Novel passivation device for surface treatment for metal casting

A metal casting and surface treatment technology, which is applied in the field of passivation devices for the surface treatment of new metal castings, can solve the problems of poor passivation effect, poor use effect, and environmental pollution, and achieve reasonable structure, improved passivation effect, The effect of uniform concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

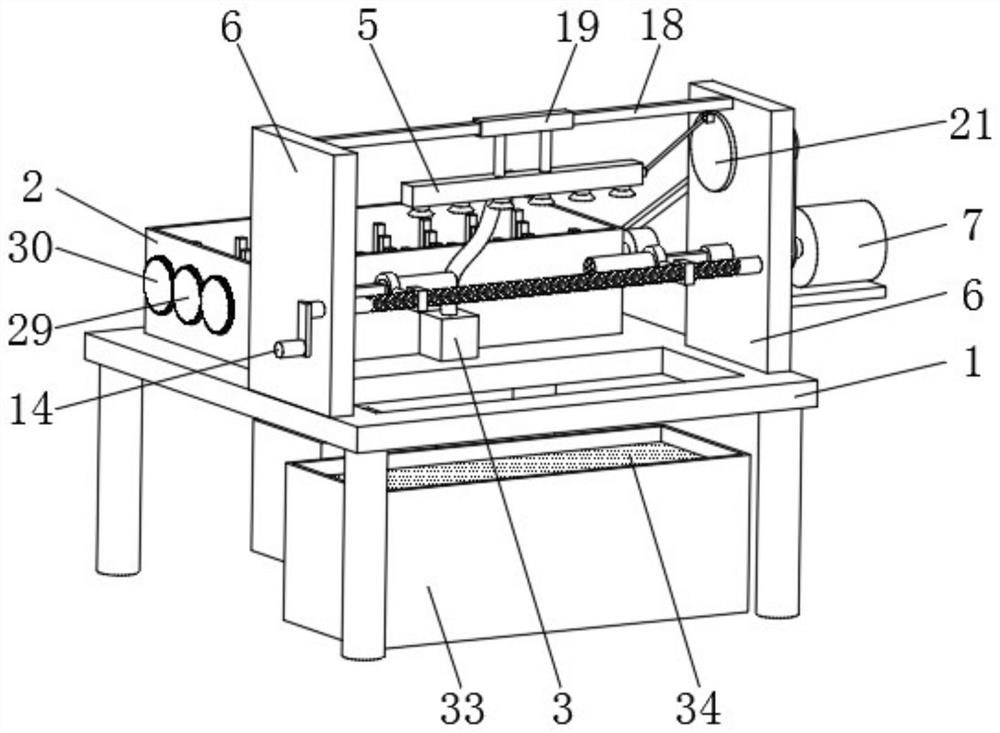

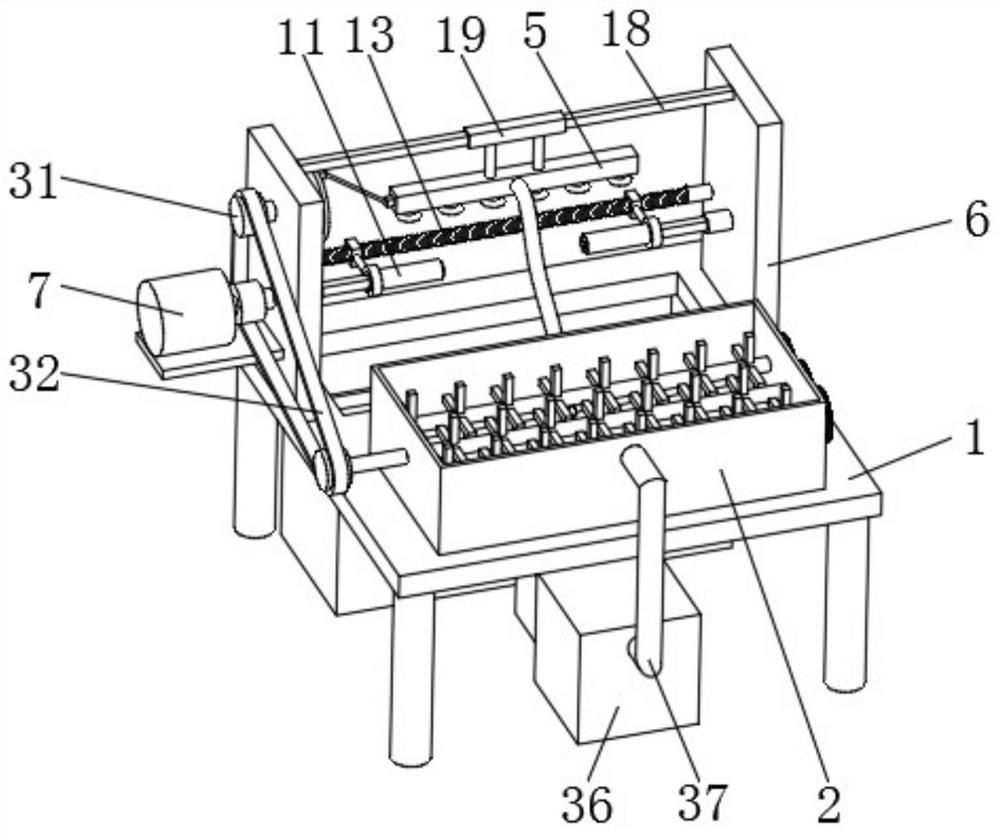

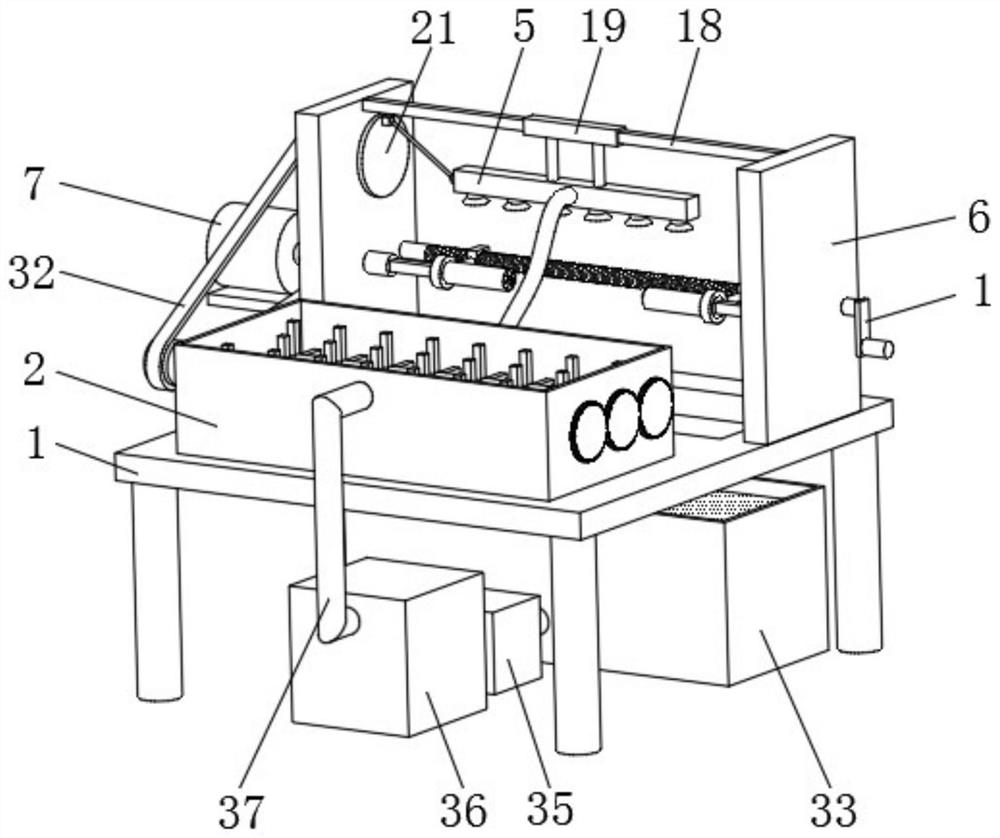

[0039] Example: Reference Figure 1-8 A novel passivation device for surface treatment of metal castings shown includes a treatment table 1, which can be any table structure in the prior art, such as a metal table.

[0040] A liquid storage tank 2 is fixedly installed on the top of the processing table 1, and the liquid storage tank 2 may be any metal box in the prior art, which is screwed to the top of the processing table 1 for fixing.

[0041] A liquid suction pump 3 is fixedly installed on one side of the liquid storage tank 2, and a liquid suction pipe is fixedly installed at the liquid suction port of the liquid suction pump 3, and one end of the liquid suction pipe extends into the liquid storage tank 2, and the liquid outlet of the liquid suction pump 3 A flexible pipe 4 is fixedly installed at the mouth, and a connecting pipe 5 is fixedly installed at one end of the flexible pipe 4. A plurality of spray heads are evenly fixedly installed on the bottom of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com