Preparation method of double-sided PERC battery

A battery, double-sided technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of affecting the opening voltage and conversion efficiency of the battery, destroying the passivation film, and reducing the conversion efficiency of the front side, so as to improve the open circuit voltage and conversion efficiency , reduce erosion, shorten the effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. However, this embodiment does not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to this embodiment are included in the protection scope of the present invention.

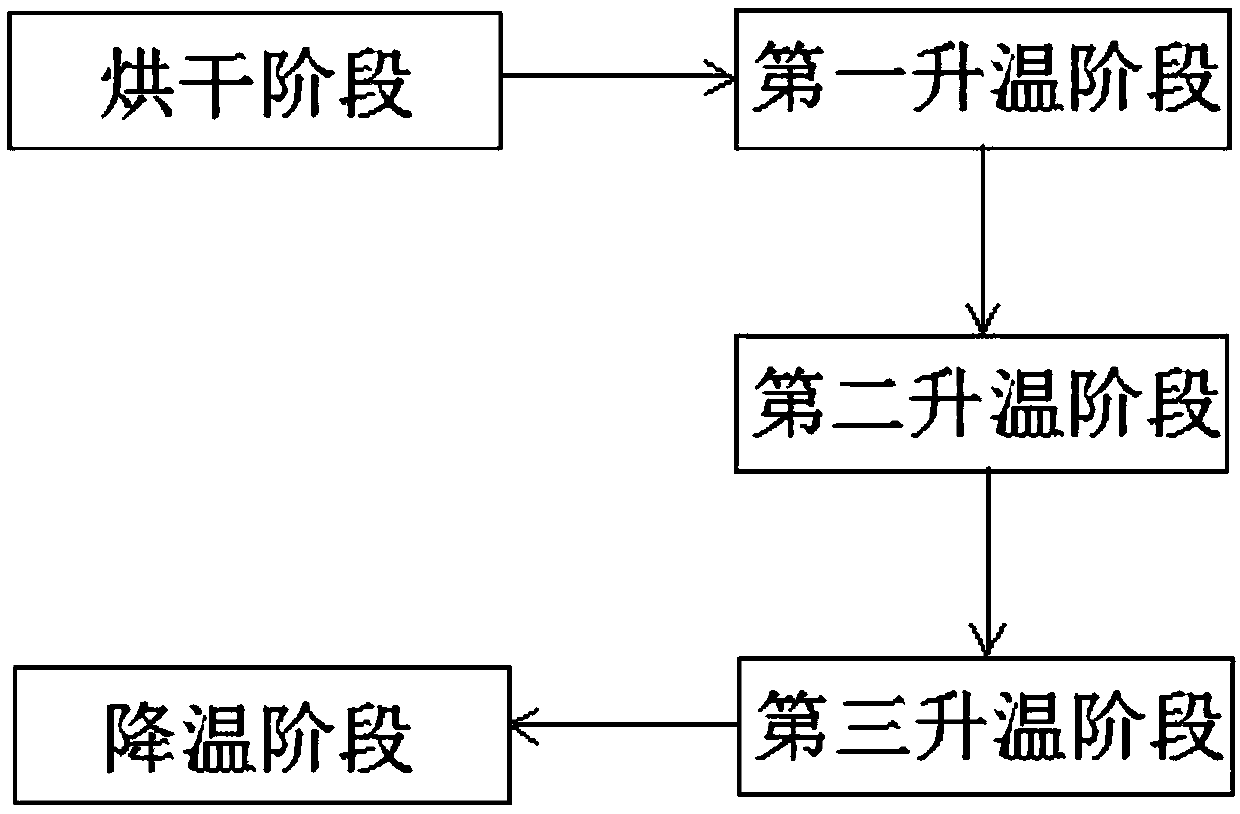

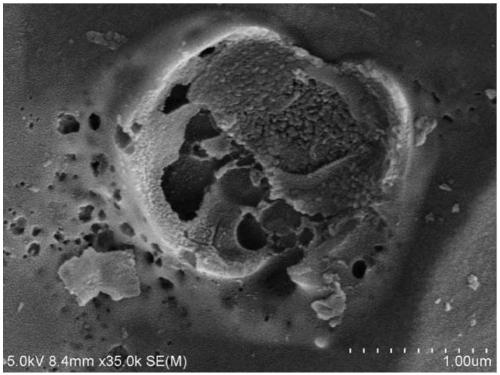

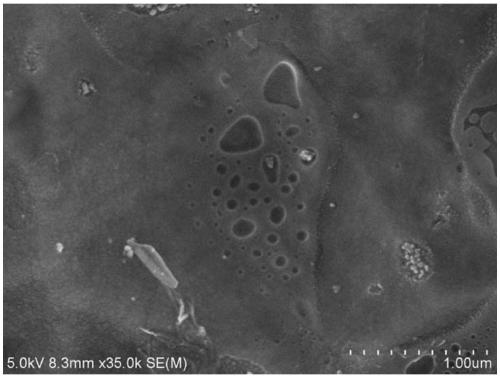

[0019] The preparation method of the double-sided PERC battery provided by the present invention mainly includes the steps of texturing, diffusion, edge etching and back surface polishing, coating, slotting, printing and sintering. Wherein, the coating step includes sequentially preparing a passivation film and a back anti-reflection film on the back surface of the silicon wafer, and preparing a front anti-reflection film on the front surface of the silicon wafer; the slotting step includes opening electrodes on the passivation film and the back anti-reflection film Opening; the printing step includes printing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com