Patents

Literature

99 results about "Mechanical splice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

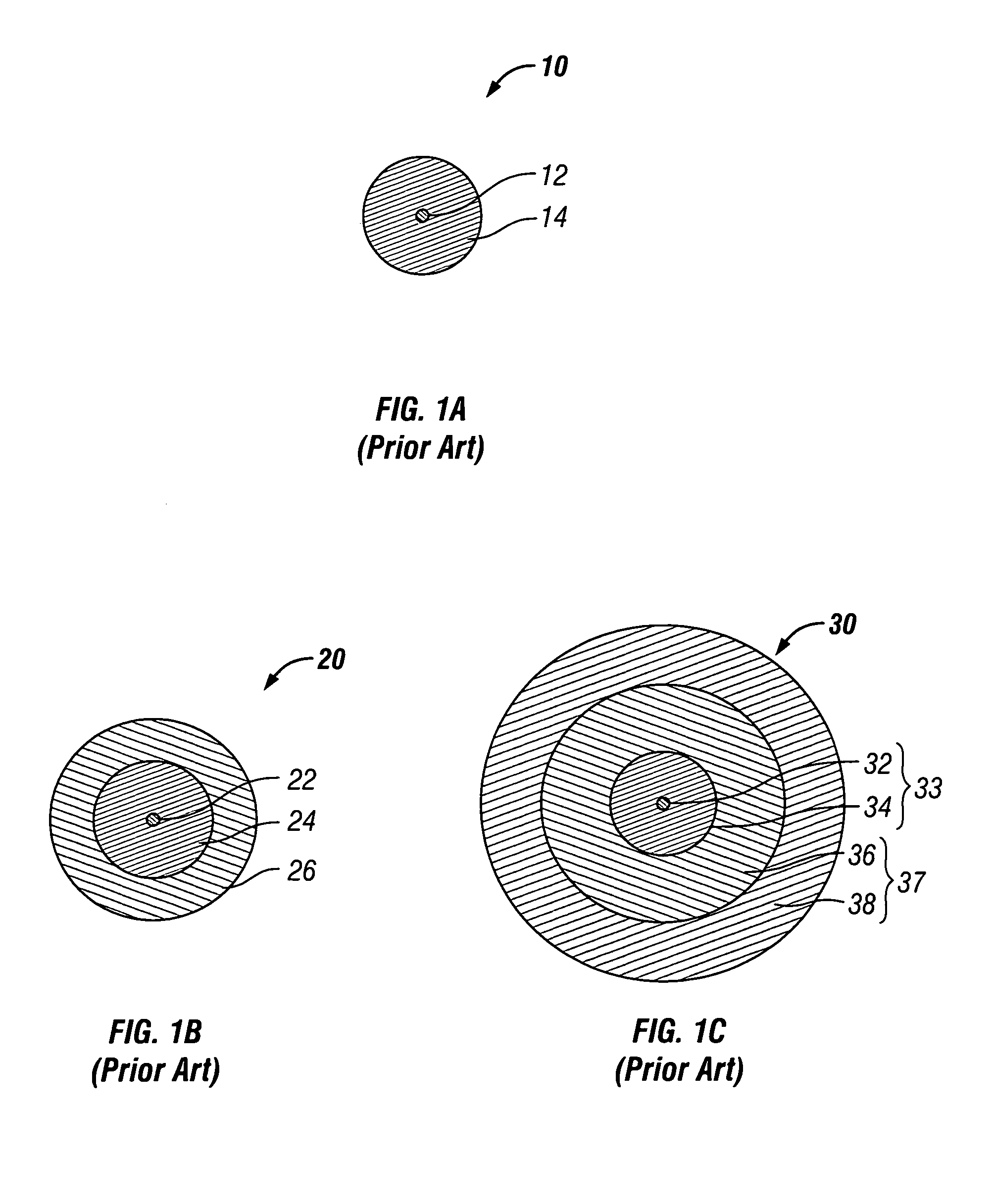

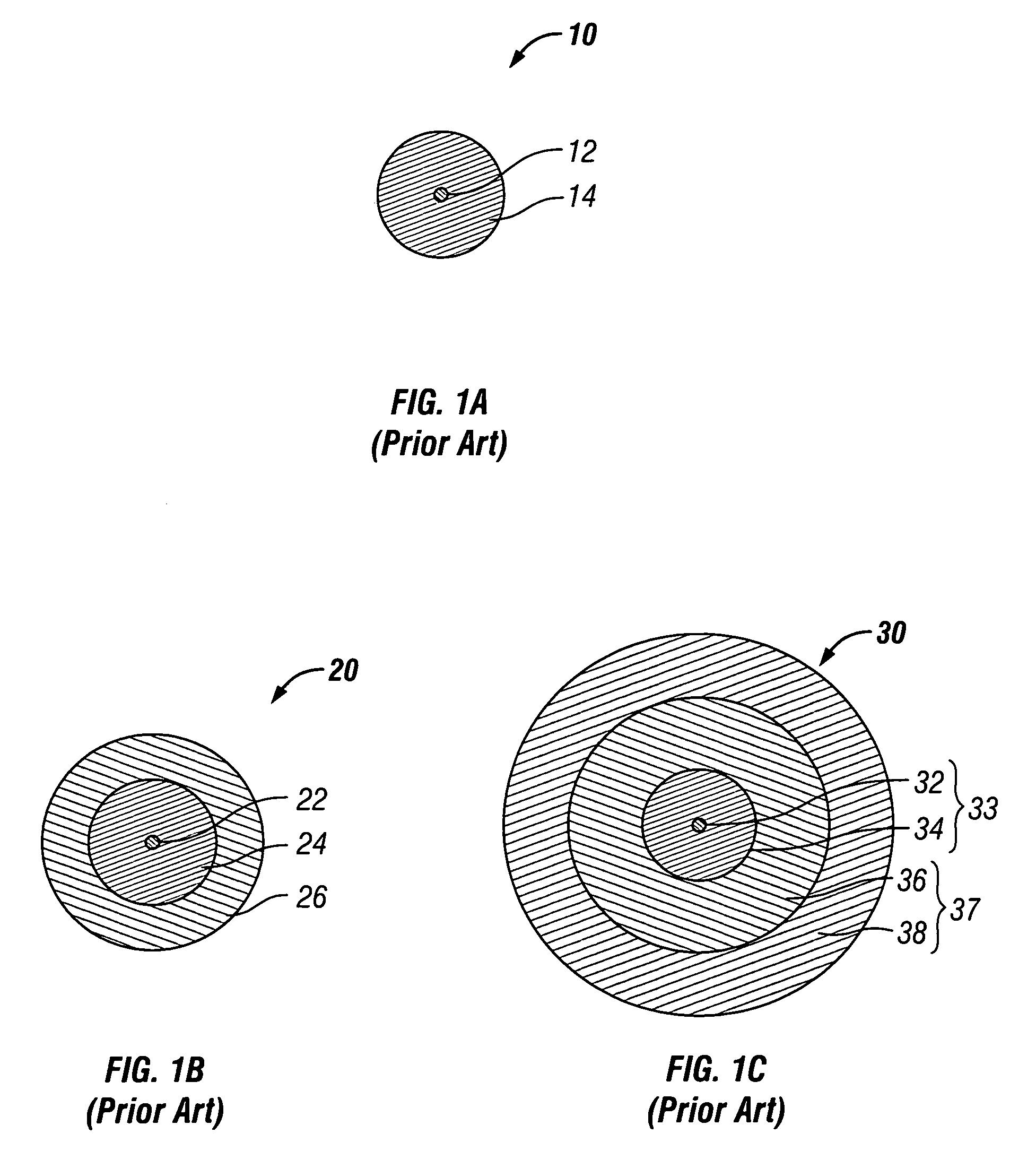

A mechanical splice is a junction of two or more optical fibers that are aligned and held in place by a self-contained assembly (usually the size of a large carpenter's nail). The fibers are not permanently joined, just precisely held together so that light can pass from one to another.

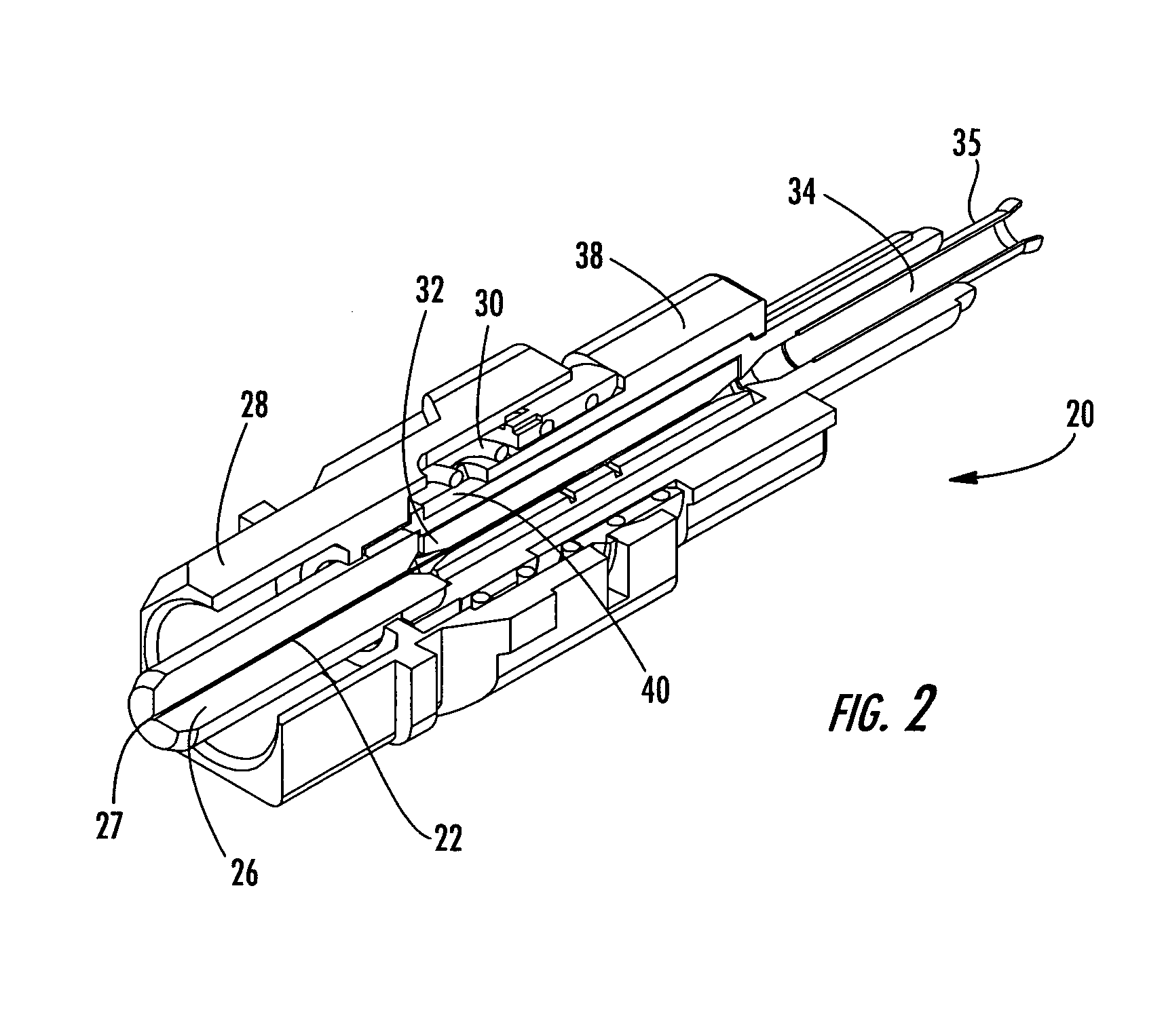

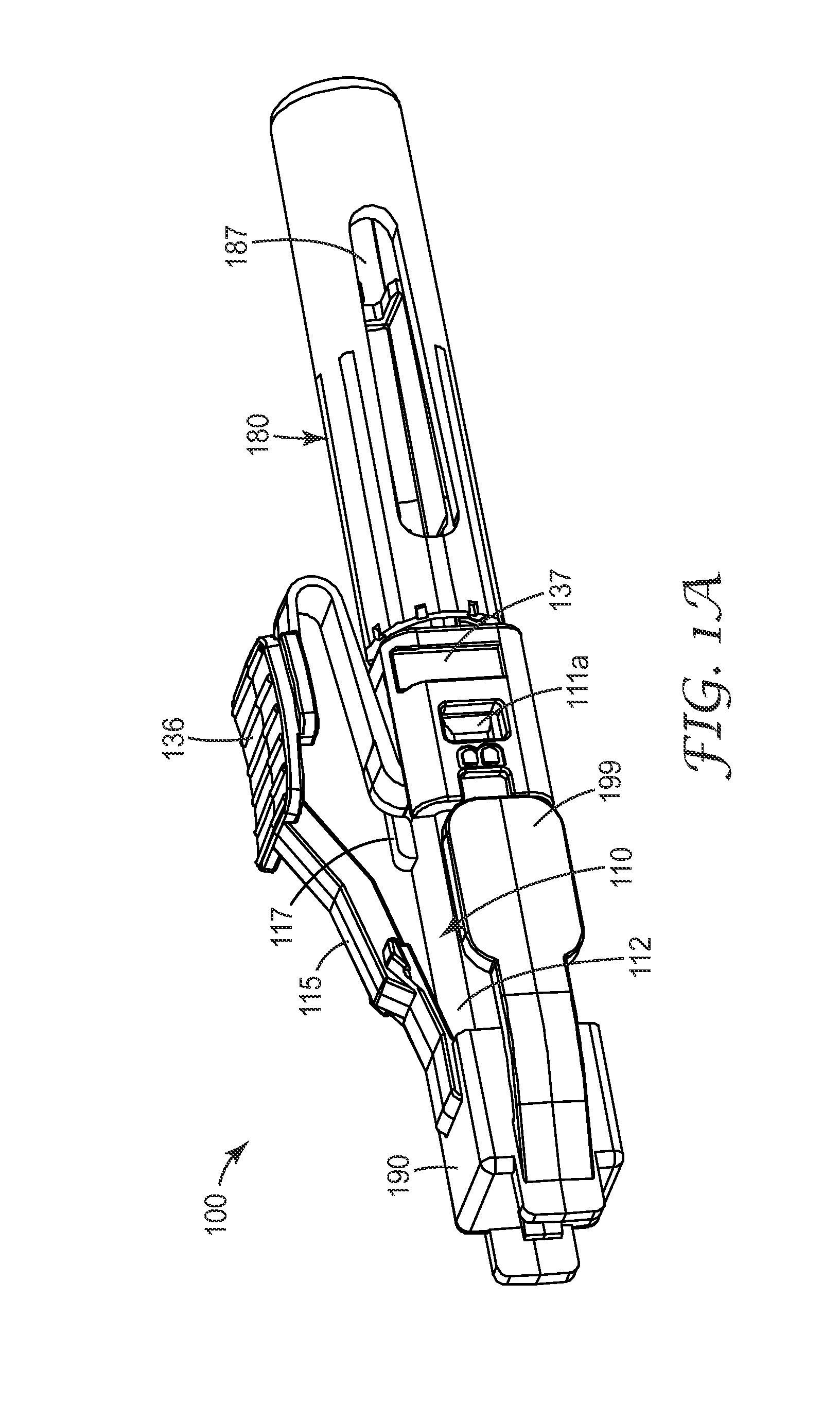

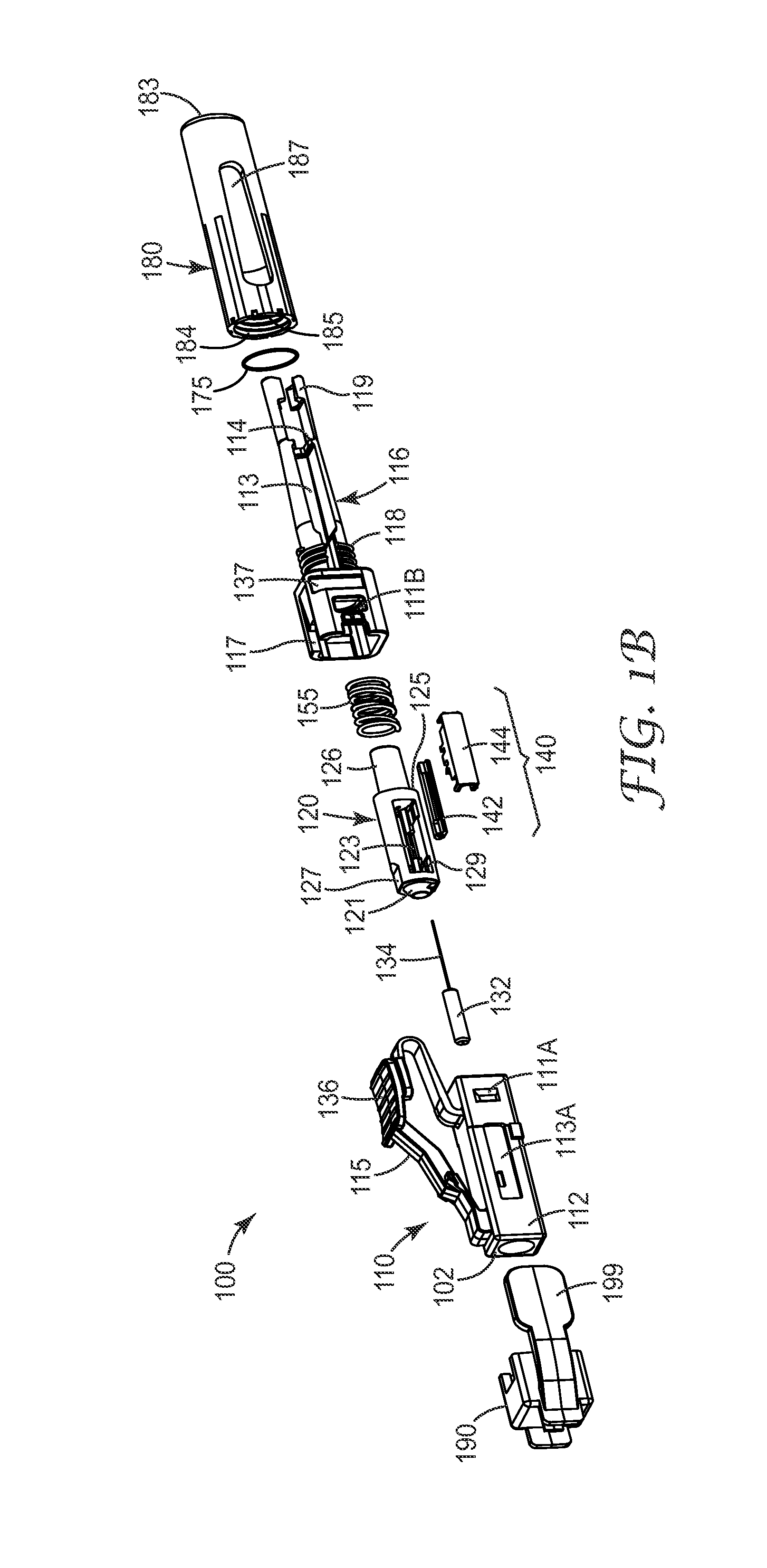

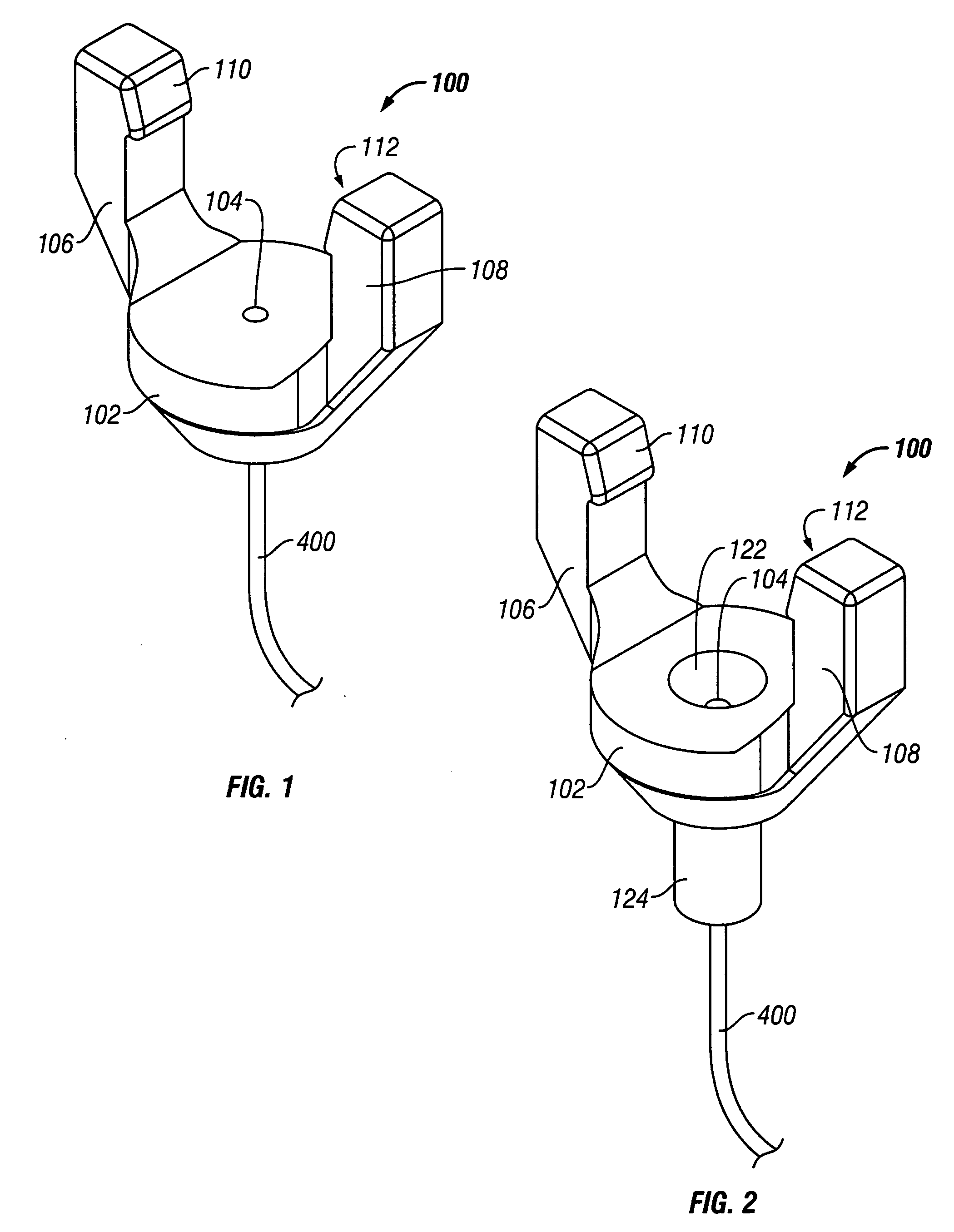

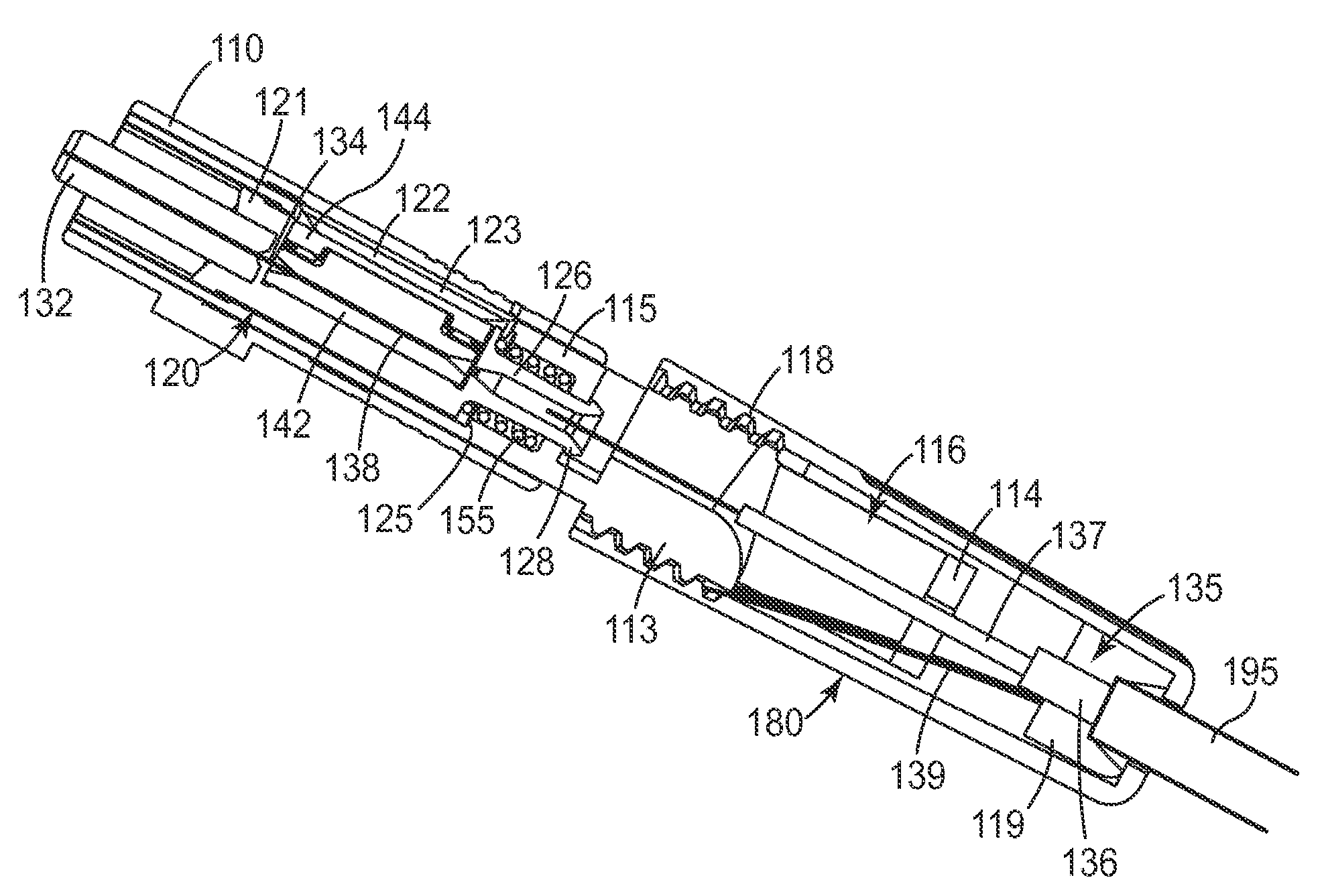

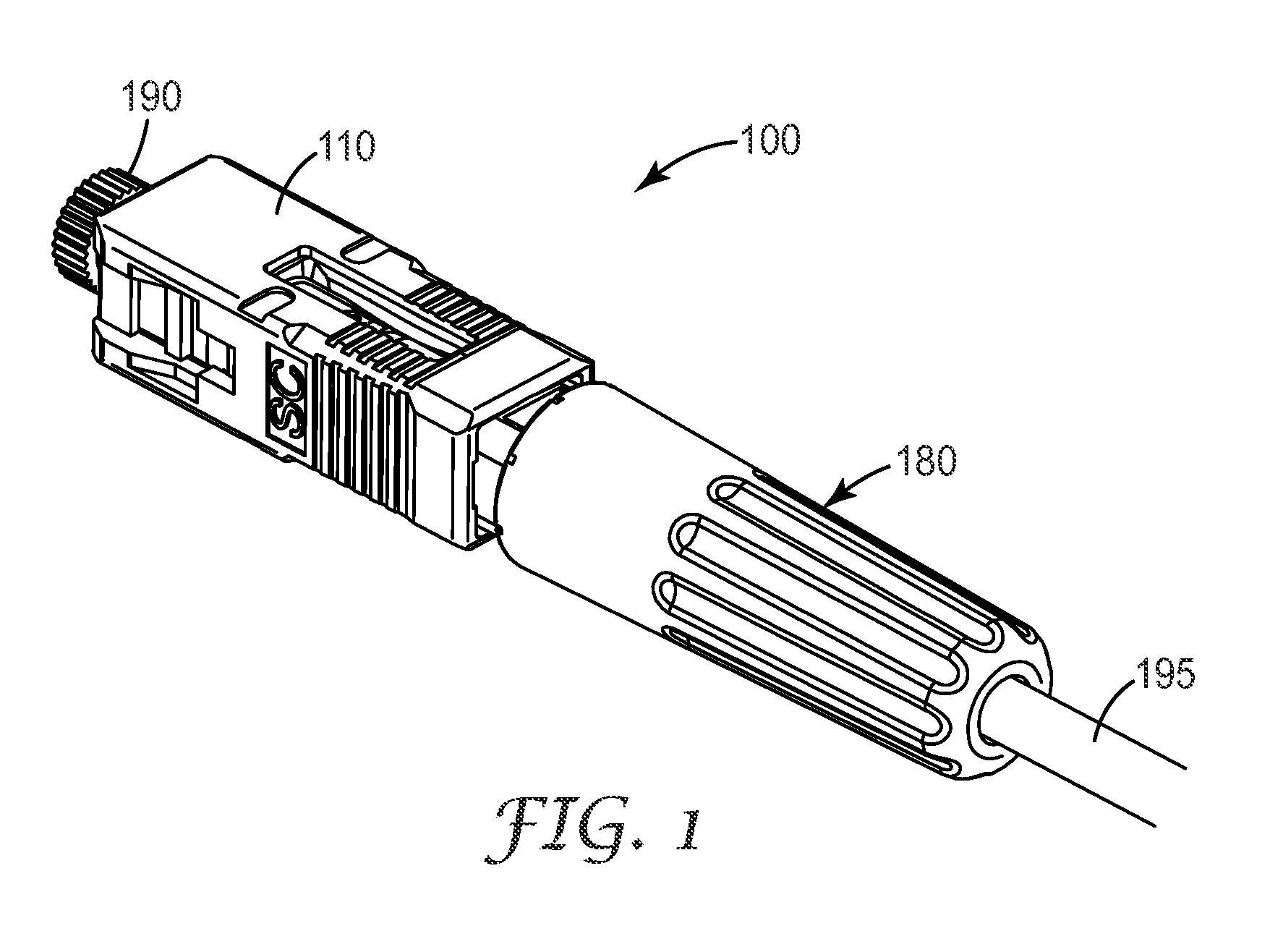

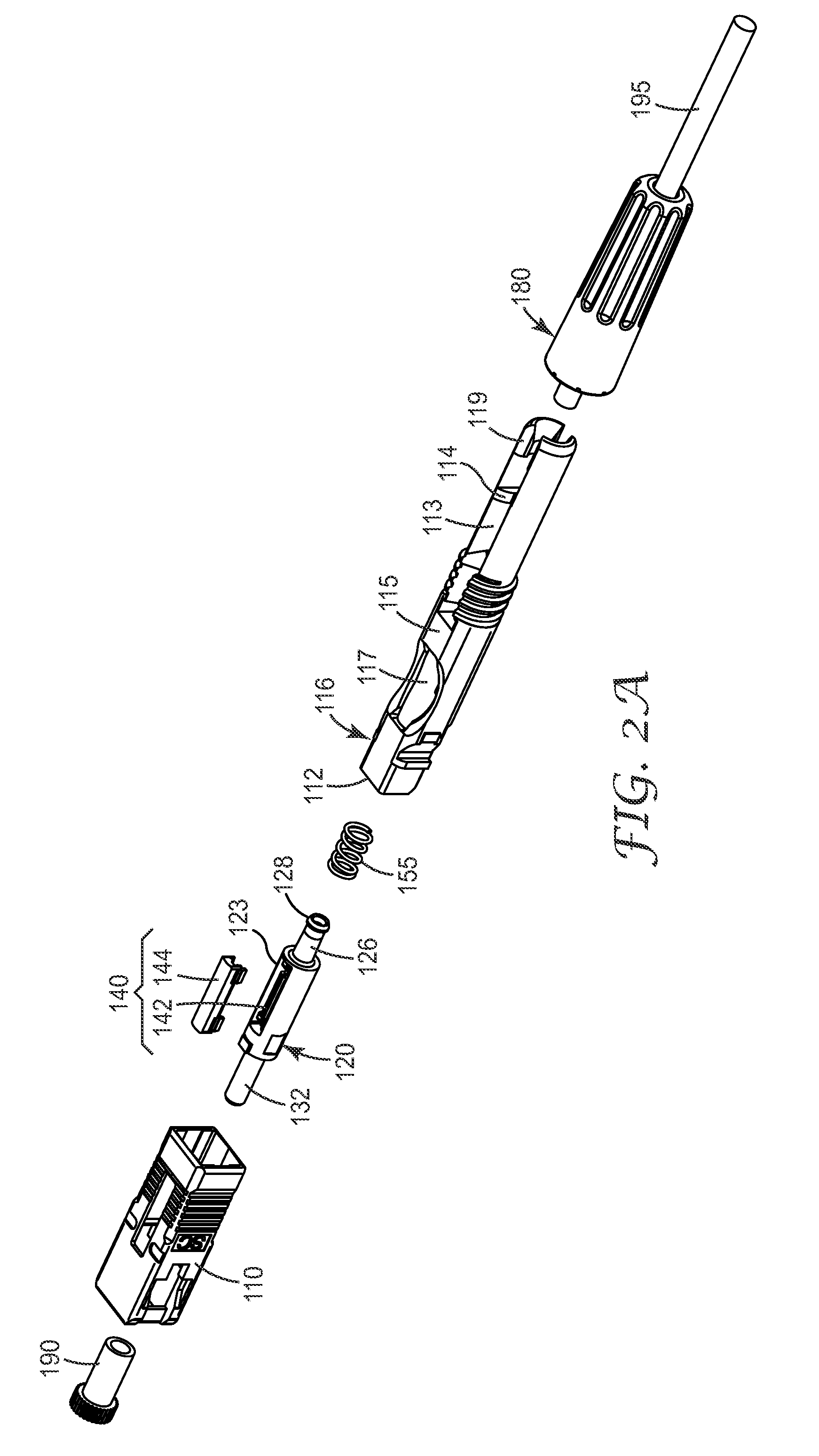

Field terminable optical fiber connector with splice element

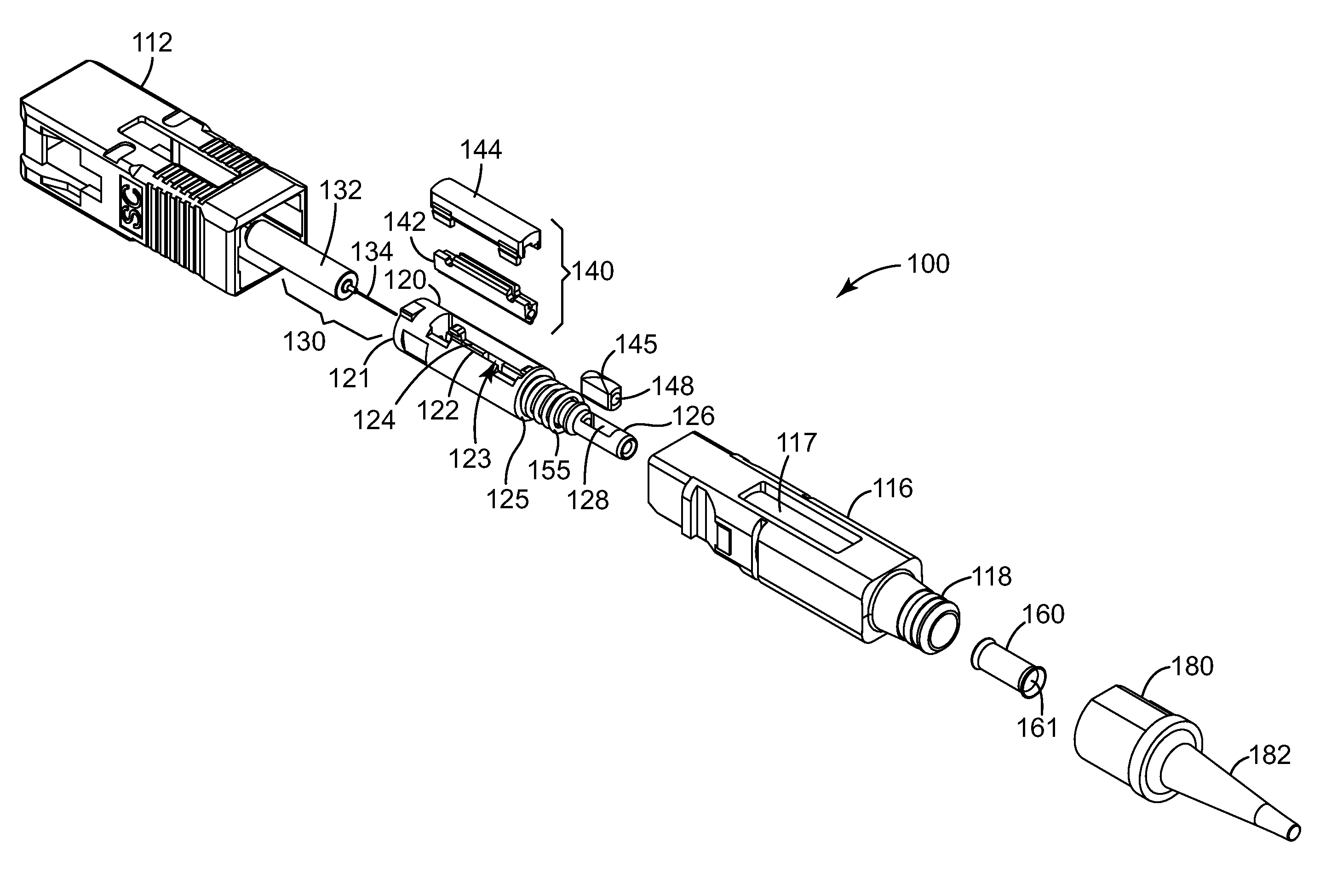

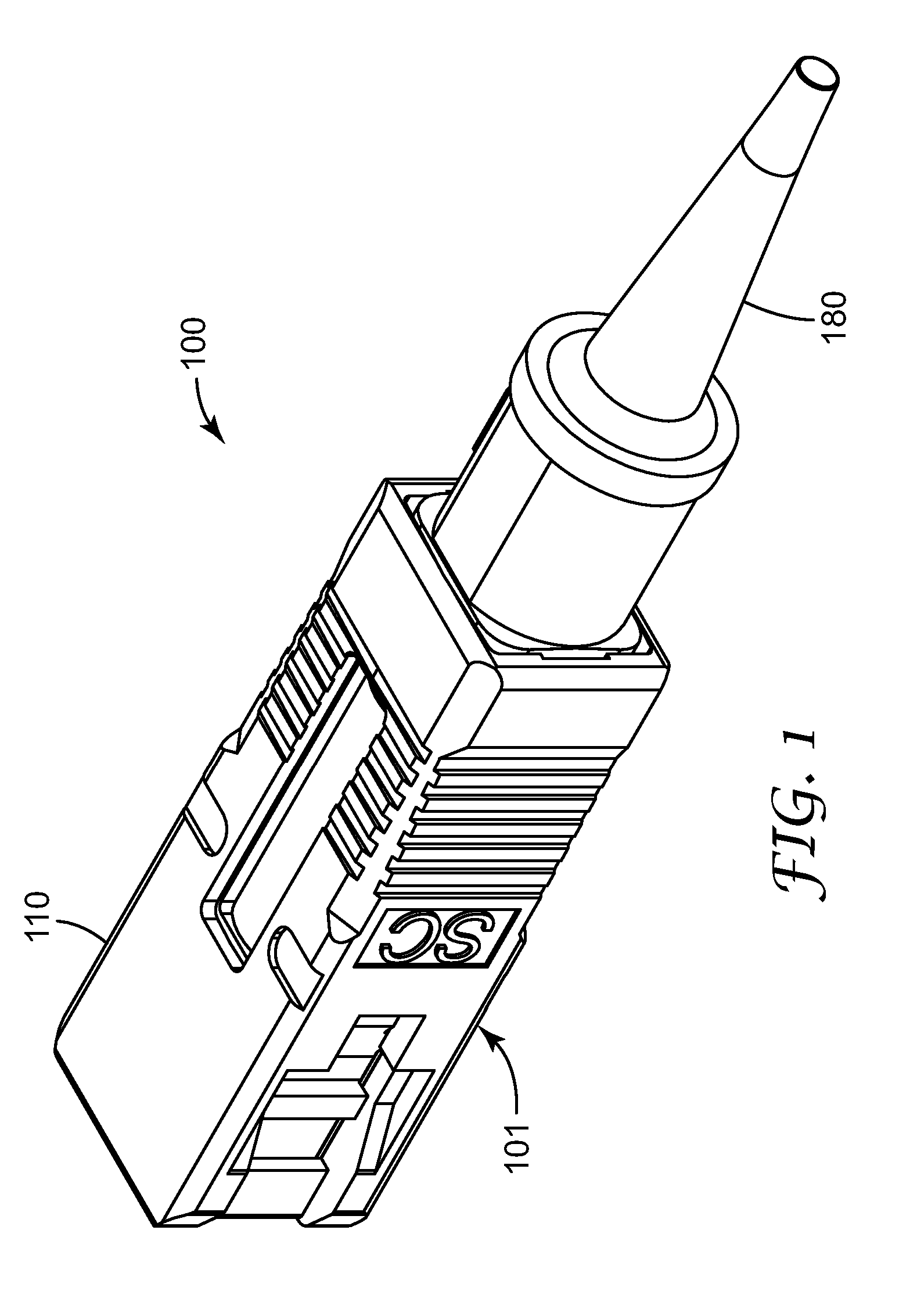

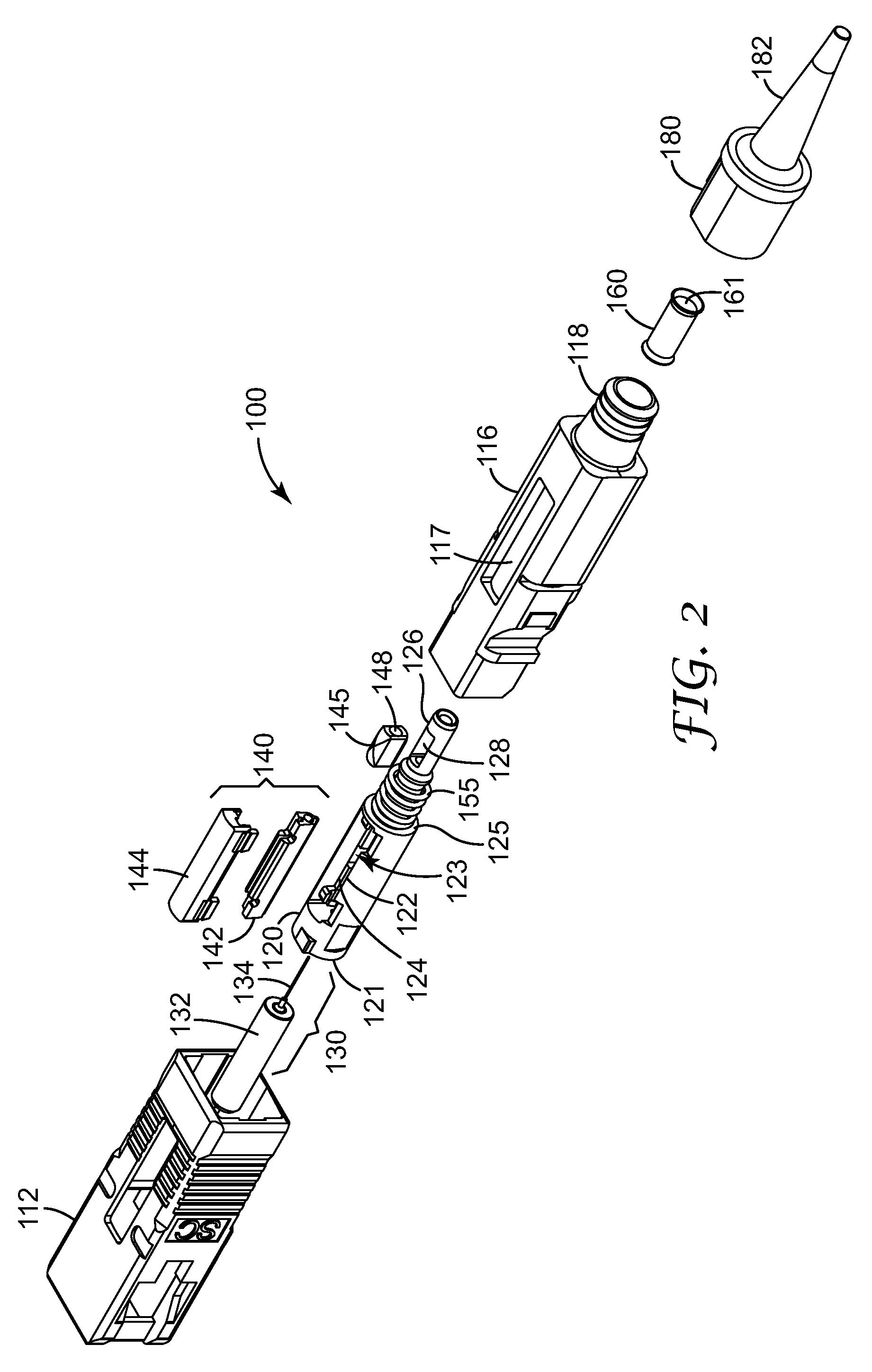

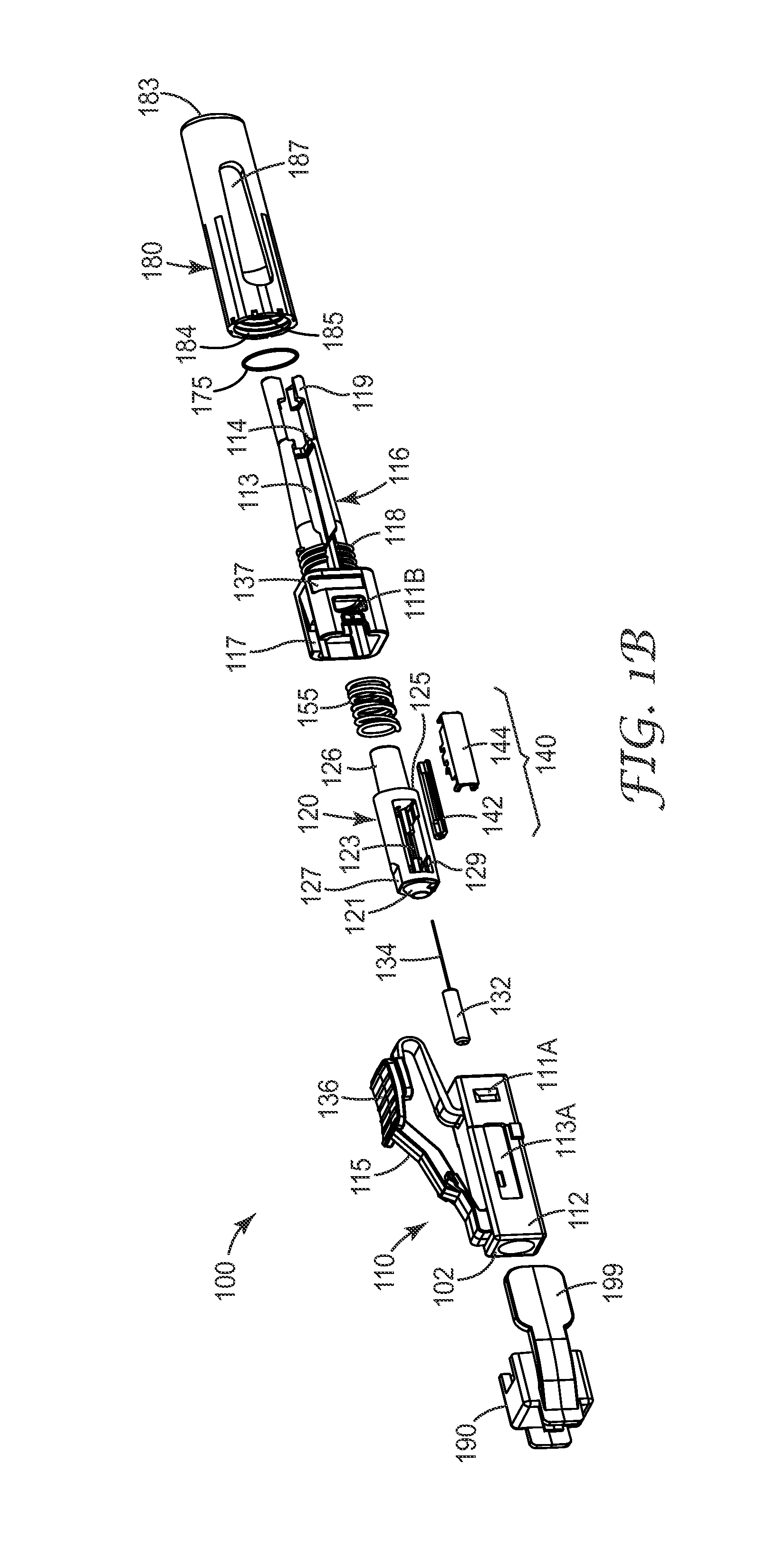

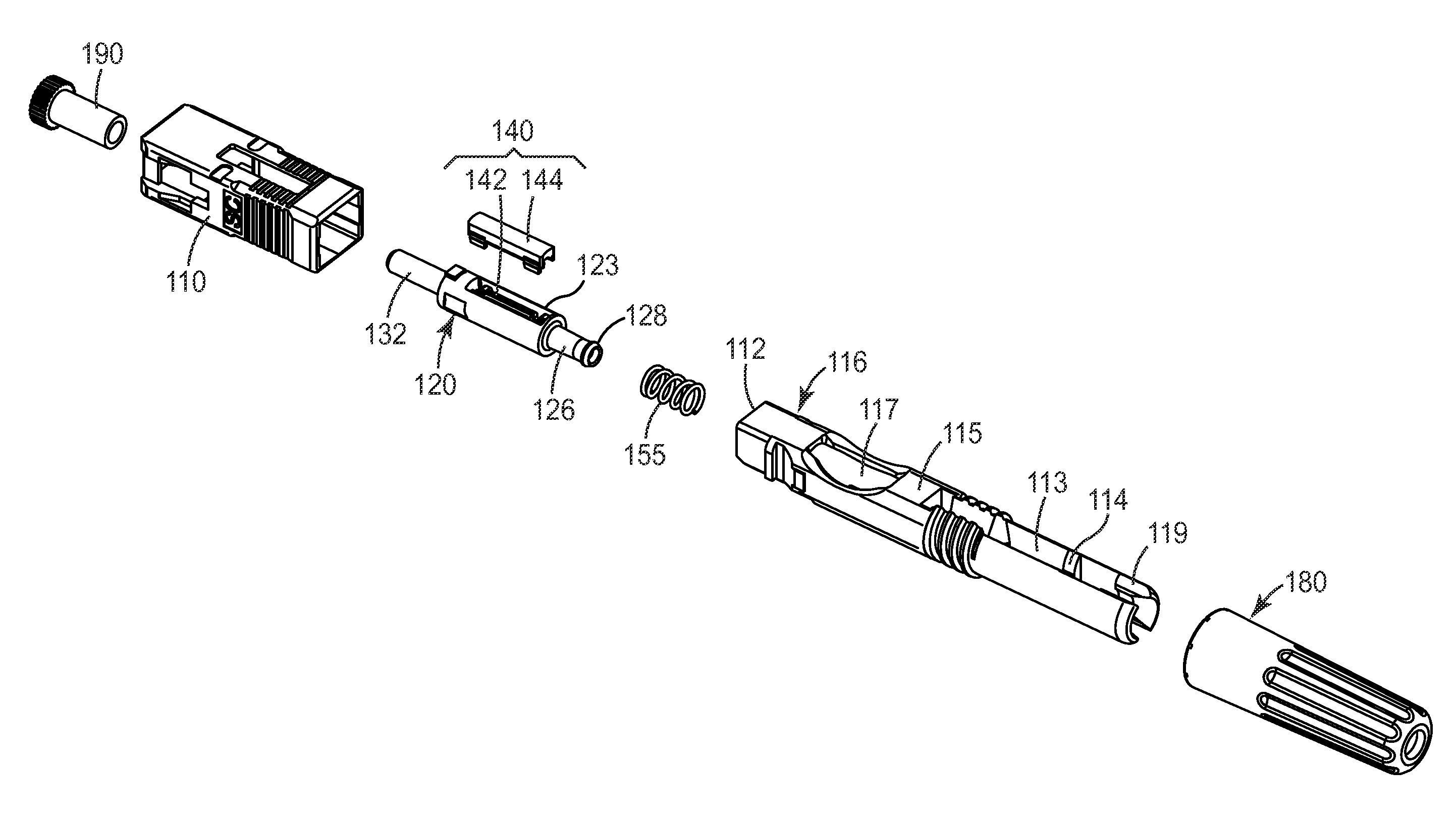

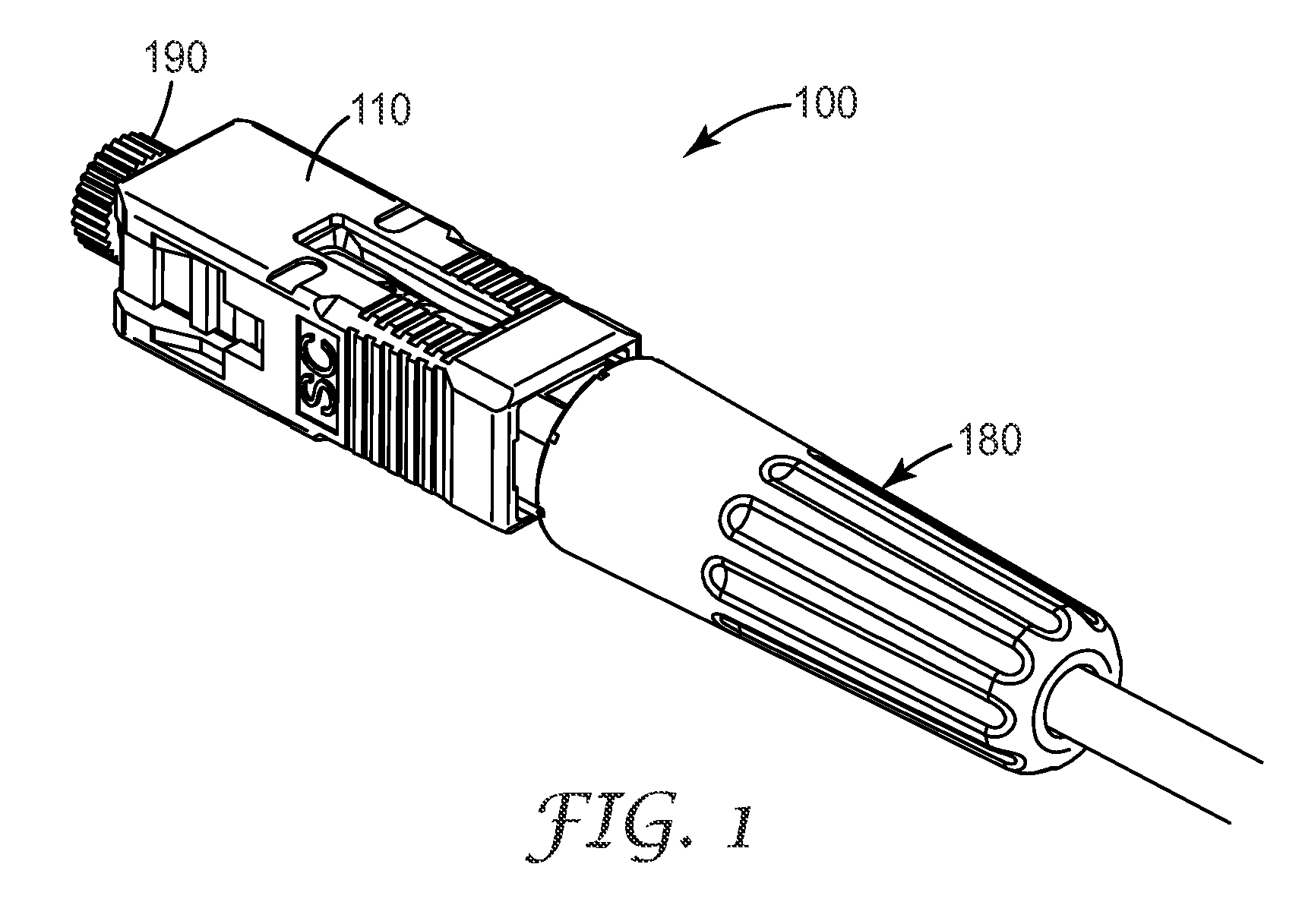

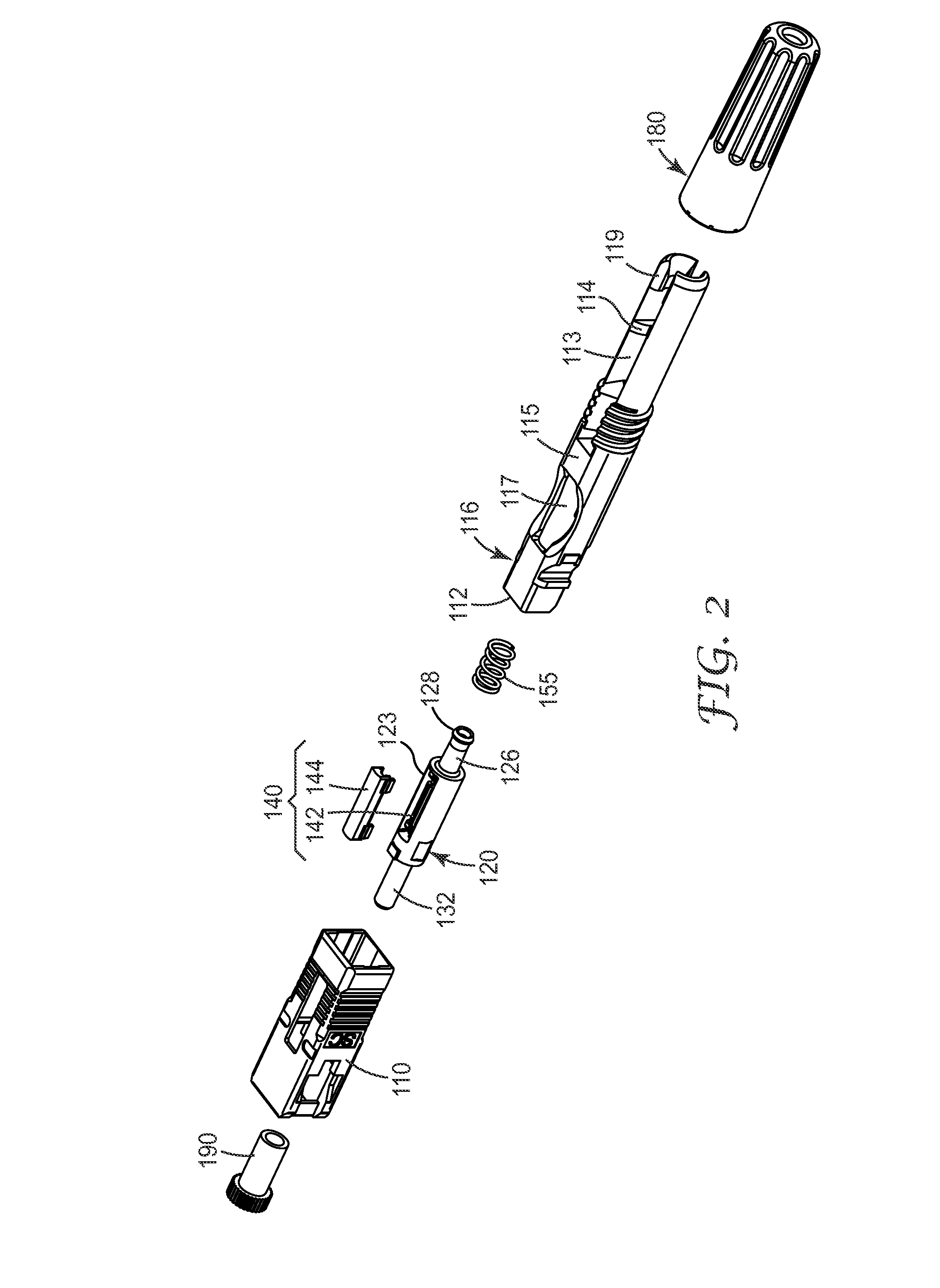

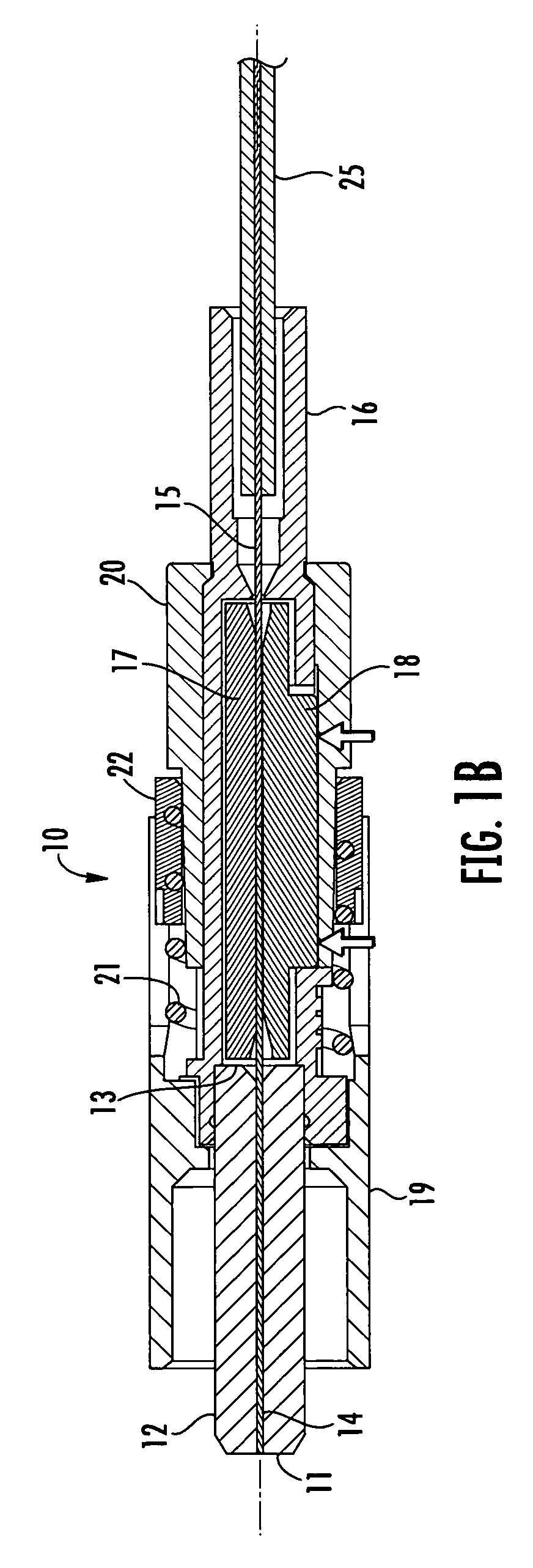

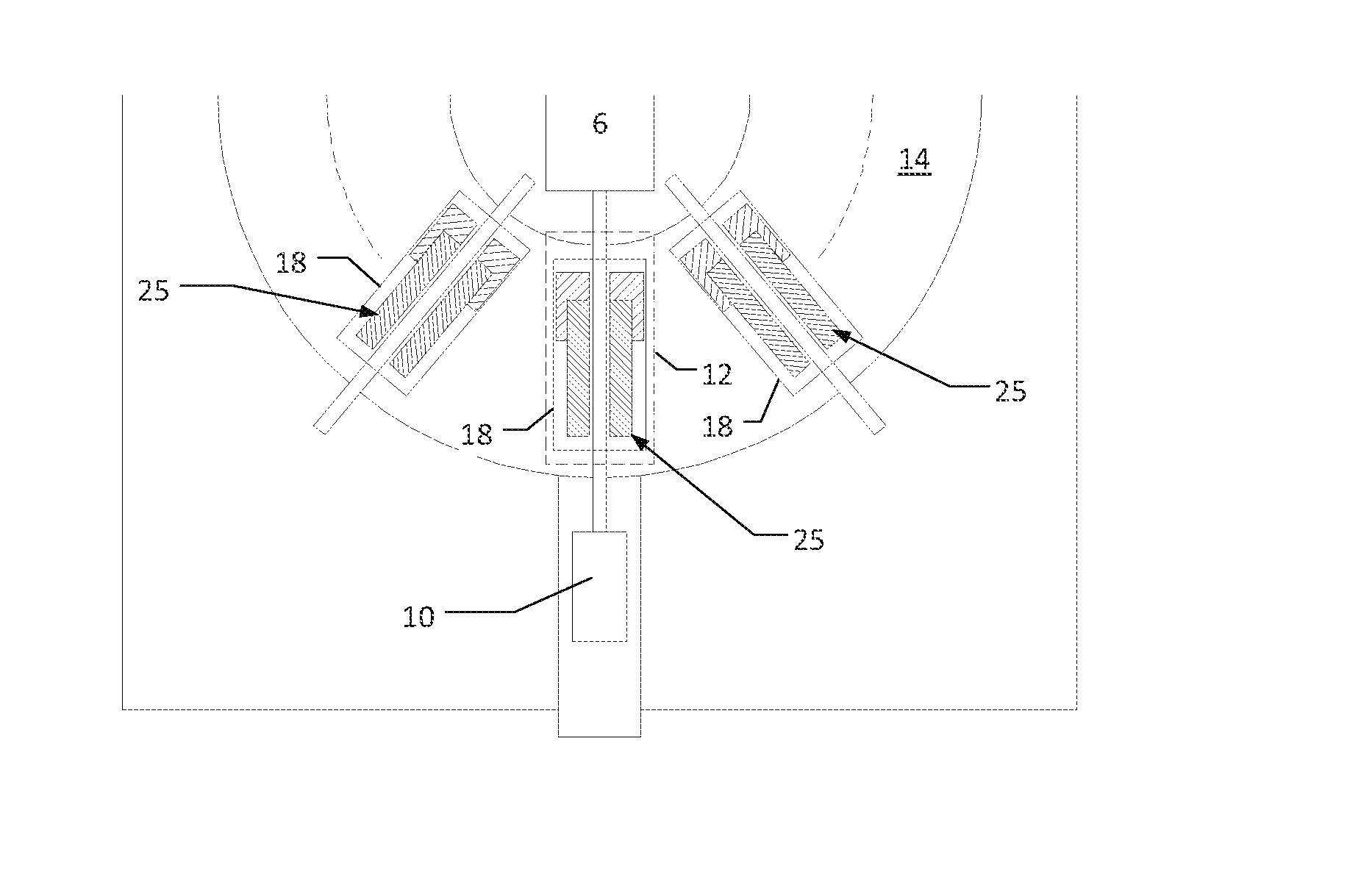

An optical fiber connector includes a housing configured to mate with a receptacle, a collar body that includes a fiber stub and a mechanical splice device, a backbone to retain the collar body within the housing, and a boot. The backbone includes a fiber jacket clamping portion to clamp a jacket portion that surrounds a portion of the terminated optical fiber upon actuation. The boot actuates the fiber jacket clamping portion of the backbone upon attachment to the backbone. The optical fiber connector can be terminated in the field without the need to use a separate termination platform or tool.

Owner:CORNING RES & DEV CORP

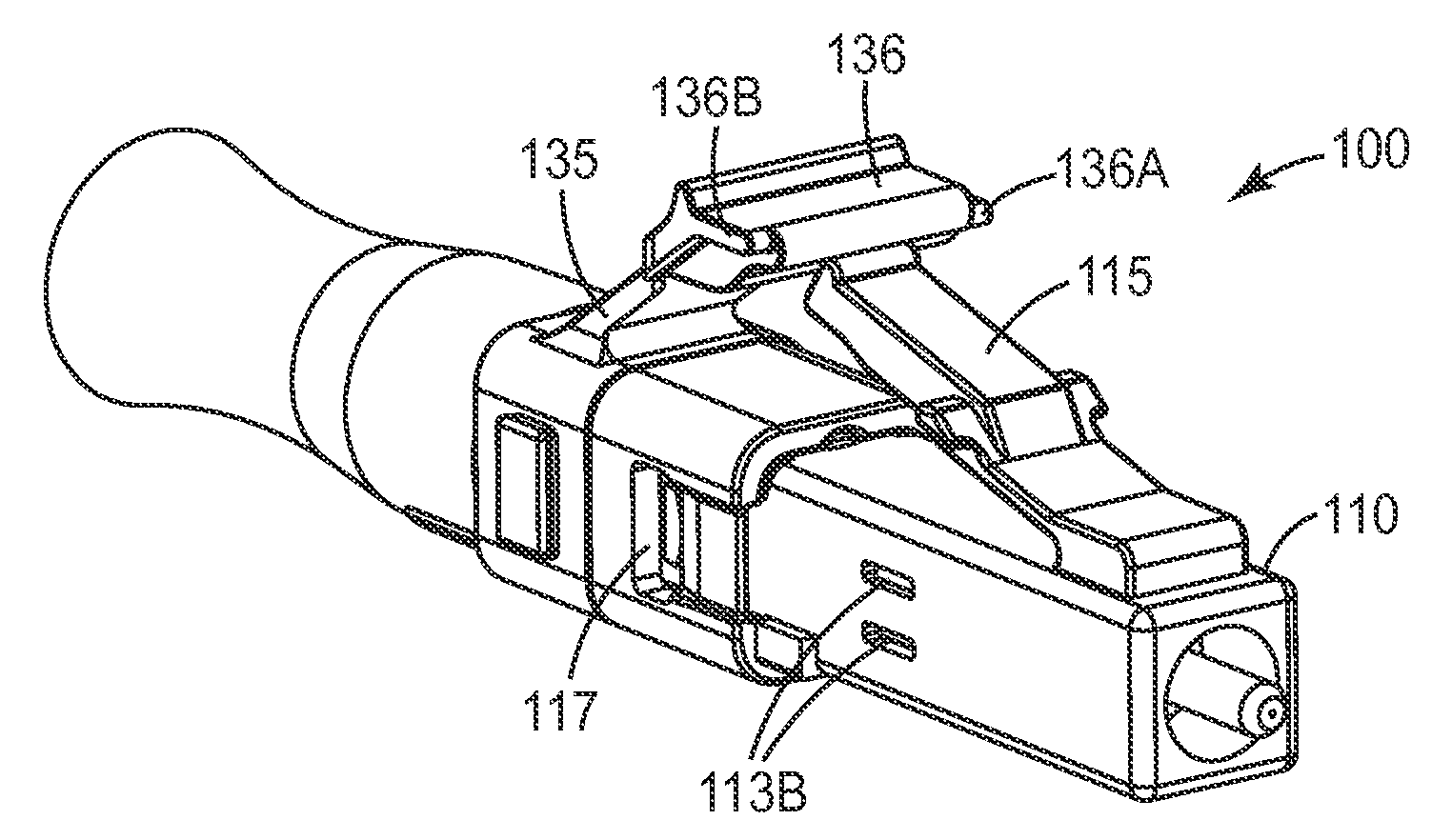

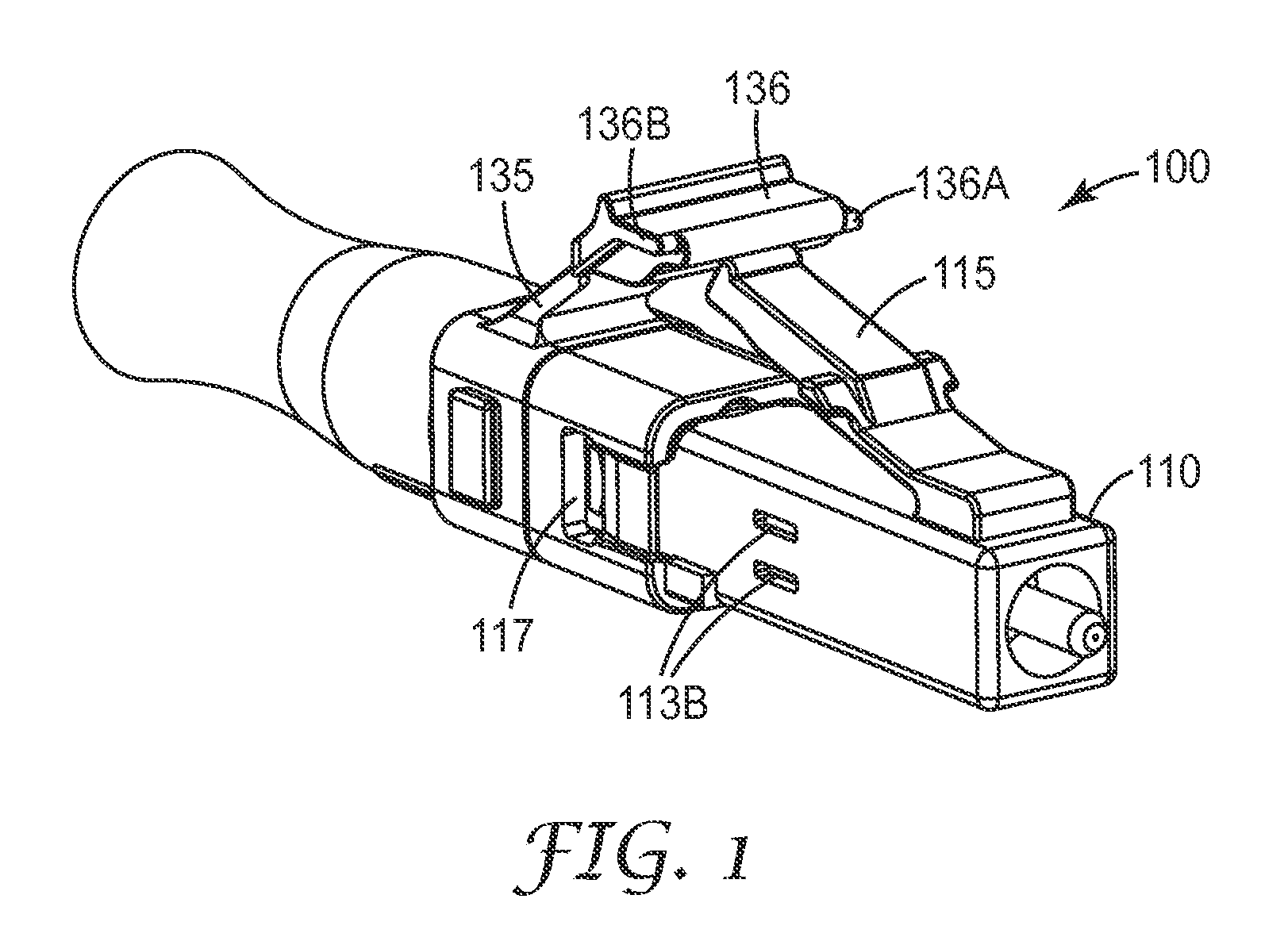

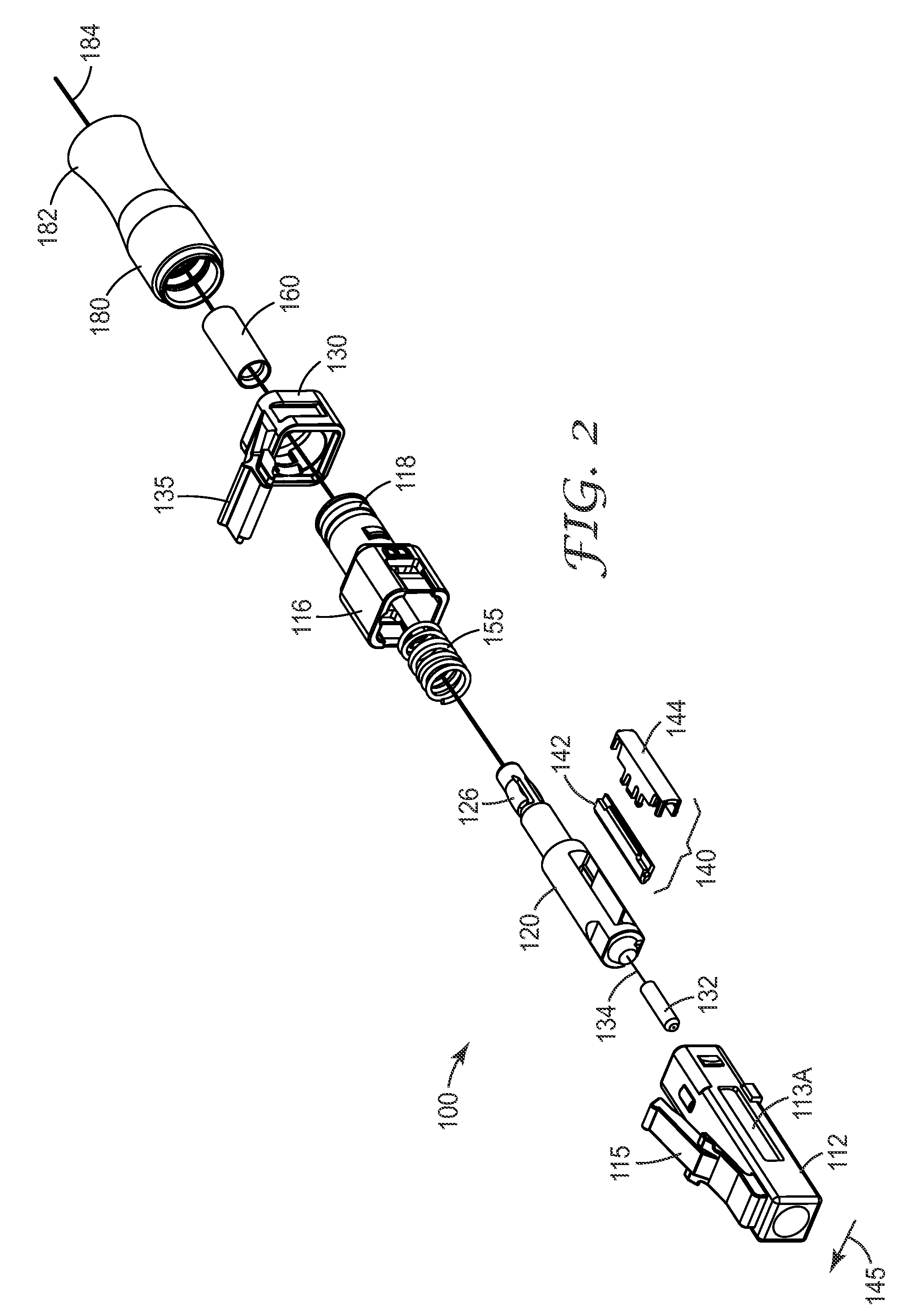

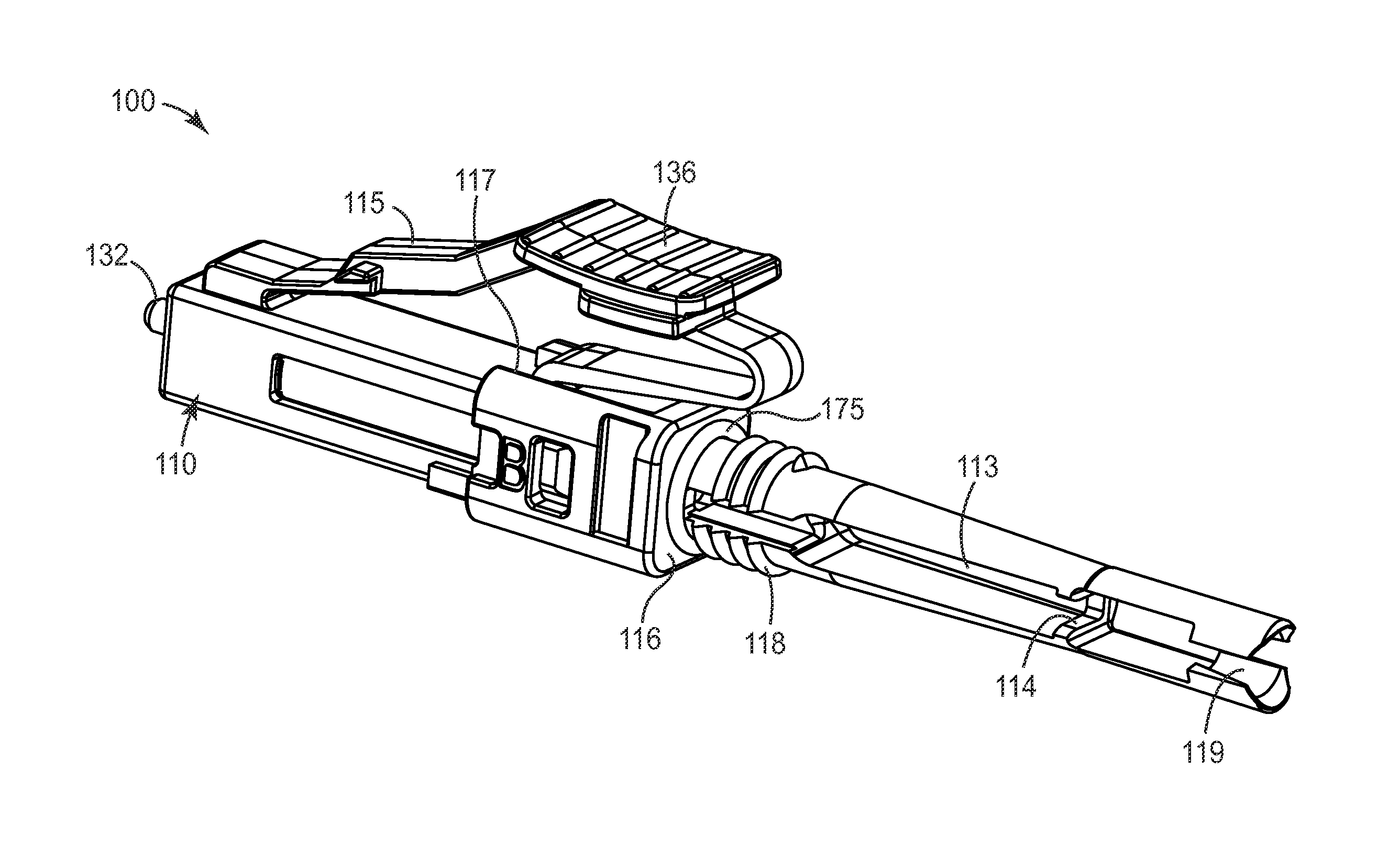

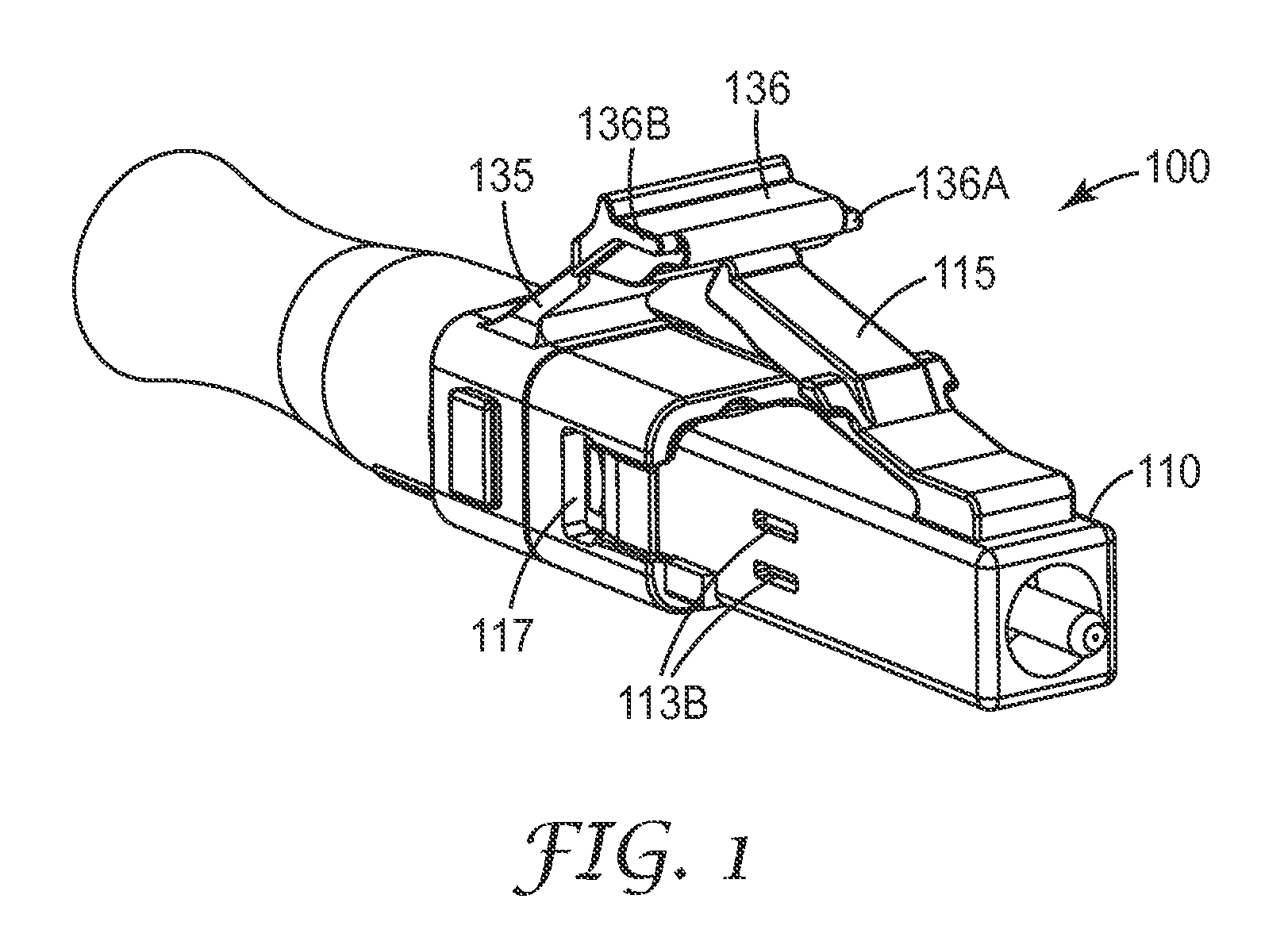

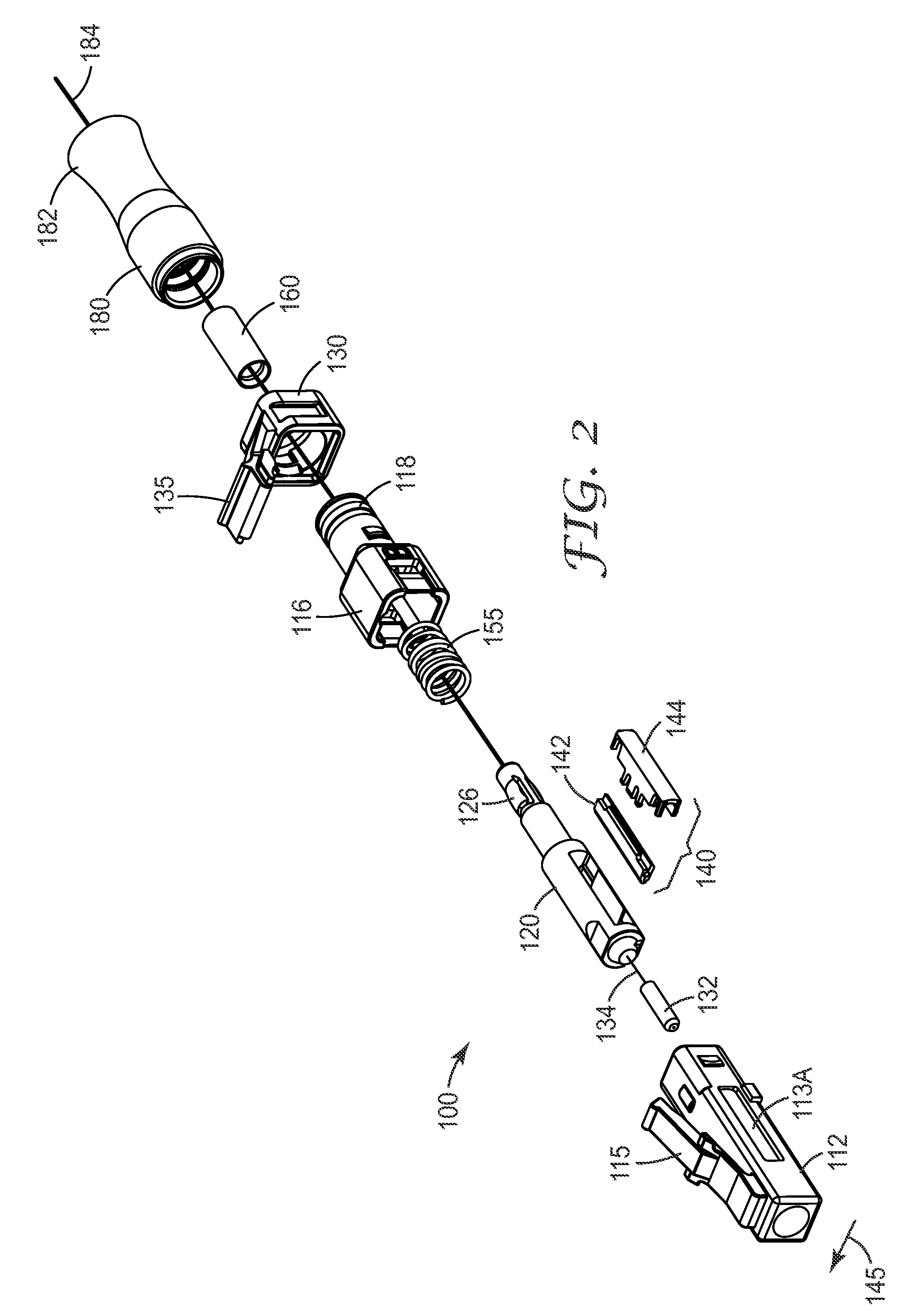

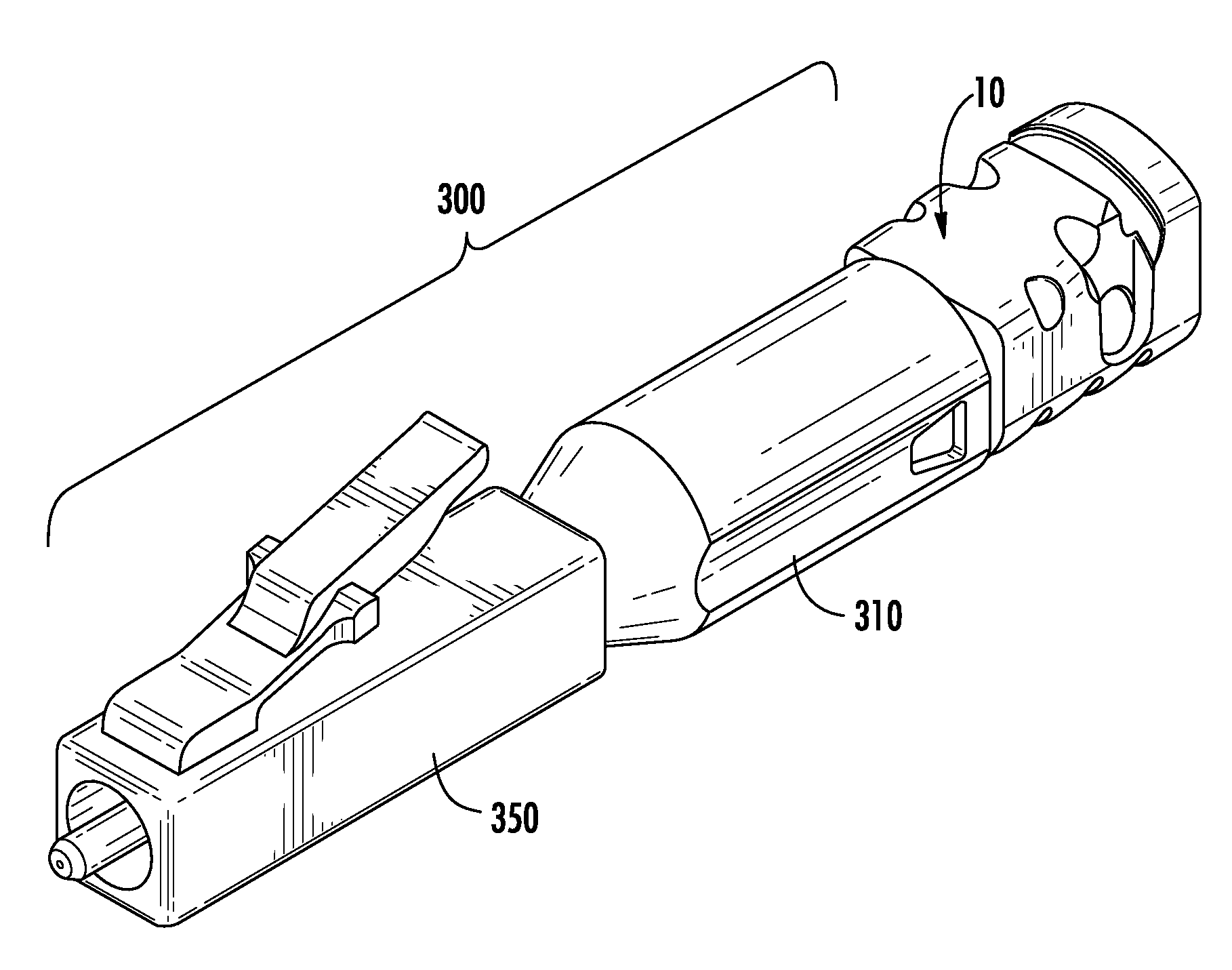

Field terminable lc format optical connector with splice element

An LC format optical connector for terminating an optical fiber includes a housing configured to mate with an LC receptacle, the housing including a shell, a first resilient latch disposed on a surface of the shell, and a backbone. The LC format connector also includes a collar body disposed in the housing and retained between the outer shell and the backbone, wherein the collar body includes a fiber stub disposed in a first portion of the collar body. The collar body further includes a mechanical splice disposed in a second portion of the collar body, the mechanical splice configured to splice the second end of the fiber stub to a second optical fiber. The LC format connector further includes a trigger coupled to an outer surface of the housing backbone, the trigger including a second latch that engages the first latch when acted upon by a pressing force. An optical connector with a single piece latch structure is also provided.

Owner:CORNING RES & DEV CORP

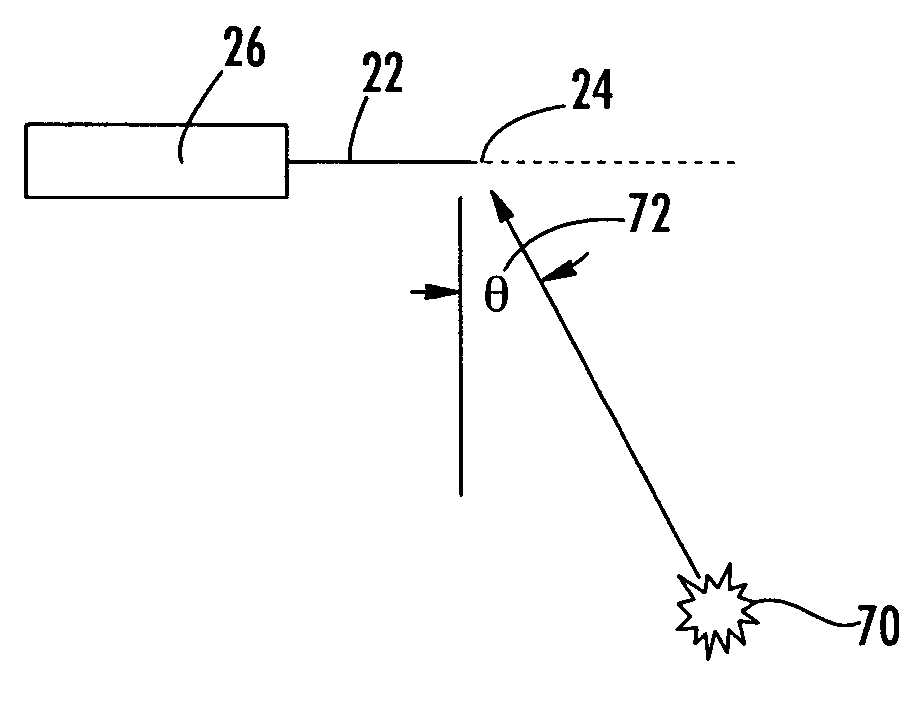

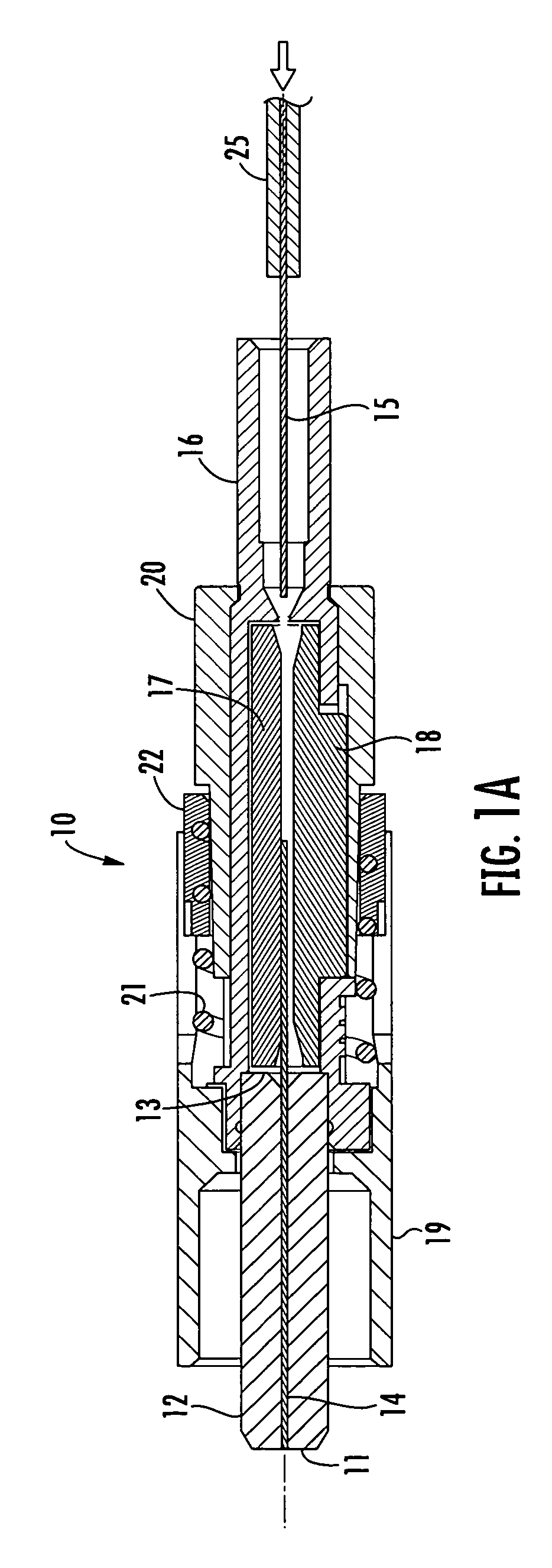

Method of making an optical fiber by laser cleaving

ActiveUS7216512B2Gap minimizationReduce or eliminate a glass defect zoneCoupling light guidesGlass reforming apparatusFiberLaser processing

A field-installable connector includes a connector housing and a ferrule having front and rear opposed faces and at least one fiber bore defined longitudinally therethrough. A laser processed stub optical fiber is disposed within the one fiber bore of the ferrule and extends a predetermined distance beyond the rear face of the ferrule. An alignment feature is operable for self-centering the stub optical fiber and a field optical fiber to perform a mechanical splice using a camming means. A method of laser processing a stub optical fiber includes rotating the stub optical fiber and sweeping a laser beam directed at a desired angle back and forth across a surface of the optical fiber. An oscillating motion of the laser is driven by an intermittent sinusoidal signal that results in two deposits of energy onto the stub optical fiber followed by a cooling period before subsequent deposits of energy occur.

Owner:CORNING OPTICAL COMM LLC

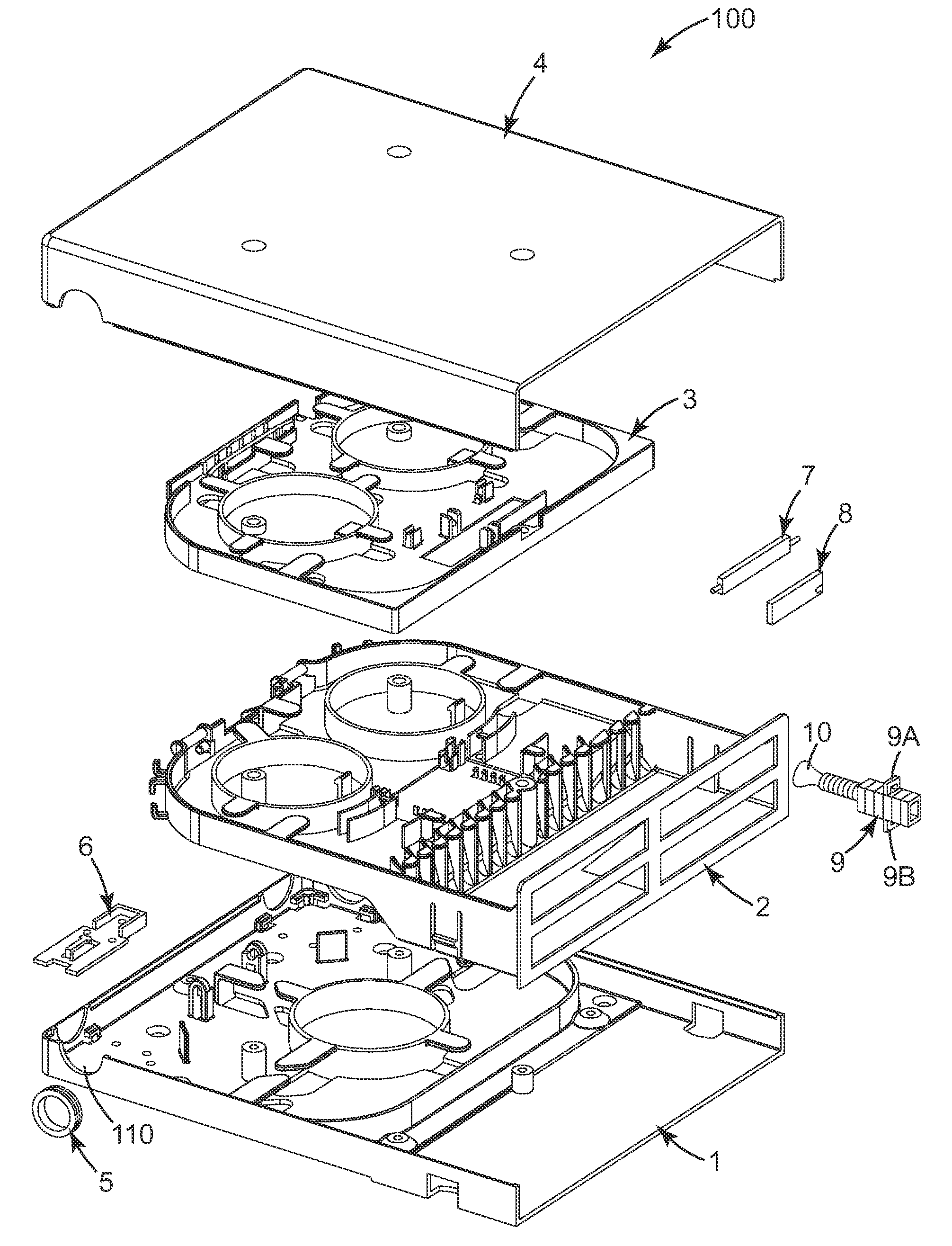

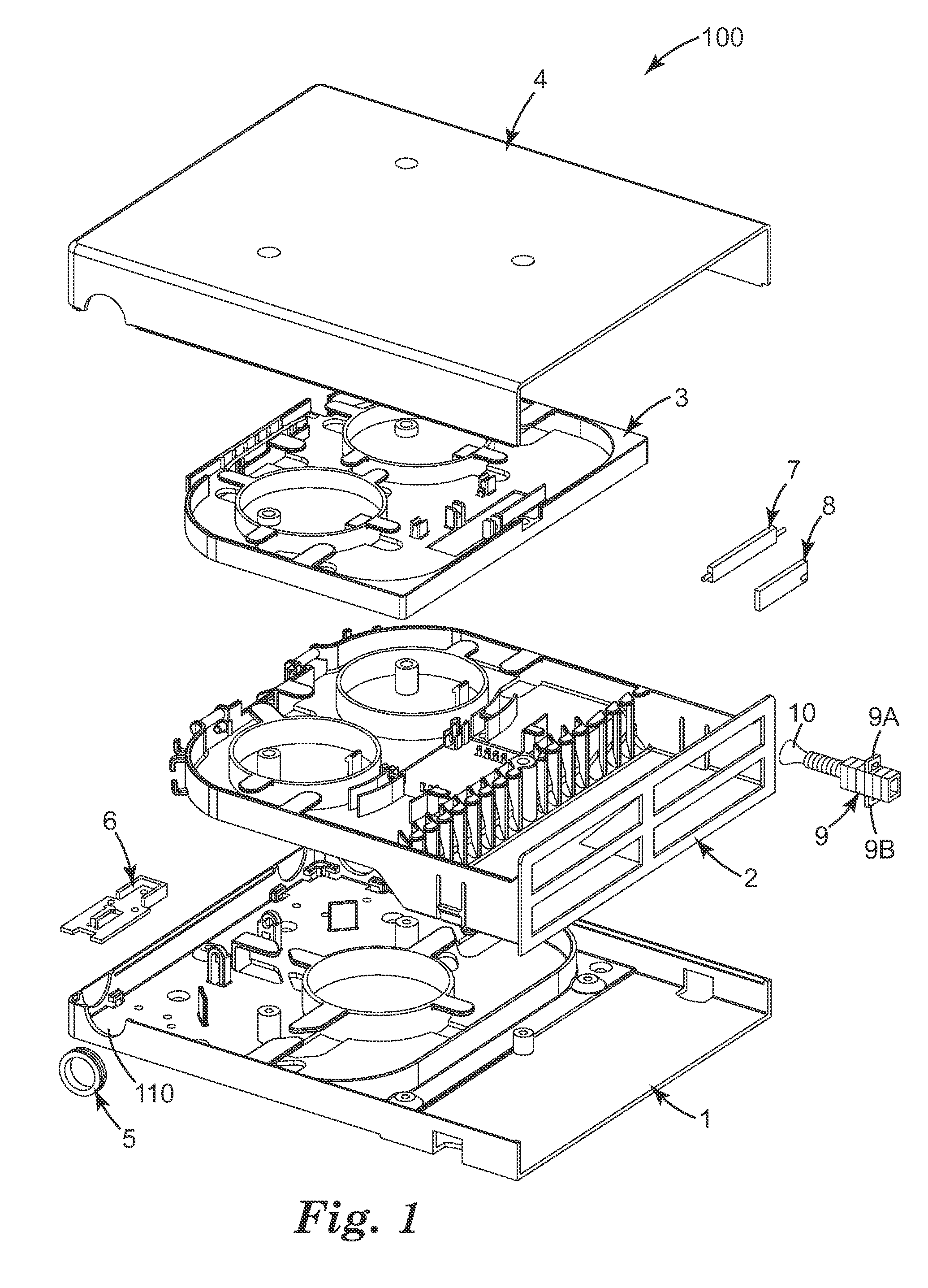

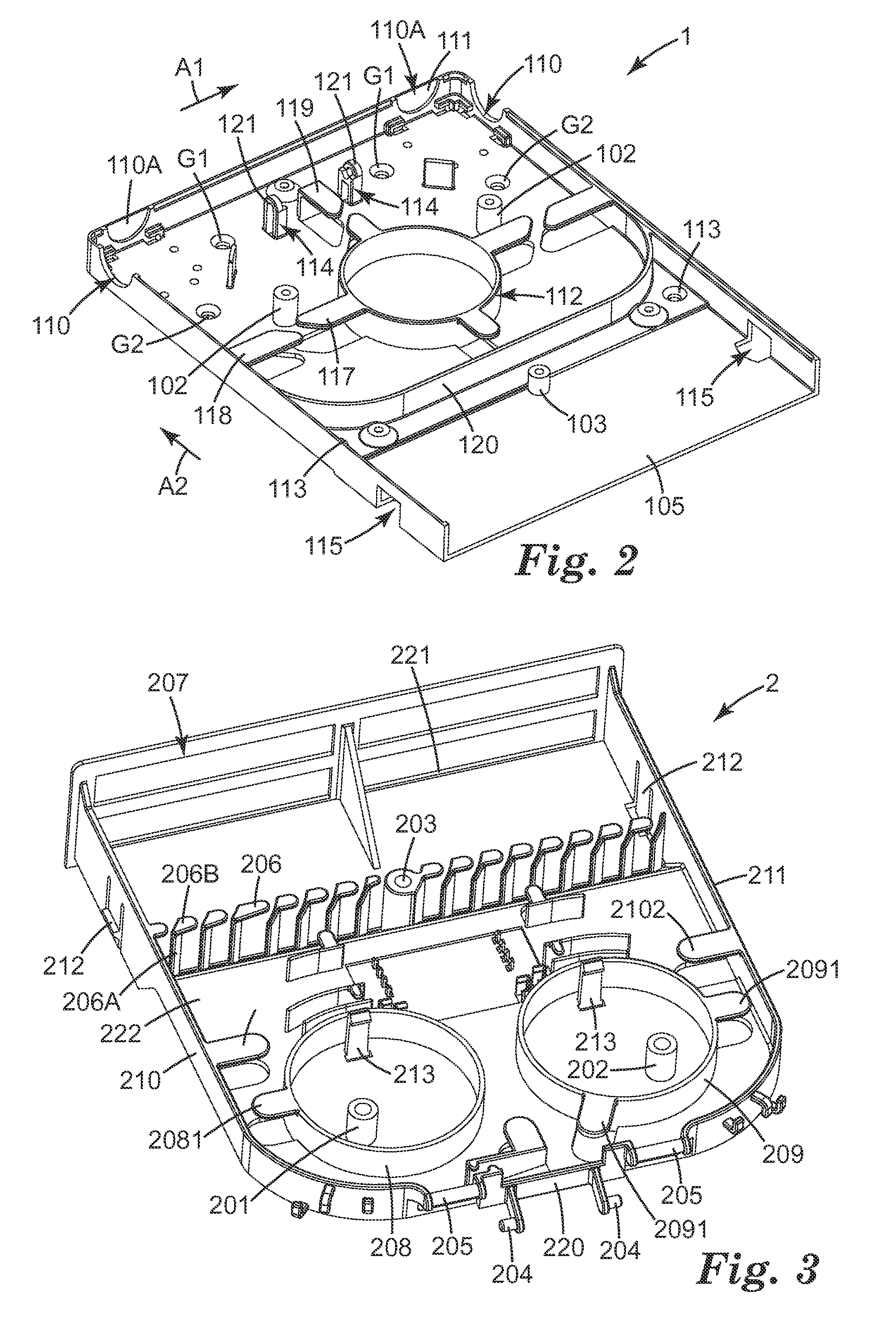

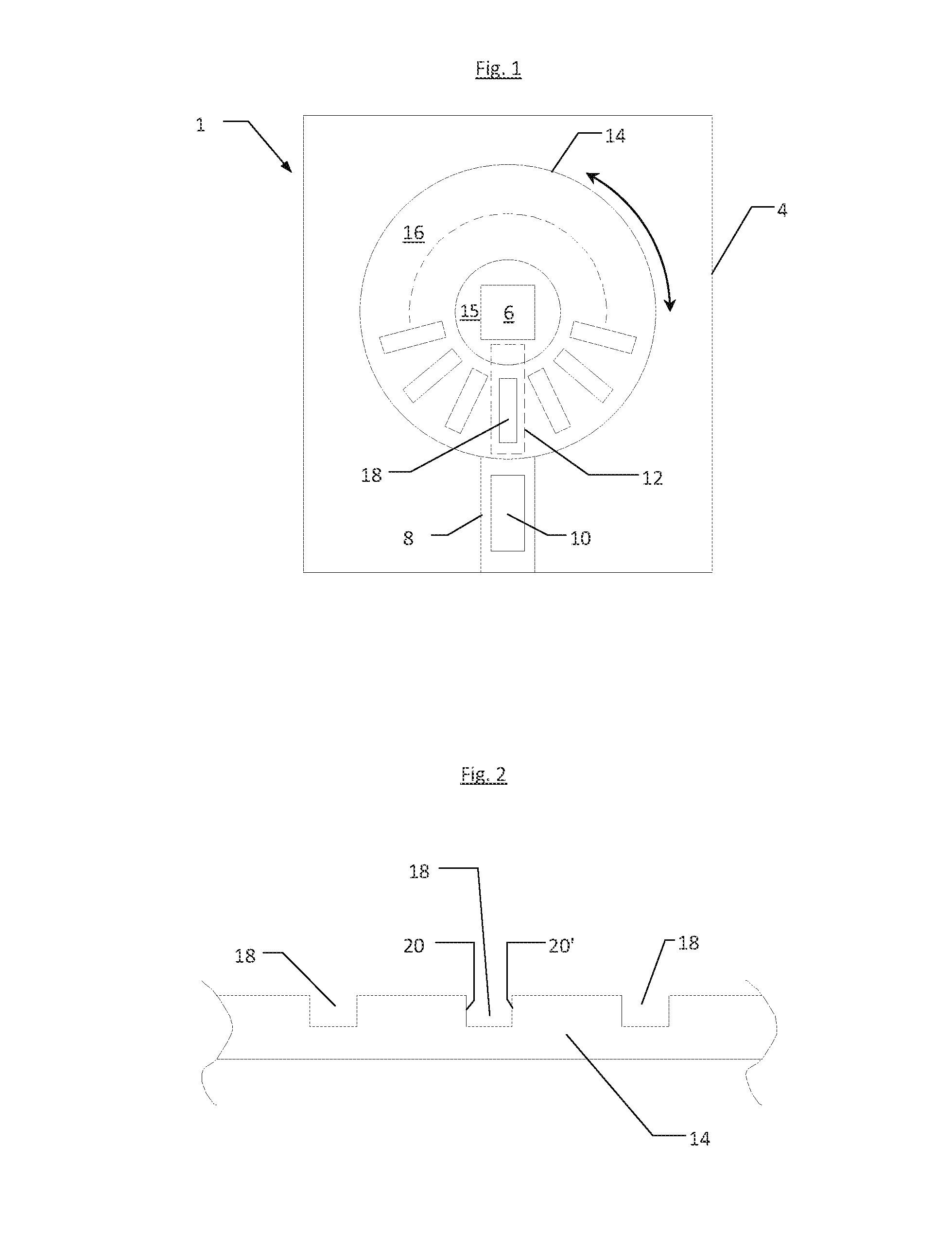

High density fiber distribution hub

InactiveUS20100329624A1Easy to operateShorten the timeOptical fibre/cable installationFiberMechanical splice

The present invention relates to a fiber distribution hub. The fiber distribution hub comprises a base case comprising at least one port portion for introducing an optical cable, wherein the optical cable includes a first fiber; a splitter case releasably attached to the base case; a splice tray rotatably hinged to the splitter case; and a cover engagable with the base case to enclose the splitter case and the splice tray. The first fiber is connected to a second fiber in the splice tray, and the second fiber is connected with a splitter in the splitter case to separate the second fiber into a plurality of separate third fibers. Thus, the invention provides a compact and modular fiber distribution hub. In addition, the fiber distribution hub can join optical fibers by mechanical splices, fusion splices and fiber optic connectors in a single unit.

Owner:3M INNOVATIVE PROPERTIES CO

Optical connector and fiber distribution unit

ActiveUS20070104425A1Reduce potential axial strain and axial movementRestrict lateral motionCoupling light guidesFiberMechanical splice

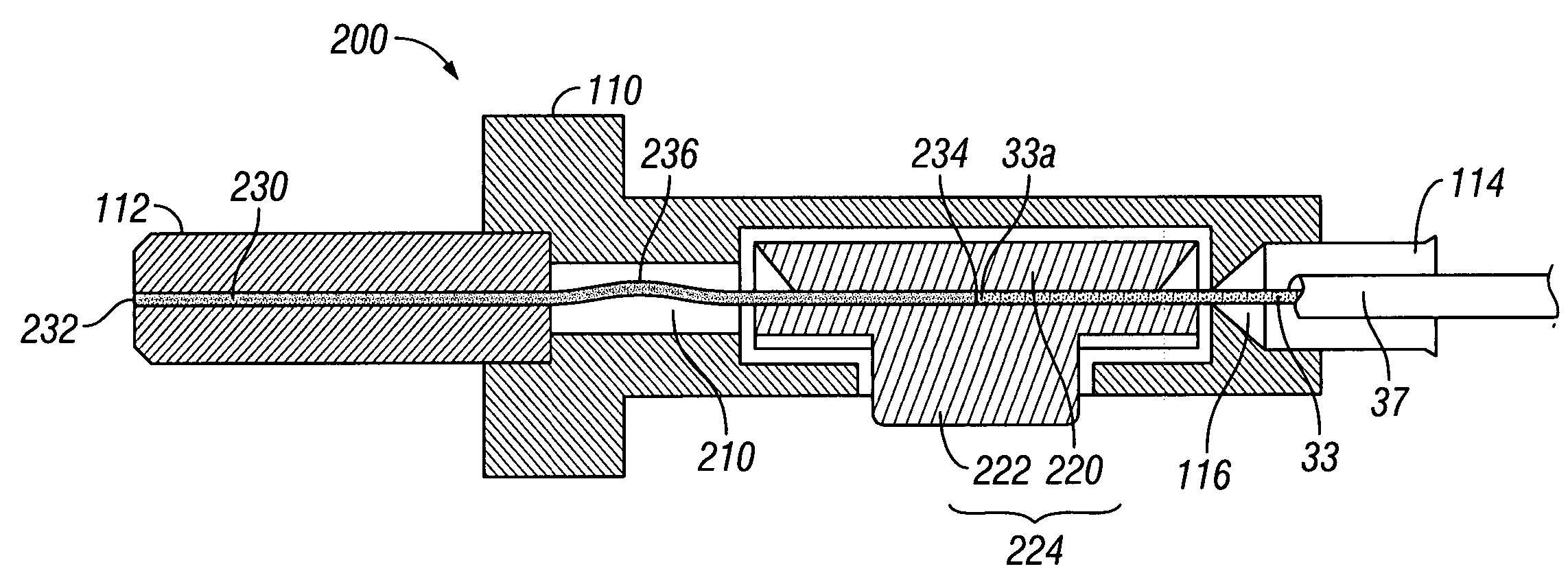

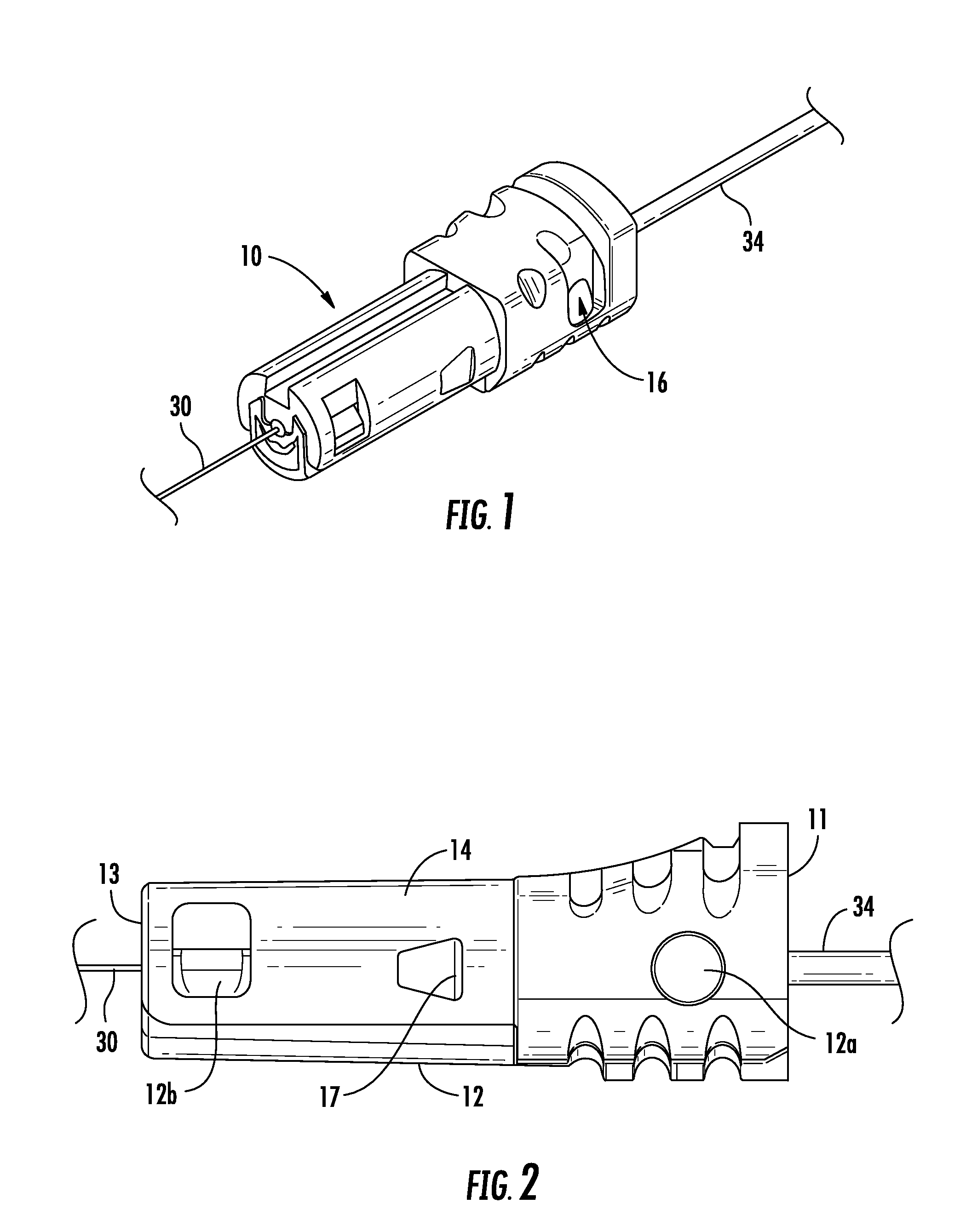

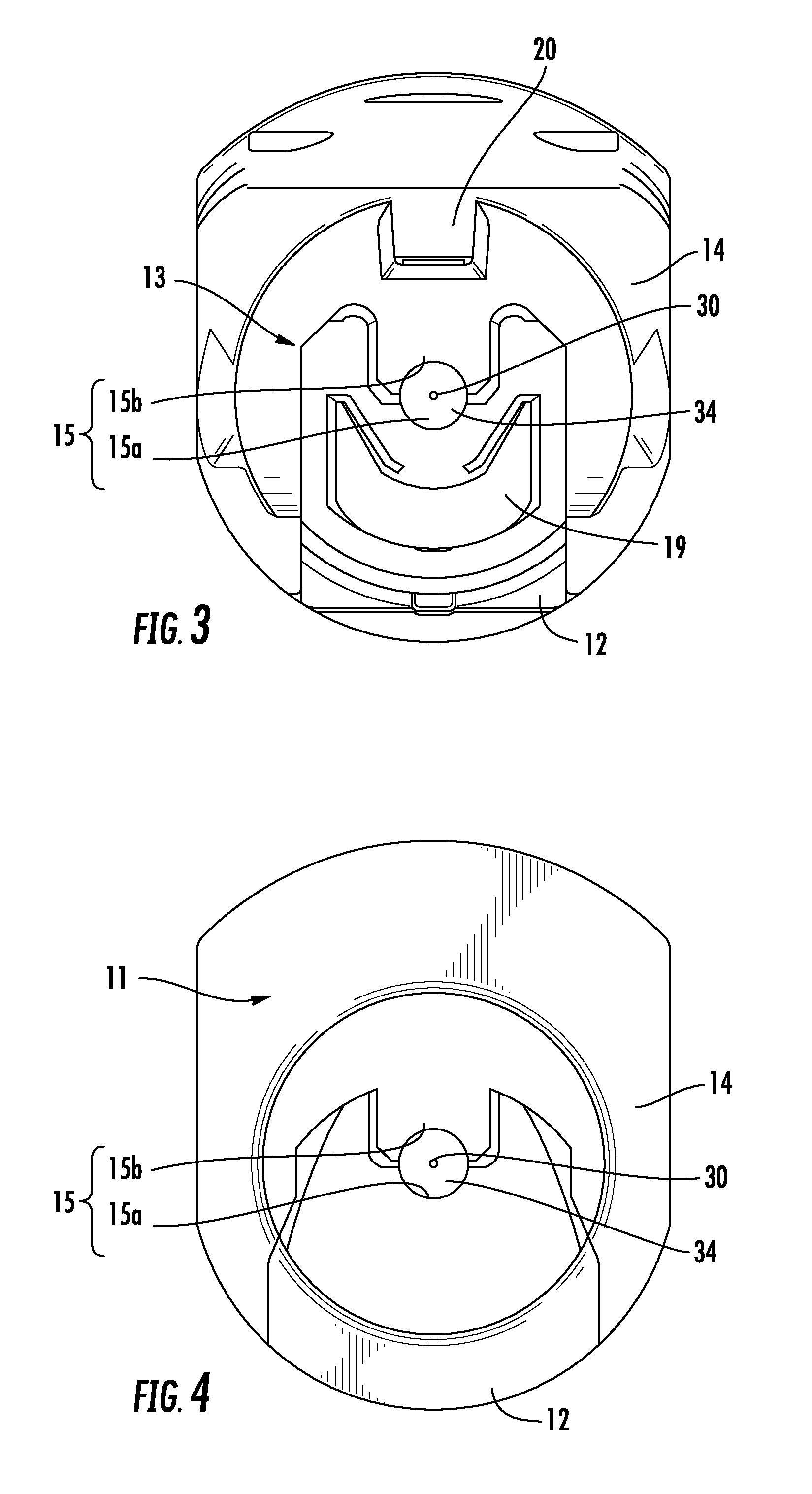

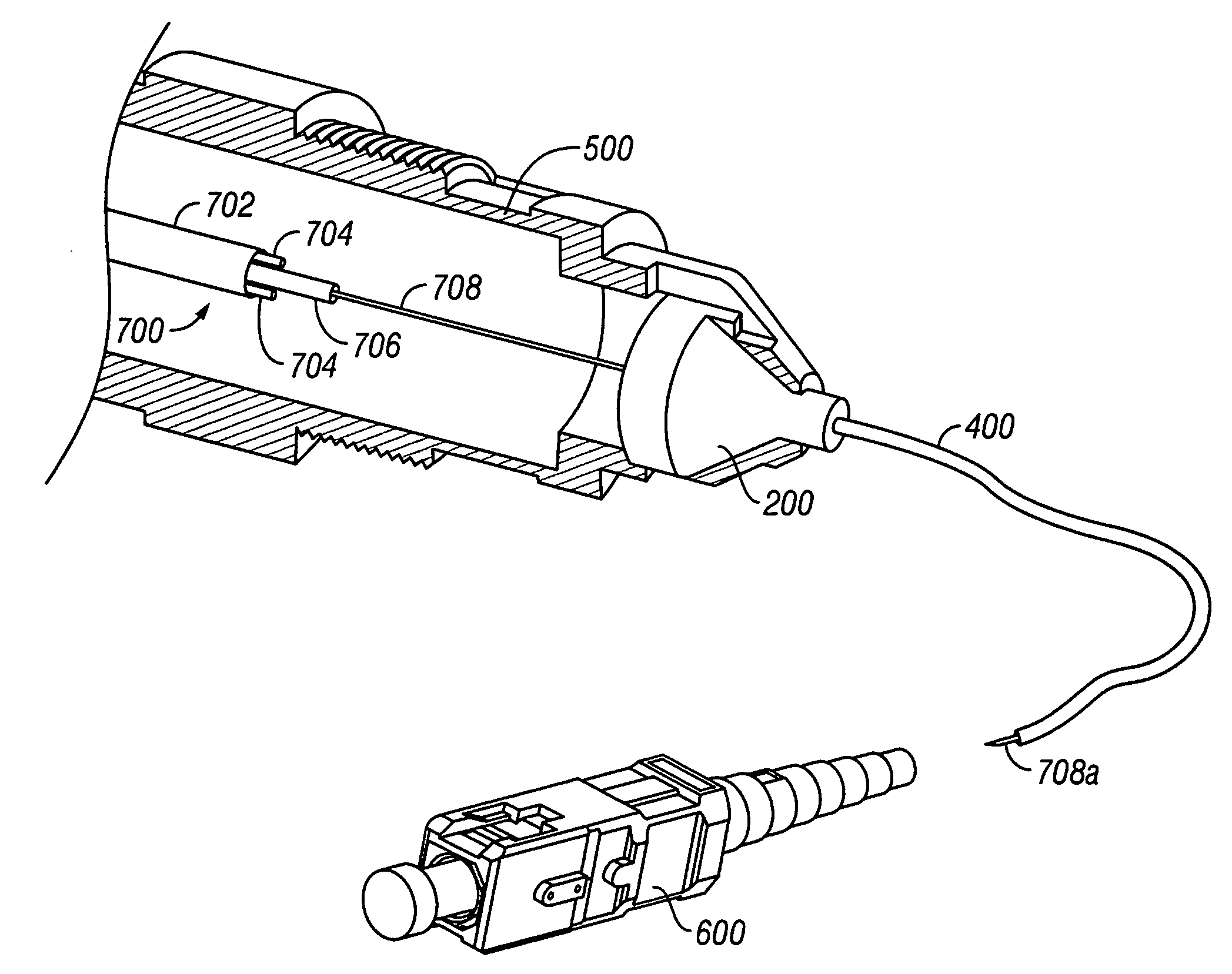

An optical connector for terminating an optical fiber comprises a housing configured to mate with a receptacle and a collar body disposed in the housing. The collar body includes a fiber stub disposed in a first portion of the collar body, the fiber stub including a first optical fiber mounted in a ferrule and having a first end proximate to an end face of the ferrule and a second end. The collar body also includes a mechanical splice disposed in a second portion of the collar body, the mechanical splice configured to splice the second end of the fiber stub to a second optical fiber. The collar body also includes a buffer clamp configured within a third portion of the collar body, the buffer clamp configured to clamp at least a portion of a buffer cladding of the second fiber upon actuation. A fiber distribution unit is also provided.

Owner:CORNING RES & DEV CORP

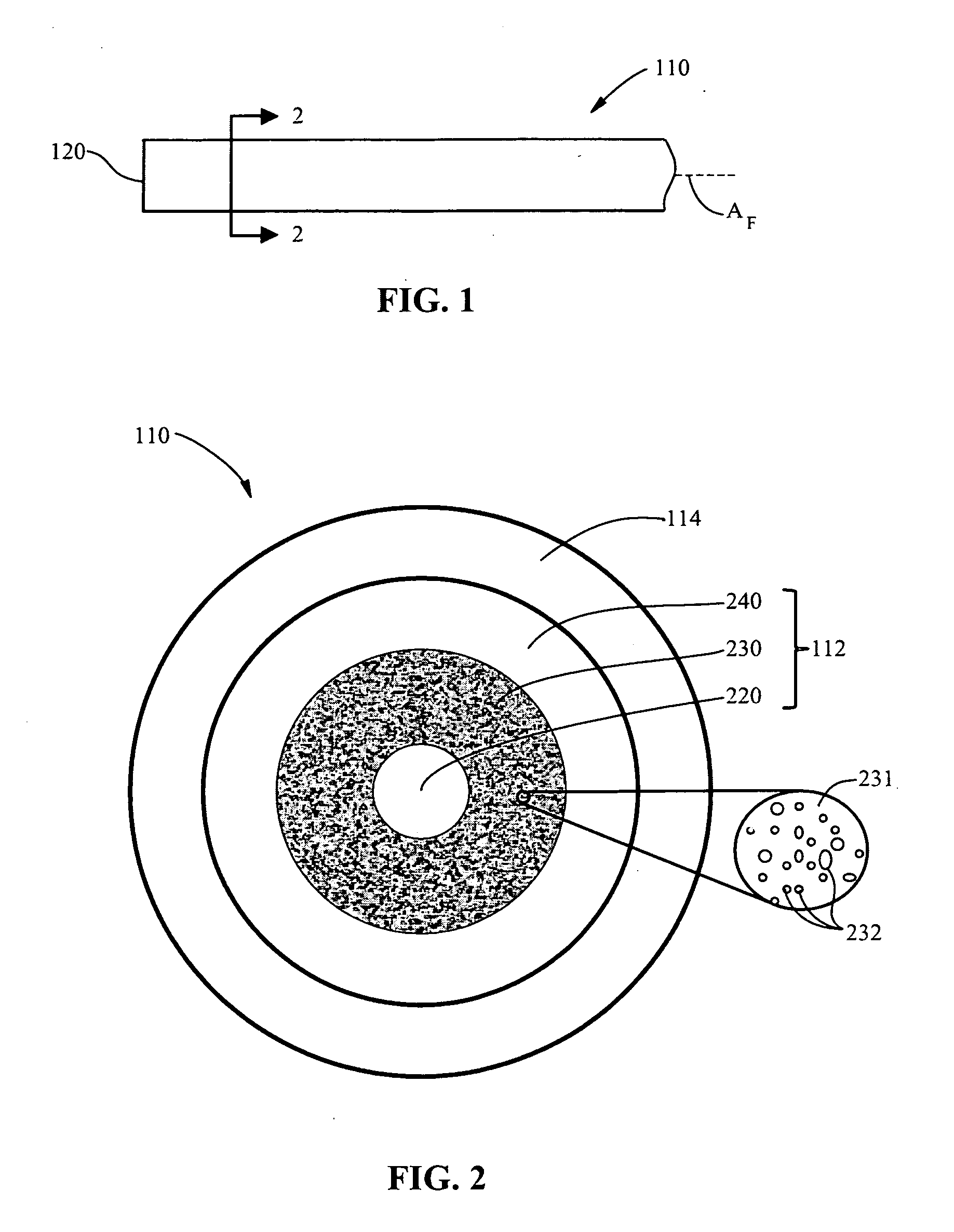

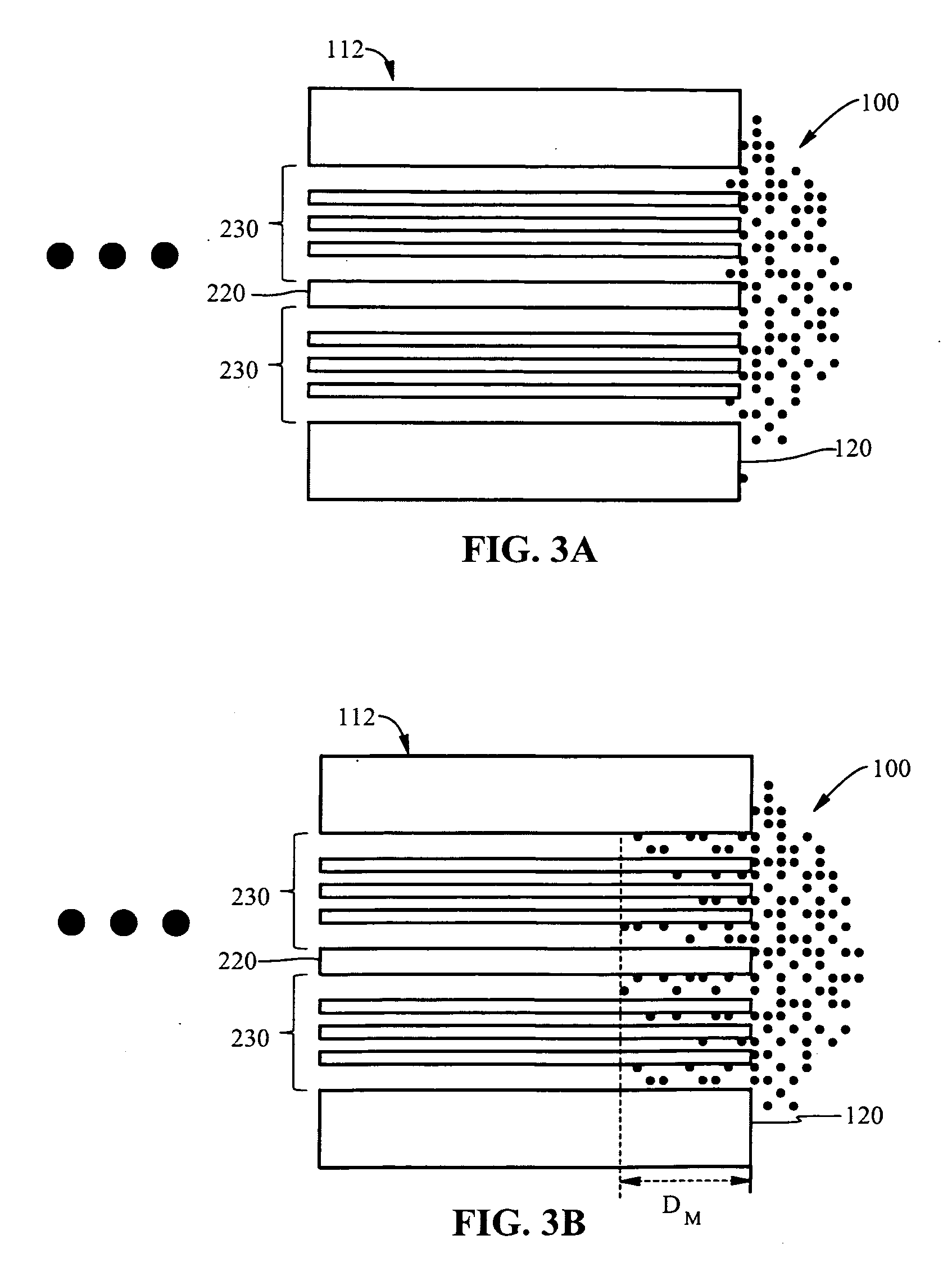

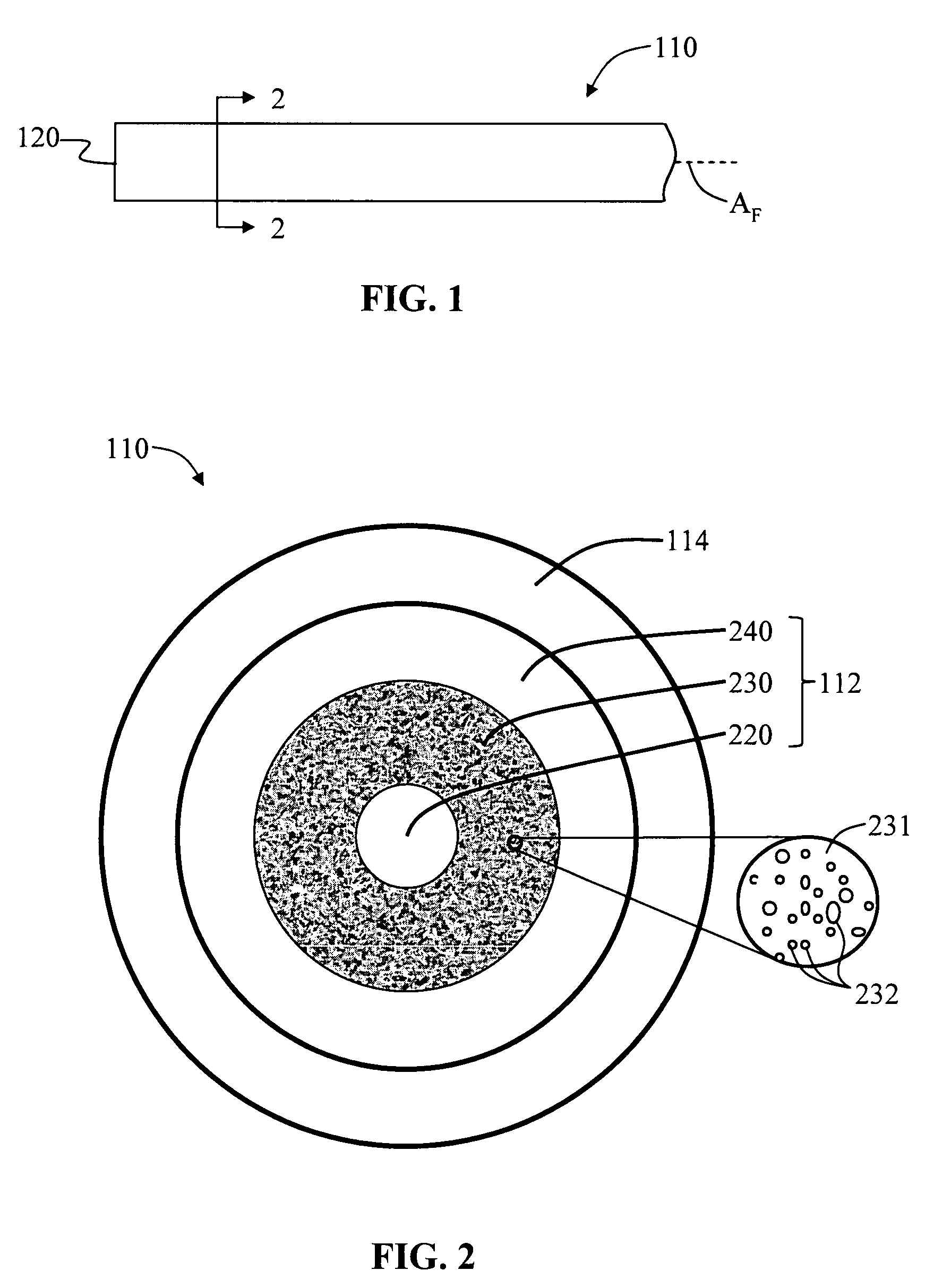

Index-matching gel for nano-engineered optical fibers and mechanical splice assemblies and connectors using same

An index-matching gel for use with nano-engineered optical fibers is disclosed. The index-matching gel is cross-linked, which prevents the gel from wicking into the voids and down the nano-engineered optical fiber to a depth where the fiber performance and / or device performance is compromised. The formulation comprises a non-reactive constituent A, two reactive constituents B and C, and a catalyst D. The gel is pre-cured and forms a cross-linked internal network that results in a single-component gel that does not require meter mixing of an additional constituent or heat curing. The gel is suitable for use in the mechanical splicing of optical fibers when at least one of the optical fibers is a nano-engineered optical fiber. The gel is also suitable for use in fiber optic connectors wherein at least one of the optical fibers constituting the connection is a nano-engineered optical fiber.

Owner:CORNING OPTICAL COMM LLC

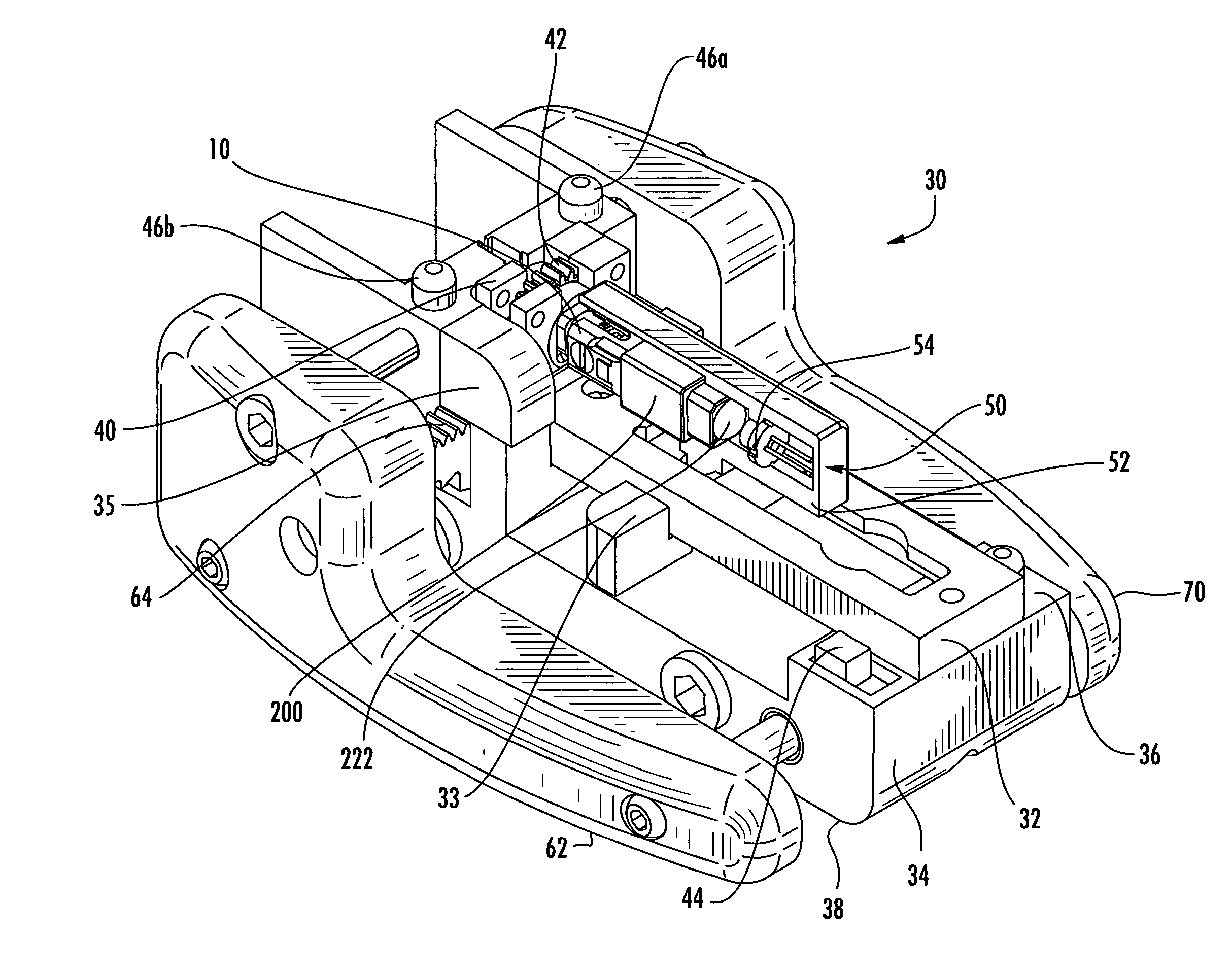

Installation tool with integrated visual fault indicator for field-installable mechanical splice connector

InactiveUS20070172179A1Improved visual fault locatorMore efficientCoupling light guidesTesting fibre optics/optical waveguide devicesFault indicatorFiber

A mechanical splice fiber optic connector installation tool operable for performing splice terminations and verifying an acceptable splice termination includes a power source, a connector holder, an integrated Visual Fault Locater having an optical transmission element and a display for displaying the status of the termination. An adapter configured to receive the connector and align the connector with the optical transmission element, such that the optical transmission element is spaced apart from the connector at a predetermined distance and is in optical communication with the connector for propagating light energy through the adapter and along the stub optical fiber to a termination area of the connector.

Owner:CORNING OPTICAL COMM LLC

Field terminable optical connector with splice element for jacketed cable

An LC format optical connector for terminating an optical fiber includes a housing configured to mate with an LC receptacle. A backbone is configured to engage an outer surface of the outer shell of the housing and includes a mounting structure that is configured to engage a boot. A collar body is retained between the outer shell and the backbone and includes a fiber stub disposed in a first portion of the collar body, the fiber stub being mounted in a ferrule. A mechanical splice is disposed in a second portion of the collar body, the mechanical splice configured to splice the fiber stub to the optical fiber. The backbone also includes a fiber jacket clamping portion to clamp a jacket portion that surrounds a portion of the optical fiber upon actuation.

Owner:CORNING RES & DEV CORP

Splice holder device

A splice holder device includes a tray mountable in a telecommunications closure, the tray including a splice mounting mechanism configured to receive a splice device. The splice holder device also includes first and second fiber clamps disposed on the tray, wherein the first and second fiber clamps are each configured to releasably secure a buffered portion of an optical fiber. The tray can include a single splice device, such as a mechanical splice, mounted therein or can include a plurality of splice devices mounted therein. The splice holder device can be configured to be securedly mounted in a telecommunications enclosure.

Owner:CORNING RES & DEV CORP

Field terminable LC format optical connector with splice element

An LC format optical connector for terminating an optical fiber includes a housing configured to mate with an LC receptacle, the housing including a shell, a first resilient latch disposed on a surface of the shell, and a backbone. The LC format connector also includes a collar body disposed in the housing and retained between the outer shell and the backbone, wherein the collar body includes a fiber stub disposed in a first portion of the collar body. The collar body further includes a mechanical splice disposed in a second portion of the collar body, the mechanical splice configured to splice the second end of the fiber stub to a second optical fiber. The LC format connector further includes a trigger coupled to an outer surface of the housing backbone, the trigger including a second latch that engages the first latch when acted upon by a pressing force. An optical connector with a single piece latch structure is also provided.

Owner:CORNING RES & DEV CORP

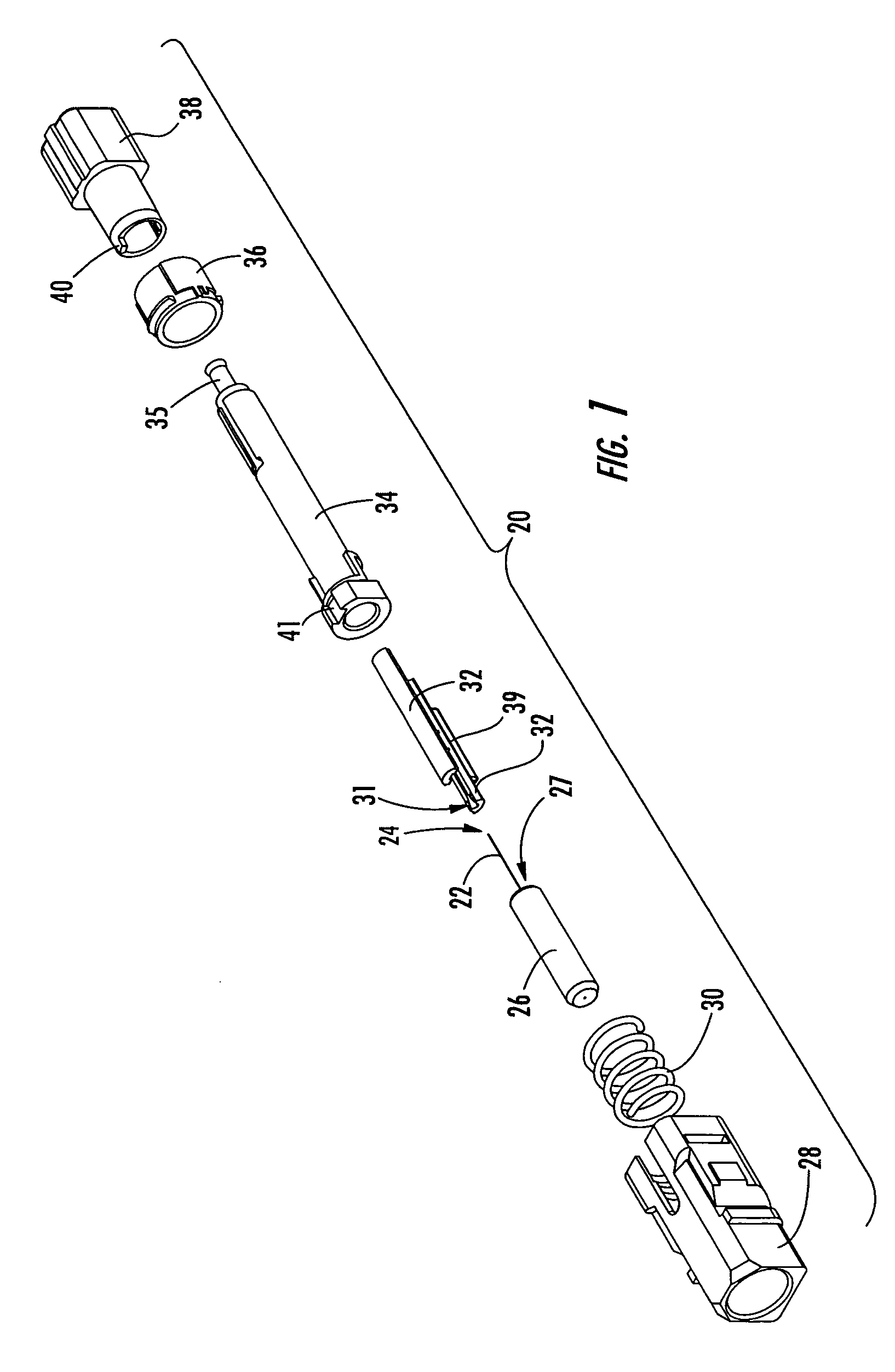

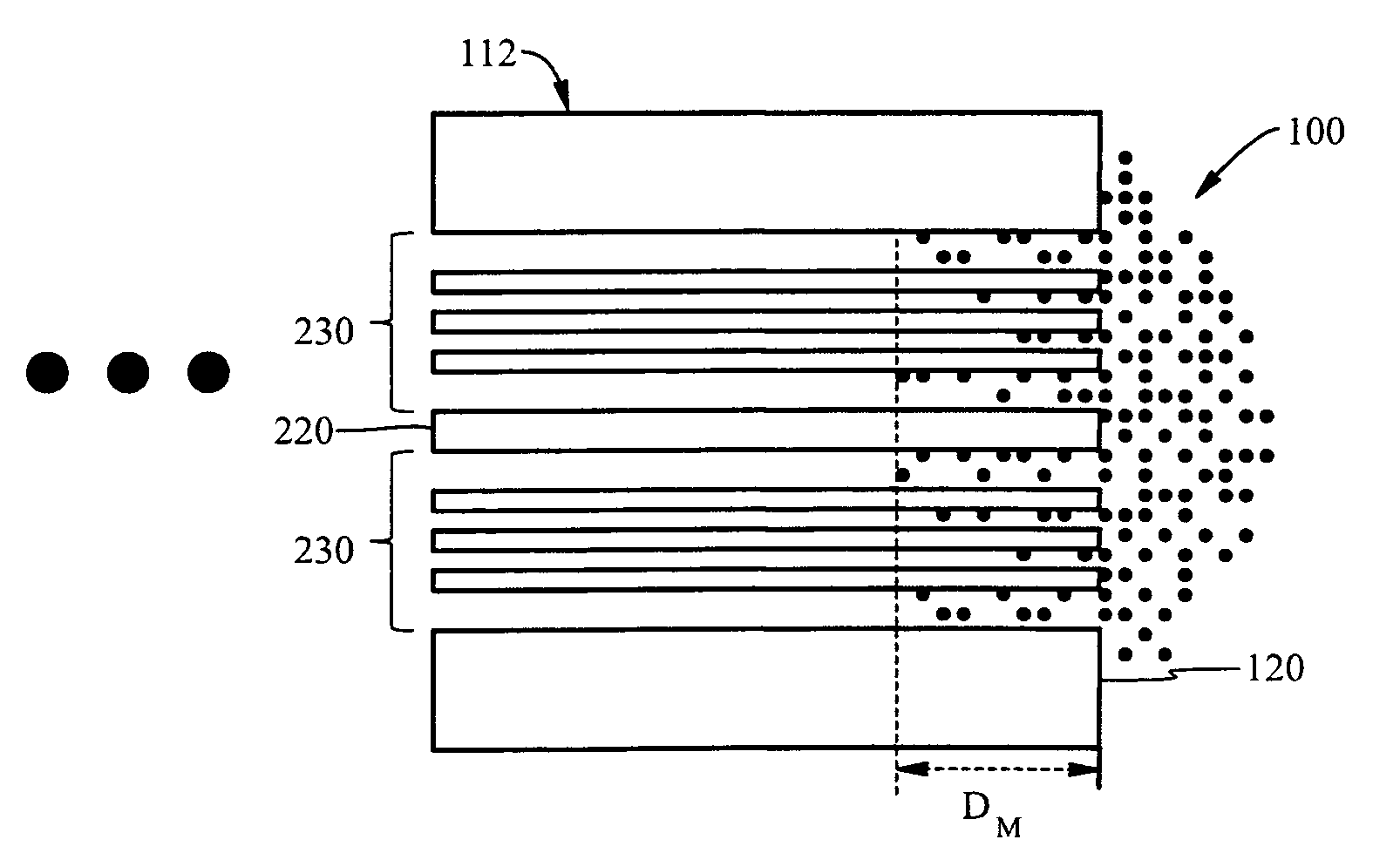

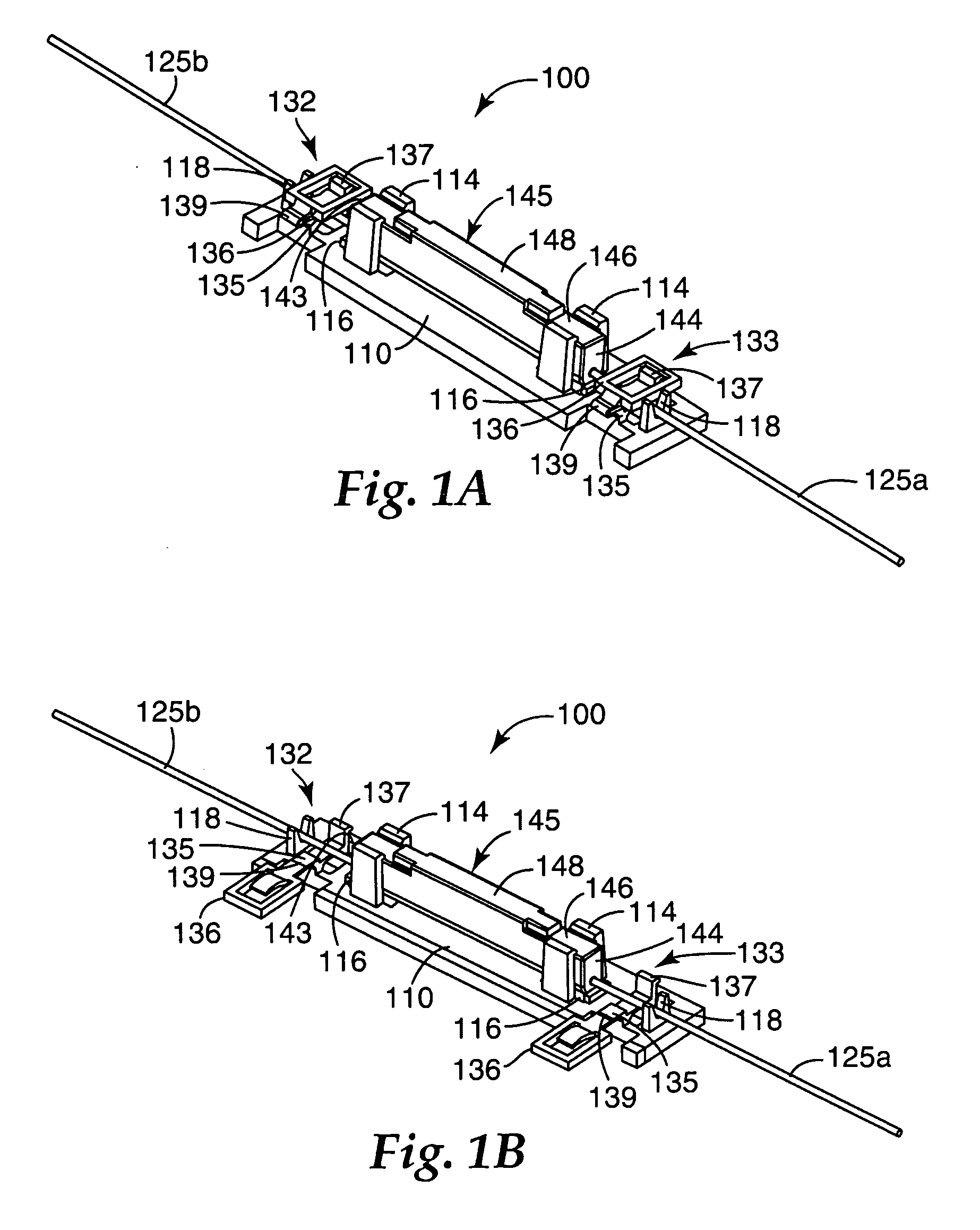

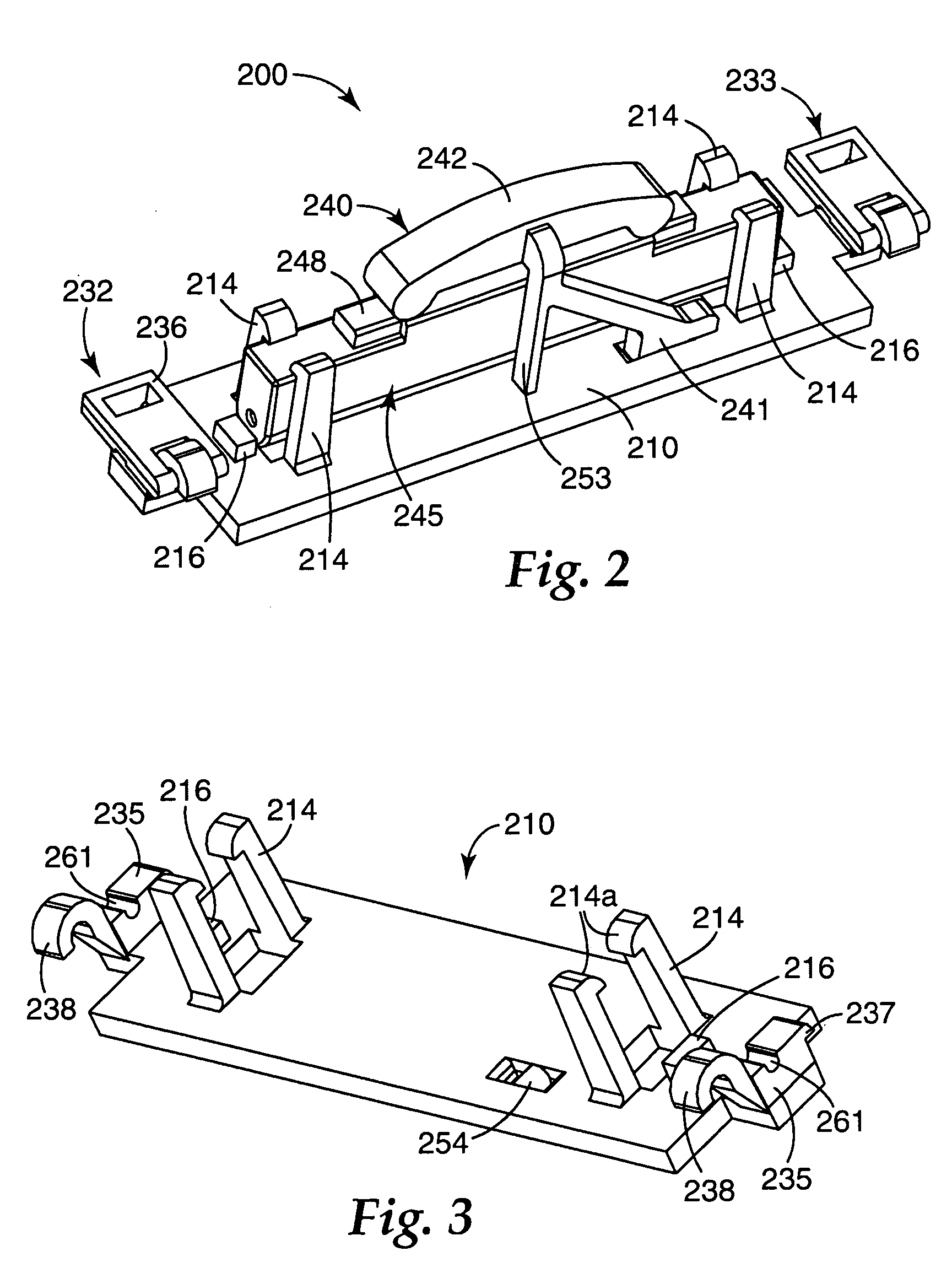

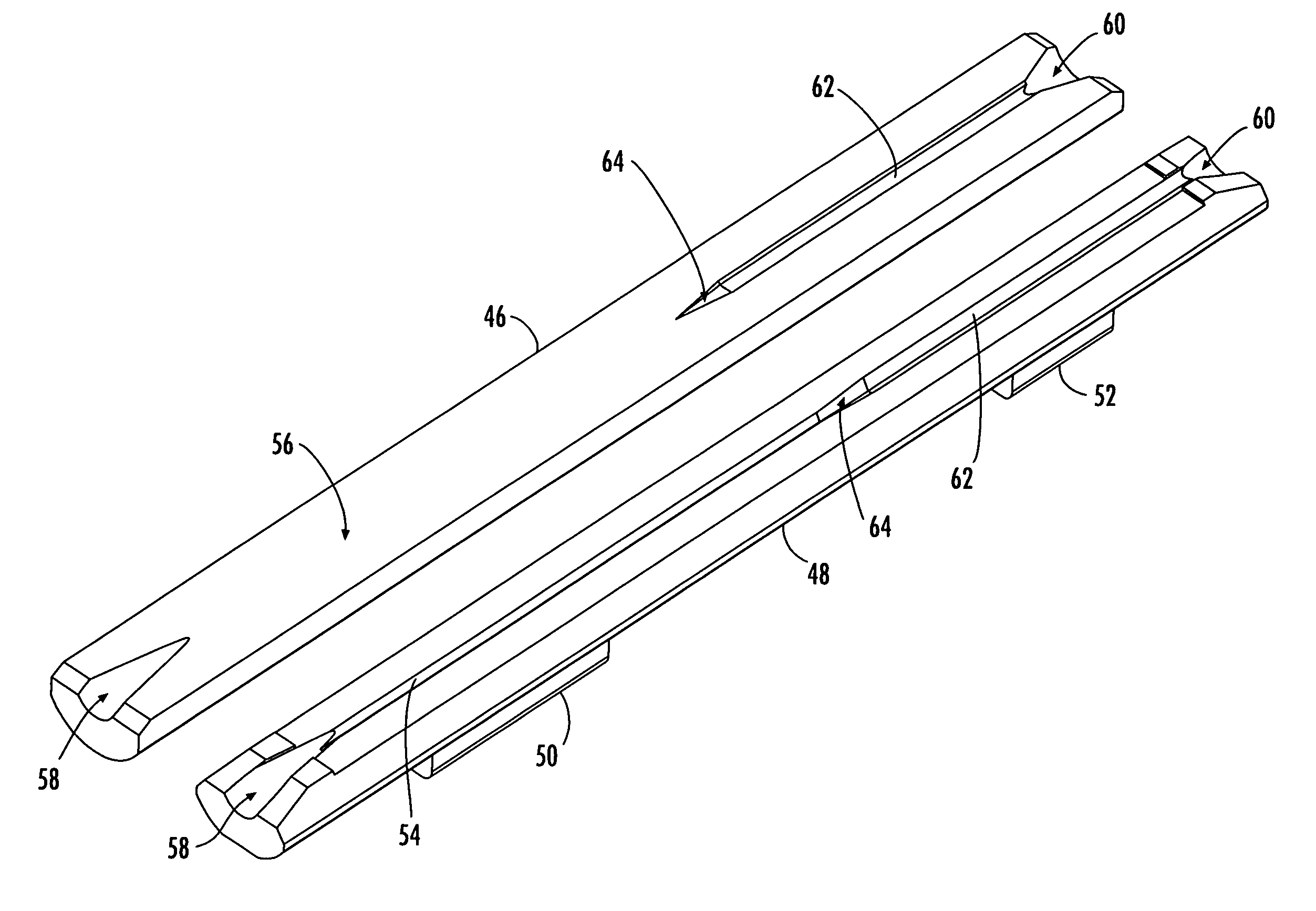

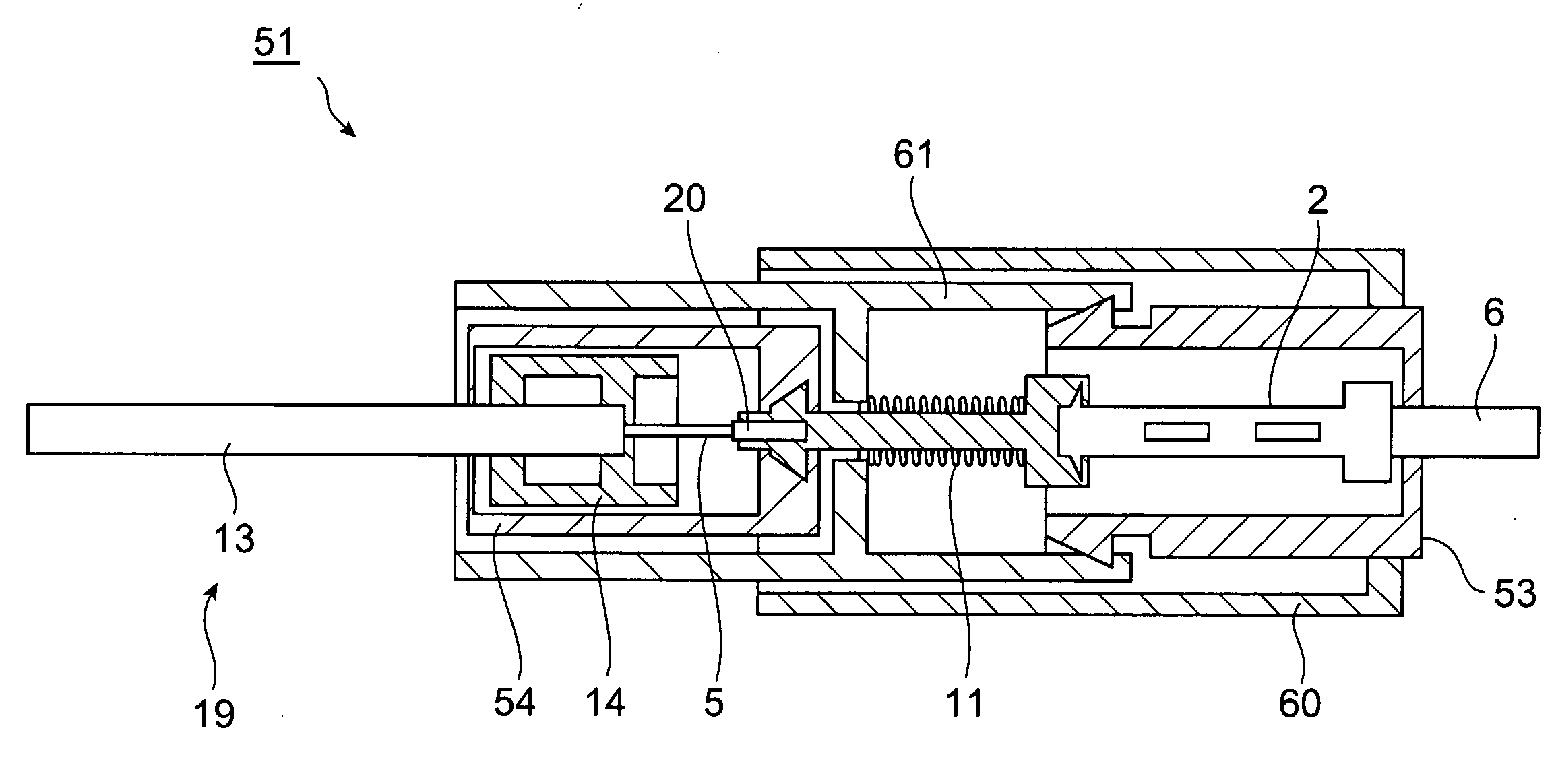

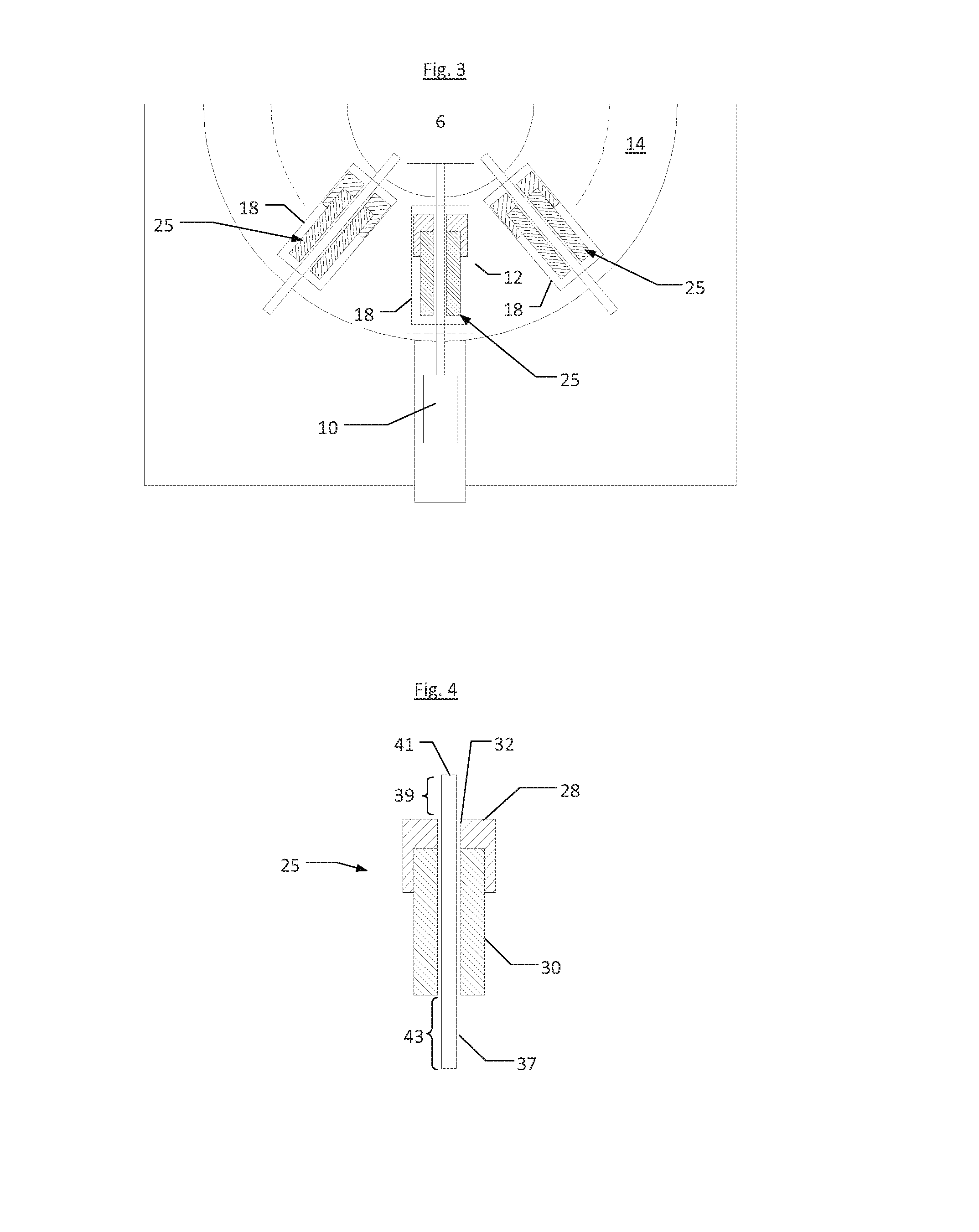

Dual function splice component for mechanical splice connector

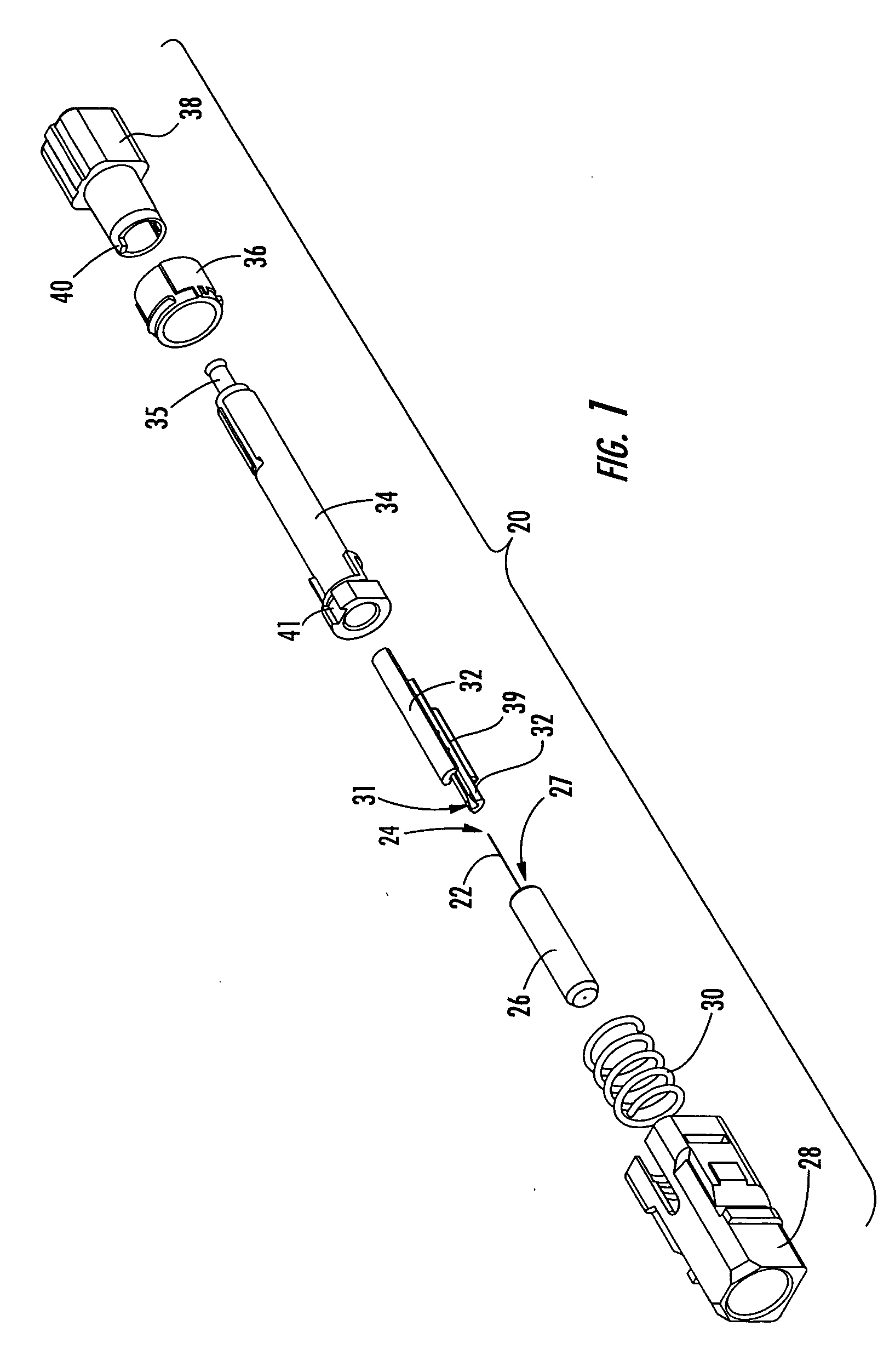

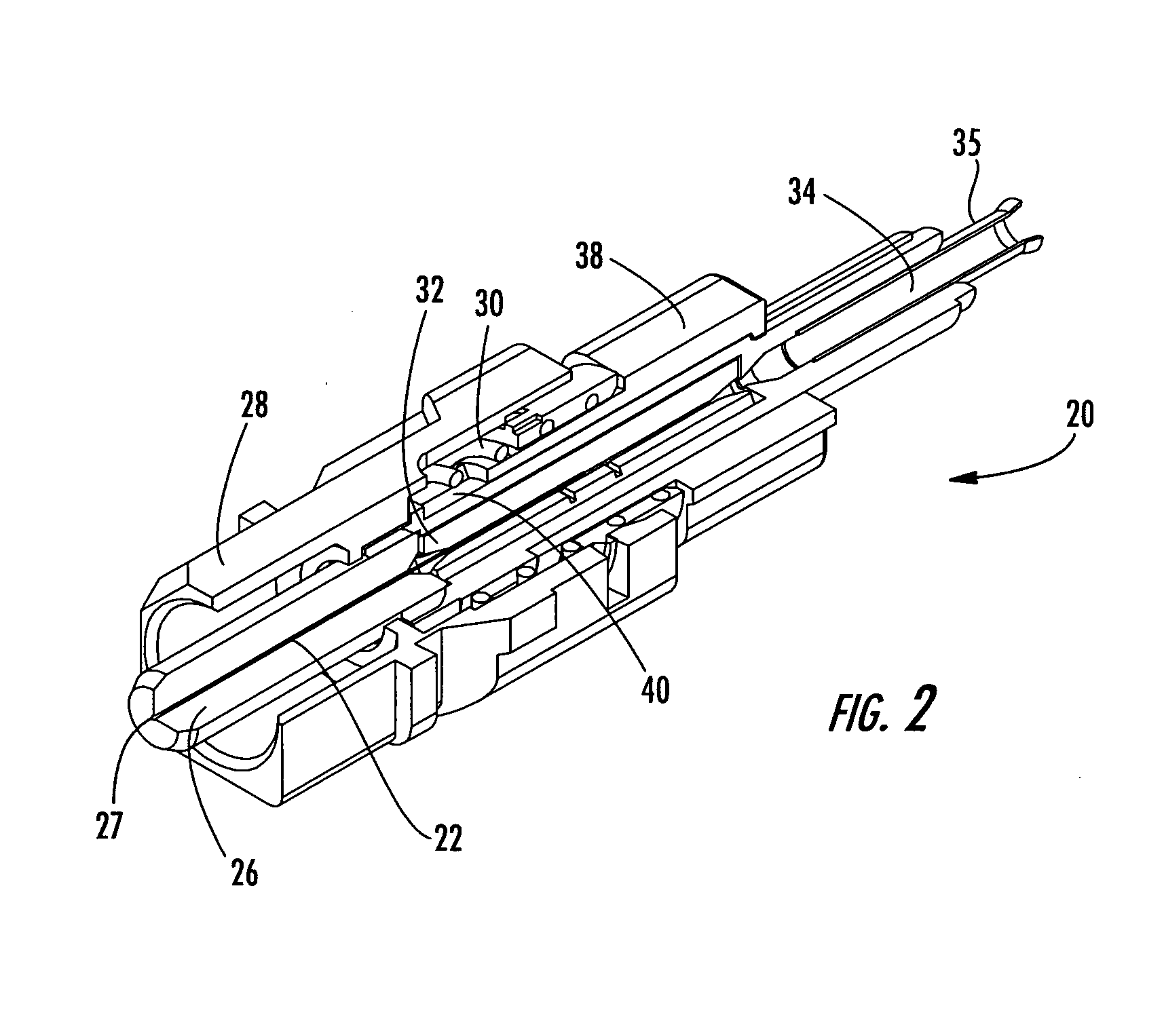

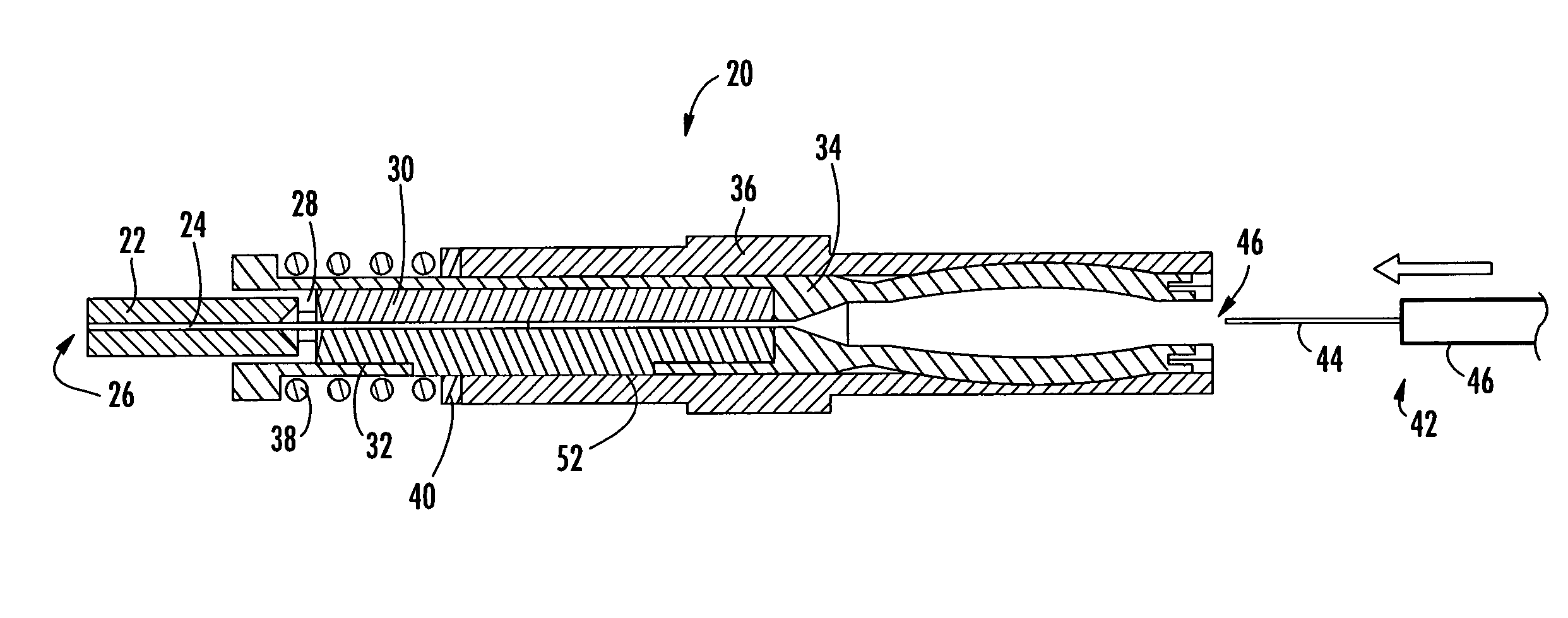

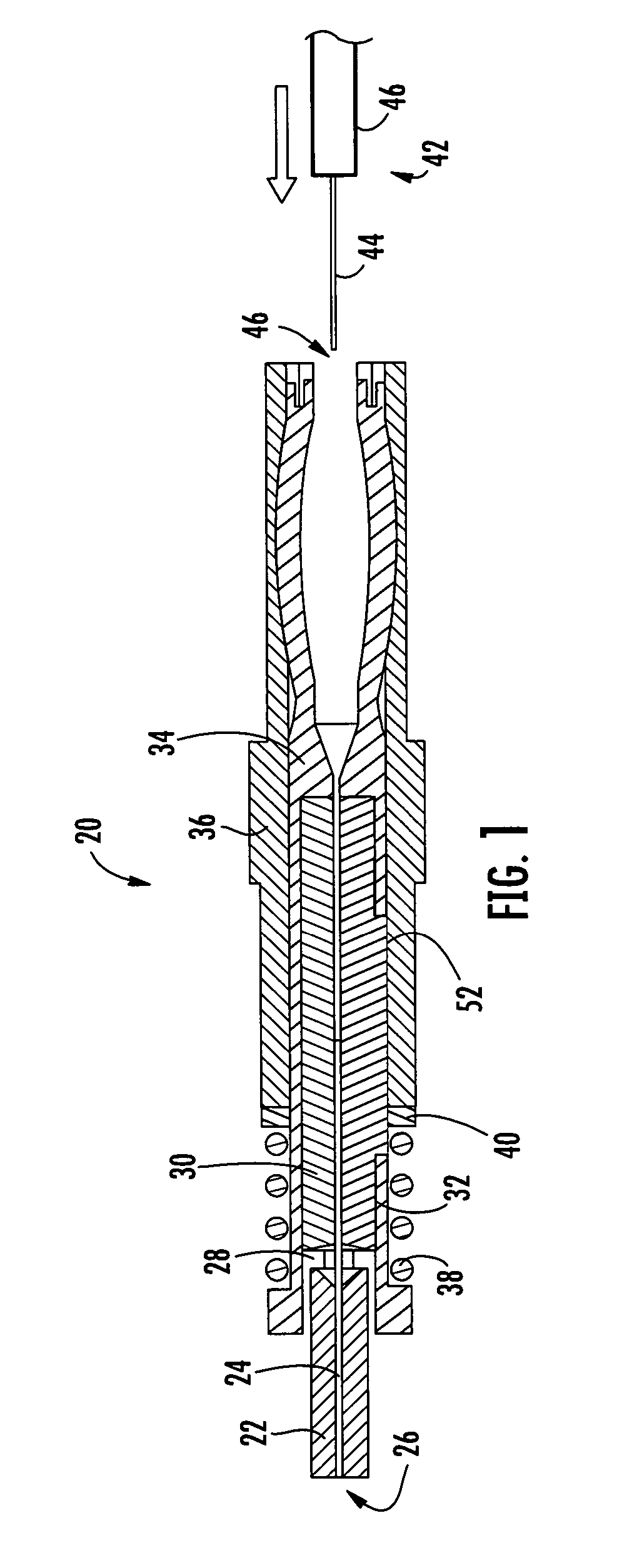

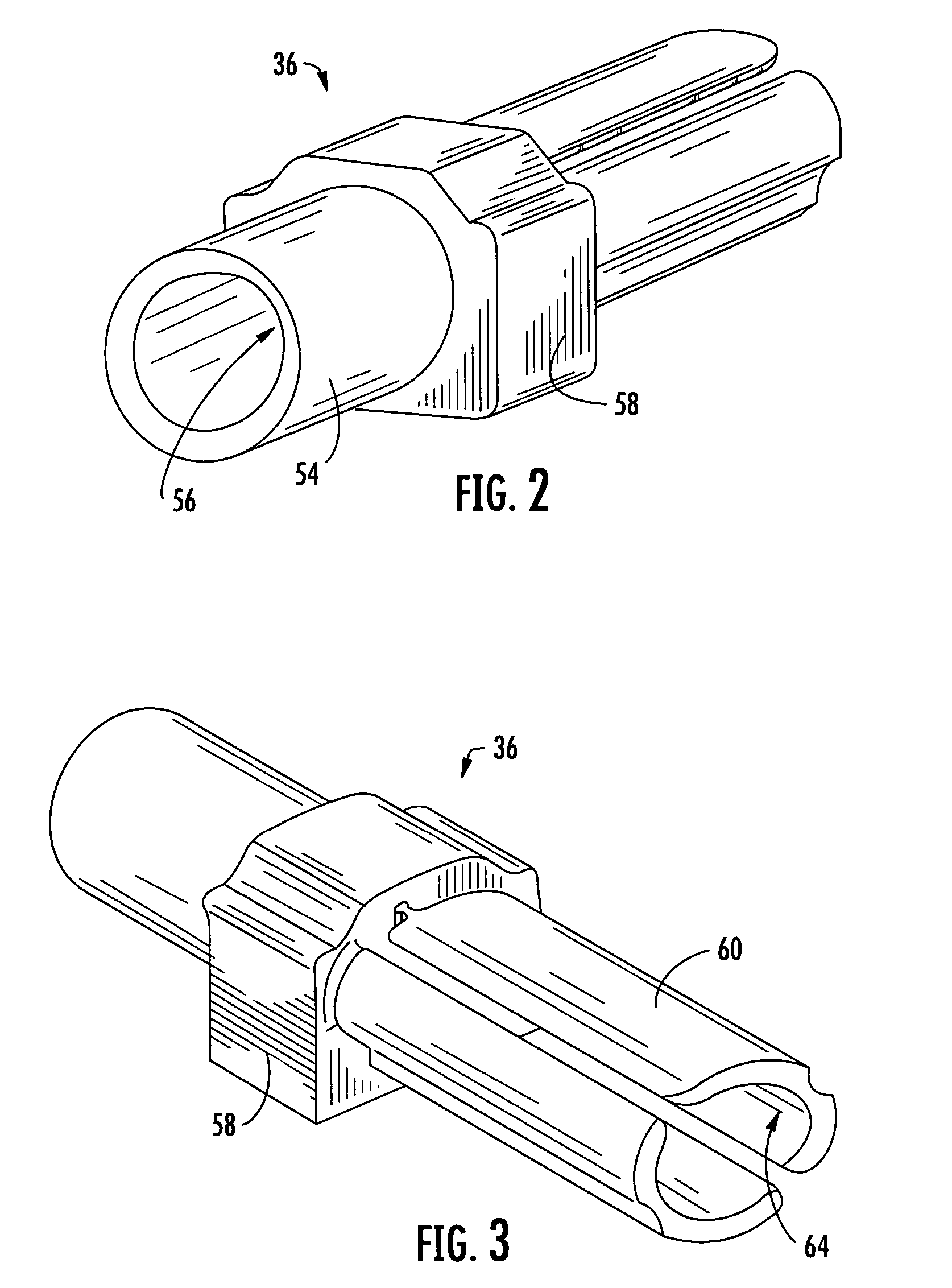

ActiveUS7264410B1Eliminate positioning effectsOptical strainCoupling light guidesFiberMechanical splice

A fiber optic mechanical splice connector including a single connector element operable for providing optical fiber alignment and strain relief includes opposed splice components that define first and second grooves for receiving the bare glass portions of mating optical fibers, as well as the coated or buffered portion of at least one of the optical fibers when the splice components are biased together by an actuator. The mating optical fibers are aligned while the coated or buffered portion of one of the optical fibers is retained within the same connector element, thus eliminating positioning problems that occur when separate connector elements are utilized for fiber alignment and strain relief. The splice components may be unbiased to allow removal of at least one of the mating optical fibers without destroying the connector assembly or potentially damaging the optical fibers.

Owner:CORNING OPTICAL COMM LLC

Index-matching gel for nanostructure optical fibers and mechanical splice assembly and connector using same

A polymer based index-matching gel for use with nanostructure optical fibers is disclosed. The index-matching gel has at least one polymer component having a viscosity η at 25° C. of 3 Pa-s≦η≦100 Pa-s, which prevents the index-matching gel from wicking into the voids and down the nanostructure optical fiber to a depth where the fiber performance and / or device performance is compromised. The gel is suitable for use when mechanically splicing optical fibers when at least one of the optical fibers is a nanostructure optical fiber. The gel is also suitable for use in fiber optic connectors wherein at least one of the optical fibers constituting the connection is a nanostructure optical fiber.

Owner:CORNING OPTICAL COMM LLC

Field-installable connector including stub optical fiber having laser shaped endface

ActiveUS20050094945A1Reduce eliminateGap minimizationCoupling light guidesGlass reforming apparatusFiberMechanical splice

A field-installable connector includes a connector housing and a ferrule having front and rear opposed faces and at least one fiber bore defined longitudinally therethrough. A laser processed stub optical fiber is disposed within the one fiber bore of the ferrule and extends a predetermined distance beyond the rear face of the ferrule. An alignment feature is operable for self-centering the stub optical fiber and a field optical fiber to perform a mechanical splice using a camming means. A method of laser processing a stub optical fiber includes rotating the stub optical fiber and sweeping a laser beam directed at a desired angle back and forth across a surface of the optical fiber. An oscillating motion of the laser is driven by an intermittent sinusoidal signal that results in two deposits of energy onto the stub optical fiber followed by a cooling period before subsequent deposits of energy occur.

Owner:CORNING OPTICAL COMM LLC

Optical fiber mechanical splice connector

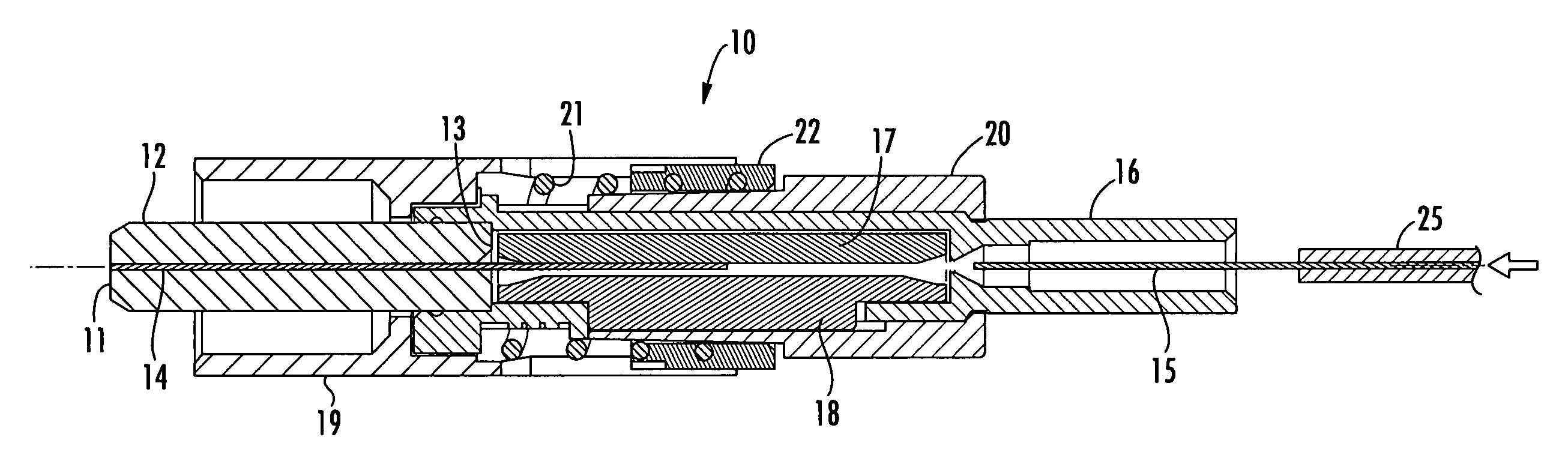

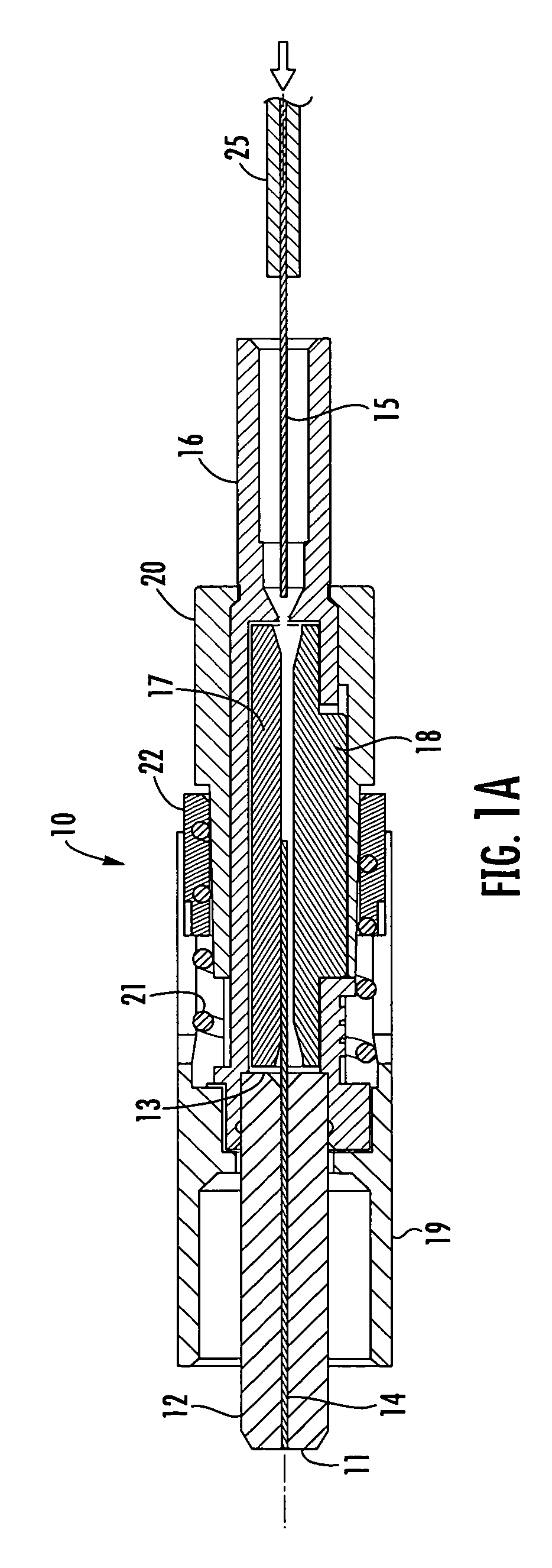

ActiveUS20080019646A1Robust and reliable connectorPrecise alignmentCoupling light guidesFiberMechanical splice

An optical fiber mechanical splice connector including a connector body having a fiber alignment mechanism and a cavity, and a ferrule including a stub fiber, wherein an end of the stub fiber extends from the ferrule through the cavity of the connector body and into the fiber alignment mechanism, and wherein the stub fiber buckles within the cavity when a field fiber is introduced into the connector body and contacts the distal end of the stub fiber. A mechanical splicing method including inserting a field fiber into a splice connector such that an end of the field fiber contacts an end of the stub fiber within an alignment mechanism of the splice connector, and applying axial force to the field fiber so as to cause the stub fiber to buckle within a cavity defined by the splice connector.

Owner:CORNING OPTICAL COMM LLC

Index-matching gel for nanostructure optical fibers and mechanical splice assembly and connector using same

A polymer based index-matching gel for use with nanostructure optical fibers is disclosed. The index-matching gel has a viscosity η at 25° C. of 3 Pa-s≦η≦100 Pa-s, which prevents the index-matching gel from wicking into the voids and down the nanostructure optical fiber to a depth where the fiber performance and / or device performance is compromised. The gel is suitable for use when mechanically splicing optical fibers when at least one of the optical fibers is a nanostructure optical fiber. The gel is also suitable for use in fiber optic connectors wherein at least one of the optical fibers constituting the connection is a nanostructure optical fiber.

Owner:CORNING OPTICAL COMM LLC

Index-matching gel for nanostructure optical fibers and mechanical splice assembly and connector using same

A polymer based index-matching gel for use with nanostructure optical fibers is disclosed. The index-matching gel has at least one polymer component having a viscosity η at 25° C. of 3 Pa-s≦η≦100 Pa-s, which prevents the index-matching gel from wicking into the voids and down the nanostructure optical fiber to a depth where the fiber performance and / or device performance is compromised. The gel is suitable for use when mechanically splicing optical fibers when at least one of the optical fibers is a nanostructure optical fiber. The gel is also suitable for use in fiber optic connectors wherein at least one of the optical fibers constituting the connection is a nanostructure optical fiber.

Owner:CORNING OPTICAL COMM LLC

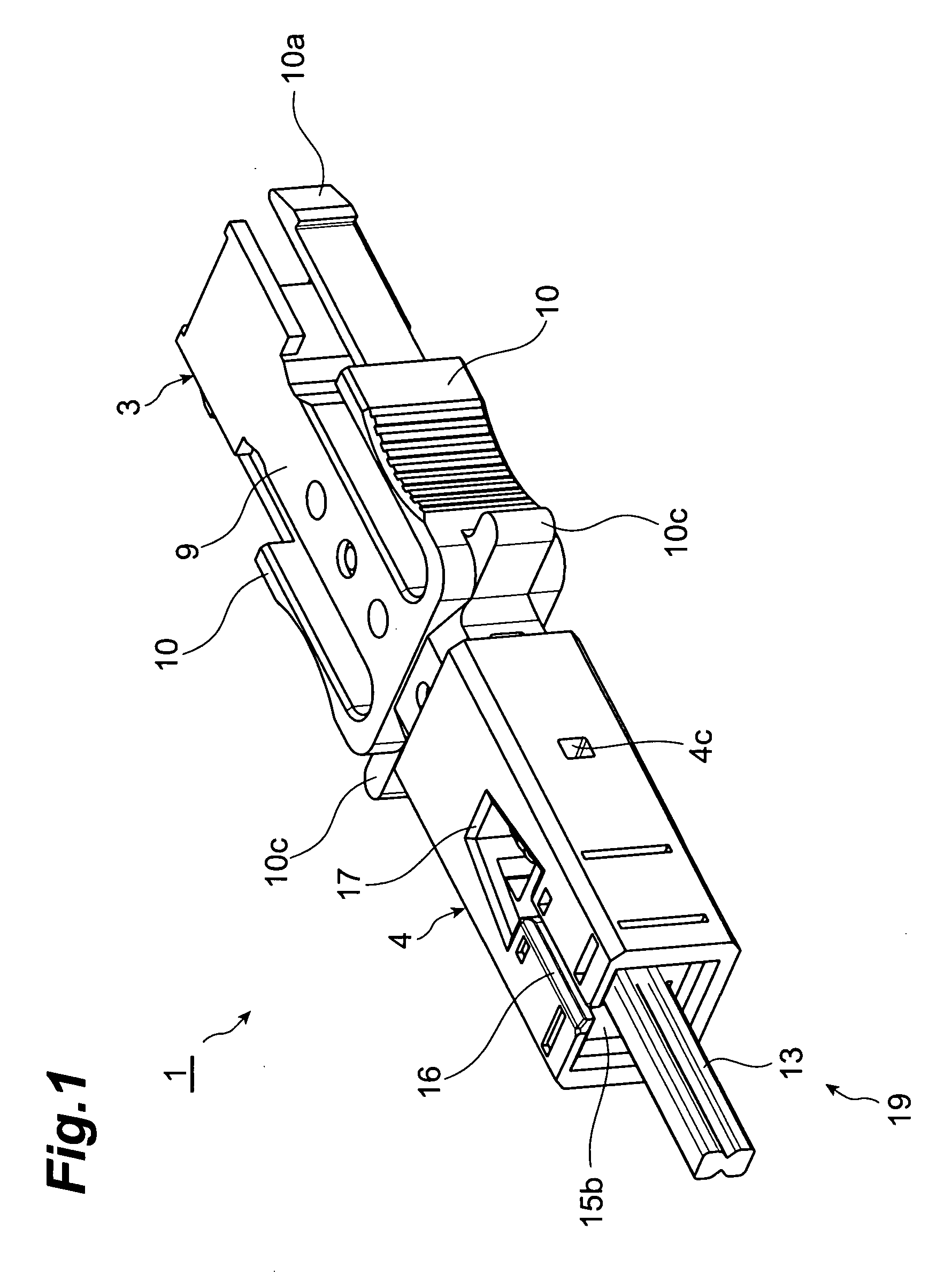

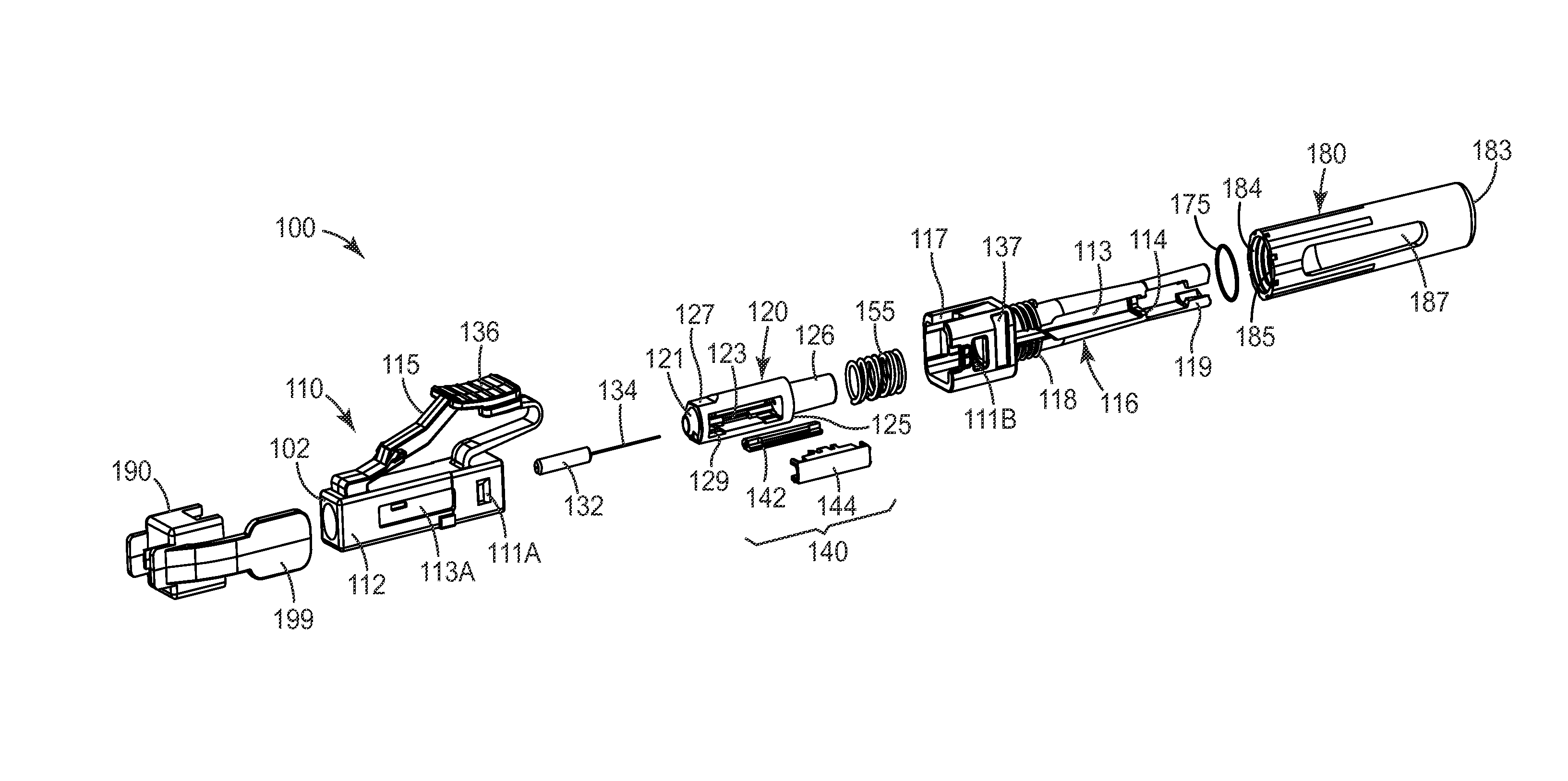

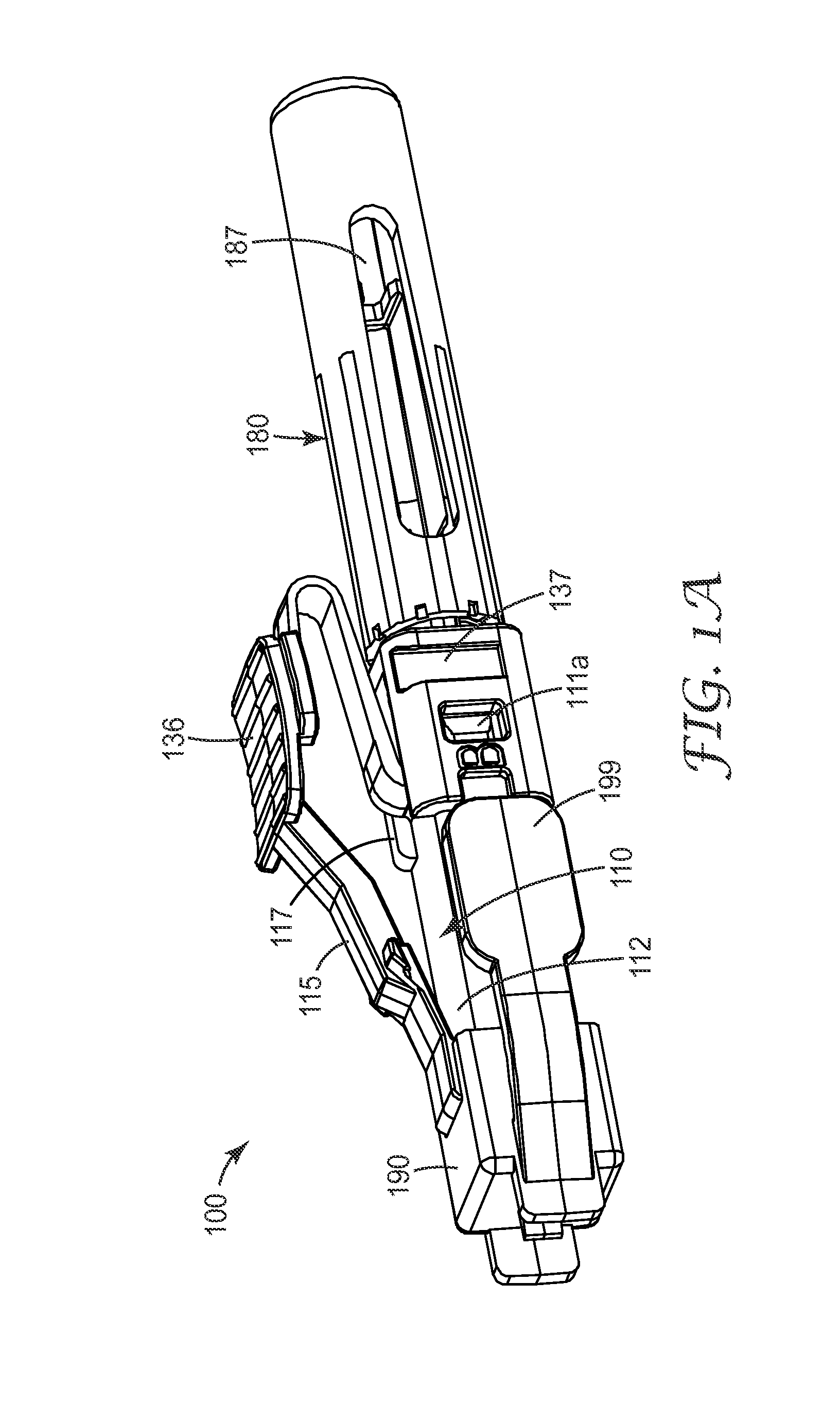

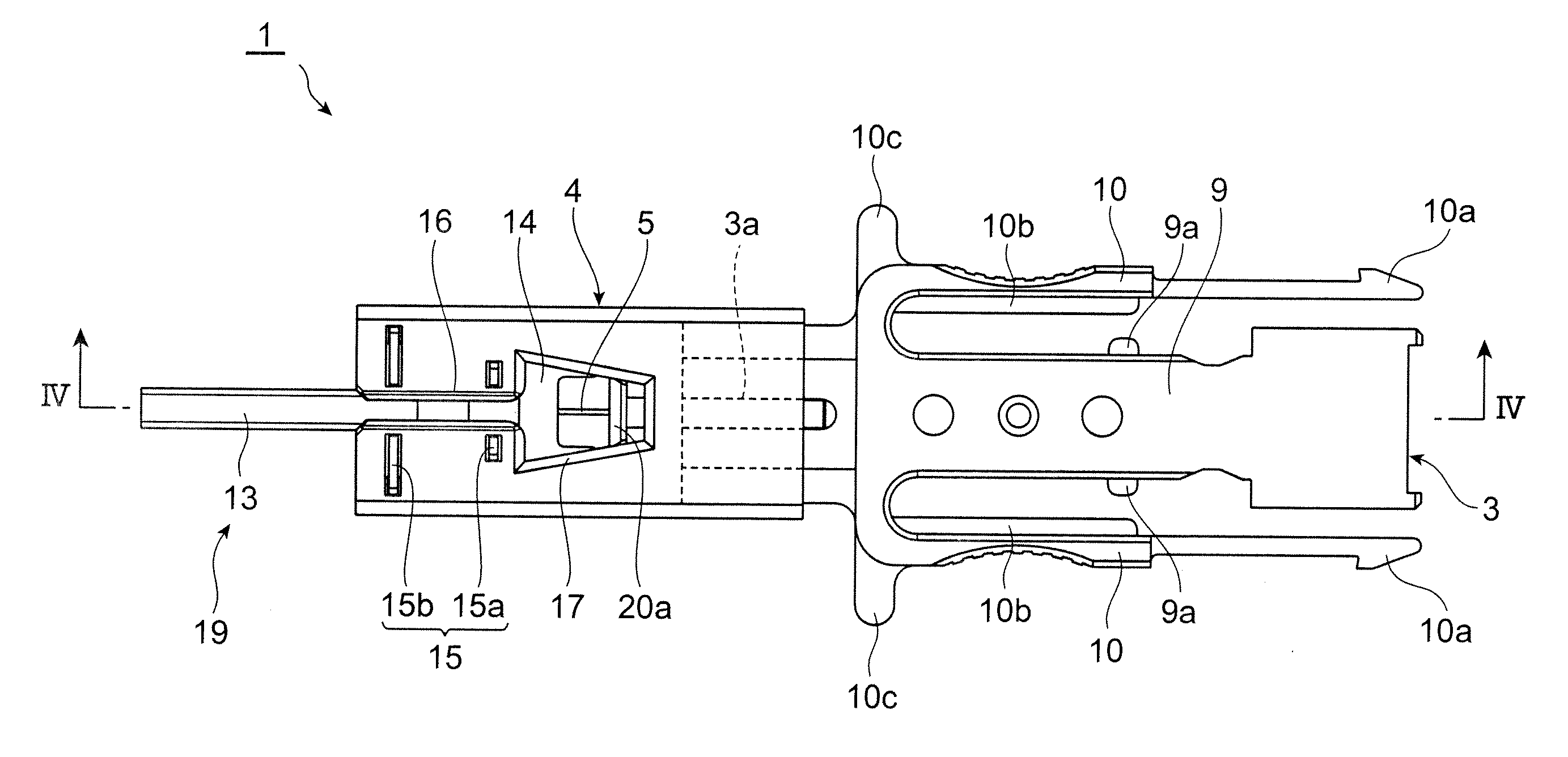

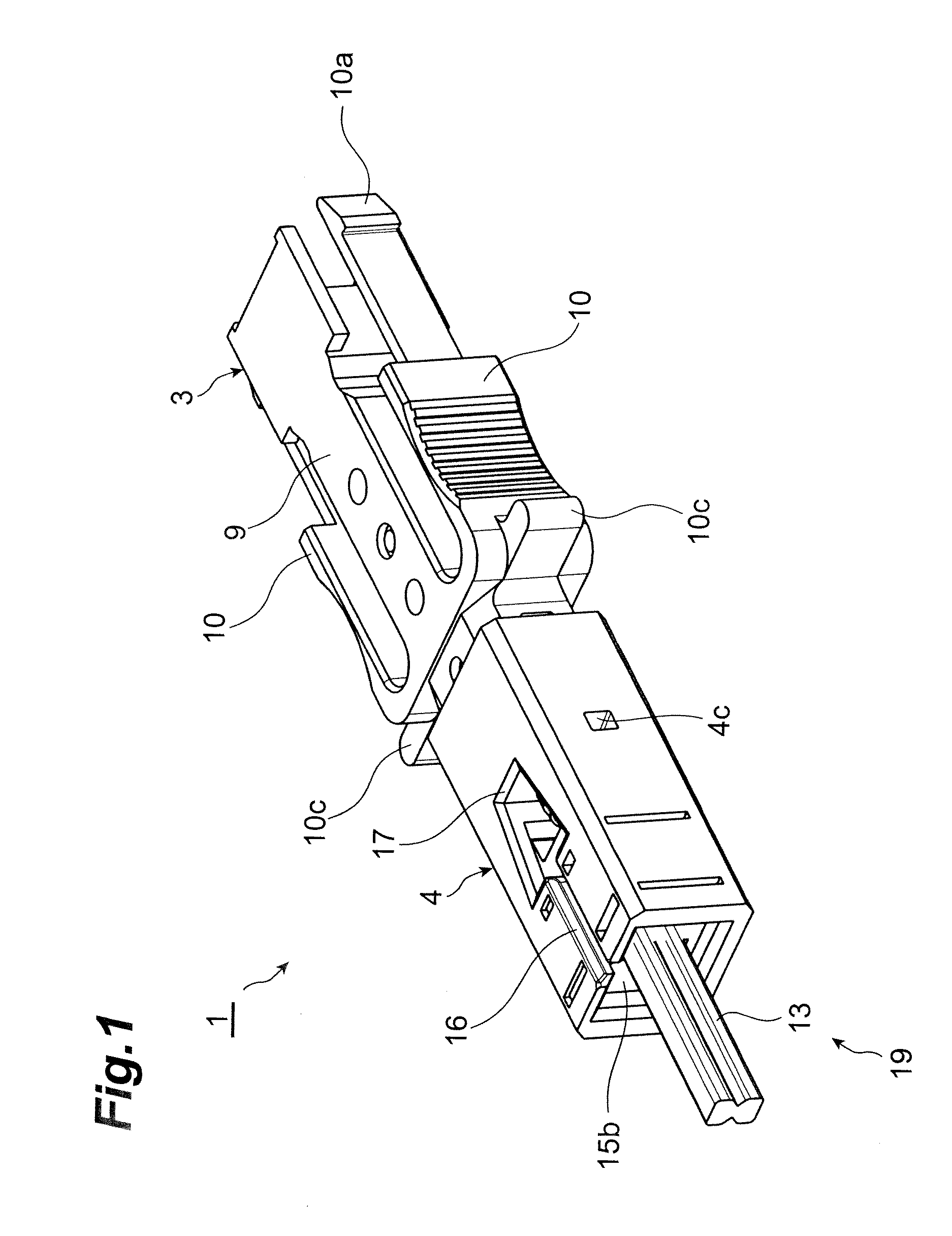

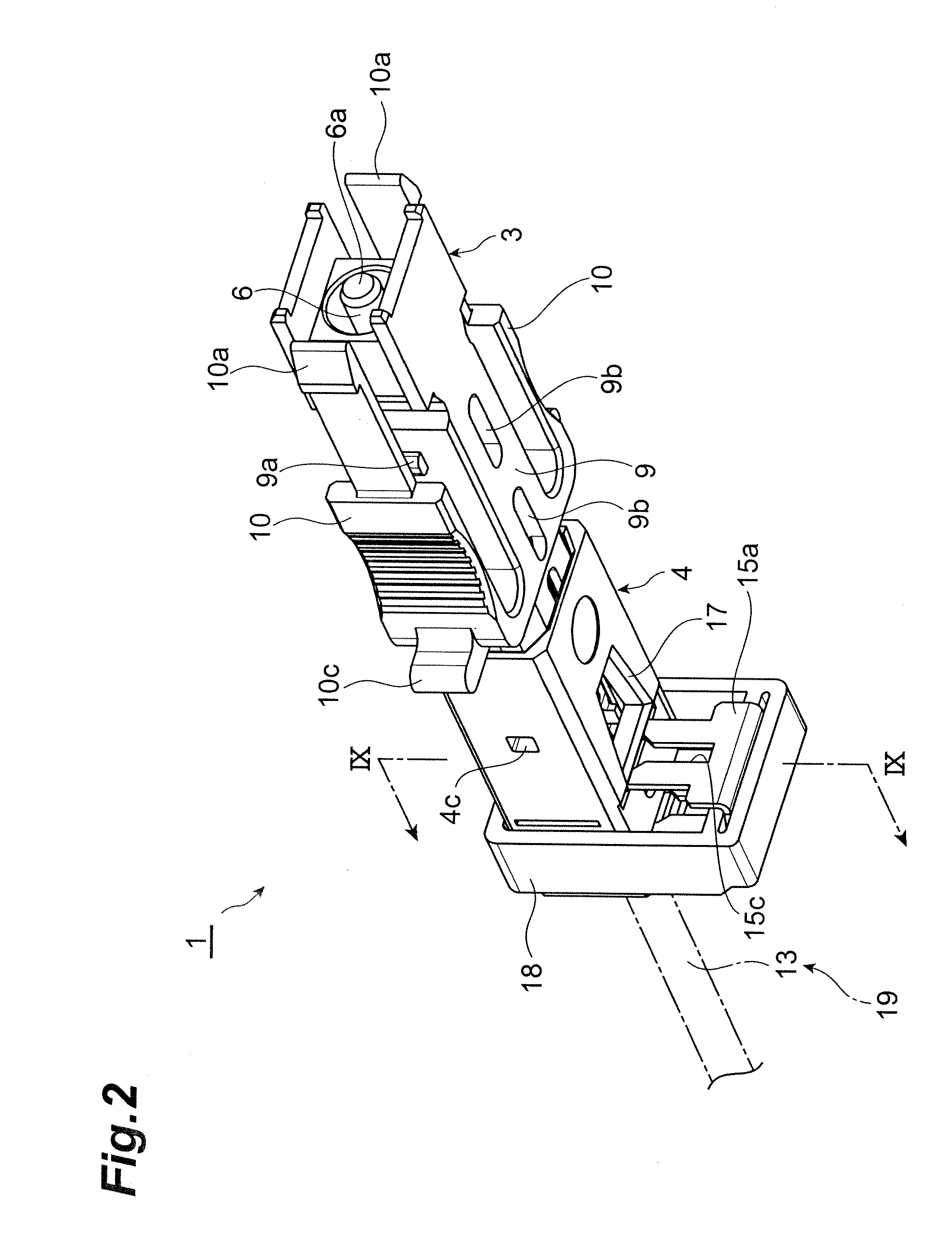

Optical Connector, and Method of Assembling Optical Connector

ActiveUS20080107381A1Improve protectionImprove workabilityCoupling light guidesFibre mechanical structuresFiberMechanical splice

An optical connector according to an embodiment of the present invention comprises (a) a ferrule incorporating a short fiber; (b) a mechanical splice having a holding part and a fixing part, and adapted so that the fixing part mechanically fixes the short fiber extending from the ferrule held by the holding part, and an optical fiber in an optical cable to butt the short fiber; (c) an outer housing having a housing part in which the mechanical splice is located, and a pair of flexible arms located on both sides of the housing part, the pair of arms each being provided with a locking claw at a tip; and (d) a jacket fixture for fixing a cable jacket, the jacket fixture being coupled to the mechanical splice so that the cable jacket is inserted therein.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

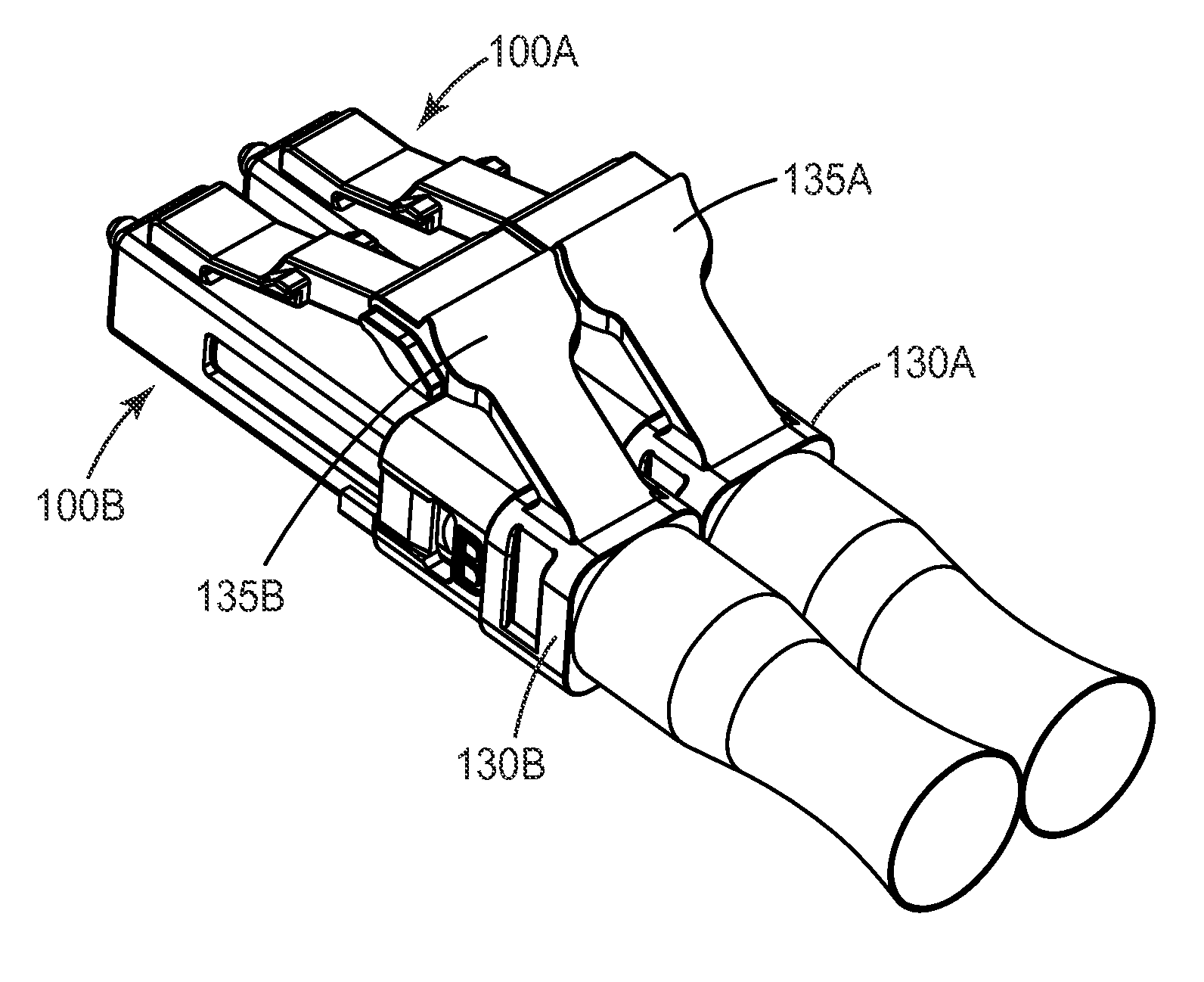

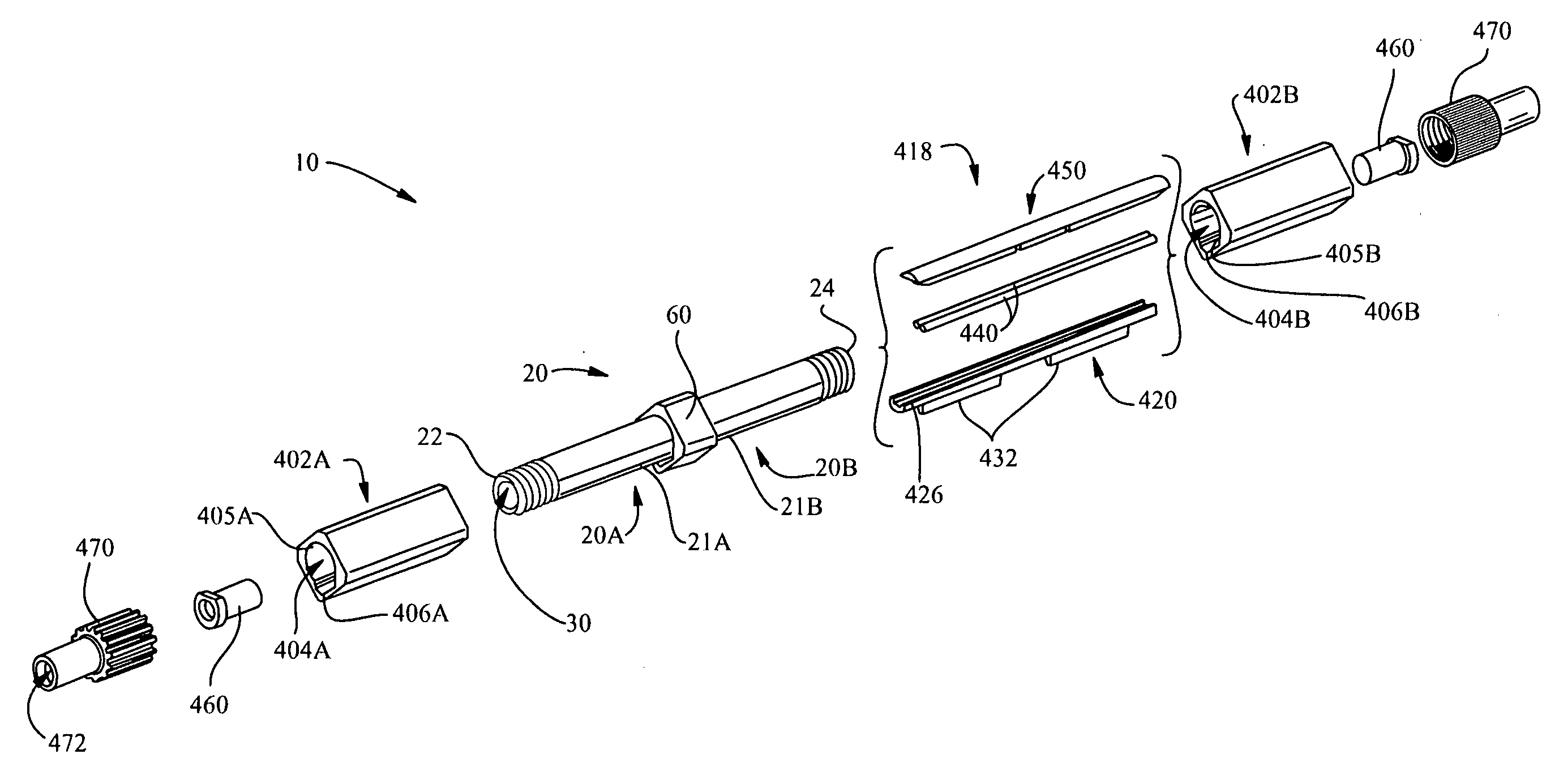

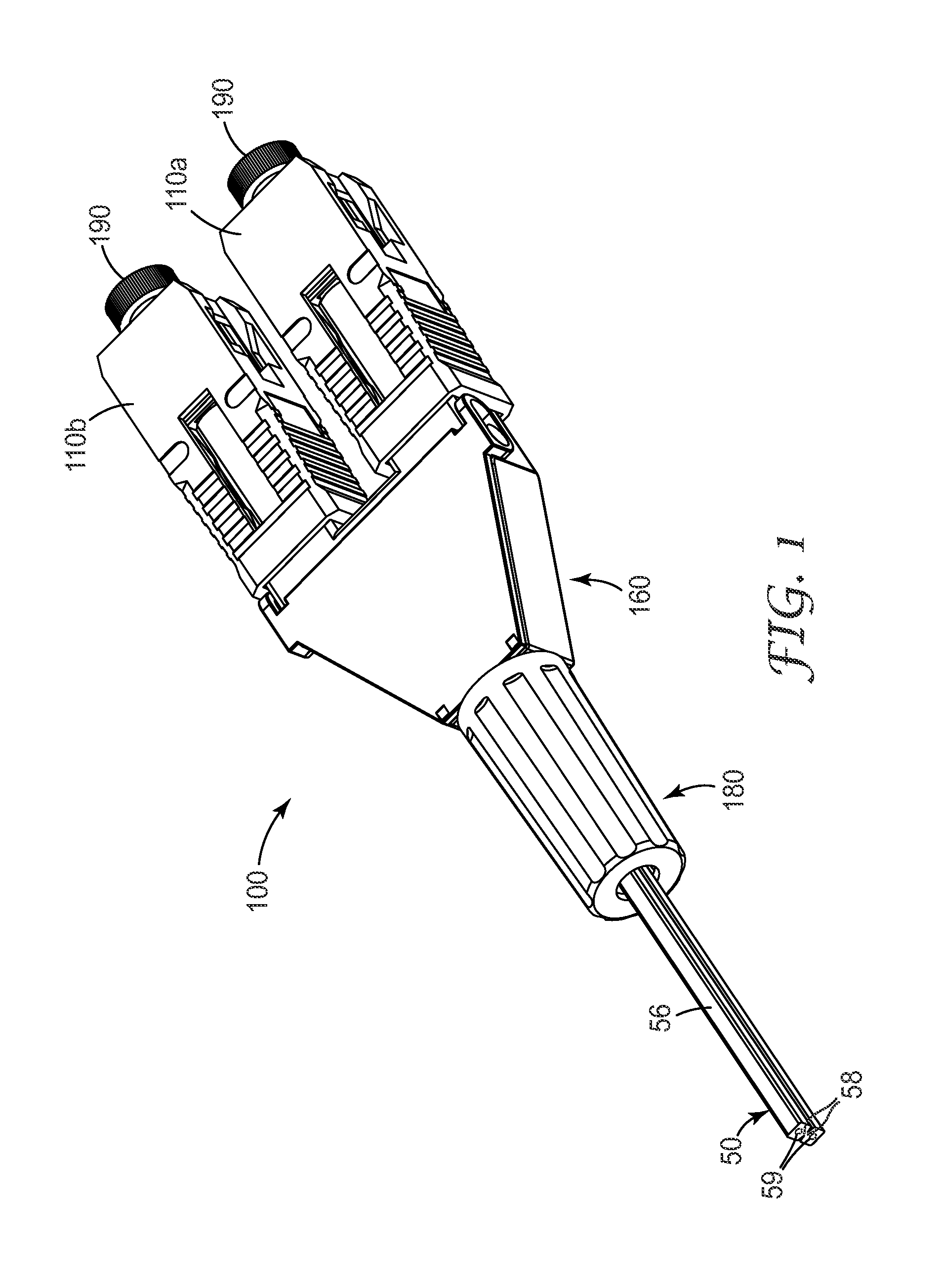

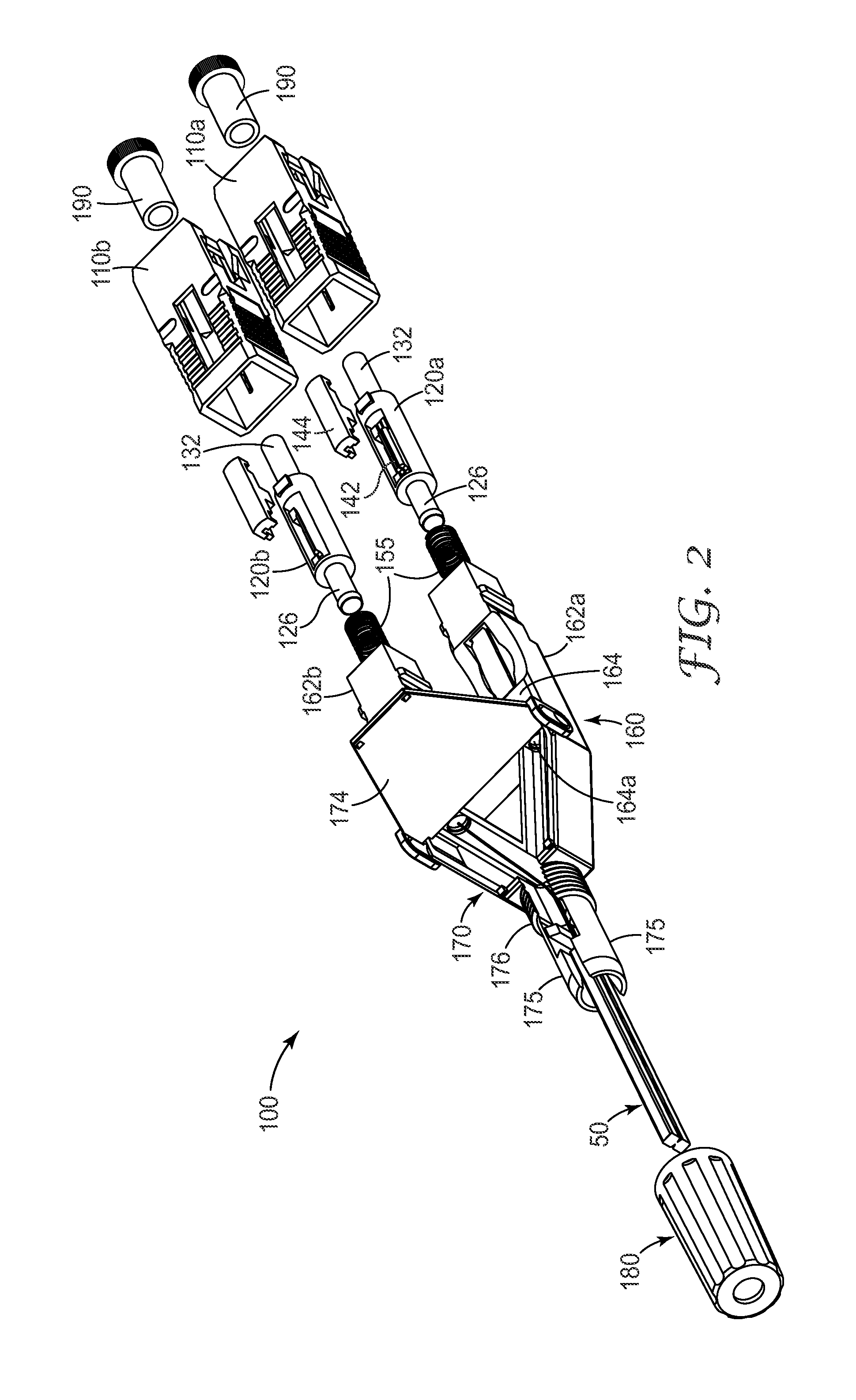

Field mountable duplex optical fiber connector with mechanical splice elements

A field mountable fiber optic connector for terminating a dual optical fiber cable is provided. The fiber optic connector includes a bifurcated housing having first and second spaced apart, parallel backbone portions extending from a cable furcation unit, first and second collar bodies respectively disposed in the first and second backbone portions, and first and second outer housings respectively disposed over the first and second backbone portions and wherein the first and second outer housings are configured to be mateable with two adjacent receptacles. The cable furcation unit comprises a threaded receiving portion and a fiber jacket clamping portion to clamp a cable jacket of the dual optical fiber cable. The fiber optic connector further includes a boot attachable to the threaded receiving portion of the cable furcation unit, wherein the boot actuates the fiber jacket clamping portion of the cable furcation unit upon attachment to the threaded receiving portion.

Owner:3M INNOVATIVE PROPERTIES CO

Optical fiber mechanical splice connector

ActiveUS7572064B2Robust and reliable connectorPrecise alignmentCoupling light guidesFiberMechanical splice

An optical fiber mechanical splice connector including a connector body having a fiber alignment mechanism and a cavity, and a ferrule including a stub fiber, wherein an end of the stub fiber extends from the ferrule through the cavity of the connector body and into the fiber alignment mechanism, and wherein the stub fiber buckles within the cavity when a field fiber is introduced into the connector body and contacts the distal end of the stub fiber. A mechanical splicing method including inserting a field fiber into a splice connector such that an end of the field fiber contacts an end of the stub fiber within an alignment mechanism of the splice connector, and applying axial force to the field fiber so as to cause the stub fiber to buckle within a cavity defined by the splice connector.

Owner:CORNING OPTICAL COMM LLC

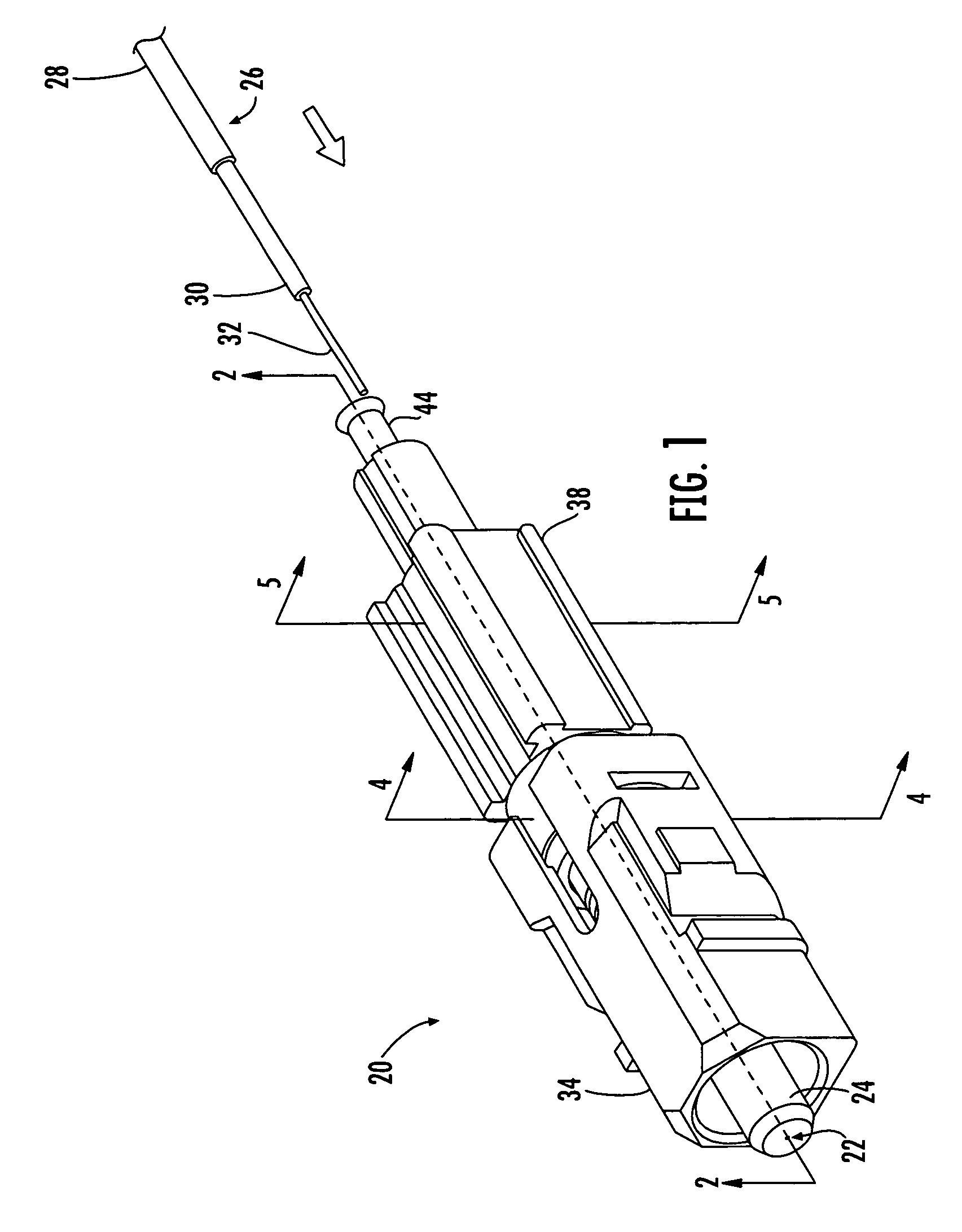

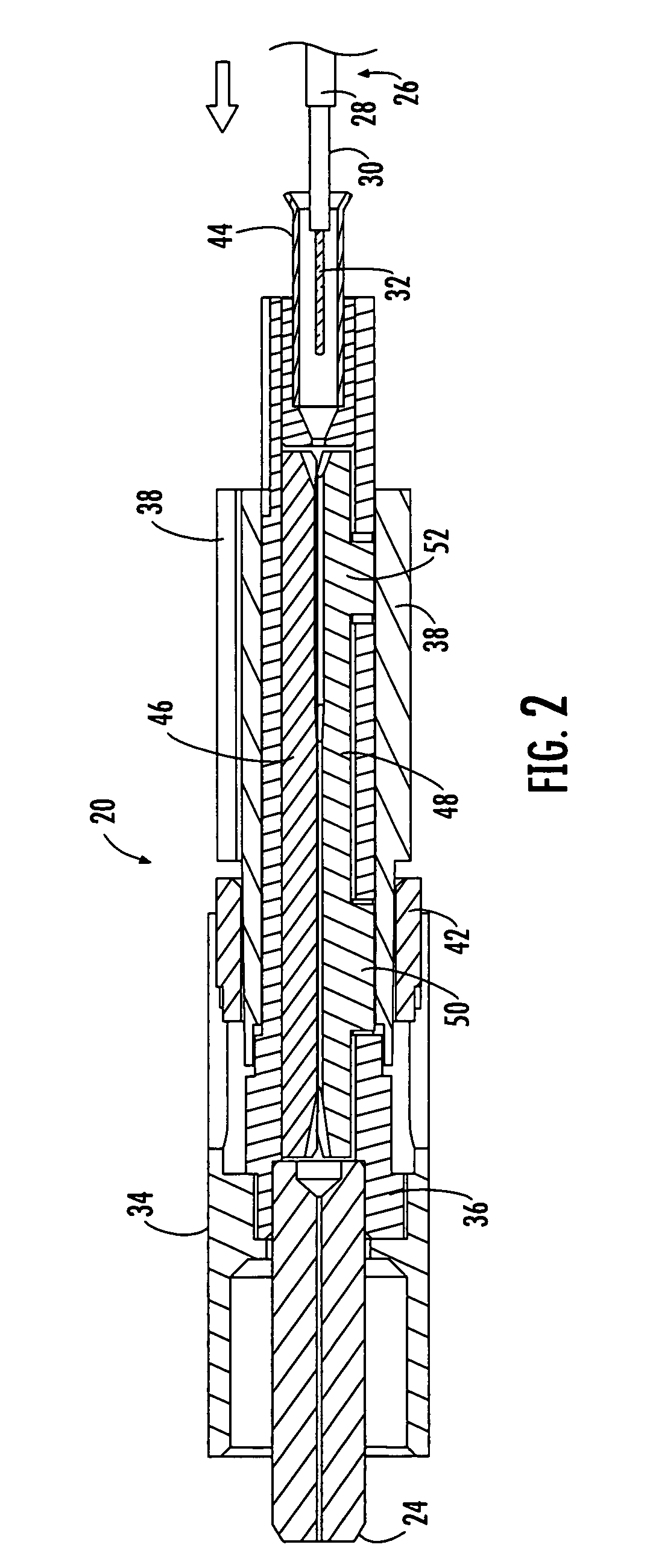

Mechanical splice connector with sequential splice and strain relief

A mechanical splice connector is shown and described for sequentially performing a splice actuation followed by a strain relief actuation by rotating a single, multiple-position cam member or multiple cam members from an unactuated position to a first actuated position and a second actuated position. The mechanical splice connector aligns and retains at least one stub optical fiber and the bare glass portion of at least one adjoining field optical fiber, as well as strain relieving a coated portion of the field optical fiber, or alternatively, a buffered portion of the field optical fiber. A method is also described for sequentially performing a splice actuation followed by a strain relief actuation, wherein the splice actuation is reversible prior to performing the strain relief actuation in the event that the optical continuity of the splice coupling is unacceptable, thereby avoiding potential damage to the field optical fiber or the connector.

Owner:CORNING OPTICAL COMM LLC

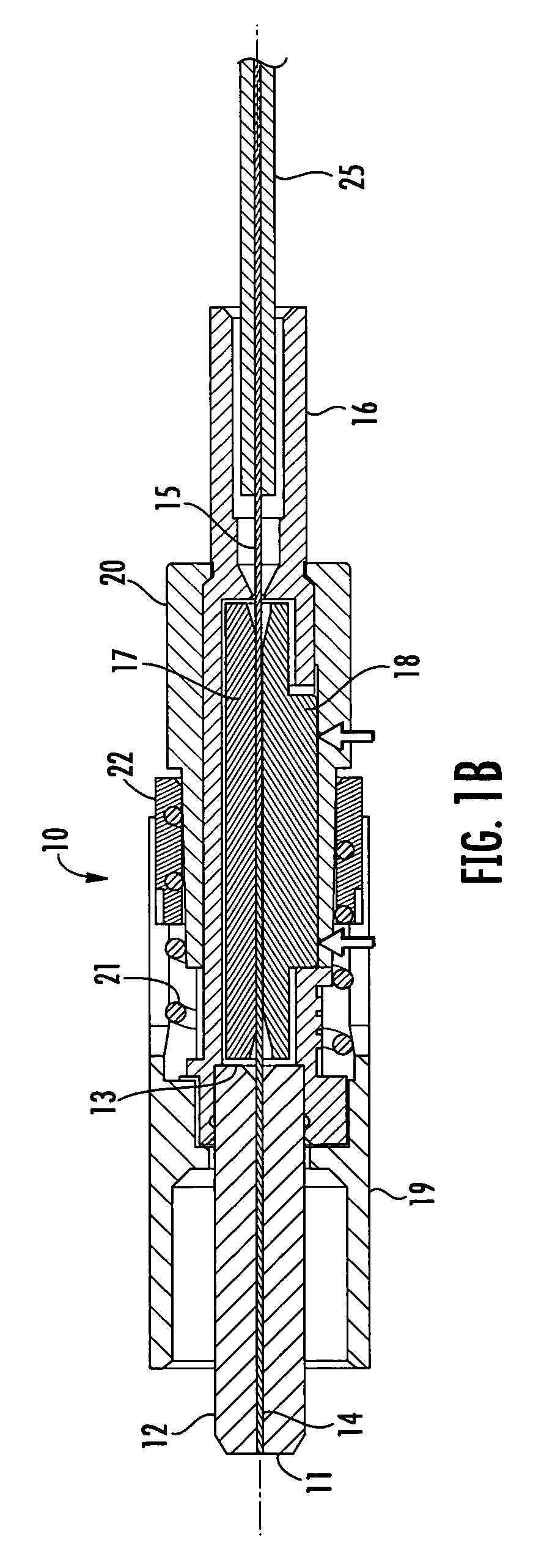

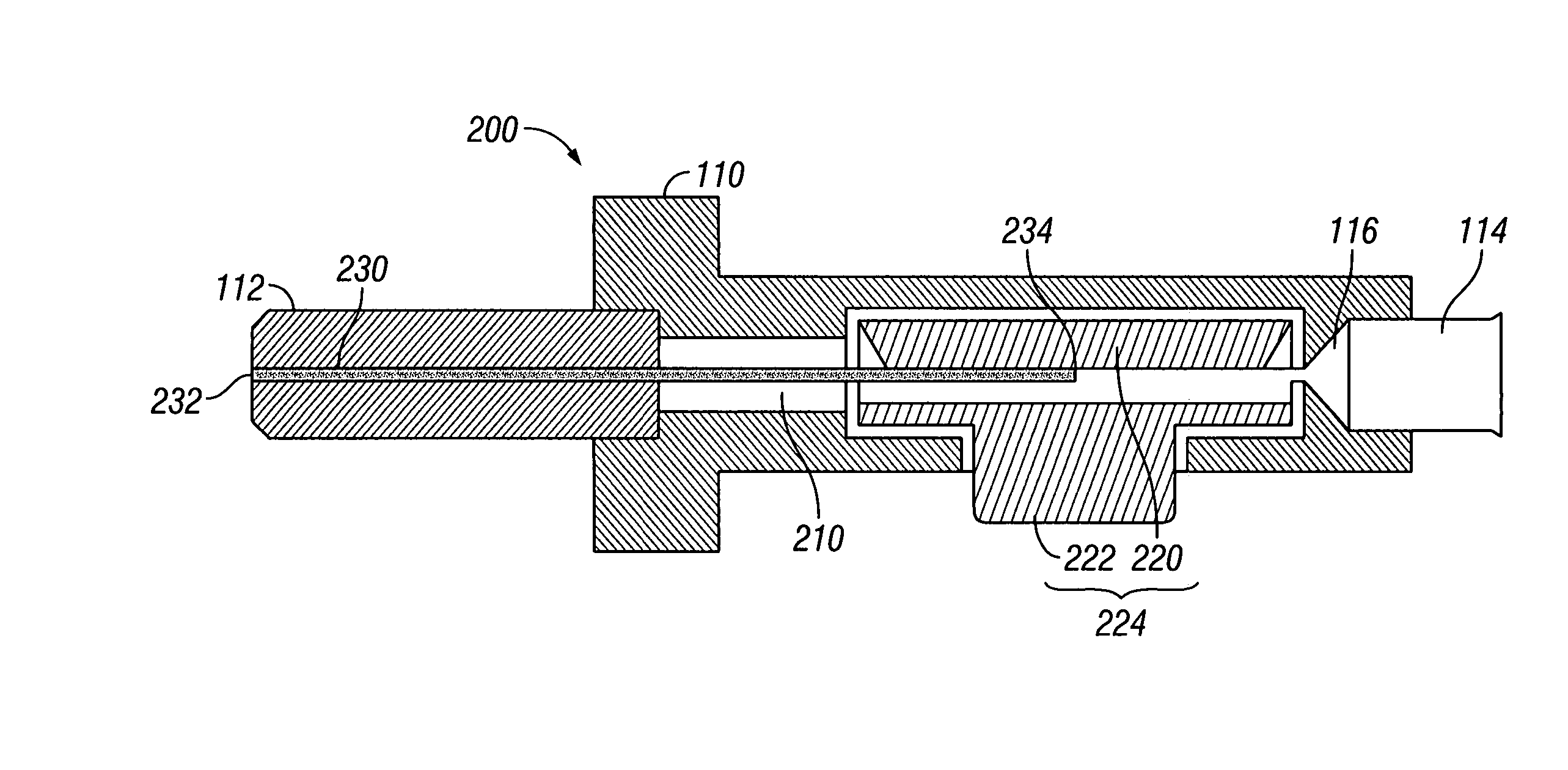

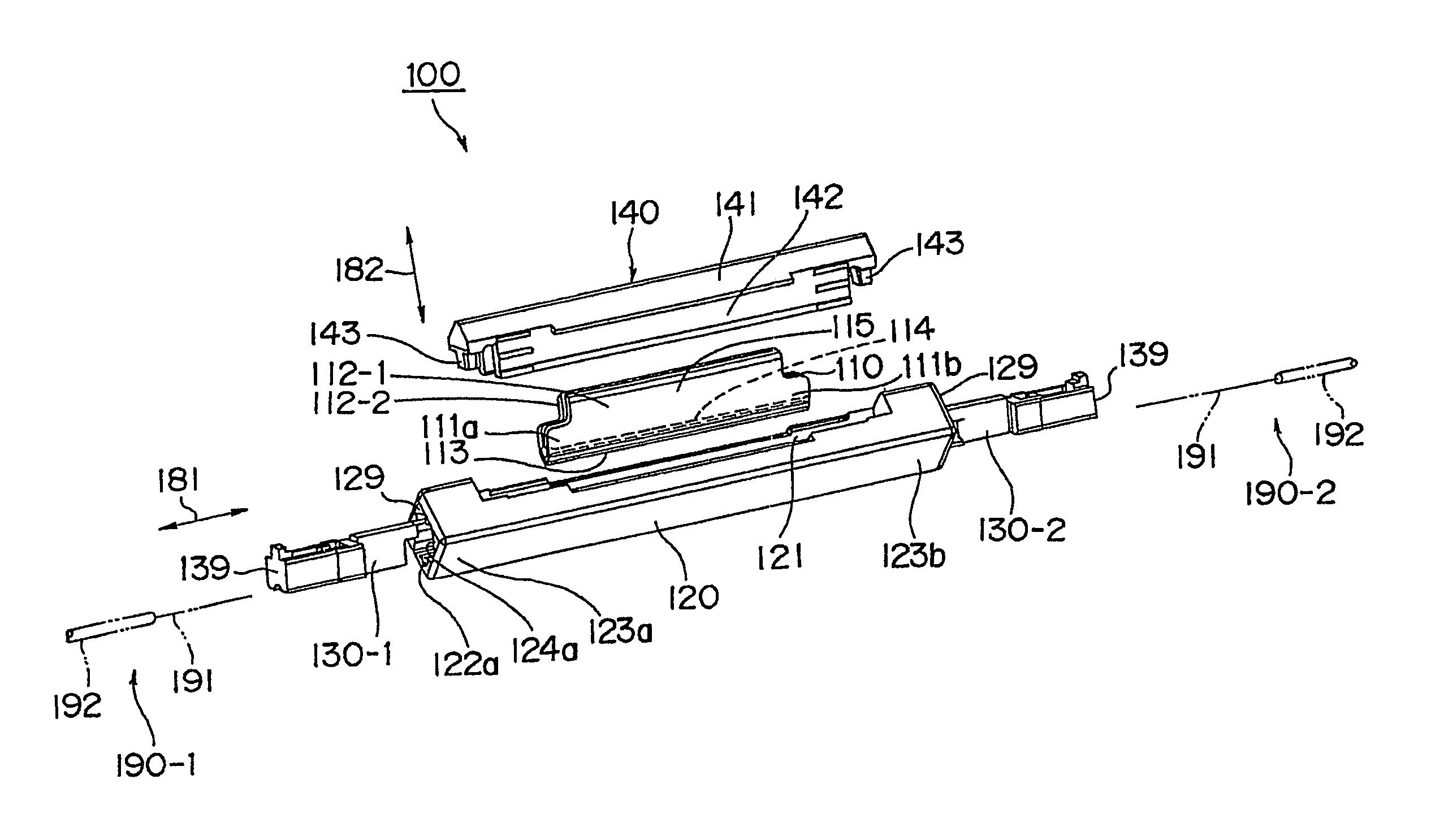

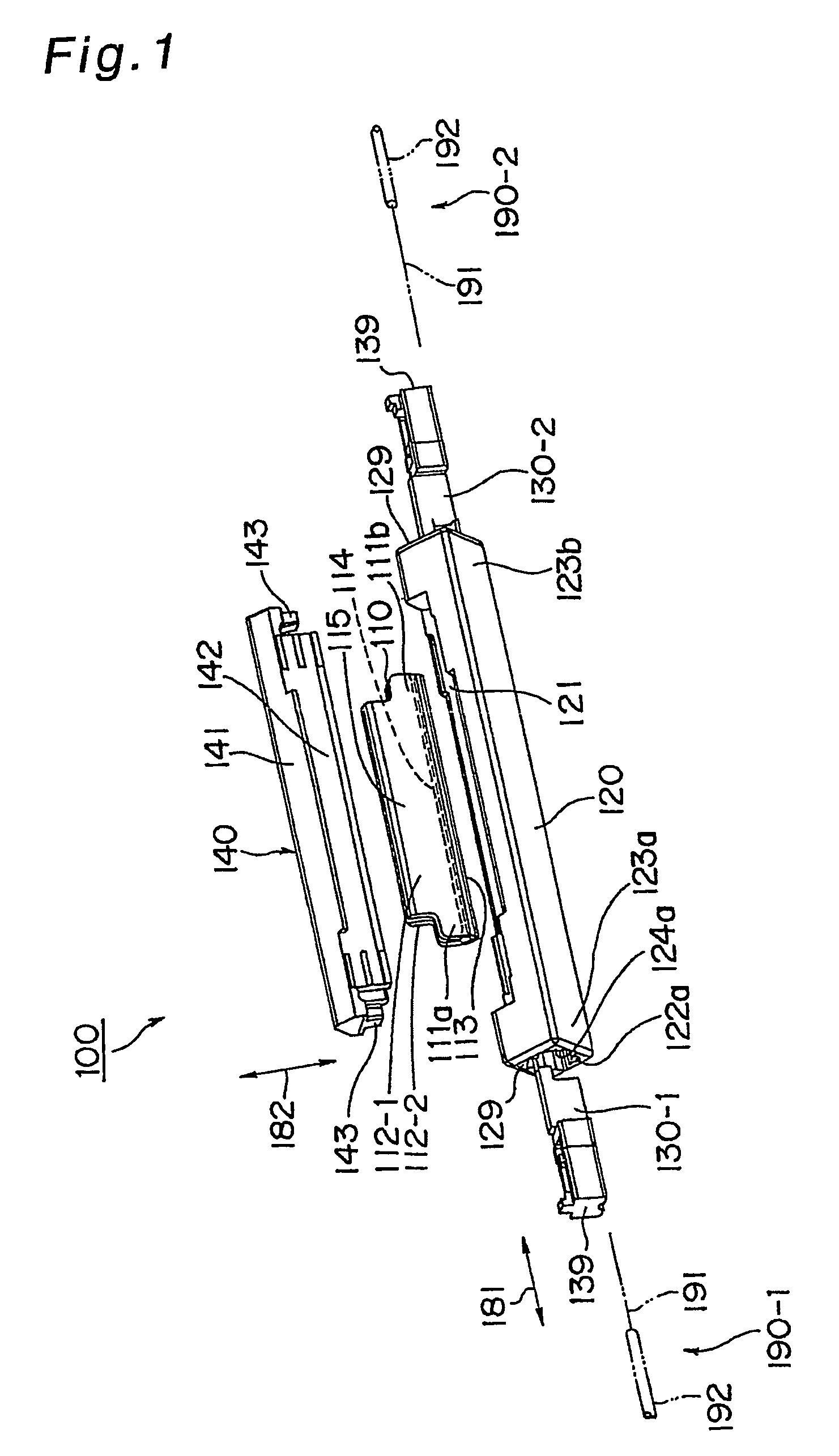

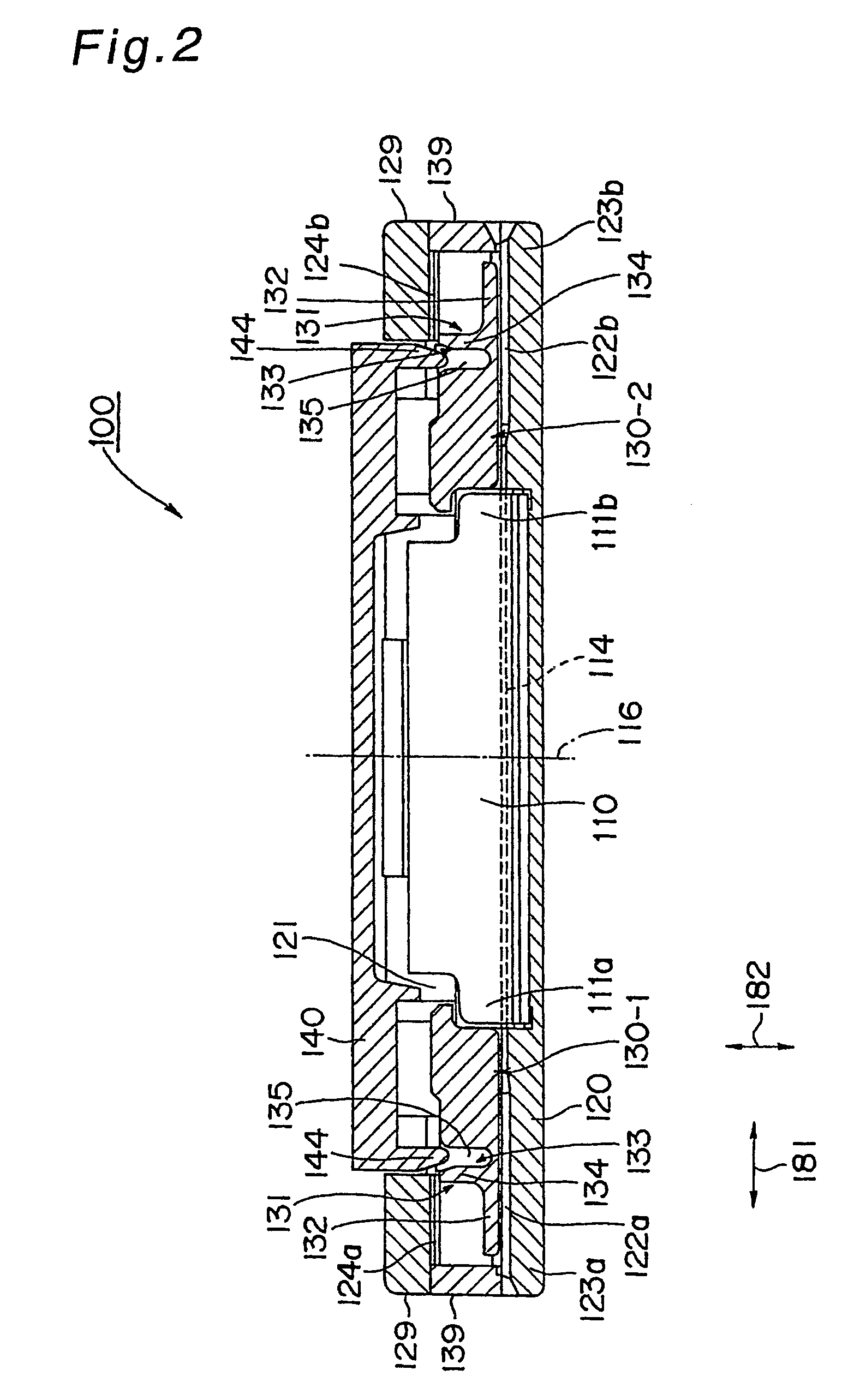

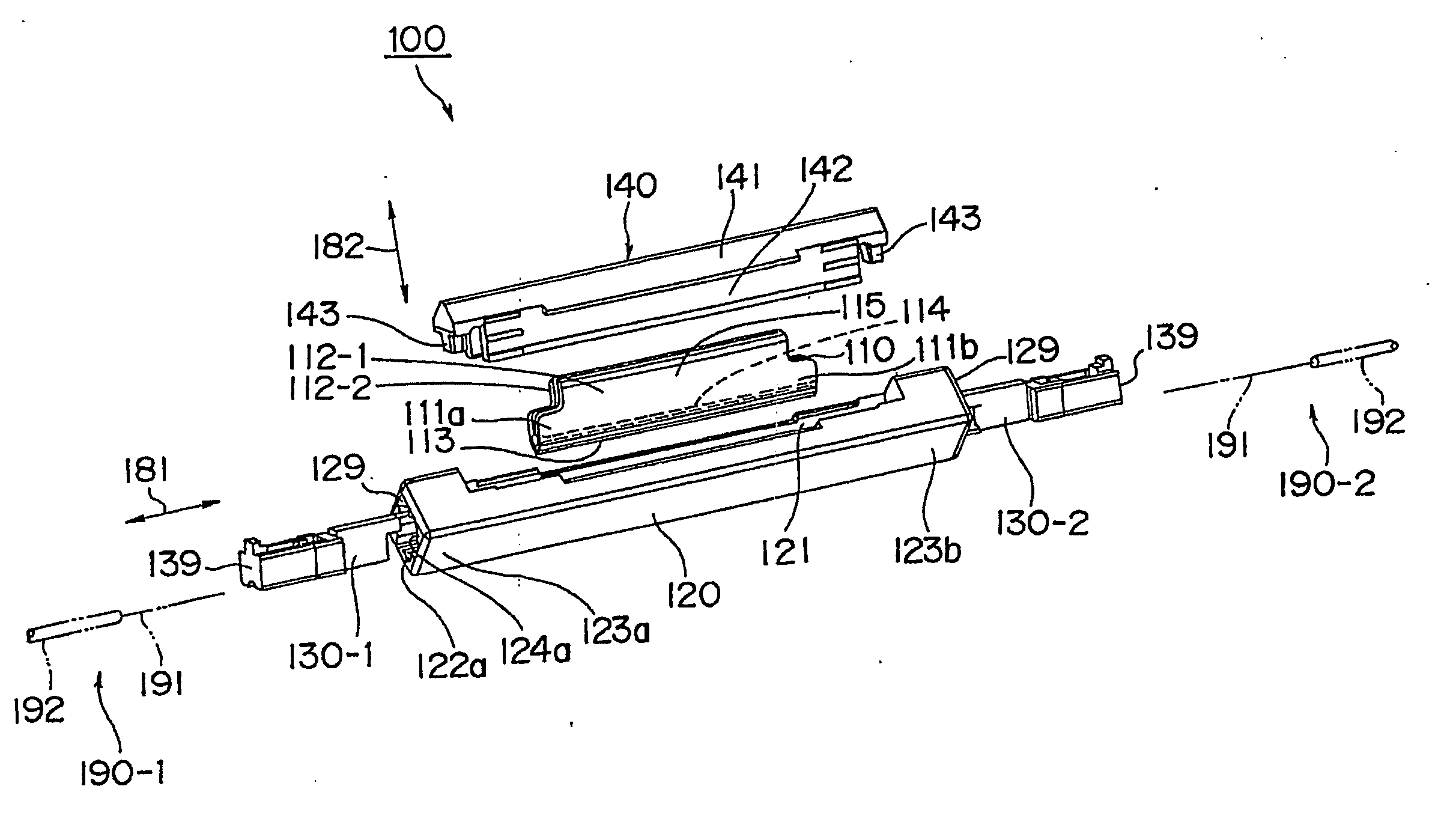

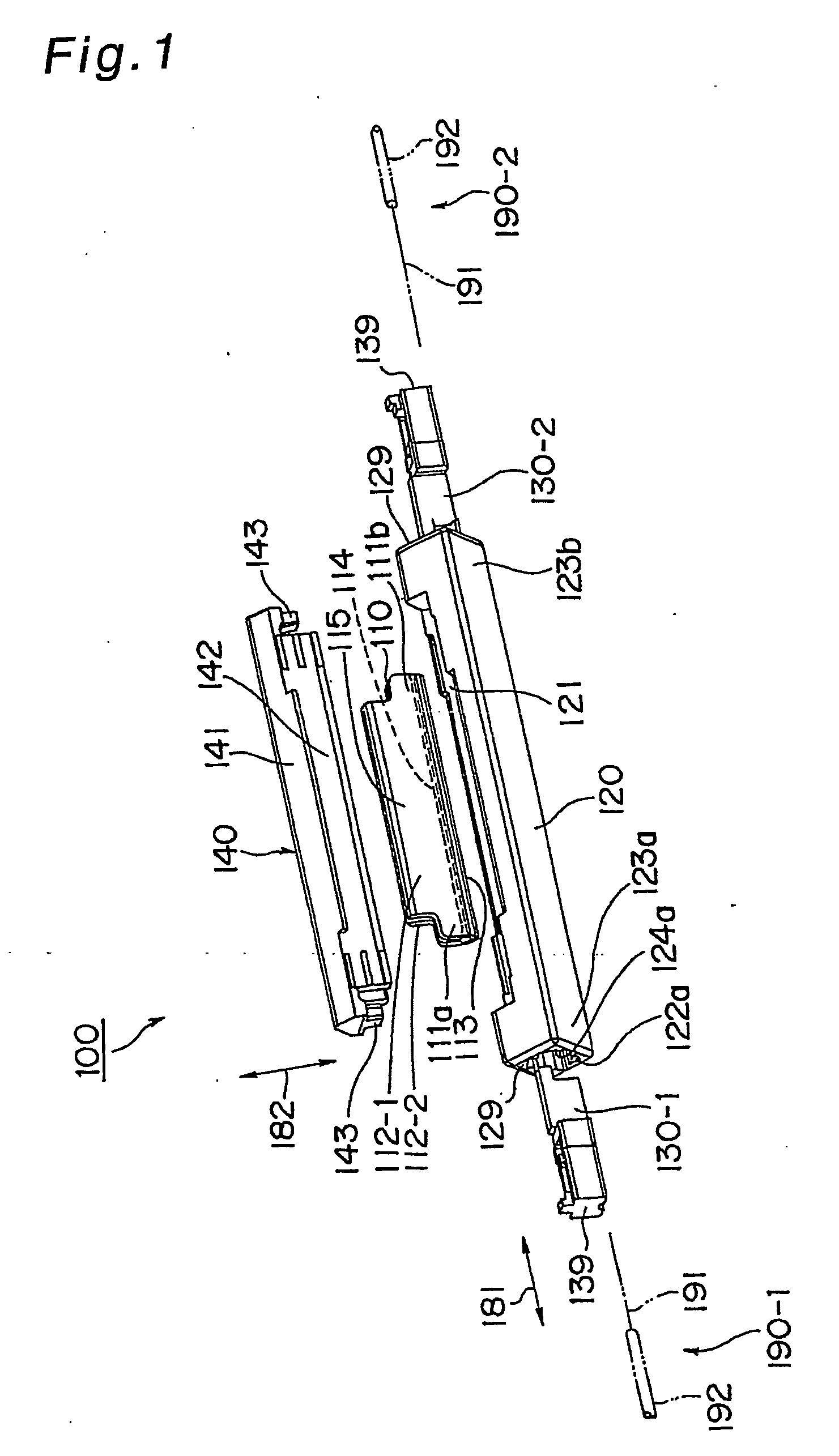

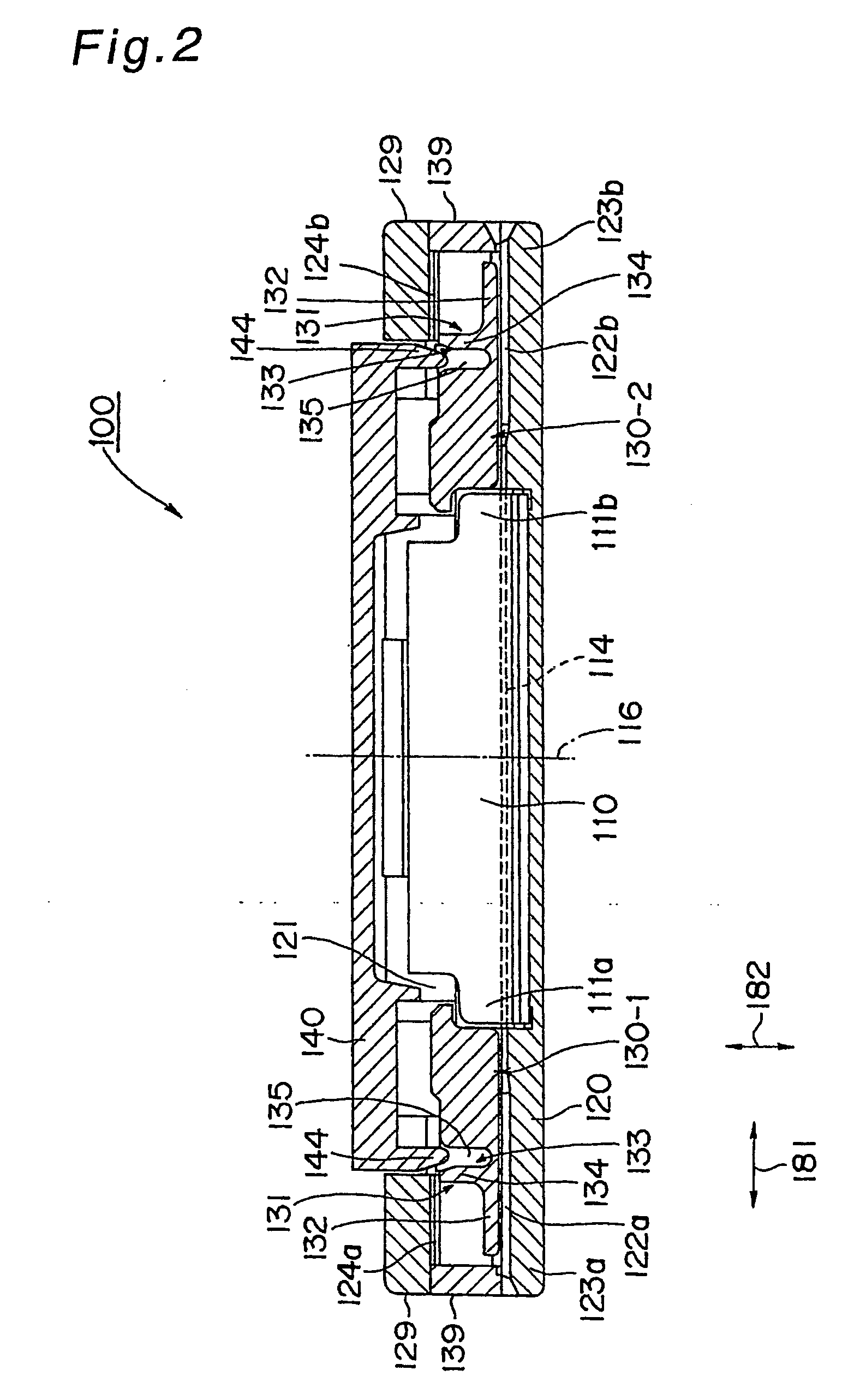

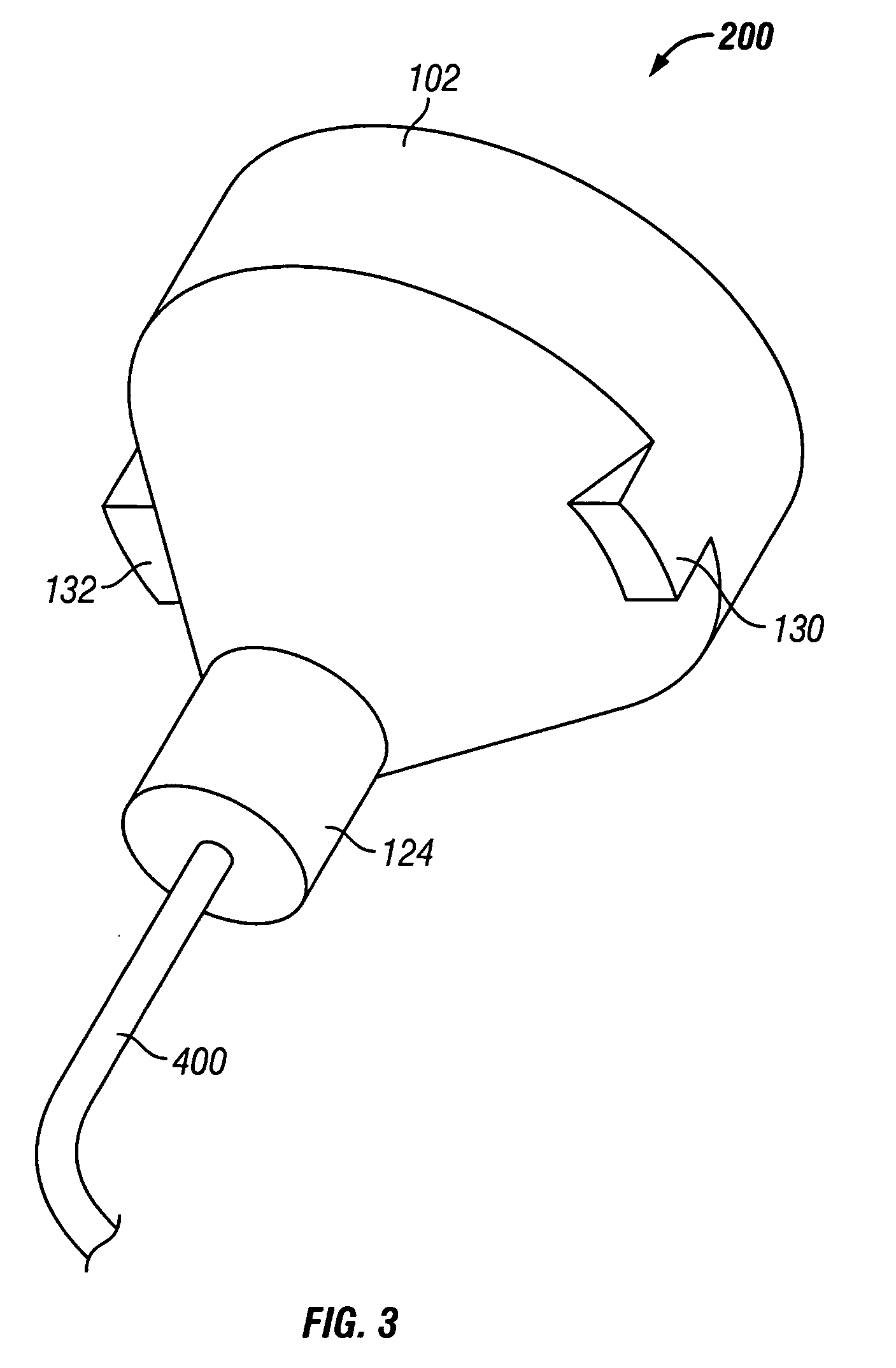

Optical fiber mechanical splice with strain relief mechanism

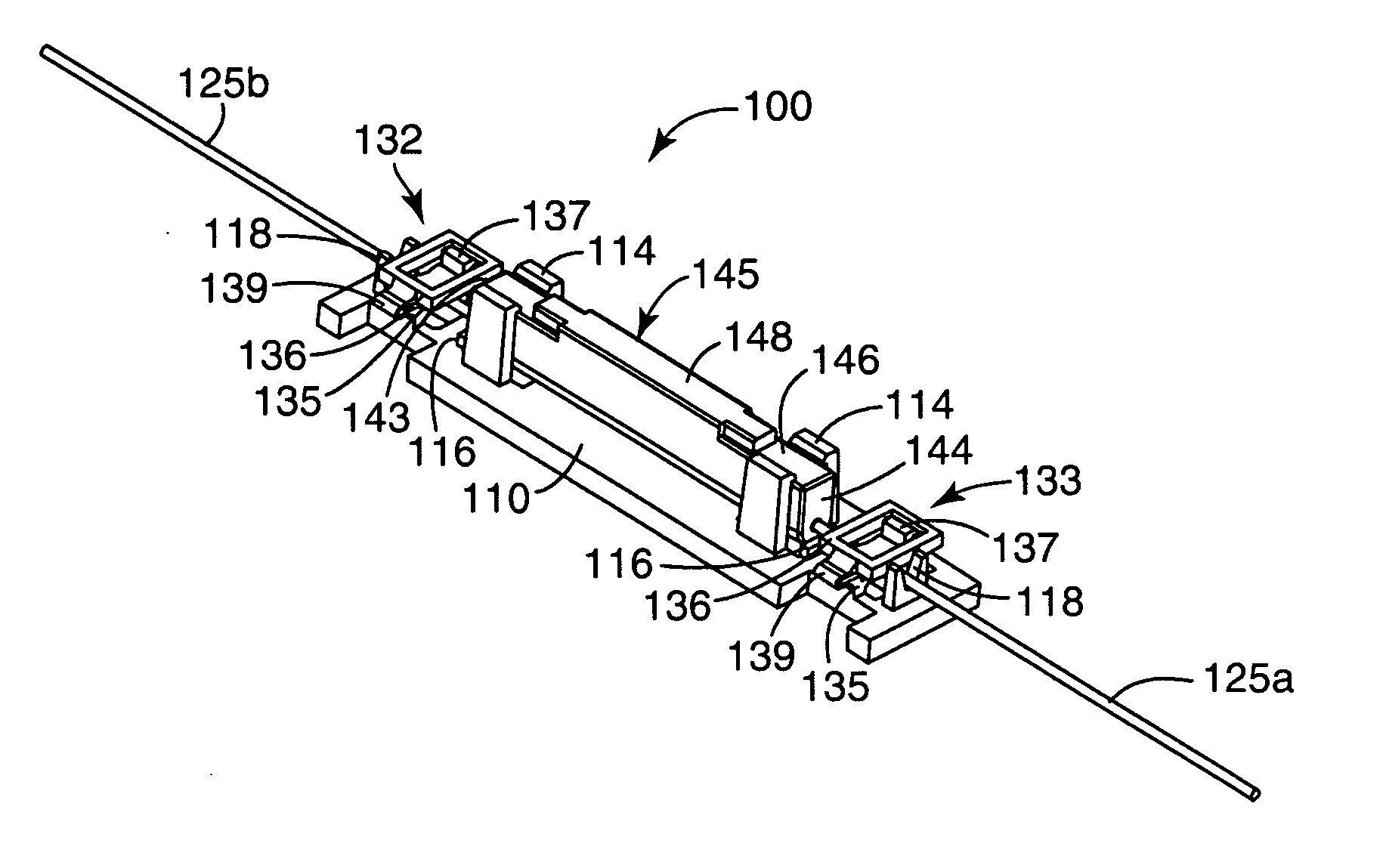

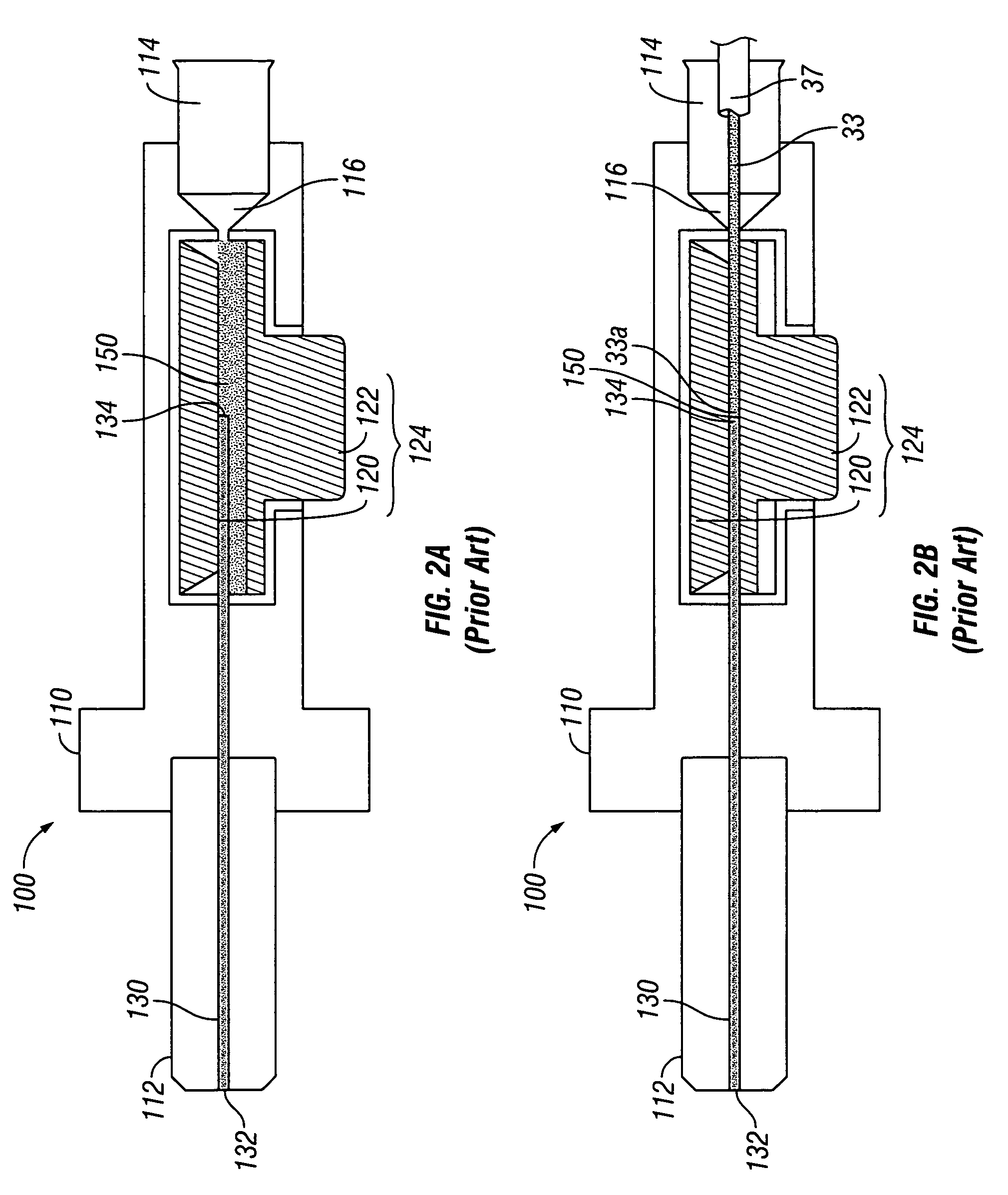

InactiveUS7140787B2Simple structureUsage existGlass making apparatusCoupling light guidesMechanical spliceBare fiber

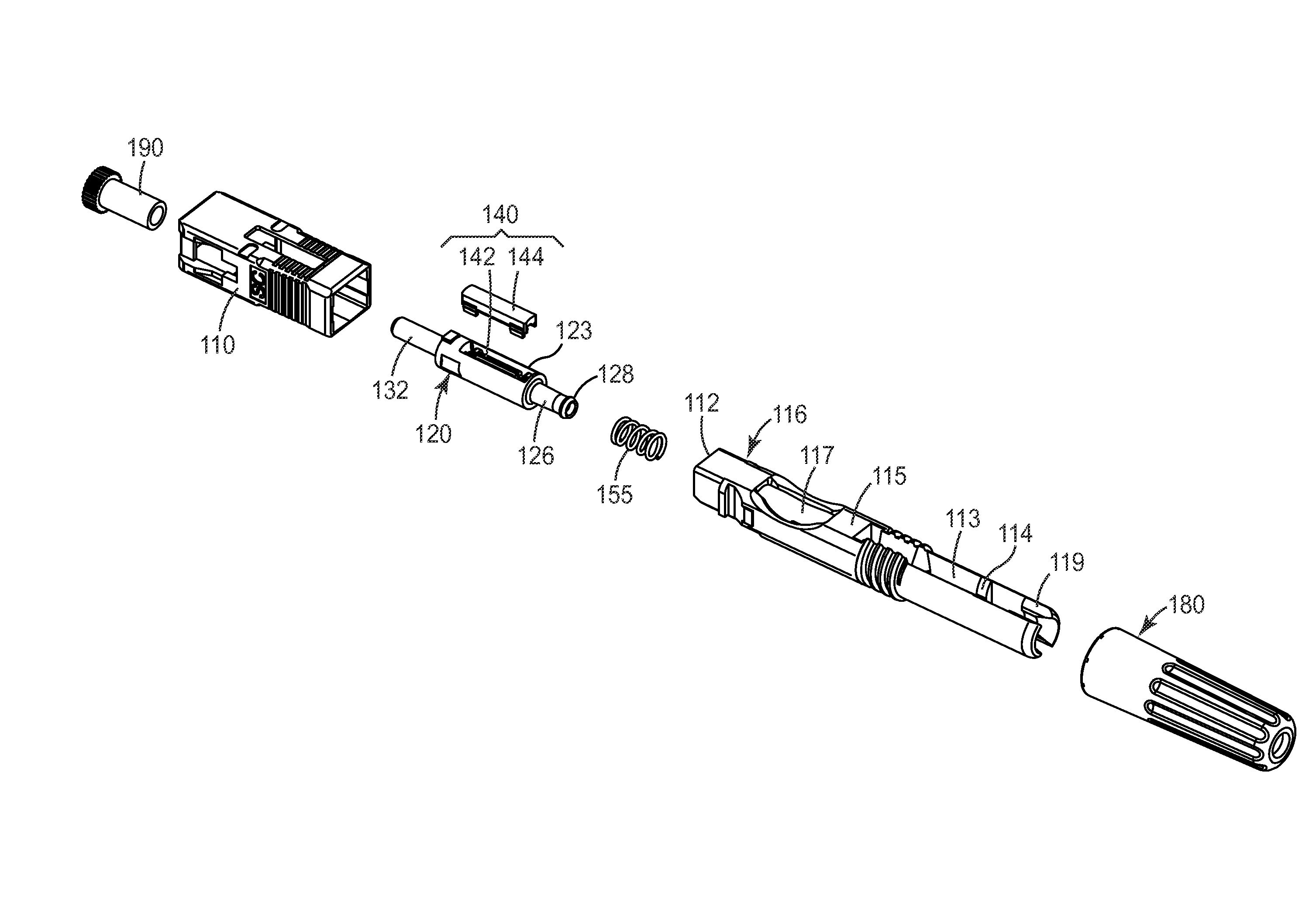

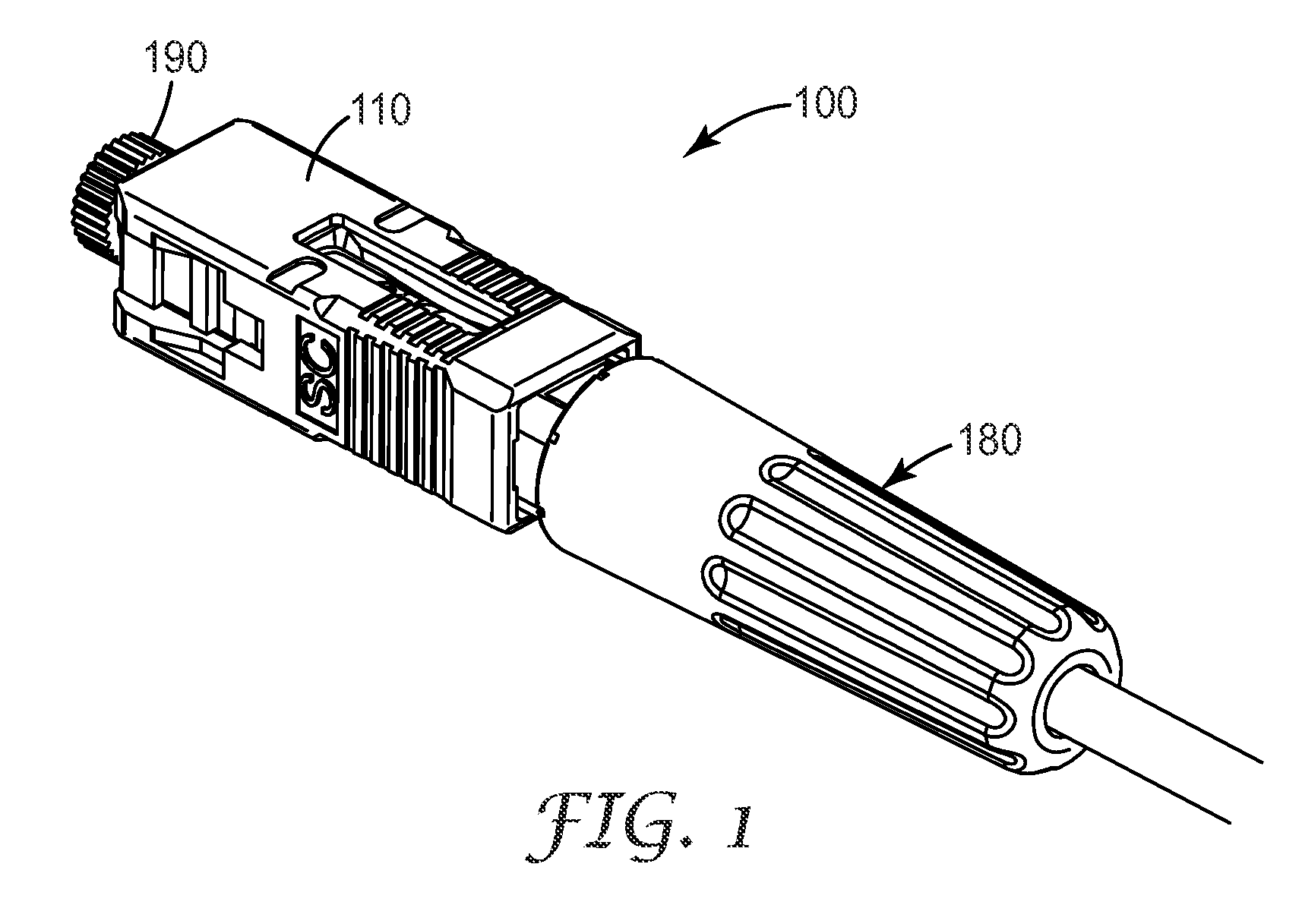

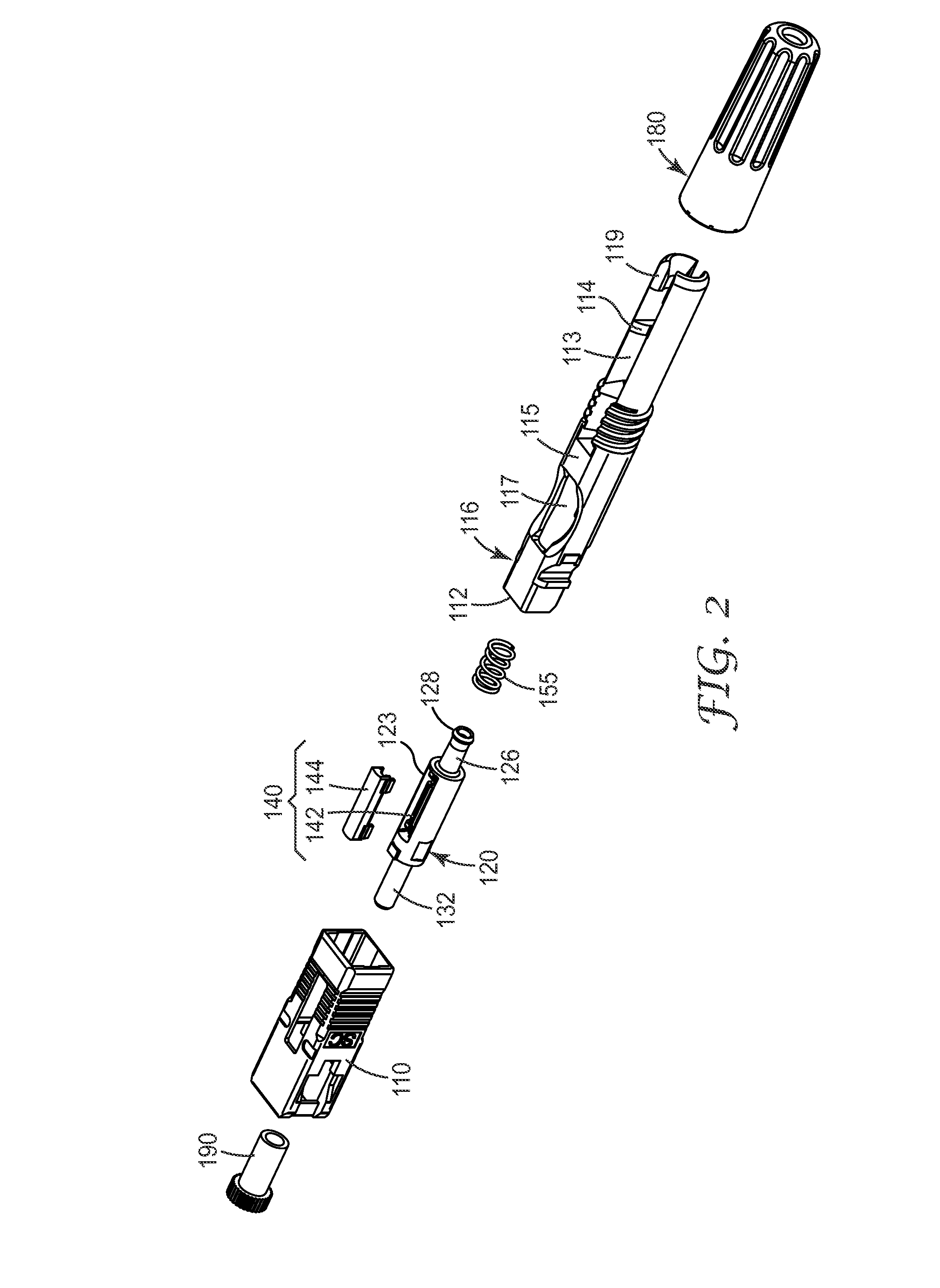

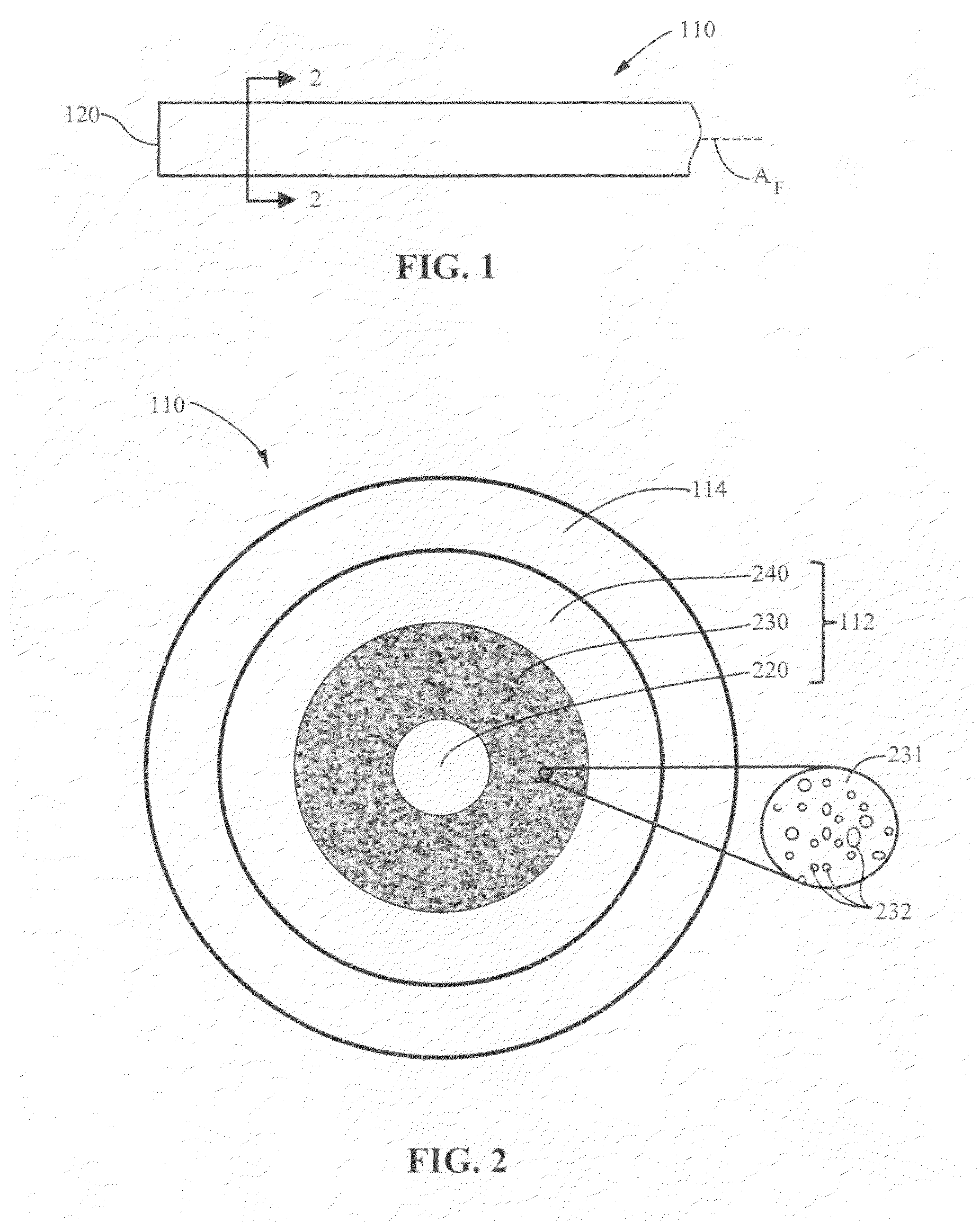

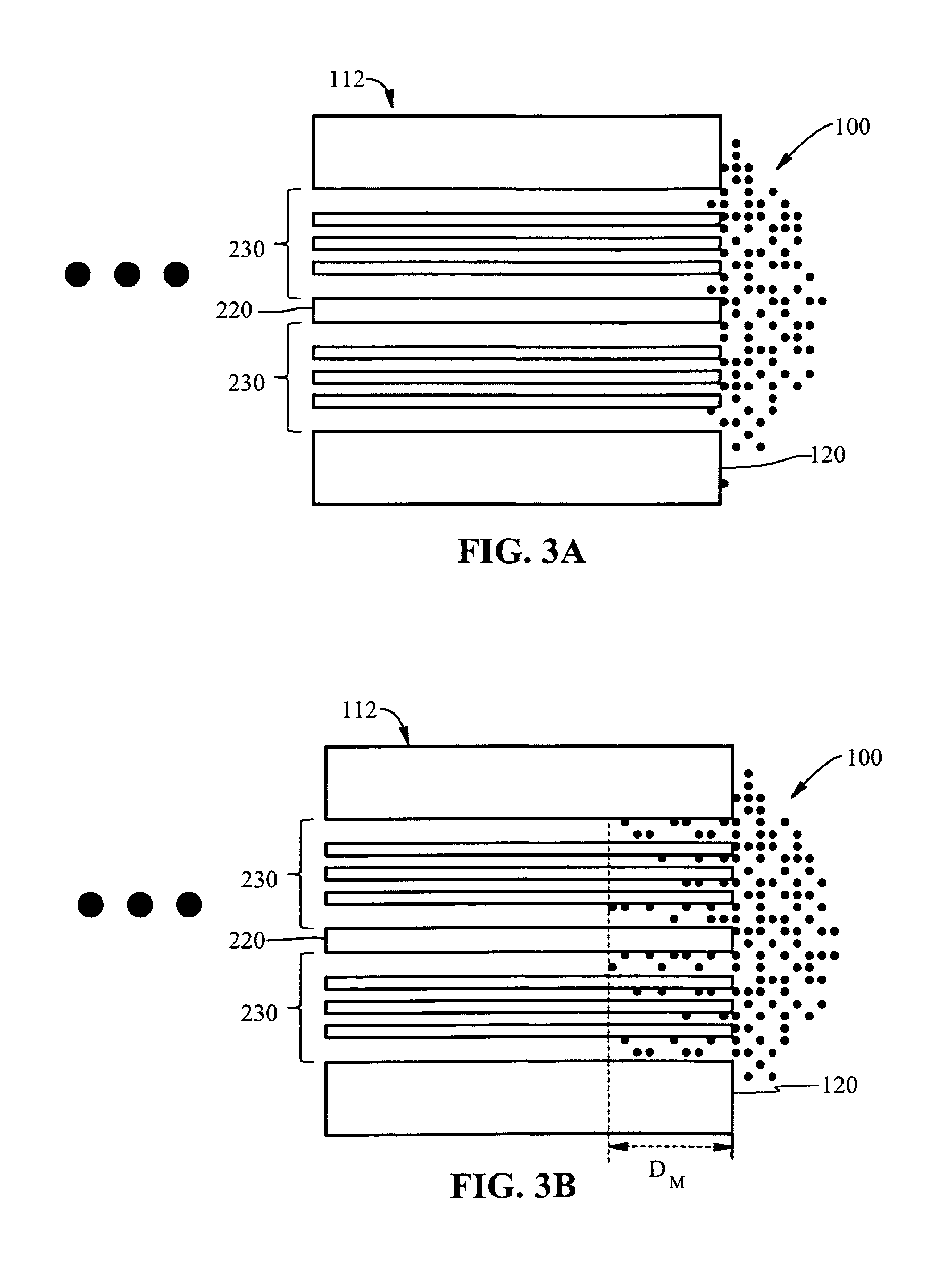

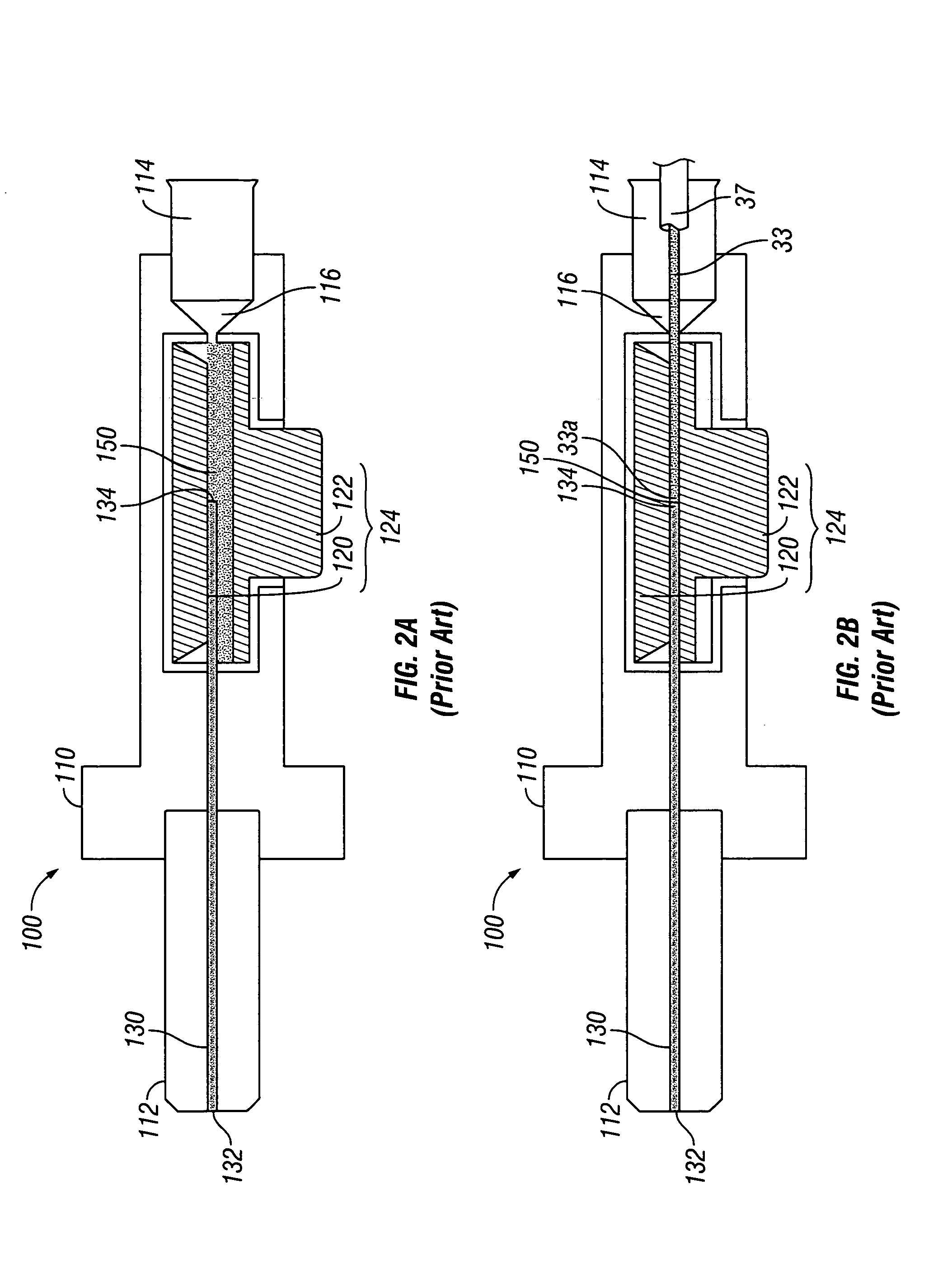

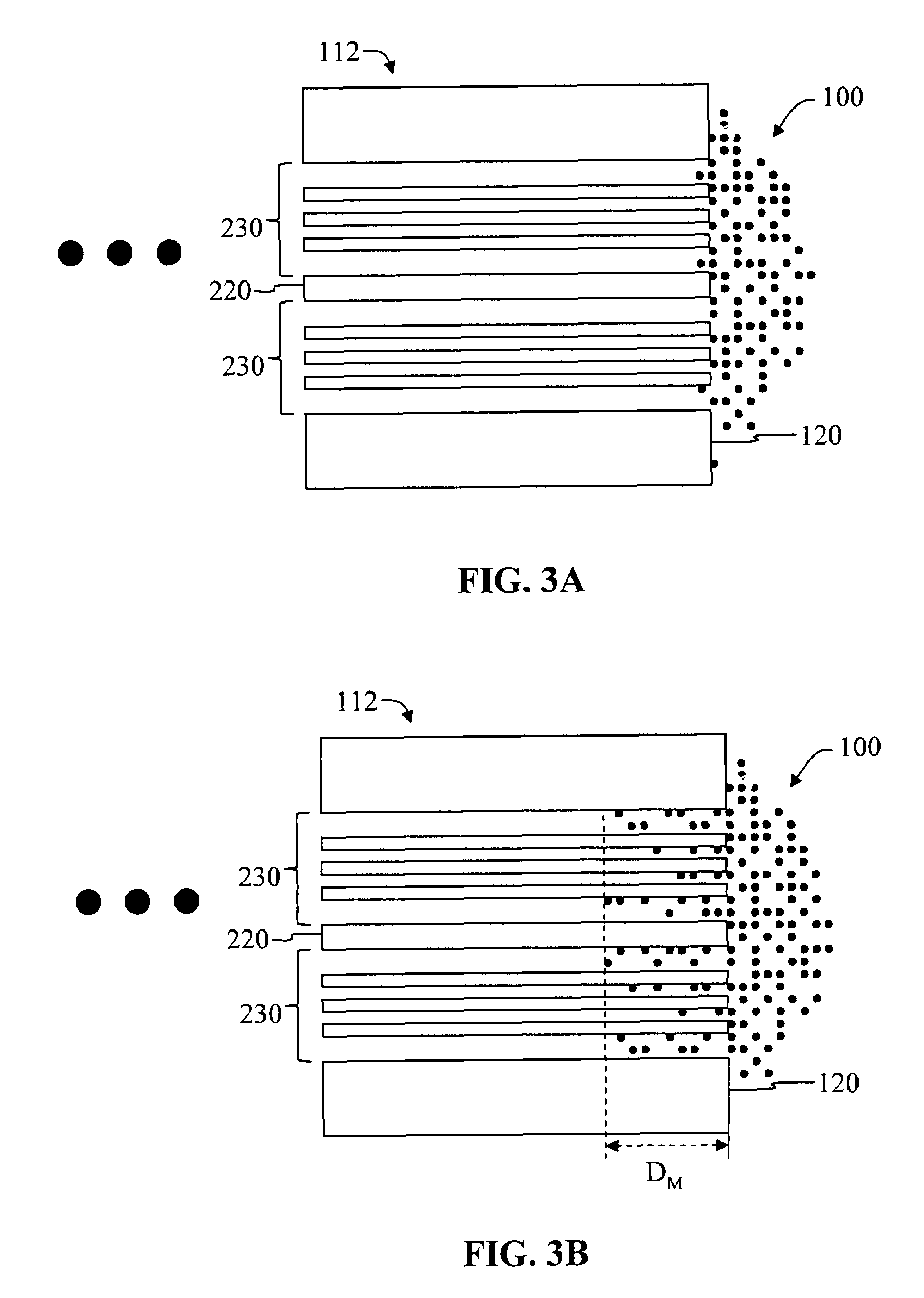

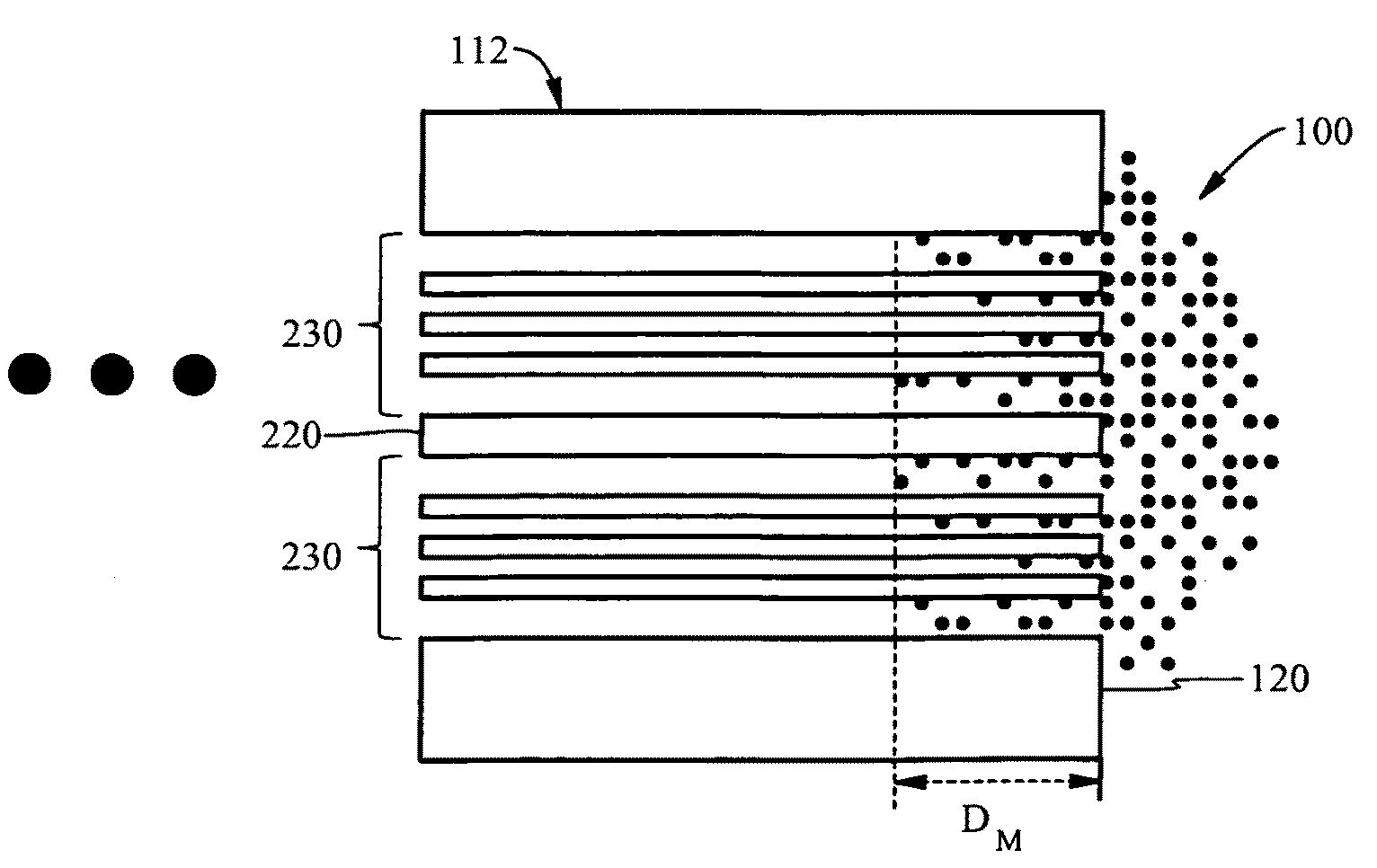

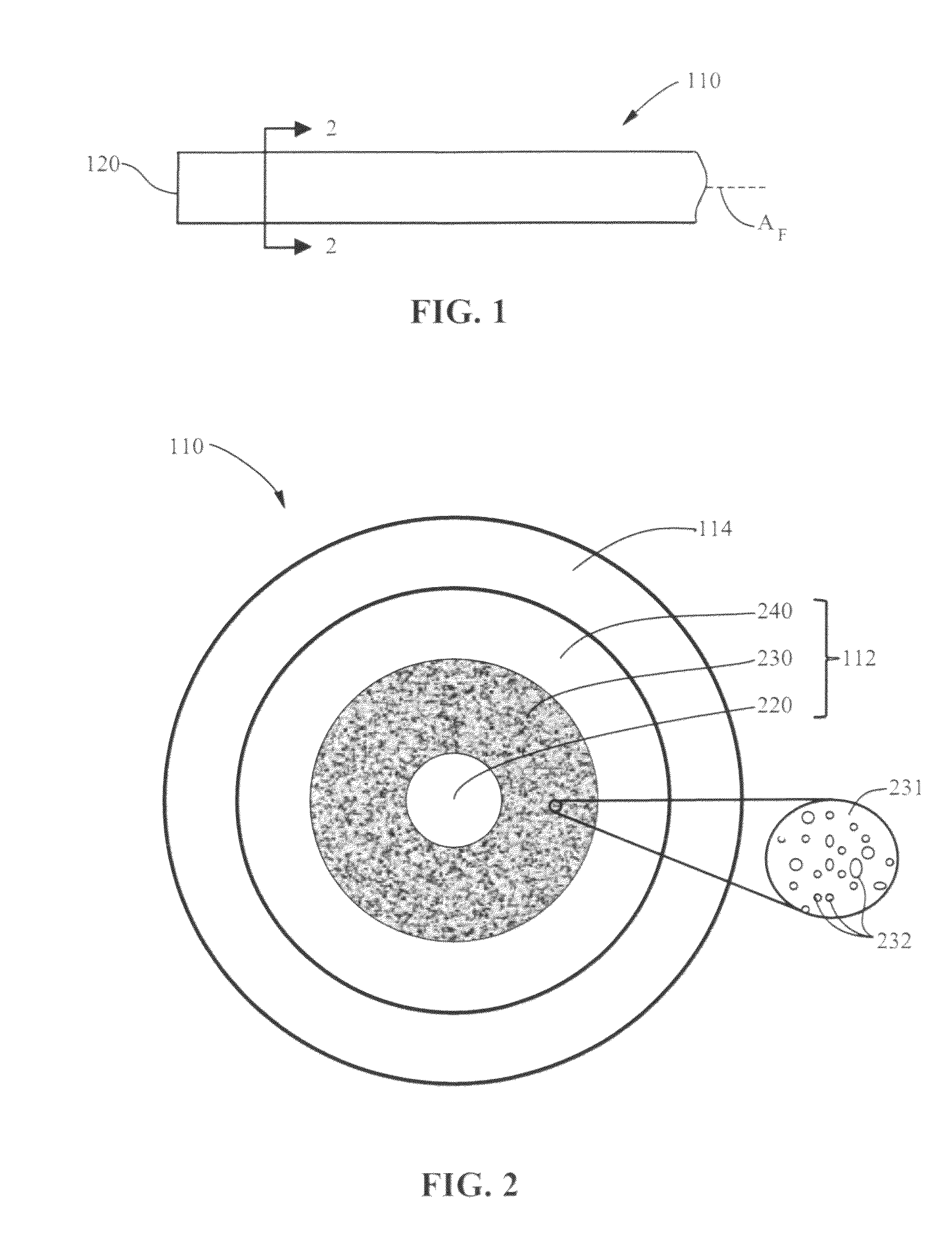

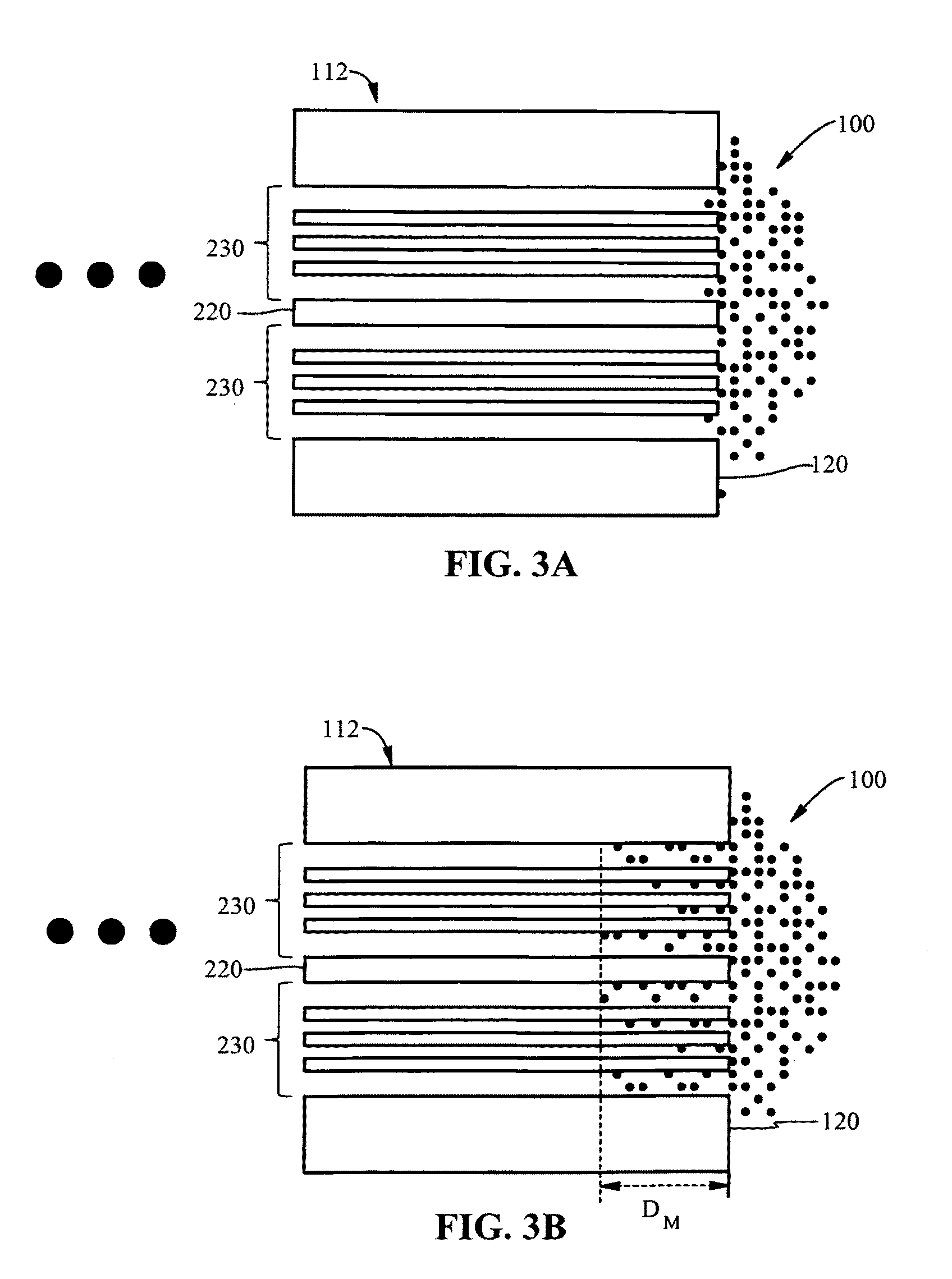

An optical fiber splicing member can hold optical fiber buffer coatings stably in a simple structure as compared with conventional art and enables use of an existing splicing tool. There are provided a joint element 110, a jacket 120, buffer retainers 131 and a cap 140. By setting and pressing the cap to the jacket, it becomes possible to splice bare fibers of optical fibers 190 with each other by the joint element and to press the buffer coatings 192 by the buffer retainers. Assembling the splicing member is thus facilitated while the existing optical fiber splicing tool is utilizable as it is. The buffer coatings can be held stably because the holding is achieved through the pressing.

Owner:CORNING RES & DEV CORP

Optical fiber mechanical splice with strain relief mechanism

InactiveUS20060072884A1Simple structureUsage existGlass making apparatusCoupling light guidesMechanical spliceBare fiber

To provide an optical fiber splicing member which can hold optical fiber buffer coatings stably in a simple structure as compared with conventional art, and which enables use of an existing splicing tool. There are provided a joint element (110), a jacket (120), buffer retainers (131) and a cap (140). By setting and pressing the cap to the jacket, it becomes possible to splice bare fibers of optical fibers (190) with each other by the joint element and to press the buffer coatings (192) by the buffer retainers. Assembling the splicing member is thus facilitated while the existing optical fiber splicing tool is utilizable as it is. The buffer coatings can be held stably because the holding is achieved through the pressing.

Owner:CORNING RES & DEV CORP

Field terminable optical connector with splice element for jacketed cable

An LC format optical connector for terminating an optical fiber includes a housing configured to mate with an LC receptacle. A backbone is configured to engage an outer surface of the outer shell of the housing and includes a mounting structure that is configured to engage a boot. A collar body is retained between the outer shell and the backbone and includes a fiber stub disposed in a first portion of the collar body, the fiber stub being mounted in a ferrule. A mechanical splice is disposed in a second portion of the collar body, the mechanical splice configured to splice the fiber stub to the optical fiber. The backbone also includes a fiber jacket clamping portion to clamp a jacket portion that surrounds a portion of the optical fiber upon actuation.

Owner:CORNING RES & DEV CORP

Fiber optic connector of a fiber optic connection termination system

InactiveUS20110176780A1Simple and reliable and easy terminationLine/current collector detailsCoupling light guidesFiberMechanical splice

A fiber optic connector for making a mechanical splice with an optical fiber secured in an optical fiber handler is disclosed. The fiber optic connector provides the craft with a simple, fast and reliable way for terminating the optical fiber.

Owner:CORNING OPTICAL COMM LLC

Field terminable optical fiber connector with splice element

An optical fiber connector includes a housing configured to mate with a receptacle, a collar body that includes a fiber stub and a mechanical splice device, a backbone to retain the collar body within the housing, and a boot. The backbone includes a fiber jacket clamping portion to clamp a jacket portion that surrounds a portion of the terminated optical fiber upon actuation. The boot actuates the fiber jacket clamping portion of the backbone upon attachment to the backbone. The optical fiber connector can be terminated in the field without the need to use a separate termination platform or tool.

Owner:CORNING RES & DEV CORP

Optical fiber transition device

InactiveUS20080013888A1Reduce amountMinimizes cable slack storageCoupling light guidesFibre mechanical structuresFiberMechanical splice

The present invention addresses the need for a stress relieving device and protective jacket for exposed fiber within a field-installed optical network enclosure, such as a network interface device. The present invention incorporates a furcation tube coupled with a furcation body. The coupling may be accomplished by a direct connection or with use of an external or internal transition body. The present invention enables a field-installer to transition an optical fiber cable from the field into a furcation tube thereby providing a means for attaching an optical connector, such as a mechanical splice connector, onto the optical fiber and furcation tube.

Owner:CORNING OPTICAL COMM LLC

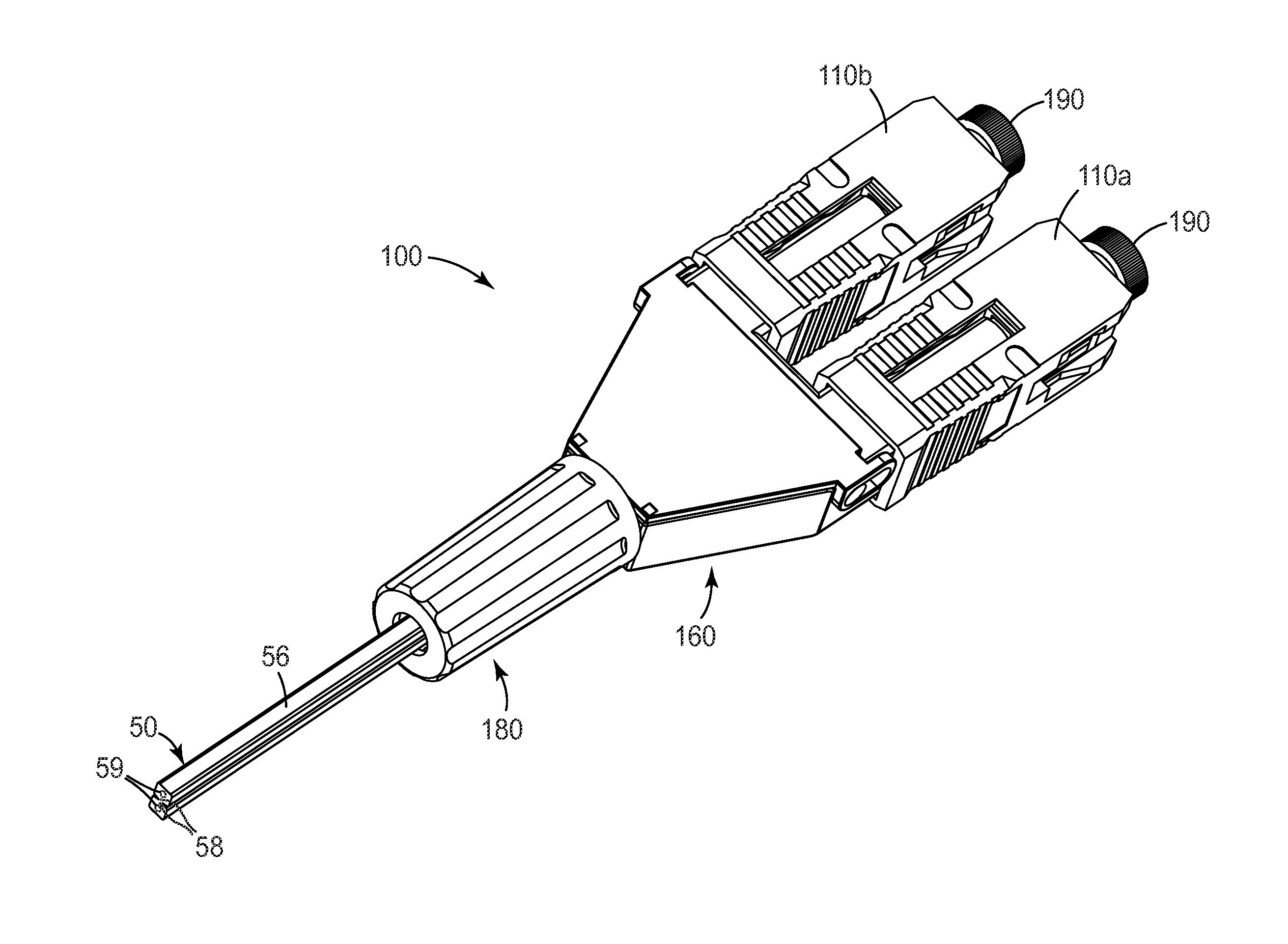

Installation tool with integrated visual fault indicator for field-installable mechanical splice connector

InactiveUS7680384B2Improved visual fault locatorMore efficientTesting fibre optics/optical waveguide devicesOptical light guidesFault indicatorFiber

A mechanical splice fiber optic connector installation tool operable for performing splice terminations and verifying an acceptable splice termination includes a power source, a connector holder, an integrated Visual Fault Locater having an optical transmission element and a display for displaying the status of the termination. An adapter configured to receive the connector and align the connector with the optical transmission element, such that the optical transmission element is spaced apart from the connector at a predetermined distance and is in optical communication with the connector for propagating light energy through the adapter and along the stub optical fiber to a termination area of the connector.

Owner:CORNING OPTICAL COMM LLC

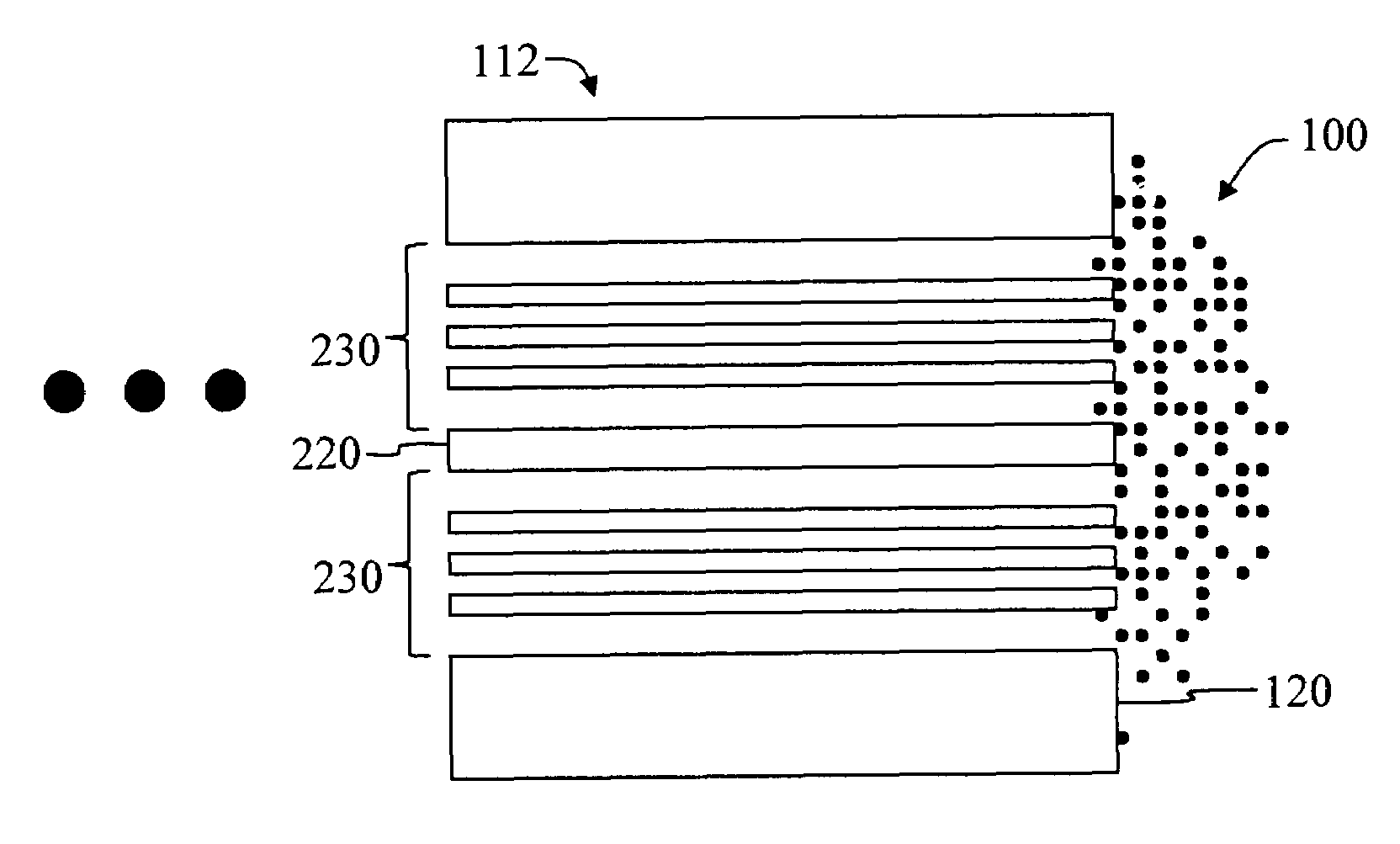

Apparatus and Method for Mass Producing Optical Fiber Splice-On Connector Subunits

The invention provides and apparatus and method for mass producing a plurality of fiber optic mechanical splice-on connector subunits. The apparatus utilizes a magazine detachably mounted on a frame and containing a plurality of slots. The slots contain a plurality of subunits, each of which includes a ferrule assembly carrying a fiber stub coated in uncured epoxy. The slots are moved through a cleaving zone on the apparatus defined by the area between a cleaver and fiber holder, wherein the fiber stubs are cleaved and then pulled so the portion of the fiber stub extending from the ferrule assembly to the cleaved end has a specified length. After cleaving and pulling all the fiber stubs in the magazine, the magazine is detached from the apparatus and moved to an oven wherein the epoxy is cured. After cooling, the subunits and removed from the magazine to provide a plurality of subunits, each containing a cleaved fiber stub securely oriented therein.

Owner:GOFOTON HLDG

Field installed optical fiber connector for jacketed fiber cable and termination method

An optical fiber connector includes a housing configured to mate with a receptacle, a collar body that includes a fiber stub and a mechanical splice device, a backbone to retain the collar body within the housing, and a boot. The backbone includes a cable jacket clamping portion to clamp a cable jacket that surrounds a portion of the terminated optical fiber upon actuation. The boot actuates the cable jacket clamping portion of the backbone upon attachment to the backbone. A method for terminating the optical fiber in the field includes slitting or removing a portion of the cable jacket prior to splicing the optical fiber to the fiber stub. The method also includes utilizing a protective sheath or tube to protect exposed portion of the fiber cable and provide structural integrity to the optical connector.

Owner:3M INNOVATIVE PROPERTIES CO

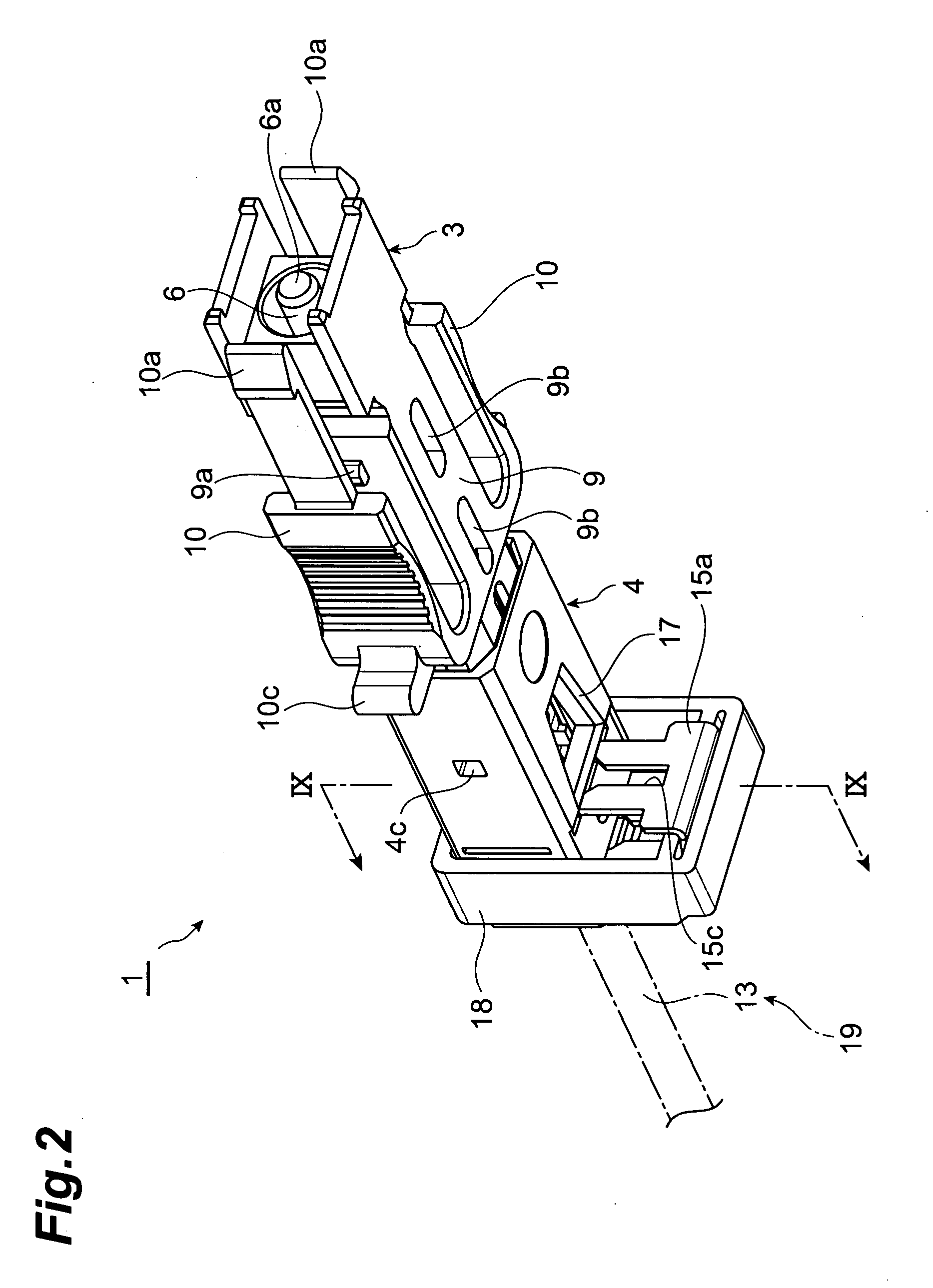

Optical connector, and assembling method of optical connector

InactiveUS20110116745A1Improve protectionImprove workabilityCoupling light guidesFiberMechanical splice

An optical connector according to an embodiment of the present invention comprises (a) a ferrule incorporating a short fiber; (b) a mechanical splice having a holding part and a fixing part, and adapted so that the fixing part mechanically fixes the short fiber extending from the ferrule held by the holding part, and an optical fiber in an optical cable to butt the short fiber; (c) an outer housing having a housing part in which the mechanical splice is located, and a pair of flexible arms located on both sides of the housing part, the pair of arms each being provided with a locking claw at a tip; and (d) a jacket fixture for fixing a cable jacket, the jacket fixture being coupled to the mechanical splice so that the cable jacket is inserted therein.

Owner:SUMITOMO ELECTRIC IND LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com