Heavy goods carrying table and method for using same

A technology for handling table and heavy objects, applied in the field of heavy object handling table, can solve the problems of difficult fixing, unfavorable cost, unfavorable saving of resources, etc., and achieves the effects of good operability, ensuring stability and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

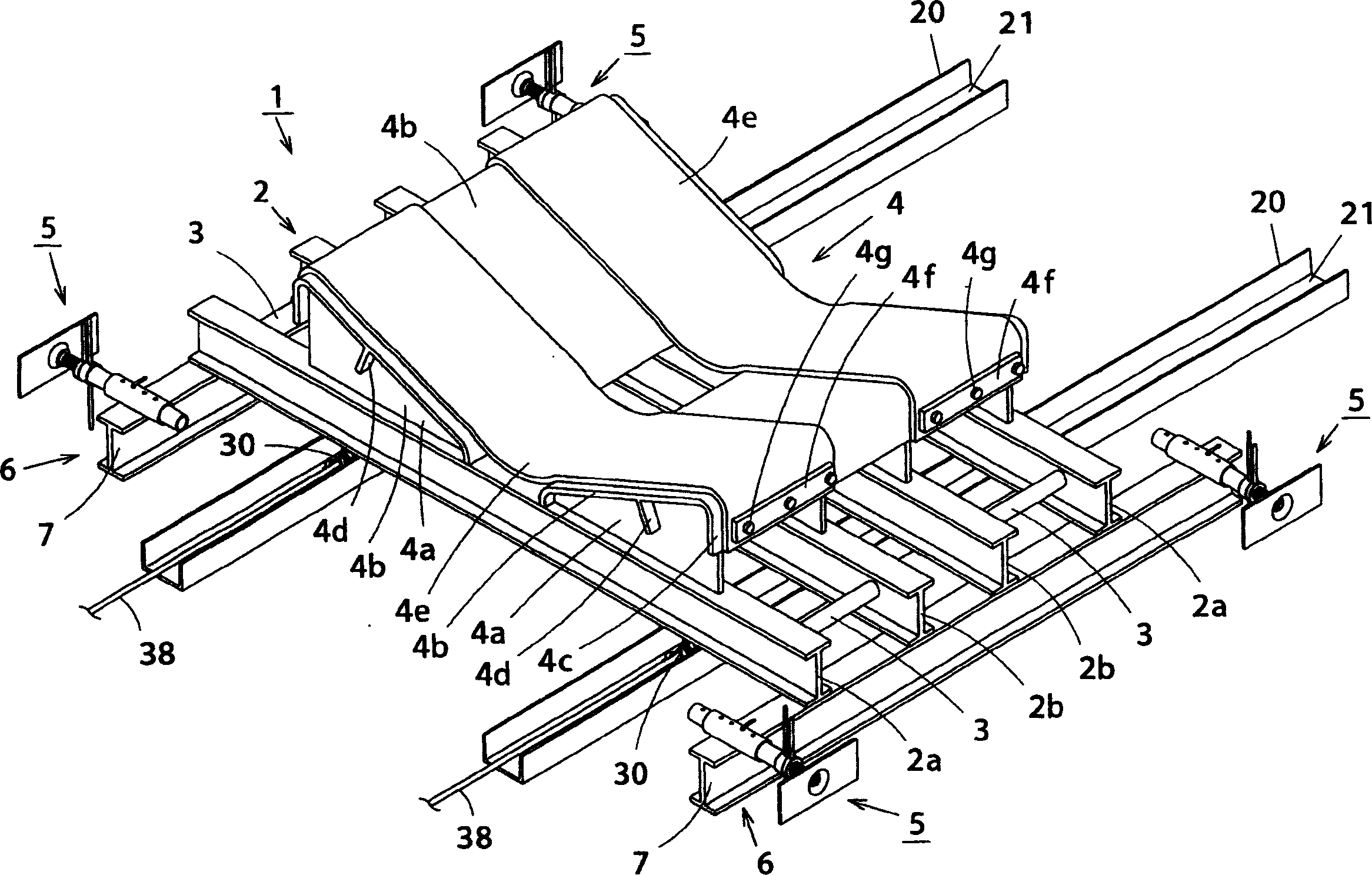

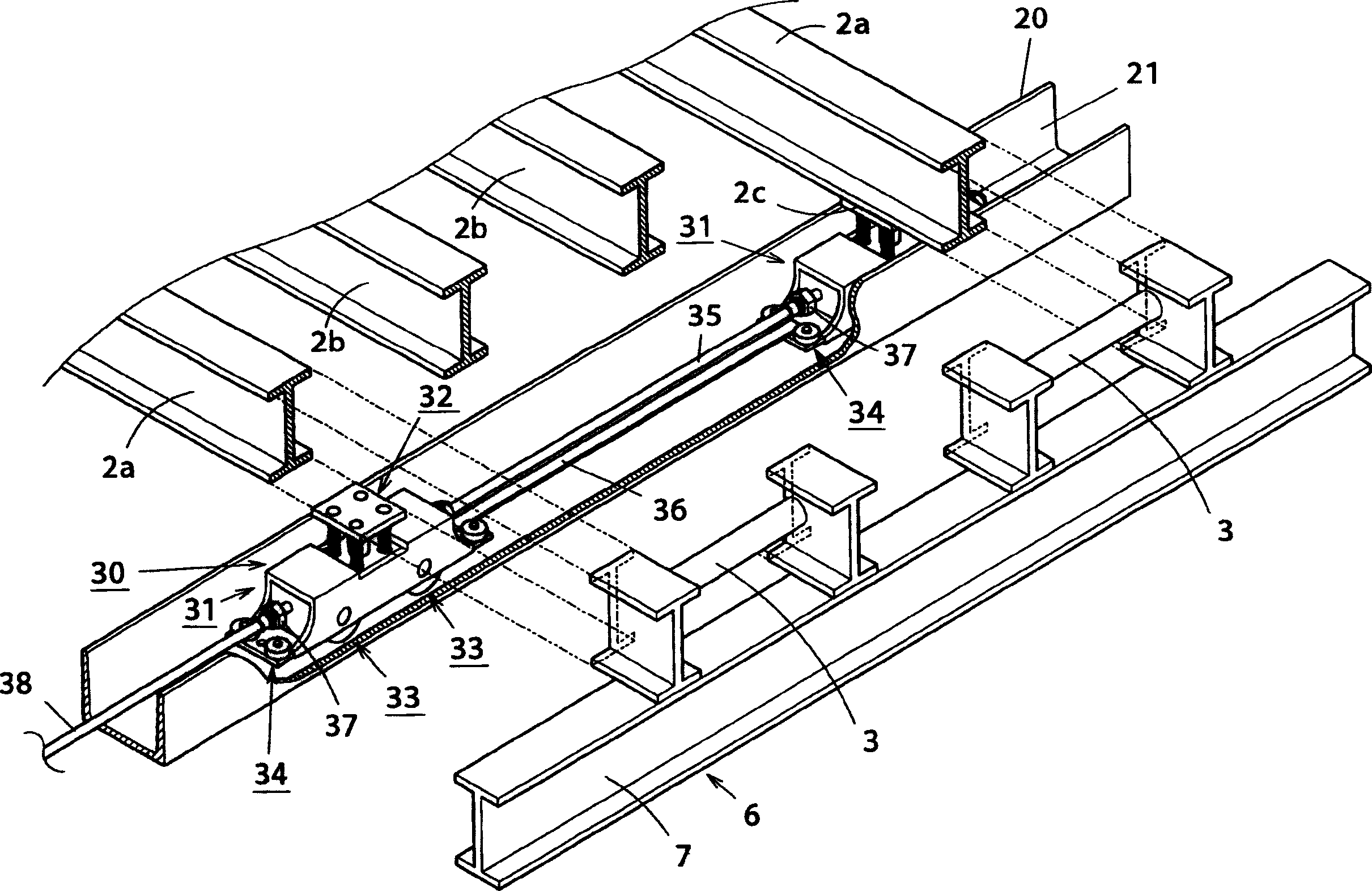

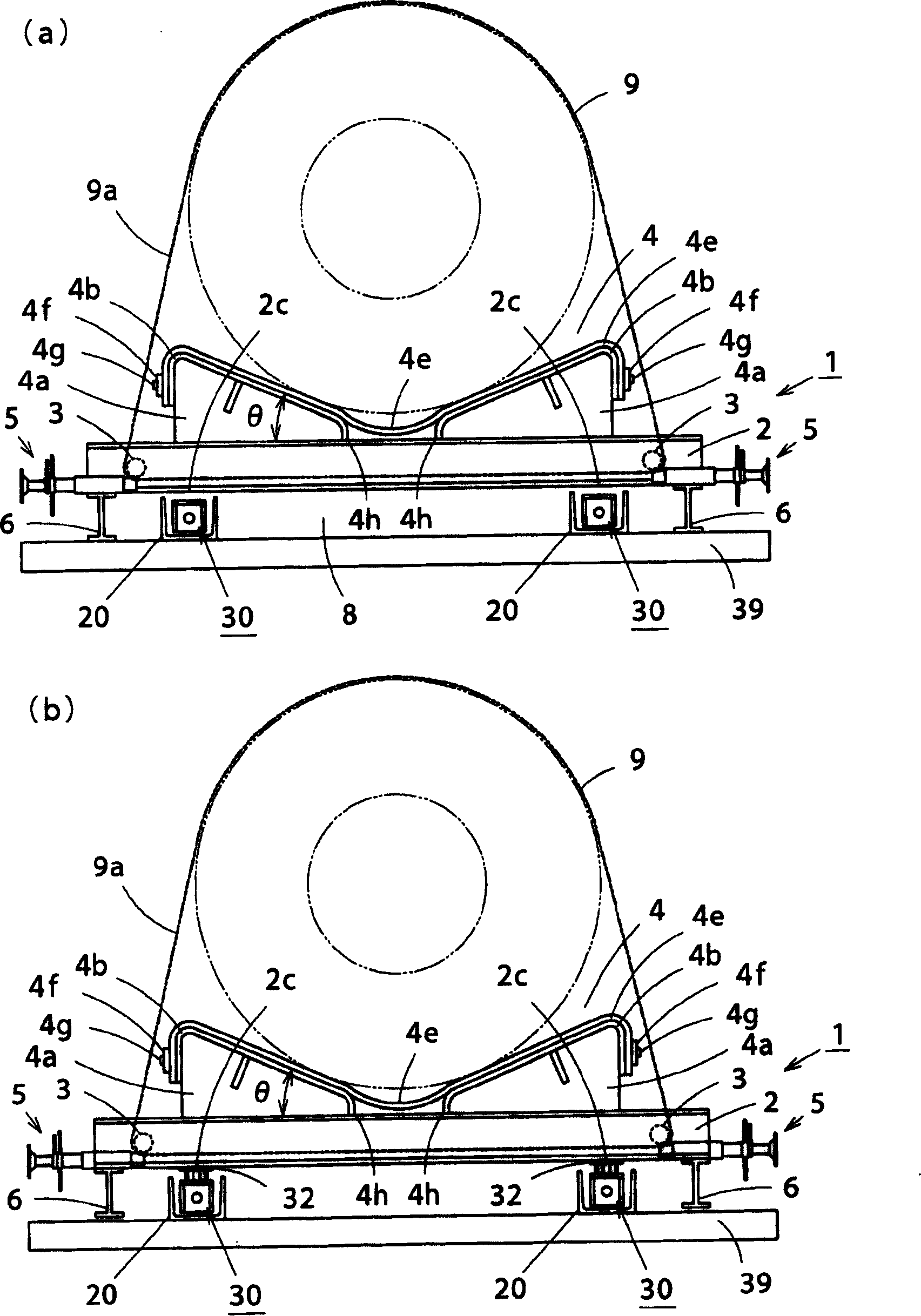

[0111] figure 1 It is a perspective view showing the heavy object transfer platform of the first embodiment of the present invention, figure 2 It is a cutaway perspective view of main parts showing a heavy object transfer platform and a part of guide rails according to the first embodiment of the present invention, image 3 (a) is a front schematic view showing a state in which the lifting unit of the conveying device according to the first embodiment of the present invention is in a lowered state, image 3 (b) is a front schematic view showing a state in which the lifting portion of the conveying device according to the first embodiment of the present invention is raised, Figure 4 It is a perspective view showing the transfer table jig of the first embodiment of the present invention, Figure 5 It is a longitudinal cross-sectional view showing the transfer table jig of the first embodiment of the present invention.

[0112] exist figure 1Among them, 1 is the heavy objec...

no. 2 approach

[0158] Figure 7 It is a perspective view which shows the heavy object transfer platform of 2nd Embodiment of this invention, Figure 8 (a) is a cross-sectional view showing main parts when the transfer table jig of the heavy object transfer table according to the second embodiment of the present invention is stored, Figure 8 (b) is a half sectional view showing the use of the transfer table jig. In addition, the same reference numerals are assigned to the same components as those described in the first embodiment, and description thereof will be omitted.

[0159] exist Figure 7Among them, 60 is a heavy object transfer platform according to the second embodiment; 61 is a platform part, one side of which is provided in the horizontal direction and the other side is provided in the vertical direction, and the platform part is made of a plurality of steel materials arranged approximately in parallel at predetermined intervals, etc. (In this embodiment, two L-shaped steels) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com