Automobile air dryer assembling and testing production line

An air dryer and production line technology, which is used in vehicle testing, machine/structural component testing, and liquid/vacuum tightness measurement. , poor coordination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

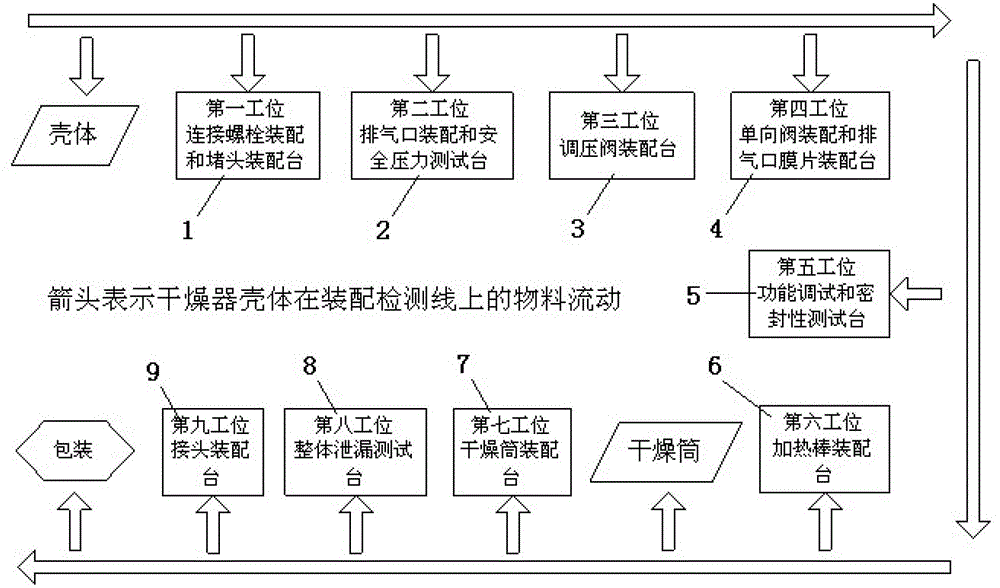

[0066] Example: see figure 1 , the embodiment of the present invention includes connecting bolt assembly and plug assembly platform 1, exhaust port assembly and safety pressure test platform 2, pressure regulating valve assembly platform 3, one-way valve assembly and exhaust port diaphragm assembly platform 4, function debugging And tightness test bench 5, heating rod assembly bench 6, drying cylinder assembly bench 7, overall leakage test bench 8, joint assembly and muffler assembly bench 9.

[0067] The whole production line includes a U-shaped workbench line body. The U-shaped workbench line body includes six assembly stations, two inspection stations, and one assembly additional inspection station, which are divided into first, second, and third stations in turn. , four, five, six, seven, eight, nine stations. Adjacent stations are connected to each other through material conveyor belts.

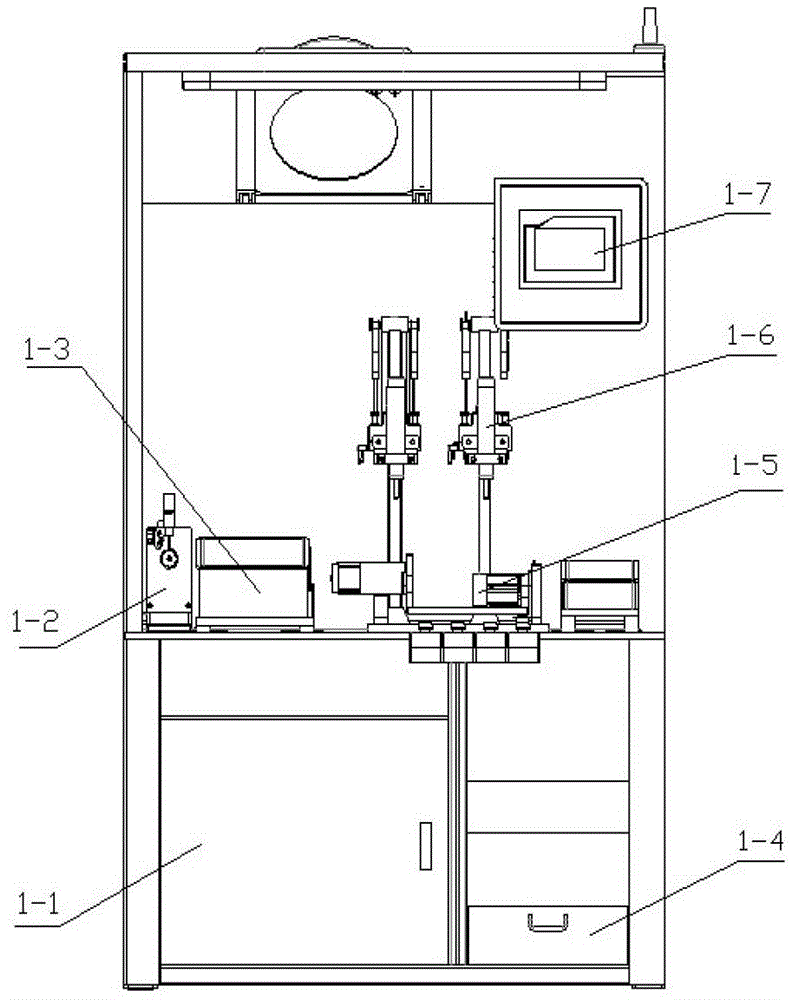

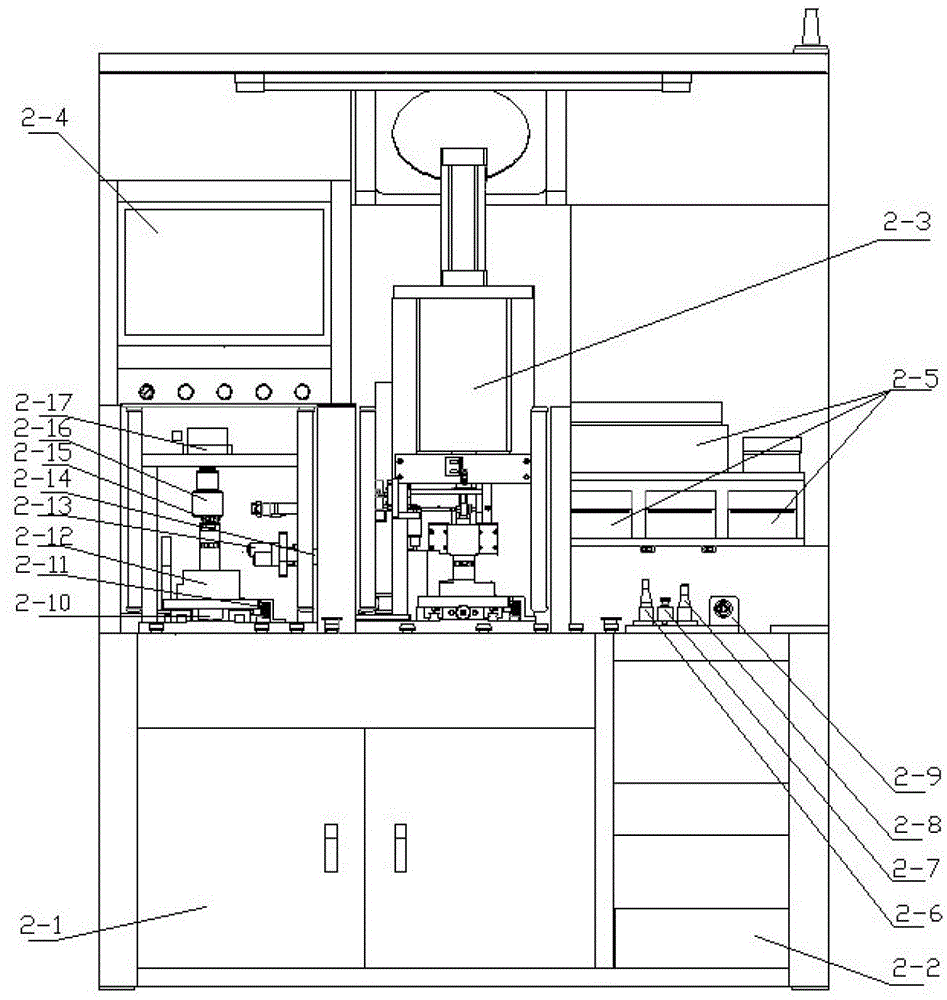

[0068] like figure 2 As shown, the first station is connecting bolt assembly and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com