Copper foil surface passivation treatment process in copper foil surface treatment process

A passivation treatment and surface treatment technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of strong carcinogenicity of hexavalent chromium, human body and environmental hazards, etc., to eliminate environmental barriers and ensure sustainable Good growth and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preparation of passivation solution

[0018] Add 500ml of deionized water into 1L passivation tank, add 17-25ml of phytic acid with a concentration of 70% into the passivation tank, and then dilute to 1L with deionized water to make the required passivation solution.

[0019] Passivation treatment of copper foil

[0020] Put the copper foil after surface roughening and curing treatment in the copper foil surface treatment process into the passivation tank, according to the working temperature of 12-42 ℃, and the current density of 0.4-4.0A / dm 2 , The passivation treatment time is 8-45s to complete the passivation treatment of copper foil.

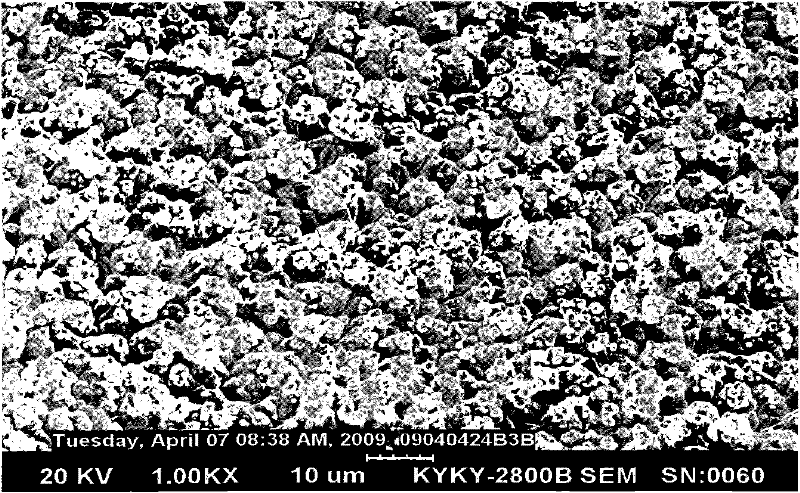

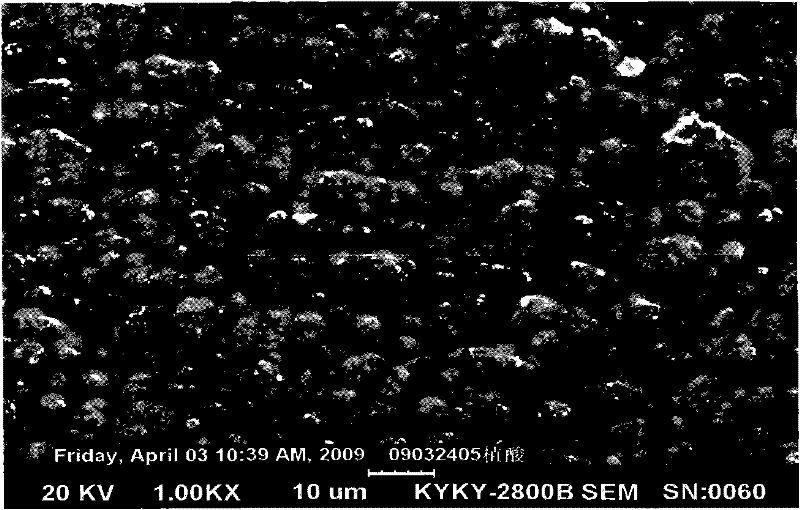

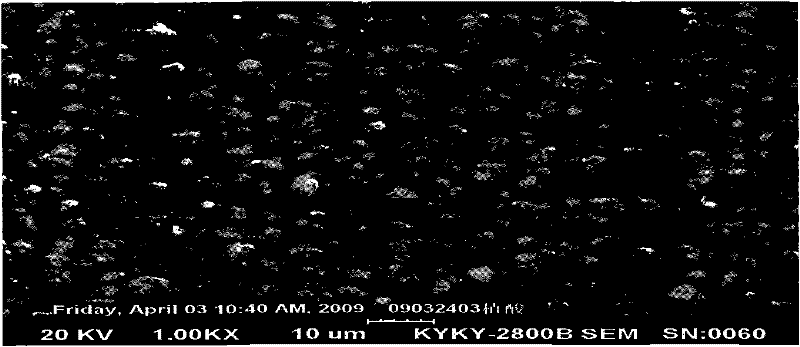

[0021] figure 1 For the use of phytic acid addition 20ml / L, passivation working temperature 15-30 ℃, current density 0.5-2A / dm 2 , Passivation treatment time 15s electron microscope scanning picture after passivation treatment of copper foil.

[0022] It can be seen from the figure that the surface of the copper foil is smooth an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com