Annealing treatment process for PERC battery

An annealing treatment and process technology, which is applied in the field of solar cell manufacturing, can solve the problems of reduced minority carrier lifetime, small temperature curve adjustment space, and low negative charge density, and achieve the effects of improving minority carrier lifetime, overcoming adverse effects, and reducing interfacial recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

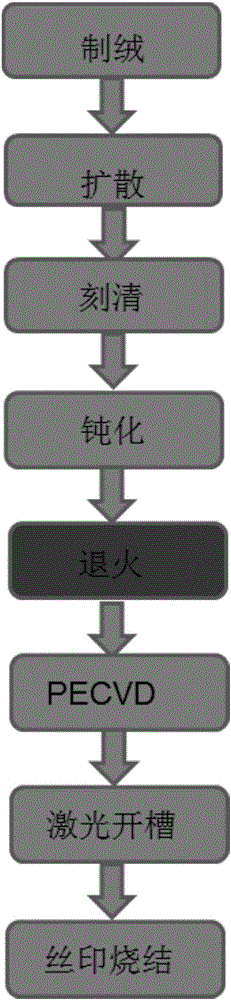

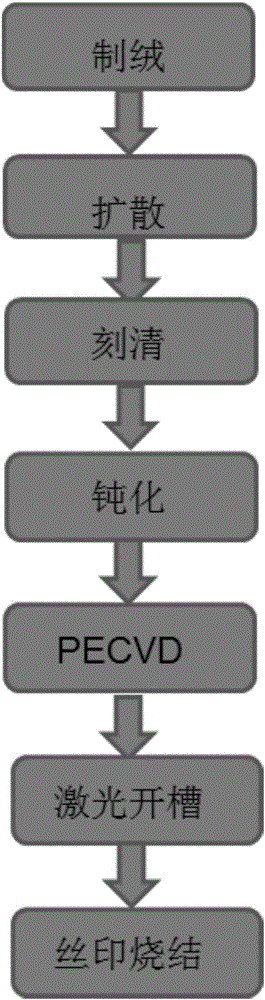

[0027] A kind of annealing treatment process of PERC battery of the present invention, comprises the following steps:

[0028] (1) Perform texturing, diffusion, and engraving on silicon wafers. Engraving is the name of a process in the solar cell manufacturing process, also known as "edge isolation" and "secondary cleaning".

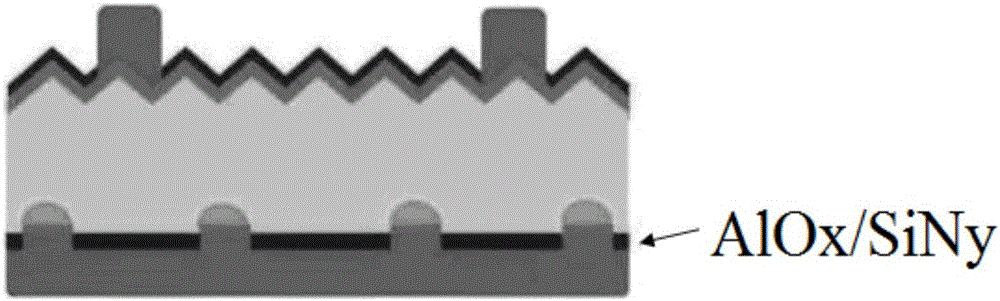

[0029] (2) After the silicon wafer is treated in step (1), a PECVD method is used to prepare an aluminum oxide thin film on the back of the silicon wafer with a thickness of 25 nm. The process parameters of the PECVD method used are: trimethylaluminum and laughing gas are used as reactants, the high-frequency power supply is 4000W, the flow rate of trimethylaluminum is 800mg / min, the flow rate of laughing gas is 2500sccm, and the flow rate of argon gas is 600sccm , the reaction temperature is 400°C.

[0030] (3) A silicon nitride film was prepared on the Al2O3 film prepared in step (2) by PECVD method, the thickness of which was 120nm, and a silicon wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com