Pre-embedded bag for multi-stage remediation of uranium-contaminated soil and use method thereof

A soil remediation and soil remediation agent technology, which is applied in the field of pre-embedded bags for multi-level remediation of uranium-contaminated soil, can solve the problems of difficulty in limiting diffusion speed, slow remediation speed, high cost, etc., and achieve the purpose of increasing soil organic matter content and soil fertility, Improves the effect of adsorption and accumulation, improving repair speed and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

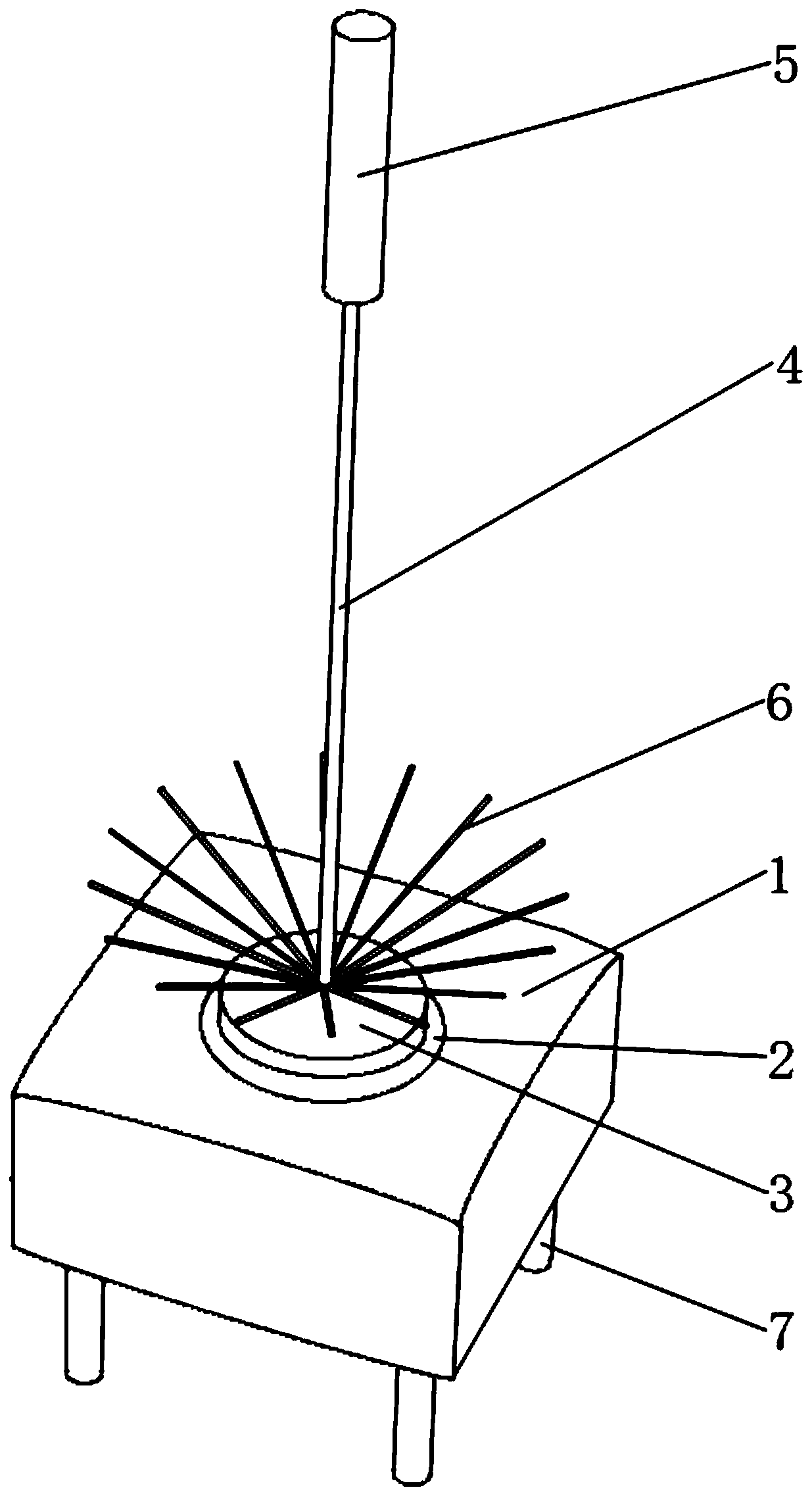

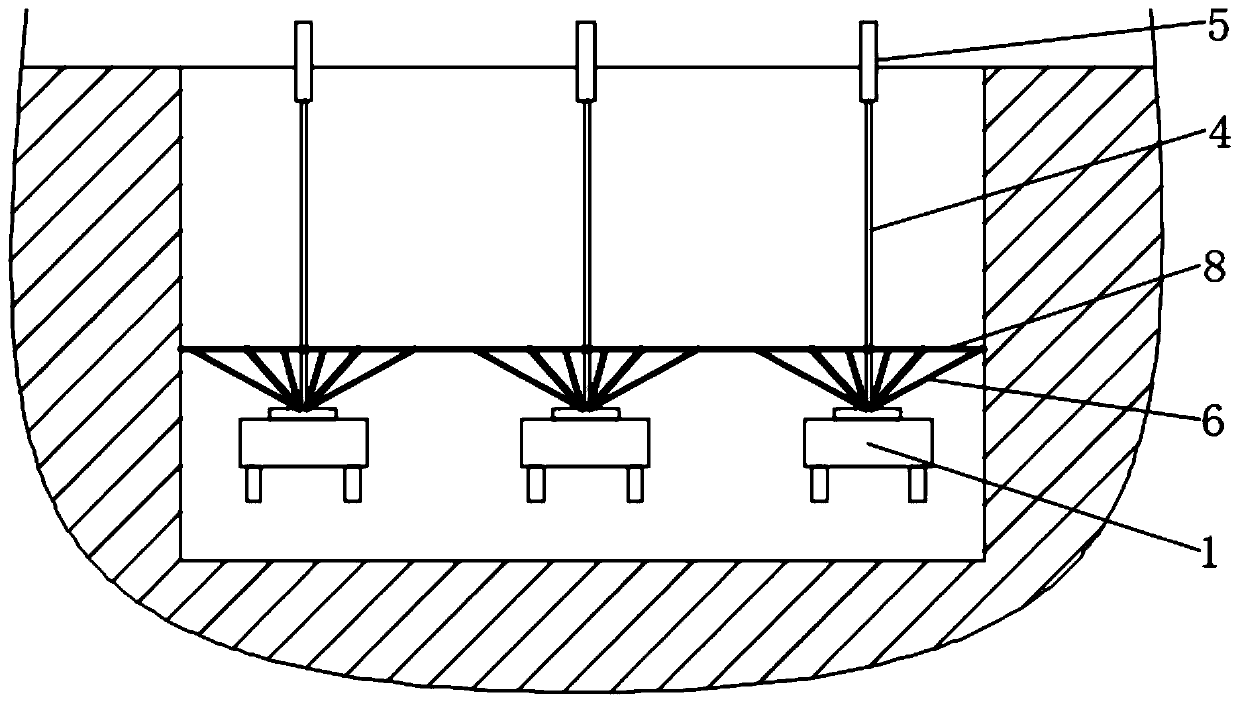

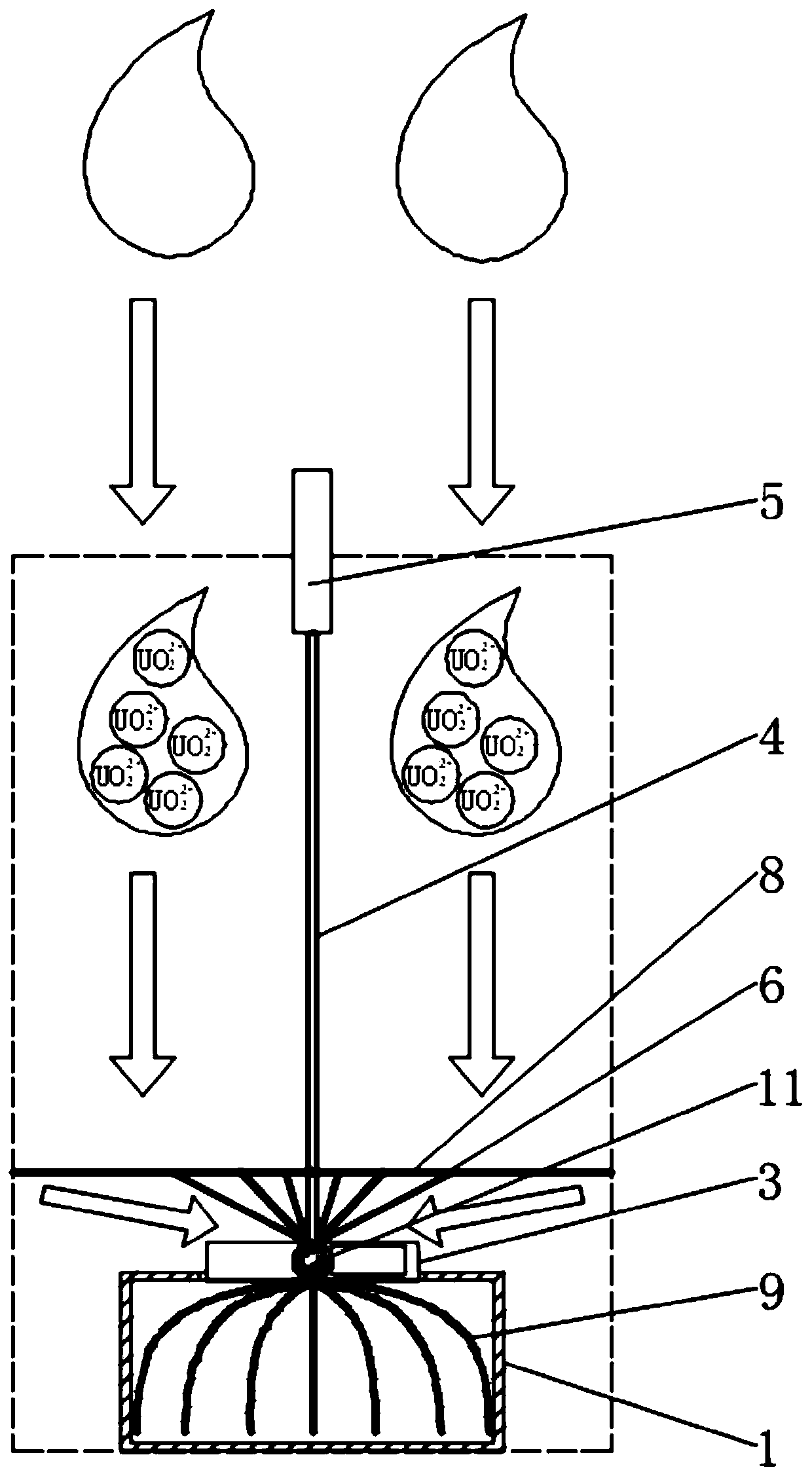

[0047] see figure 1 with image 3 , a pre-embedded bag for multi-level restoration of uranium-contaminated soil, the pre-embedded bag includes a pre-embedded bag body 1, the pre-embedded bag body 1 is a semipermeable membrane, allowing water molecules, nutrients, and uranyl ions to pass through, and the pre-embedded bag body 1 is filled with soil remediation agent, the upper end of the pre-embedded bag body 1 is drilled with an assembly hole, the inner end wall of the assembly hole is fixedly connected with a threaded sleeve 2, and the inner end of the threaded sleeve 2 is threaded with a threaded platform 3, which is convenient for installation and disassembly, and the threaded platform 3 A connection hole is dug in the center, and a transition ball 11 is fixedly connected in the connection hole to play the role of water transfer. The upper end of the transition ball 11 is fixedly connected with a deformation rod 4, which includes a cylindrical electric airbag, and the electr...

Embodiment 2

[0061] The soil remediation agent includes 35 parts by weight of organic silicon microbial fertilizer, 25 parts of modified medical stone powder, 10 parts of bentonite, 8 parts of natural zeolite, 8 parts of apatite, and 10 parts of chelating agent. After the active agent functionalizes Deinococcus radiata, it is mixed with decomposed pig manure and corn stalks, fully mixed and evenly composted, aerobically fermented, mixed with hydrolyzed silicate, fully dried and powdered to obtain fertilizer powder, then mix the fertilizer powder with polysiloxane, platinum catalyst, dimethyl silicone oil and ethyl orthosilicate, heat and solidify to obtain a gel solid, and heat the gel solid to 600°C for pyrolysis under an inert atmosphere The nanoporous repair material is obtained. The porosity of the nanoporous repair material is 80%-95%, and the pore diameter is 1nm-100nm. The lethal and mutational effects of various DNA damage media such as showing amazing resistance, known as "the mos...

Embodiment 3

[0071] The soil remediation agent includes 40 parts by weight of organic silicon microbial fertilizer, 30 parts of modified medical stone powder, 20 parts of bentonite, 10 parts of natural zeolite, 10 parts of apatite, and 15 parts of chelating agent. After the active agent functionalizes Deinococcus radiata, it is mixed with decomposed pig manure and corn stalks, fully mixed and evenly composted, aerobically fermented, mixed with hydrolyzed silicate, fully dried and powdered to obtain fertilizer powder, then mix fertilizer powder with polysiloxane, platinum catalyst, simethicone and ethyl orthosilicate, heat and solidify to form a gel solid, and heat the gel solid to 850°C for pyrolysis under an inert atmosphere The nanoporous repair material is obtained. The porosity of the nanoporous repair material is 80%-95%, and the pore diameter is 1nm-100nm. The lethal and mutational effects of various DNA damage media such as showing amazing resistance, known as "the most tenacious ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com