A method for reducing the activity of heavy metal ions in livestock and poultry manure by adding ethionyl nitrogen

A technology of heavy metal ions and livestock and poultry manure, applied in organic fertilizers, climate change adaptation, fertilization devices, etc., can solve the problems of difficult plant treatment, high economic cost, low economic cost, etc., and achieve wide source of raw materials and good industrial feasibility , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

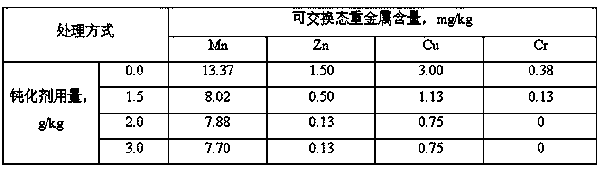

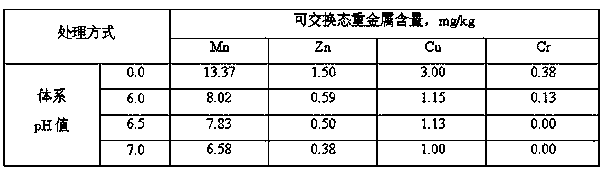

[0021] Under the condition of constant turning or stirring, spray the ethion nitrogen aqueous solution into the fresh goose manure, the mass concentration of the ethion nitrogen aqueous solution is 20%, the application amount is to add 1.5g ethion nitrogen per 1000kg of raw materials, and control the pH value=6.2 , and then left to stand for 2 hours to passivate the exchangeable heavy metal ions in the feces through a complex reaction with ethionyl nitrogen, and the ion activity is reduced. The passivation effect is shown in Table 1.

Embodiment 2

[0023] Under the condition of constant turning or stirring, spray the ethion nitrogen aqueous solution into the fresh goose manure, the mass concentration of the ethion nitrogen aqueous solution is 20%, and the application amount is to add 2.0g ethion nitrogen per 1000kg of raw materials, and control the pH value=6.2 , and then left to stand for 2 hours to passivate the exchangeable heavy metal ions in the feces through a complex reaction with ethionyl nitrogen, and the ion activity is reduced. The passivation effect is shown in Table 1.

Embodiment 3

[0025] Under the condition of constant turning or stirring, spray the ethion nitrogen aqueous solution into the fresh goose manure, the mass concentration of the ethion nitrogen aqueous solution is 20%, the application amount is to add 3.0g ethion nitrogen per 1000kg of raw materials, and control the pH value=6.2 , and then left to stand for 2 hours to passivate the exchangeable heavy metal ions in the feces through a complex reaction with ethionyl nitrogen, reducing its biological activity. The passivation effect is shown in Table 1.

[0026] The passivation effect of heavy metals is shown in Table 1, taking the goose manure without passivating agent as a control.

[0027] Table 1 Passivation effect of heavy metal passivators on exchangeable heavy metals in goose manure

[0028]

[0029] It can be seen from Table 1 that the passivation effect of ethyl disulfide on the exchangeable Mn, Zn, Cu and Cr in livestock and poultry manure is significant, and the passivation rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com