Shell plane weld joint passivation device for machining

A kind of machining and shell technology, applied in the direction of metal material coating process, etc., can solve the problems of long welding seam, passivation effect of laying on the bottom, etc., to enhance the dispersion effect, increase the collision effect of passivation liquid flow, and improve the contact The effect of passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

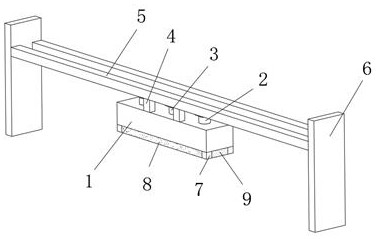

[0028] refer to Figure 1-3 , a shell plane weld passivation device for mechanical processing, comprising a passivation piece 1, a passivation cavity is opened at the bottom of the passivation piece 1, and a liquid inlet pipe 2 and a liquid outlet pipe are connected to the top of the passivation piece 1 3. Both sides of the top outer wall of the passivation piece 1 are fixed with a connecting piece 4, and the top of the connecting piece 4 is connected with a moving guide rail 5. Both positions are fixed with fixed blocks 7, and both sides of the bottom outer wall of the passivation part 1 are fixed with spacer pads 8, and both ends of the bottom outer wall of the passivation part 1 are fixed with smoothing pads 9;

[0029] When the device is in use, the lifting frame 6 is used to cover the passivation part 1 at the position of the weld, and the passivation liquid is circulated in the passivation chamber through the liquid inlet pipe 2 and the liquid outlet pipe 3, and the devi...

Embodiment 2

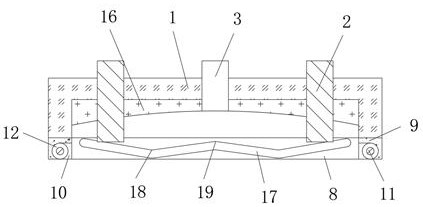

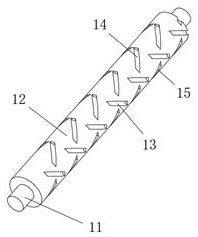

[0035] refer to Figure 1-5 , a shell plane weld passivation device for mechanical processing, a flow guide 16 is fixed on the top inner wall of the passivation piece 1, and the bottom outer wall of the flow guide 16 is set in an arc-shaped structure with an upward arch at the middle position, and the The liquid pipe 3 is fixed at the position corresponding to the top of the passivation piece 1 and the middle of the guide piece 16. There are two liquid inlet pipes 2, and the two liquid inlet pipes 2 are respectively fixed at the two ends of the passivation piece 1, so that the blunt The passivation solution in the passivation part 1 enters and fills from both ends and is drawn out from the middle position. Cooperating with the overall movement of the passivation part 1 and the diversion effect of the guide part 16 on the passivation liquid and solid debris, the two The passivation liquid at the position of end troweling roller 12 is kept clean to ensure the actual passivation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com