Fully-automatic optical element cleaning device with ultrasonic-megasonic composite frequency

A technology of composite frequency and optical components, which is applied in the direction of cleaning flexible objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of water consumption, difficulty in cleaning, and reduced cleaning efficiency, so as to avoid the problem of too large angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

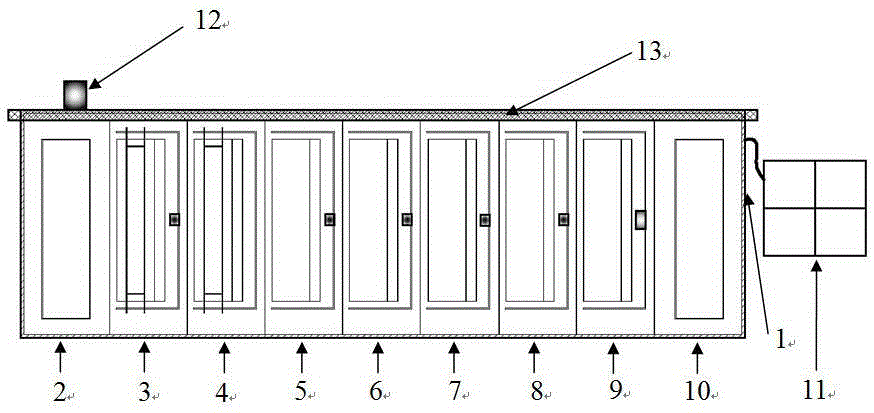

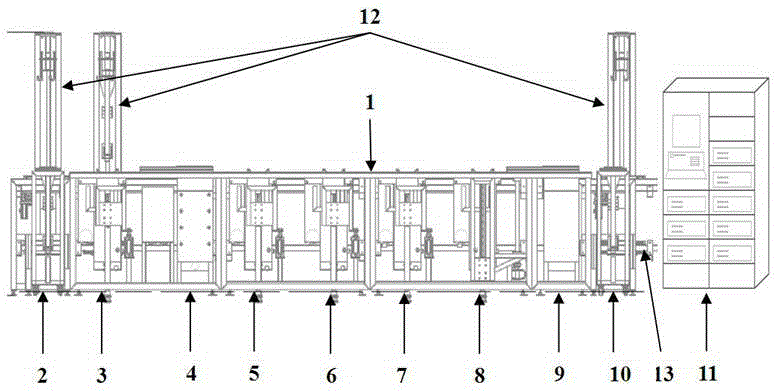

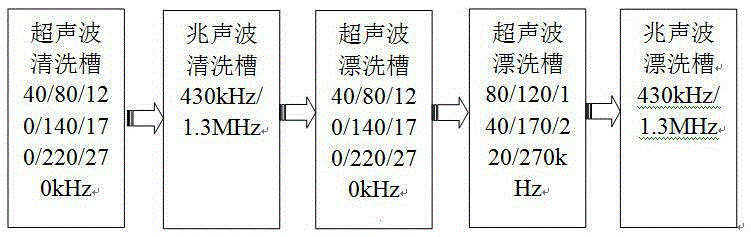

[0039] Embodiment 1: Fig. 1 (a) and (b) are the tank layout structure diagram of ultrasonic-megasonic composite water-based automatic cleaning device, (a) is a top view, (b) is a front view. It can be seen from Figure 1 that the device integrates water-based chemical solution cleaning, ultrasonic cleaning, megasonic cleaning, ultrapure water spraying, slow pulling dehydration and air knife drying technology to realize fully automatic cleaning of large-sized optical parts. The tank body has 7 slots and 2 workpiece loading and unloading areas from left to right, which are the cleaning tank frame 1, the workpiece loading area 2 (including the racking trolley shown in the figure), the solution soaking ultrasonic cleaning tank 3, and the spraying Slot 4, megasonic cleaning tank 5, first ultrasonic rinsing tank 6, second ultrasonic rinsing tank 7, megasonic rinsing and dehydration tank 8 and drying tank 9, workpiece unloading area 10, control cabinet 11, The workpiece moves the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com