Apparatus and method for inspecting preform

A technology of preforms and inspection devices, which is applied to measuring devices, instruments, and material analysis through optical means, and can solve the problems of reduced resolution, inability to form a horizontal cut surface, and difficulty in inspecting the interior of the billet neck, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

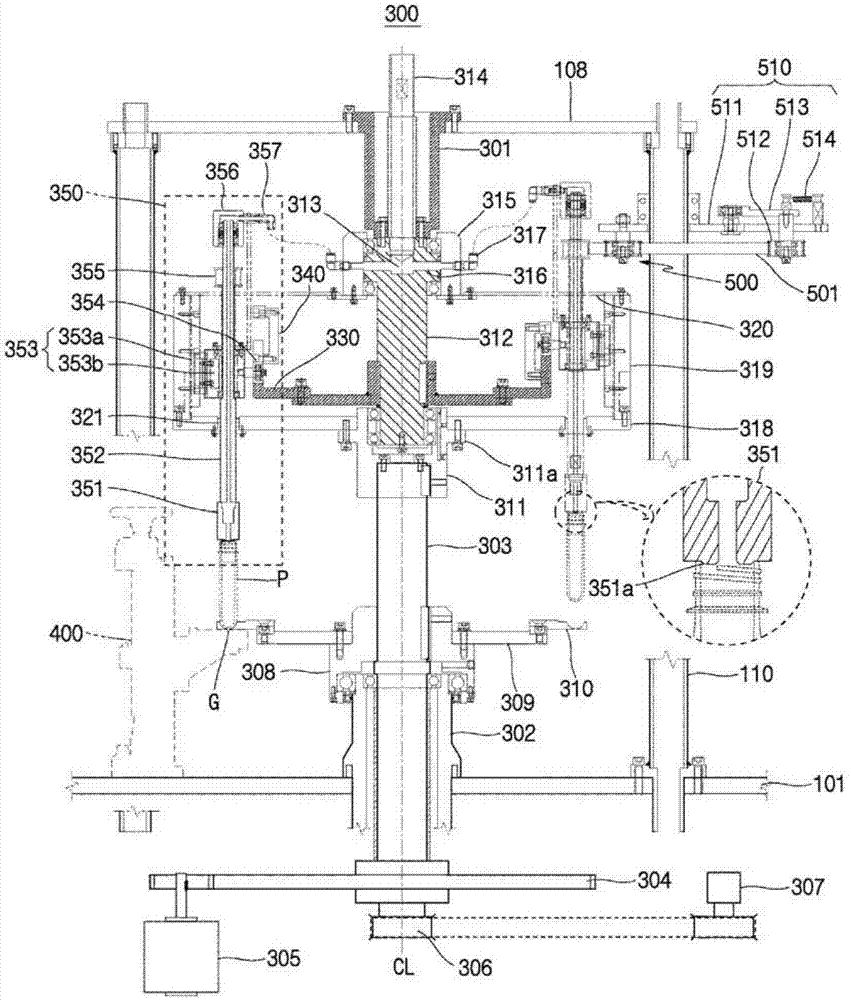

[0112] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, when describing the present invention, when it is judged that the detailed description of related known configurations or functions may obscure the gist of the present invention, the detailed description will be omitted. In particular, the present embodiment can also be applied to the preform inspection device mentioned as the background art, so the description of the present embodiment may not include structures that can be understood from the background art or are structurally similar.

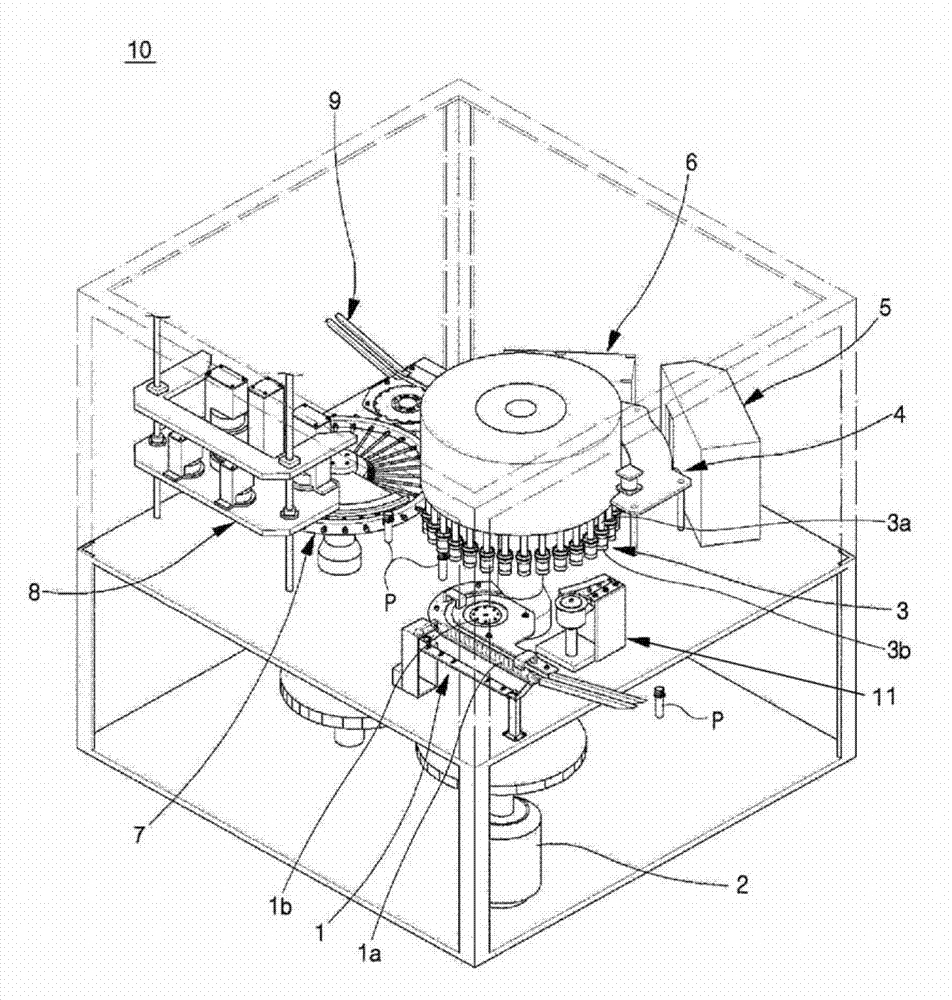

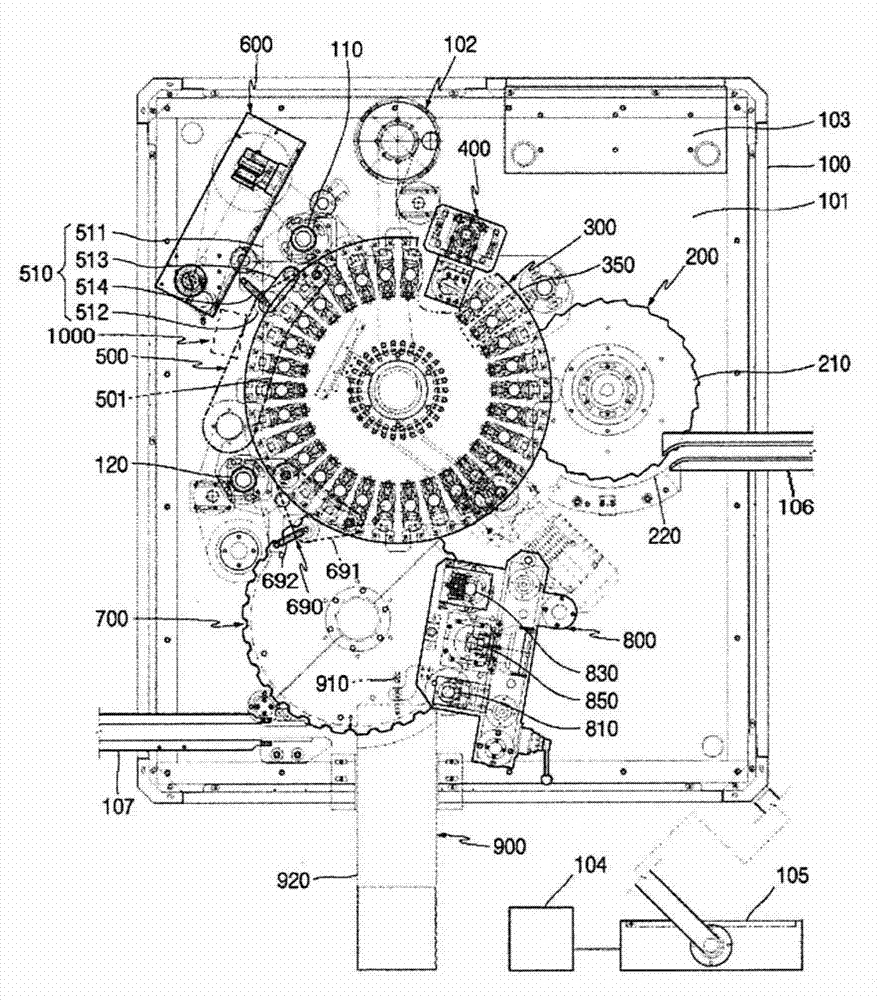

[0113] In the attached picture, figure 2 It is a top view of the preform inspection apparatus which concerns on one Embodiment of this invention.

[0114] refer to figure 2 , this embodiment includes a device frame 100 , an in star wheel (in star wheel) 200 , a turret assembly (turret assembly) 300 , a gate dividing part 400 , a preform rotating part 500 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com