Method for improving corrosion resistance of 1Cr17Ni2 martensitic stainless steel fastener

A martensitic stainless steel, 1cr17ni2 technology, applied in metal material coating process and other directions, can solve problems such as poor corrosion resistance, improve corrosion resistance, avoid surface corrosion, and facilitate daily analysis and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

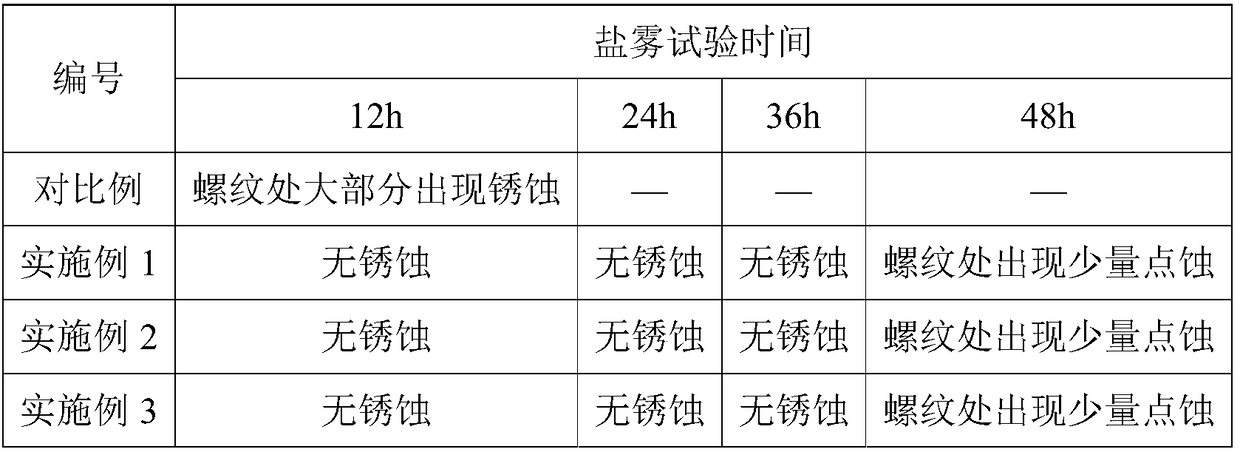

Examples

Embodiment 1

[0021] Embodiment 1 of the method for improving the corrosion resistance of 1Cr17Ni2 martensitic stainless steel fasteners of the present invention adopts the following steps:

[0022] 1) Put the fastener in lye (sodium hydroxide 220g / L, potassium permanganate 70g / L, solvent is water) and cook at 95°C for 25min to loosen the scale, and the fastener after alkali boiling Place in electropolishing solution for electropolishing treatment; wash with water after treatment for later use;

[0023] The composition of the electropolishing solution is: sulfuric acid 200mL / L, phosphoric acid 650mL / L, chromic anhydride 80g / L, and the solvent is water; during electropolishing, the temperature is 80°C and the current density is 40A / dm 2 , The voltage is 15V, and the time is 1min.

[0024] 2) Place the electropolished fasteners in a passivation solution for passivation treatment; wash with water and dry for later use;

[0025] The composition of passivation solution is: nitric acid 350mL / L,...

Embodiment 2

[0028] Embodiment 2 of the method for improving the corrosion resistance of 1Cr17Ni2 martensitic stainless steel fasteners of the present invention adopts the following steps:

[0029] 1) Put the fastener in lye (sodium hydroxide 180g / L, potassium permanganate 60g / L, solvent is water) and cook at 90°C for 20min to loosen the scale, and the fastener after alkali boiling Place in electropolishing solution for electropolishing treatment; wash with water after treatment for later use;

[0030] The composition of the electropolishing solution is: sulfuric acid 175mL / L, phosphoric acid 600mL / L, chromic anhydride 65g / L, and the solvent is water; during electropolishing, the temperature is 75°C and the current density is 25A / dm 2 , The voltage is 12V, and the time is 1.5min.

[0031] 2) Place the electropolished fasteners in a passivation solution for passivation treatment; wash with water and dry for later use;

[0032] The composition of passivation solution is: nitric acid 300mL / ...

Embodiment 3

[0035] Embodiment 3 of the method for improving the corrosion resistance of 1Cr17Ni2 martensitic stainless steel fasteners of the present invention adopts the following steps:

[0036] 1) Put the fastener in lye (sodium hydroxide 250g / L, potassium permanganate 80g / L, solvent is water) and cook at 100°C for 30 minutes to loosen the scale, and the fastener after alkali boiling Place in electropolishing solution for electropolishing treatment; wash with water after treatment for later use;

[0037] The composition of the electropolishing solution is: sulfuric acid 150mL / L, phosphoric acid 500mL / L, chromic anhydride 50g / L, and the solvent is water; during electropolishing, the temperature is 70°C and the current density is 15A / dm 2 , the voltage is 10V, and the time is 2min.

[0038] 2) Place the electropolished fasteners in a passivation solution for passivation treatment; wash with water and dry for later use;

[0039] The composition of passivation solution is: nitric acid 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com