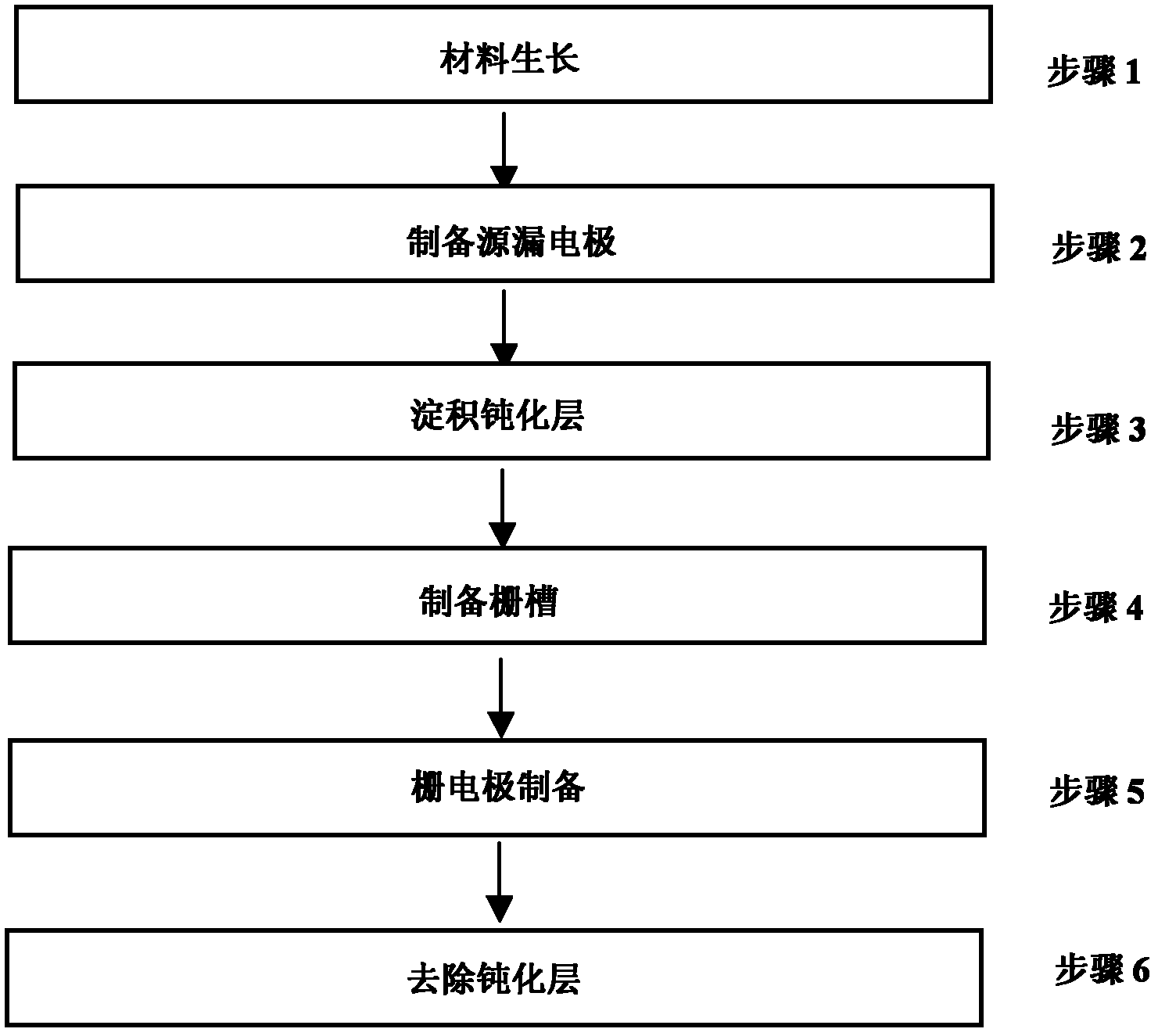

SiO2/SiN double layer passivation layer T-typed grid AlGaN/GaN HEMT and manufacturing method thereof

A production method and passivation layer technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as reducing the current cut-off frequency, and achieve improved current cut-off frequency, good passivation effect, and low gate parasitics The effect of capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

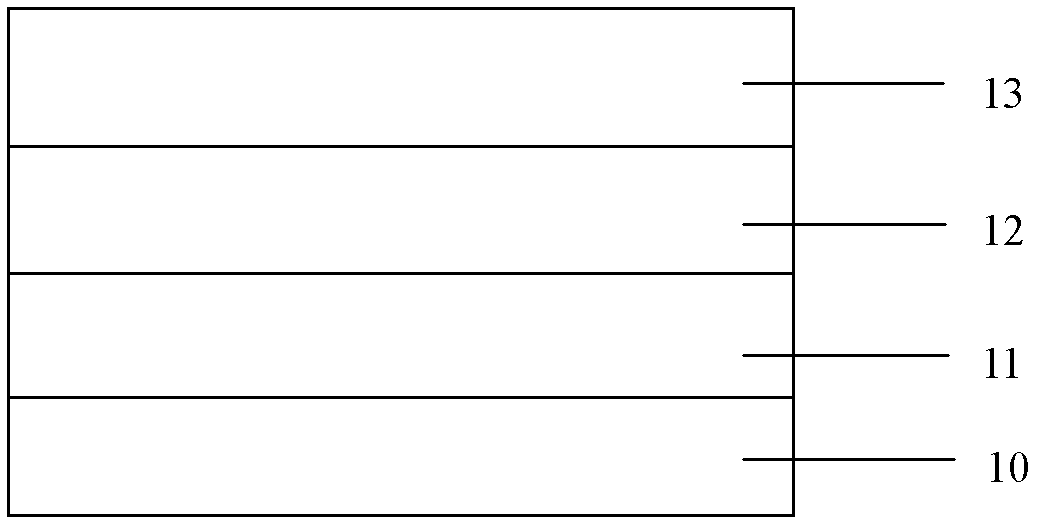

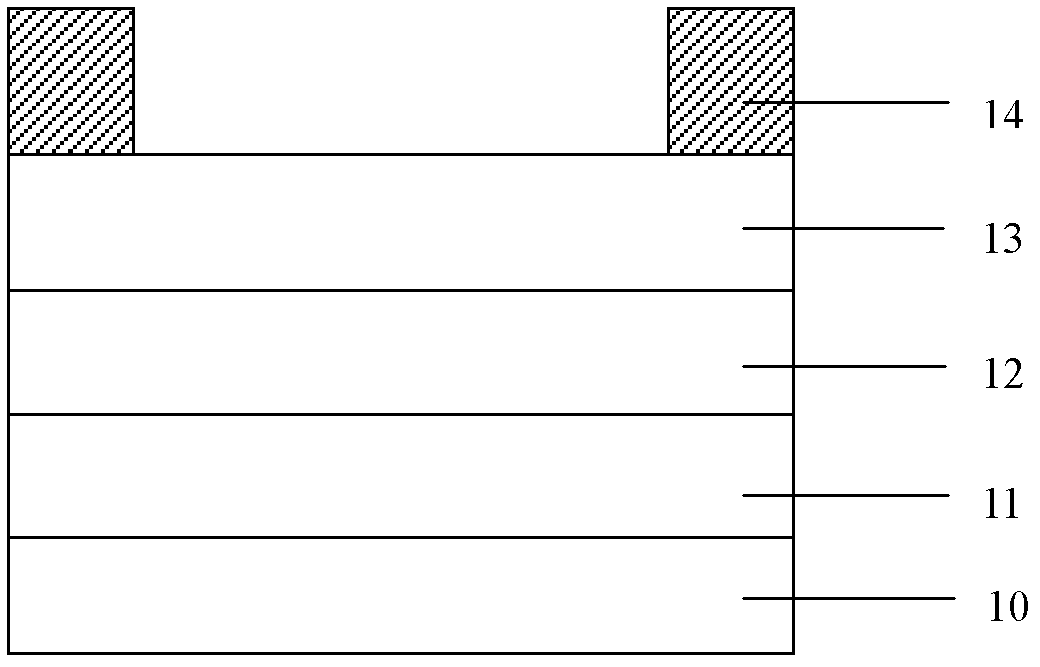

[0043] Referring to Fig. 6, the present invention provides a SiO 2 / SiN double-layer passivated T-gate AlGaN / GaN HEMTs, including:

[0044] A substrate 10, on which a GaN buffer layer 11, a GaN intrinsic layer 12 and an Al 0.25 Ga 0.75 N barrier layer 13, the material of the substrate 10 is sapphire;

[0045] A source-drain electrode 14, the source-drain electrode 14 is made on both sides above the barrier layer 13, and the material of the source-drain electrode 14 is Ti / Al / Ni / Au;

[0046] A lower passivation layer 15 is formed between the source and drain electrodes 14 and on the barrier layer 13, the material of the lower passivation layer 15 is SiN, and the thickness is 20nm;

[0047] An upper passivation layer 16 is made between the source and drain electrodes 14 and on the lower passivation layer 15, the material of the upper passivation layer 16 is SiO 2 , with a thickness of 80nm;

[0048] Wherein the middle of the lower passivation layer 15 and the upper passivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com