Production method of gray cast iron

A production method, the technology of gray cast iron, which is applied in the field of cast iron processing, can solve the problems of easy cracking, failure, and low service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

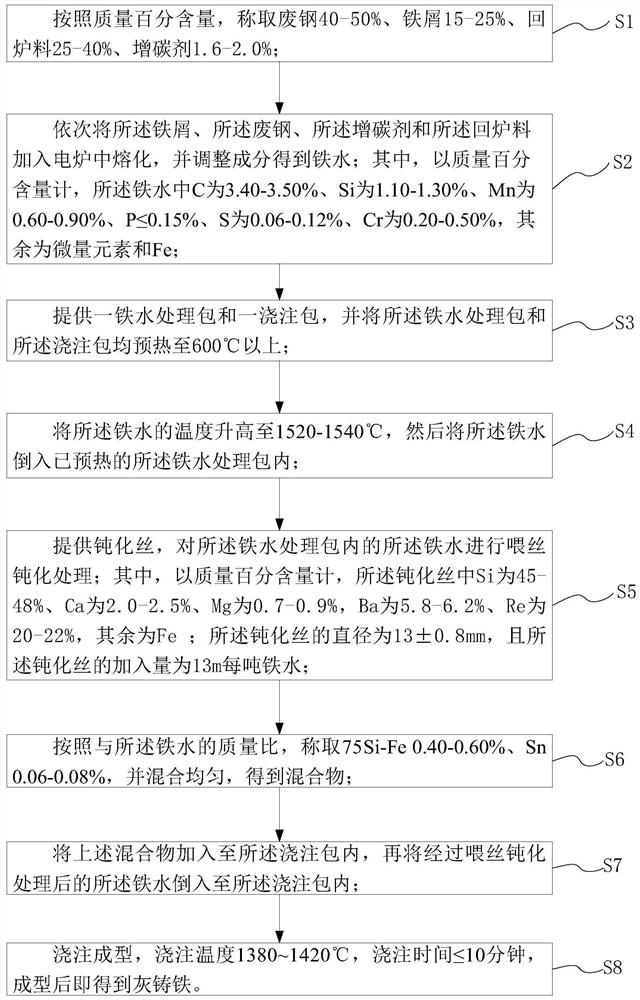

Method used

Image

Examples

Embodiment 1

[0078] According to the mass percentage content, 50% of steel scrap, 15% of iron filings, 33.4% of returned charge, and 1.6% of recarburizer were weighed.

[0079] Sequentially add steel scrap, iron filings, returned charge and recarburizer into the electric furnace to melt, and adjust the composition to obtain molten iron; wherein, in terms of mass percentage, C in the molten iron is 3.40-3.50%, Si is 1.10-1.30%, Mn 0.60-0.90%, P≤0.15%, S 0.06-0.12%, Cr 0.20-0.50%, and the rest are trace elements and Fe.

[0080] Both the molten iron treatment ladle and the pouring ladle are preheated to 800°C.

[0081] The temperature of the molten iron is raised to 1520° C., and then the molten iron is poured into the above-mentioned preheated molten iron treatment ladle.

[0082] Provide passivation wire, and passivate the molten iron in the molten iron treatment ladle; the diameter of the passivation wire is 13±0.8mm, and the amount of passivation wire added is 13m per ton of molten iron...

Embodiment 2

[0087] According to the mass percentage, weigh 40% of steel scrap, 23% of iron filings, 35% of returned charge, and 2.0% of recarburizer.

[0088] Sequentially add steel scrap, iron filings, returned charge and recarburizer into the electric furnace to melt, and adjust the composition to obtain molten iron; wherein, in terms of mass percentage, C in the molten iron is 3.40-3.50%, Si is 1.10-1.30%, Mn 0.60-0.90%, P≤0.15%, S 0.06-0.12%, Cr 0.20-0.50%, and the rest are trace elements and Fe.

[0089] Both the molten iron treatment ladle and the pouring ladle are preheated to 700°C.

[0090] The temperature of the molten iron is raised to 1540° C., and then the molten iron is poured into the above-mentioned preheated molten iron treatment ladle.

[0091] Provide passivation wire, and passivate the molten iron in the molten iron treatment ladle; the diameter of the passivation wire is 13±0.8mm, and the amount of passivation wire added is 13m per ton of molten iron.

[0092] Accor...

Embodiment 3

[0096] According to the mass percentage content, 40% of steel scrap, 18.4% of iron filings, 40% of returned charge, and 1.6% of recarburizer were weighed.

[0097] Sequentially add steel scrap, iron filings, returned charge and recarburizer into the electric furnace to melt, and adjust the composition to obtain molten iron; wherein, in terms of mass percentage, C in the molten iron is 3.40-3.50%, Si is 1.10-1.30%, Mn 0.60-0.90%, P≤0.15%, S 0.06-0.12%, Cr 0.20-0.50%, and the rest are trace elements and Fe.

[0098] Both the molten iron treatment ladle and the pouring ladle are preheated to 900°C.

[0099] The temperature of the molten iron is raised to 1530° C., and then the molten iron is poured into the above-mentioned preheated molten iron treatment ladle.

[0100] Provide passivation wire, and passivate the molten iron in the molten iron treatment ladle; the diameter of the passivation wire is 13±0.8mm, and the amount of passivation wire added is 13m per ton of molten iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com