A method for manufacturing a solar cell and a solar cell sintering device

A technology of solar cells and manufacturing methods, which is applied to the manufacture of circuits, electrical components, and final products, and can solve problems such as difficulty in reducing the warpage of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

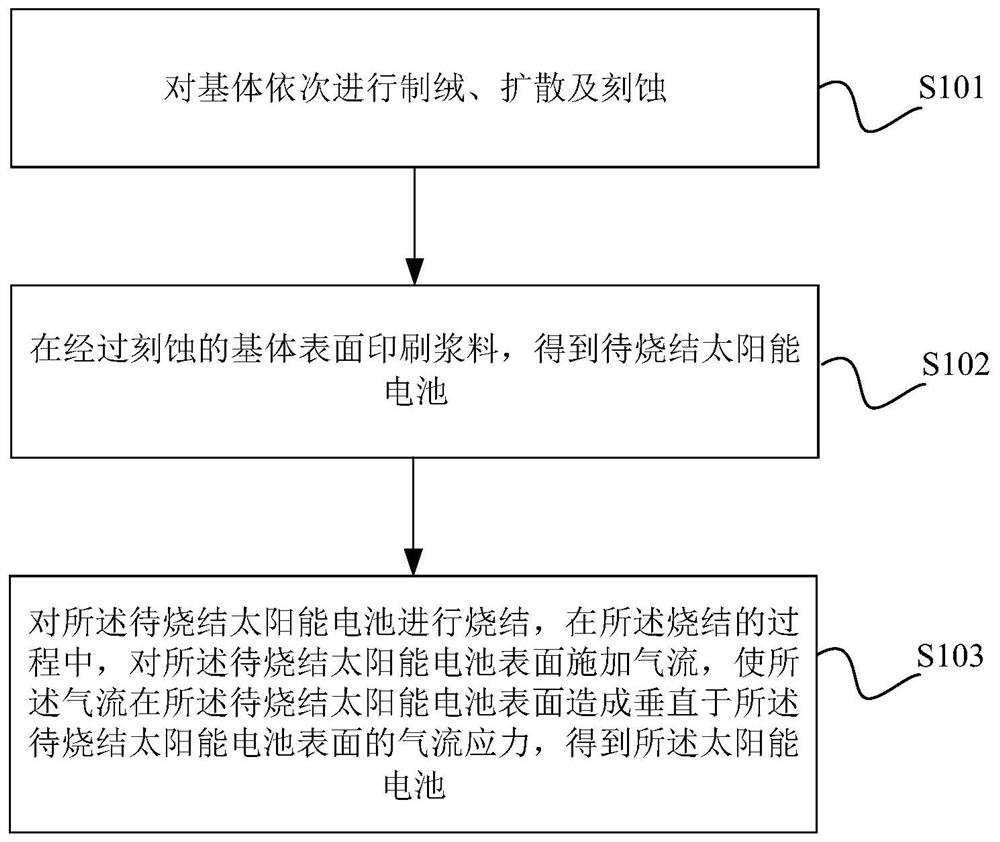

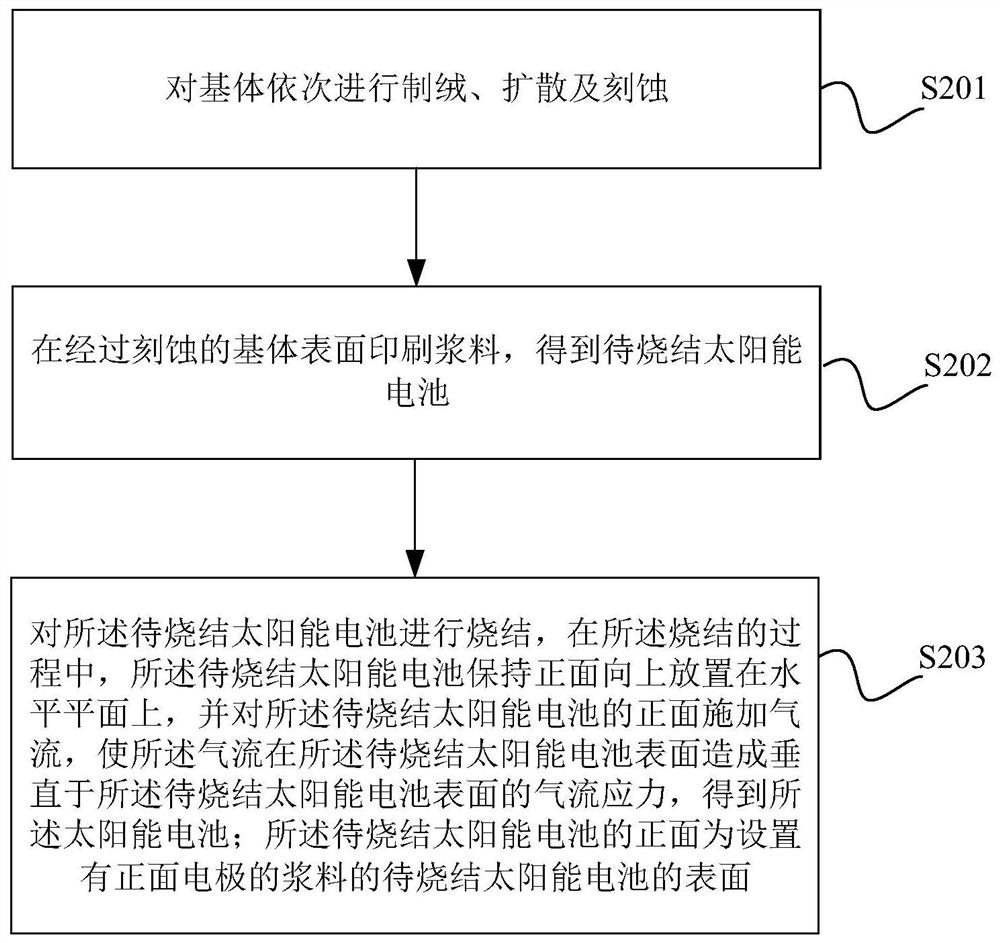

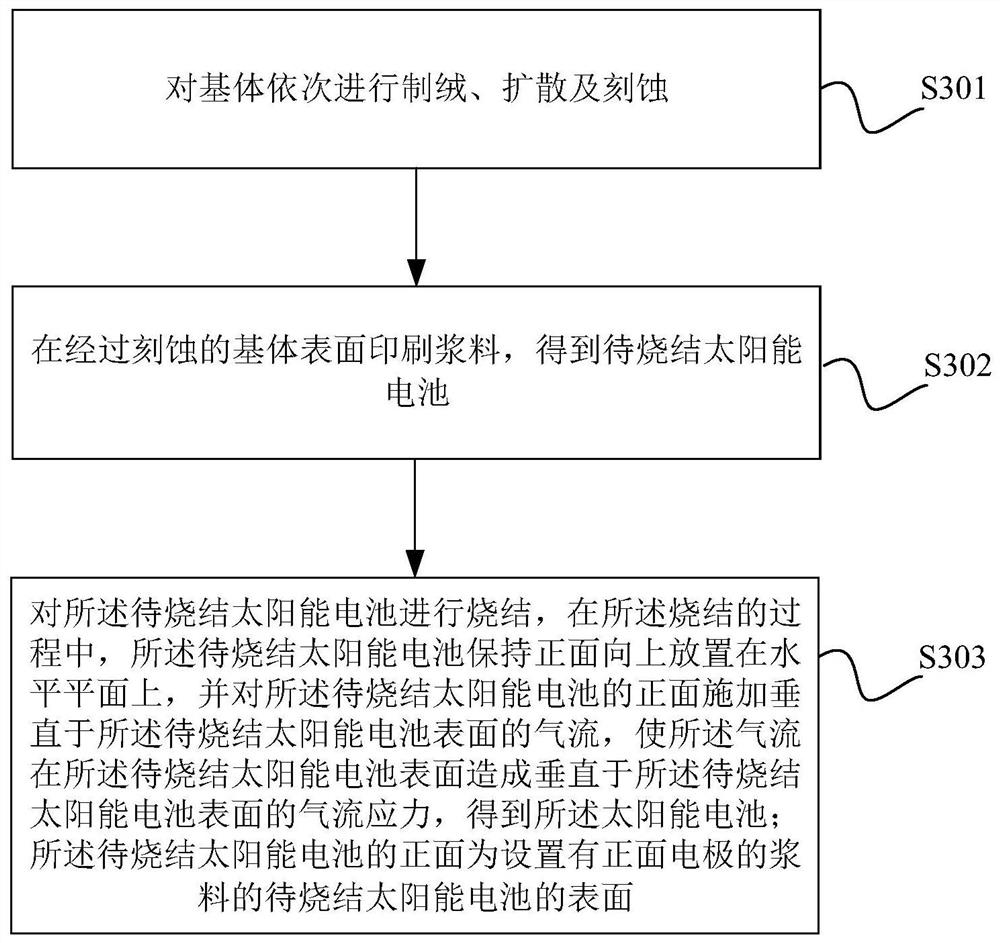

[0031] The core of the present invention is to provide a method for manufacturing a solar cell, and a schematic flow chart of a specific implementation thereof is as follows: figure 1 As shown, it is called the first specific implementation mode, including:

[0032] Step S101: performing texturing, diffusion and etching on the substrate in sequence.

[0033] Step S102: printing paste on the etched substrate surface to obtain a solar cell to be sintered.

[0034] Step S103: Sintering the above-mentioned solar cell to be sintered, during the above-mentioned sintering process, applying an airflow to the surface of the above-mentioned solar cell to be sintered, so that the above-mentioned airflow forms an airflow perpendicular to the surface of the above-mentioned solar cell to be sintered on the surface of the above-mentioned solar cell to be sintered stress, to obtain the above-mentioned solar cell.

[0035] Furthermore, the airflow stress on the surface of the solar cell to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com