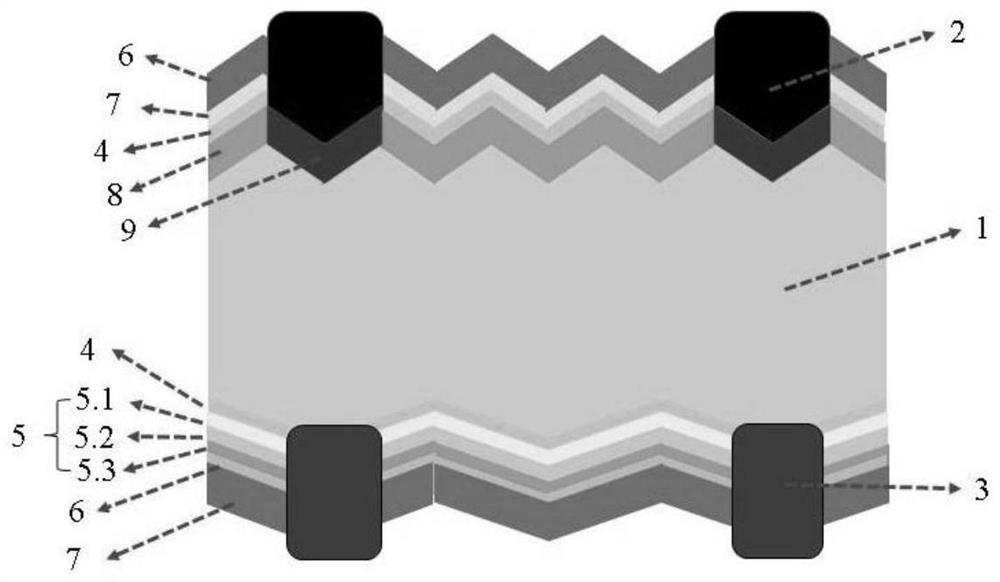

Efficient silicon heterojunction solar cell and preparation method thereof

The invention discloses an efficient silicon heterojunction solar cell and a preparation method thereof, and belongs to the technical field of solar cells. A thin SiO2 layer, a hydrogenated amorphous silicon oxycarbide thin film layer, a C-doped SiO2 layer, an amorphous silicon doped N-type layer, a TCO conductive layer and an electrode are sequentially arranged on the front surface of an N-type crystal silicon wafer of the battery; a thin SiO2 layer, a hydrogenated amorphous silicon oxycarbide thin film layer, a C-doped SiO2 layer, an amorphous silicon doped P-type layer, a TCO conductive layer and an electrode are sequentially arranged on the back surface of the substrate; and the amorphous silicon doped P-type layer comprises a light B-doped amorphous silicon layer and a heavy B-doped amorphous silicon layer. According to the heterojunction solar cell with the hydrogenated amorphous carbon silicon oxide thin film as the intrinsic passivation layer, the excellent passivation effect on the crystalline silicon surface is achieved, and interface carrier recombination is reduced; and meanwhile, an improved double-diffusion B process is adopted, so that reduction of forbidden bandwidth and unnecessary passive film doping caused by diffusion of B atoms to the intrinsic amorphous silicon layer during B2H6 doping are prevented, and the conversion efficiency of the silicon heterojunction battery is improved.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +4

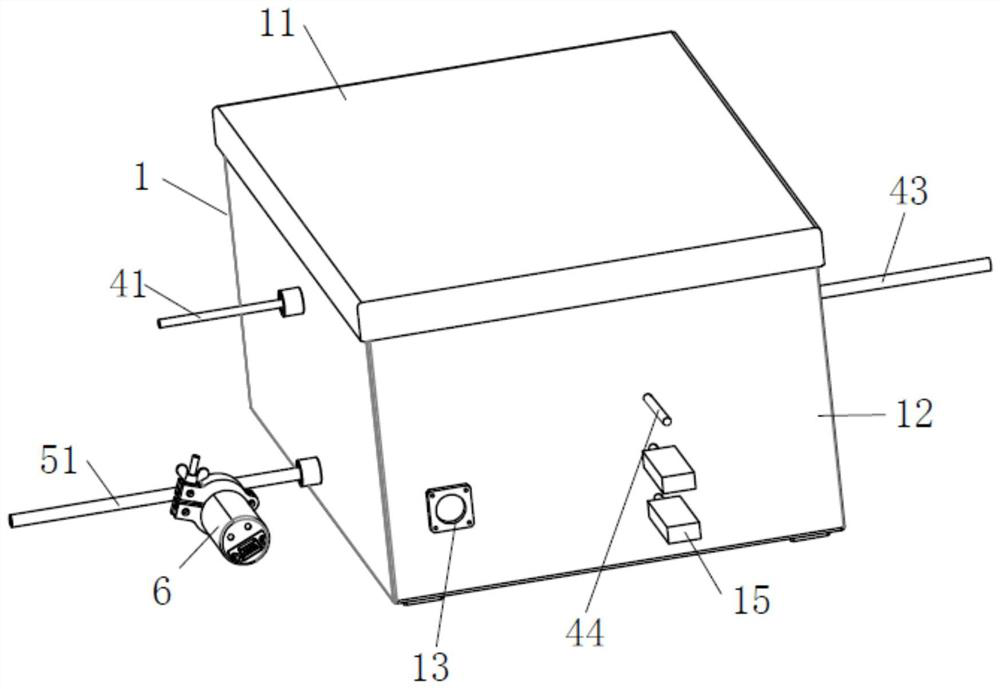

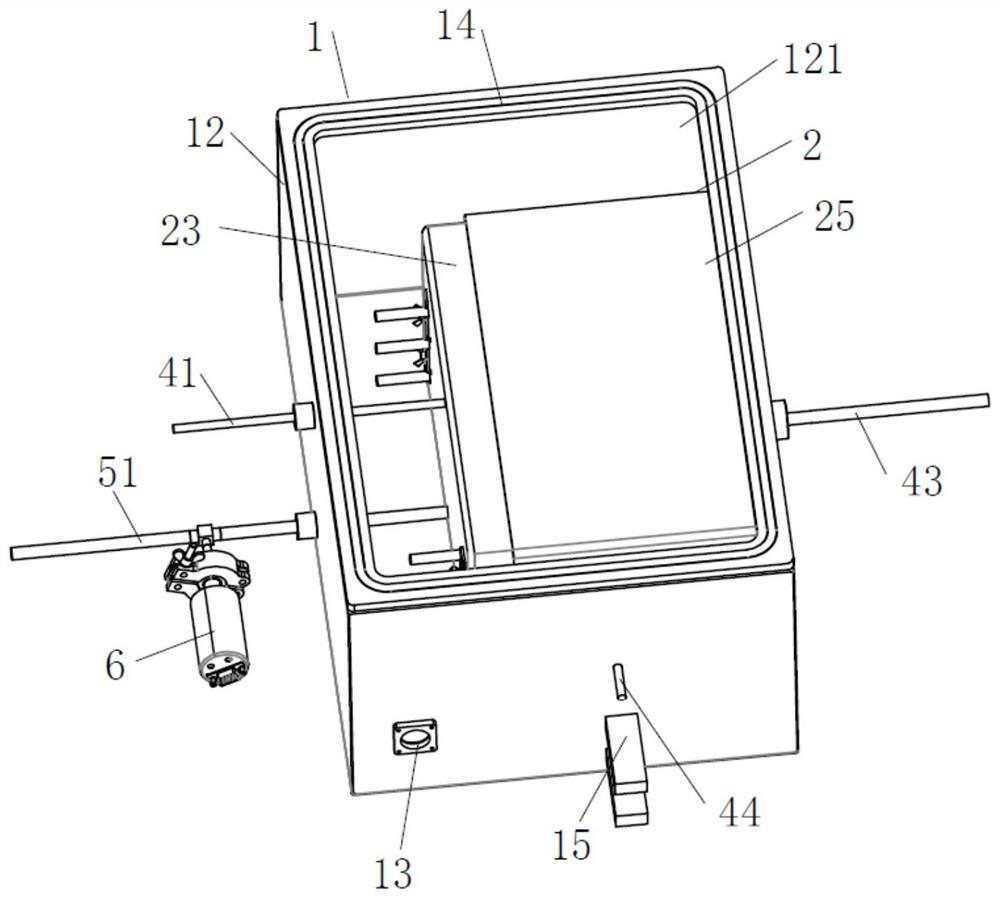

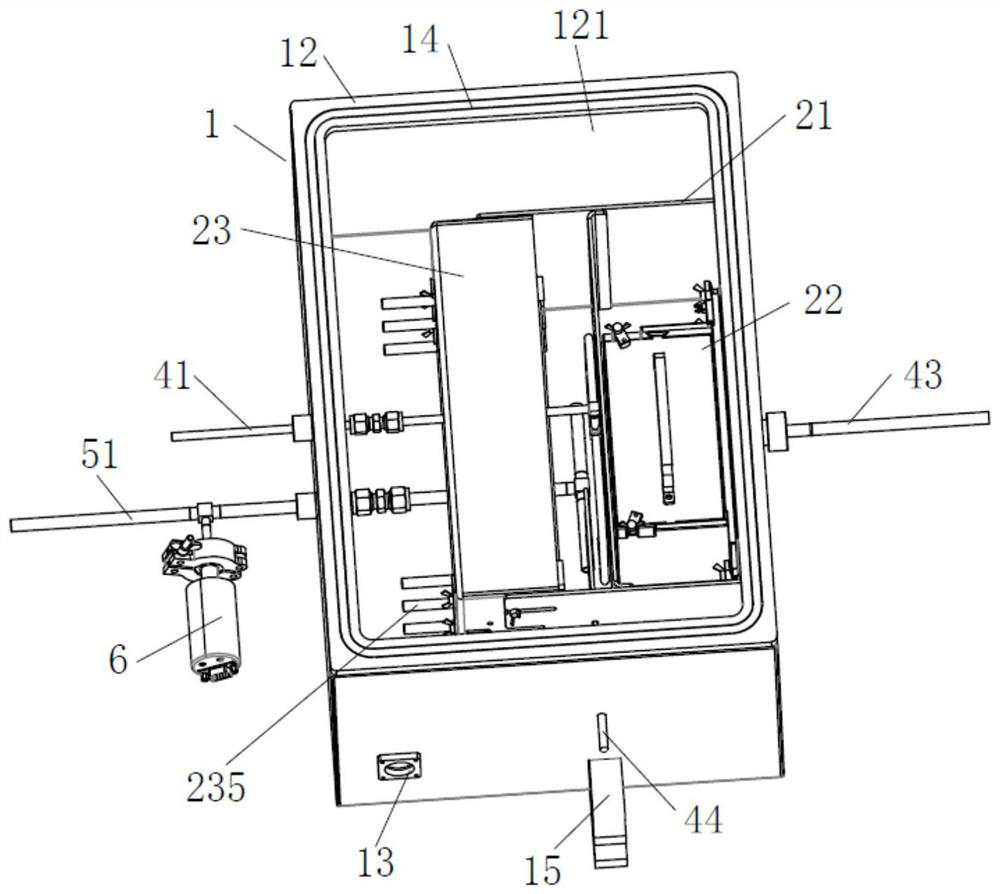

Novel passivation device for surface treatment for metal casting

InactiveCN112941502AReasonable structureGuaranteed passivation effectMetallic material coating processesElectric machineryDrive motor

The invention discloses a novel passivation device for surface treatment for a metal casting, and relates to the field of passivation for metal castings. The novel passivation device for surface treatment for the metal casting comprises a treatment table, wherein a liquid storage box is fixedly installed at the top of the treatment table, a liquid extraction pump is fixedly installed at one side of the liquid storage box, and a liquid extraction pipe is fixedly installed at a liquid extraction port of the liquid extraction pump; and one end of the liquid extraction pipe extends into the liquid storage box, a hose is fixedly installed at a liquid outlet port of the liquid extraction pump, a communicating pipe is fixedly installed at one end of the hose, and a plurality of spraying heads are uniformly and fixedly installed at the bottom of the communicating pipe. The novel passivation device for surface treatment for the metal casting is reasonable in structure, when a driving motor and the liquid extraction pump are started, passivation liquid can be evenly sprayed to the surface of the metal casting, and the concentration of the sprayed passivation liquid cannot be reduced, so that the passivation effect of the device is ensured; and when a circulating pump is started, waste liquid can be pumped out and purified and then flows into the liquid storage box through a liquid outlet pipe, so that recycling for the waste liquid is realized, the environment is not polluted, and resources are saved.

Owner:温州米树新材料科技有限公司

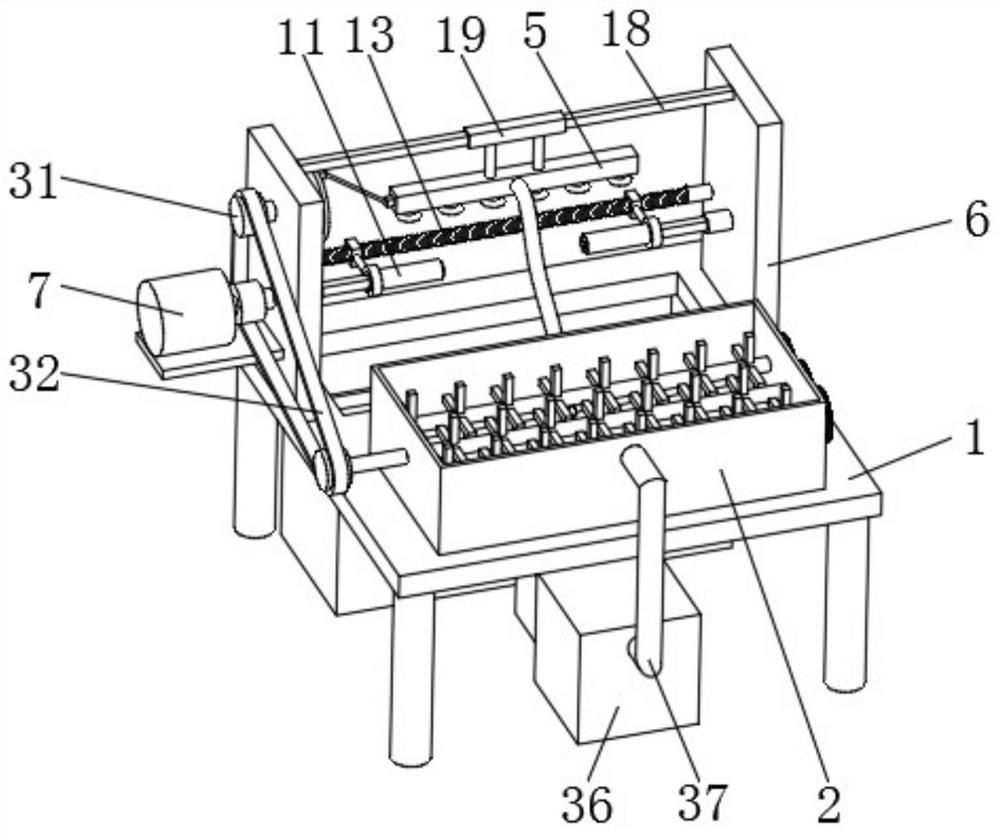

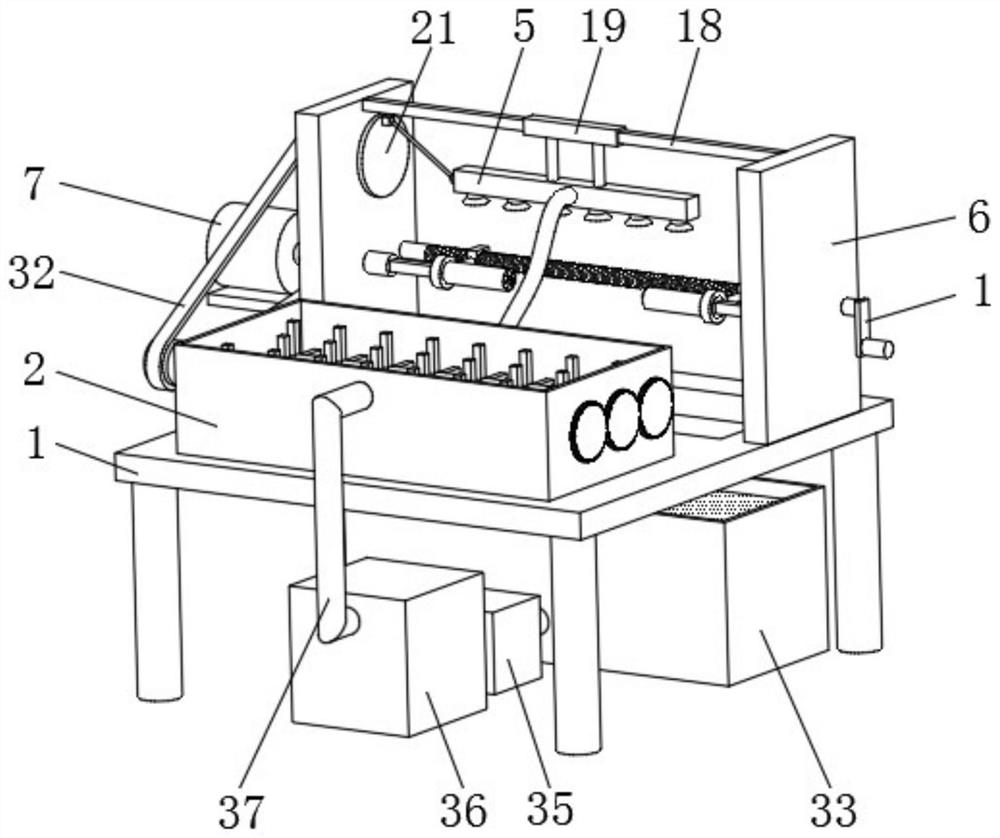

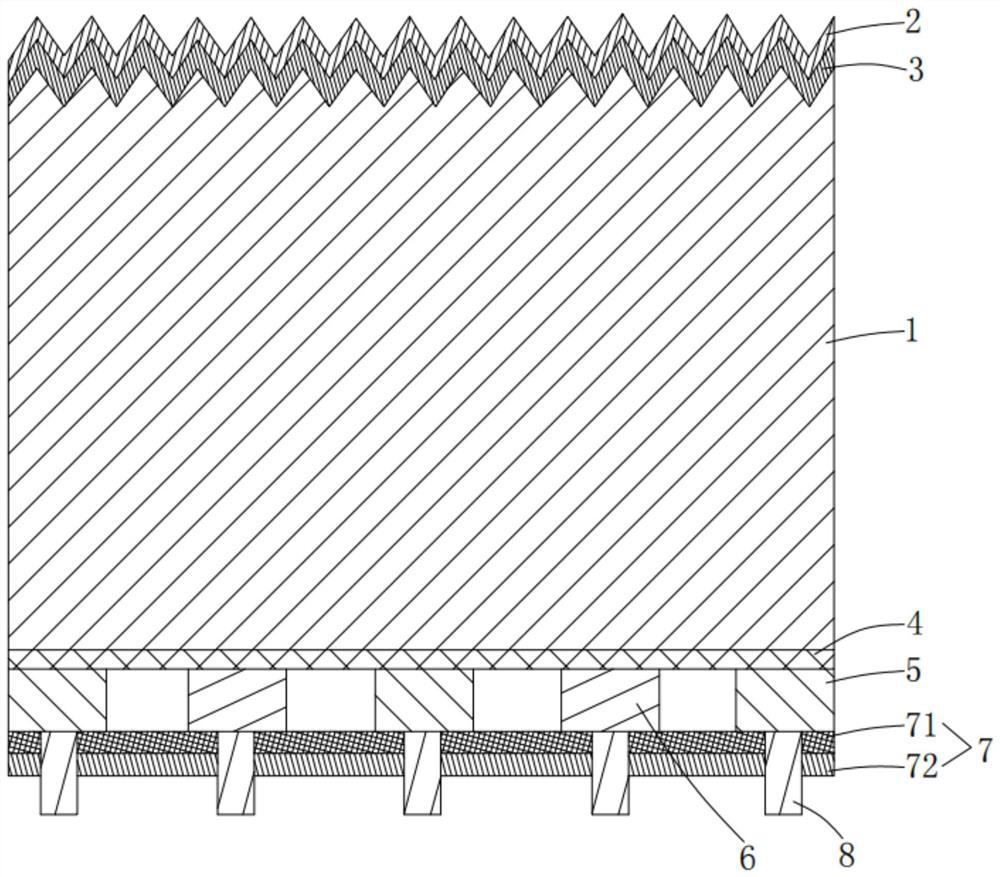

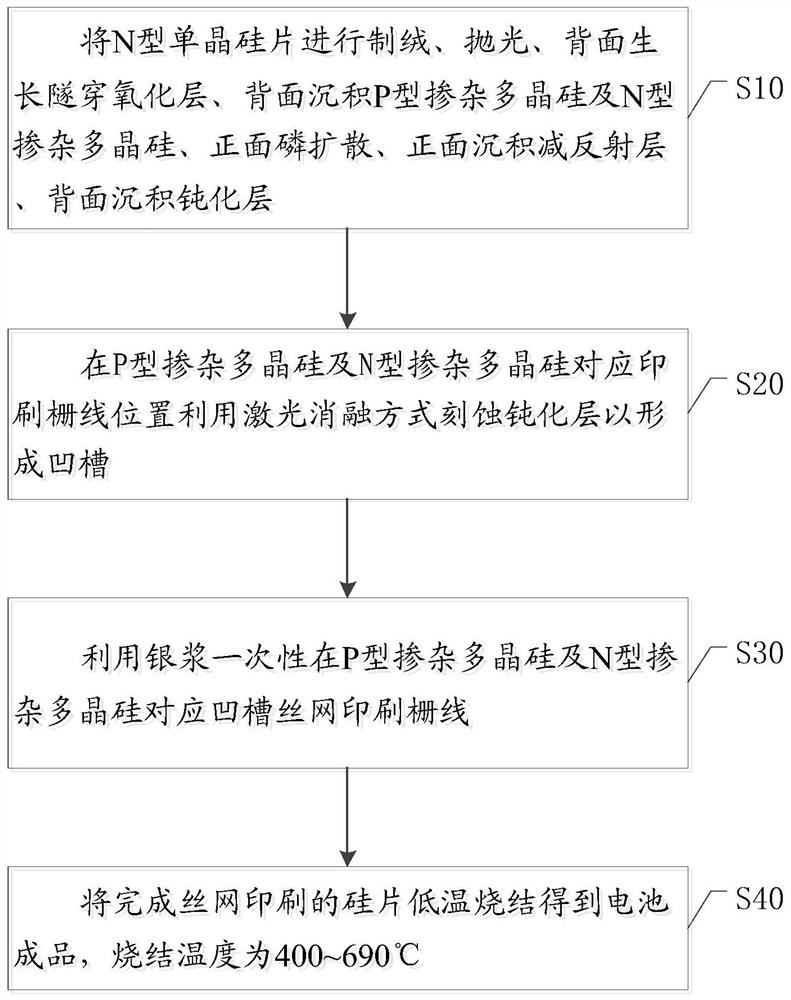

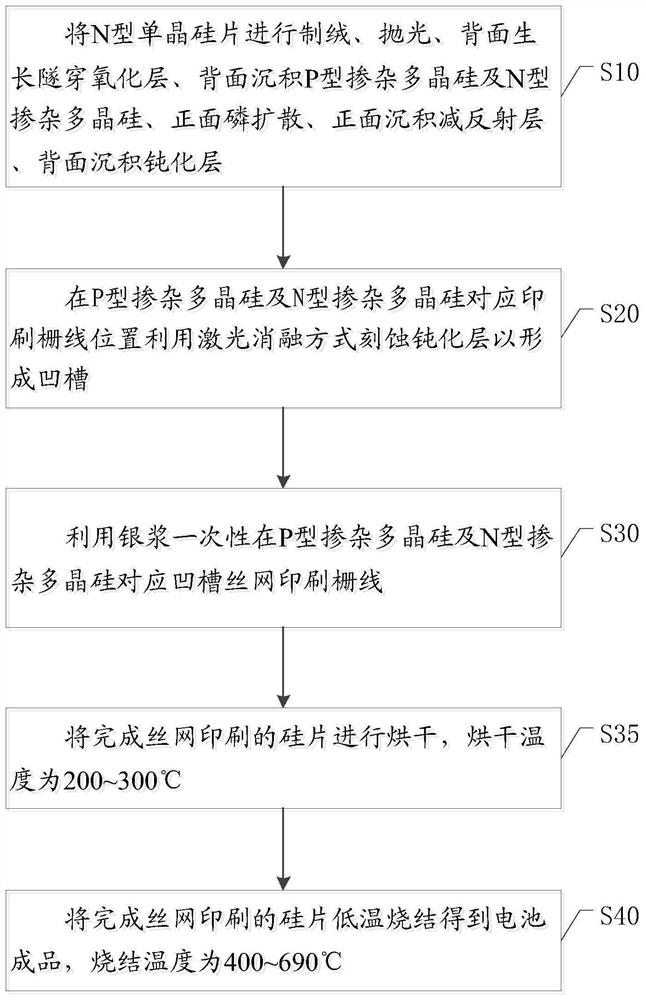

Processing technology of IBC battery with passivation contact structure

PendingCN113284982AImprove efficiencyGuaranteed passivation effectFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The invention is applicable to the technical field of solar cells, and provides a processing technology of an IBC battery with a passivation contact structure. The technology comprises the following steps: texturing and polishing an N-type monocrystalline silicon wafer, growing a tunneling oxide layer on the back surface, depositing P-type / N-type doped polycrystalline silicon on the back surface, performing phosphorus diffusion on the front surface, depositing an antireflection layer on the front surface, and depositing a passivation layer on the back surface; etching the passivation layer at the position of the P-type / N-type doped polycrystalline silicon printing grid line by using laser ablation to form a groove; utilizing silver paste to carry out silk-screen printing on grid lines in the groove corresponding to the P-type / N-type doped polycrystalline silicon at one time; and sintering at a low temperature of 400-690 DEG C to obtain a battery finished product. According to the processing technology of the IBC battery with the passivation contact structure, the groove is etched at the position of the P-type / N-type doped polycrystalline silicon printing grid line through laser ablation, ohmic contact between the grid line and the polycrystalline silicon can be achieved through low-temperature sintering, damage to the polycrystalline silicon and the tunneling oxide layer is avoided, the passivation effect of the battery is ensured, and metal induced recombination in a grid line area is reduced, and the battery efficiency is improved.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +2

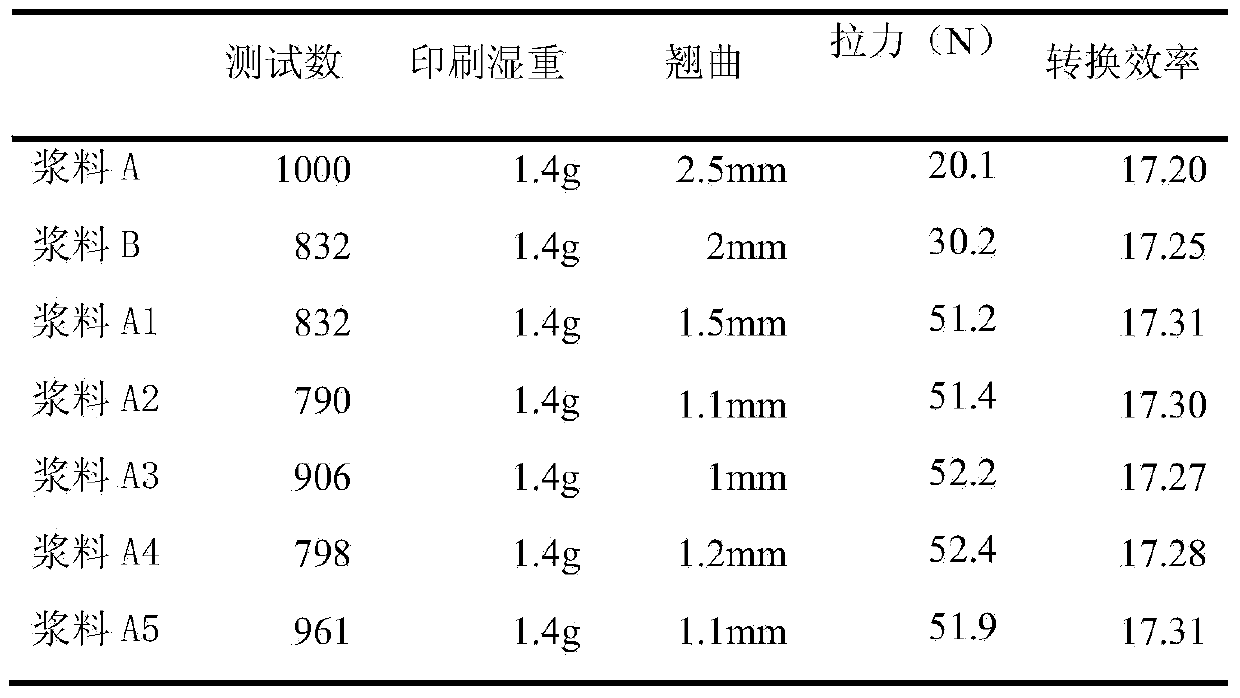

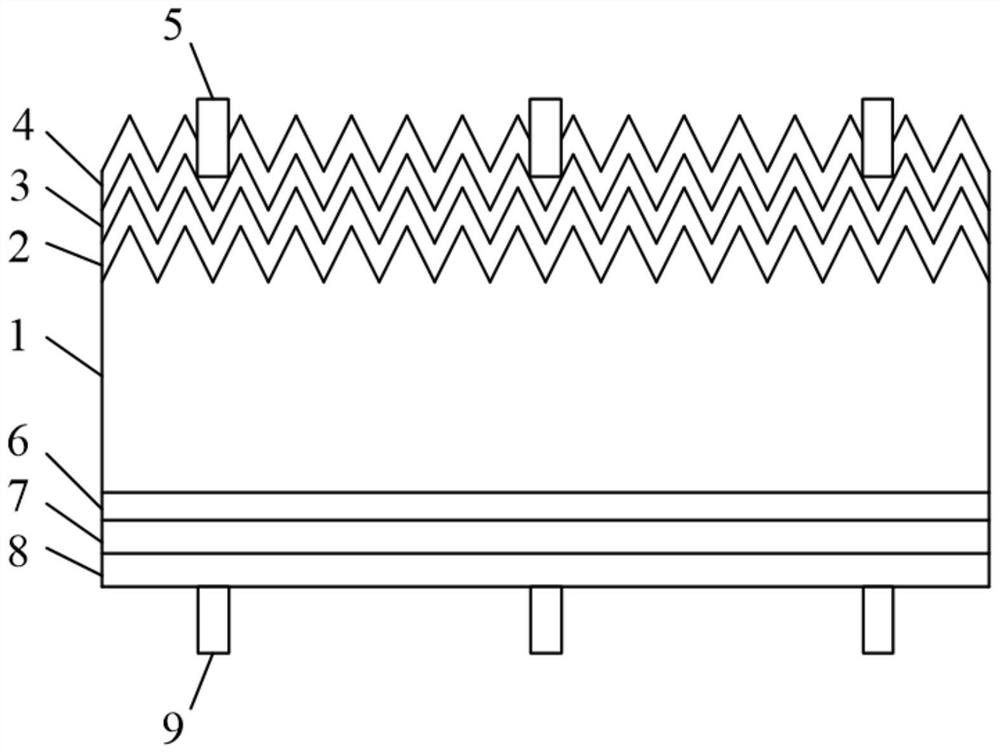

HJT battery with high photoelectric conversion efficiency and preparation method thereof

PendingCN112768549APrevent proliferationImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesHeterojunctionSilicon heterojunction

The invention discloses an HJT battery with high photoelectric conversion efficiency and a preparation method thereof, and belongs to the technical field of solar cells. The HJT battery comprises an N-type crystal silicon wafer, wherein an intrinsic amorphous silicon layer, a SiO2 layer, a C-doped SiO2 layer, an amorphous silicon doped N-type layer, a TCO conductive layer and an electrode are sequentially arranged on the front surface of the N-type crystal silicon wafer; an intrinsic amorphous silicon layer, a SiO2 layer, a C-doped SiO2 layer, an amorphous silicon doped P-type layer, a TCO conductive layer and an electrode are sequentially arranged on the back surface of the N-type crystal silicon wafer; and the amorphous silicon doped P-type layer comprises a lightly doped B amorphous silicon layer and a heavily doped B amorphous silicon layer. According to the prepared heterojunction solar cell, the photoelectric conversion efficiency can be improved to 24.3% or above, the short-circuit current and the open-circuit voltage are obviously improved, and the photoelectric conversion efficiency of the silicon heterojunction solar cell can be effectively improved.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +4

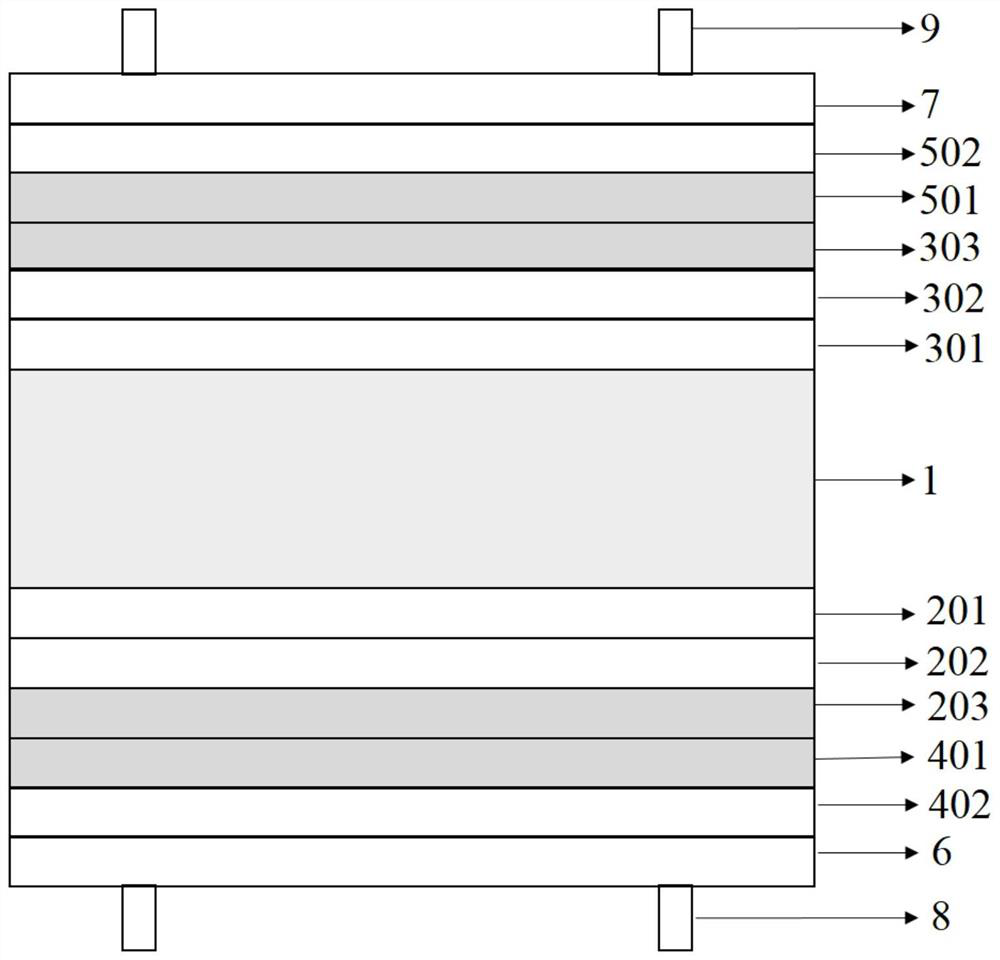

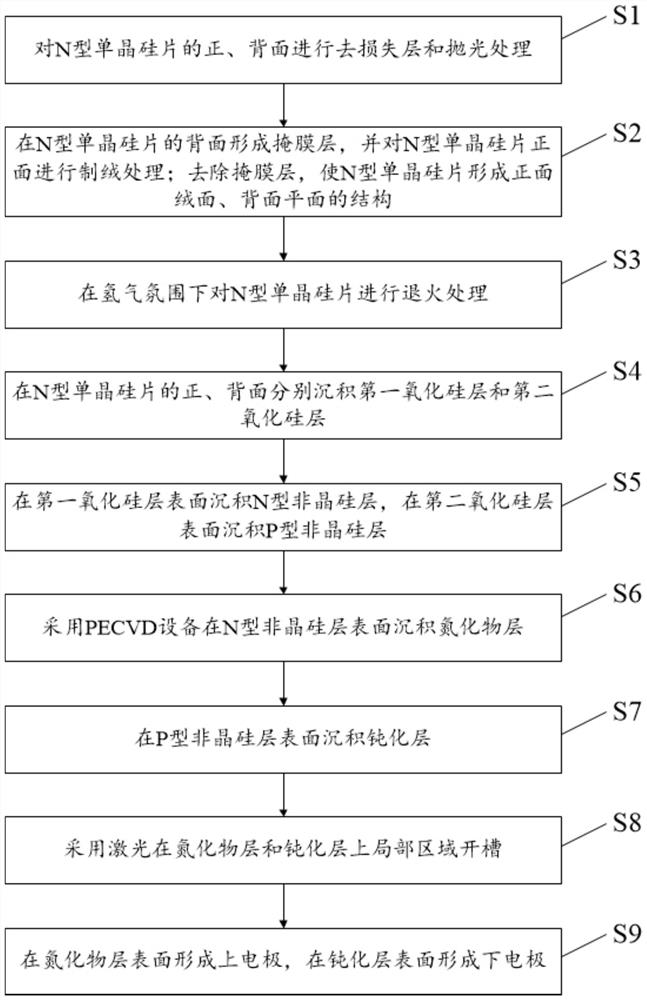

Heterojunction solar cell and preparation method thereof

InactiveCN113066874AIncrease short circuit currentImprove passivation effectFinal product manufacturePhotovoltaic energy generationHeterojunctionEngineering

The invention discloses a heterojunction solar cell which comprises an N-type monocrystalline silicon wafer, and a first silicon oxide layer, an N-type amorphous silicon layer, a nitride layer and an upper electrode are sequentially arranged on the front face of the N-type monocrystalline silicon wafer. A second silicon dioxide layer, a P-type amorphous silicon layer, a passivation layer and a lower electrode are sequentially arranged on the back surface of the N-type monocrystalline silicon wafer; the N-type monocrystalline silicon wafer is of a structure with a suede front surface and a plane back surface; and the passivation layer is an aluminum oxide layer or a combination of the aluminum oxide layer and a silicon nitride layer. The invention also discloses a preparation method of the heterojunction solar cell, which is simple to operate and low in production cost. By adopting the heterojunction solar cell, parasitic absorption can be reduced, short-circuit current can be increased, and the heterojunction solar cell which is high in conversion efficiency, good in passivation effect and low in cost can be obtained.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +2

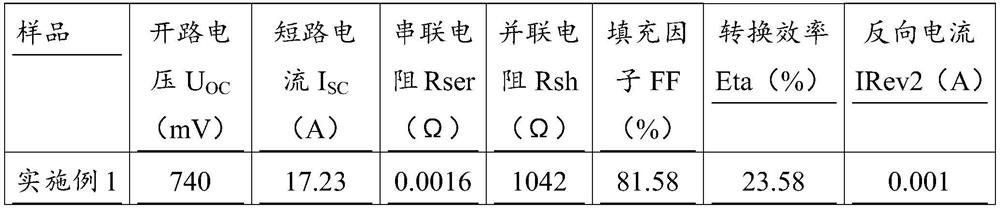

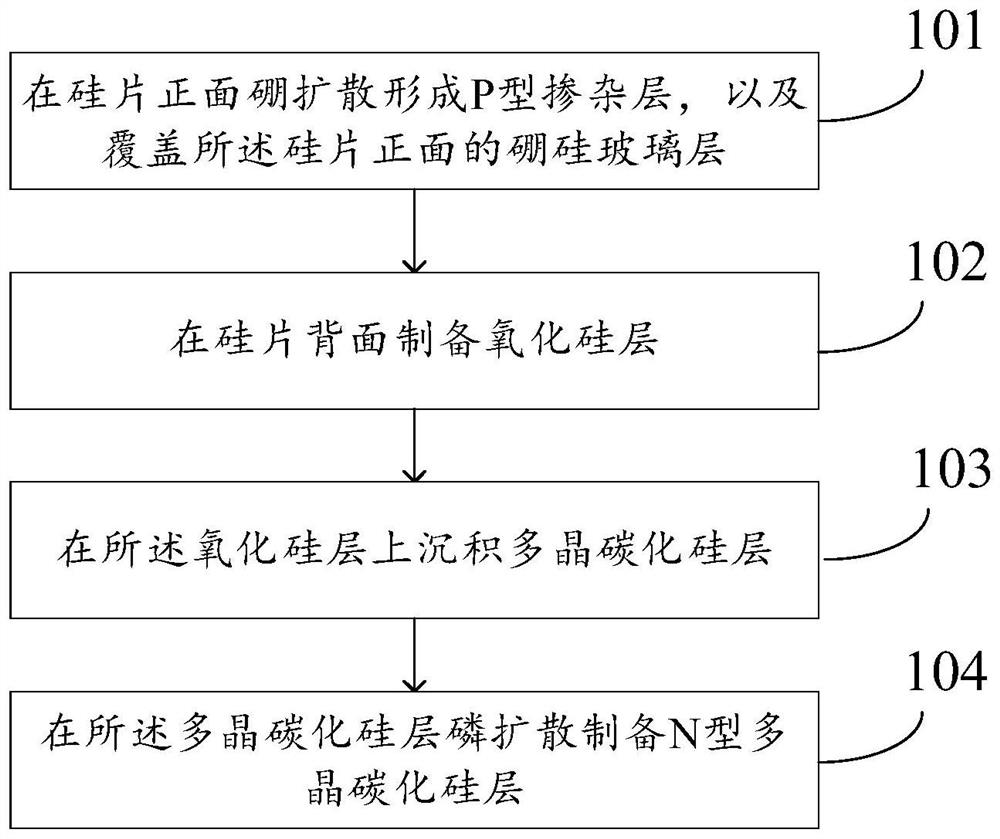

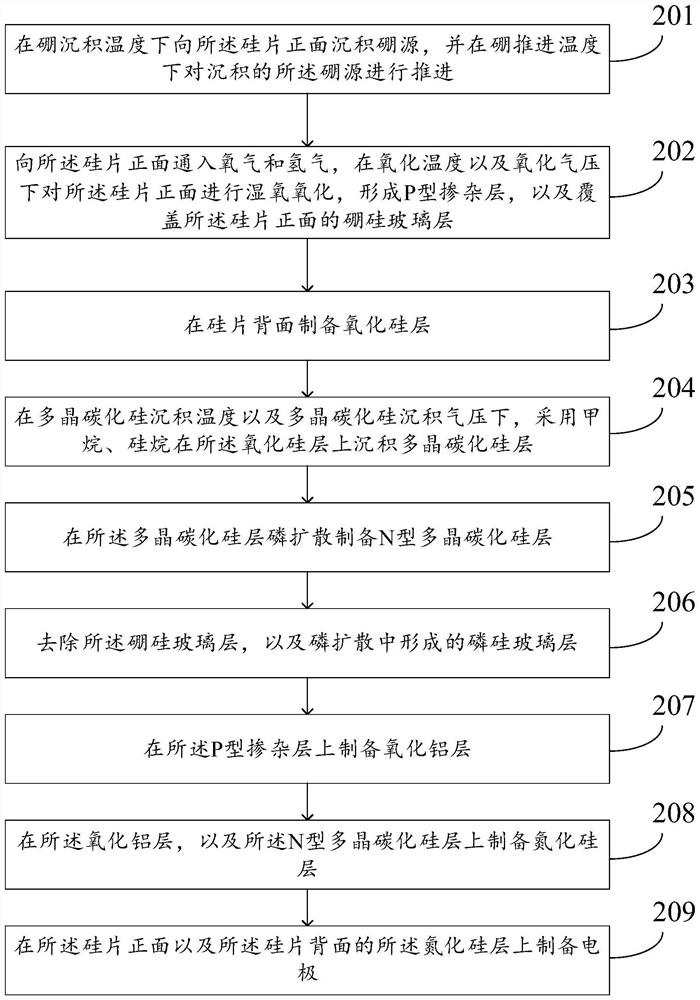

Preparation method of passivated contact cell and passivated contact cell

PendingCN114420786AAvoid destructionControllable depositionFinal product manufactureSemiconductor devicesCarbide siliconPolycrystalline silicon carbide

The invention provides a preparation method of a passivation contact cell and the passivation contact cell, and relates to the technical field of solar photovoltaics. Wherein in the process of preparing the passivation contact cell, boron diffusion is performed on the front surface of a silicon wafer to form a P-type doped layer, and a borosilicate glass layer covering the front surface of the silicon wafer is formed, so that an effective mask protection effect can be achieved in the subsequent process, and the front surface structure is prevented from being damaged; the polycrystalline silicon carbide layer is adopted on the back face of the silicon wafer to achieve the field passivation effect, loss of light parasitic absorption is avoided, phosphorus diffusion preparation is carried out after deposition of the N-type polycrystalline silicon carbide layer, deposition of the polycrystalline silicon carbide layer is more controllable, it can be guaranteed that the film layer is uniform and not prone to falling off or blistering, high-temperature crystallization is not needed after diffusion, and the process efficiency and the passivation effect are guaranteed.

Owner:LONGI SOLAR TECH (XIAN) CO LTD

Solar cell and preparation method thereof

ActiveCN110289339AImprove stabilityStrictly limit the contact areaFinal product manufacturePhotovoltaic energy generationSilver pasteSlurry

The invention discloses a solar cell and a preparation method thereof, belongs to the technical field of solar cells. The preparation method of the solar cell comprises the following steps: carrying out double-sided texturing; performing tubular phosphorus diffusion on the suede; performing etching; coating the front surface of the silicon wafer with a film; performing Al2O3 passivation on the back surface of the silicon wafer; after passivation is finished, printing a back electrode with silver paste and performing drying; printing and drying the back electric field by adopting ceramic slurry, and reserving an aluminum slurry printing position; performing aluminum paste printing and drying on the back electric field at the reserved position; performing silver paste printing and drying on the positive electrode; and feeding a battery piece into a sintering furnace for sintering. Compared with a PERC battery piece manufacturing process, the method has the advantages that the processes of back silicon nitride coating and laser grooving are omitted, and the equipment transformation and investment cost can be greatly reduced. The invention also provides the solar cell which contains the ceramic slurry, so that the stability of the average conversion rate of the cell is improved.

Owner:江苏辉伦太阳能科技有限公司

Efficient passivation structure battery and preparation method thereof

PendingCN112670354AReduce compoundingImprove shortwave responseFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The invention relates to the technical field of solar batteries, and discloses an efficient passivation structure battery and a preparation method thereof in order to solve the problems of poor compactness and thickness uniformity of a passivation film in the prior art. The efficient passivation structure battery comprises P-type crystalline silicon, two positive electrodes arranged on the front surface of the P-type crystalline silicon and two negative electrodes arranged on the back surface of the P-type crystalline silicon, wherein a SiO2 layer is arranged on the back surface of the P-type crystalline silicon, and a Ga2O3 / AlN / Ta2O5 laminated passivation film is arranged on the SiO2 layer. According to the invention, the SiO2+Ga2O3 / AlN / Ta2O5 laminated passivation film, silicon oxynitride and the silicon nitride composite passivation film are adopted on the back surface, the efficiency is improved through a battery end, the fixed negative charge density of each layer of the Ga2O3 / AlN / Ta2O5 laminated passivation film is different and is lower than that of aluminum oxide, the adverse effect caused by positive charge reduction passivation can be relieved while the passivation effect is ensured through multi-layer superposition, and PID is improved.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

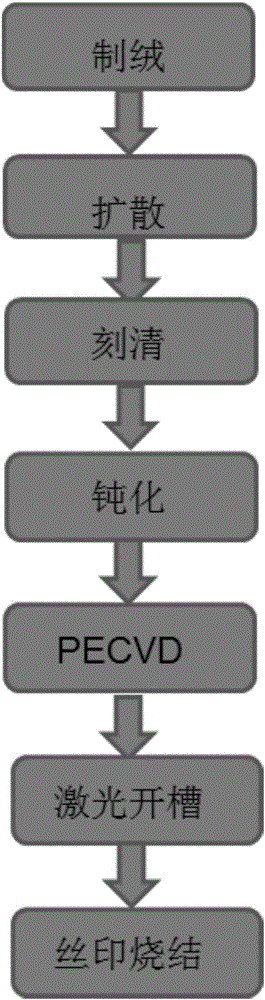

Preparation method of PERC battery piece

ActiveCN112071928AGuaranteed uniformityAchieve high concentration dopingFinal product manufacturePhotovoltaic energy generationScreen printingEngineering physics

The invention discloses a preparation method of a PERC battery piece. The preparation method comprises the following steps: (1) cleaning and texturing; (2) performing diffusion and laser propulsion; (3) etching, polishing and removing phosphorosilicate glass; (4) carrying out Al2O3 atomic deposition on the back surface of the polished monocrystalline silicon wafer; (5) coating the front surface ofthe monocrystalline silicon wafer subjected to back passivation; (6) carrying out back surface coating on the monocrystalline silicon wafer subjected to front surface coating; (7) carrying out lasergrooving on the monocrystalline silicon wafer with the back surface coated with the film; and (8) performing silk-screen printing and sintering to obtain the PERC battery piece. The preparation methodof the PERC battery piece is simple, lattice defects of the silicon wafer can be reduced, the minority carrier lifetime is prolonged, the passivation effect of the back surface of the silicon wafer is better, and the conversion efficiency of the battery piece is further improved.

Owner:JINENG CLEAN ENERGY TECH LTD +1

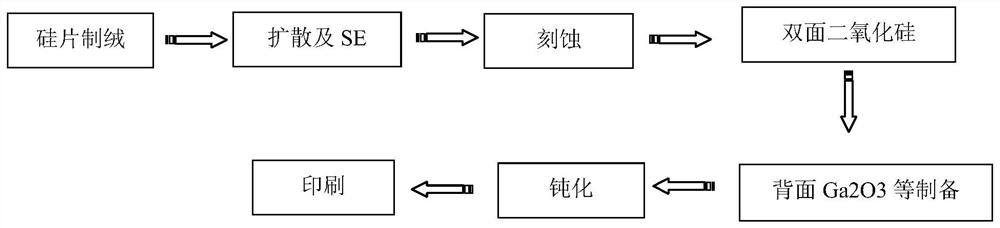

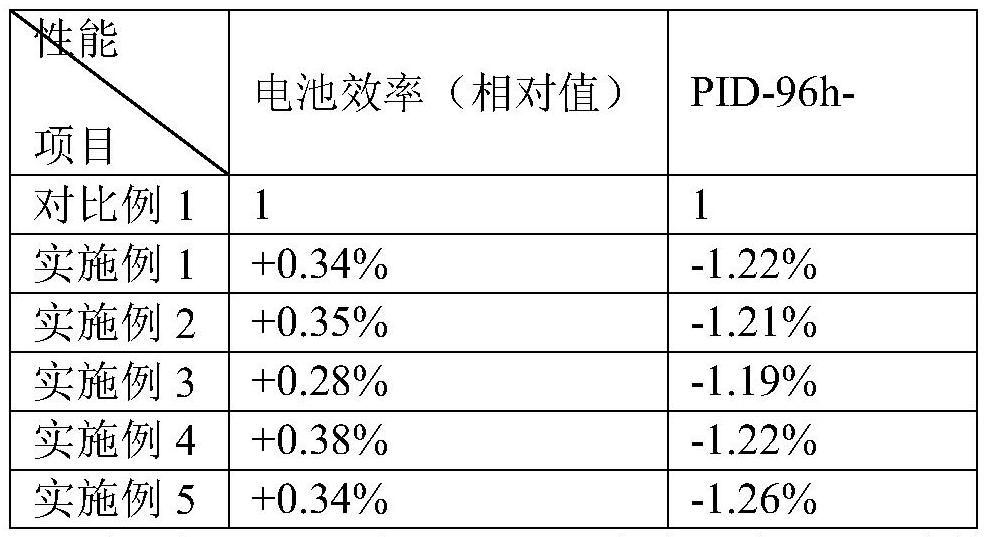

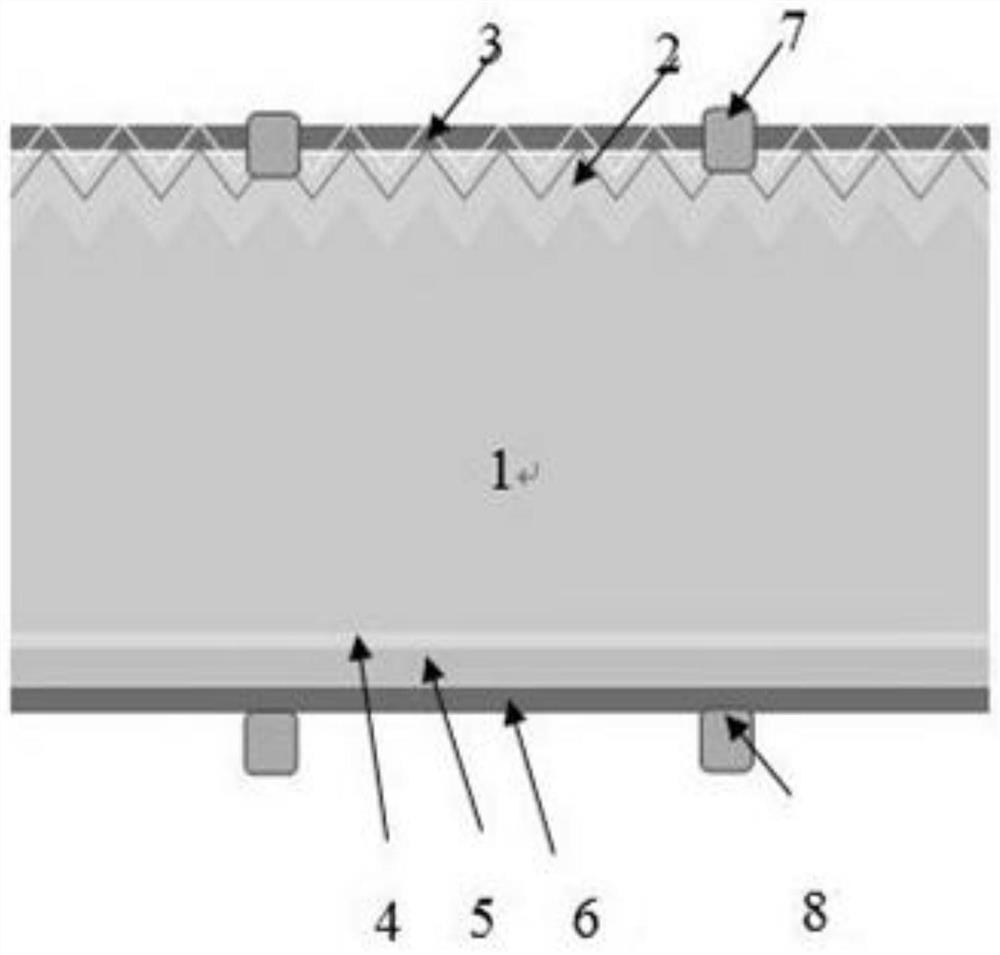

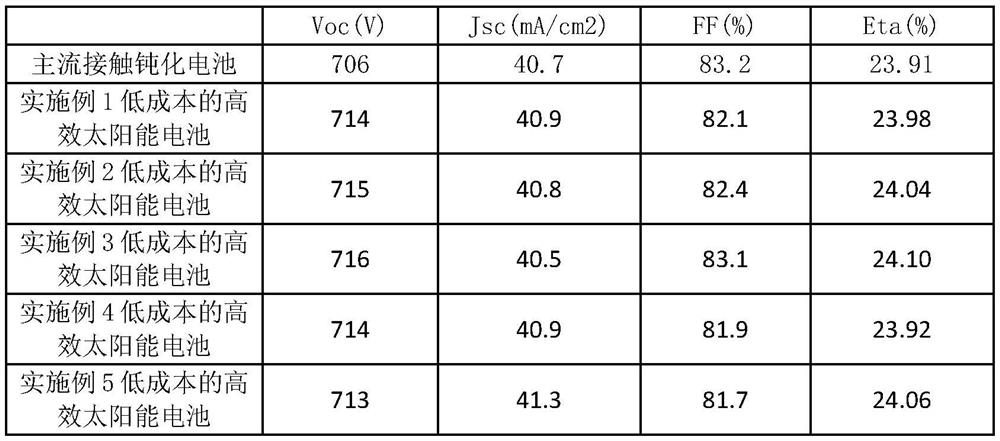

Low-cost high-efficiency solar cell and preparation method thereof

InactiveCN112397596AGood electrical propertiesLow costFinal product manufactureSemiconductor devicesSilver pasteOhmic contact

The invention relates to the technical field of solar cells, in particular to a low-cost high-efficiency solar cell and a preparation method thereof, and the solar cell comprises a substrate, a diffusion layer located on the upper surface of the substrate, a passivation layer located on the upper surface of the diffusion layer, a silicon oxide layer located on the lower surface of the substrate, adoped polycrystalline silicon layer located on the lower surface of the silicon oxide layer, a hydrogenated transparent conductive film positioned on the lower surface of the doped polycrystalline silicon layer, an upper electrode positioned on the upper surface of the passivation layer, and a lower electrode positioned on the lower surface of the hydrogenated transparent conductive film. According to the invention, a passivation layer on the surface of polycrystalline silicon is replaced by the hydrogenated TCO thin film, the TCO thin film has good electrical properties and can form good ohmic contact with the slurry, and the slurry does not need to be burnt through to be in contact with the polycrystalline silicon, so that non-burnt-through slurry such as aluminum slurry can be adoptedto replace silver slurry, and the cost is reduced.

Owner:RISEN ENERGY

N-TOPCon solar cell, module and system, and method and equipment for preparing double-sided silicon oxide in cell

PendingCN113193074AControl thicknessGuaranteed passivation effectFinal product manufacturePhotovoltaic energy generationMetallic electrodeThin membrane

The invention relates to an N-TOPCon solar cell, module and system, and a method and equipment for preparing double-sided silicon oxide in the N-TOPCon solar cell. The method comprises the steps of: S1, preparing a p + doped region on the front surface of the N-type silicon serving as a substrate; S2, preparing a silicon oxide film on the front surface of the N-type silicon, and preparing a tunneling oxide layer on the back surface of the N-type silicon; S3, preparing phosphorus-doped polycrystalline silicon on the back surface of the N-type silicon; and S4, preparing passivation films on the front surface and the back surface of the N-type silicon, and then printing metal electrodes. According to the method, the cleanliness is guaranteed, meanwhile, the working procedures are reduced, the problem that the number of N-TOPCon working procedures is large is solved, and the core competitiveness of N-TOPCon is enhanced.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

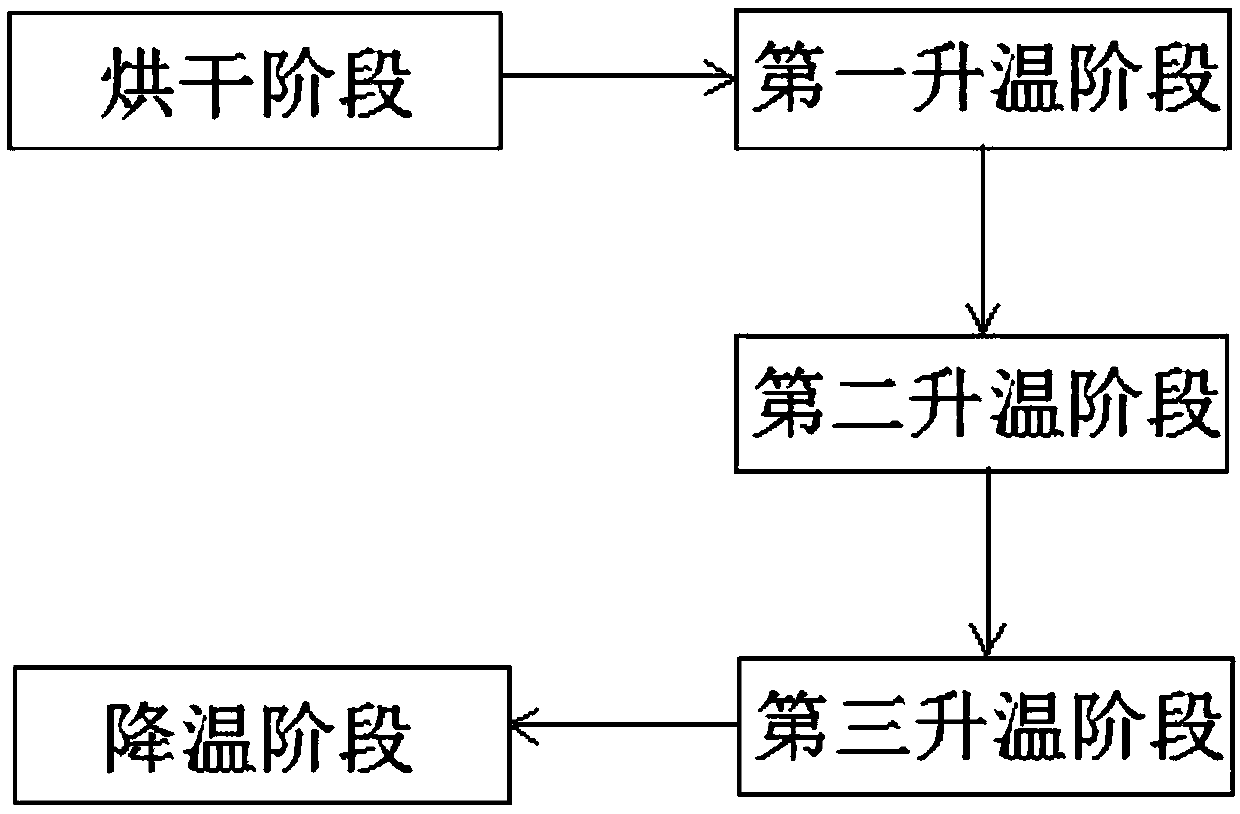

Preparation method of double-sided PERC battery

PendingCN111341877AIncrease the open circuit voltageImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationBack surface fieldBattery cell

The invention provides a preparation method of a double-sided PERC battery, and the method comprises the steps of film coating, slotting, printing and sintering in sequence; the sintering step comprises a drying stage, a first heating stage, a second heating stage and a third heating stage; the initial temperature of the second heating stage is 480-520 DEG C, the final temperature of the second heating stage is 550-580 DEG C, and the heating rate of the second heating stage is set to be 7-25 DEG C / s. According to the preparation method provided by the invention, a relatively slow temperature rise interval is arranged, so the formation of an aluminum back surface field BSF is facilitated, the aluminum burning reaction time is reasonably shortened, the erosion of back electrode aluminum paste is reduced, and the open-circuit voltage and the conversion efficiency of the double-sided PERC battery are improved.

Owner:CSI CELLS CO LTD +1

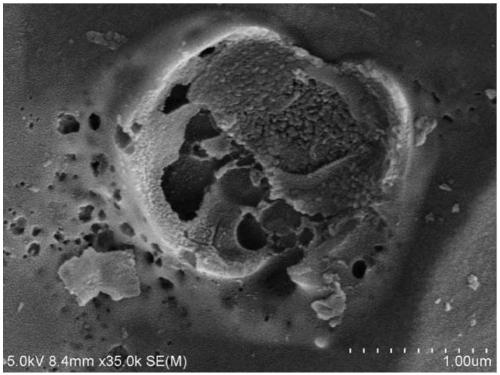

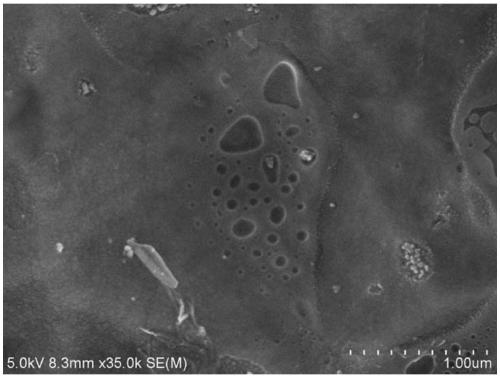

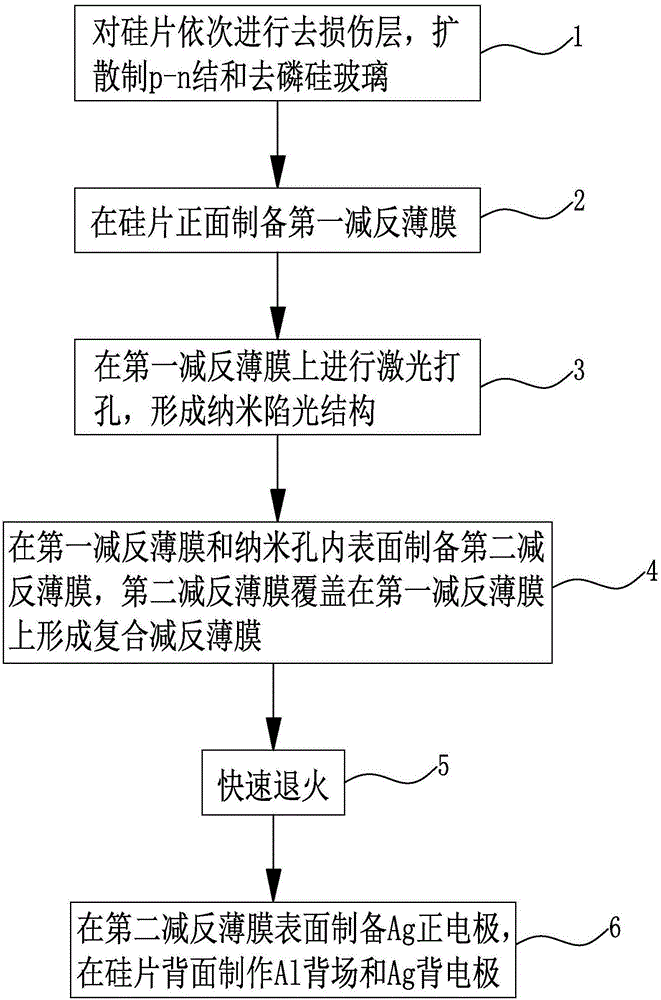

Low reflectivity solar crystalline silicon cell and manufacturing method thereof

InactiveCN105206705AGuaranteed passivation effectAvoid surface damageFinal product manufacturePhotovoltaic energy generationPunchingSilicon solar cell

The invention discloses a low reflectivity solar crystalline silicon cell and a manufacturing method thereof. The method comprises steps that, a), a damaged layer of a silicon chip is sequentially removed, and a p-n knot and dephosphorization silicon glass are prepared through expansion; b), a first anti-reflection film is prepared at the front face of the silicon chip; c), laser punching is carried out on the first anti-reflection film to form a nano light tripping structure; d), a second anti-reflection film is prepared on the surface of the first anti-reflection film and in a nano hole, and the second anti-reflection film covers the first anti-reflection film to form a composite anti-reflection film; e), rapid annealing is carried out; and f), a Ag positive electrode is prepared on the surface of the second anti-reflection film, and an Al back field and a Ag back electrode are prepared on the back face of the silicon chip. Compared with the prior art, the method is advantaged in that, the surface of the crystalline silicon is prevented from being damaged, a carrier composition rate on the silicon surface is reduced, reflectivity is reduced, and cell conversion efficiency is improved. The invention further discloses the low reflectivity solar crystalline silicon cell prepared through the manufacturing method.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

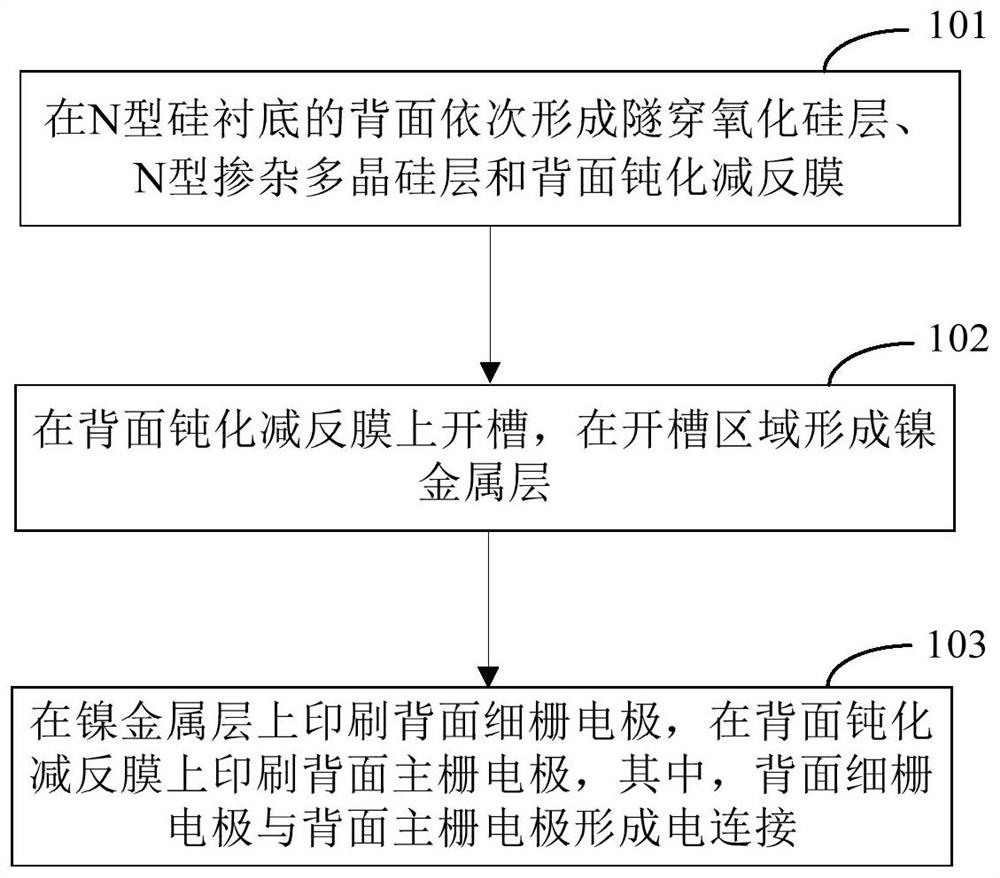

Solar cell and preparation method thereof

PendingCN114005908AAvoid destructionGuaranteed bondingFinal product manufacturePhotovoltaic energy generationElectrical batterySilicon oxide

The invention discloses a solar cell and a preparation method of the solar cell. The preparation method of the solar cell comprises the following steps: sequentially forming a tunneling silicon oxide layer, an N-type doped polycrystalline silicon layer and a back passivation anti-reflection film on the back surface of an N-type silicon substrate; grooving the back passivation anti-reflection film, and forming a nickel metal layer in a grooving area; printing a back fine gate electrode on the nickel metal layer, printing a back main gate electrode on the back passivation anti-reflection film, and electrically connecting the back fine gate electrode with the back main gate electrode. According to the preparation method, the binding force between the metal gate line and silicon can be ensured, meanwhile, the damage of the slurry to the thin polycrystalline silicon layer in the using process is avoided, the passivation effect of the passivation contact structure is ensured, the manufacturing cost of the solar cell is reduced, parasitic light absorption is reduced, and the light utilization efficiency is improved. And the efficiency of the solar cell is improved.

Owner:JA SOLAR TECH YANGZHOU

Passivation solution and preparation method thereof

InactiveCN106756929AQuality improvementStable passivation working fluidMetallic material coating processesPorositySalt spray test

The invention provides a passivation solution which is prepared by dissolving various raw materials in deionized water. The materials comprise 6-9 g / L of chromium sulfate hexahydrate, 2-4 g / L of cobalt sulfate heptahydrate, 4-8 g / L of sodium chlorate, 2-3 g / L of ammonium fluoride, 1-2 g / L of sulfuric acid, 2-3 g / L of citric acid and the balance water. According to an obtained passivation film, the corrosion resisting property is good, a salt spray test can be kept for 120 h or longer, the workpiece surface has no white rust or white spot, the porosity is low, and no sealing agent is needed for treatment.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

Copper foil surface passivation treatment process in copper foil surface treatment process

InactiveCN101935858BSimple ingredientsConvenient sourceSurface reaction electrolytic coatingMetallurgyPhytic acid

The invention discloses a copper foil surface passivation treatment process in a copper foil surface treatment process. The process particularly comprises the steps of preparing passivation solution from de-ionized water serving as a basic solvent and phytic acid serving as an additive and performing passivation treatment on a copper foil. The formula of the invention saves the conventional hexavalent chromium component on the premise of ensuring the passivation effect, so that the technical guarantee for eliminating the environmental protection barrier of copper foil manufacturers and ensuring continuous development of enterprises is provided.

Owner:JIANGXI UNIV OF SCI & TECH +1

Passivation equipment

ActiveCN112820798AEasy to operateProduced in various waysFinal product manufactureSemiconductor devicesEngineering physicsBattery cell

The invention discloses passivation equipment which comprises an isolation box and a passivation box, the passivation box is located in the isolation box, the passivation box internally comprises a loading structure, a carrier device, a spraying device and a heating device, the loading structure bears the carrier device, the spraying device and the heating device, the spraying device is located between the carrier device and the heating device, and the heating device is located between the carrier device and the heating device. The spraying device sprays oxygen or passivating gas, the spraying device sprays the passivating gas to make contact with the section of the sliced battery, the technical scheme that the spraying device sprays ozone to the section of the sliced battery for passivating treatment is adopted, operation is easy, and industrial and large-scale development can be formed. The spraying pipe of the spraying device is used for spraying the passivation gas to the section of the sliced battery, so that the passivation gas is uniformly sprayed, and the passivation effect is ensured.

Owner:LAPLACE RENEWABLE ENERGY TECH CO LTD

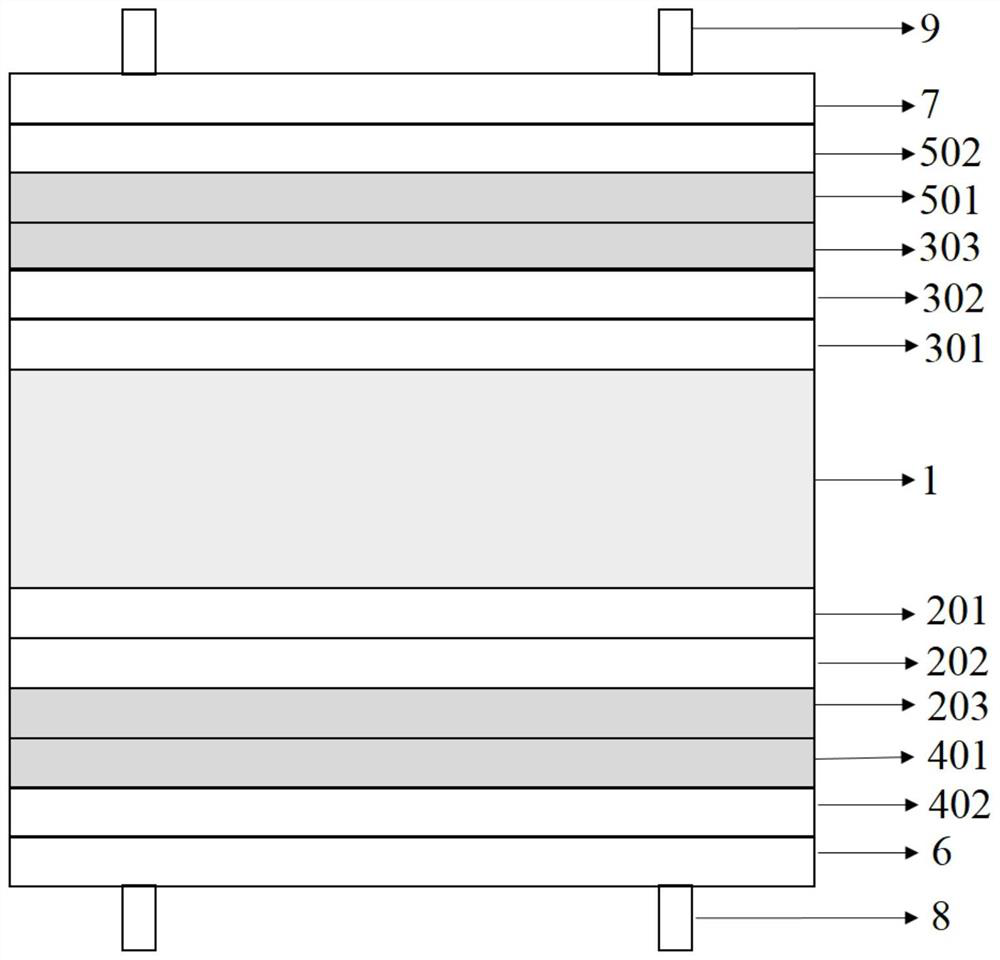

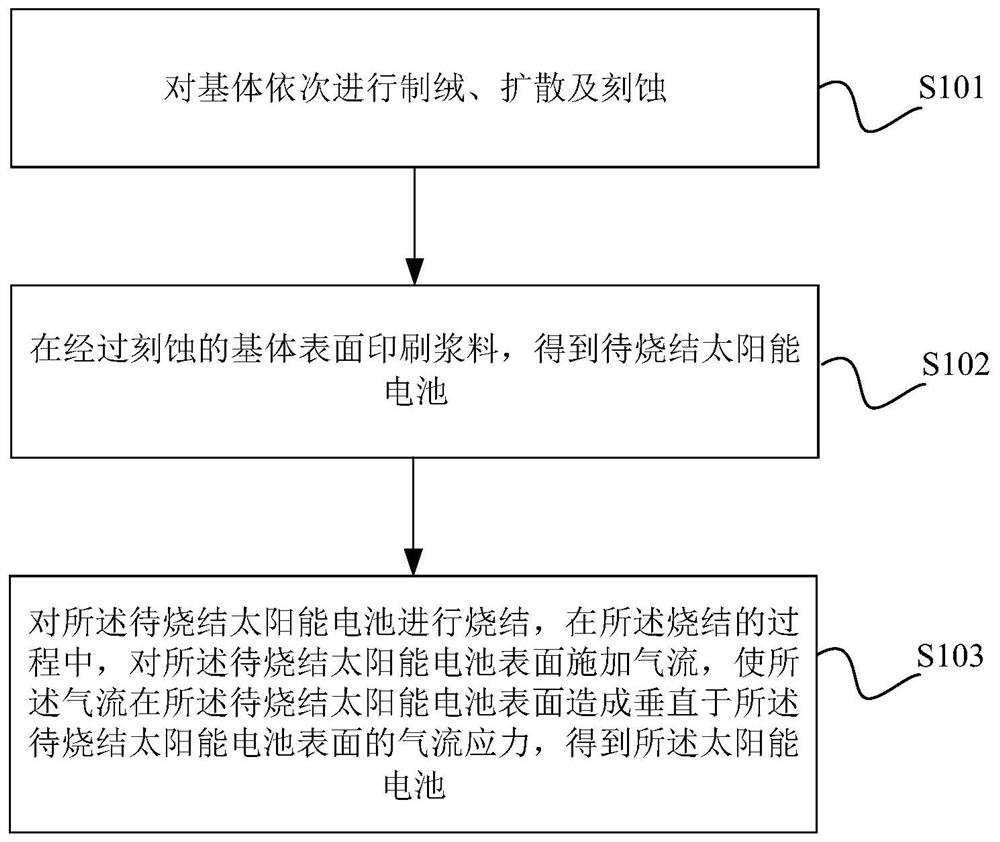

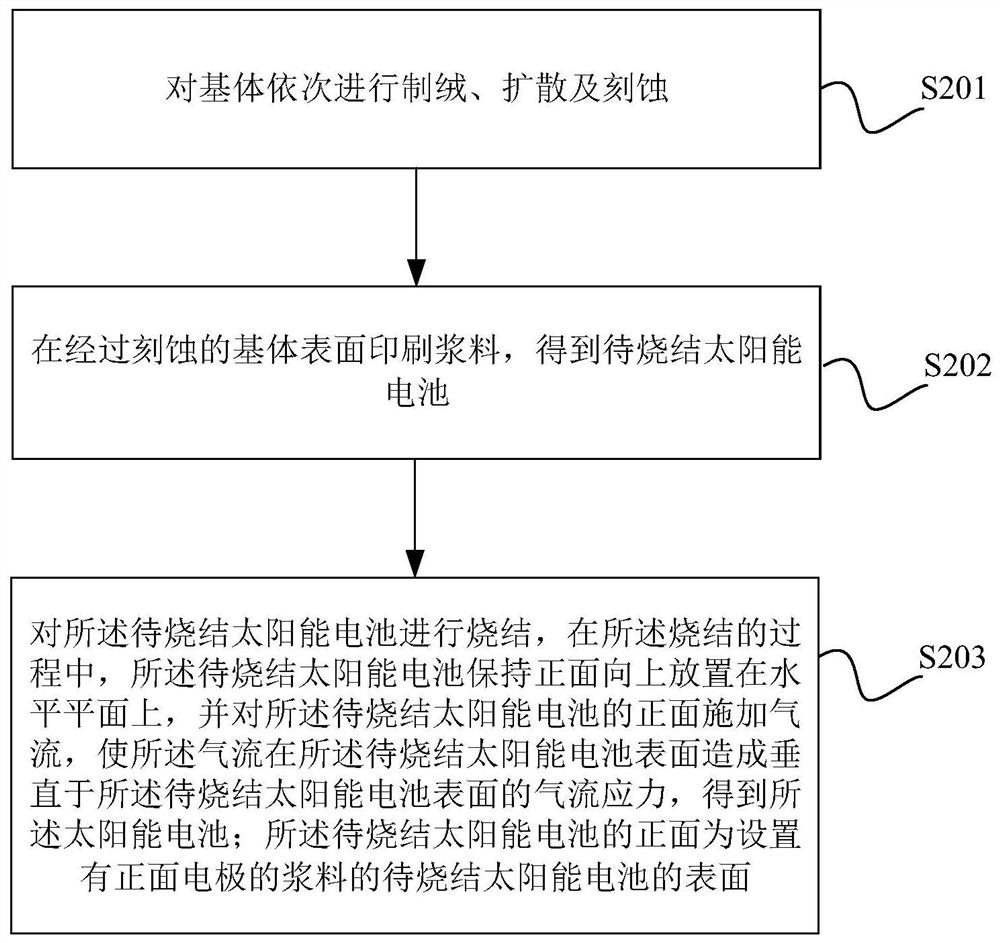

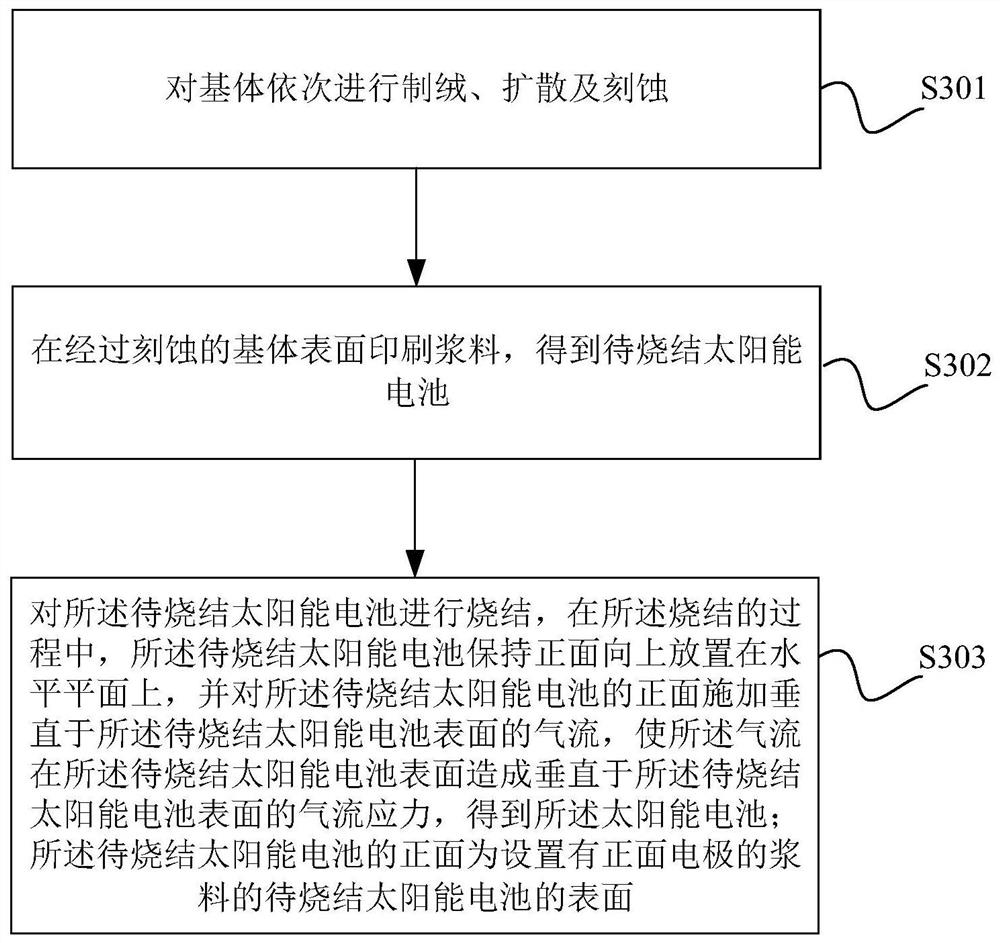

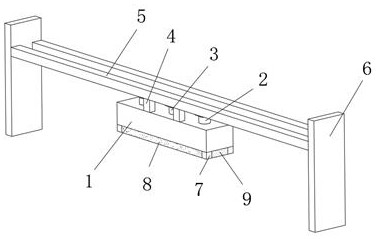

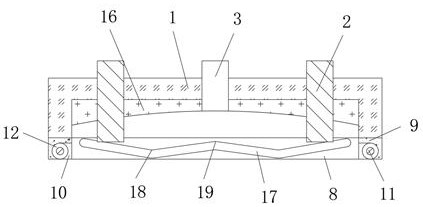

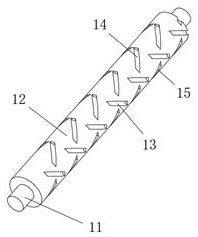

A method for manufacturing a solar cell and a solar cell sintering device

ActiveCN109742191BPrevent warpageGuarantee the quality of the back fieldFinal product manufactureSemiconductor devicesElectrical batteryPhysical chemistry

The invention discloses a manufacturing method of a solar battery, which comprises the steps of: sequentially carrying out texturing, diffusion and etching on a matrix; printing a sizing agent on thesurface of the etched matrix to obtain a to-be-sintered solar battery; and carrying out sintering on the to-be-sintered solar battery, and int he sintering process, applying gas flow to the surface ofthe to-be-sintered solar battery, enabling the gas flow to form a gas flow stress perpendicular to the surface of the to-be-sintered solar battery on the surface of the to-be-sintered solar battery,so as to obtain the solar battery. According to the invention, the stress formed by the gas flow and a sintering stress generated in the sintering process of the solar battery reach balance to the greatest extent so as to inhibit a warping phenomenon of the solar battery in the sintering process, which is generated due to the sintering stress, meanwhile, ensure a passivation effect on the solar battery and promote battery efficiency. Meanwhile, the invention also provides a solar battery sintering device and a solar battery which have the above-mentioned beneficial effects.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

Shell plane weld joint passivation device for machining

InactiveCN112064004AImprove passivation effectIncrease the collision dispersion effectMetallic material coating processesStructural engineeringWeld bead

The invention belongs to the technical field of machining, particularly relates to a shell plane weld joint passivation device for machining. Specific to the problem of the poor passivation effect ona metal shell plane weld joint in the prior art, the following scheme is now put forwards. According to the following scheme, the shell plane weld joint passivation device for machining comprises a passivation part; a passivation cavity is formed in the bottom of the passivation part; a liquid inlet pipe and a liquid outlet pipe are connected to the top of the passivation part; connecting parts are fixed to the two sides of the outer wall of the top of the passivation part; movable guide rails are connected to the top ends of the connecting parts; lifting frames are connected to the two ends of each movable guide rail; and fixing blocks are fixed to the four corners of the bottom of the passivation part. According to the shell plane weld joint passivation device for machining, the overallmovement of the passivation part is matched with the circulation of internal passivation liquid, so that the chips generated by passivation are prevented from always staying at a certain position to influence the actual passivation effect, and trowelling rollers at the two ends are used for trowelling the positions of weld joints which just enter and are to be discharged so as to improve the actual passivation effect on the weld joints.

Owner:董华珍

Solar cell rear passivation method

ActiveCN104701390BGuaranteed hydrogen passivation effectAvoid erosionFinal product manufactureSemiconductor devicesSolar cellTotal thickness

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

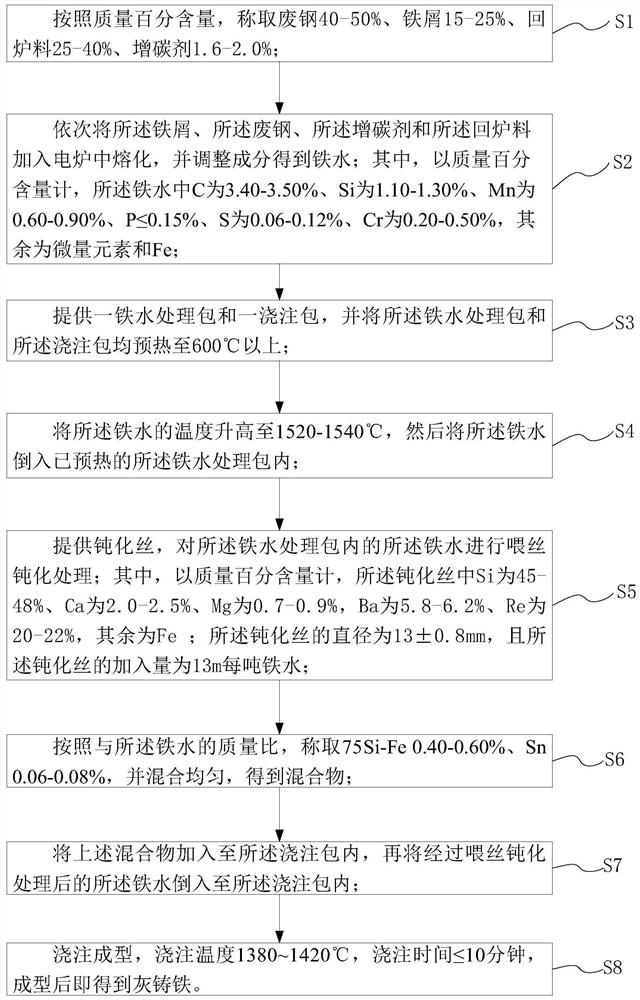

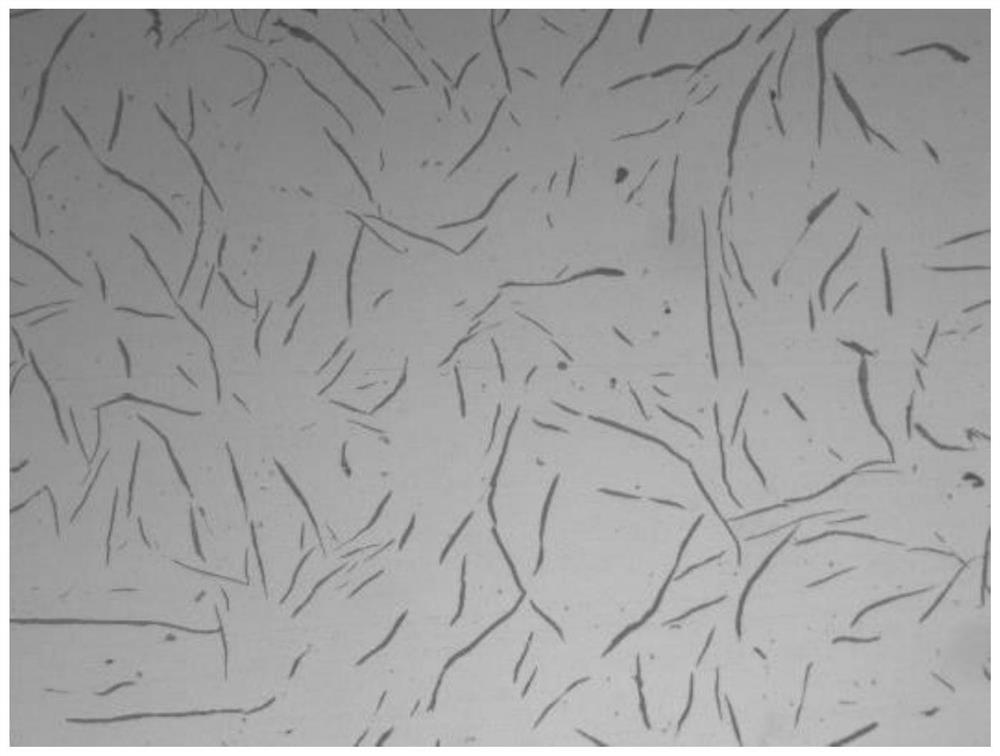

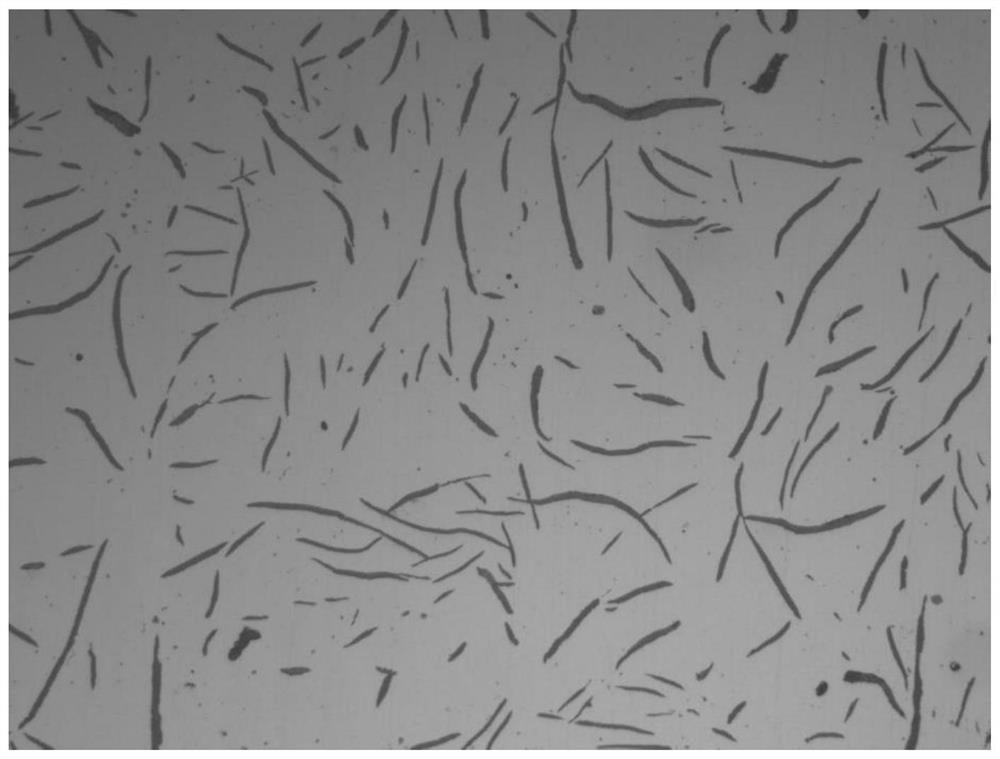

Production method of gray cast iron

ActiveCN111850381BImprove passivation rateImprove mechanical propertiesProcess efficiency improvementWater processingCast iron

Owner:ZHUMADIAN ZHONGJI HUAJUN CASTING +1

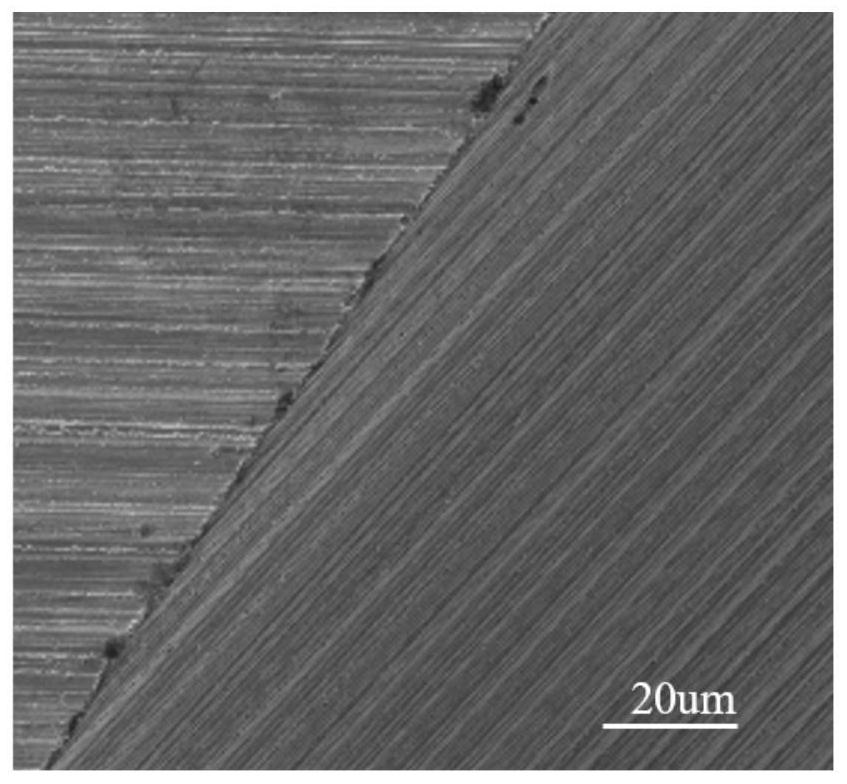

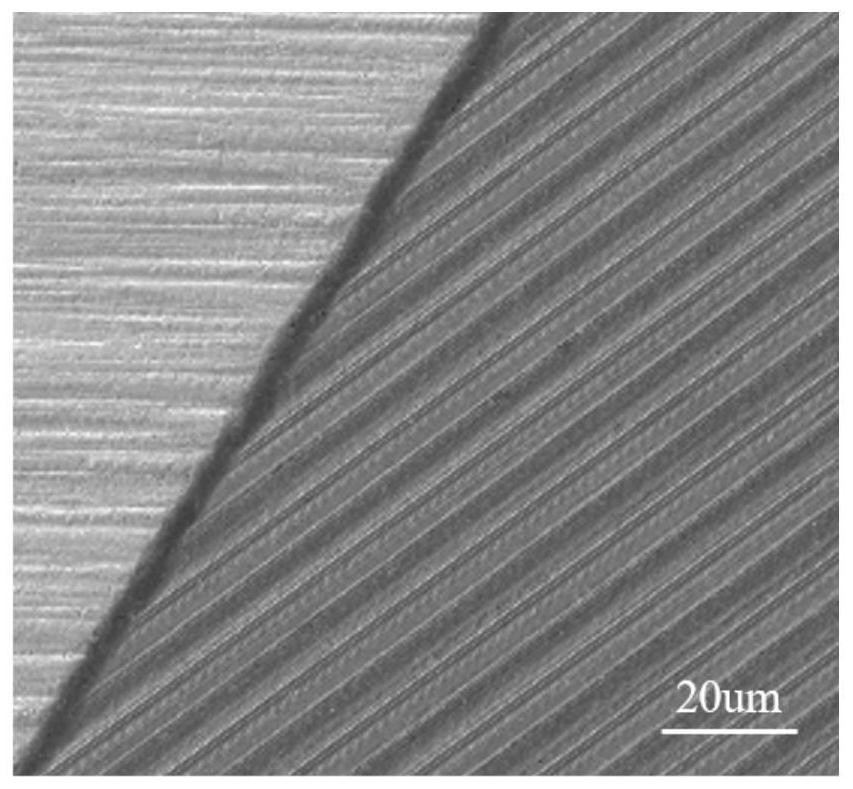

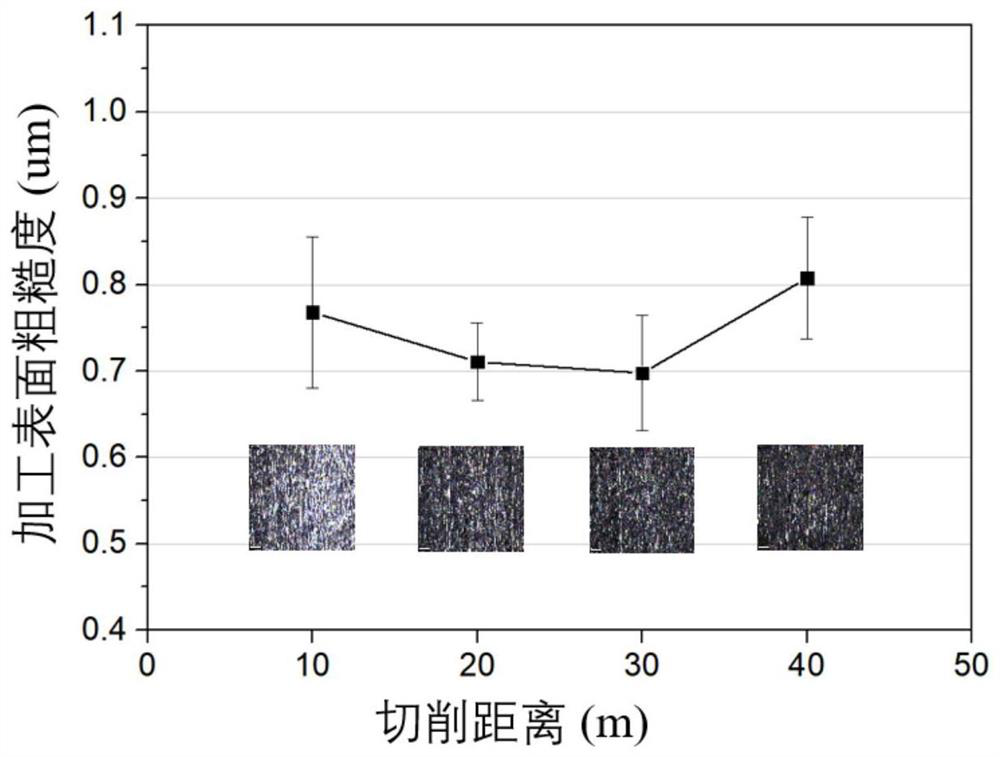

Cutter cutting edge machining method

ActiveCN112372514AHigh strengthExtend your lifeAbrasive machine appurtenancesMilling cutterSand blasting

The invention discloses a cutter cutting edge machining method, which comprises the following steps: a rough cleaning step: primarily cleaning a cutter to remove pollutants on the surface of the cutter; a wet-type sand blasting passivation step: wet-type sand blasting treatment is conducted on the surface of the cutter through a nozzle, and the machining condition of wet-type sand blasting is determined according to the type of the cutter and the material of the cutter; wherein the type of the cutter comprises a milling cutter and a fine trimming blade, and the cutter is made of high-speed steel and hard alloy; a fine cleaning step: after passivation, sequentially carrying out alkali liquor cleaning, acid liquor cleaning and pure water cleaning on the cutter, and finally cleaning by adopting an antirust agent solution; and a drying step: carrying out drying treatment after the cutter is finely cleaned. The cutting edge of the cutter manufactured through the method is smooth in surface,high in strength, even in stress in the cutting process and good in durability.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com