Detection equipment of film solar cell and method thereof

A technology of solar cells and thin films, applied in the monitoring of photovoltaic systems, photovoltaic power generation, electrical components, etc., can solve the problems of many processes, heavy workload, waste of materials, etc., to avoid secondary pollution, reduce human errors, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

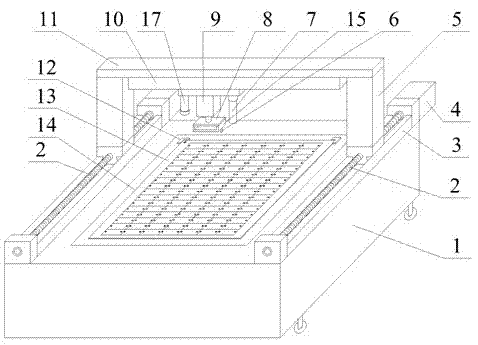

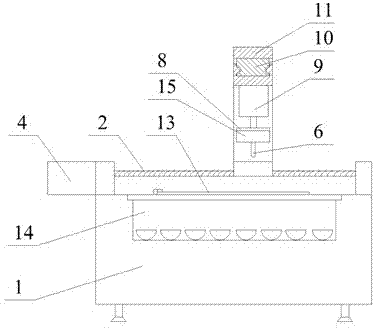

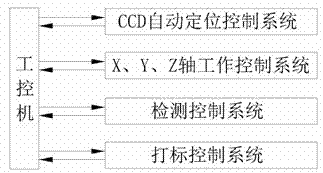

[0043] See figure 1 , figure 2 , the test device for thin-film solar cells is mainly composed of a base 1, a light box 14, an X-axis motion mechanism, a Y-axis motion mechanism, a Z-axis motion mechanism, a detection mechanism, and a marking mechanism. The light box 14 is placed on the base 1, and the Y-axis motion mechanism The movement mechanism is mainly composed of a screw 2, a guide rail 3, a column 5, a beam 11 and a motor 4. The motor 4 drives the screw 2 on both sides to move, and the screw 2 drives the upper column 5 to move along the guide rail 3 in the Y-axis. The beam 11 connected by the two uprights also realizes the Y-axis movement. The X-axis motion mechanism mainly includes a rodless cylinder 10, which is fixed under the beam 11, and the beam 11 drives the rodless cylinder 10 to move in the Y axis, and the rodless cylinder 10 itself can realize the X axis motion. The Z-axis motion mechanism is mainly composed of a cylinder 9 and a fixed plate 8. The cylinder...

Embodiment 2

[0046] The size of the large-format thin-film solar cell core board 13 is 14 inches × 16 inches, including 7 × 7 = 49 unit cell arrays. The unit battery detection method at the same time, the detection mechanism is equipped with 14 detection probes 6, respectively contacting the positive and negative electrodes, the detection probes 6 are compressible spring probes, fixed on the probe fixing plate 15, inkjet marking is adopted, CCD is automatically positioned, Motor 4 is a servo motor. The detection process is as follows: place the thin-film solar cell core board 13 at the limit position of the positioning block 12 fixed on the light box 14, the industrial computer locks the positioning origin through the CCD, and starts to work. The servo motor 4 drives the screw 2 to drive the column 5 Move in the Y direction on the guide rail 3, move the rodless cylinder 10 in the X direction, move the detection probe 6 to the position corresponding to the electrode of the first row of unit...

Embodiment 3

[0048] The size of the large-format thin-film solar cell core plate 13 is 14 inches x 16 inches, including 7 x 7 = 49 unit cell arrays. Simultaneous detection method, 49 groups of 108 detection probes 6 are set on the detection mechanism, respectively contacting the positive and negative poles, the detection probes 6 are compressible spring probes, fixed on the probe fixing plate 15, laser marking is used, and the motor 4 is a servo motor . The detection process is as follows: the thin-film solar cell core board 13 is placed at the limit position of the positioning block 12 fixed on the light box 14, the servo motor 4 drives the screw 2 to drive the column 5 to move in the Y direction on the guide rail 3, and the industrial computer The origin is locked and positioned by the CCD. When starting to work, the cylinder 9 pushes the fixed plate 8 and starts to move downward in the Z direction, so that the detection probe 6 moves downward at the same time and stops after touching th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com