Patents

Literature

332results about How to "Avoid surface damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

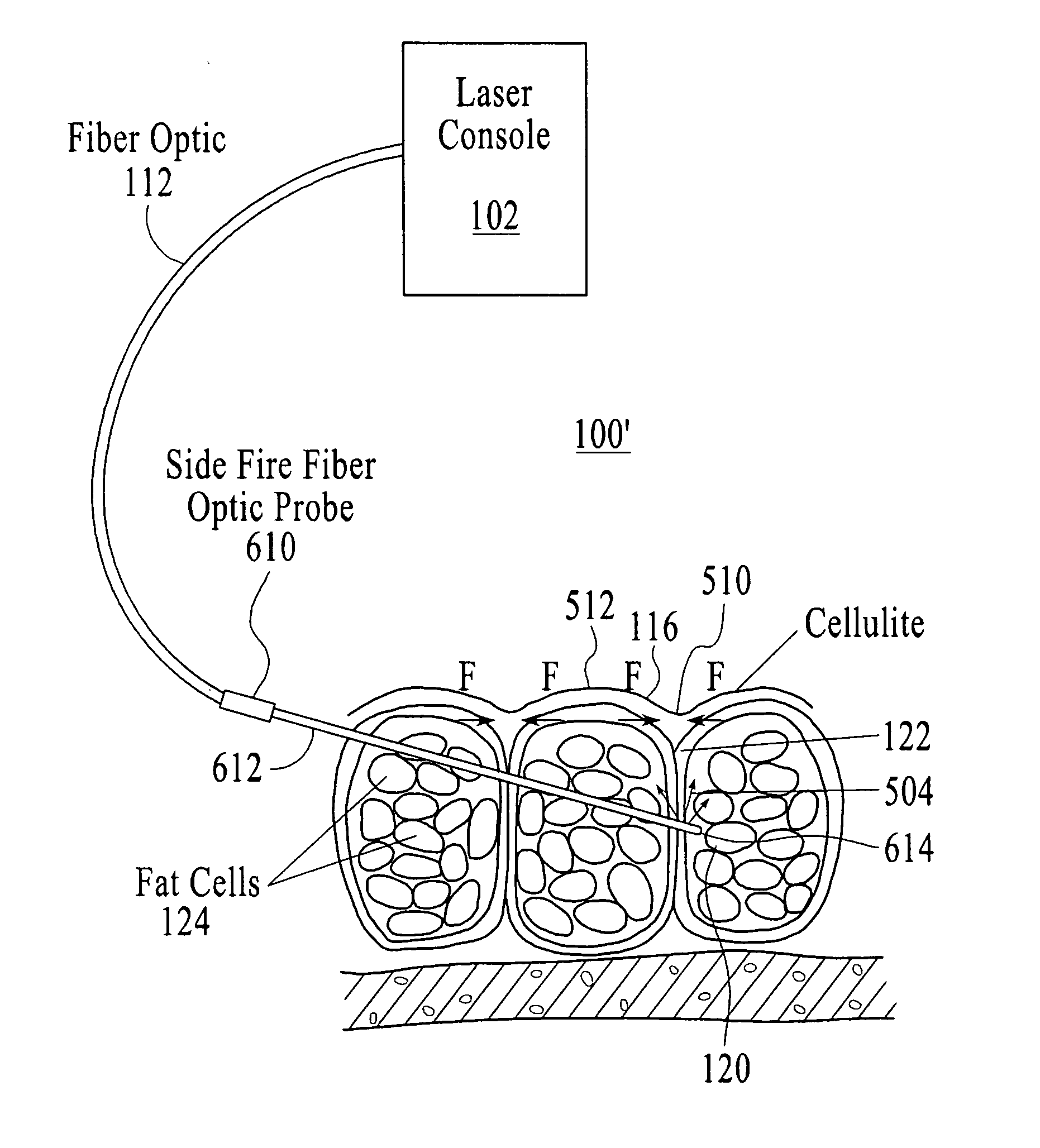

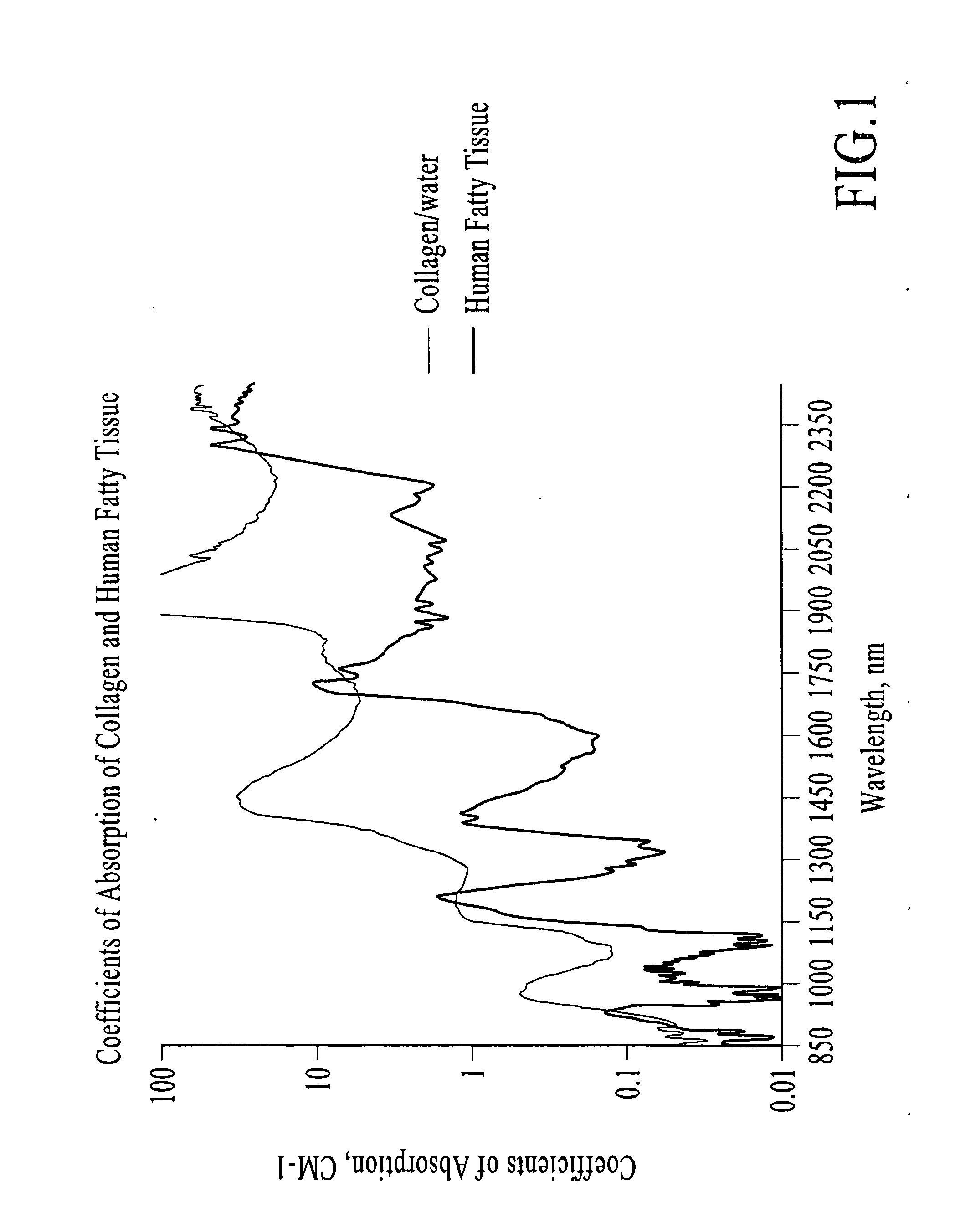

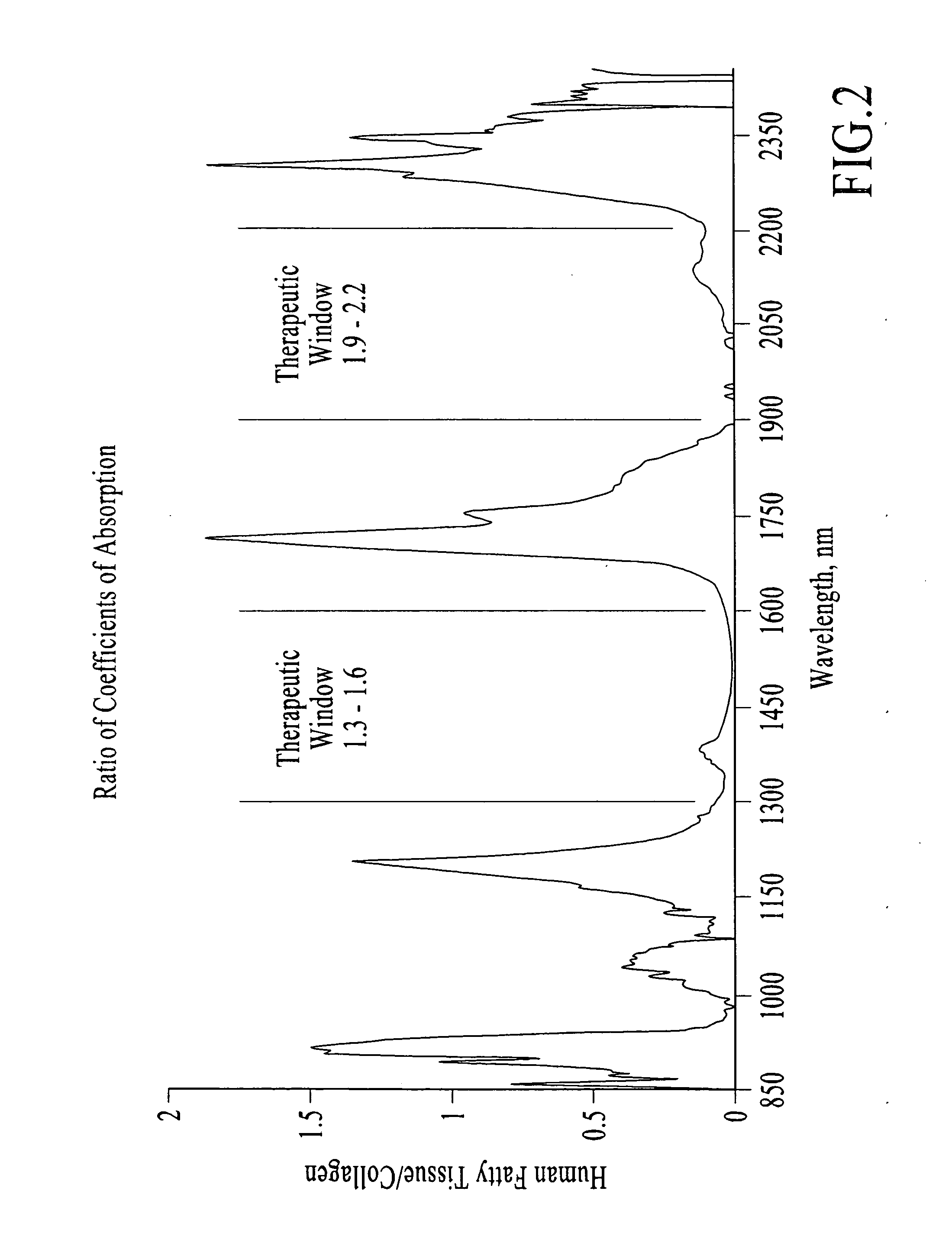

Treatment of cellulite and adipose tissue with mid-infrared radiation

InactiveUS20080188835A1Avoid epidermal damagePoor absorptionSurgical needlesSurgical instrument detailsLaser assisted liposuctionMid infrared

A handpiece and method of use for laser-assisted liposuction for melting, disrupting, and removing cellulite and adipose tissue. Electromagnetic energy is used to selectively melt or disrupt cellulite and adipose tissue and ablate the collagen in the constricting bands of connective tissue that causes the dimpled appearance of cellulite and adipose tissue, while avoiding damage to the surrounding fatty cells.

Owner:NEW STAR LASERS

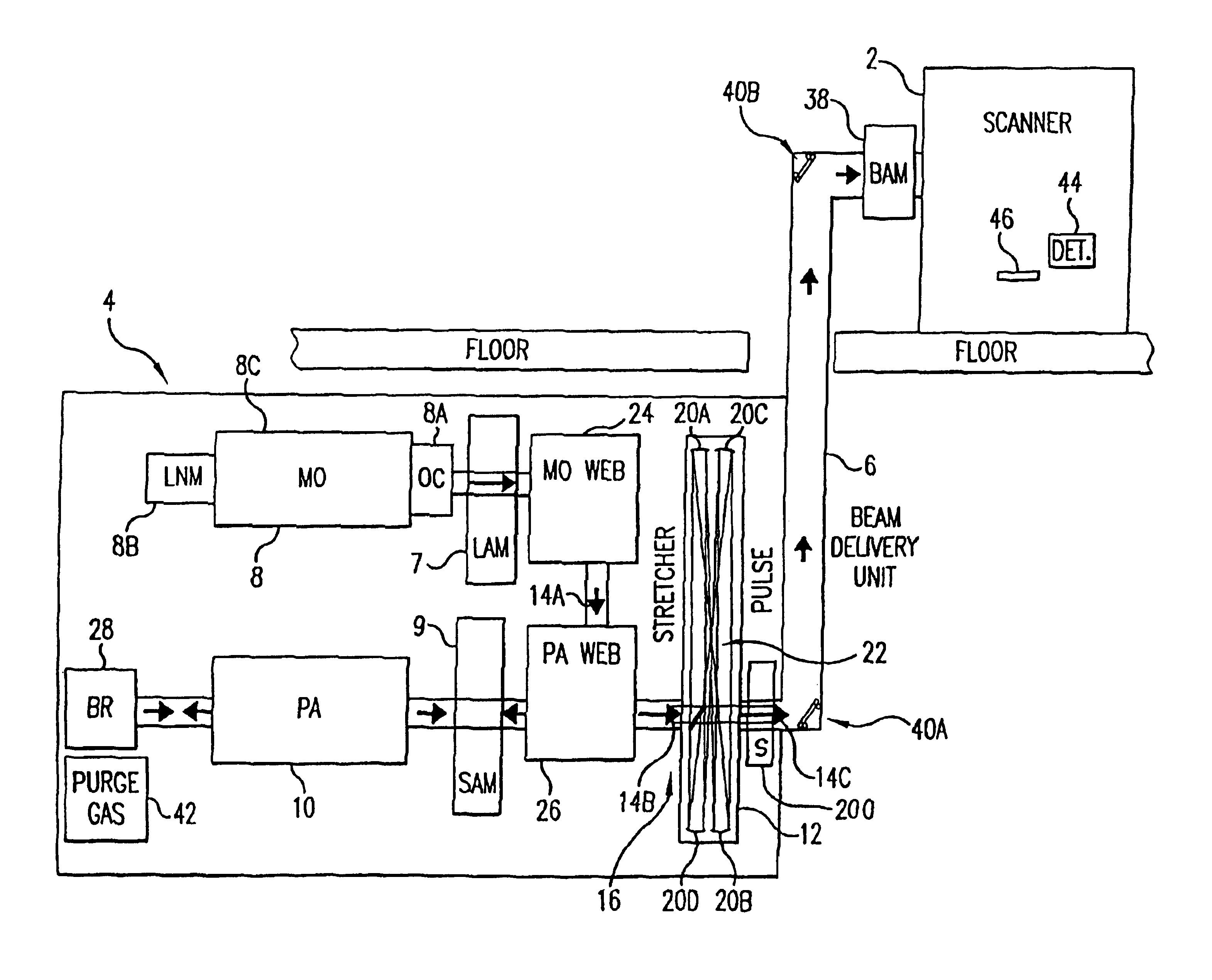

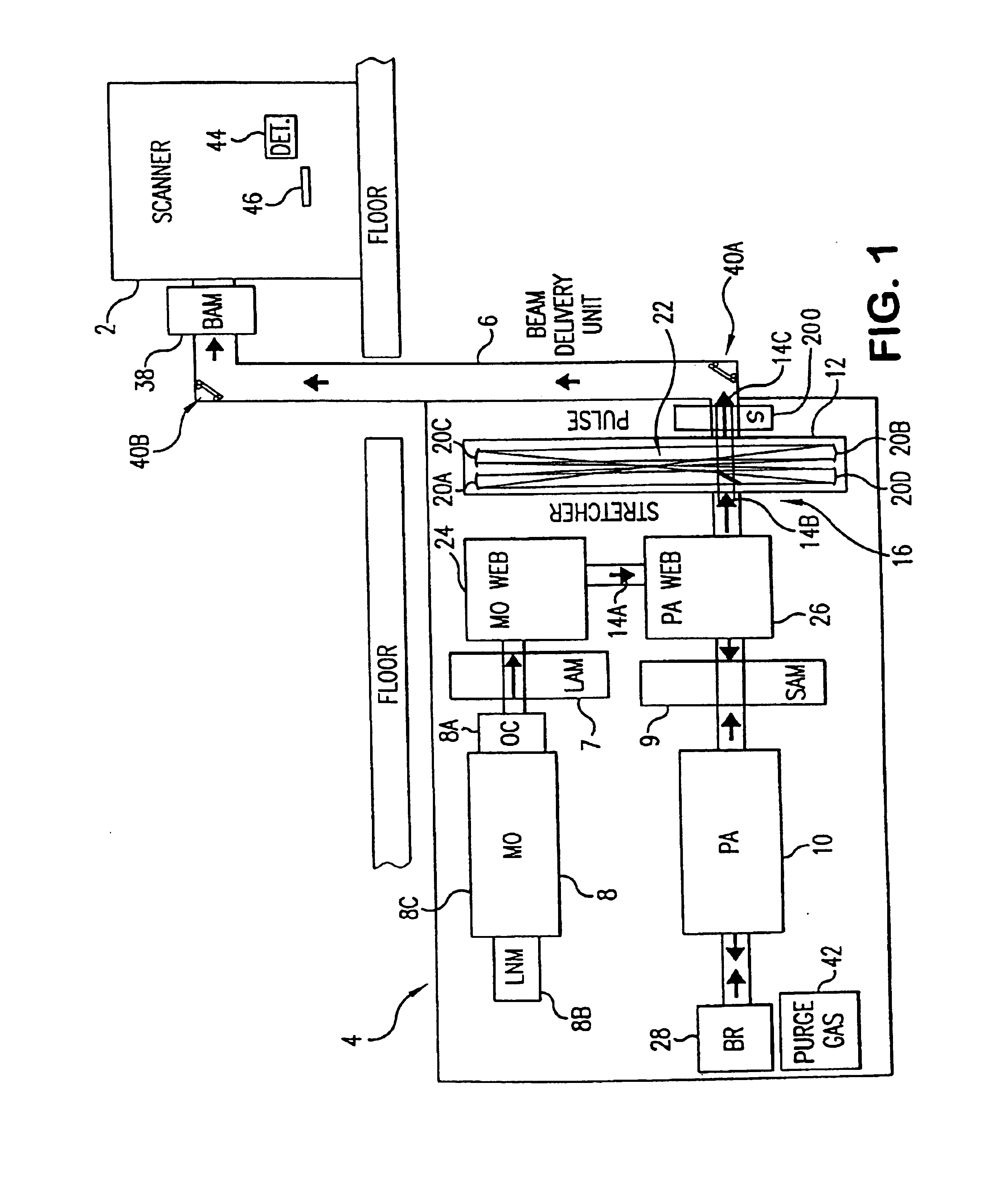

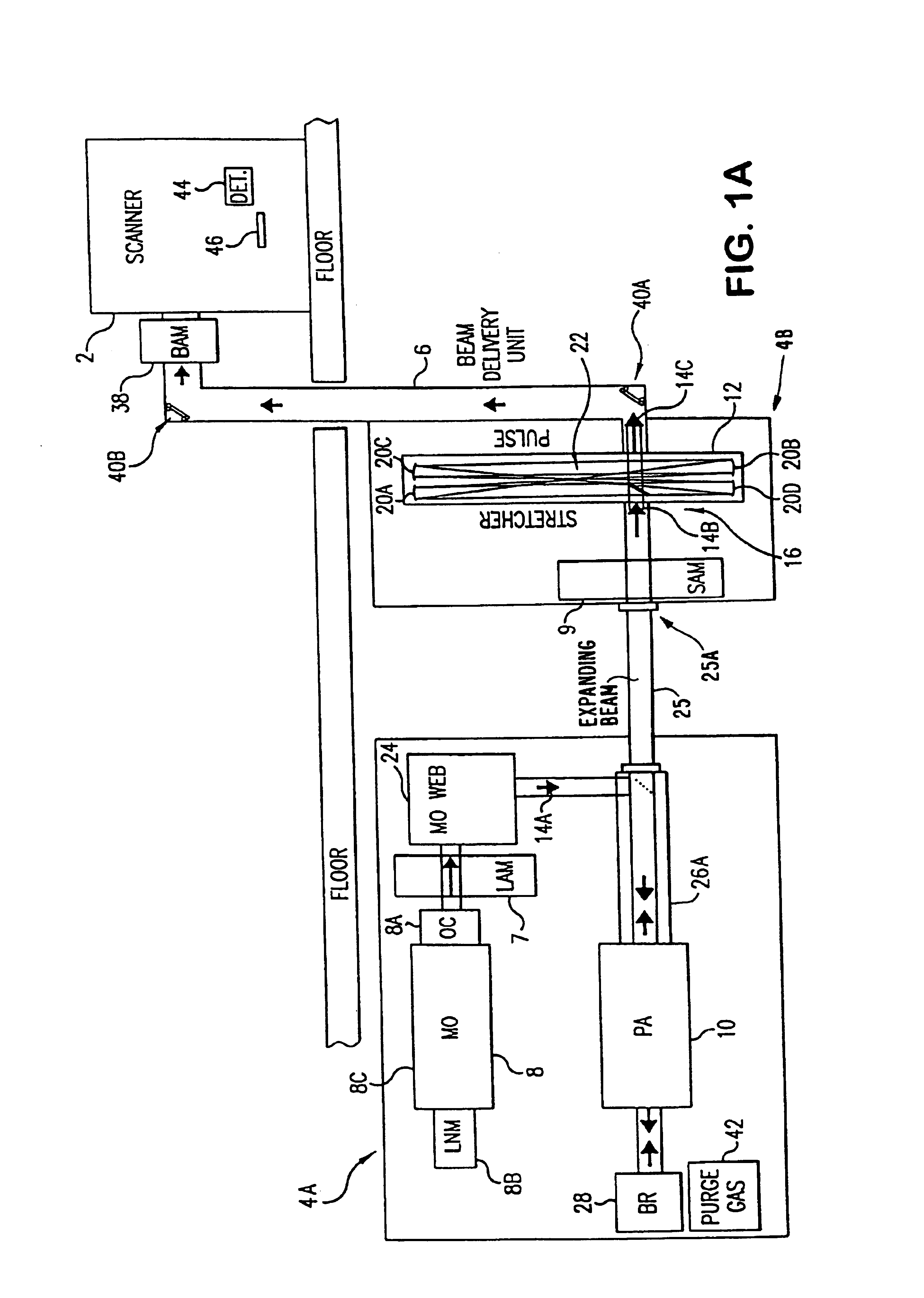

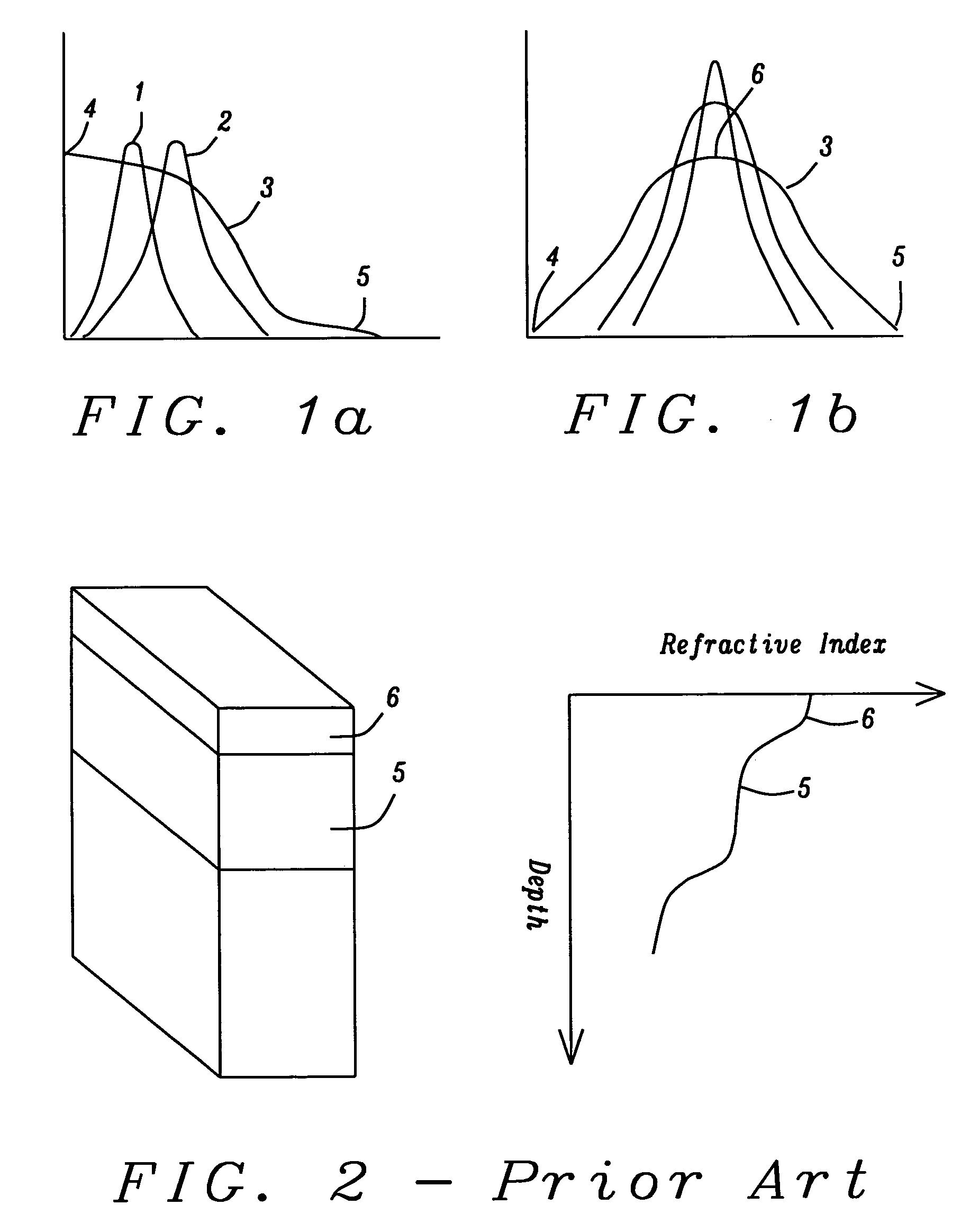

High power deep ultraviolet laser with long life optics

InactiveUS6904073B2Output powerBeam quality specificationOptical resonator shape and constructionLaser arrangementsPhysicsPulse energy density

The present invention provides long life optics for a modular, high repetition rate, ultraviolet gas discharge laser systems producing a high repetition rate high power output beam. The invention includes solutions to a surface damage problem discovered by Applicants on CaF2 optics located in high pulse intensity sections of the output beam of prototype laser systems. Embodiments include an enclosed and purged beam path with beam pointing control for beam delivery of billions of output laser pulses. Optical components and modules described herein are capable of controlling ultraviolet laser output pulses with wavelength less than 200 nm with average output pulse intensities greater than 1.75×106 Watts / cm2 and with peak intensity or greater 3.5×106 Watts / cm2 for many billions of pulses as compared to prior art components and modules which failed after only a few minutes in these pulse intensities. Techniques and components are disclosed for minimizing the potential for optical damage and for reducing the pulse energy density to less than 100×10−6 J / cm3. Important improvements described in this specification have been grouped into the following subject matter categories: (1) Solution to CaF2 surface damage discovered by Applicants, (2) description of a high power ArF MOPA laser system, (3) description of beam delivery units, (4) polarization considerations (5) a high speed water-cooled auto shutter energy detector module and (6) other improvements.

Owner:CYMER INC

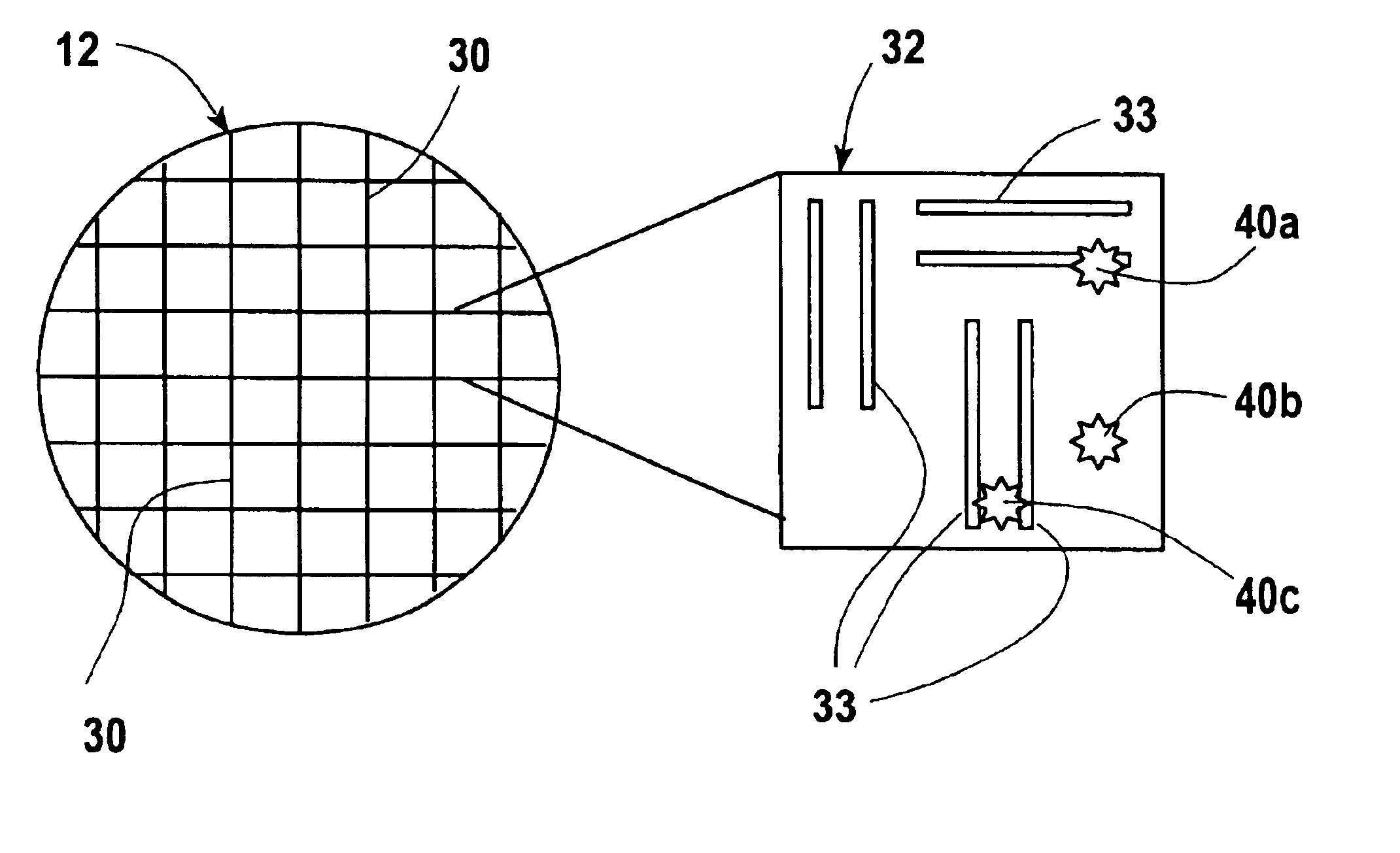

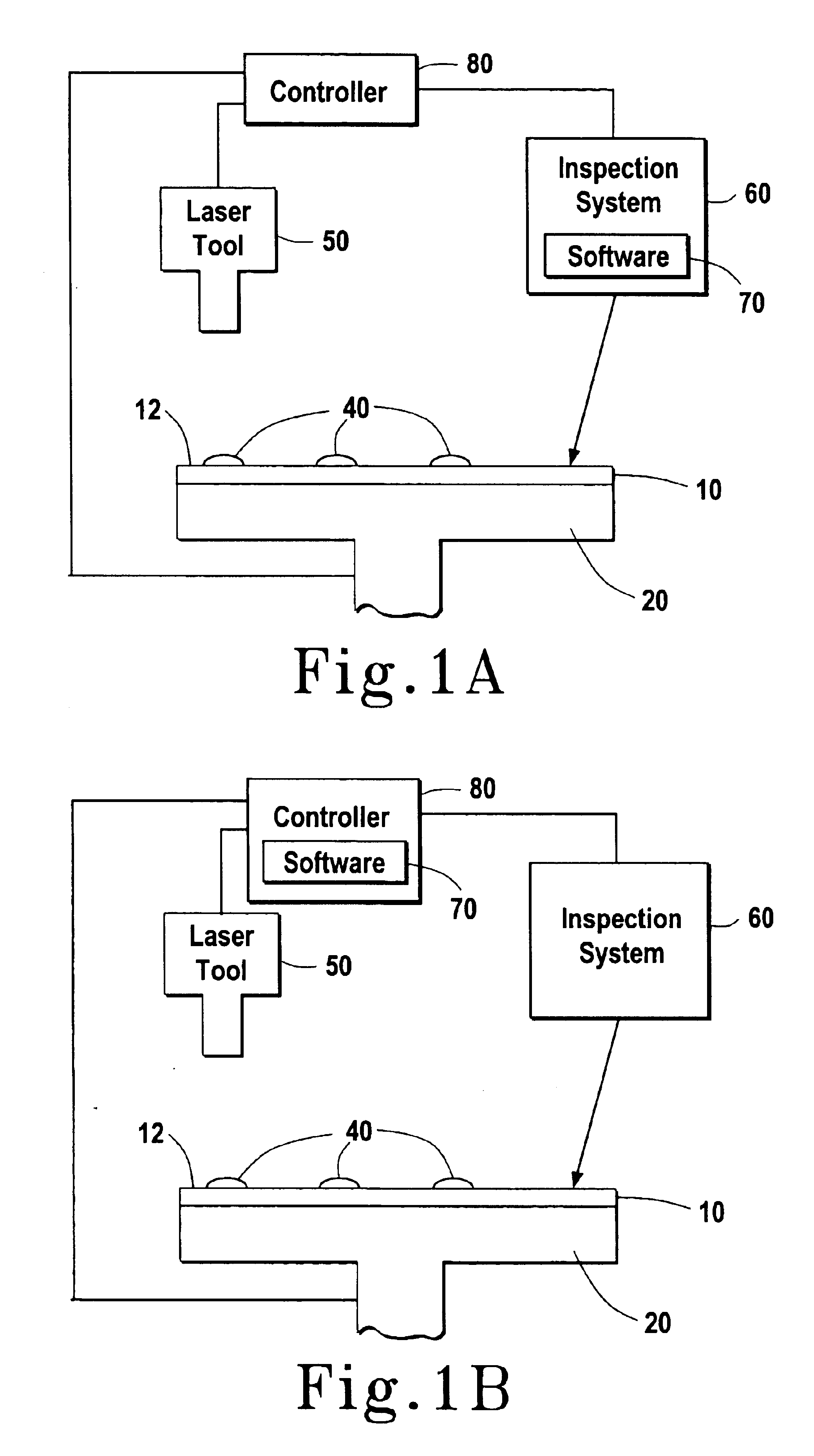

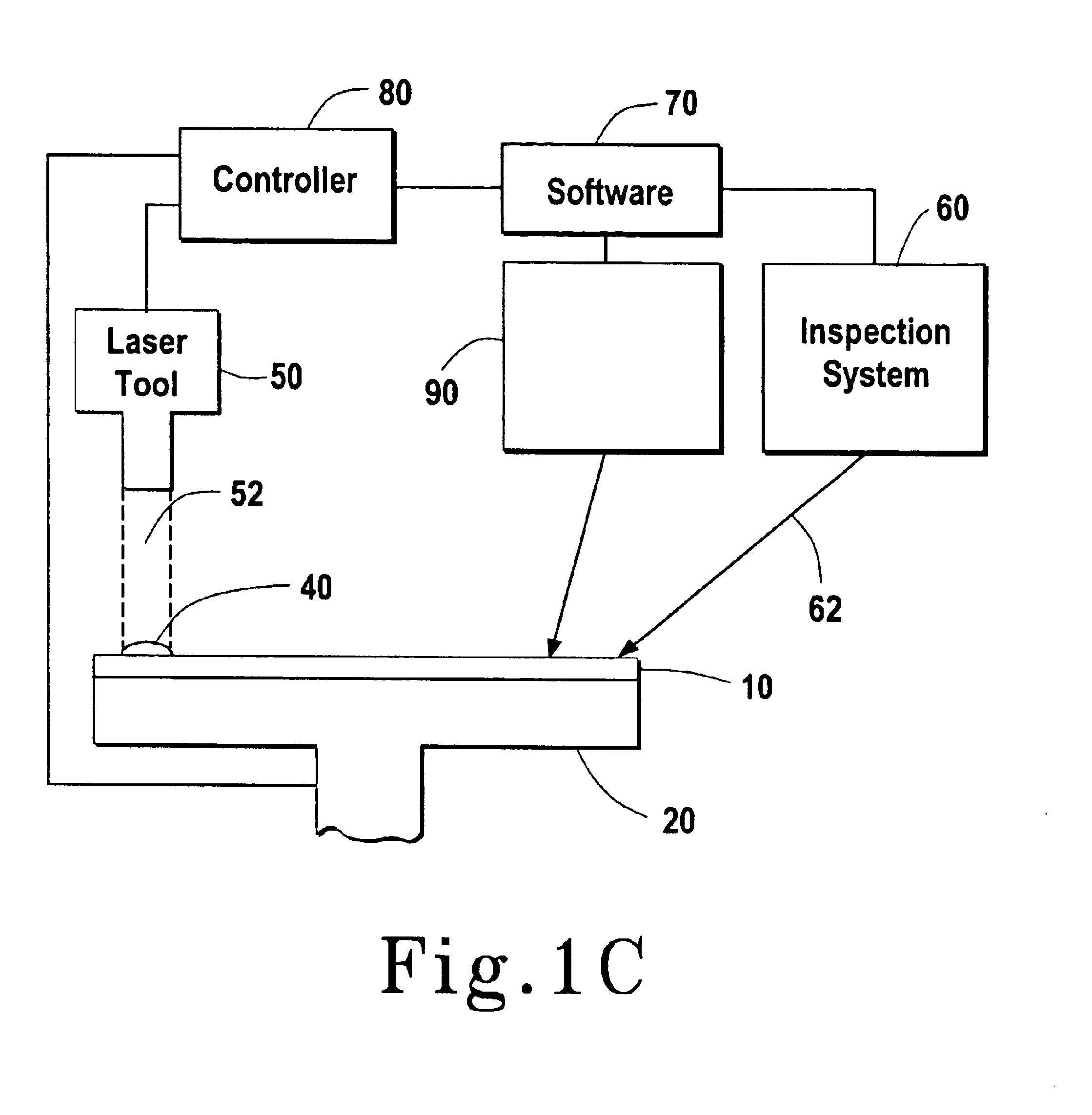

Spot cleaning of particles after inspection

InactiveUS6747243B1Prevent redepositionEffectively and easily removing contaminants from a substrate surfaceSemiconductor/solid-state device manufacturingLaser beam welding apparatusOptoelectronicsSubstrate surface

A method and cluster tool for selectively removing contaminating particles from a substrate surface using a laser. An inspection tool scans the substrate surface to detect and identify any defects on the substrate surface, and then suitable software analyzes the scanned data to determine characteristics of the defect including the type of defect, the number of defects, sizes of each defect and the planar x, y coordinates of each defect. This data is used to command a laser tool to remove only those defects identified as contaminants that are capable of being removed from the surface of the substrate and may be detrimental to subsequent substrate processing techniques. The laser contacts this identified contaminant at its x, y coordinates to remove only such contaminant while not substantially treating or directly contacting the area surrounding the contaminant, thereby preventing damaging or altering the substrate surface.

Owner:NOVELLUS SYSTEMS

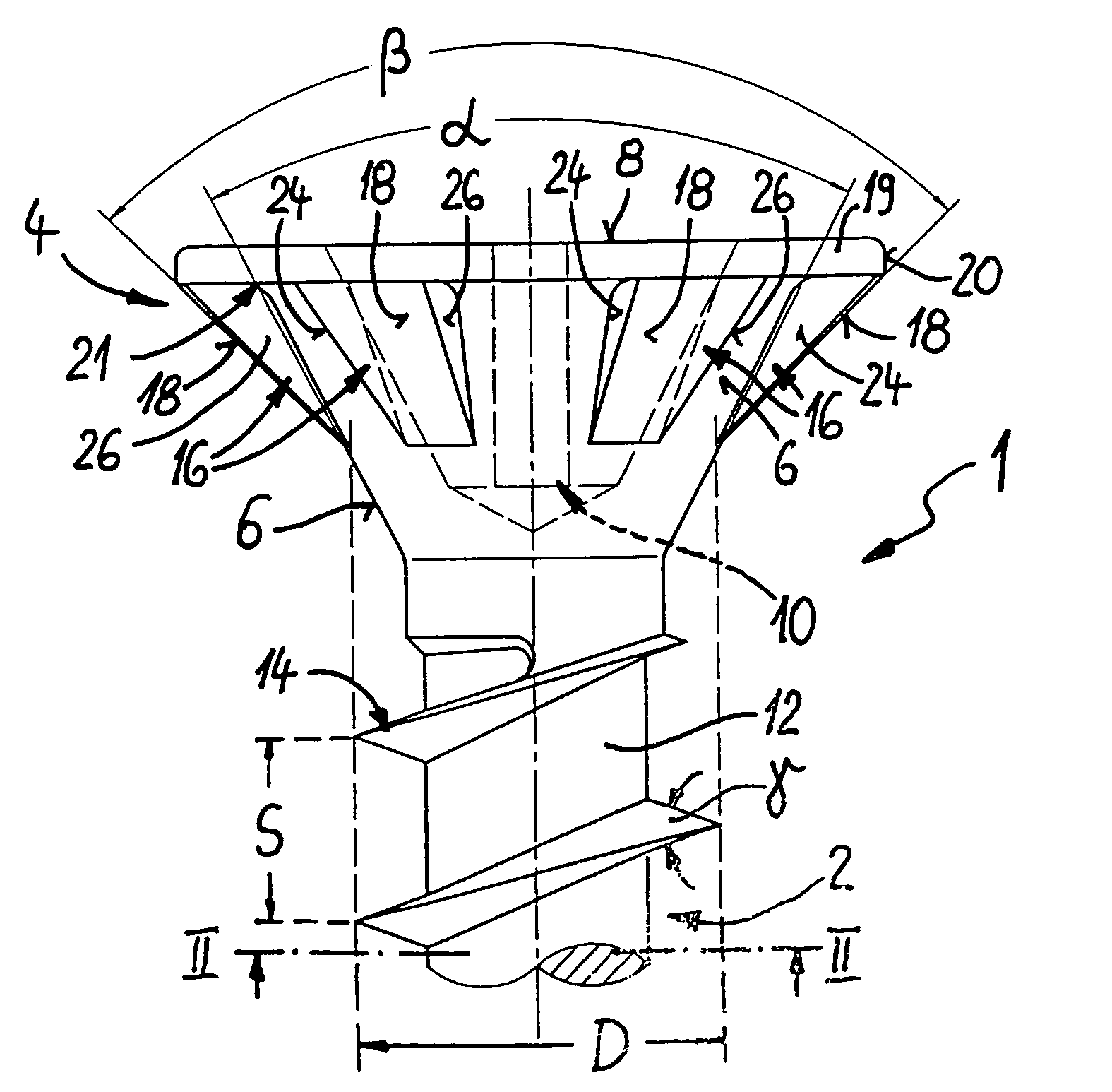

Cleaning device for cleaning a surface comprising a brush and a squeegee element

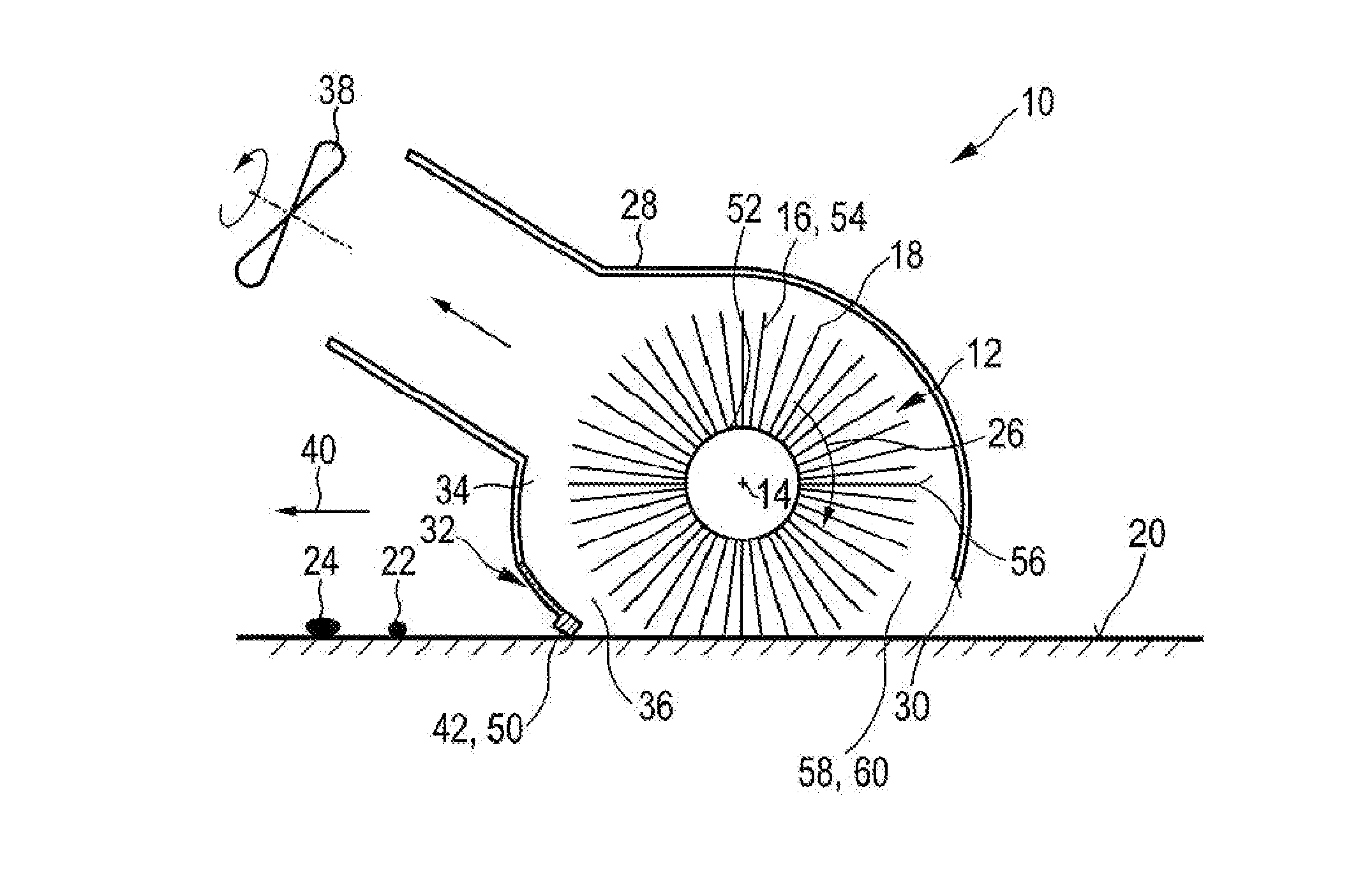

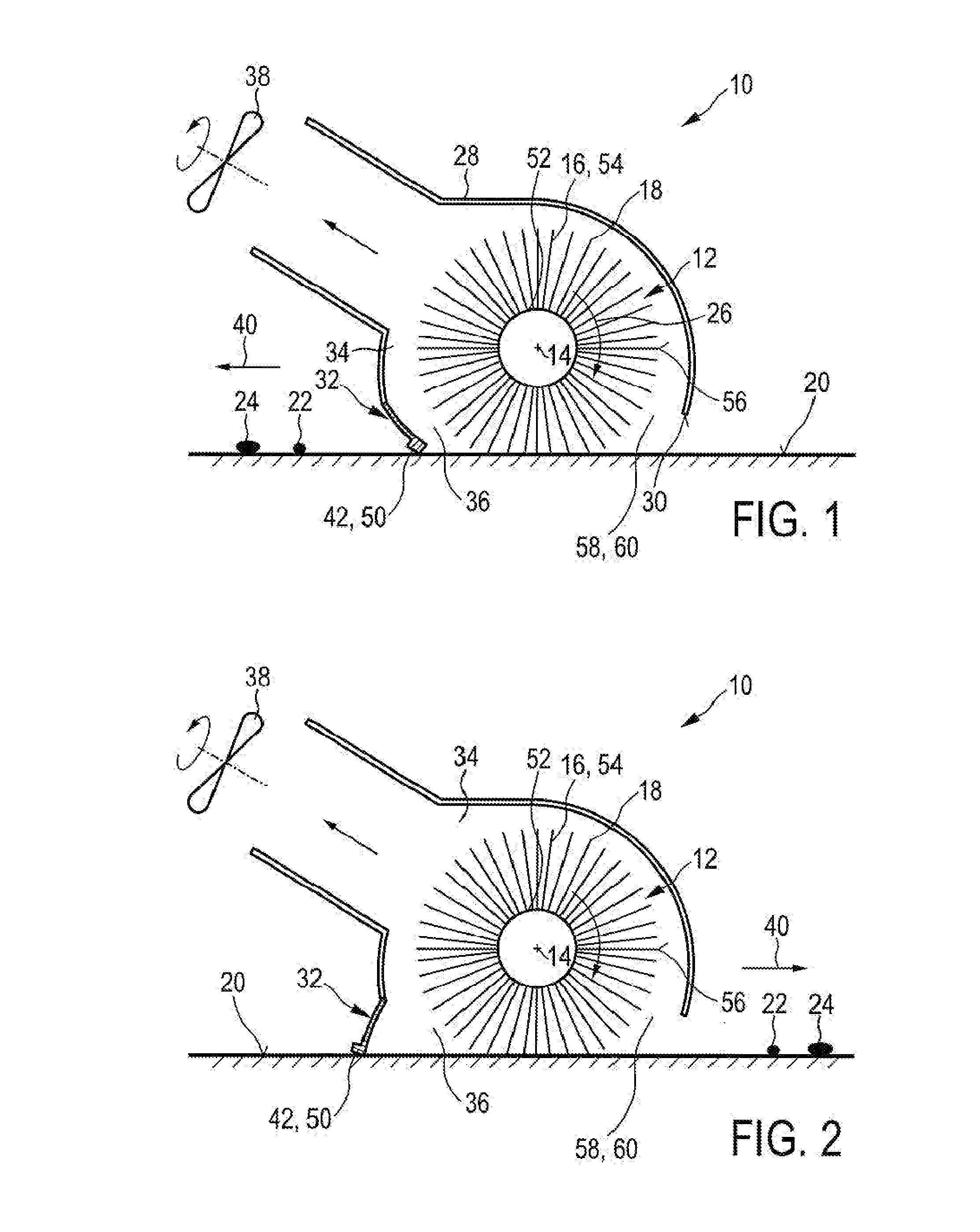

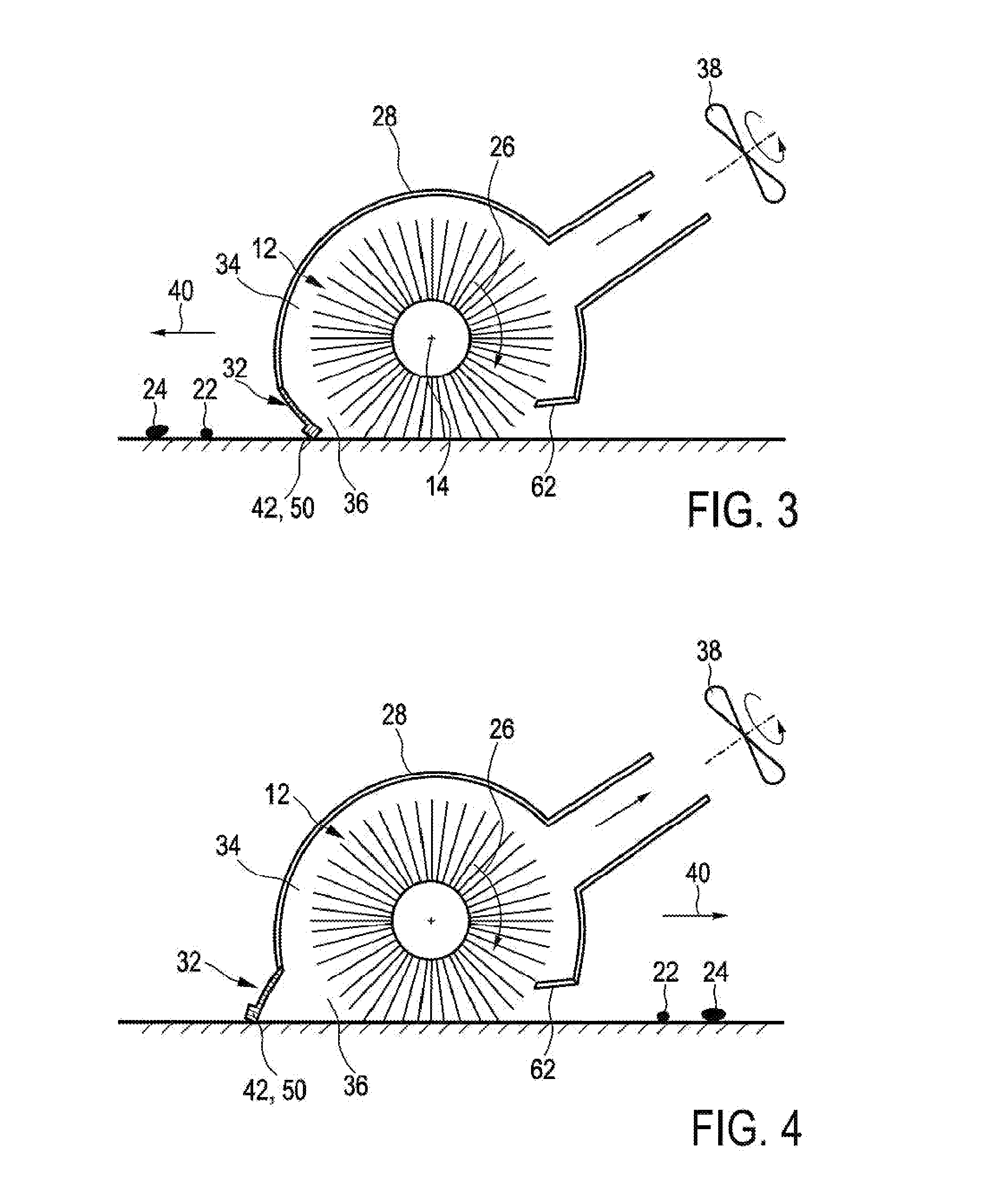

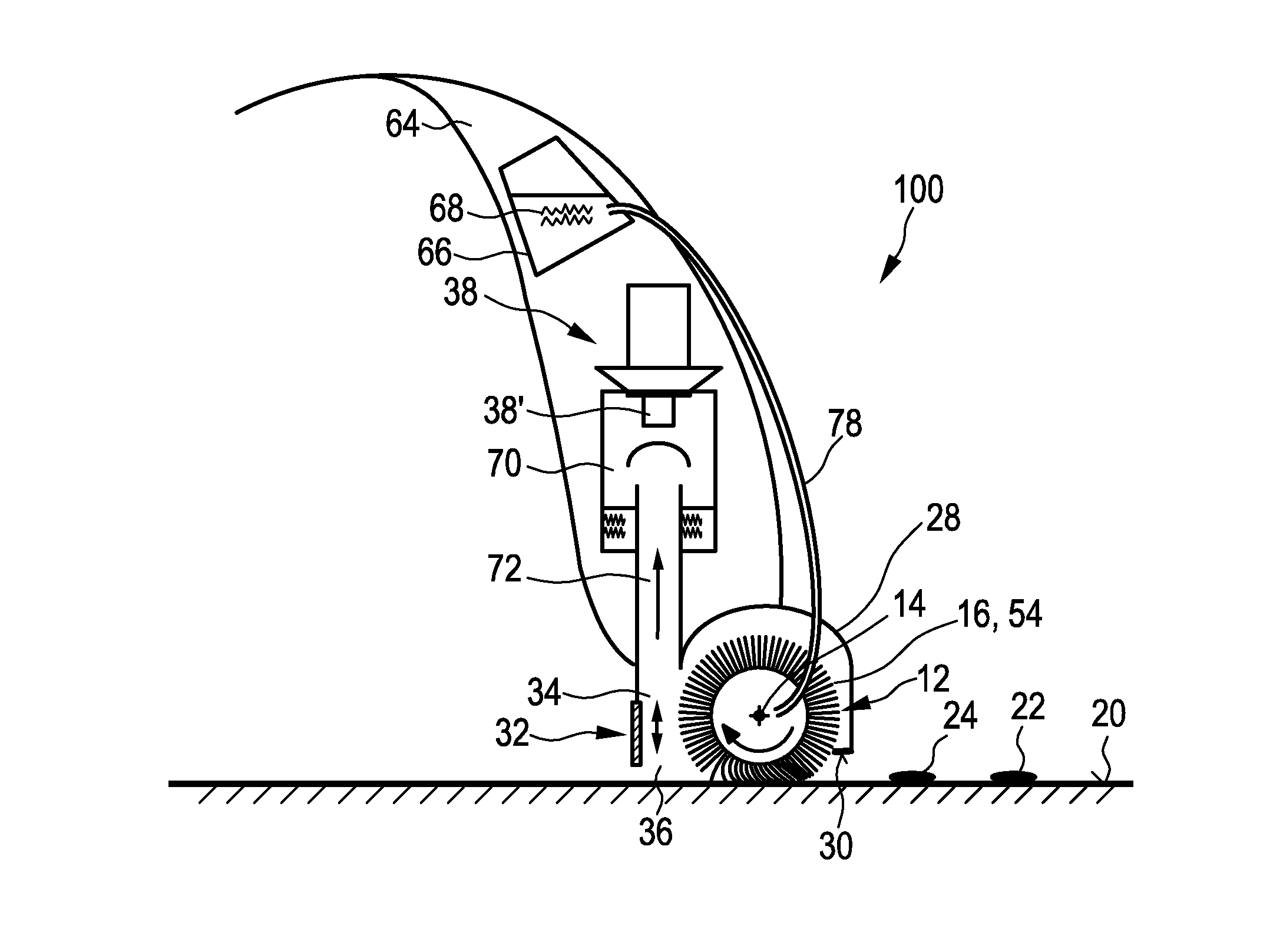

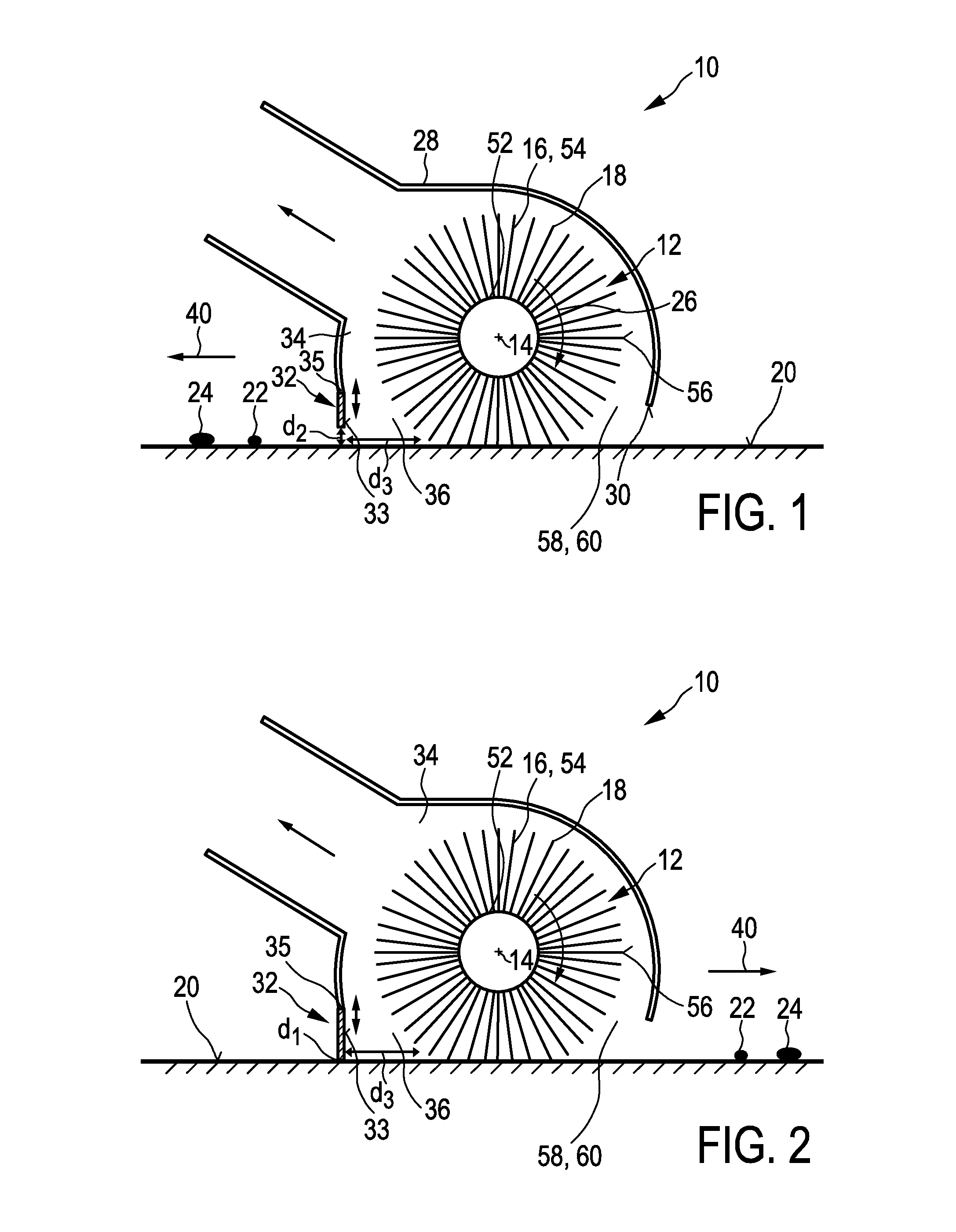

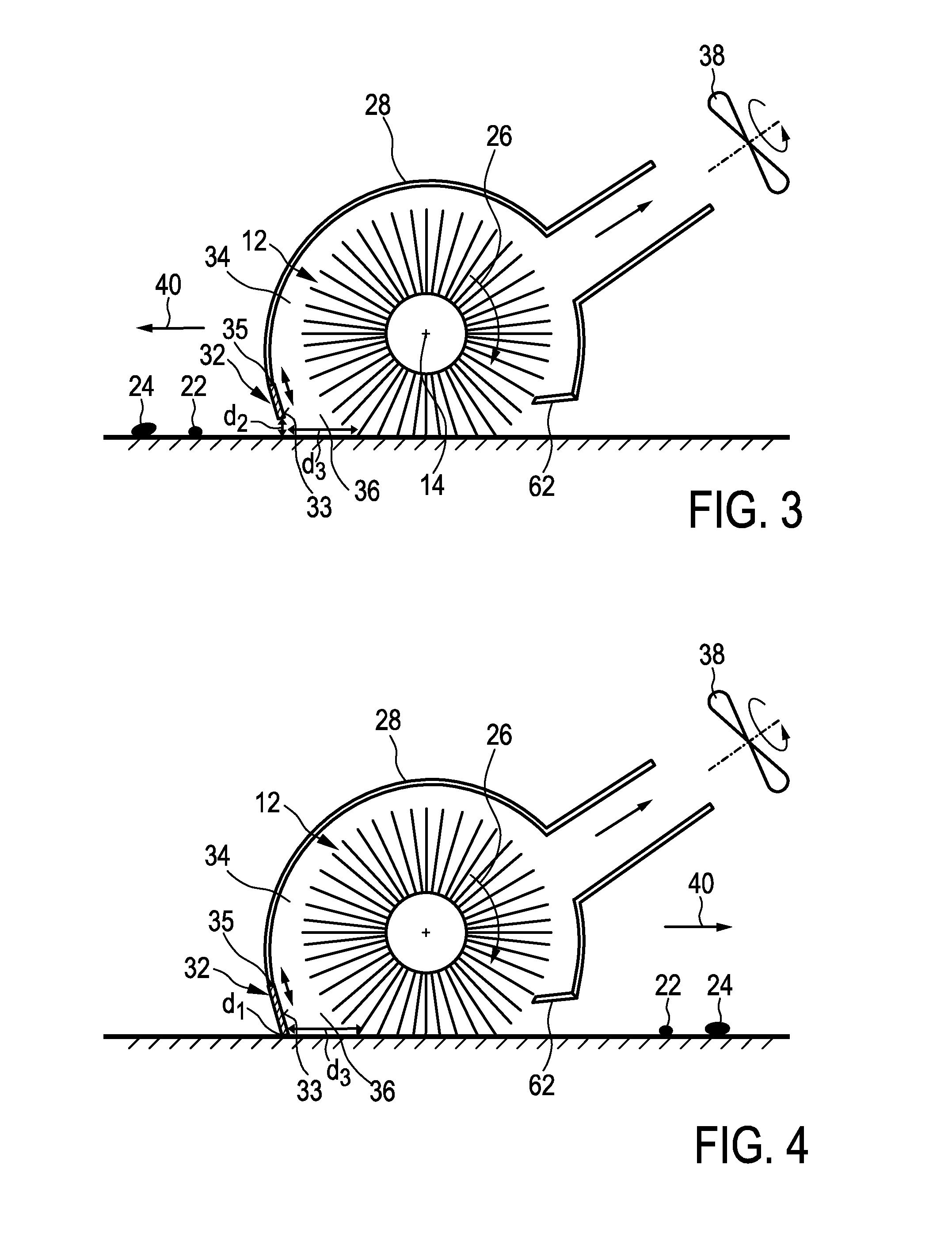

PendingUS20140182079A1Increase heightHigh strengthCarpet cleanersFloor cleanersEngineeringVolumetric Mass Density

The present invention relates to a cleaning device for cleaning a surface (20), comprising: —a nozzle arrangement (10) that comprises i) a brush (12) rotatable about a brush axis (14), said brush (12) being provided with flexible brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt particles (22) and liquid (24) from the surface (20) during a pick-up period when the brush elements (16) contact the surface (20) during the rotation of the brush (12), wherein a linear mass density of a plurality of the brush elements (16) is, at least at the tip portions (18), lower than 150 g per 10 km, and ii) a single squeegee element (32) for pushing or wiping dirt particles (22) and liquid (24) across or off the surface to be cleaned (20) during movement of the cleaning device (100), said squeegee element (32) being spaced apart from the brush (12) and extending substantially along a longitudinal direction (48) being substantially parallel to the brush axis (14), wherein a suction area (34) is defined within the nozzle arrangement (10) between the squeegee element (32) and the brush (12), —a drive means for driving the brush (12) in rotation, wherein the drive means are adapted to realize a centrifugal acceleration at the tip portions (18) which is, in particular during a dirt release period when the brush elements (16) are free from contact to the surface (20) during rotation of the brush (12), at least 3,000 m / s 2, and —a vacuum aggregate (38) for generating an under-pressure in the suction area (34) for ingesting dirt particles (22) and liquid (24).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

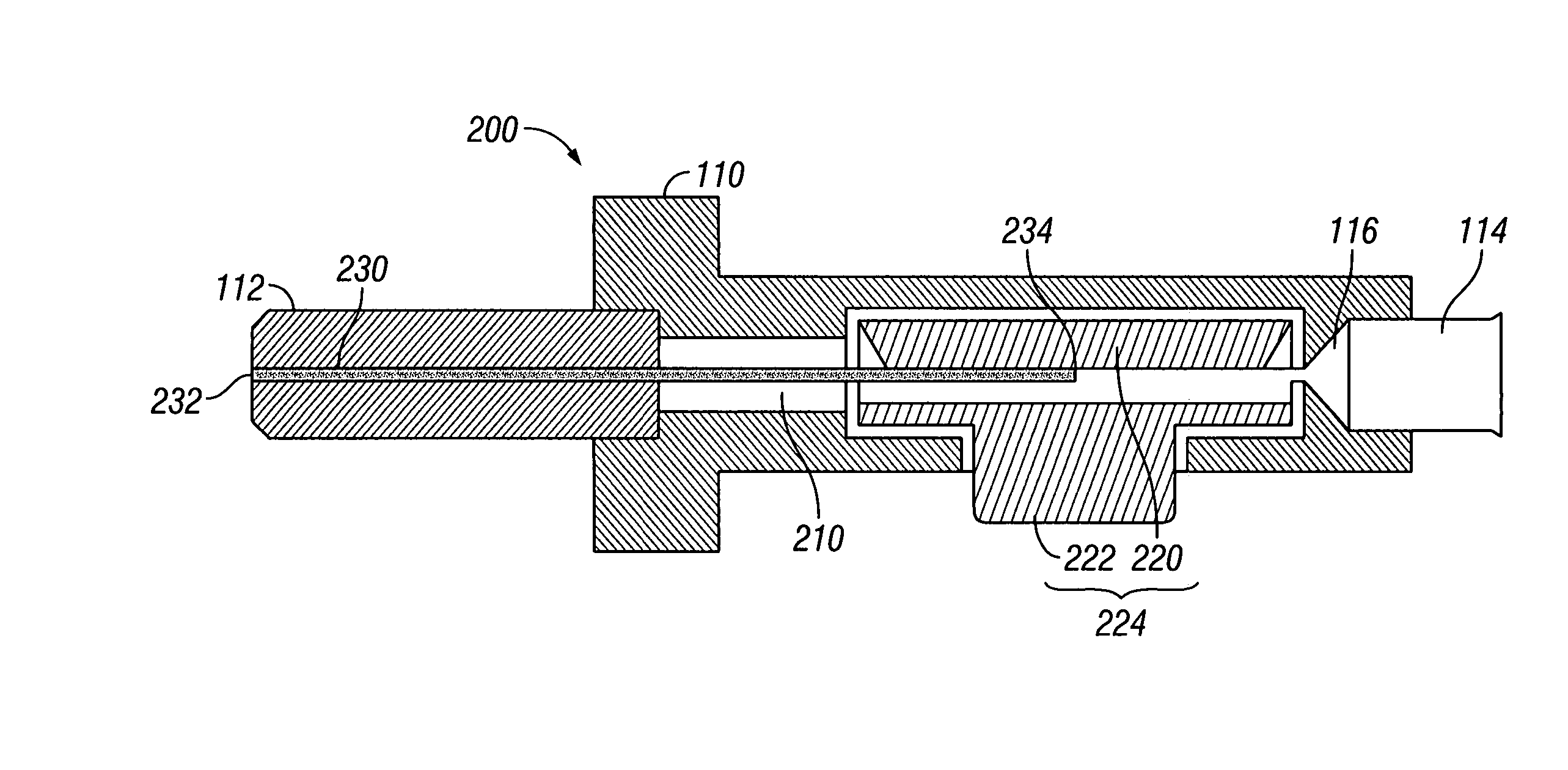

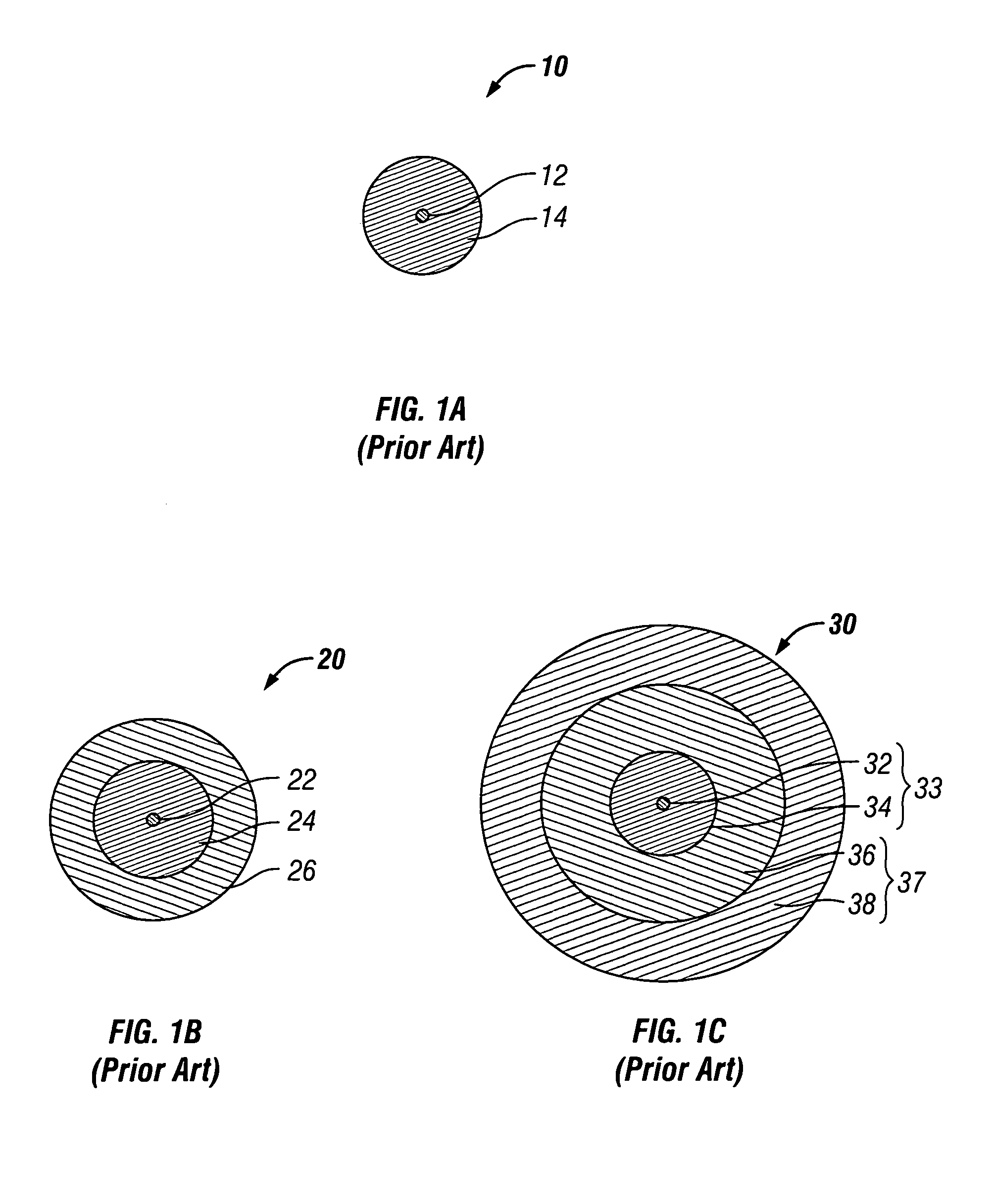

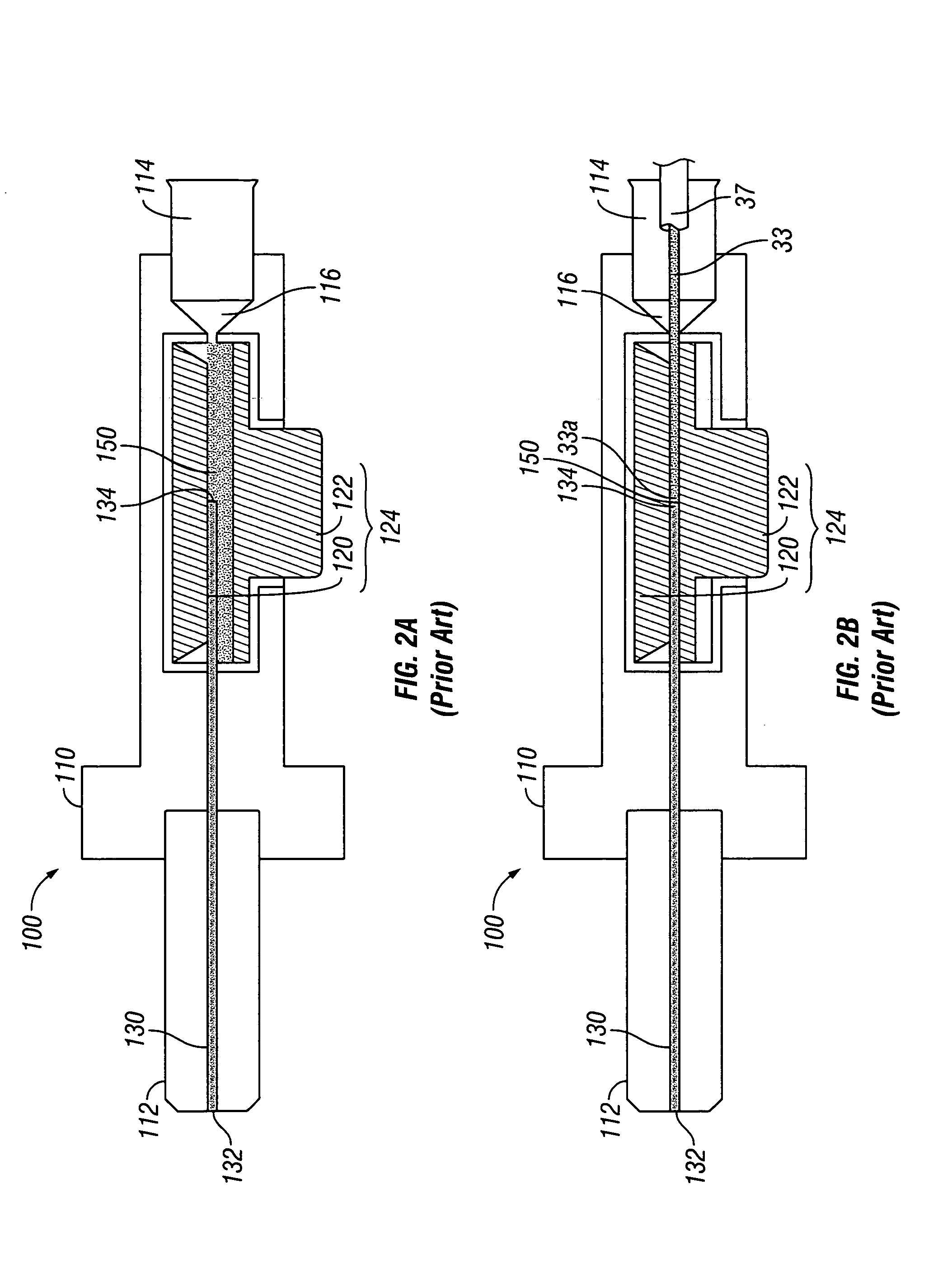

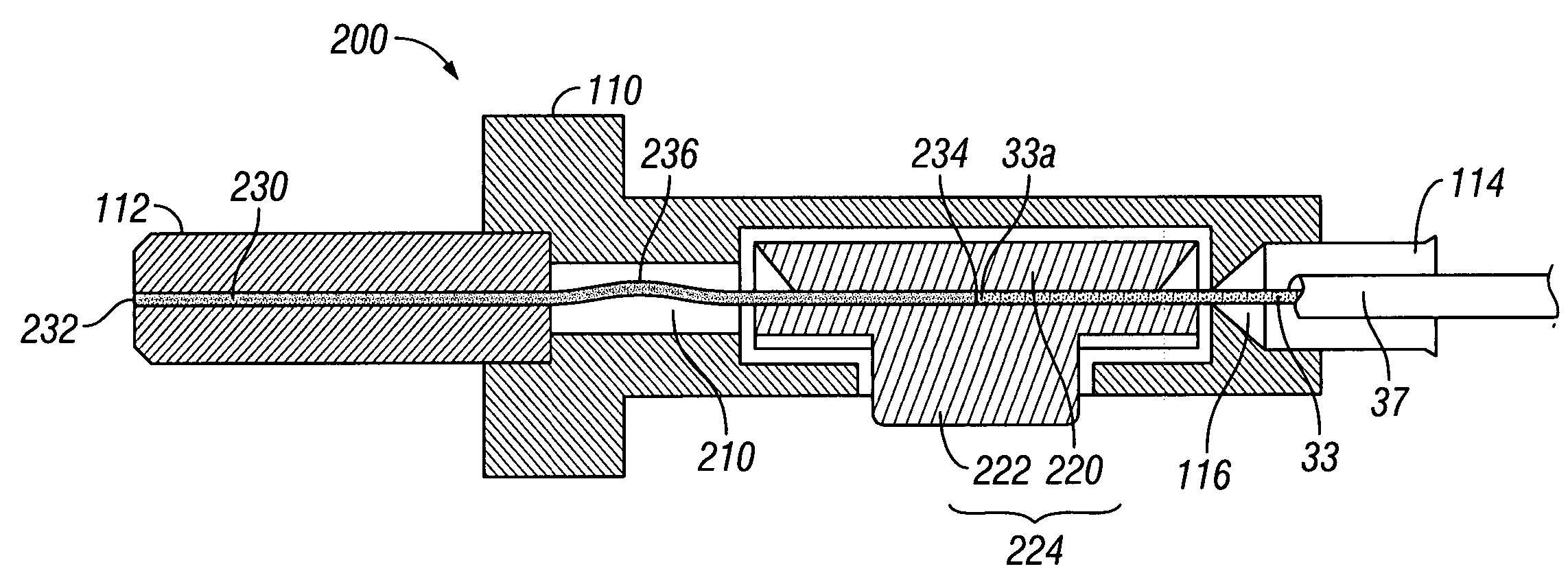

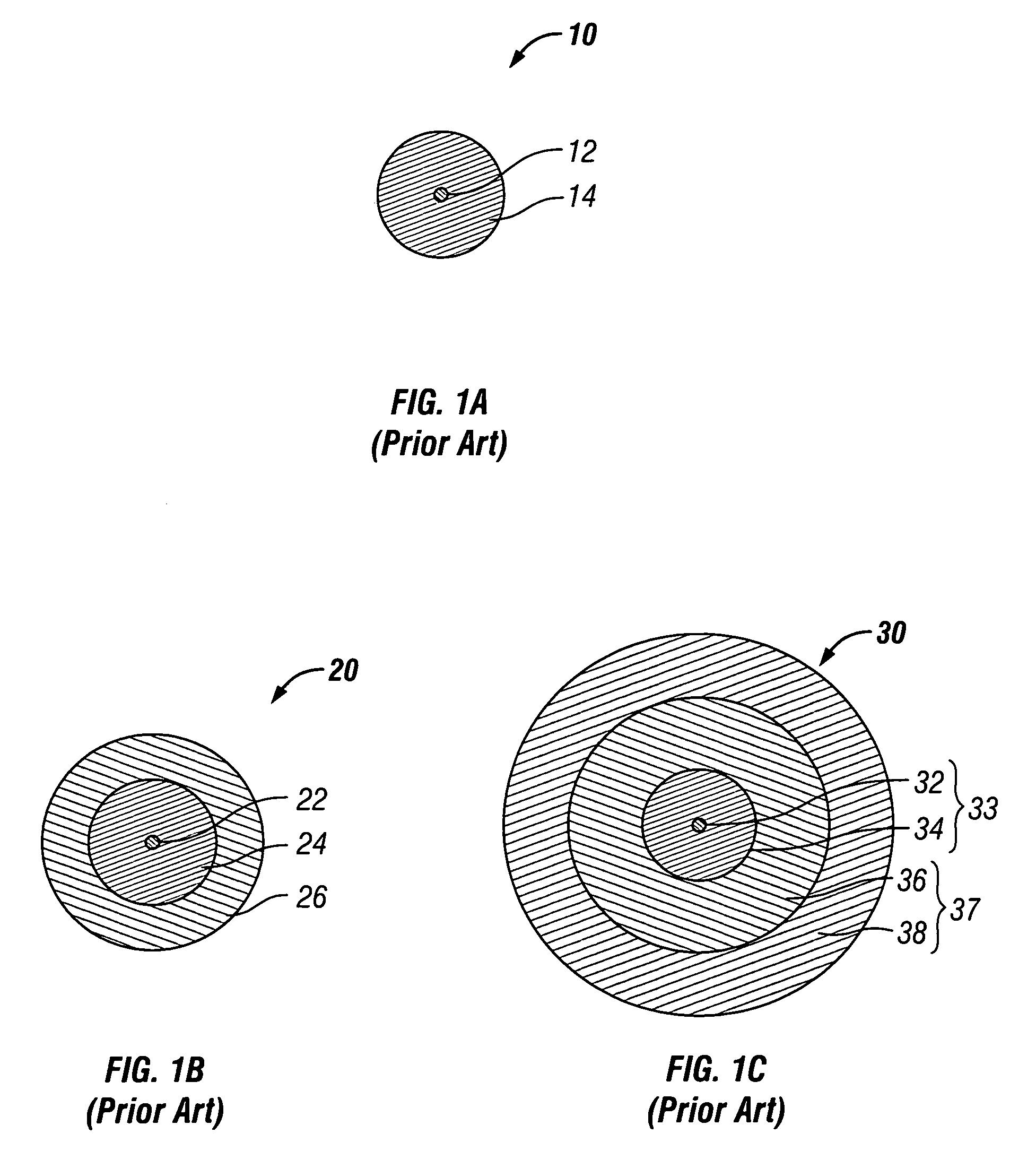

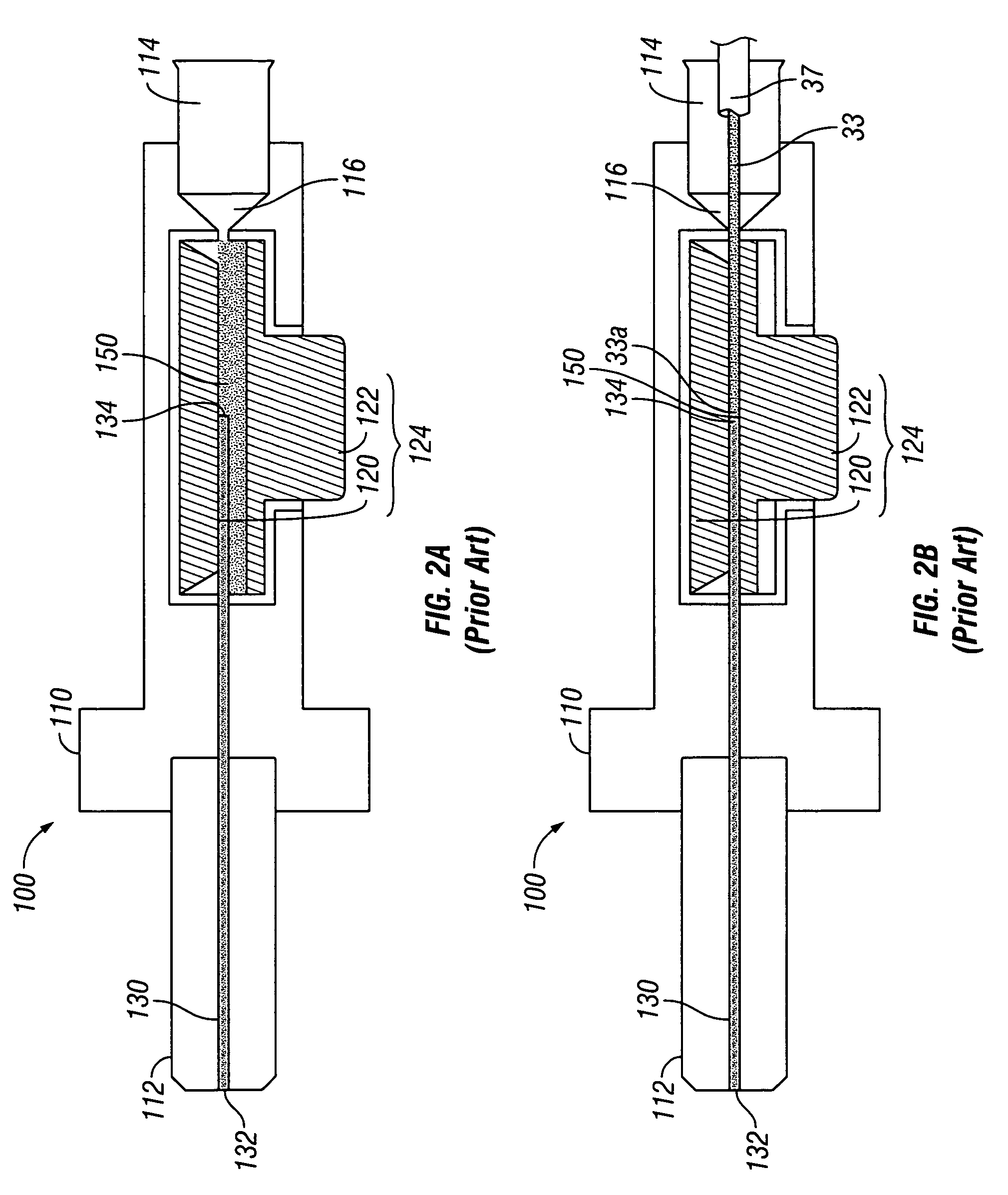

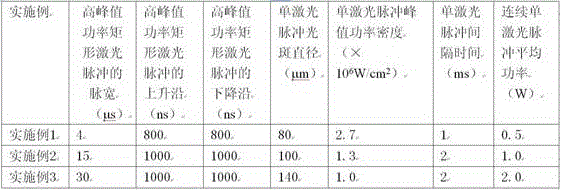

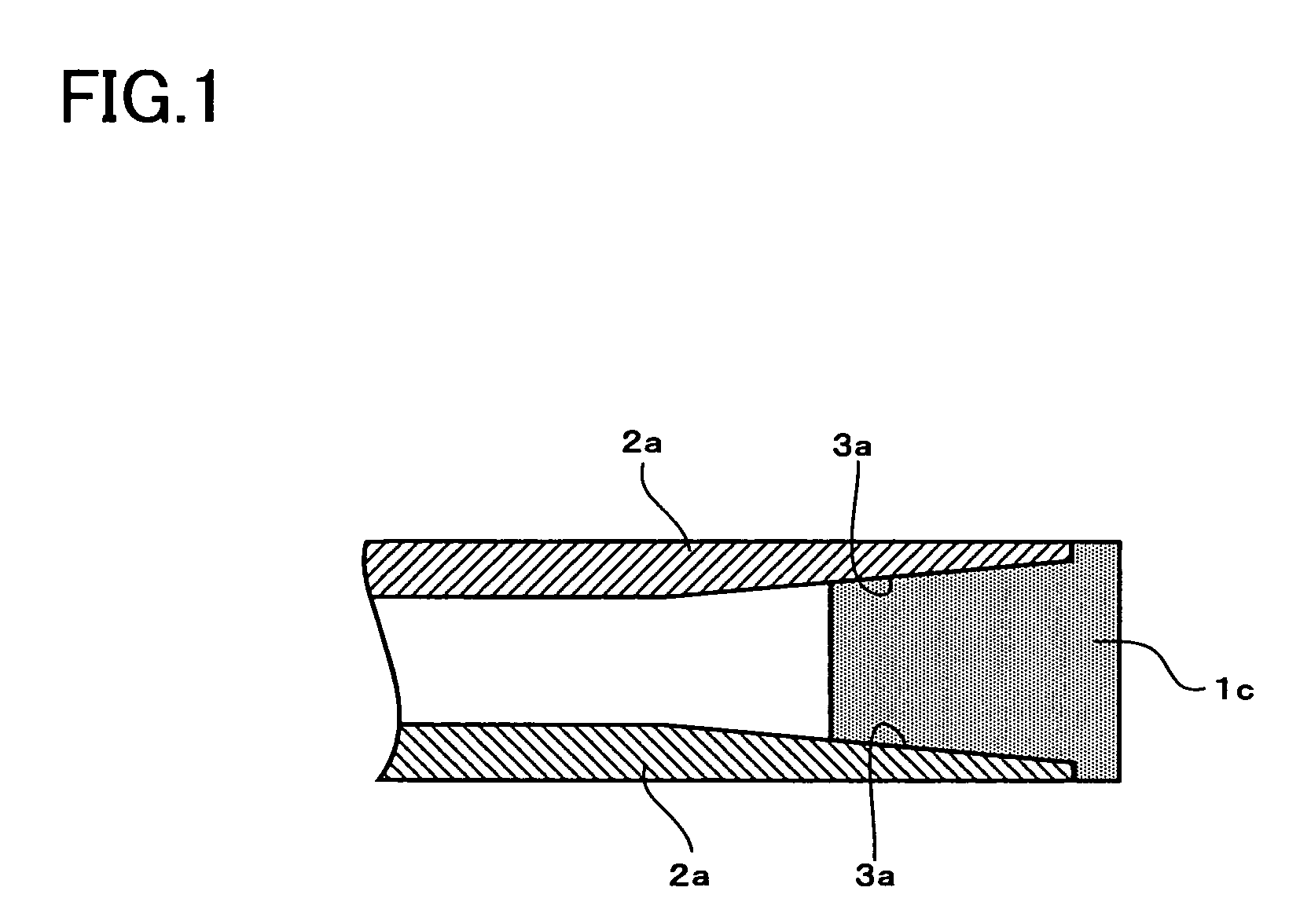

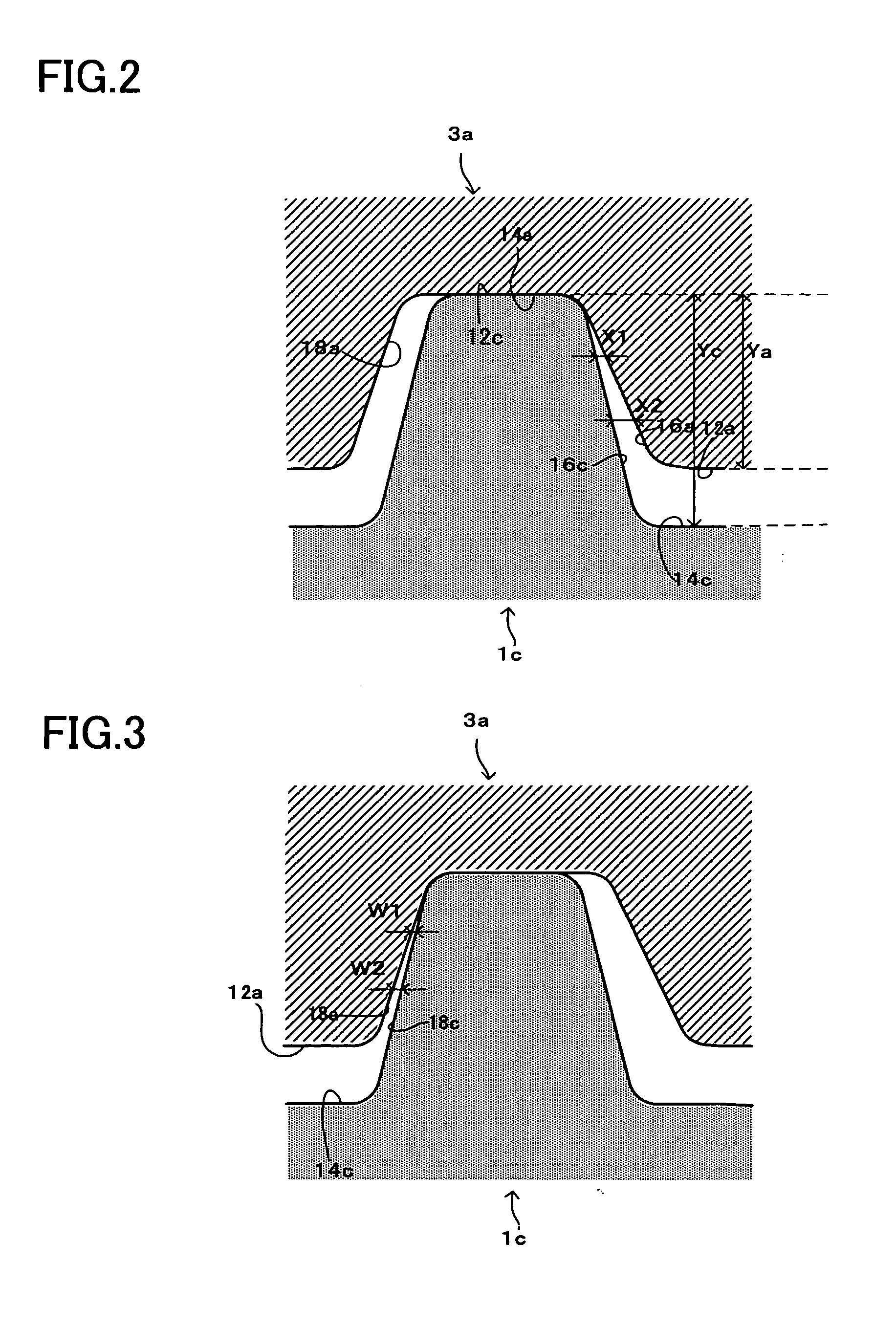

Optical fiber mechanical splice connector

ActiveUS20080019646A1Robust and reliable connectorPrecise alignmentCoupling light guidesFiberMechanical splice

An optical fiber mechanical splice connector including a connector body having a fiber alignment mechanism and a cavity, and a ferrule including a stub fiber, wherein an end of the stub fiber extends from the ferrule through the cavity of the connector body and into the fiber alignment mechanism, and wherein the stub fiber buckles within the cavity when a field fiber is introduced into the connector body and contacts the distal end of the stub fiber. A mechanical splicing method including inserting a field fiber into a splice connector such that an end of the field fiber contacts an end of the stub fiber within an alignment mechanism of the splice connector, and applying axial force to the field fiber so as to cause the stub fiber to buckle within a cavity defined by the splice connector.

Owner:CORNING OPTICAL COMM LLC

Optical fiber mechanical splice connector

ActiveUS7572064B2Robust and reliable connectorPrecise alignmentCoupling light guidesFiberMechanical splice

An optical fiber mechanical splice connector including a connector body having a fiber alignment mechanism and a cavity, and a ferrule including a stub fiber, wherein an end of the stub fiber extends from the ferrule through the cavity of the connector body and into the fiber alignment mechanism, and wherein the stub fiber buckles within the cavity when a field fiber is introduced into the connector body and contacts the distal end of the stub fiber. A mechanical splicing method including inserting a field fiber into a splice connector such that an end of the field fiber contacts an end of the stub fiber within an alignment mechanism of the splice connector, and applying axial force to the field fiber so as to cause the stub fiber to buckle within a cavity defined by the splice connector.

Owner:CORNING OPTICAL COMM LLC

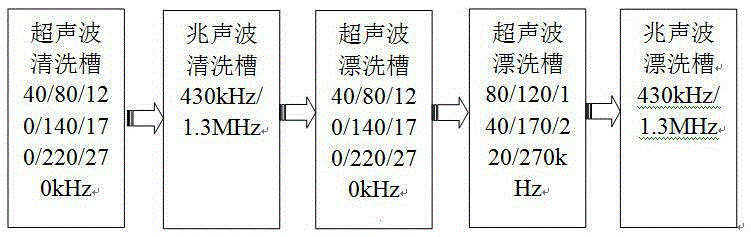

Fully-automatic optical element cleaning device with ultrasonic-megasonic composite frequency

InactiveCN105195465AInhibition retentionMeet cleaning and removal needsFlexible article cleaningCleaning using liquidsMicron scaleFiltration

The invention discloses a fully-automatic optical element cleaning device with an ultrasonic-megasonic composite frequency. The ultrasonic-megasonic composite frequency covers low / intermediate / high ultrasonic frequencies and low / intermediate / high megasonic frequencies. Particularly, an appropriate program and process parameters are selected to aim at super-clean washing requirements for an optical element, and pollutants from a micron scale to a nanometer scale on the surface of the optical element can be effectively removed. The fully-automatic optical element cleaning device with the ultrasonic-megasonic composite frequency has the main characteristics that an ultrasonic solution soaking cleaning tank, a megasonic cleaning tank and a spraying tank are designed; different frequency ultrasonic and megasonic waves are adopted, and cleaning requirements from a micron size to a nanometer size are covered; a workpiece is driven by a cylinder to reciprocate up and down in a tank body, a wave node of a standing wave field is prevented from being generated in a fixed area of the surface of the workpiece by virtue of a frequency sweeping function of an ultrasonic-megasonic generator, and the surface damage is avoided; the tank body adopts overflow cycle heating filtration; the total length of an overflow front edge is increased by using a trapezoidal saw-tooth type overflow edge design to obtain uniform and stable overflow; an inclined workpiece clamping device cooperates with an air knife and a slow lifting mechanism to dry the workpiece.

Owner:TONGJI UNIV +1

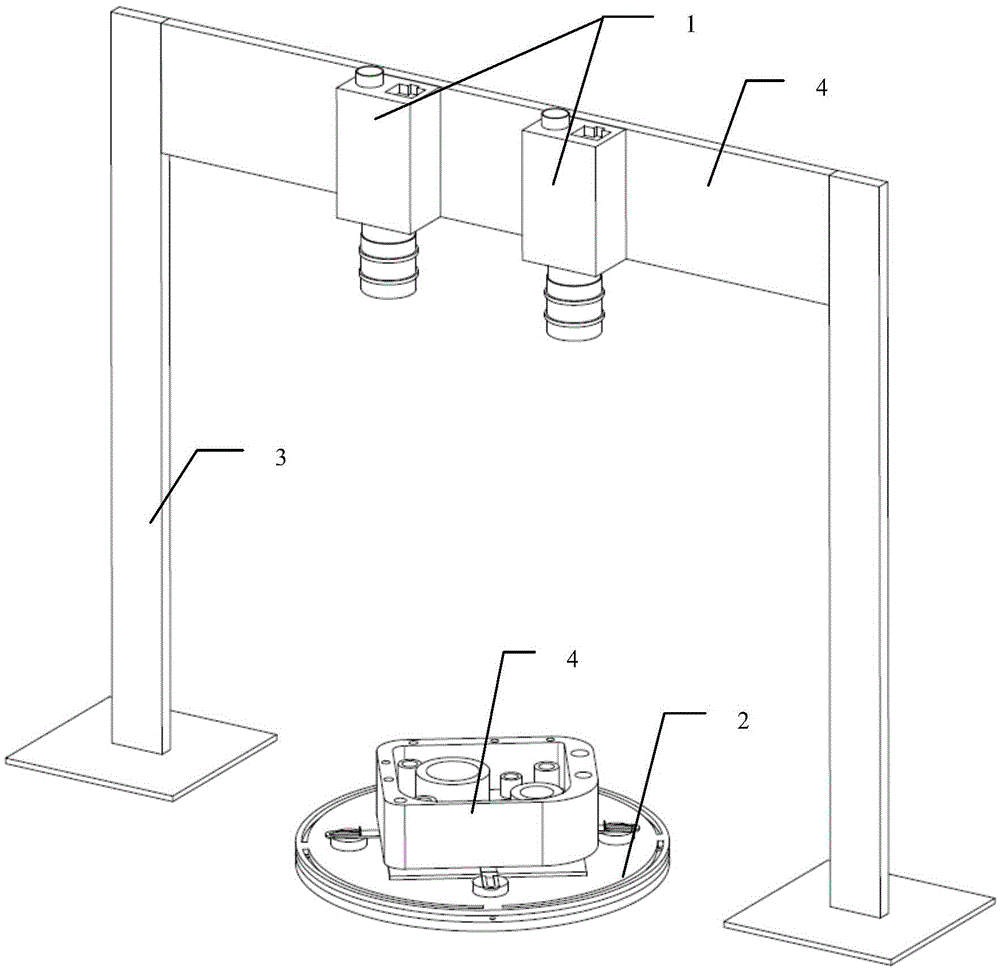

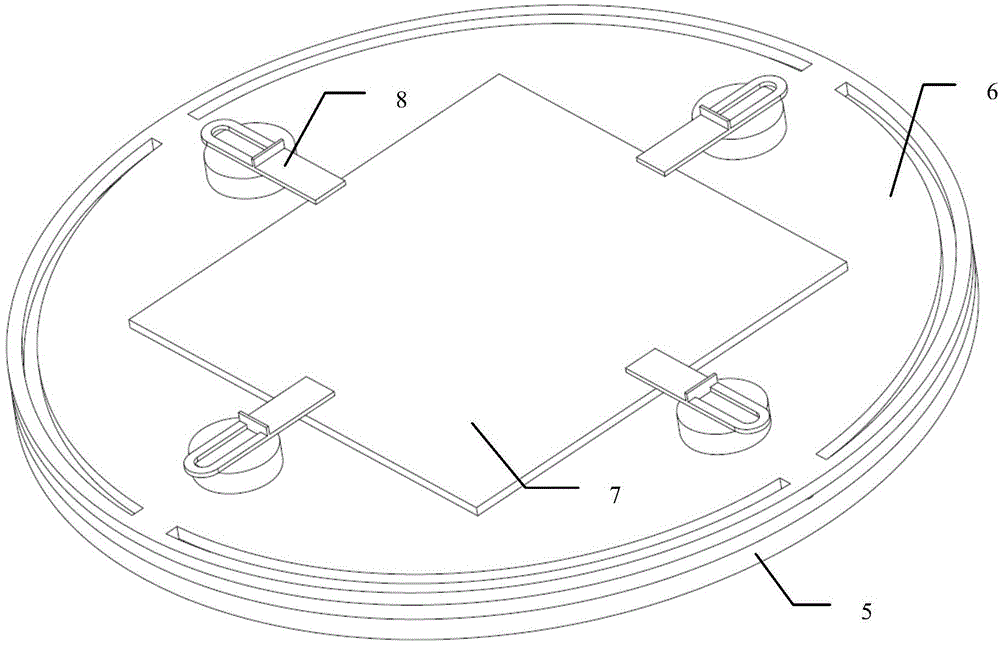

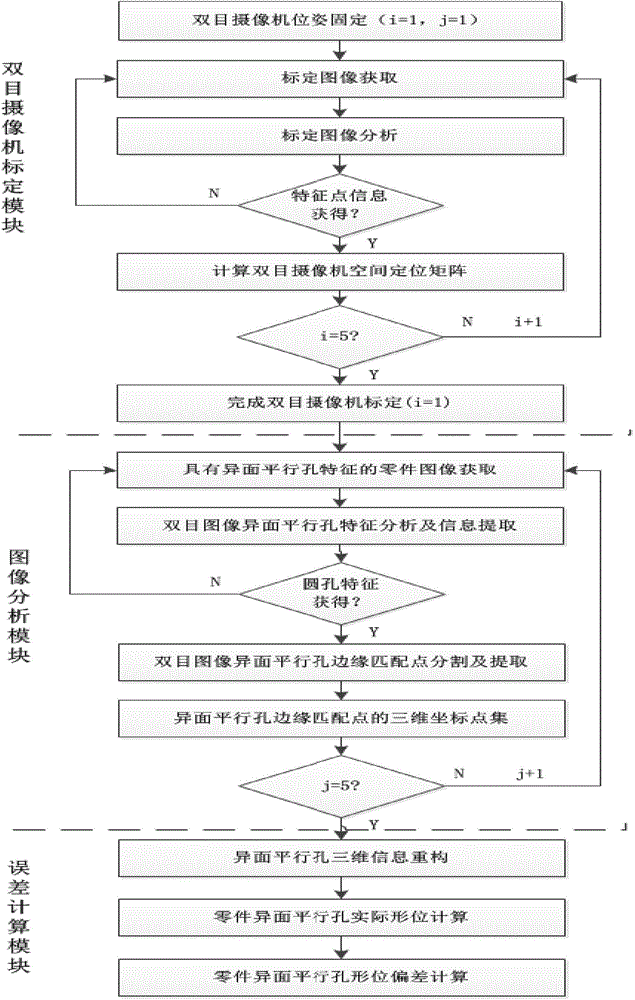

Component different-surface-parallel-hole form and position deviation visual measuring method and device

InactiveCN104897062AAvoid surface damageHigh measurement accuracyUsing optical meansAlgorithmEngineering

The invention provides a component different-surface-parallel-hole form and position deviation visual measuring method and device. The method comprises the following steps which are carried out in sequence: [1] binocular camera parameter calibration; [2] different-surface-parallel-hole feature analysis and treatment of a component entity image; [3] different-surface-parallel-hole match feature point extraction of the component entity image; [4] component different-surface-parallel-hole three-dimension information reconstruction, and analysis and calculation of form and position deviation parameters such as diameter, circular degree, hole pitch and depth distribution of holes. According to the invention, measurement of the component feature hole form and position deviation can be completed rapidly and effectively, precision requirements of high-precision measurement can be met, and advantages of simple measurement operation, low equipment maintenance cost and the like can be achieved.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

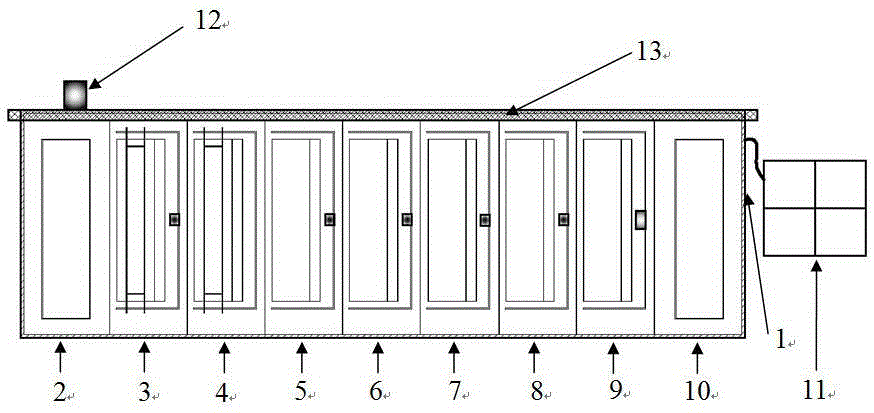

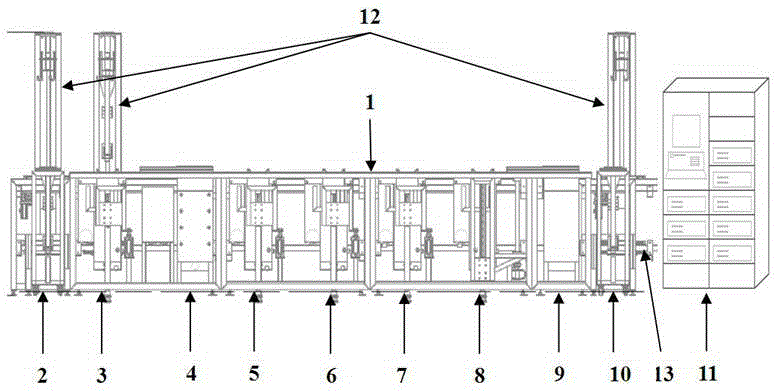

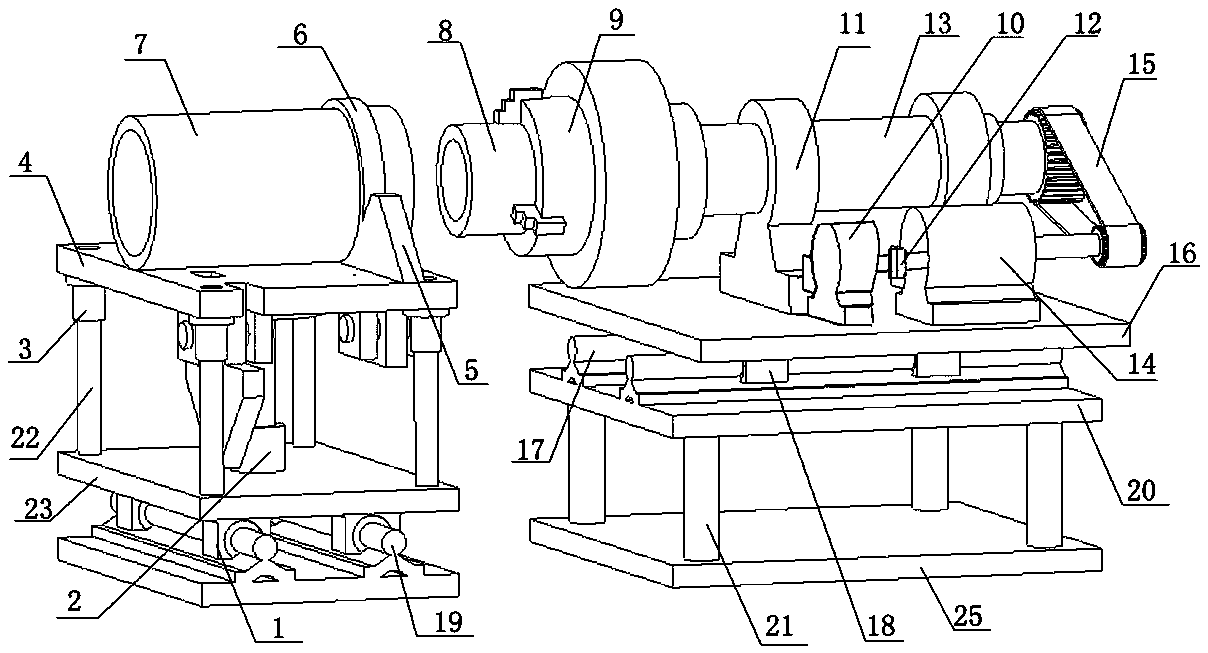

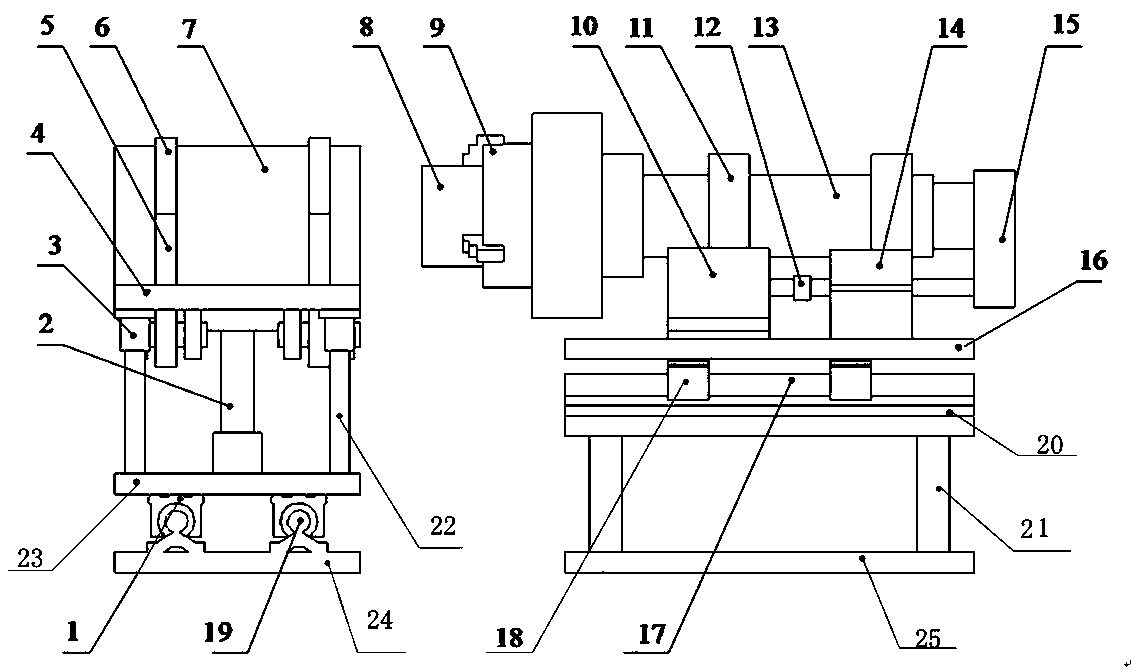

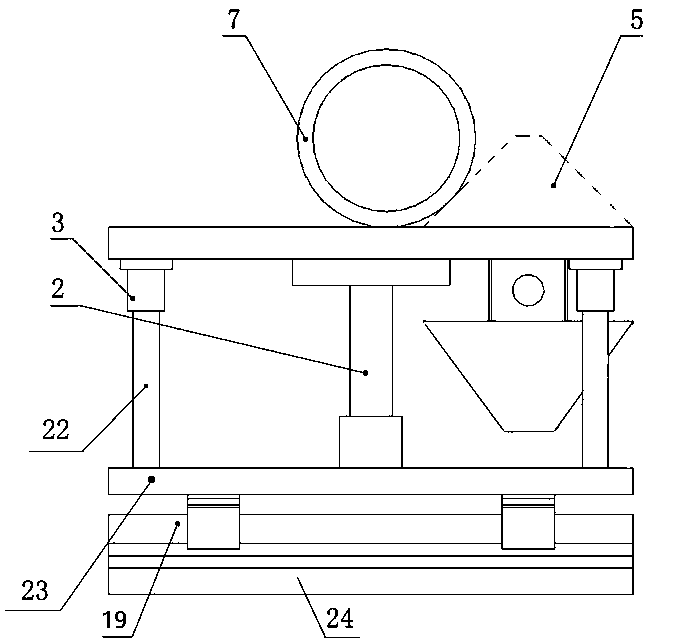

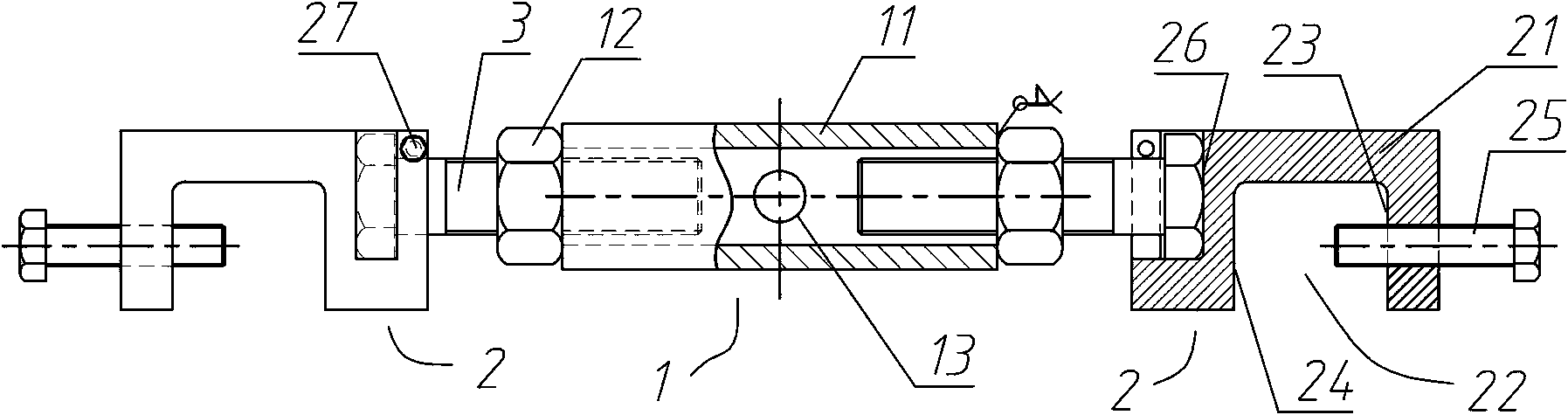

Self-adaptation flexible assembling device for hydraulic cylinder head body

InactiveCN109015468AFast and accurate vertical liftingQuick dockingWork holdersMetal working apparatusHydraulic cylinderCylinder head

The invention relates to the technical field of automatic machine assembling, in particular to a self-adaptation flexible assembling device for a hydraulic cylinder head body. The technical problem ofassembling of a cylinder barrel and a cylinder head body of a large multistage hydraulic cylinder is solved. The self-adaptation flexible assembling device comprises a cylinder barrel flexible clamping platform and a cylinder head body flexible clamping platform which are independent from each other and need to be used in cooperation with each other. The cylinder barrel flexible clamping platformis used for fixing a cylinder barrel, and the cylinder barrel flexible clamping platform can do perpendicular lifting motion and horizontal motion in the radial direction of the cylinder barrel. Thecylinder head body flexible clamping platform is used for fixing a cylinder head body, the cylinder head body flexible clamping platform can do horizontal motion along the axis of the cylinder barrel,the cylinder head body flexible clamping platform drives the cylinder head body to move towards the cylinder barrel and rotate synchronously, and finally the cylinder head body and the cylinder barrel can be assembled through thread connection. By means of the self-adaptation flexible assembling device, the historic problems that operation is complex, the assembling efficiency is low, the surface, making contact with a lifting clamp, of the cylinder barrel is likely to be damaged, and even the cylinder barrel is disengaged in the traditional cylinder barrel and cylinder head body assembling process can be effectively solved.

Owner:SHANXI UNIV

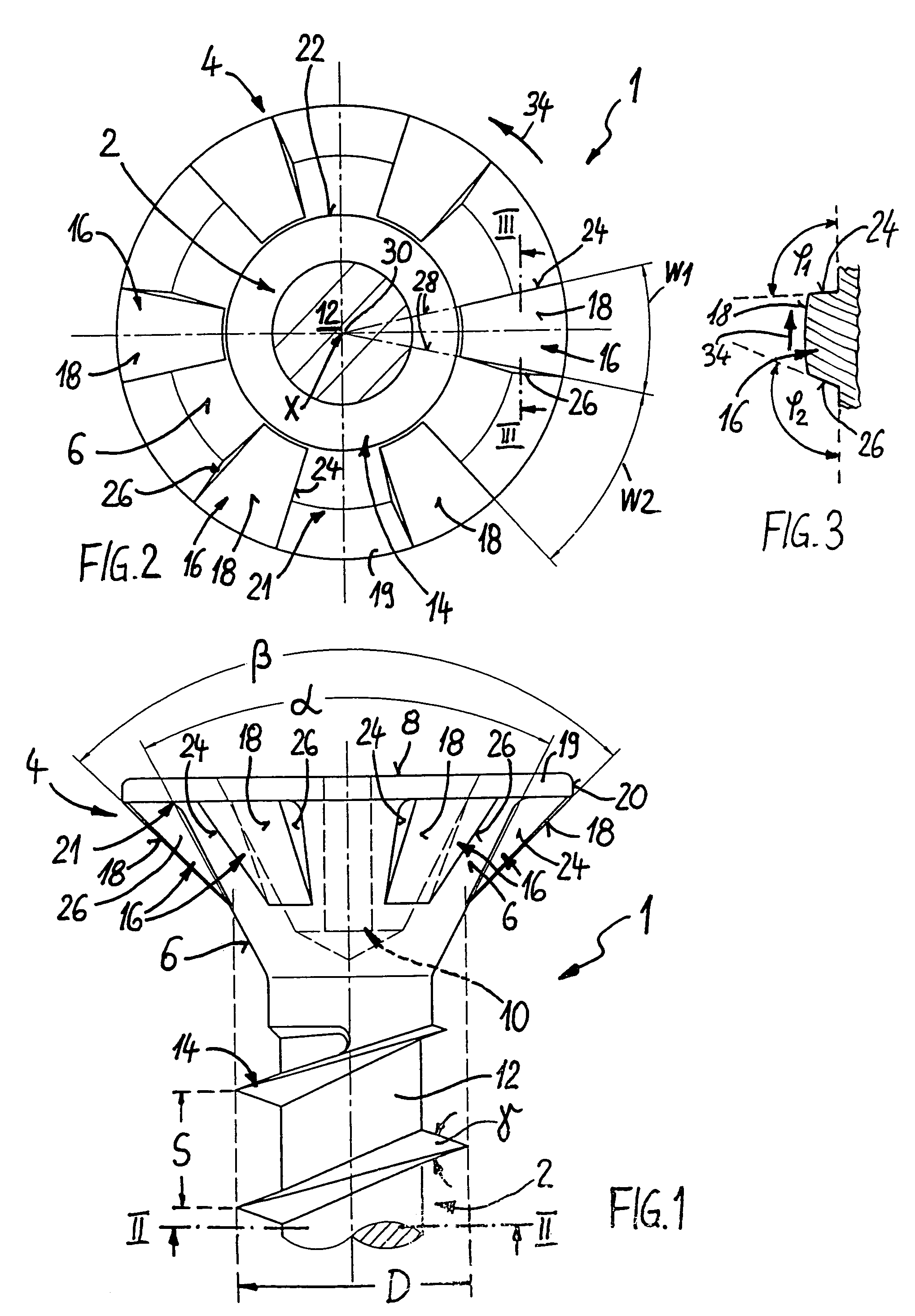

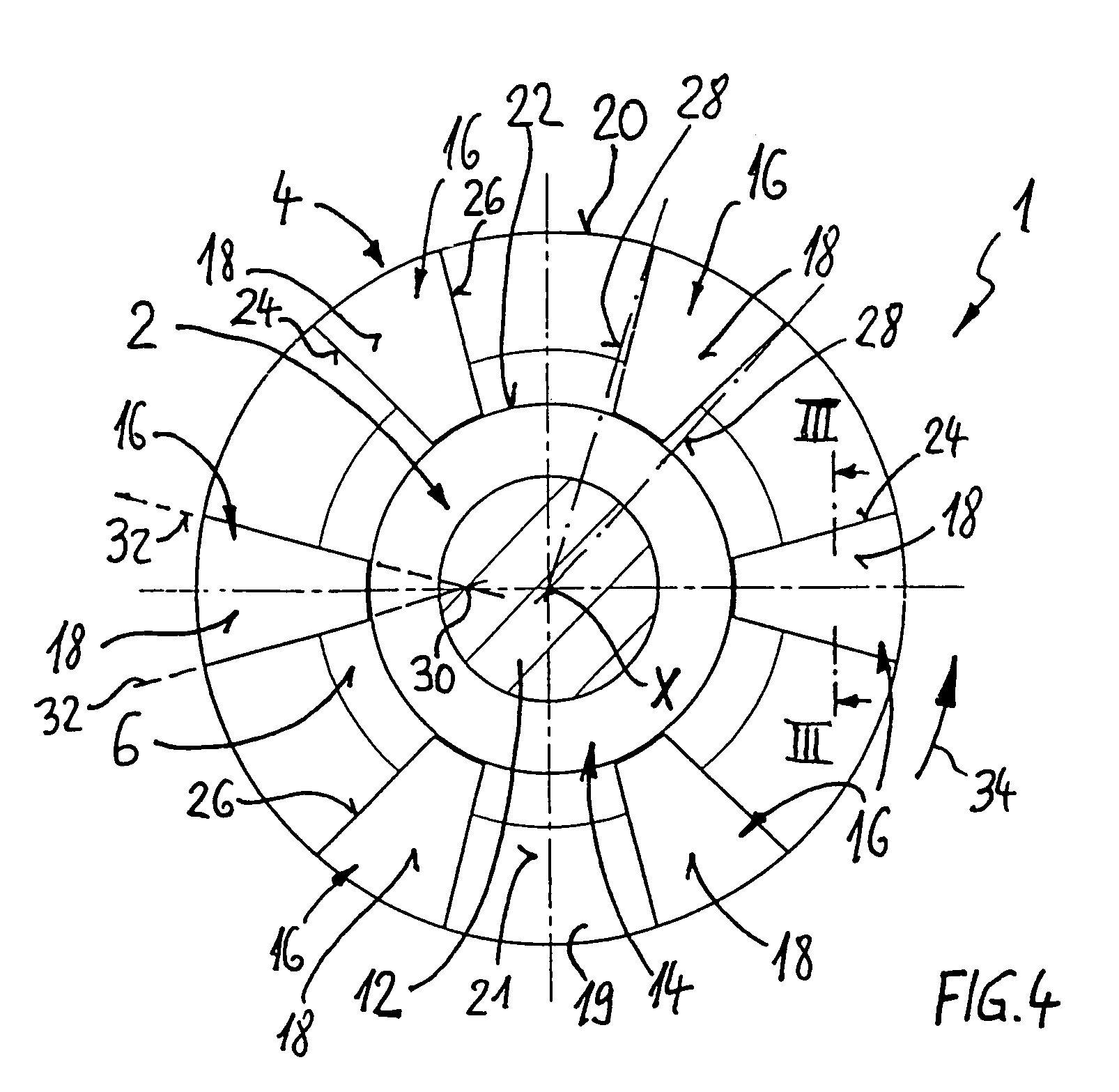

Countersunk screw

Owner:SPAX INT

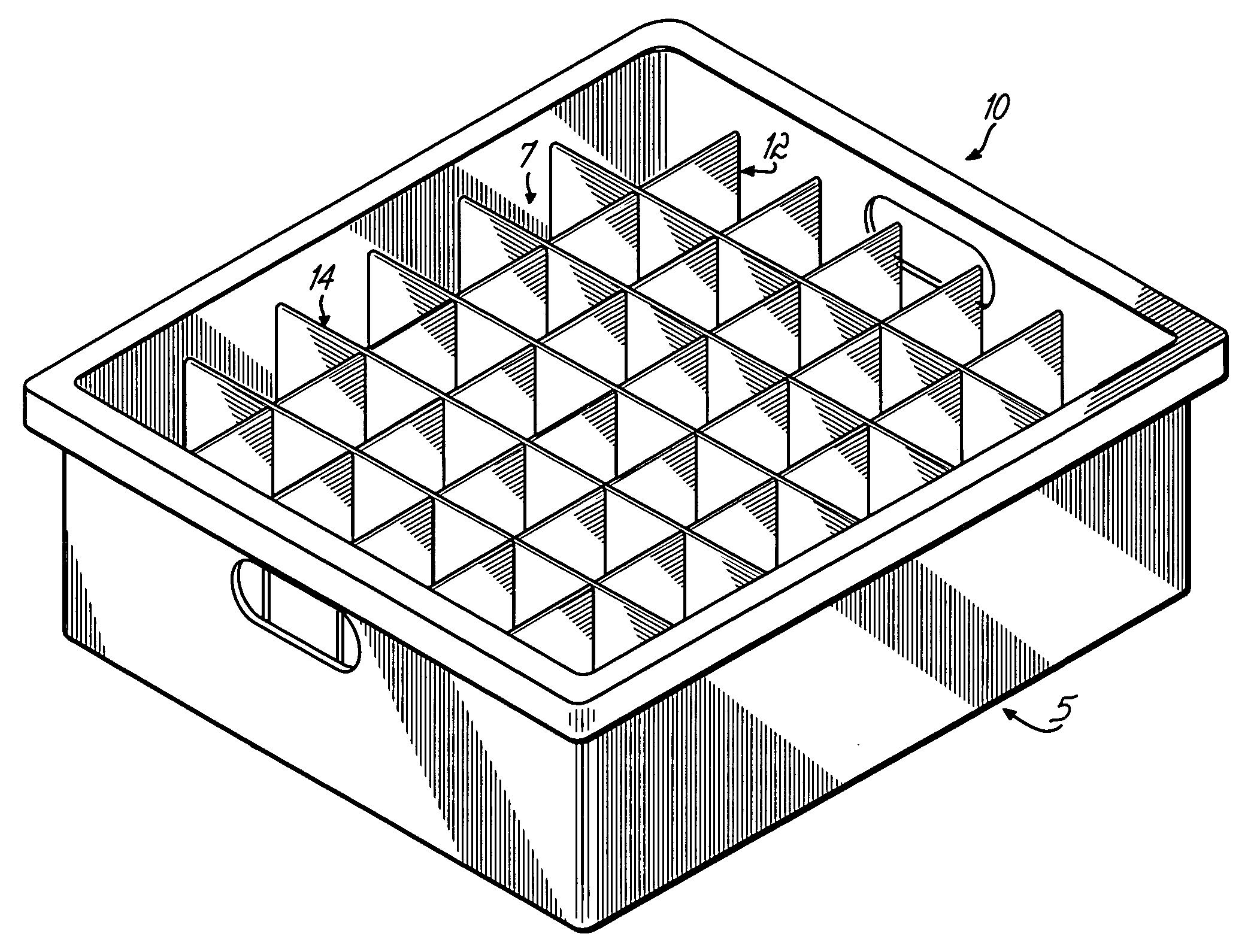

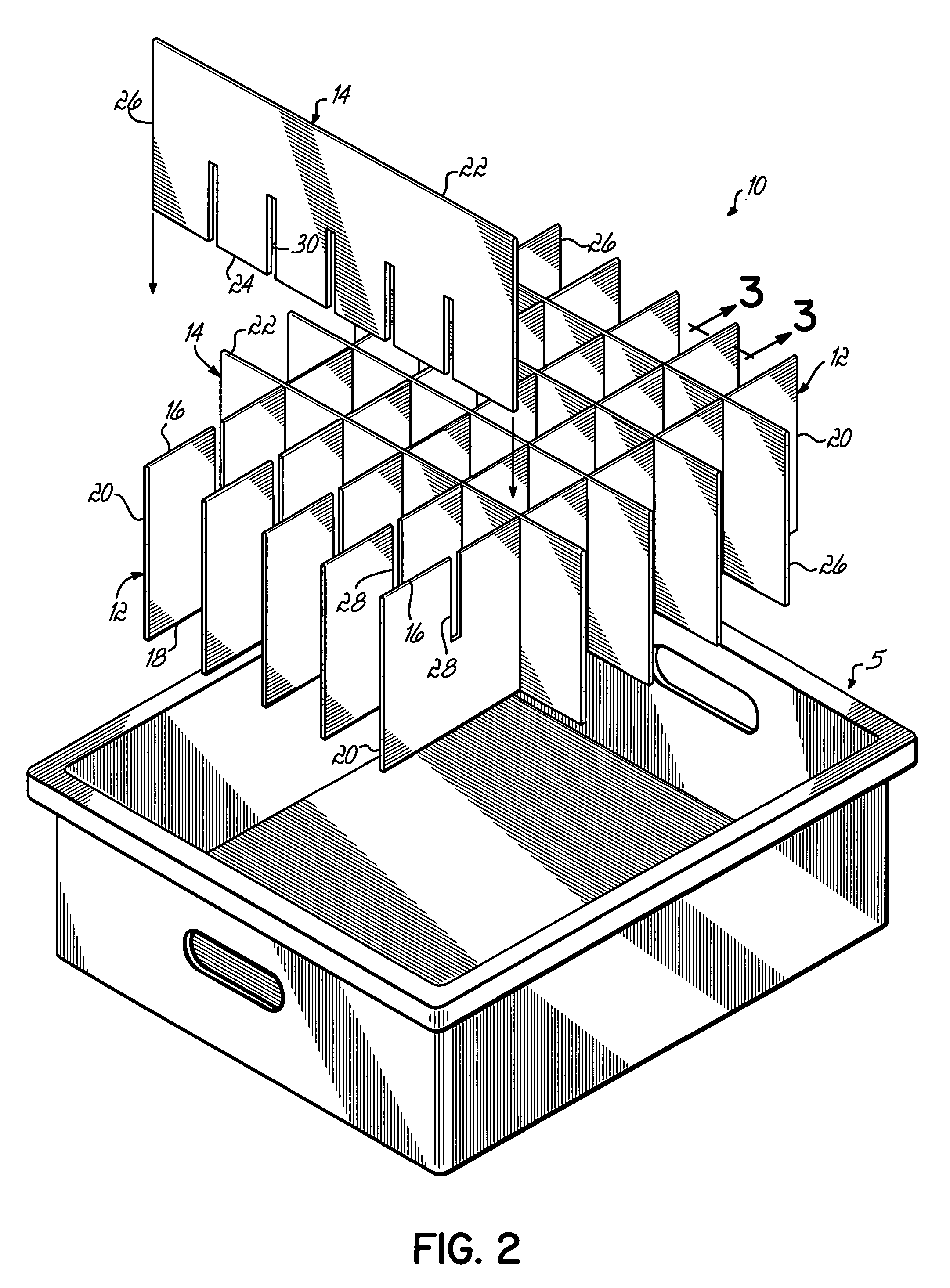

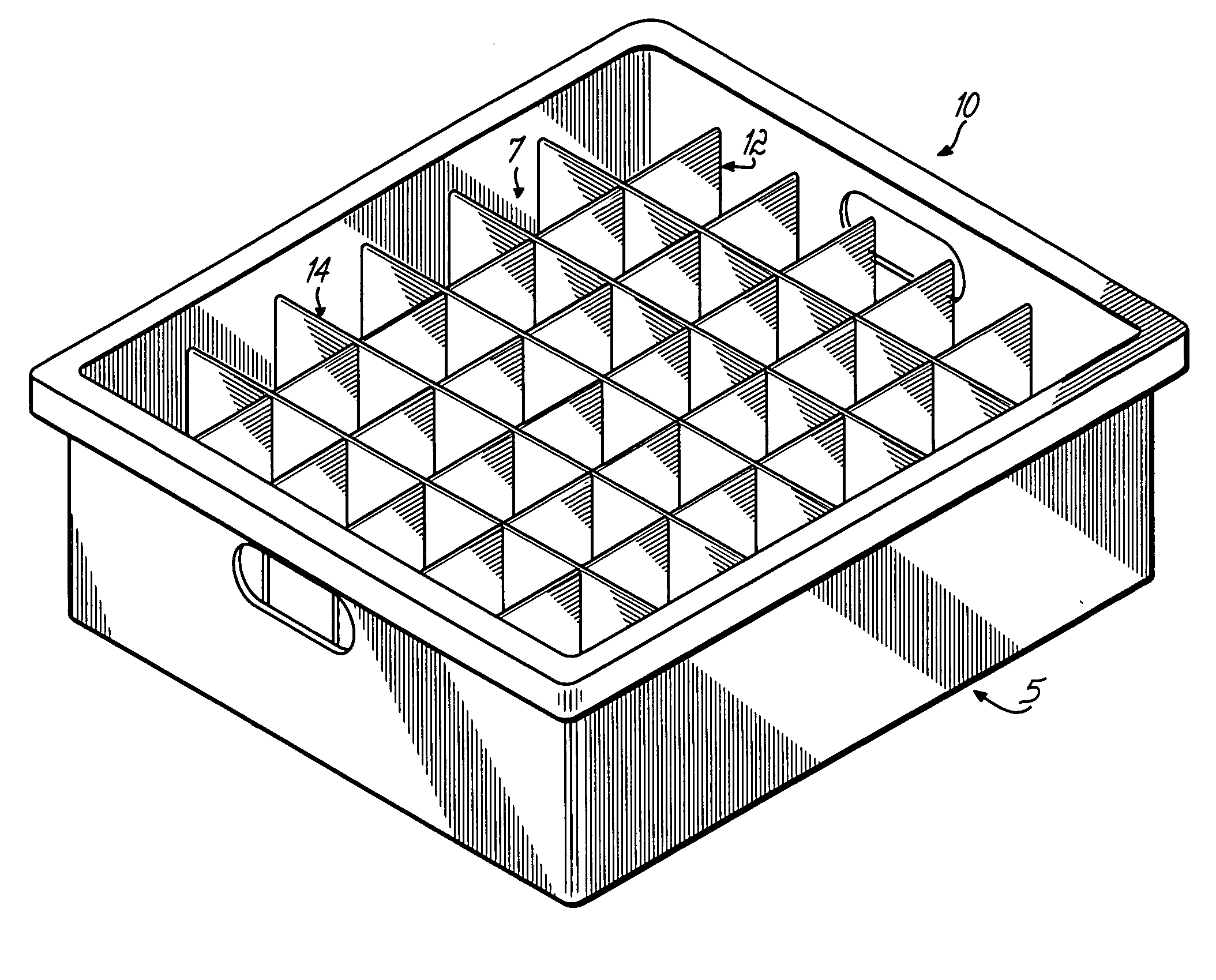

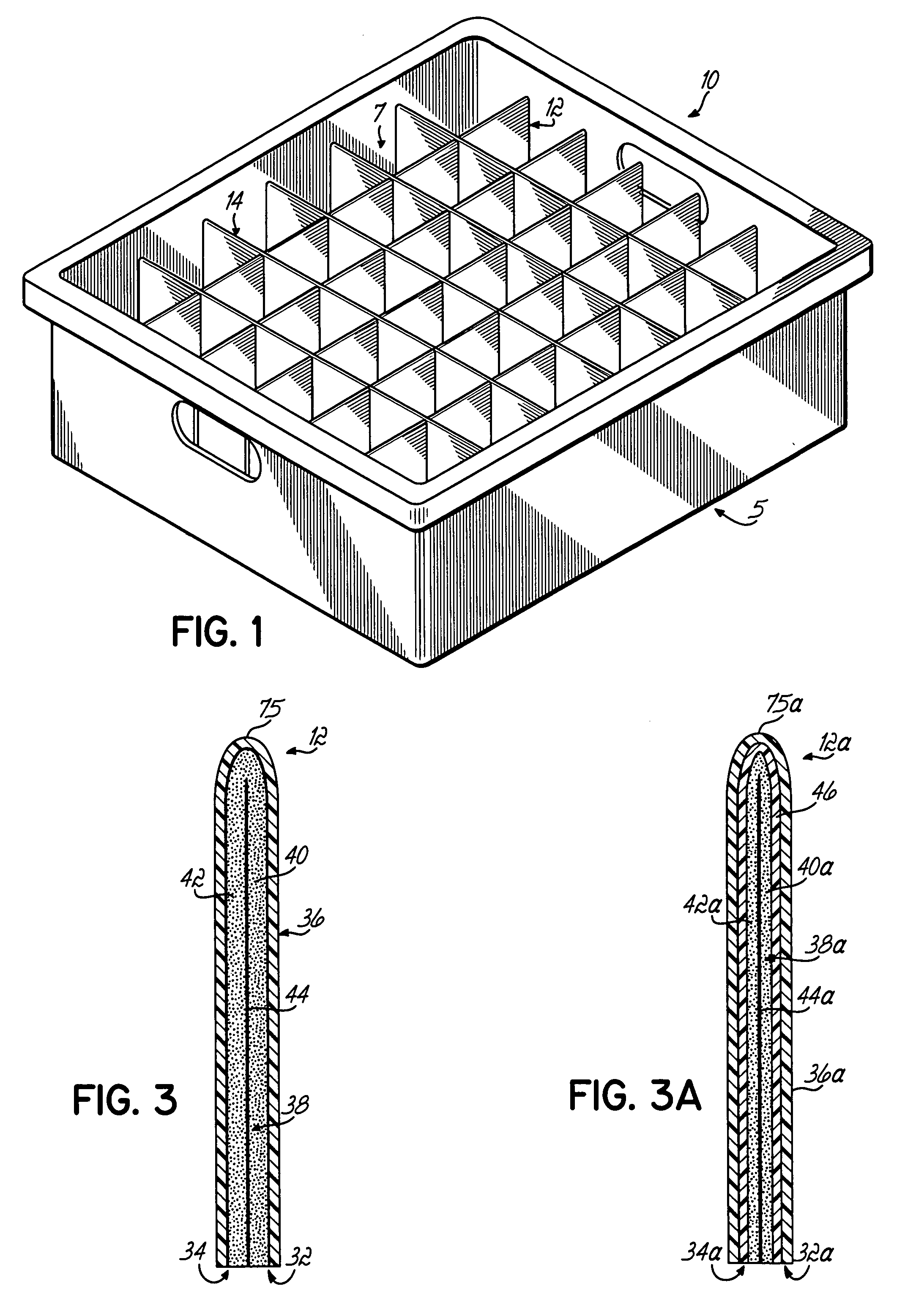

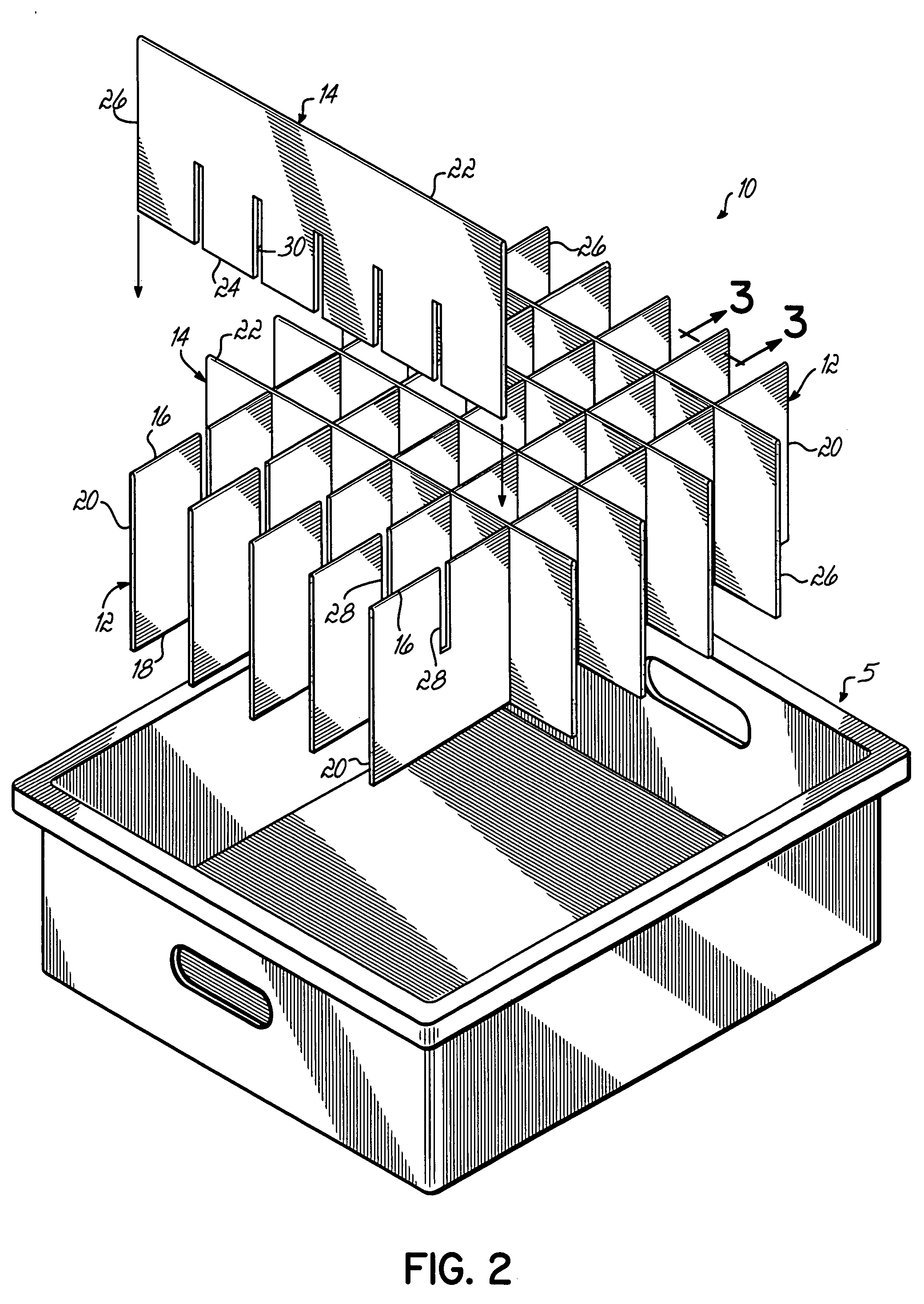

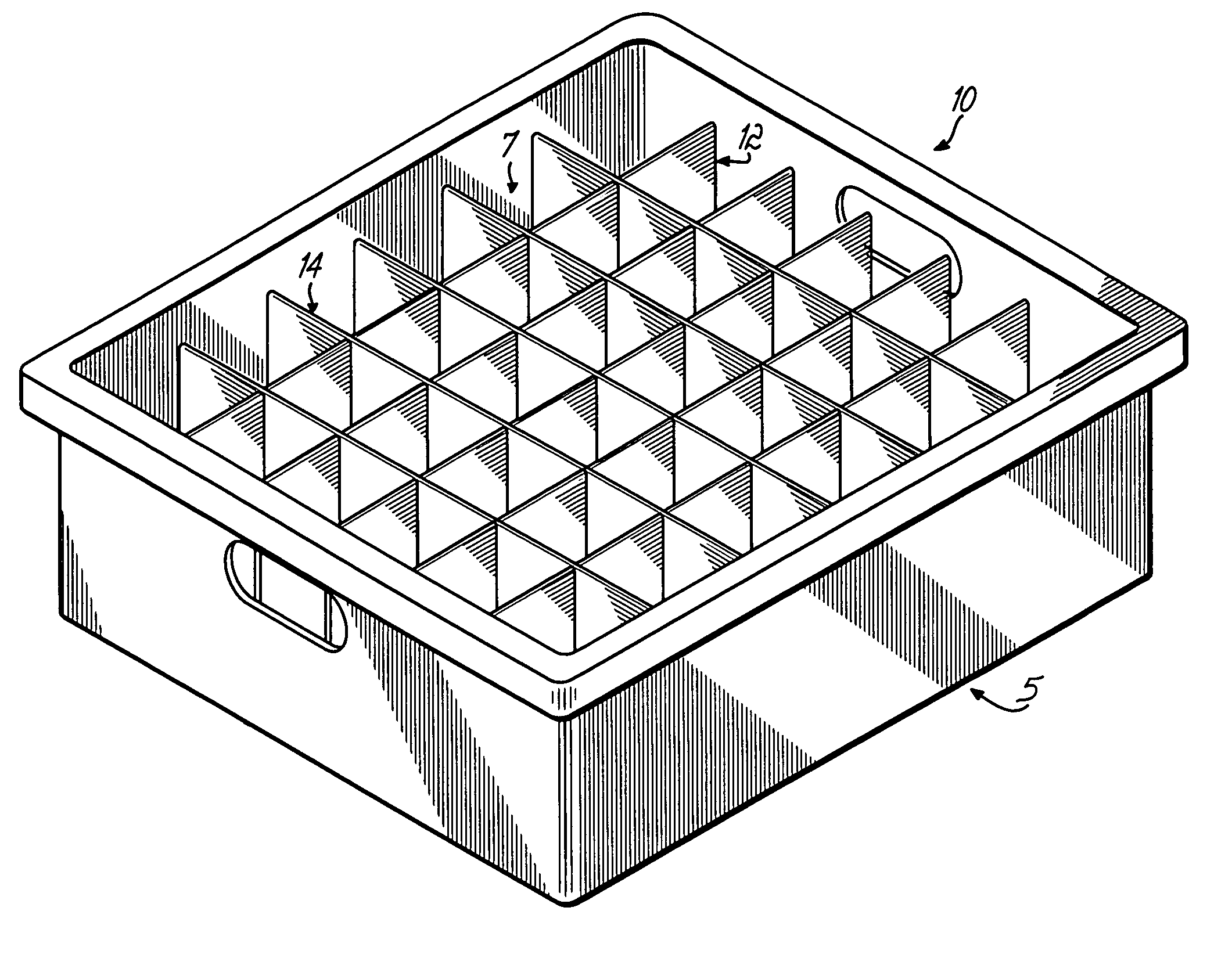

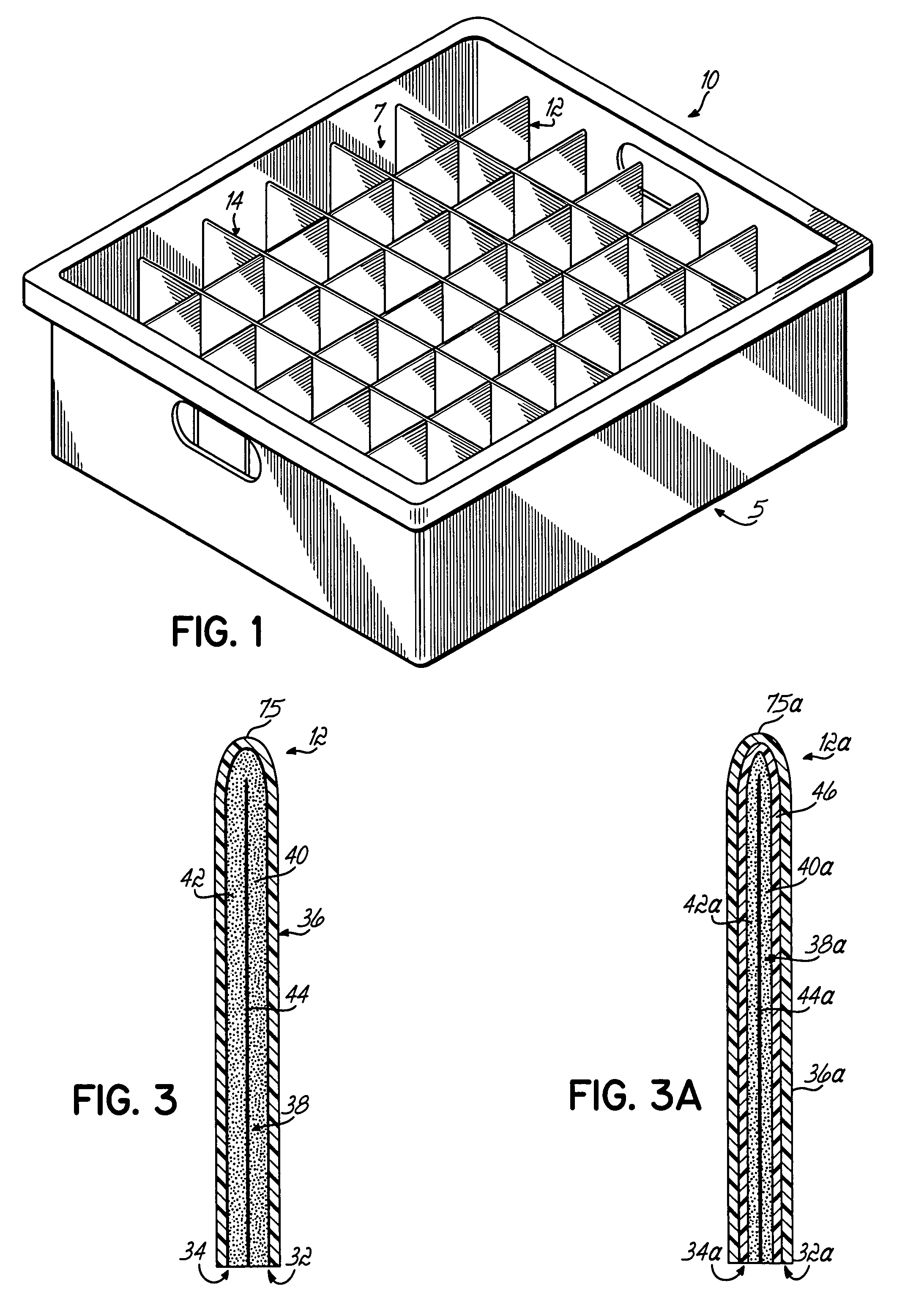

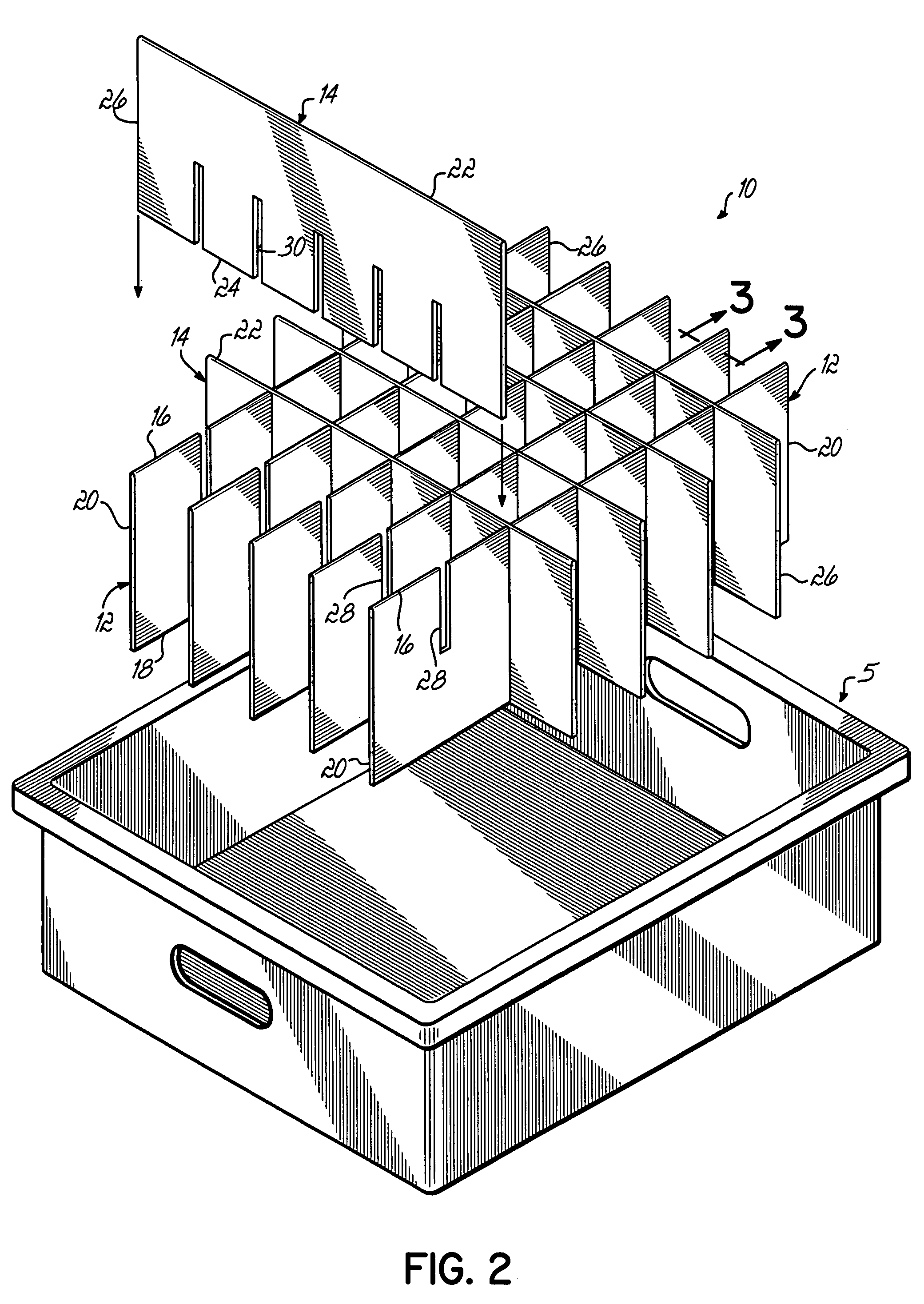

Partition assembly made with multiple ply partitions

ActiveUS7344043B2Avoid surface damageLow costDomestic cooling apparatusPaper/cardboard articlesPartition matrixMechanical engineering

A partition assembly comprising a partition matrix made up of intersecting first and second slotted partitions, each of the partitions having at least one slot. The slots of the partitions are engaged with each other at a plurality of intersections. The partitions are made by folding over a partition blank and securing a foam portion of the folded partition blank to itself. The foam may be heated with hot air before being cooled under pressure to secure opposed plies of the partition together.

Owner:BRADFORD CO

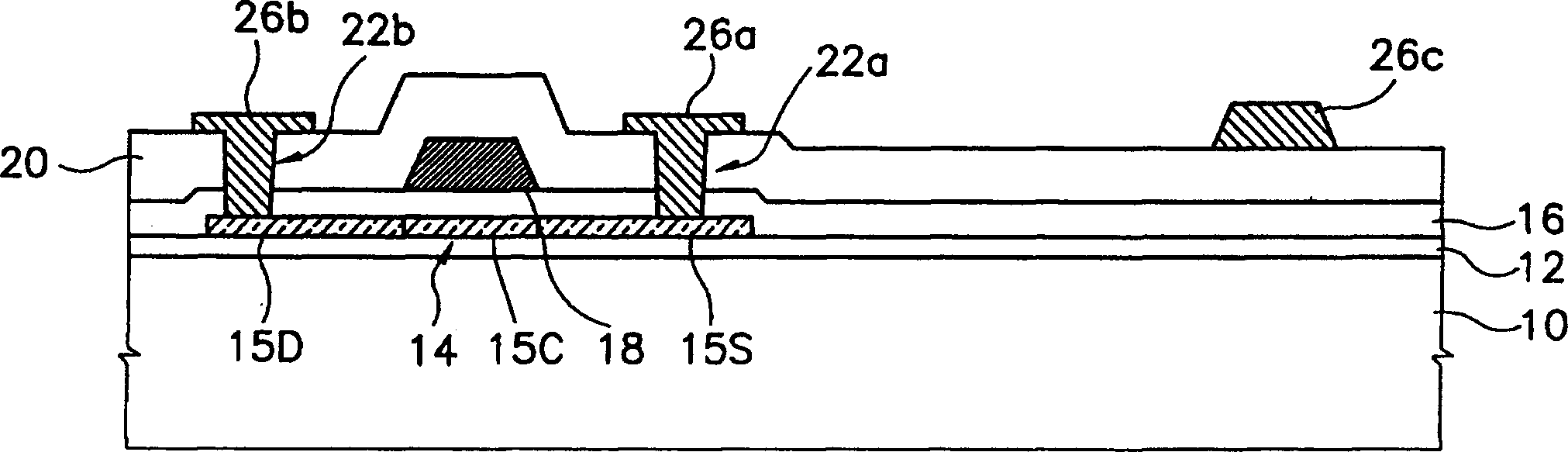

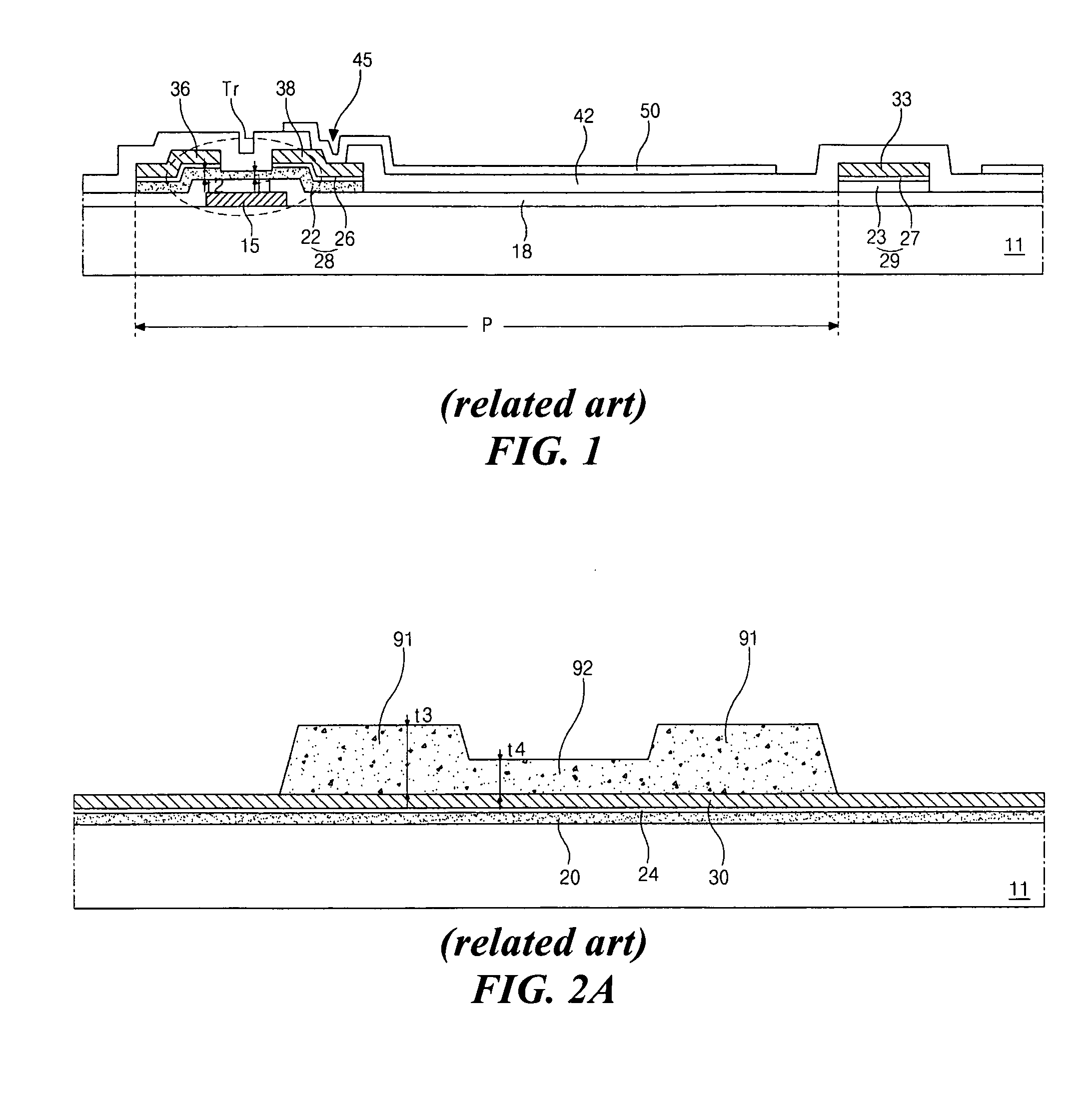

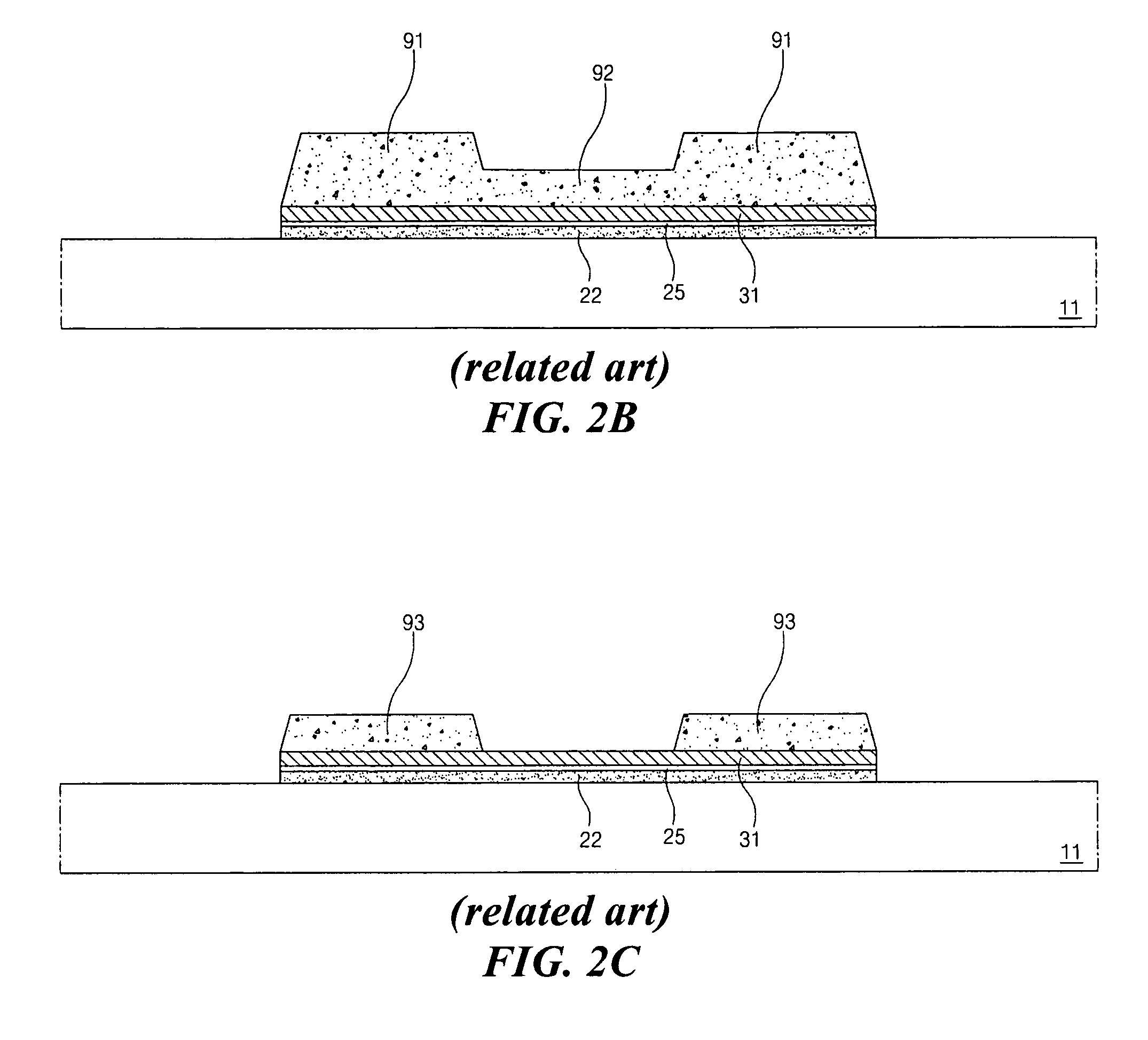

Polysilicon film transistor of liquid crystal display device and its mfg. method

InactiveCN1383214AAvoid surface damageReduce in quantityTransistorSolid-state devicesLiquid-crystal displayEngineering

The invention discloses a polysilicon TFT used for LCD and a manufacturing method thereof. The TFT includes an effective pattern formed on the substrate, a gate insulating layer formed on the substrate including the effective pattern, and a gate insulating layer formed on the gate insulating layer across the effective pattern and includes a method for defining the first impurity region, the second impurity region and the The gate line of the gate electrode of the channel region, the insulating interlayer formed on the gate insulating layer including the gate line, the data line formed on the insulating interlayer and connected to the second impurity region through the first contact hole, and formed on the The pixel electrode on the same insulating interlayer as the data line and connected to the first impurity region through the second contact hole, wherein the first contact hole is formed on the second impurity region through the gate insulating layer and the insulating interlayer, and the second contact A hole is formed on the first impurity region through the gate insulating layer and the insulating interlayer. The number of masks can be reduced to 5 or 6, thus simplifying the production process.

Owner:SAMSUNG DISPLAY CO LTD

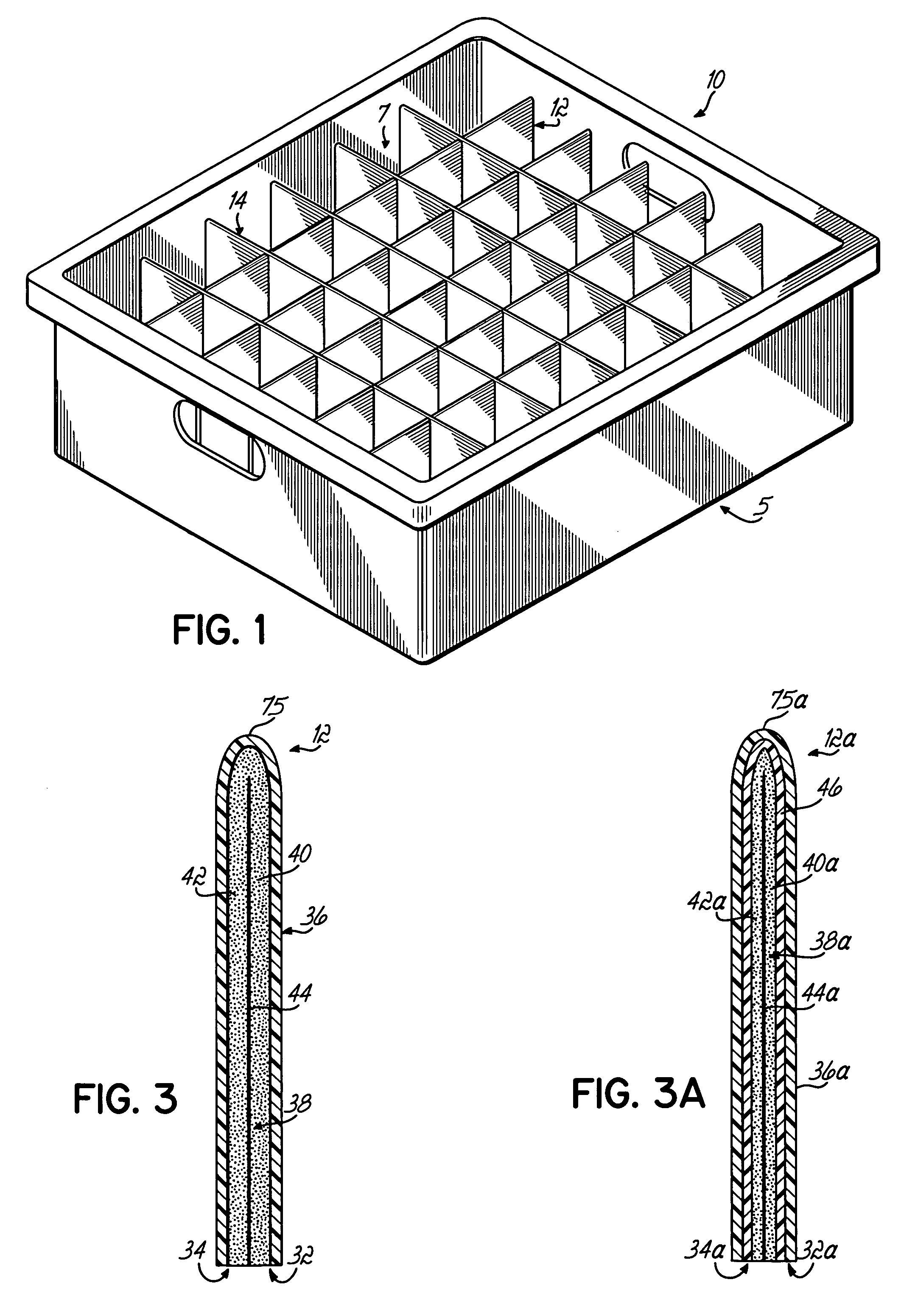

Partition assembly having floor parent welded to partitions

InactiveUS20060157489A1Avoid surface damageBoxes/cartons making machineryDomestic cooling apparatusPartition matrixMechanical engineering

A non-disassembling partition assembly comprising a partition matrix made up of intersecting first and second slotted partitions, each of the partitions having at least one slot. The slots of the partitions are engaged with each other at a plurality of intersections. The partitions may be made by folding over a partition blank and securing a foam portion of the folded partition blank to itself. The foam may be heated before being cooled under pressure to secure opposed plies of the partition together. The partition assembly is held together by a floor parent welded to the intersecting partitions. The floor has a lower outer skin and a foam layer to which the partitions are parent welded.

Owner:BRADFORD CO

Anti-pollution separation membrane and preparation method

ActiveCN102728241AStrong bindingImprove anti-pollution performanceSemi-permeable membranesMethacrylateMethyl carbonate

The invention discloses an anti-pollution separation membrane and a preparation method, wherein aiming at the shortages of a preparation technology for the present anti-pollution PVDF (polyvinylidene fluoride) separation membrane, the invention provides a novel method for preparing an anti-microbial pollution PVDF separation membrane. The novel method provided by the invention comprises the following steps of: synthesising the random copolymer with a zwitterionic structure, of MMA (methl methacrylate), DMC (dimethyl carbonate) and AMPS (2-acrylamido-2-methylpropane sulfonic acid) via free radical polymerization at first, adding the copolymer and a porogenic agent, i.e., polyethylene glycol (PEG) in PVDF, and preparing the anti-pollution separation membrane by using N,N-dimethyl formamide (DMF) as a solvent and using water as a coagulating agent through a phase inversion method. Electropositive quaternary amine group and electronegative sulfonic group exist in the structure of the copolymer simultaneously, and have a binding capacity for water molecules which is much stronger than the binding capacity of traditional polyethylene glycol and the derivatives of the traditional polyethylene glycol, and the formed hydration layer is more stable; therefore, the prepared novel PVDF membrane is lasting in anti-pollution performance.

Owner:TIANJIN POLYTECHNIC UNIV

Floor nozzle for vacuum cleaner

The present invention relates to a cleaning device for cleaning a surface, with a nozzle arrangement (10) comprising: —a brush (12) rotatable about a brush axis (14), said brush (12) being provided with brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt particles (22) and / or liquid (24) from the surface (20) during the rotation of the brush (12), —a drive means for driving the brush (12) in rotation, —a bouncing element (32) comprising a bouncing surface (33) that is configured to let the dirt particles (22) and / or liquid (24), that are released from the brush (12) during rotation, rebound to the brush (12), said bouncing surface (33) being spaced apart from the brush (12) and extending substantially parallel to the brush axis (14), and —an adjustment means (35) for adjusting the position of the bouncing element (32) relative to the surface (20) depending on a direction of movement (40) of the device, wherein the adjustment means (35) is adapted to arrange the bouncing element (32) in a first position in which the bouncing element (32) has a first distance d1 to the surface (20), when the cleaning device is moved in a forward direction, in which the bouncing element (32) is, seen in the direction of movement of the device (40), located behind the brush (12), and to arrange the bouncing element (32) in a second position in which the bouncing element (32) has a second distance d2 to the surface, when the cleaning device is moved in an opposite backward direction, wherein d2 is greater than d1 and equal to d3*tan(α), d3 being the distance between the bouncing surface (33) and the position of the brush (12) where the tip portions (18) lose contact from the surface to be cleaned (20) during the rotation of the brush (12), and α being an angle that is equal to or smaller than 20°.

Owner:VERSUNI HLDG BV

Spraying assembly line for sheet metal part products

InactiveCN104368477AAvoid surface damageGuarantee product surface qualitySpraying apparatusPretreated surfacesEngineeringAssembly line

The invention discloses a spraying assembly line for sheet metal part products. The spraying assembly line comprises an assembly line support, a closed assembly line conveying track, locating elements, a driving device and a plurality of machining regions, wherein the assembly line conveying track is used for conveying products to be machined, is arranged on the assembly line support and comprises a track body and a transmission line arranged in the track body; the locating elements are used for locating the products to be machined, evenly distributed below the assembly line conveying track and connected with the transmission line; the driving device is connected with the transmission line in a driving mode so as to drive the locating elements to move cyclically along the track body; the machining regions are arranged along the outer edge of the assembly line conveying track. By the adoption of the spraying assembly line for the sheet metal part products, all spraying processes can be sequentially completed one by one immediately after the products are located; before the next process is carried out, the products do not need to be hung up or down; as a result, while the surface quality of the products is improved, a large amount of machining time is saved, and spraying efficiency is improved.

Owner:SUZHOU FENGSHI SHEET METAL

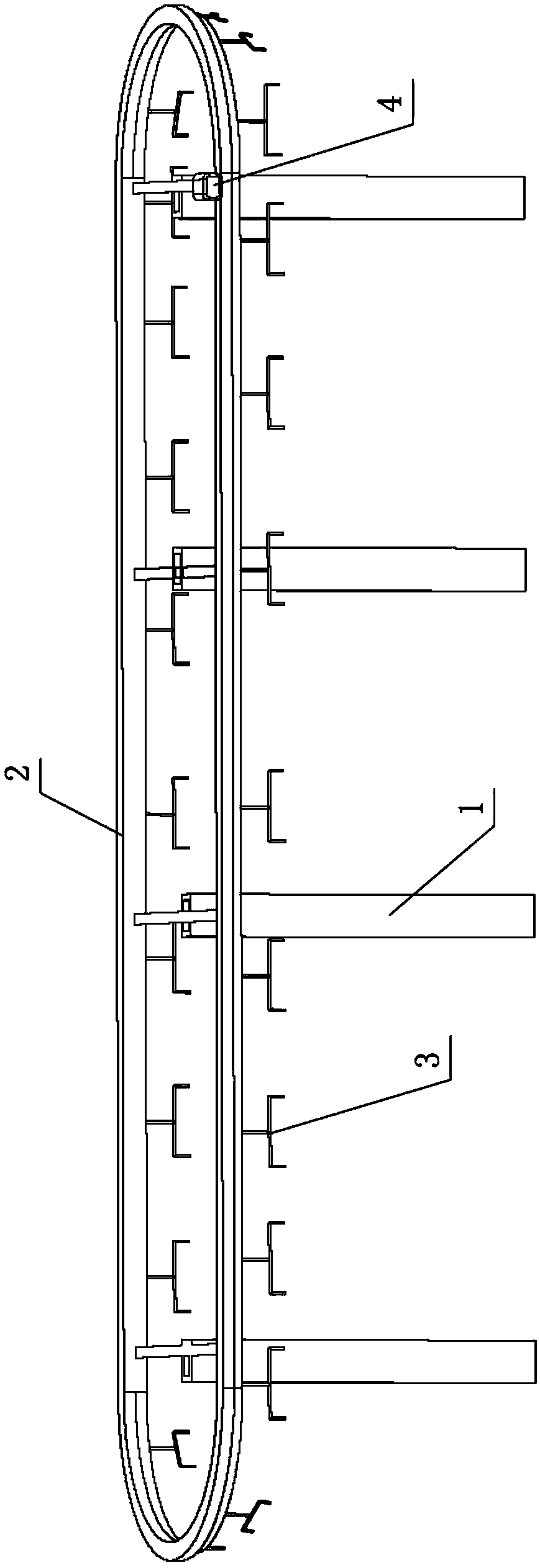

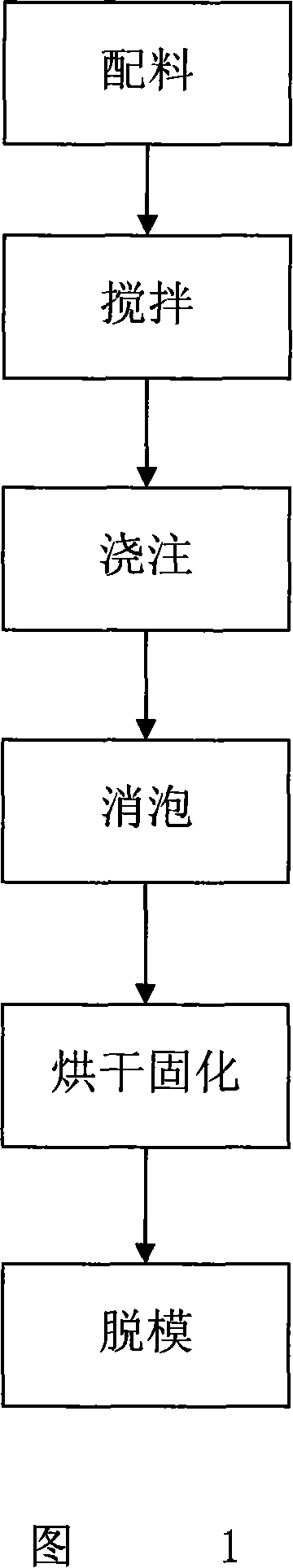

Semi-fixing abrasive grain grinding tool and method of producing the same

InactiveCN101134298AHigh bonding strengthImprove material removal rateAbrasion apparatusGrinding devicesWear particleAdhesive

The present invention is one kind of grinding tool with semi-fixed abrasive particle and its making process. The grinding tool consists of abrasive grain in 80-90 wt%, adhesive 1-10 wt% and additive 5-15 wt%. Its making process includes the following steps: 1. mixing abrasive grain, adhesive and additive, sieving and mixing with water; 2. molding the mixture in a mold; 3. eliminating bubbles from the molded grinding tool; and 4. stoving the grinding toll in a stove for curing and demolding to obtain the grinding tool with semi-fixed abrasive particle. The present invention has high processing precision and high processing efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

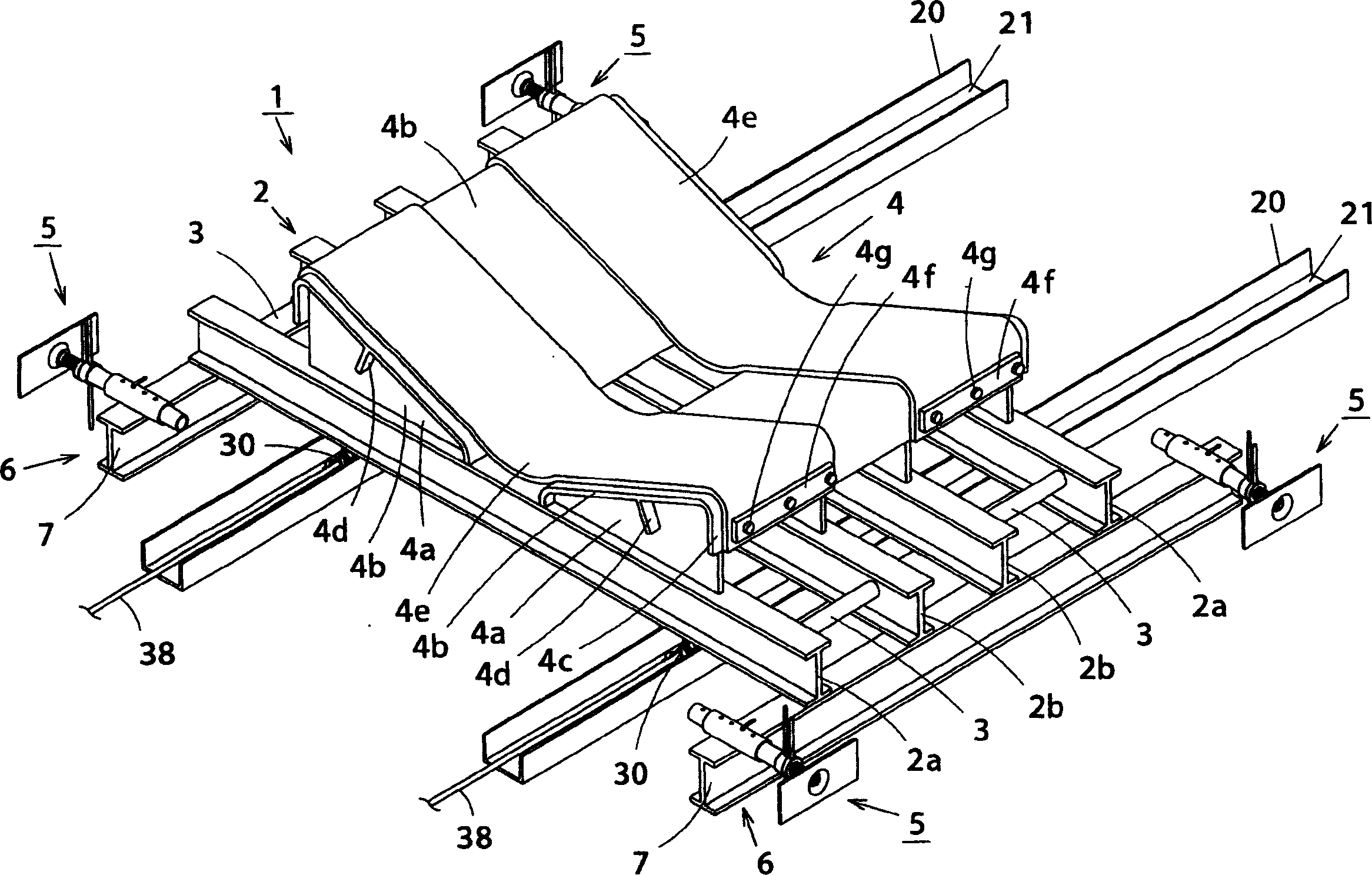

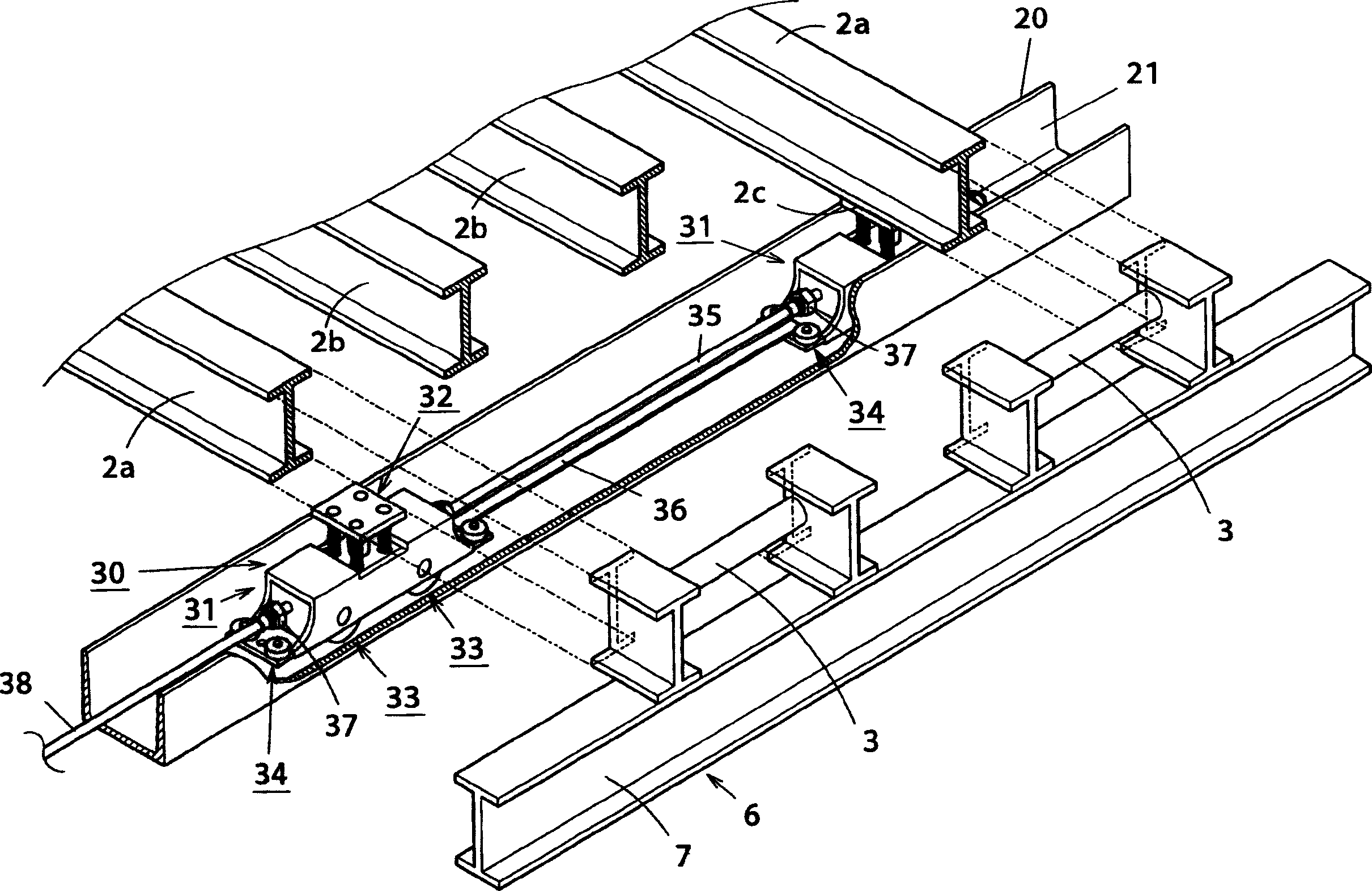

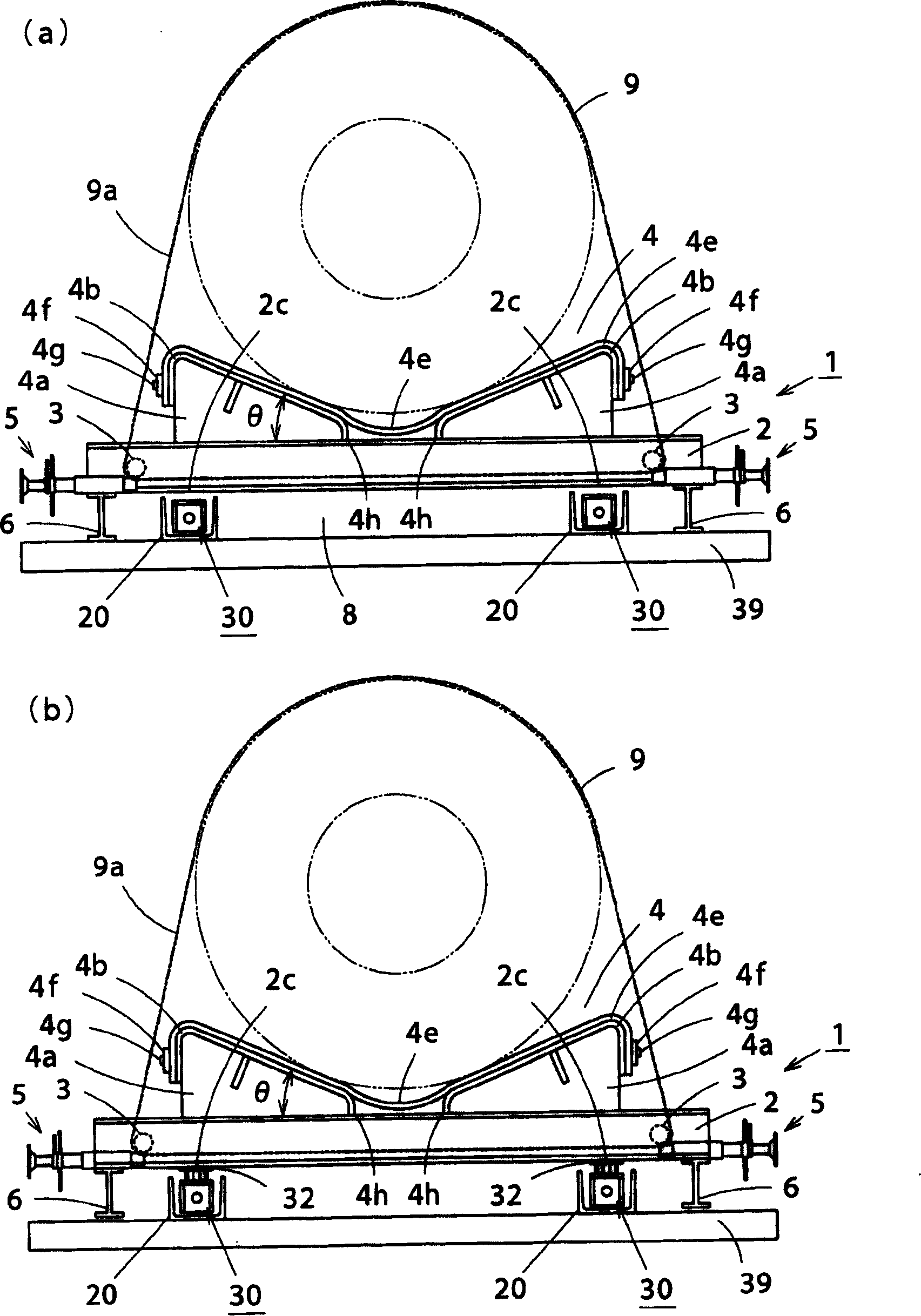

Heavy goods carrying table and method for using same

The invention aims to provide a transferring table of a heavy load which hardly shifts when laid on a floor of a transferring vessel such as a container or the like, is easily positioned and stably fixed to a predetermined position of the inner side of the transferring vessel, shows stability to the roll and pitch of a ship, and enables easy carrying-in and carrying-out of the heavy load with a small force such a human power. The transferring table 1 of the heavy load transfers a cylindrical heavy load using a transferring means arranged on the floor, and has: a table portion 2; leg portions 6 arranged on both sides of the lower part of the table 2; a cylindrical heavy load placement portion 4 forming a pair of inclination surfaces arranged on and fixed to the table portion 2 and facing to each other; and a fastening material fixing portion 3 arranged at a predetermined portion of the table 2 or the leg portions 6 and fixing the fastening material such as a hoop material, a steel band or the like which fastens the cylindrical heavy load to the cylindrical heavy load placement portion 4.

Owner:TSUNEISHI HLDG CORP

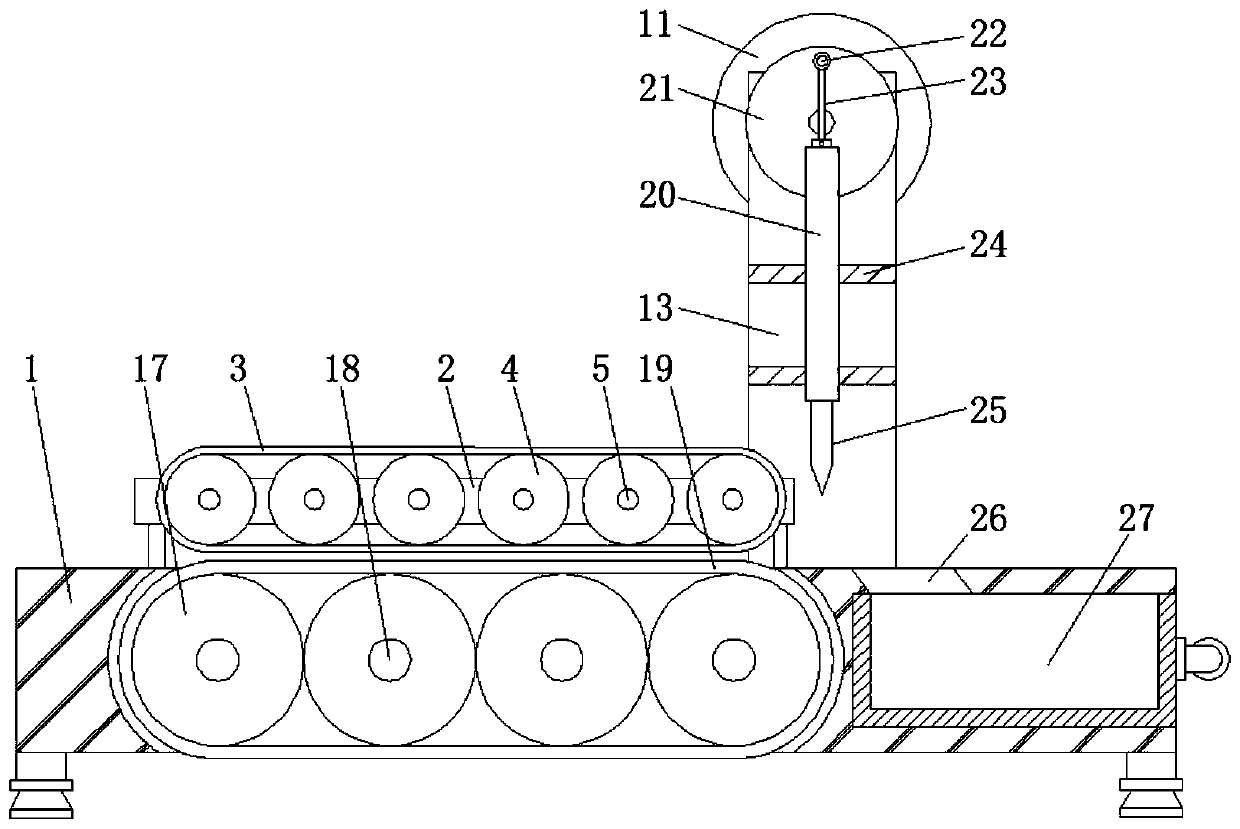

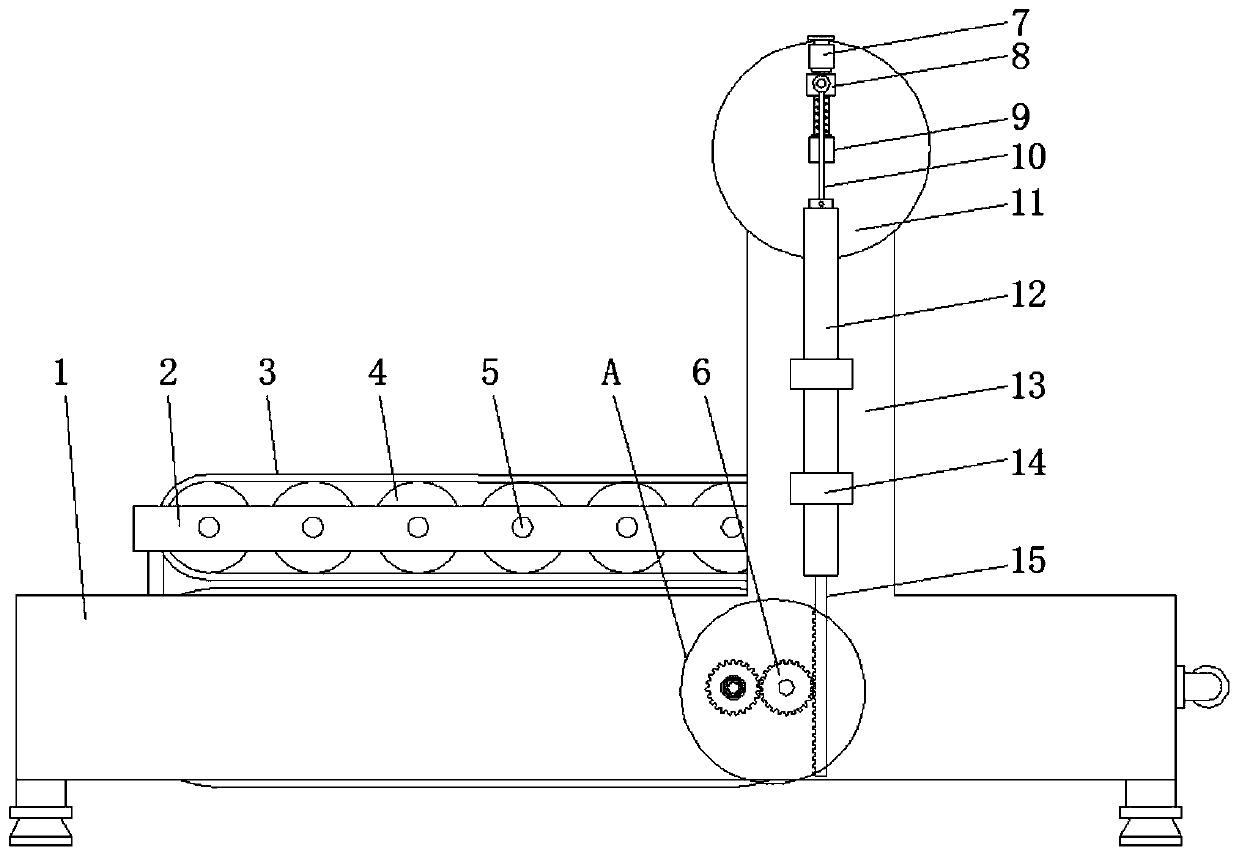

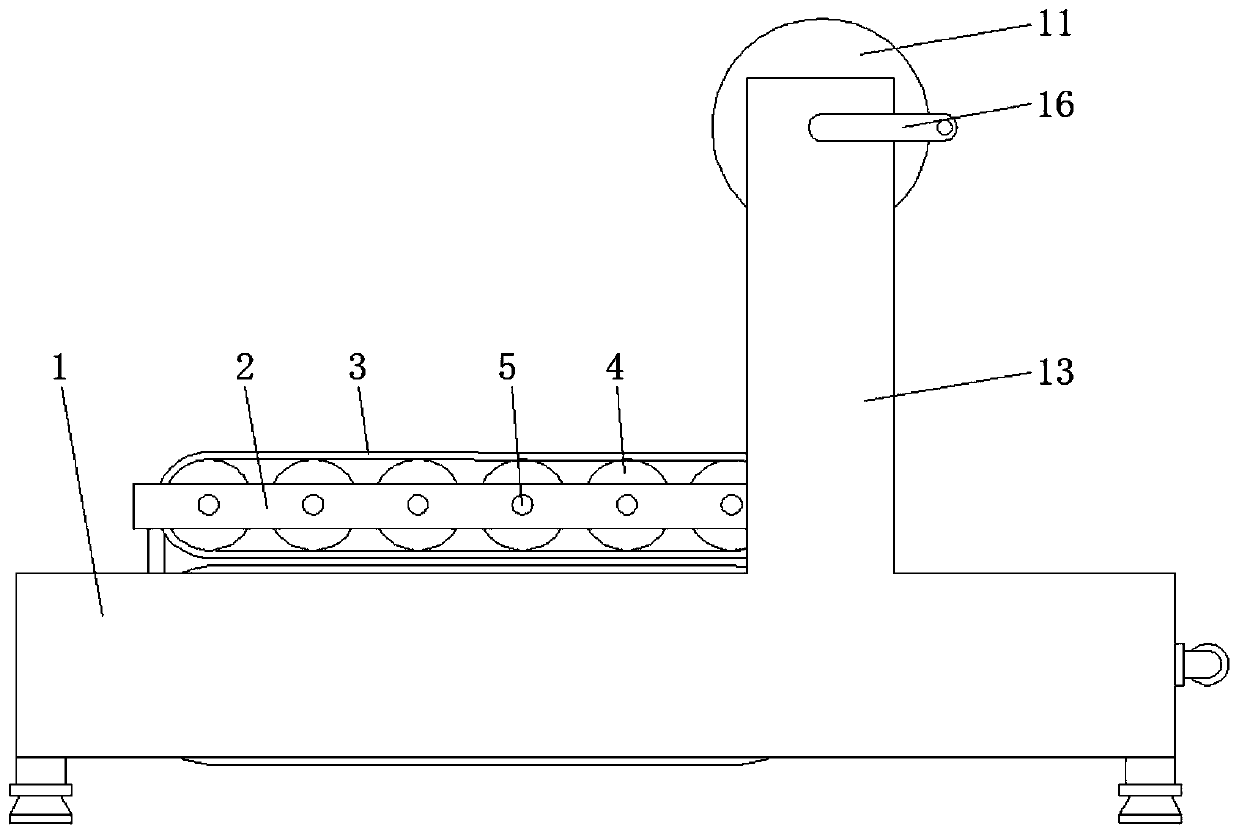

Traditional Chinese medicinal material slicing device

The invention discloses a traditional Chinese medicinal material slicing device which comprises a processing seat, fixed racks, a feeding mechanism, a driving mechanism, a slicing mechanism and a material frame. One end of the processing seat is slidably connected to the material frame, a discharging slot is formed in the processing seat above one end of the material frame, the fixed racks are connected to two sides of the top of the processing seat at two ends of the discharging slot, the slicing mechanism is connected between the fixed racks, the feeding mechanism is connected to the centerof one side of the fixed rack, and the driving mechanism is connected to the outer side of the fixed rack; the slicing mechanism comprises a tool apron, a second rotary wheel, a driving shaft, a second driving rod, a limiting plate and a slicer. The feeding mechanism comprises an upper end transfer part and a lower end transfer part. The driving mechanism comprises a transmission gear, a handwheeland an adjusting part. The traditional Chinese medicinal material slicing device can feed and slice traditional Chinese medicinal materials automatically by operating the handwheel by an operator andcan avoid a phenomenon of surface damage as the traditional Chinese medicinal materials are excessively extruded effectively, so that the integrity of the traditional Chinese medicinal materials is improved.

Owner:吕福杰

Partition assembly having floor parent welded to partitions

InactiveUS7344044B2Avoid surface damageBoxes/cartons making machineryDomestic cooling apparatusPartition matrixMechanical engineering

A non-disassembling partition assembly comprising a partition matrix made up of intersecting first and second slotted partitions, each of the partitions having at least one slot. The slots of the partitions are engaged with each other at a plurality of intersections. The partitions may be made by folding over a partition blank and securing a foam portion of the folded partition blank to itself. The foam may be heated before being cooled under pressure to secure opposed plies of the partition together. The partition assembly is held together by a floor parent welded to the intersecting partitions. The floor has a lower outer skin and a foam layer to which the partitions are parent welded.

Owner:BRADFORD CO

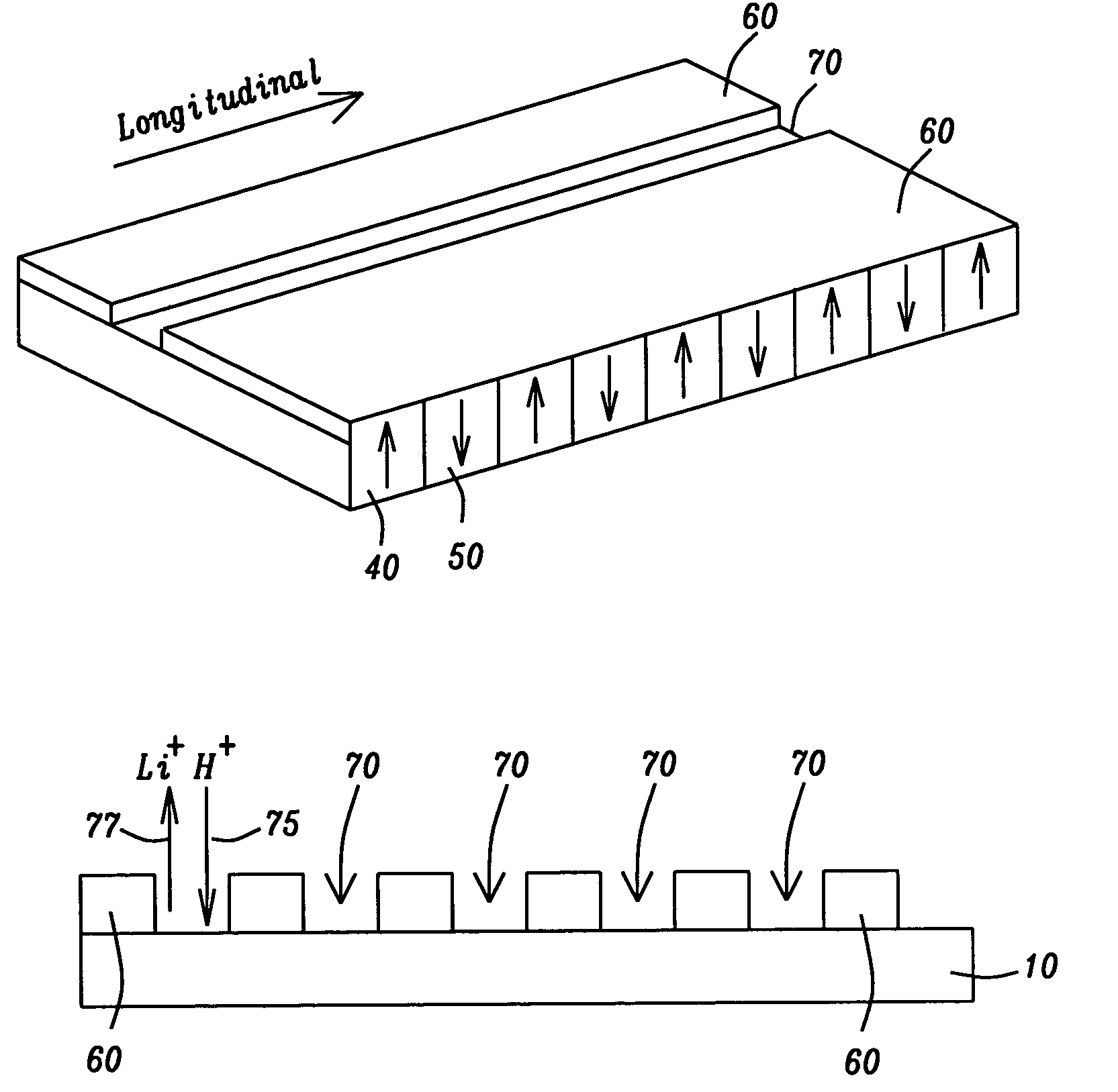

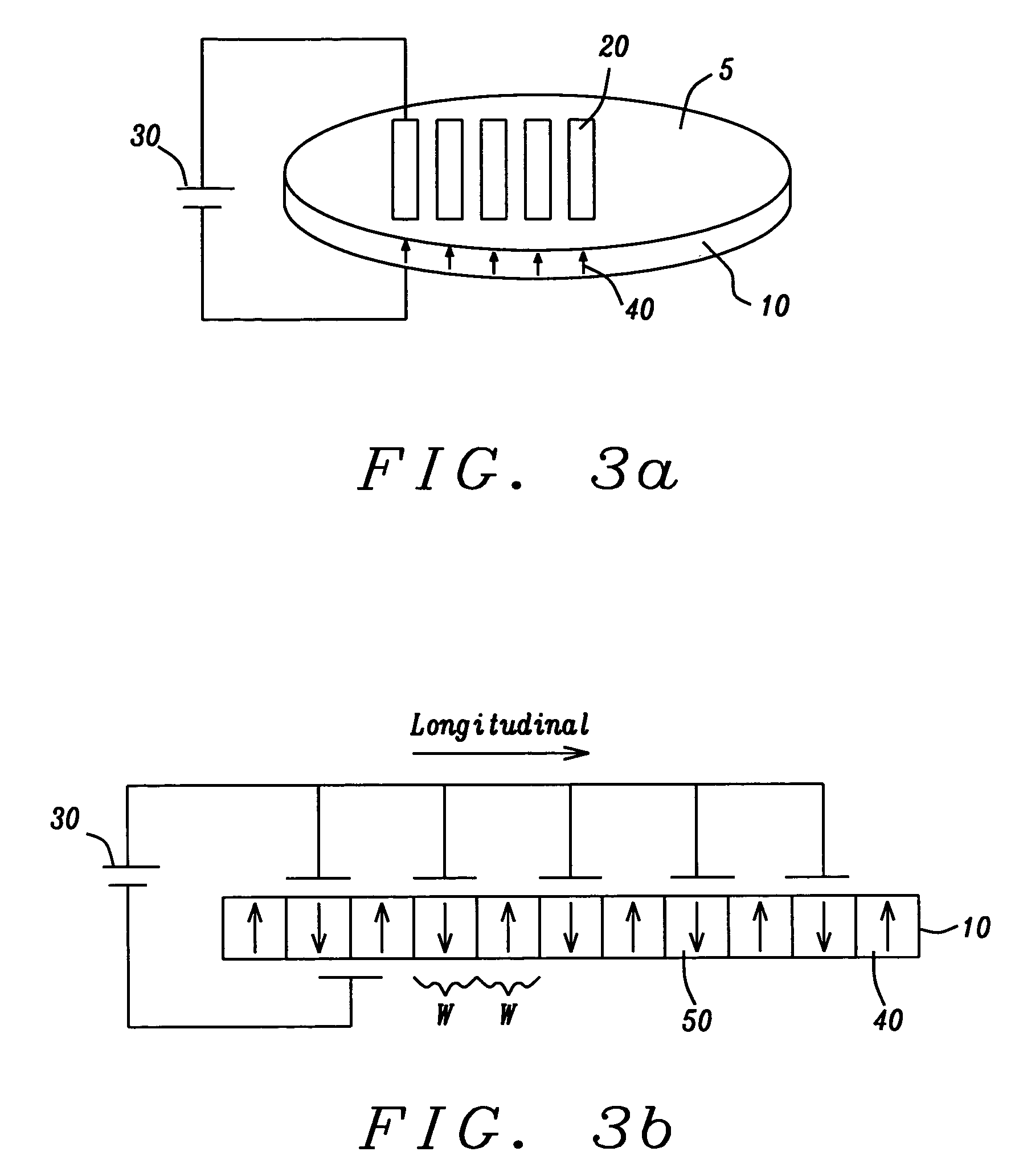

High efficiency wavelength converters

InactiveUS7170671B2Efficiently obtainedAvoid surface damageAfter-treatment detailsBy pulling from meltEnergy transferHigh rate

A method is provided for forming a waveguide region within a periodically domain reversed ferroelectric crystal wherein the waveguide region has a refractive index profile that is vertically and horizontally symmetric. The symmetric profile produces effective overlapping between quasi-phasematched waves, a corresponding high rate of energy transfer between the waves and a symmetric cross-section of the radiated wave. The symmetric refractive index profile is produced by a method that combines the use of a diluted proton exchange medium at a high temperature which produces a region of high index relatively deeply beneath the crystal surface, followed by a reversed proton exchange which restores the original crystal index of refraction immediately beneath the crystal surface.

Owner:HC PHOTONICS

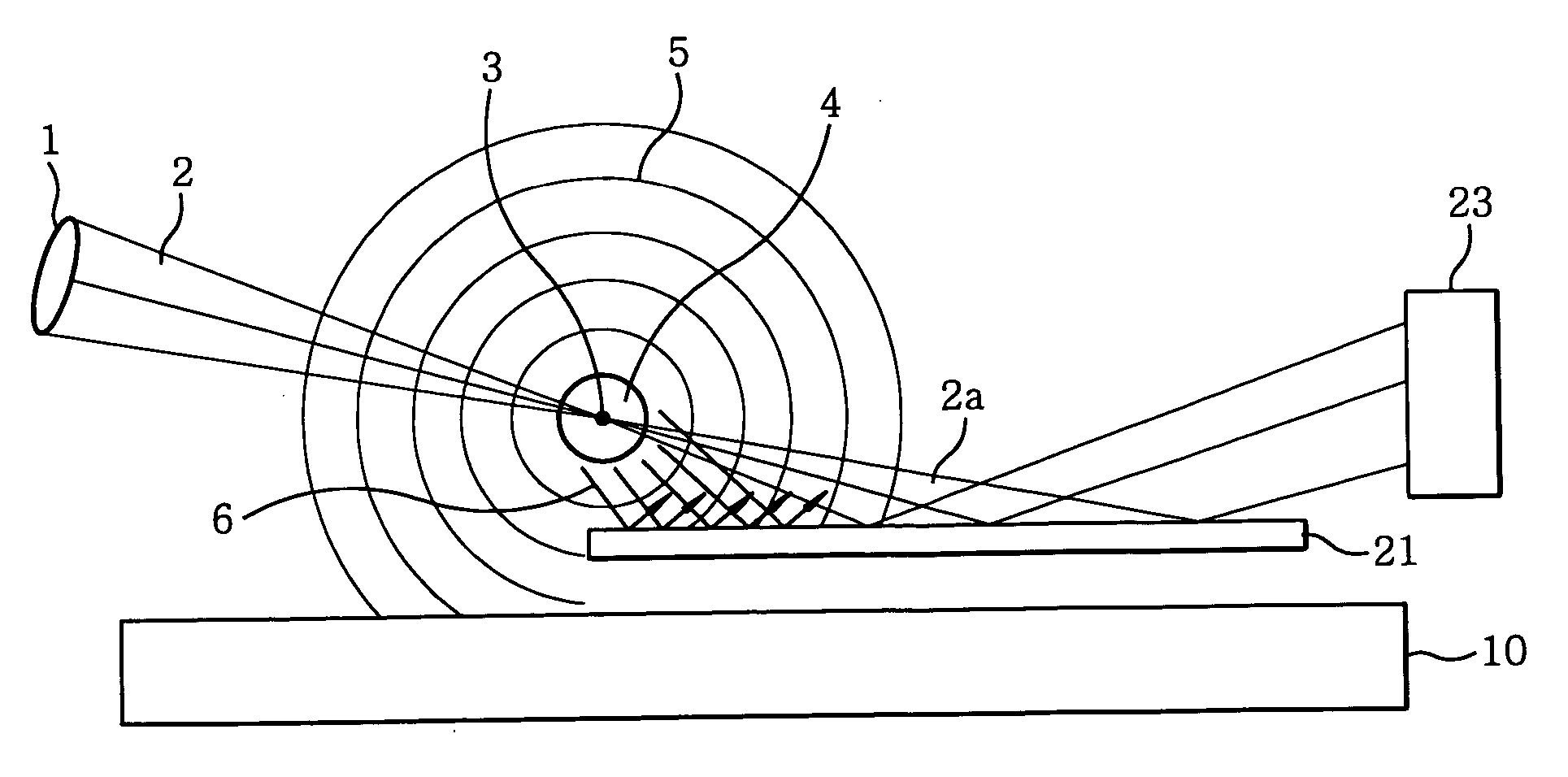

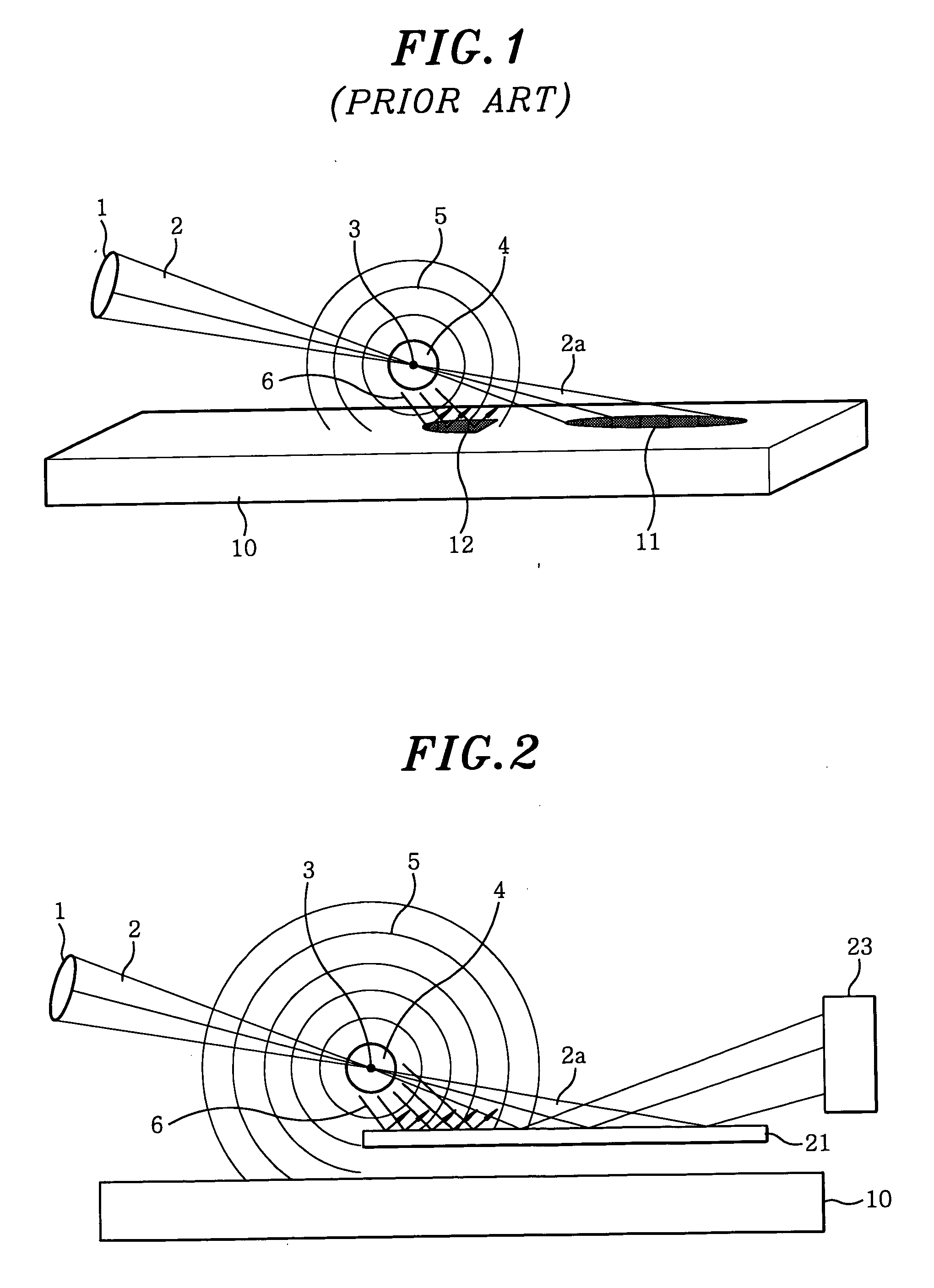

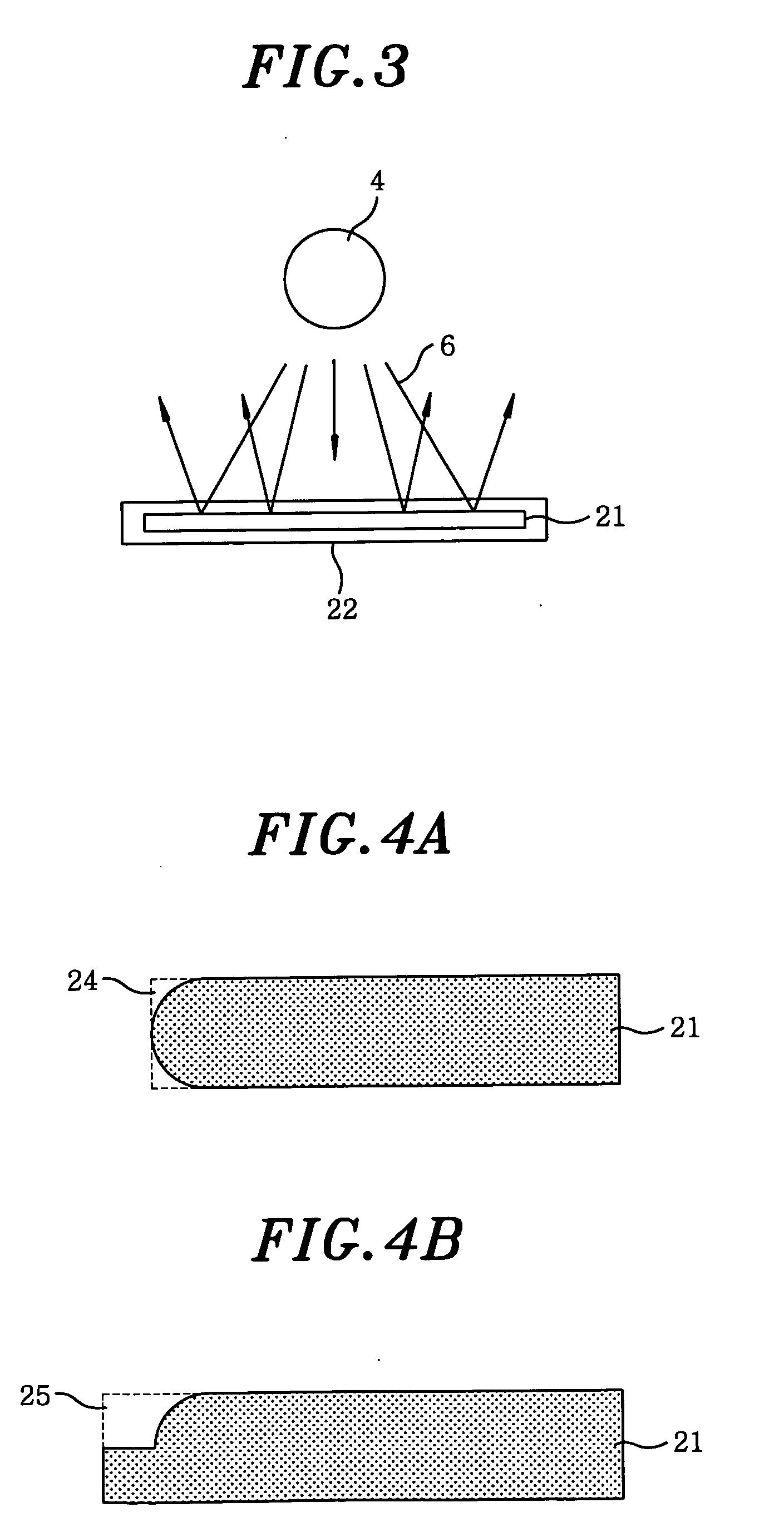

Apparatus for dry-surface cleaning using a laser

InactiveUS20060108330A1Avoid surface damageSemiconductor/solid-state device manufacturingCleaning processes and apparatusShock waveSurface cleaning

A dry-surface cleaning apparatus includes a laser for generating laser beams, a focus lens for generating a plasma shock wave around a laser focus by converging the laser beams into the laser focus around a workpiece to be cleaned, wherein contaminants on the workpiece are removed by colliding the plasma shock wave against the workpiece, and a thermal radiation protector for avoiding a surface damage on the workpiece induced by a plasma thermal radiation entailed by the generation of the plasma shock wave. The thermal radiation protector is installed between the laser focus and the workpiece and is extended toward a downstream of the laser focus to a position where a portion of remaining laser beam when generating the plasma shock wave reaches in order to reflect the remaining laser beam.

Owner:IM TECH CO LTD

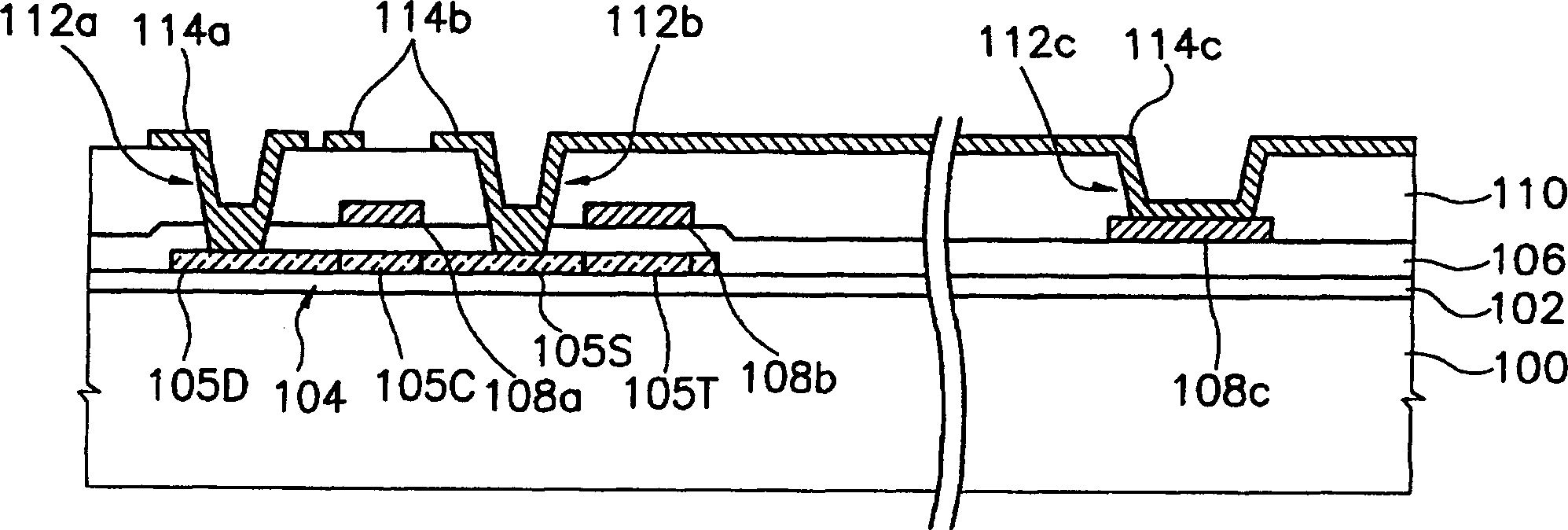

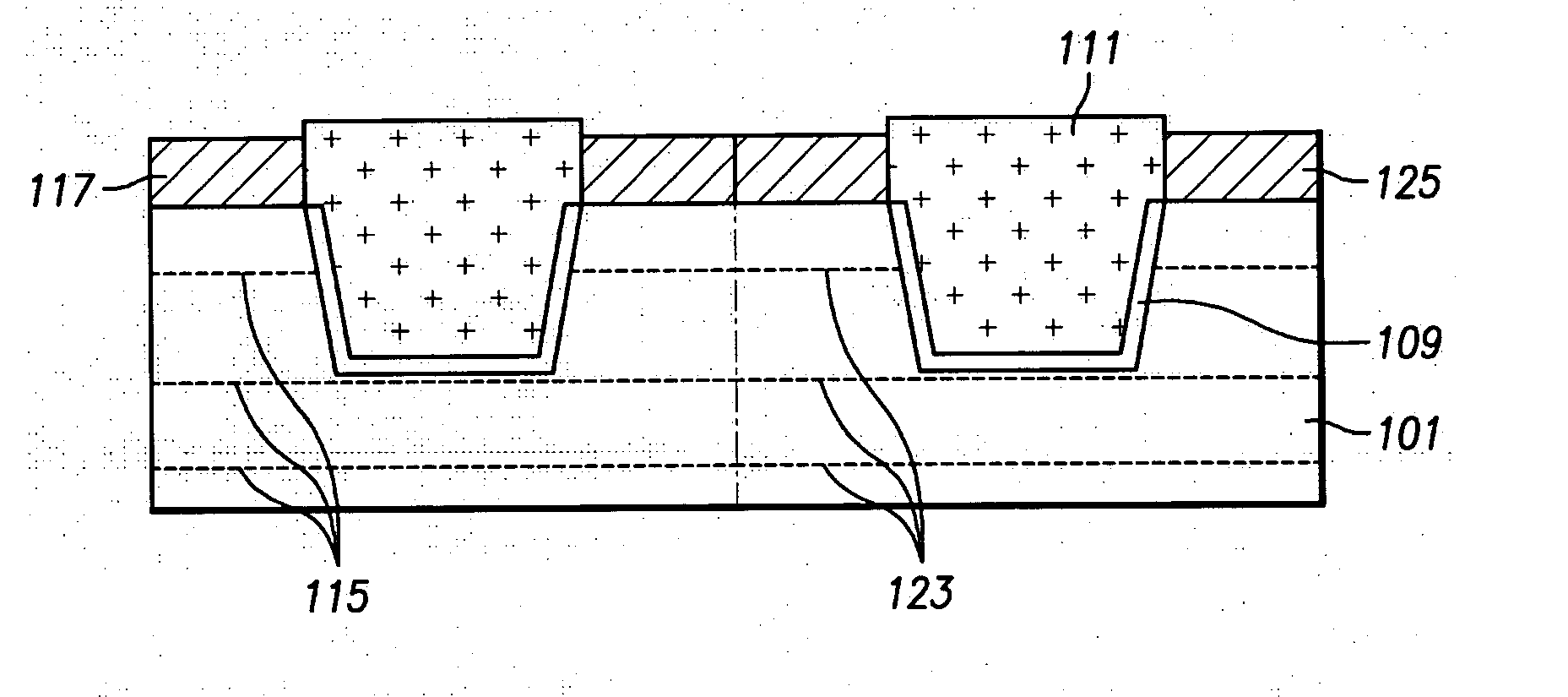

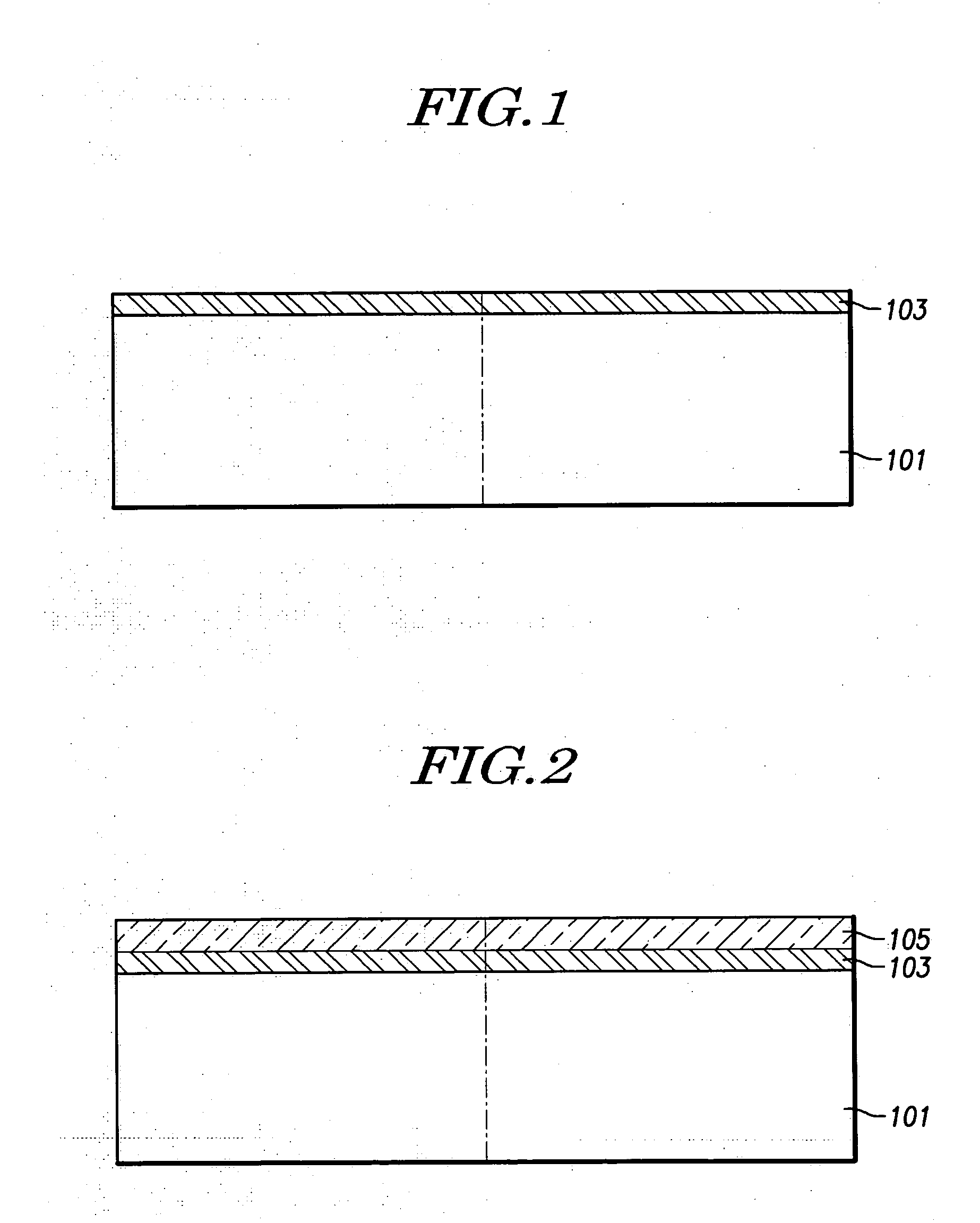

Semiconductor device using EPI-layer and method of forming the same

ActiveUS20070037360A1Reduce and prevent surface damageImprove isolation effectSemiconductor/solid-state device manufacturingSemiconductor devicesOxideDopant

A method of fabricating a semiconductor device includes forming a pad oxide film and a nitride film on a semiconductor substrate; exposing the semiconductor substrate by selectively etching the pad oxide film and the nitride film; forming a trench in the exposed semiconductor substrate; forming a gap-fill dielectric film in the trench; exposing an active area of the semiconductor substrate by removing the pad oxide film and the nitride film; forming an epitaxial layer including a dopant in the exposed active area; forming a gate electrode on the epitaxial layer; and forming source and drain regions in the active area beside the gate electrode. The semiconductor device can prevent surface damage of a semiconductor substrate, may occur when performing ion implantation for threshold voltage control, and does not require annealing after ion implantation. Additionally, the semiconductor device can enhance an isolation effect by protecting an oxide film in a corner portion of the STI, to prevent an occurrence of a moat phenomenon in the STI, and to prevent the damage of the gap-fill dielectric film.

Owner:TAIWAN SEMICON MFG CO LTD

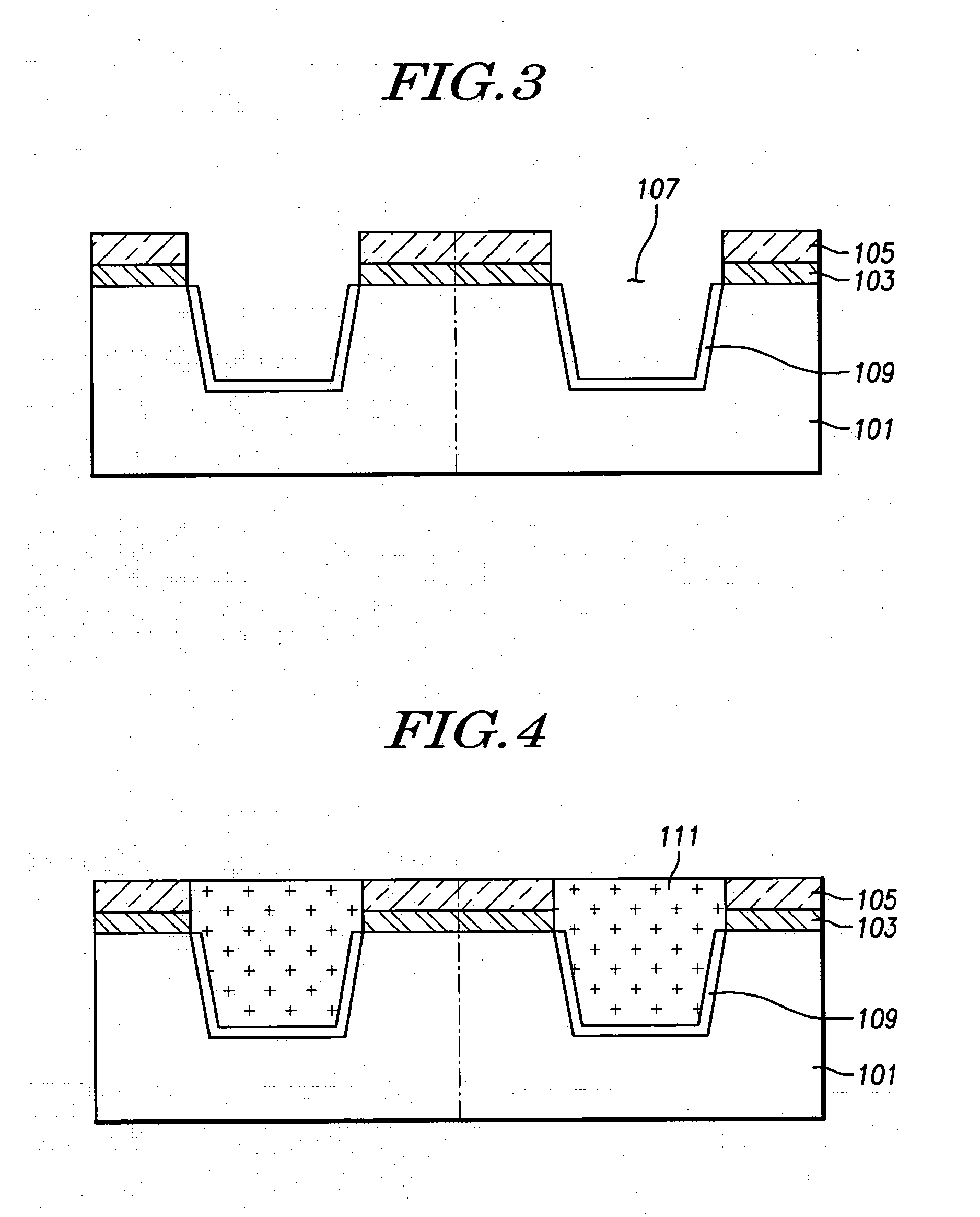

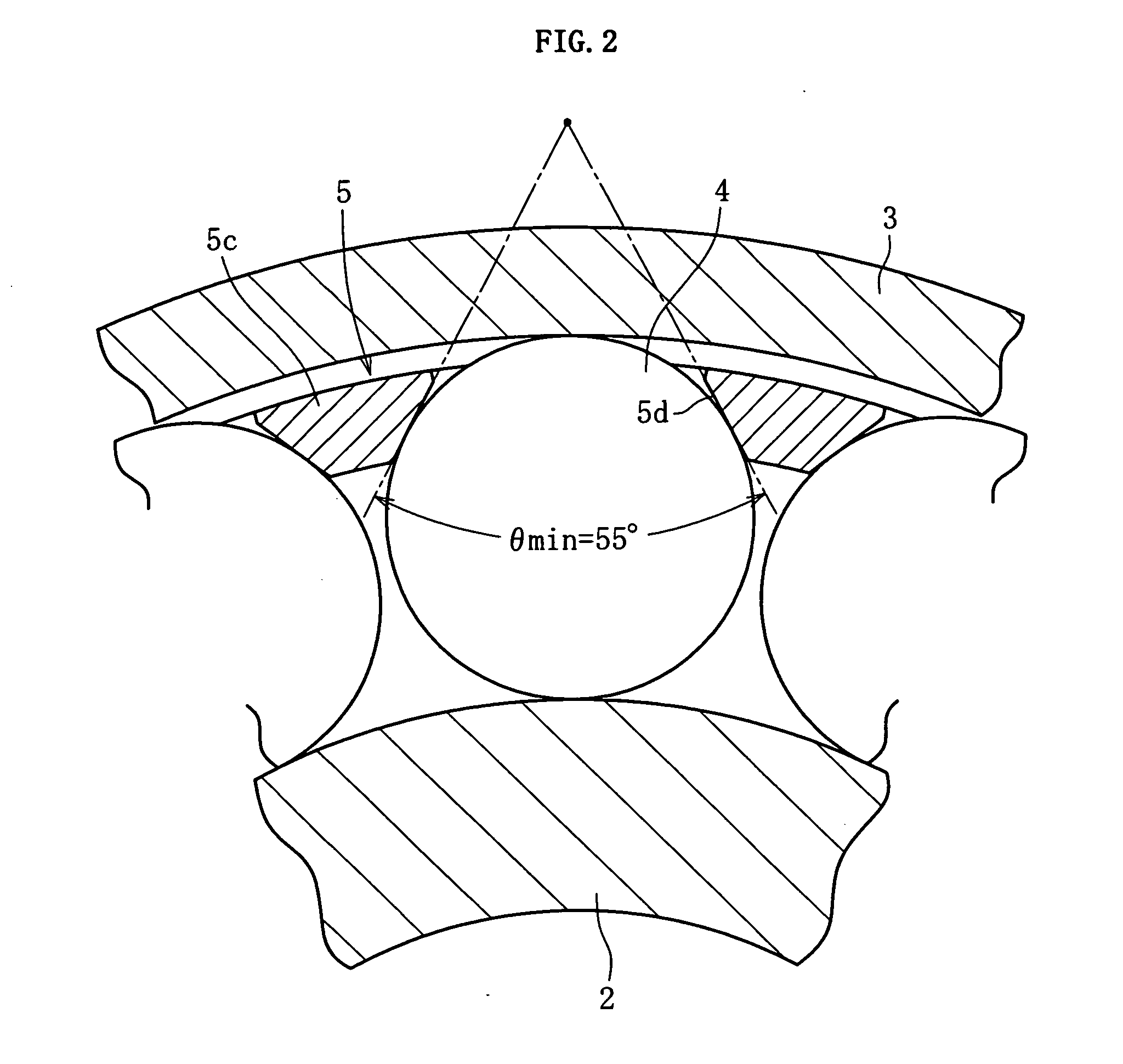

Tapered roller bearing

InactiveUS20090016664A1Avoid failureAmount of oil is smallRolling contact bearingsShaftsSurface roughnessEngineering

A tapered roller bearing includes: an inner ring; an outer ring; a plurality of tapered rollers which are rollably disposed between the inner ring and the outer ring; and a retainer which retains the tapered rollers at predetermined circumferential intervals. In this tapered roller bearing, a roller coefficient {γ=(the number of rollers×average roller diameter) exceeds 0.94, a number of indentations having a micro recess-like shape are randomly provided at least on a surface of the tapered roller, a surface roughness parameter Ryni of the surface having the indentations falls within a range of 0.4 μm≦Ryni≦1.0 μm, and an Sk value is −1.6 or less.

Owner:NTN CORP

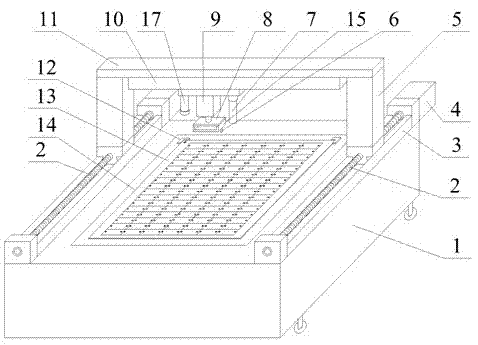

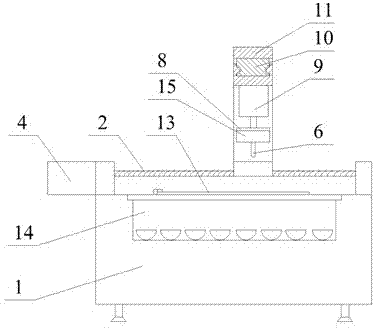

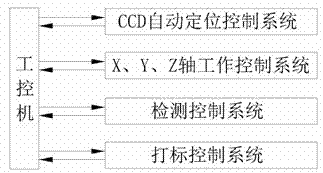

Detection equipment of film solar cell and method thereof

ActiveCN102565655AAchieve traceabilityEliminates the possibility of mixingPhotovoltaic monitoringPhotovoltaic energy generationElectricityElectrical performance

The invention relates to detection equipment of a film solar cell and a method thereof, belonging to the field of solar cell technology. The automatic detection equipment of the film solar cell comprises a workbench and an X-Y-Z shaft motion mechanism. A crossbeam of a Y shaft motion mechanism is connected with an X shaft. The detection equipment is characterized in that: the X shaft is provided with a CCD positioner with automatic origin positioning, a marking mechanism, and a Z shaft with a detection mechanism, a four-in-one machine with integration of positioning, X-Y-Z shaft motion, detection and marking is formed, the four-in-one machine is controlled by an industrial control computer program to detect electrical performance of each unit cell in a film solar cell core plate, and a qualified unit cell in detection is marked with a character. The detection equipment with the integration of positioning, X-Y-Z shaft motion, detection and marking can clearly identify and classify a qualified product and an unqualified product before a cutting procedure, possibility of mixing of the qualified product and the unqualified product in classification is eliminated, a production procedure is saved, and production efficiency is raised.

Owner:SHEN ZHEN TRONY SCI & TECH DEV CO LTD

Lug plate adjusting and fixing device for hinged support

ActiveCN104128726AAdjustable spacingEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringScrew thread

Owner:HENAN WEIHUA HEAVY MACHINE

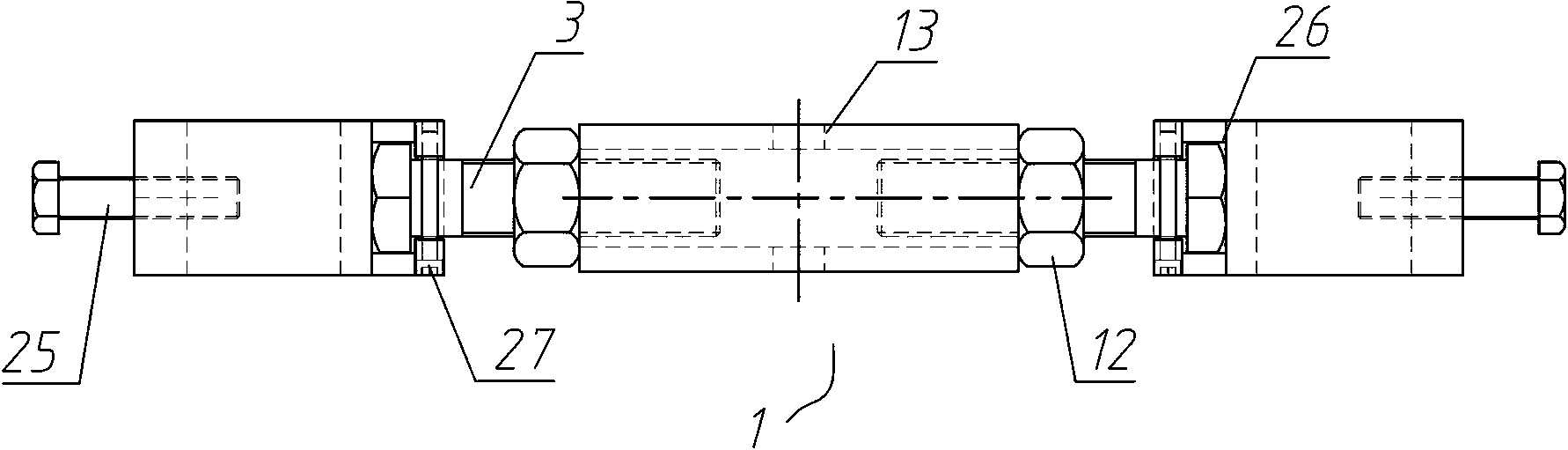

Method for repairing laser damage of fused quartz without thermal residual stress

ActiveCN105948519AControlling High Temperature Structural RelaxationThermal Residual Stress SuppressionRepair timeOptoelectronics

The invention provides a method for repairing laser damage of fused quartz without thermal residual stress. According to the method, rectangular laser pulses with high-peak power are acquired by intercepting peak segments of pulses output from a laser device; the rectangular laser pulses with high-peak power are focused, and single laser pulses with super-high-peak power density are acquired; the single laser pulses are used for peeling a material at a single point of a damaged part on a fused quartz substrate through transient gasification; the interval of the single laser pulses is controlled, so that the substrate is cooled sufficiently; gasification peeling is performed repeatedly through the single laser pulses until the material at the whole damaged part is removed. With the adoption of the method, high-temperature structural relaxation of the fused quartz substrate is effectively controlled, the damage of the fused quartz is repaired without thermal residual stress, the anti-damage capacity of damage points of a fused quartz optical element is improved, surface damage and development of surface damage of the fused quartz optical element are inhibited, the service life of the fused quartz optical element is prolonged, and the method has the advantages of short repair time, simple and efficient process, good process stability, high controllability and high repeatability.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Thread protector

ActiveUS20050242587A1Prevent be damageAvoid surface damageDrilling rodsClosuresSurface finishingEngineering

In a protector for protecting a trapezoidal female thread of a pipe formed to an end thereof, the protector has a male thread formed thereto so as to be threaded with the female thread as well as the height of the thread of the male thread is made larger than the height of the thread of the female thread. With this arrangement, a surface treatment applied to the surface of the female thread or a male thread formed to the end of the pipe can be prevented from being damaged, and in particular, a surface treatment applied to a guide flank surface, a load flank surface, a corner portion, and the like of the thread can be prevented from being subjected to wear, damage, and the like.

Owner:NIPPON STEEL CORP

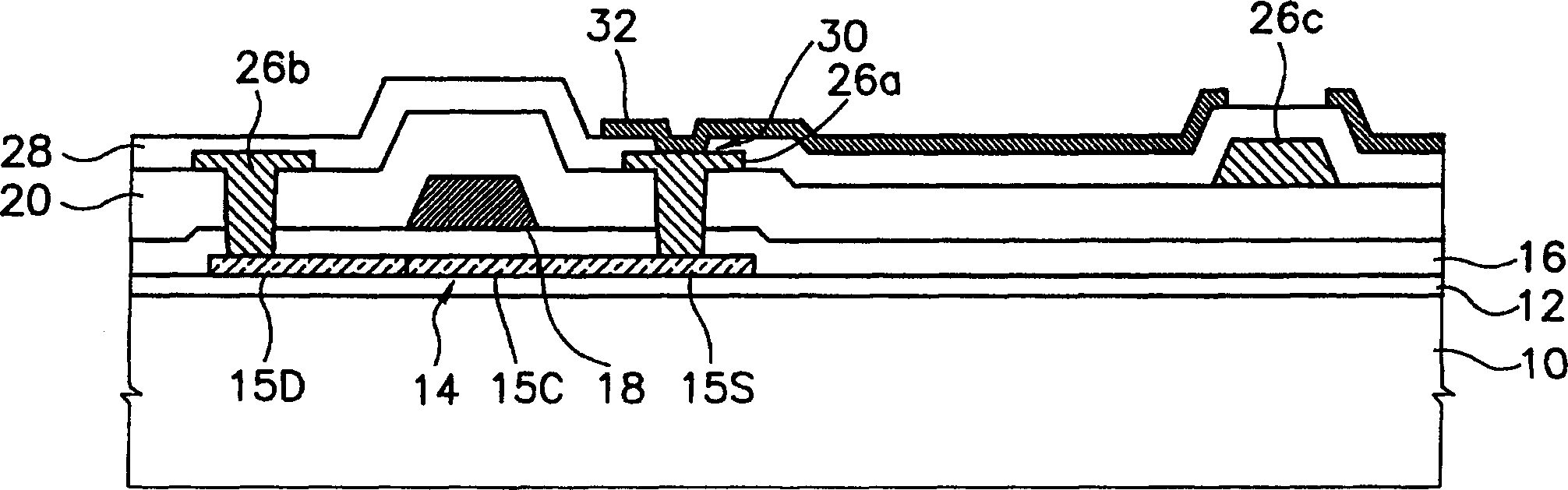

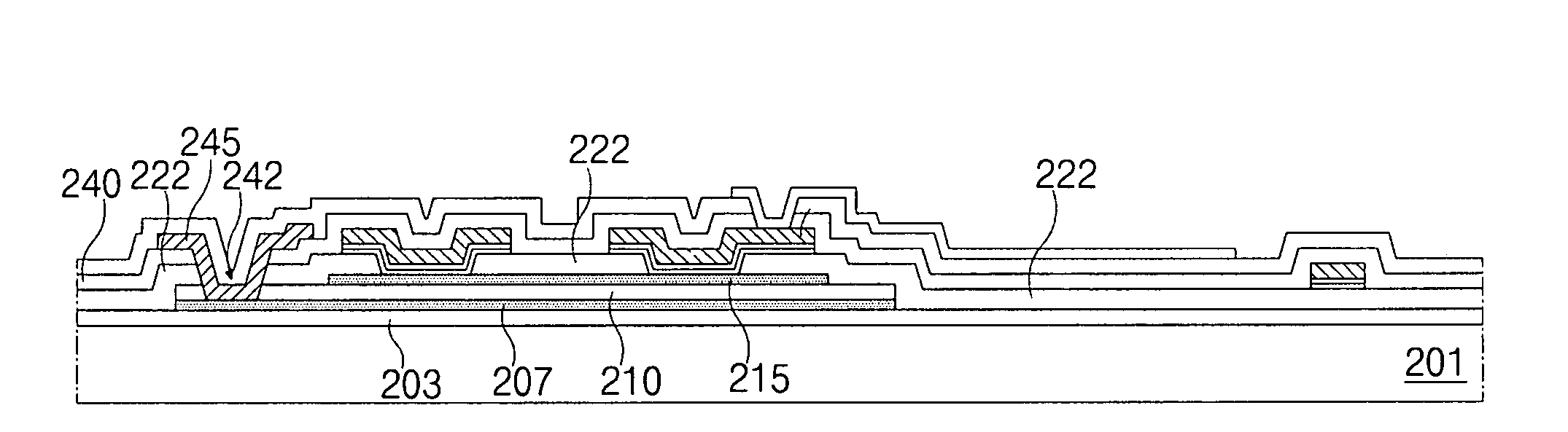

Array substrate for dislay device and method of fabricating the same

ActiveUS20100289023A1Improve characteristicPrevent surface damageSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsPolycrystalline silicon

A method of fabricating an array substrate for a display device includes: forming a buffer layer on a substrate having a pixel region; sequentially forming a gate electrode of impurity-doped polycrystalline silicon, a gate insulating layer and an active layer of intrinsic polycrystalline silicon on the buffer layer in the pixel region; forming an interlayer insulating layer of an inorganic insulating material on the active layer; sequentially forming a source barrier pattern, a source ohmic contact layer and a source electrode on the interlayer insulating layer, sequentially forming a drain barrier pattern, a drain ohmic contact layer and a drain electrode on the interlayer insulating layer, and sequentially forming a first dummy pattern, a second dummy pattern and a data line on the interlayer insulating layer; forming a first passivation layer on a surface of the interlayer insulating layer including the source electrode, the drain electrode and the data line formed thereon; forming a gate line on the first passivation layer; forming a second passivation layer on a surface of the first passivation layer including the gate line formed thereon; and forming a pixel electrode on the second passivation layer.

Owner:LG DISPLAY CO LTD

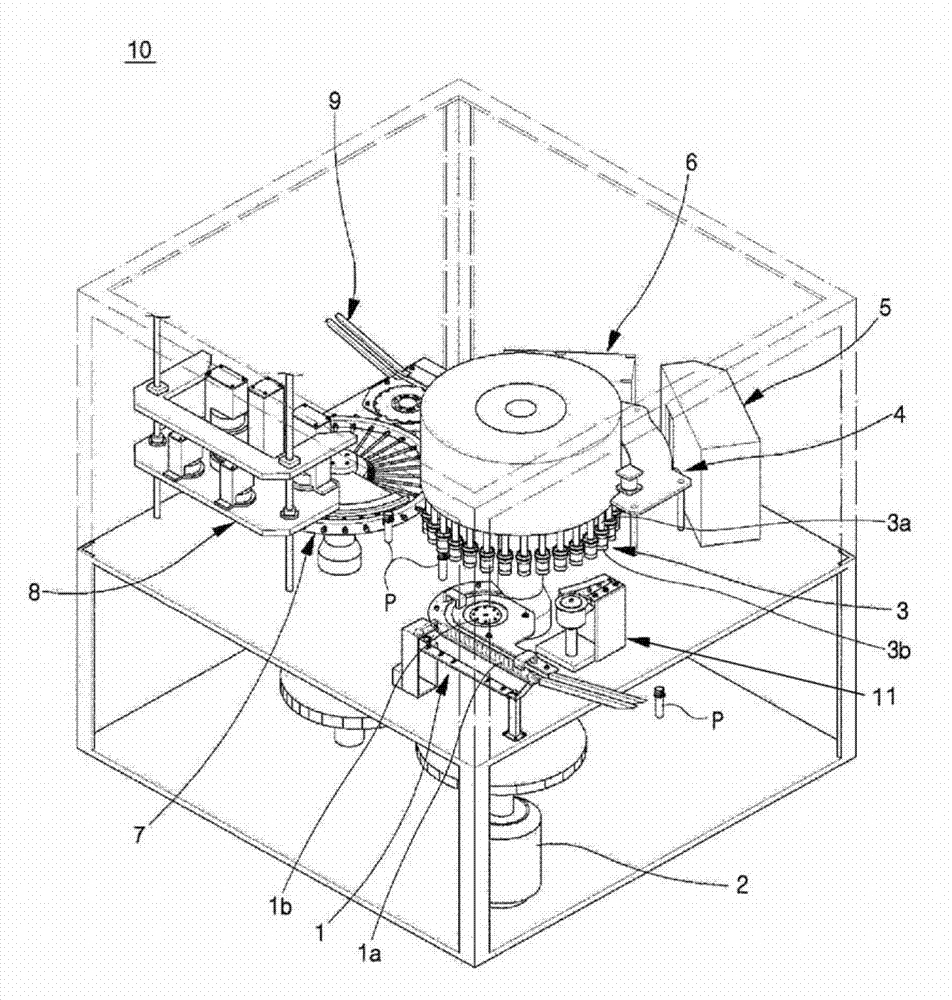

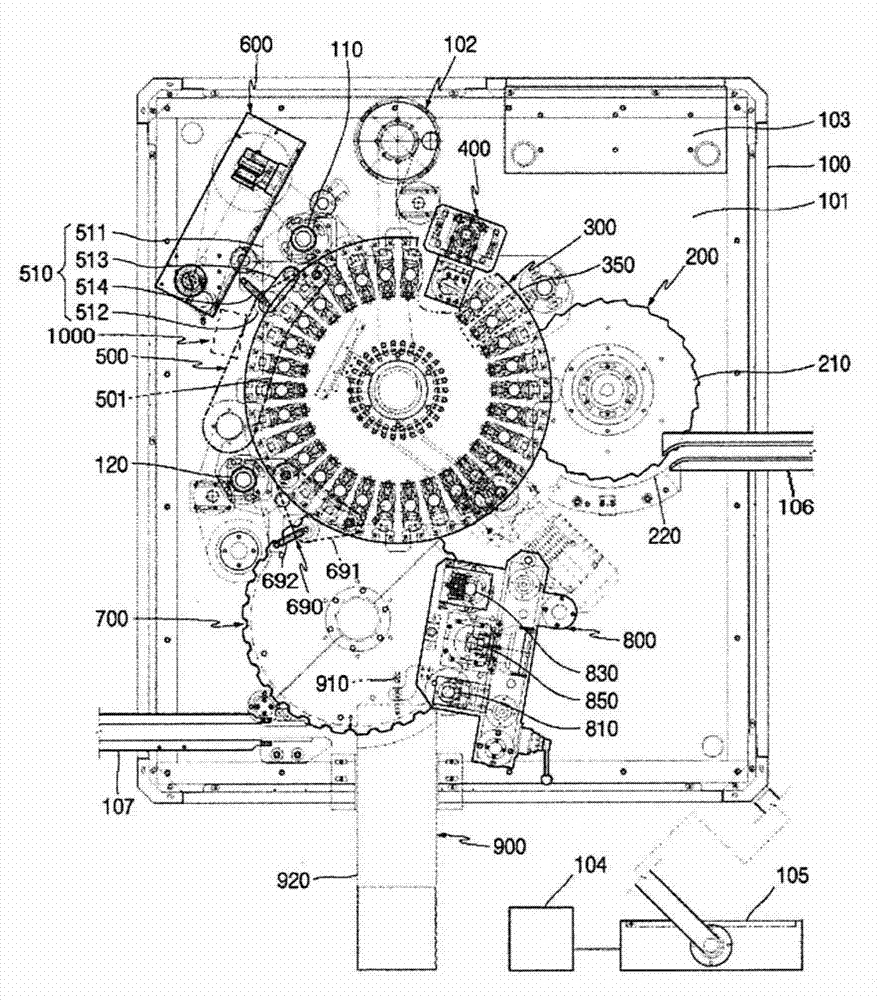

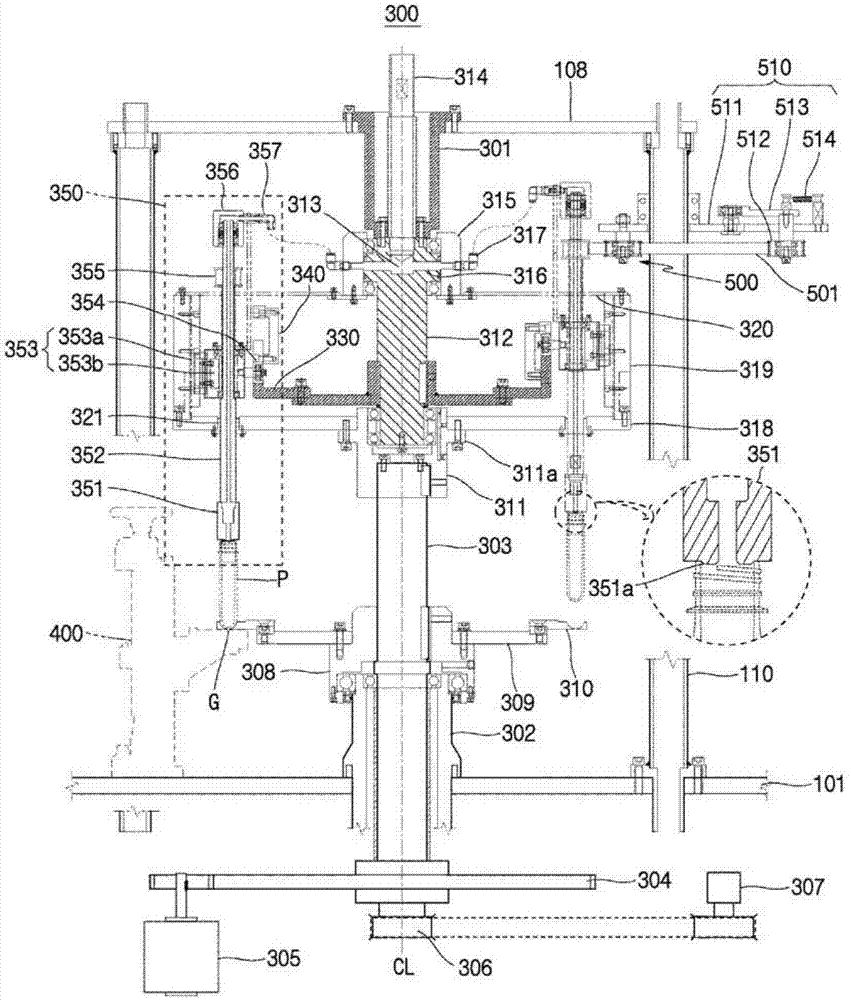

Apparatus and method for inspecting preform

ActiveCN103240863AAvoid surface damageSimple structureMaterial analysis by optical meansEngineeringForeign body

The present invention provides an apparatus and a method for inspecting a preform. The apparatus comprises the following components: an inner guide rail, an inner star wheel part, a turret assembly, a gate cutting part, a preform rotating part, a first inspecting module, an outer star wheel part, a second inspecting part and an outer guide rail. The apparatus can perform preform inspection quickly and accurately, and analyzes defects of the preform in relationship with the preform inspection result. The apparatus further comprises a supporting ring inspection part which inspects foreign object at a first area of the preform, which corresponds with the upper surface of the supporting ring, and a second area of the upper surface of the supporting ring, which is jointed with the preform neck. The apparatus further comprises the following components: a supporting frame which is vertically arranged at a mounting platform of the apparatus frame; a frame joint which is arranged at the end of the supporting frame in a manner for adjusting a photographing angle; a supporting ring inspection part which is arranged on a substrate board of a frame joint in a manner of facing the supporting ring of the preform; and a light source part which is arranged on a placement platform of the mounting platform at inside part of the preform and irradiates light to the preform side.

Owner:P&S TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com