Gas auxiliary injection molding method of car roof handle

A gas-assisted injection molding technology, applied in the field of auto parts, can solve the problems of not being able to give full play to the advantages of gas-assisted molding technology, affecting the appearance and image of injection molded parts, and reducing the strength of plastic products, so as to improve the appearance and image, improve injection molding efficiency, reduce The effect of internal stress in the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

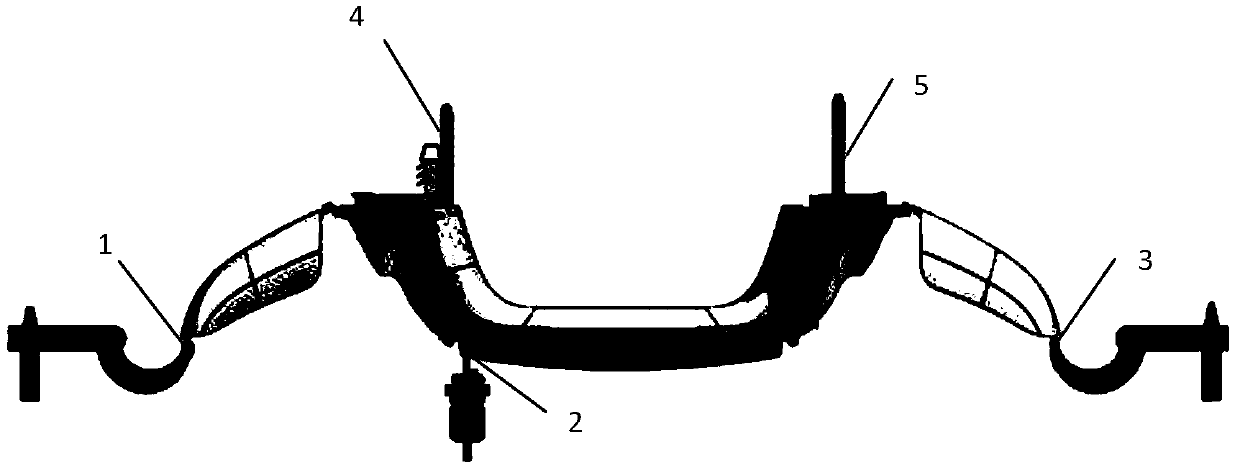

[0047] The 3 gates and 2 air inlets set in this embodiment are as follows: figure 1 As shown, molten polypropylene is injected into the mold cavity through gate 1, gate 2 and gate 3. The melt temperature is 230°C and the mold temperature is 60°C. After the mold is fully injected, hold the pressure for 2s. Close gate 1 and gate 3, then open air inlet 4 and air inlet 5, nitrogen is injected into the cavity melt through air inlet 4 and air inlet 5, and the nitrogen pressure in air inlet 5 is adjusted to 8MPa , the nitrogen pressure at the inlet 4 is 5MPa, the nitrogen temperature at the two inlets is 0°C, the gas injection time is 3s, the nitrogen pushes the fluid to flow, and the excess fluid flows back to the injection molding system from the gate 2, the plastic in the mold The melt is formed into a hollow state, and the pressure is kept for 6s, and then the mold is cooled in liquid nitrogen at -180°C, the mold is opened, and the product is taken out.

Embodiment 2

[0049] The 3 gates and 2 air inlets set in this embodiment are as follows: figure 1 As shown, the molten polypropylene is injected into the mold cavity through gate 1, gate 2 and gate 3. The melt temperature is 230°C, the mold temperature is 60°C, and the mold is filled with pressure for 6 seconds. Close gate 1 and gate 3, then open air inlet 4 and air inlet 5, nitrogen is injected into the cavity melt through air inlet 4 and air inlet 5, and the nitrogen pressure in air inlet 5 is adjusted to 8MPa , the nitrogen pressure at the inlet 4 is 5MPa, the nitrogen temperature at the two inlets is 0°C, the gas injection time is 3s, the nitrogen pushes the fluid to flow, and the excess fluid flows back to the injection molding system from the gate 2, the plastic in the mold The melt is formed into a hollow state, and the pressure is kept for 6s, and then the mold is cooled in liquid nitrogen at -180°C, the mold is opened, and the product is taken out.

Embodiment 3

[0051] The 3 gates and 2 air inlets set in this embodiment are as follows: figure 1 As shown, molten polypropylene is injected into the mold cavity through gate 1, gate 2 and gate 3. The melt temperature is 230°C and the mold temperature is 60°C. After the mold is fully injected, hold the pressure for 2s. Close gate 1 and gate 3, then open air inlet 4 and air inlet 5, nitrogen is injected into the cavity melt through air inlet 4 and air inlet 5, and the nitrogen pressure in air inlet 5 is adjusted to 8MPa , the nitrogen pressure at the inlet 4 is 5MPa, the nitrogen temperature at the two inlets is 30°C, the gas injection time is 3s, the nitrogen pushes the fluid to flow, and the excess fluid flows back to the injection molding system from the gate 2, the plastic in the mold The melt is formed into a hollow state, and the pressure is kept for 6s, and then the mold is cooled in liquid nitrogen at -180°C, the mold is opened, and the product is taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com