Lug plate adjusting and fixing device for hinged support

A fixing device and lug plate technology, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low work efficiency, ear plate damage, and inconvenient operation, so as to avoid surface damage, realize spacing, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

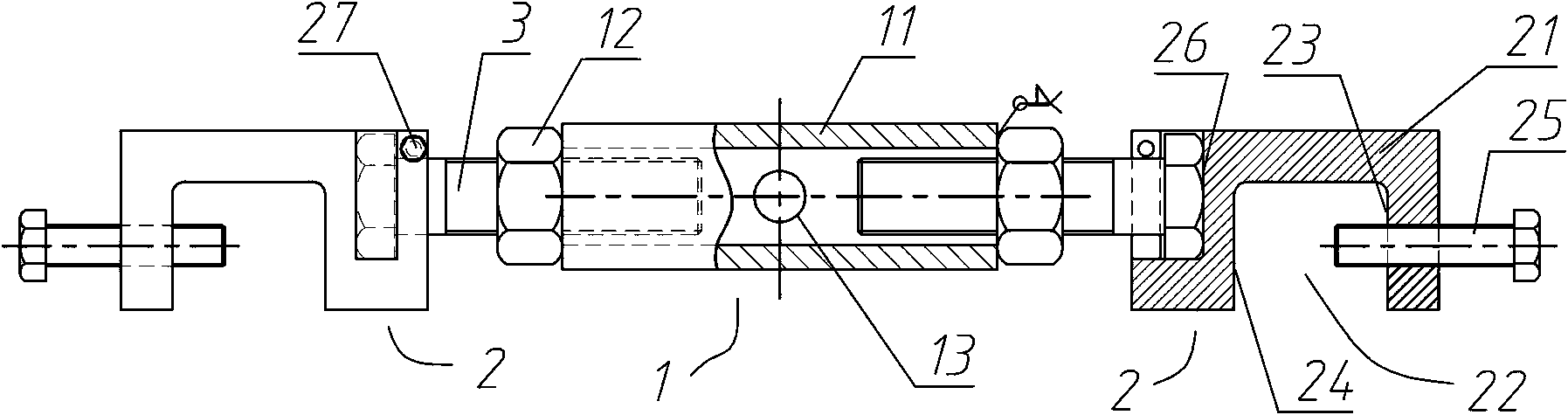

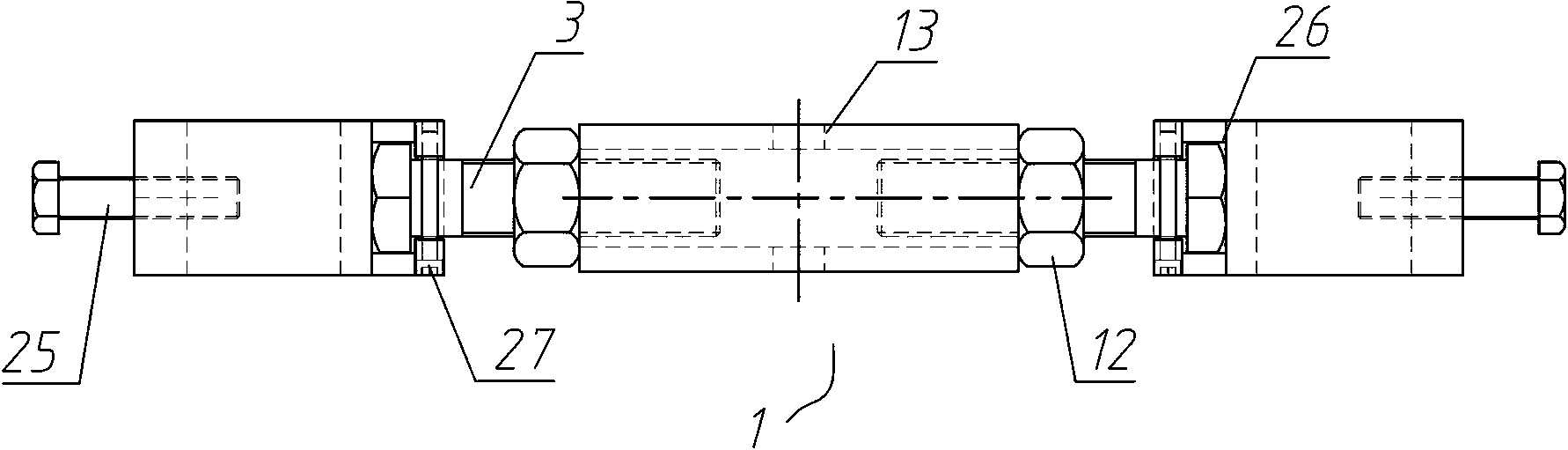

[0014] An embodiment of the hinge seat lug adjusting and fixing device of the present invention is as follows: Figure 1~Figure 2 As shown, it includes an intermediate driving member 1 and two clamping devices 2 arranged at both axial ends of the intermediate driving member 1 for clamping and fixing the lug plate.

[0015] The intermediate driving member 1 includes a steel pipe 11 and nuts 12 fixed by welding at both ends of the steel pipe 11 in the axial direction. The clamping device 2 includes a clamping seat 21, and the clamping seat 21 is provided with a through groove 22 that runs through the front and back. The outer groove side wall 23 is provided with a jacking bolt 25 through a threaded transmission connection, which is used to move toward the inner groove side wall 24 when tightening and fasten the ear plate to the inner groove side wall 24 to realize the clamping of the ear plate. Tight fix. Each clamping seat 21 is provided with a T-shaped groove 26 extending in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com