Cleaning device for cleaning a surface comprising a brush and a squeegee element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

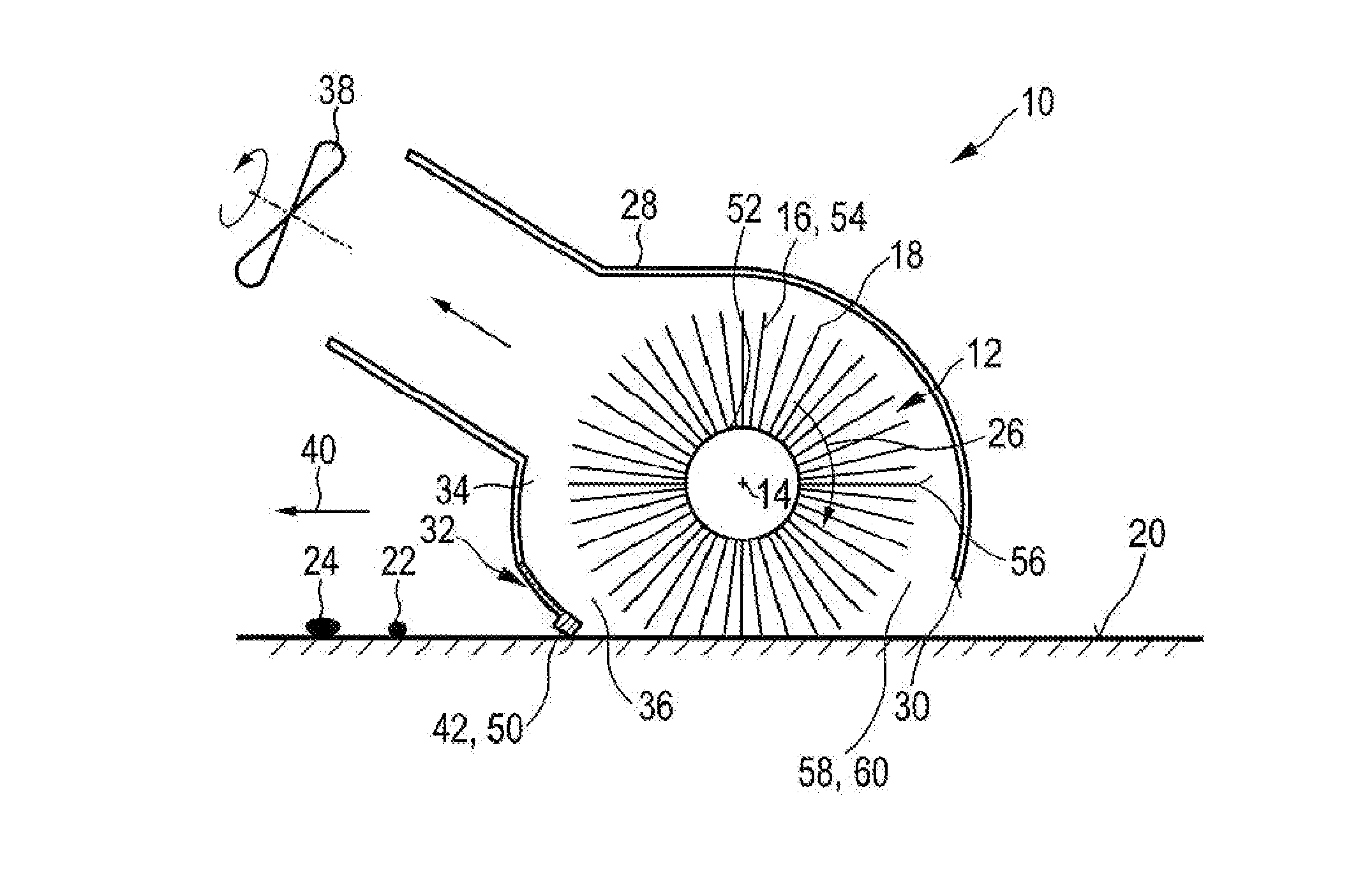

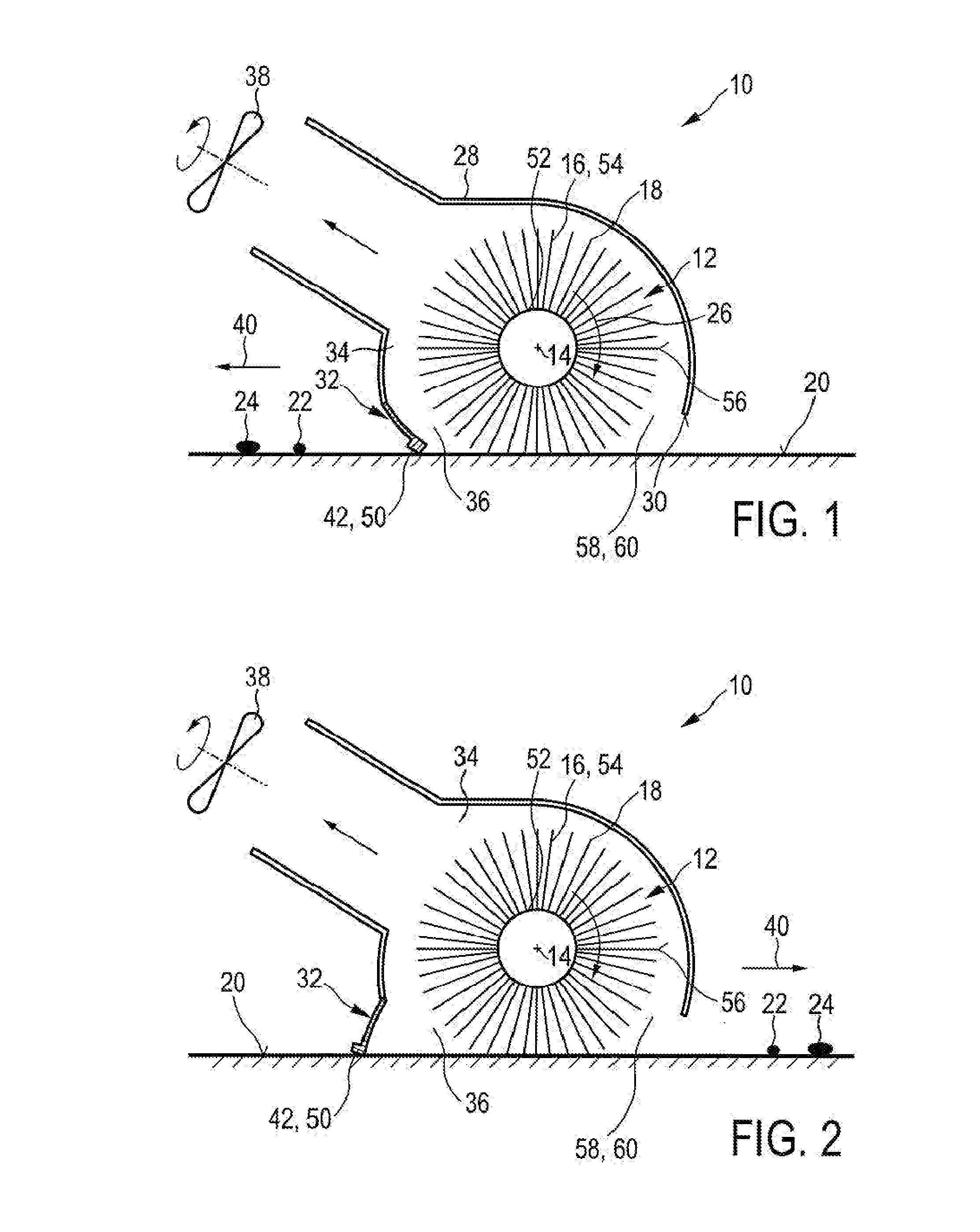

[0075]FIGS. 1 and 2 show a schematic cross-section of a nozzle arrangement 10 of a cleaning device 100 according to the present invention. In FIG. 1 the nozzle arrangement 10 is shown in a first working position, whereas in FIG. 2 the nozzle arrangement 10 is shown in a second working position. The nozzle arrangement 10 comprises a brush 12 that is rotatable about a brush axis 14. Said brush 12 is provided with flexible brush elements 16 which are preferably realized by thin microfiber hairs. The flexible brush elements 16 comprise tip portions 18 which are adapted to contact a surface to be cleaned 20 during the rotation of the brush 12 and to pick-up dirt particles 22 and liquid 24 from said surface 20 during a pick-up period when the brush elements 16 contact the surface 20.

[0076]A linear mass density of a plurality, preferably of a majority of the brush elements 16 is, at least at their tip portions 18, chosen to be lower than 150 g / 10 km. Further, the nozzle arrangement 10 comp...

second embodiment

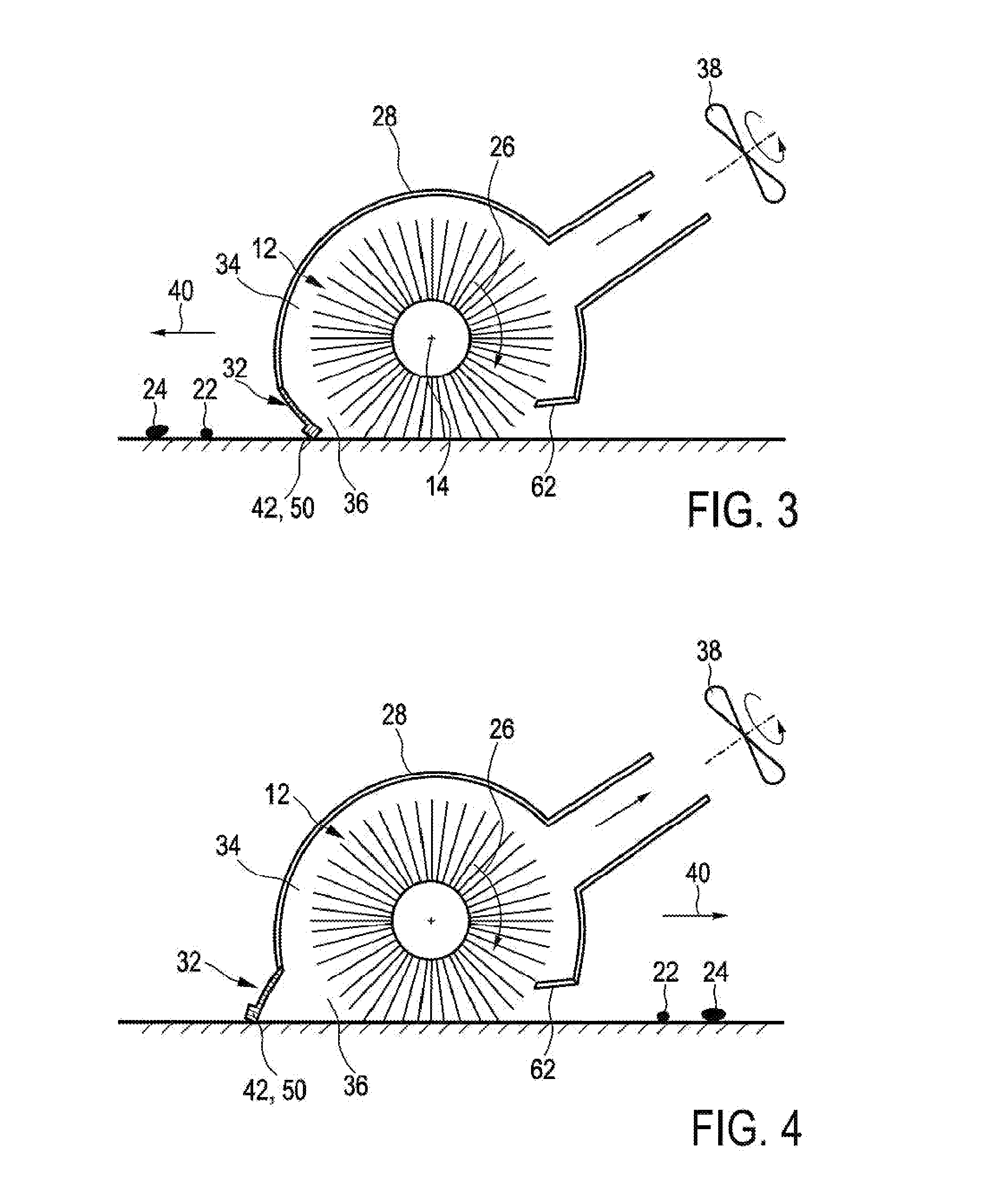

[0114]Furthermore, it is possible to use a deflector 62 for indenting the brush 12 at a position, seen in rotation direction 26, before the brush 12 contacts the surface 20, as this is exemplary shown in second embodiment which is shown in FIGS. 3 and 4. The deflector 62 has the function to press the brush elements 16 together by deflecting them. In this way air, which is present in the space between the brush elements 16, is pushed out of said space. When the brush elements 16 are, after leaving the deflector 62, moved apart from each other again, the space in between the brush elements 16 increases so that air will be sucked into the brush 12, wherein an under-pressure is created that sucks in dirt 22 and liquid particles 24. This again compensates for the air blow that is generated by the rotating brush 12. Examples of deflectors as mentioned are found in PCT / IB2009 / 054333 and PCT / IB2009 / 054334, both in the name of Applicant.

[0115]The airflow which needs to be compensated can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com