Passivation equipment

A technology of equipment and passivation box, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as degradation, lower component efficiency, lower cell efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

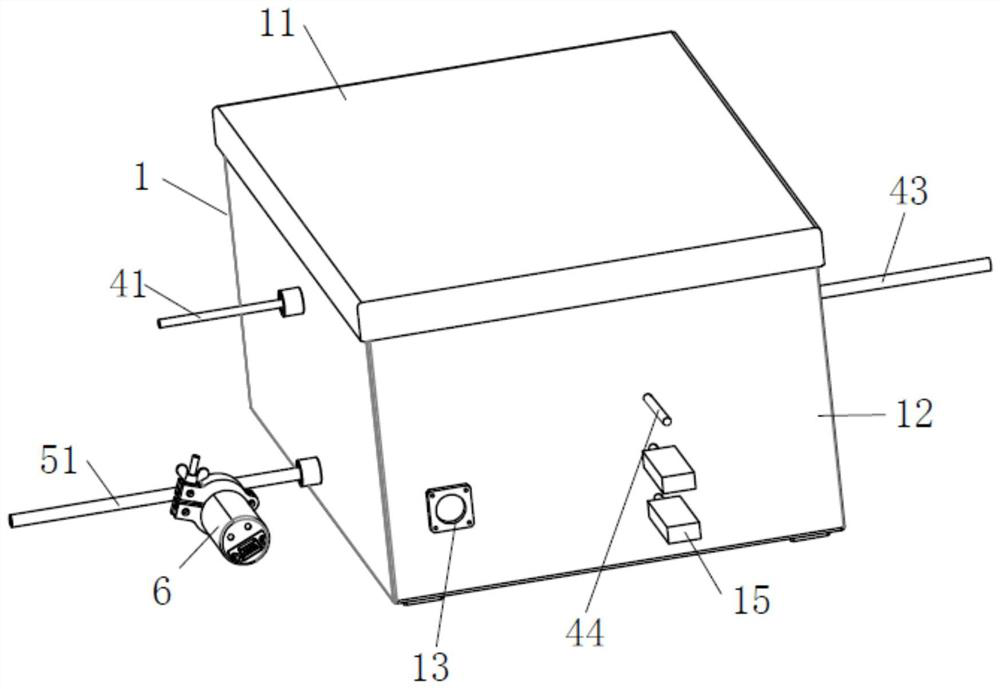

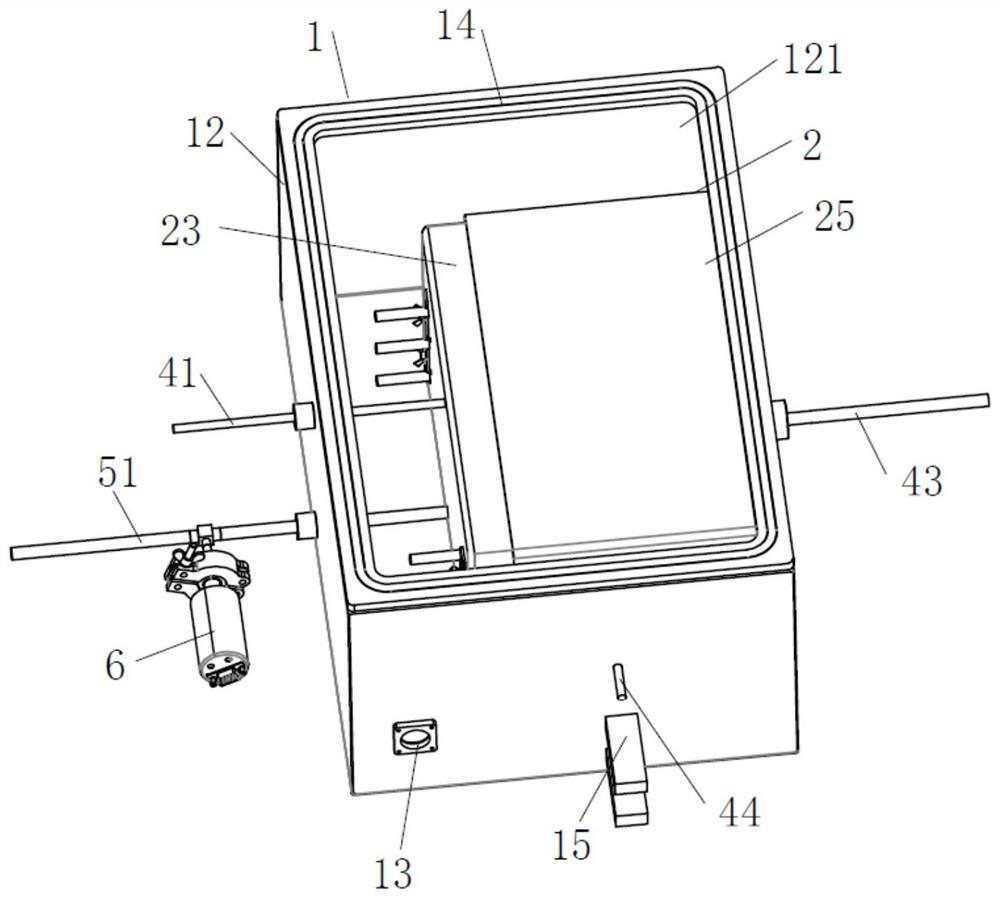

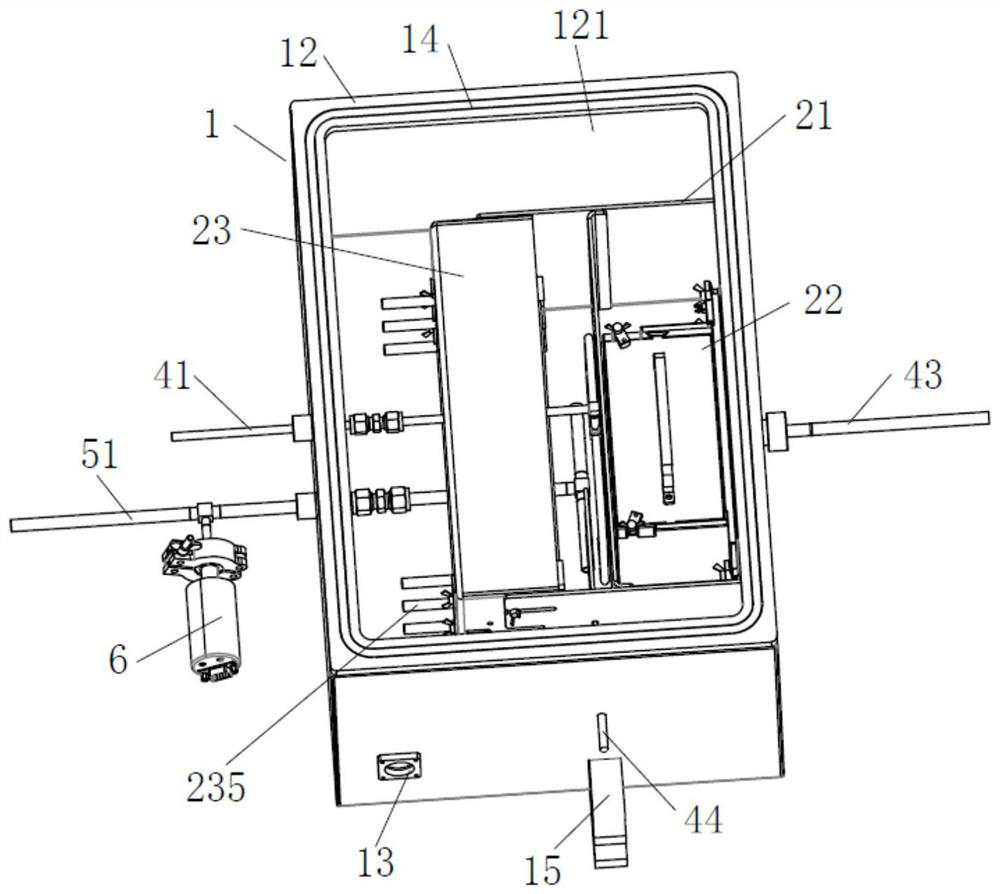

[0040] Such as Figure 1-9 As shown, a passivation equipment includes an isolation box 1 and a passivation box 2, the passivation box 2 is located inside the isolation box 1, and the passivation box 2 includes a loading structure 21, a carrier device 22, a spraying device and a heating device 23. The loading structure 21 carries the carrier device 22, the spray device and the heating device 23. The spray device is located between the carrier device 22 and the heating device 23. The spray device sprays oxygen or passivation gas, and the spray device sprays The passivating gas is in contact with the cross-sections of the sliced cells.

[0041] In this embodiment, the passivation gas is set as a mixed gas containing ozone, and the description below refers to ozone. In addition, the sliced battery 3 has at least one section.

[0042] The isolation box 1 is arranged as a square structure, and it includes an isolation body 12 and an isolation cover 11. The isolation body 12 inc...

Embodiment 2

[0059] Such as Figure 10 As shown, the difference between the present embodiment and the first embodiment is that in the first embodiment, ozone is introduced by the air duct 41 and sprayed through the spray pipe 42, while in the present embodiment, the oxygen is irradiated by the ultraviolet lamp 232 Ozone is produced.

[0060] In this embodiment, the ultraviolet lamp tube 232 is fixed on the housing 231 of the heating device 23, and the ultraviolet lamp tube 232 is provided with two groups. The tube 232 is located between the adjacent heating tubes 233. In the horizontal direction, the ultraviolet lamp tube 232 is located at the rear side of the heating tube 233, that is, the heating tube 233 is located between the ultraviolet lamp tube 232 and the carrier device 22. In order to prevent the heating tube 233 from For the radiation heating of the ultraviolet lamp tube 232, a heat insulating lampshade 234 is fixed between the two sets of fixing rods 235 of one group of heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com