Device for melt-spinning and winding synthetic threads

A filament and equipment technology, which is applied in the field of melt-spinning and winding synthetic filament equipment, can solve the problems that cannot be used in equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

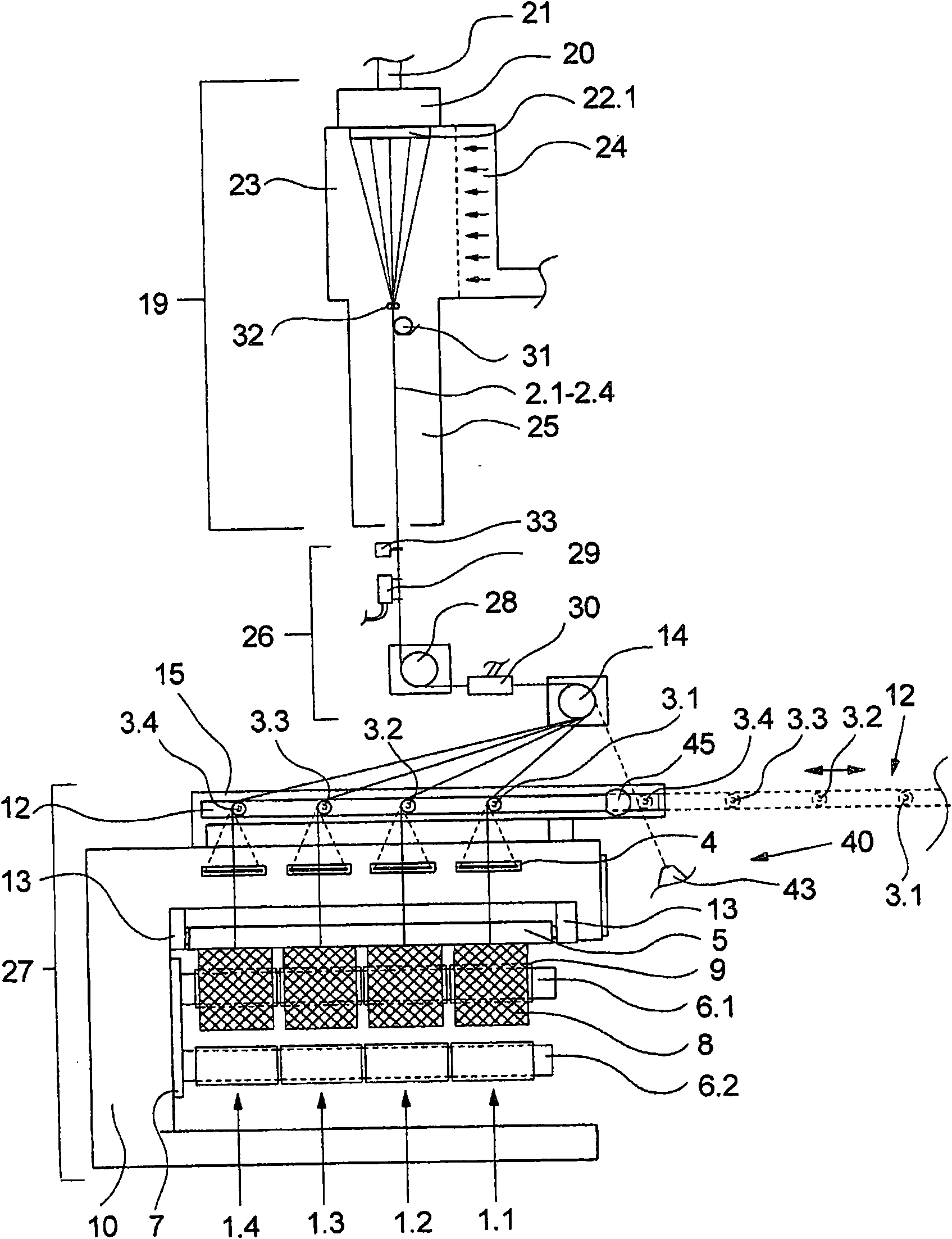

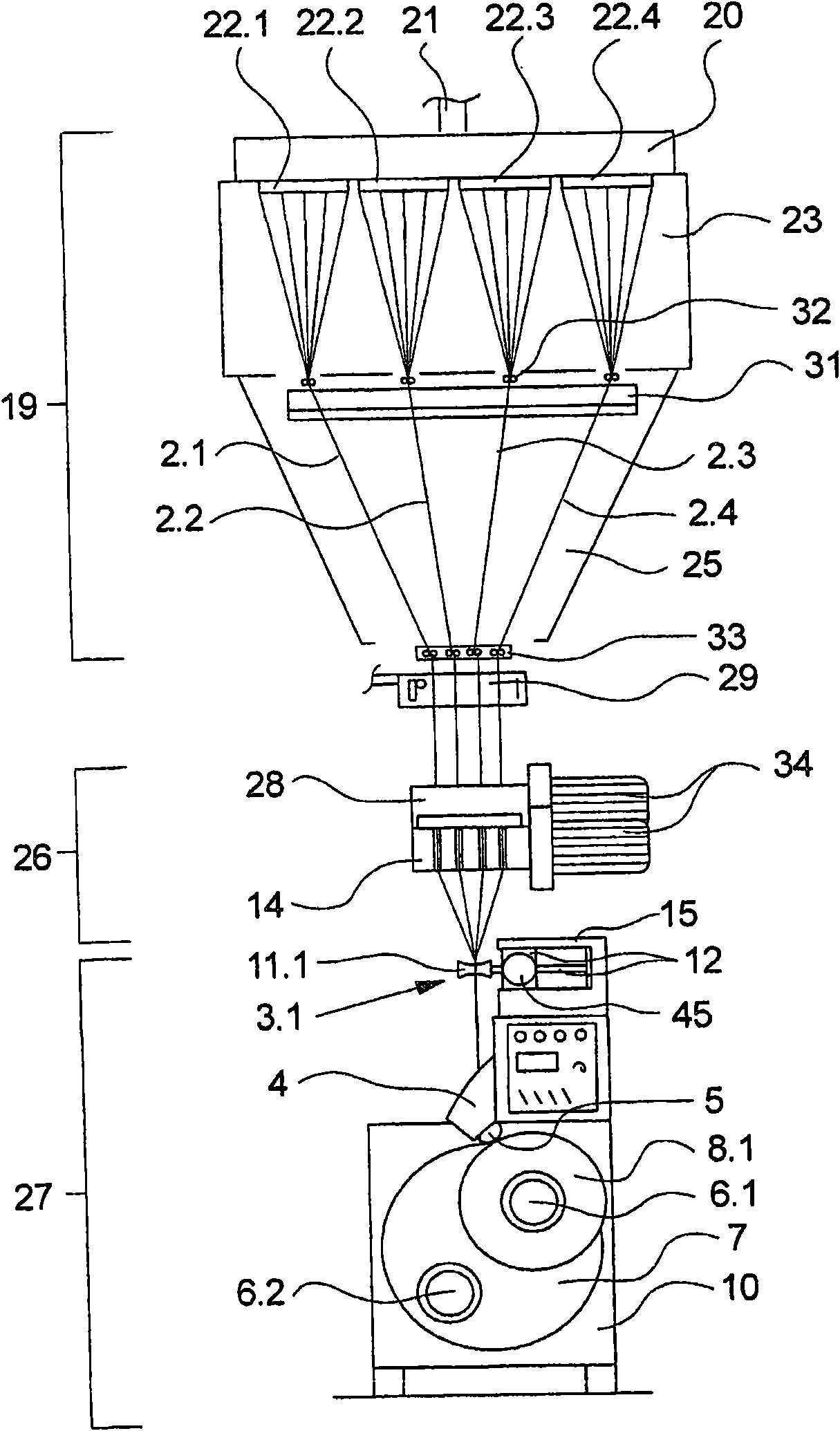

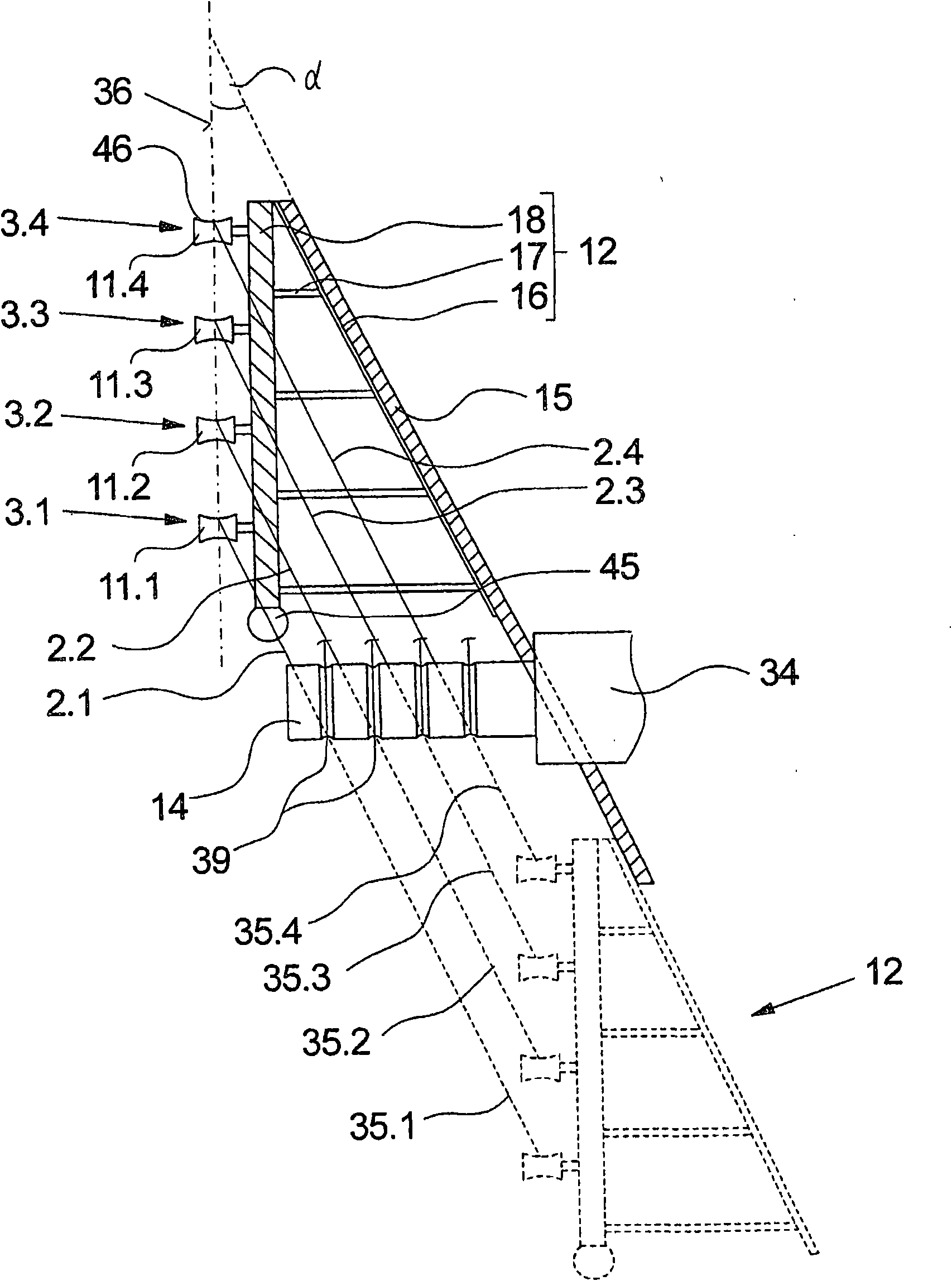

[0032] exist figure 1 , 2 A first embodiment of the device according to the invention is shown in several views in and 3 . exist figure 1 A side view of the device is shown in the figure 2 Its front view is shown in the image 3 A partial view of its top view is shown in . If no particular emphasis is placed on one of the figures, the following description applies to all figures.

[0033]The apparatus according to the invention consists of a spinning unit 19, a processing unit 26 and a winder 27, in which a plurality of synthetic filaments are produced in parallel side by side. For this purpose, in the spinning unit 19, a plurality of spinning nozzles 22.1 to 22.4 are held on a lower side of a heated spinning beam 20, which are connected via a melt supply line 21 to a melt source, for example an extruder. Outbound (not shown here) connections. In the present exemplary embodiment, a total of four spinning nozzles 22.1 to 22.4 are arranged side by side in series. The nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com