Patents

Literature

223results about How to "Reliable boot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

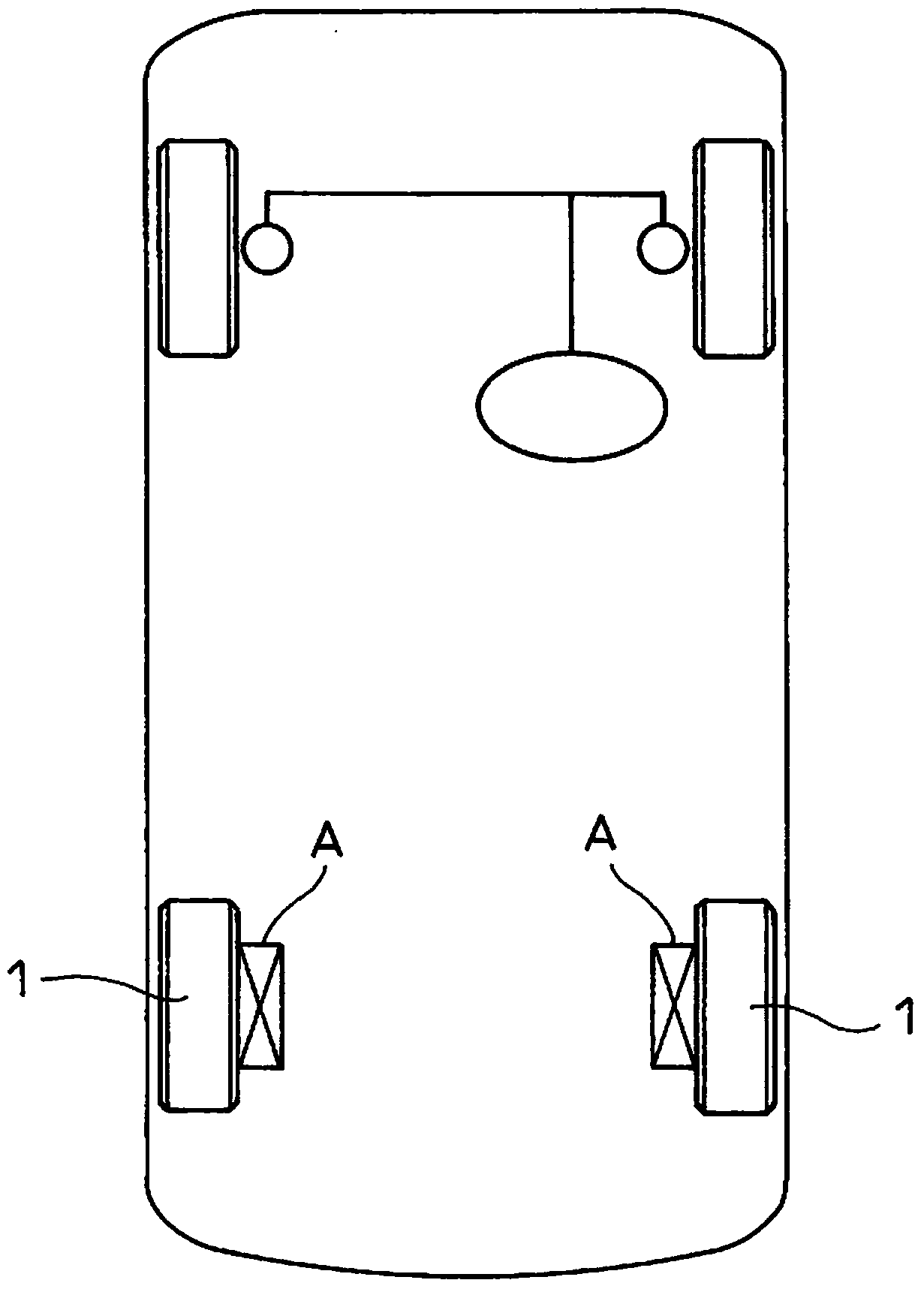

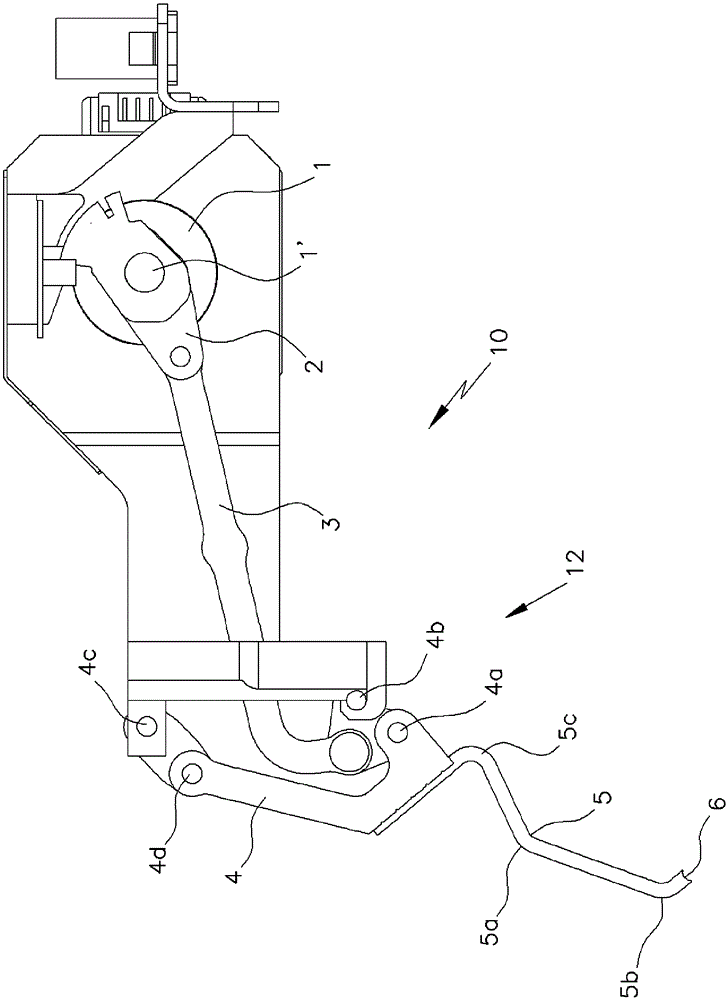

In-wheel motor system

InactiveCN101370678AGood grounding effectImprove durabilitySpeed controllerElectric devicesGround contactCoupling

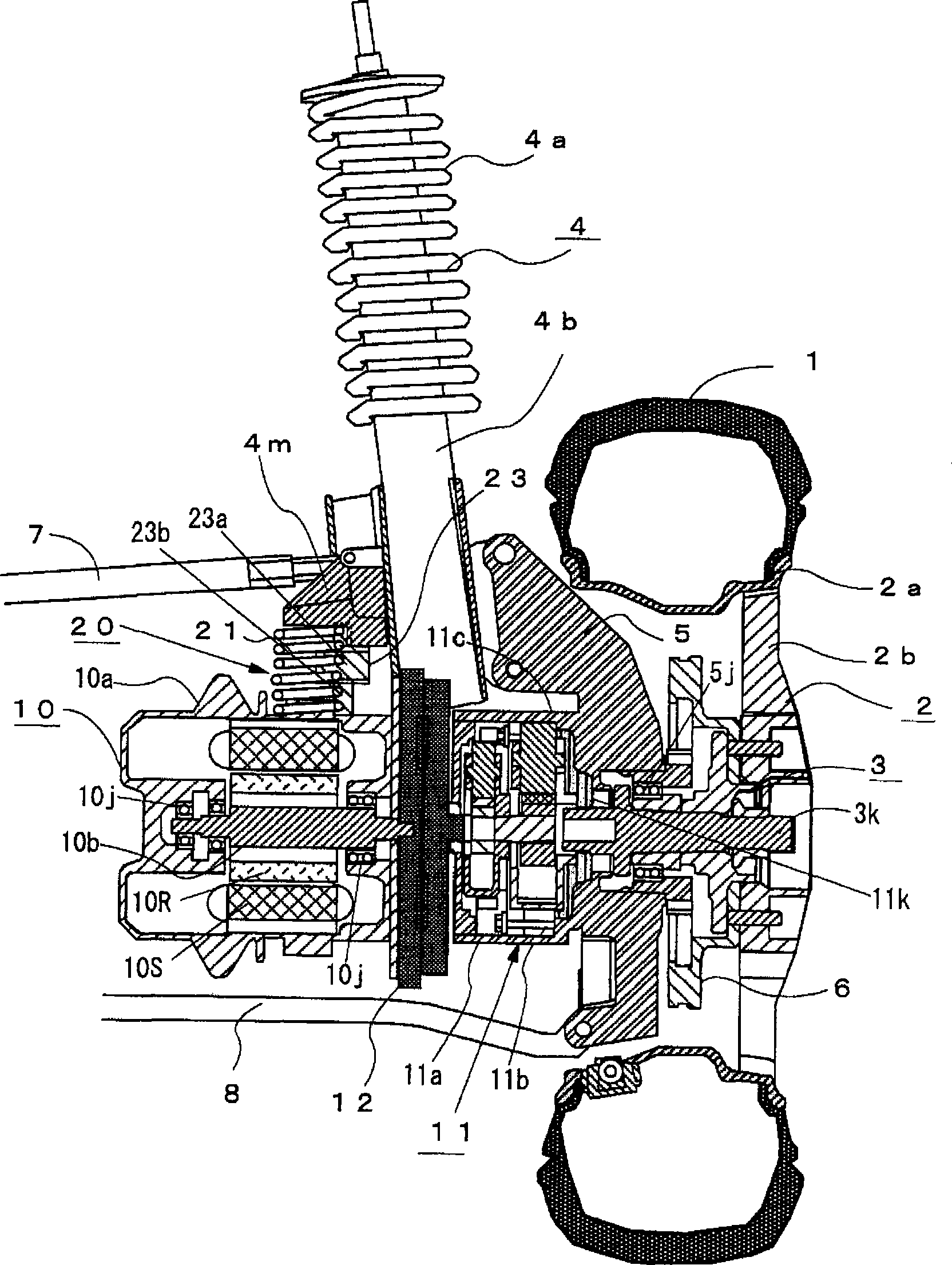

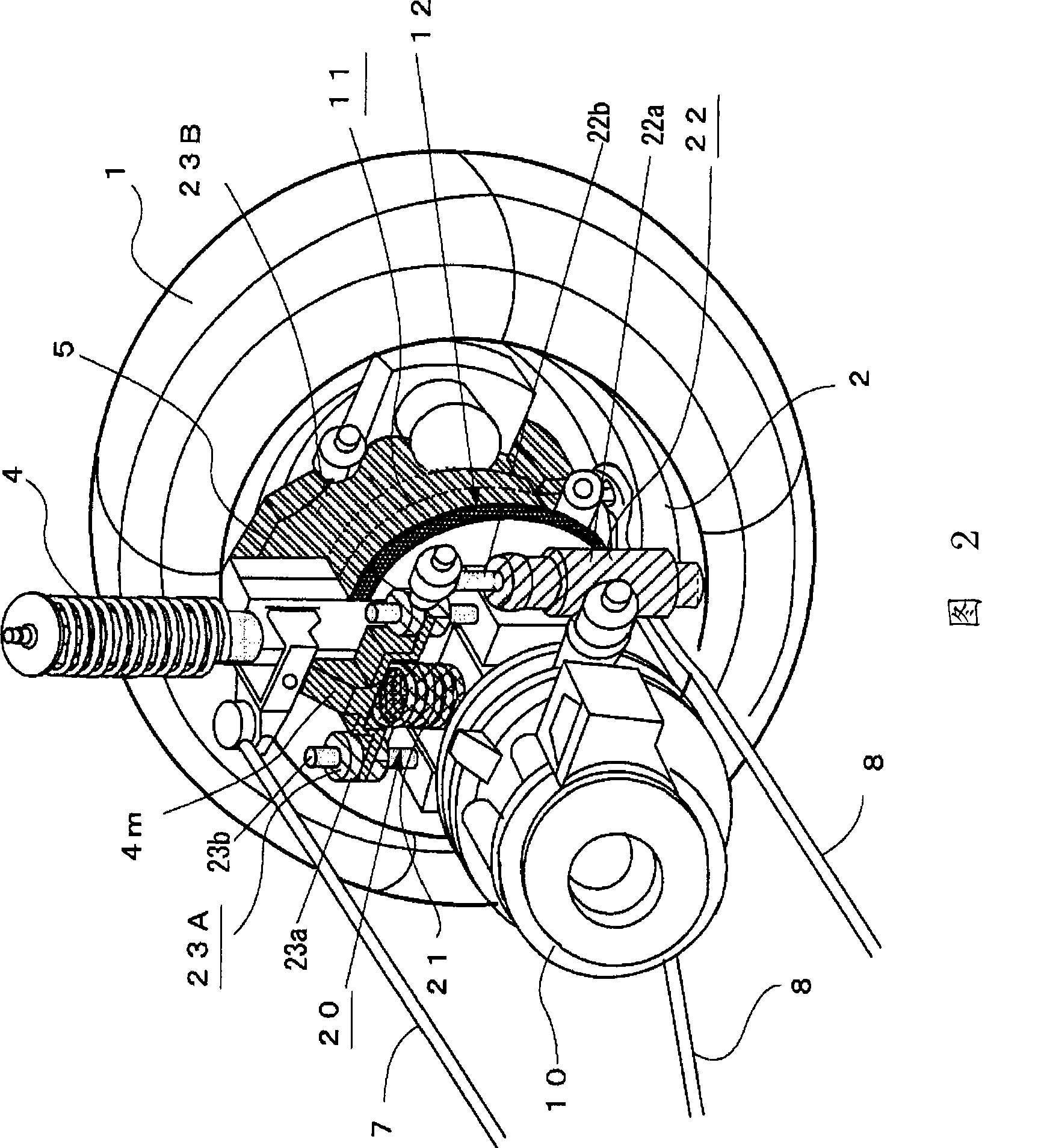

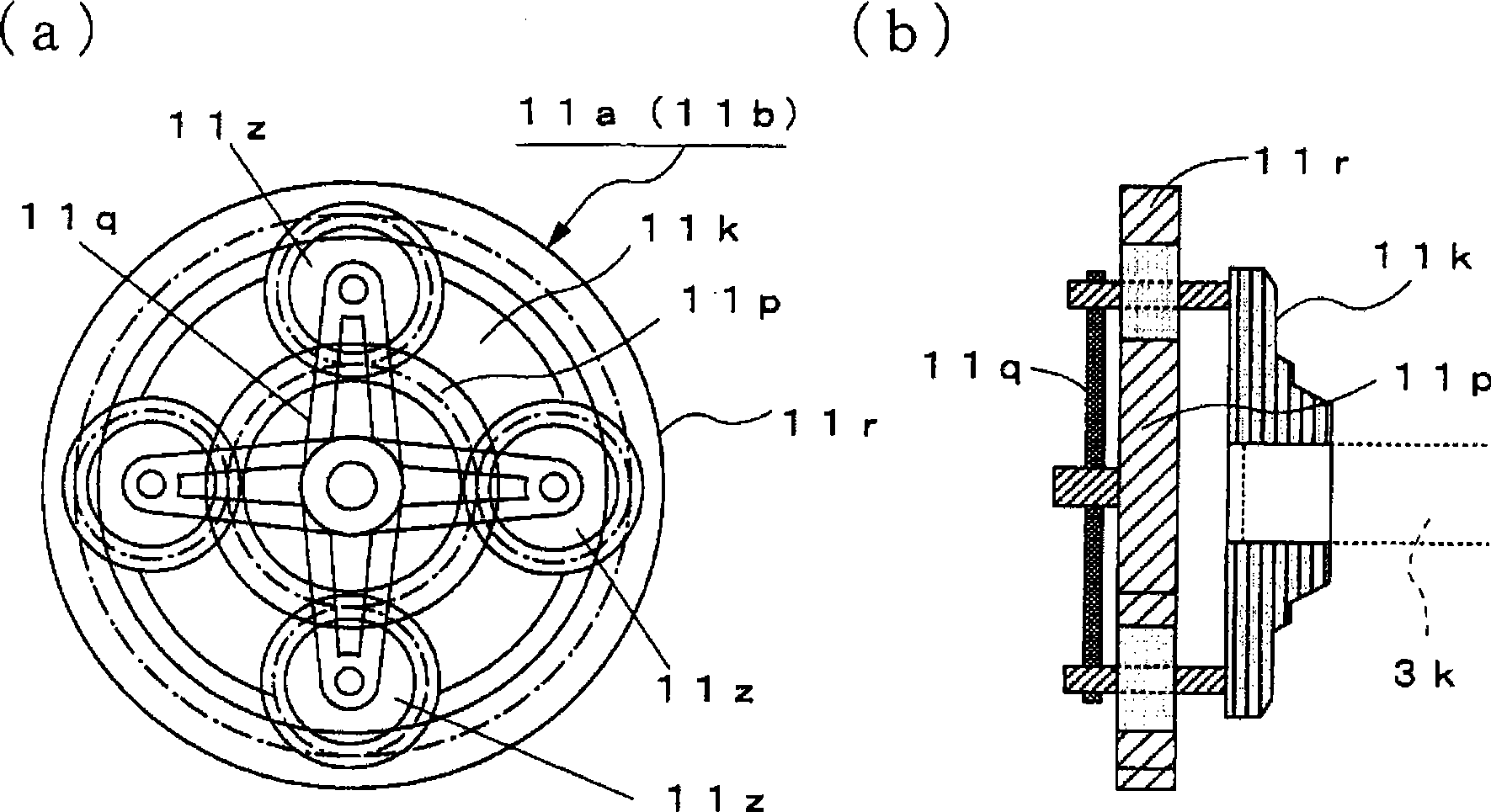

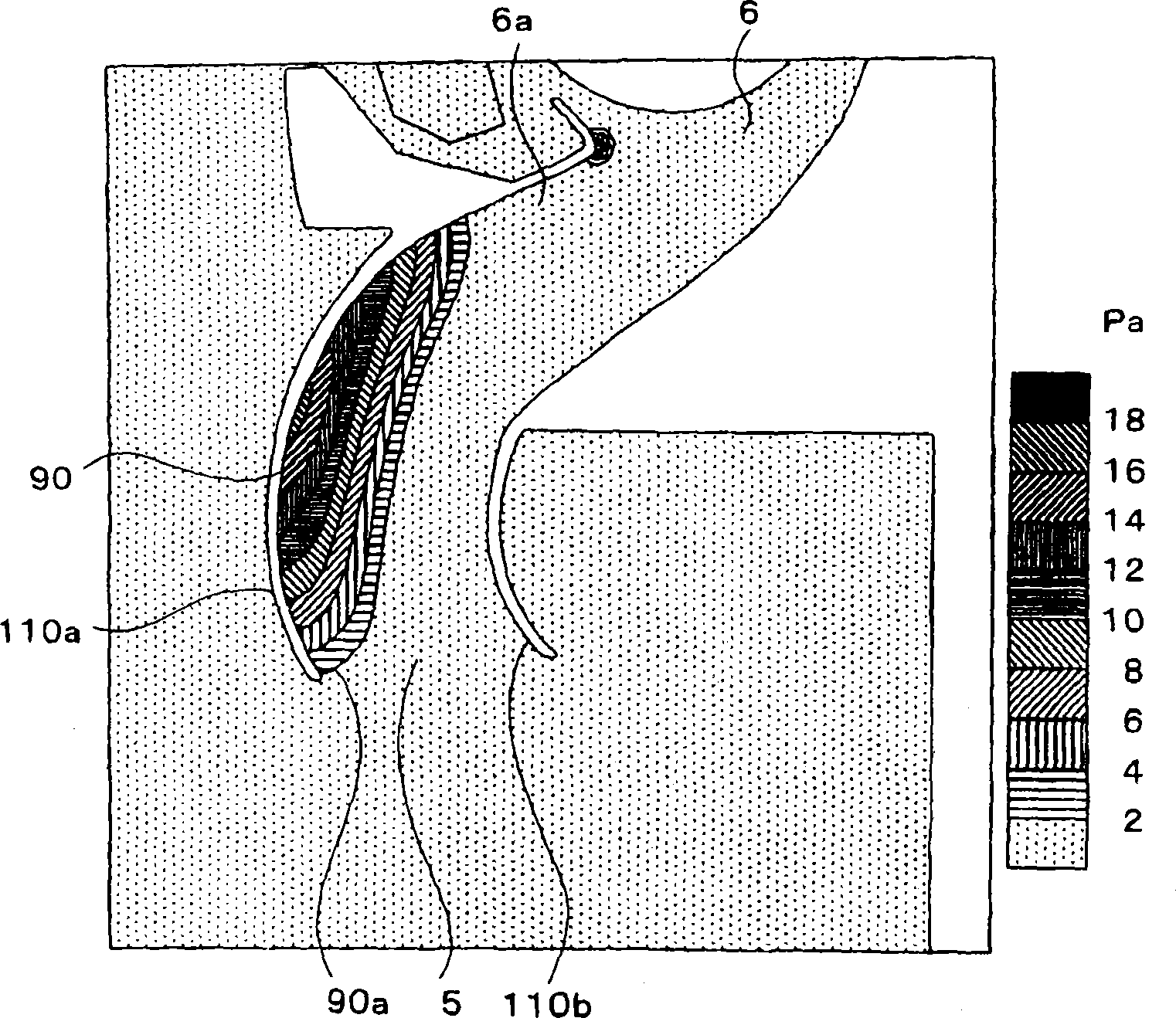

An electric motor (10) and a speed reduction gear mechanism (11) are coupled by a flexible coupling (12) that is a power transmission mechanism such as an Oldham's coupling. A casing (11c) of the speed reduction gear mechanism (11) is formed integrally with a knuckle (5) as a component of vehicle's unsprung portion, or alternatively, is attached to the knuckle (5). Further, a motor case (10a) of the electric motor (10) is attached to a motor installation member (4m) via a shock absorbing mechanism (20), the motor installation member (4m) being provided on the lower side of a strut (4) for supporting the knuckle (5). The shock absorbing mechanism (20) has a spring member (21), a damper, and two guide members (23) for guiding the direction of operation of the spring member (21) and the damper. The construction allows the mass of the motor (10) to act as the mass of a dynamic damper. An in-wheel motor system thus obtained improves ground contact performance and ride quality of a vehicle traveling on a bad road and has good space efficiency.

Owner:BRIDGESTONE CORP

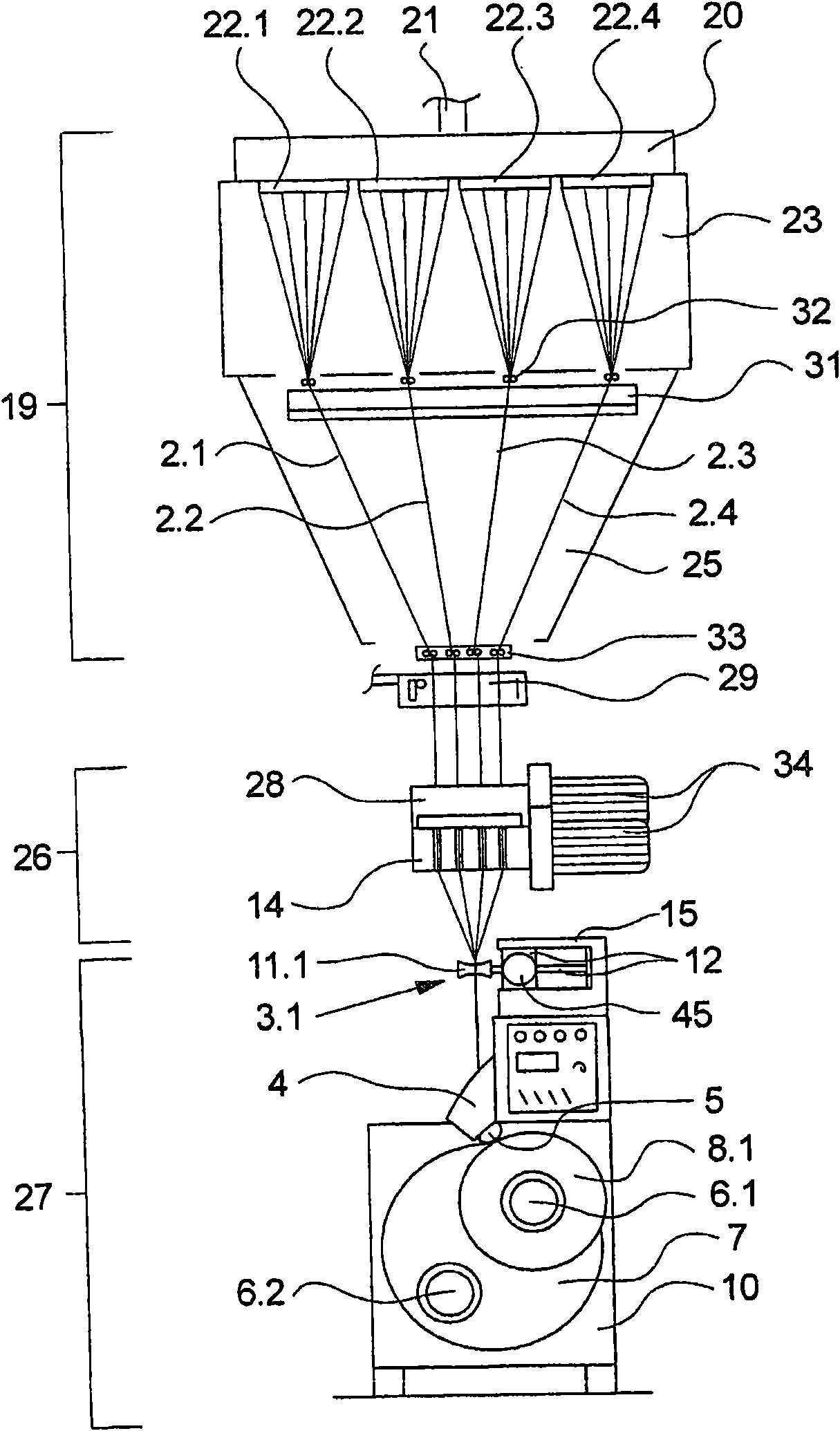

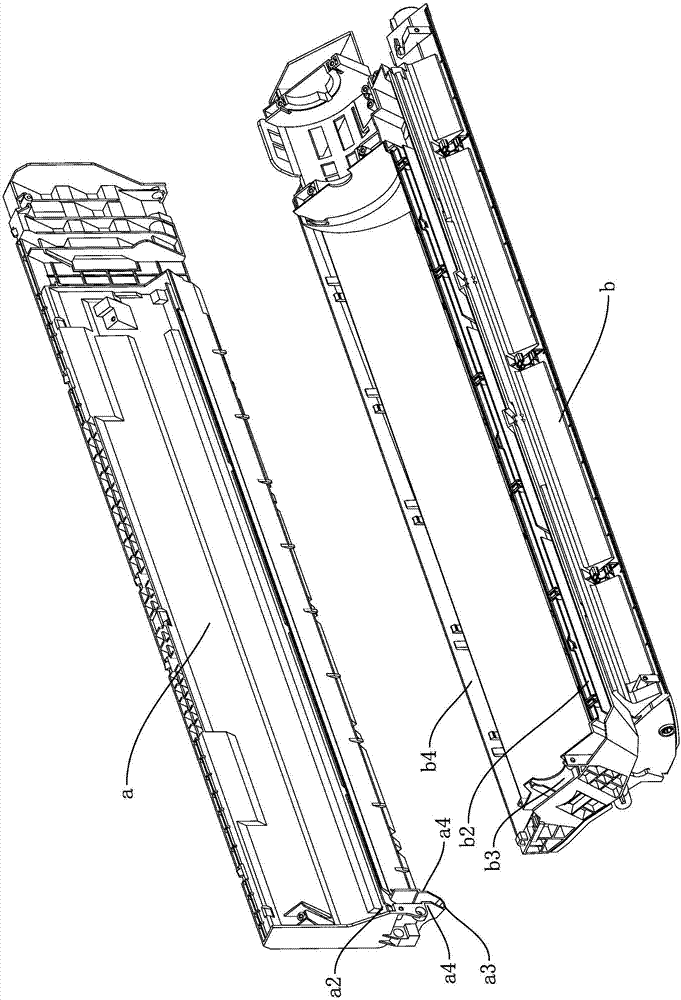

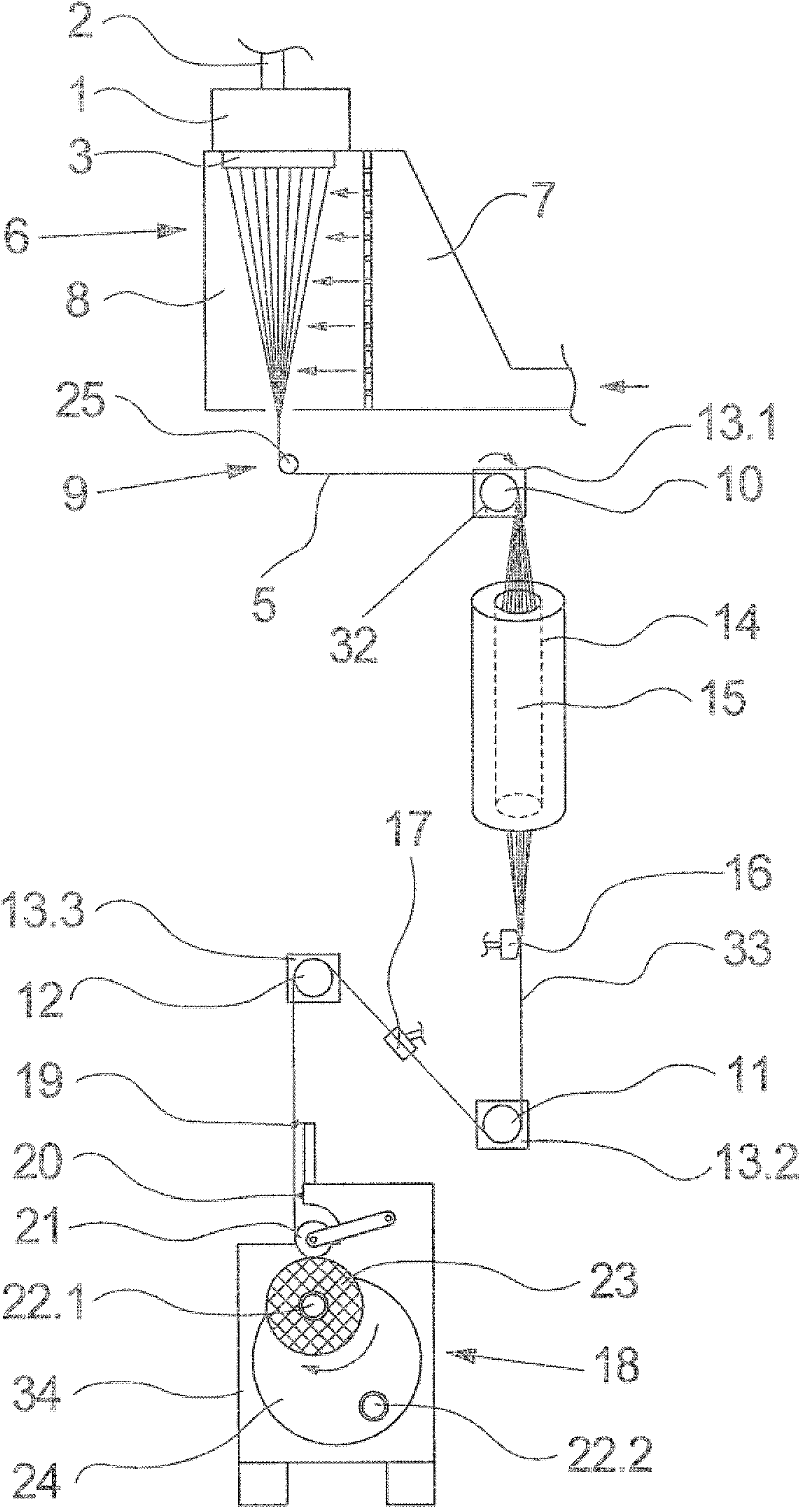

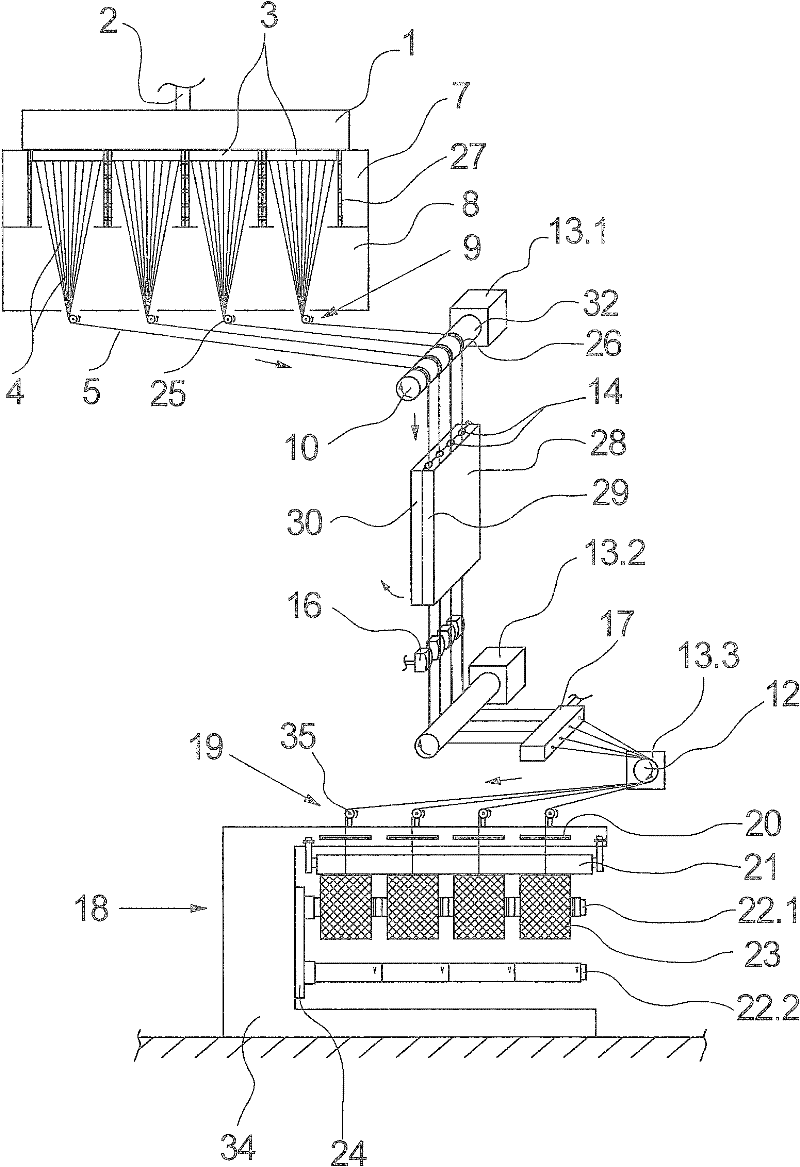

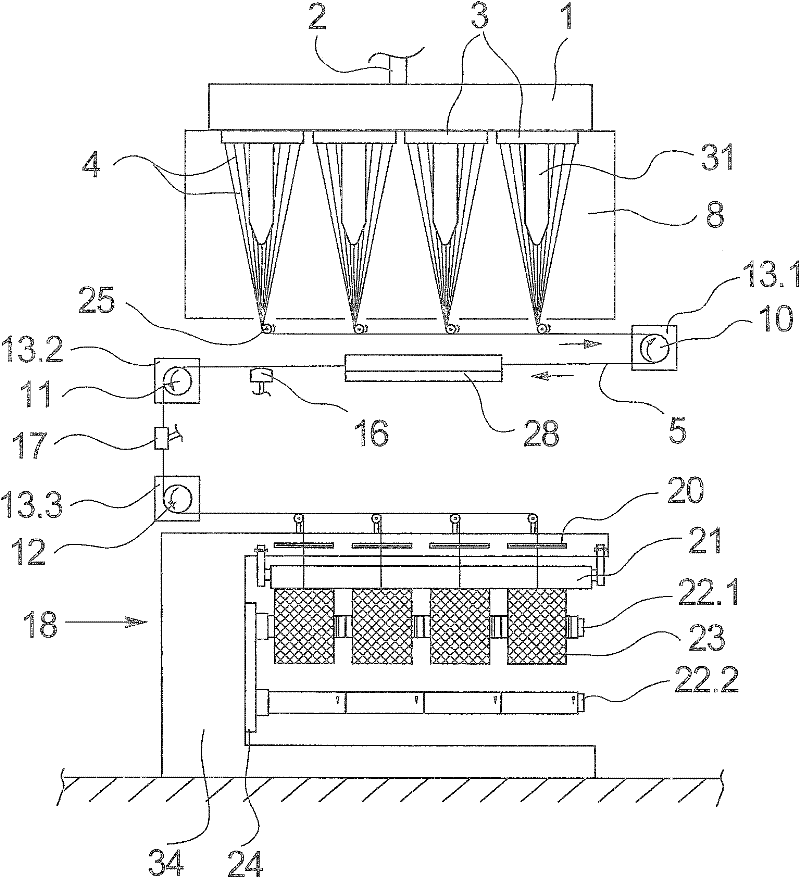

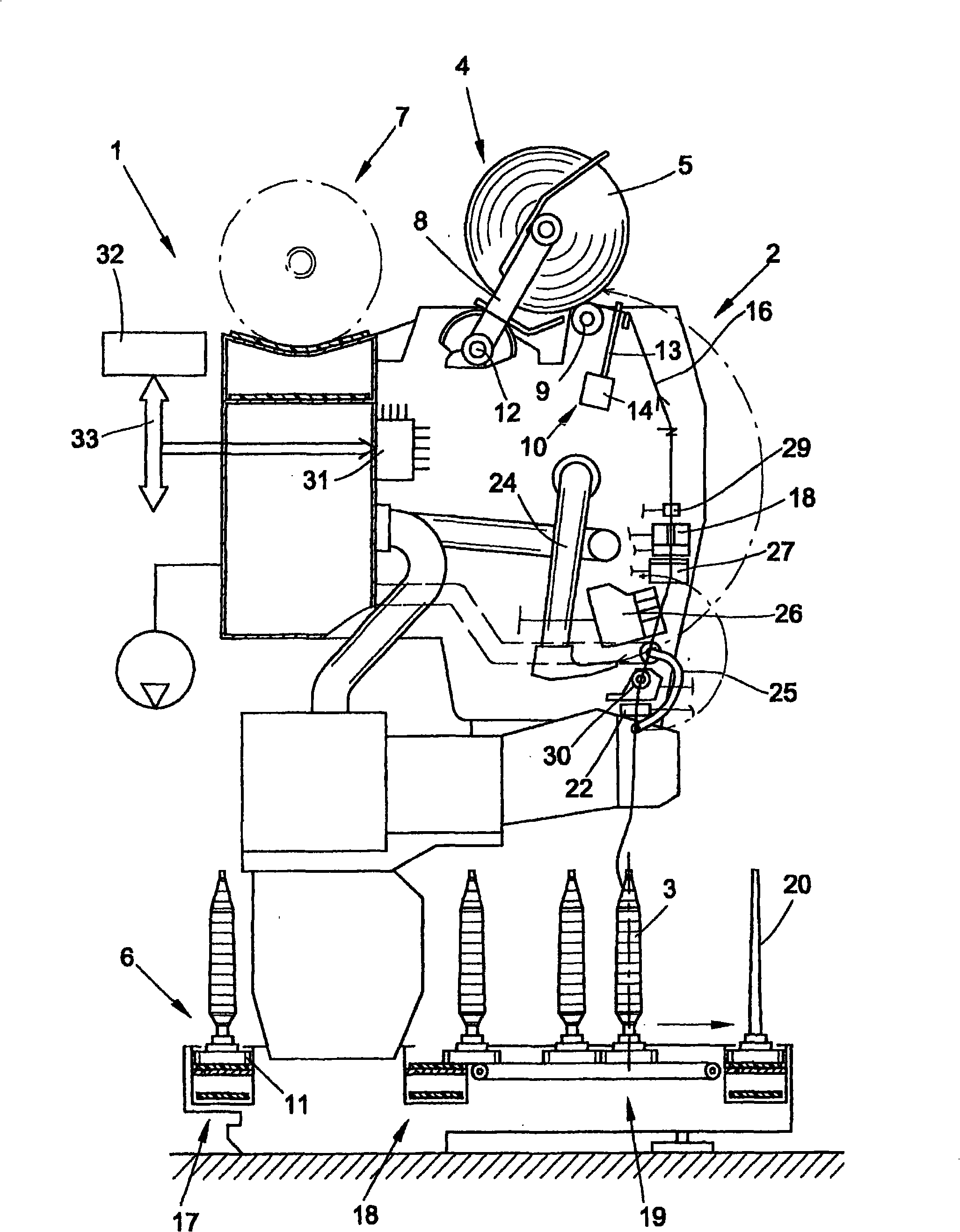

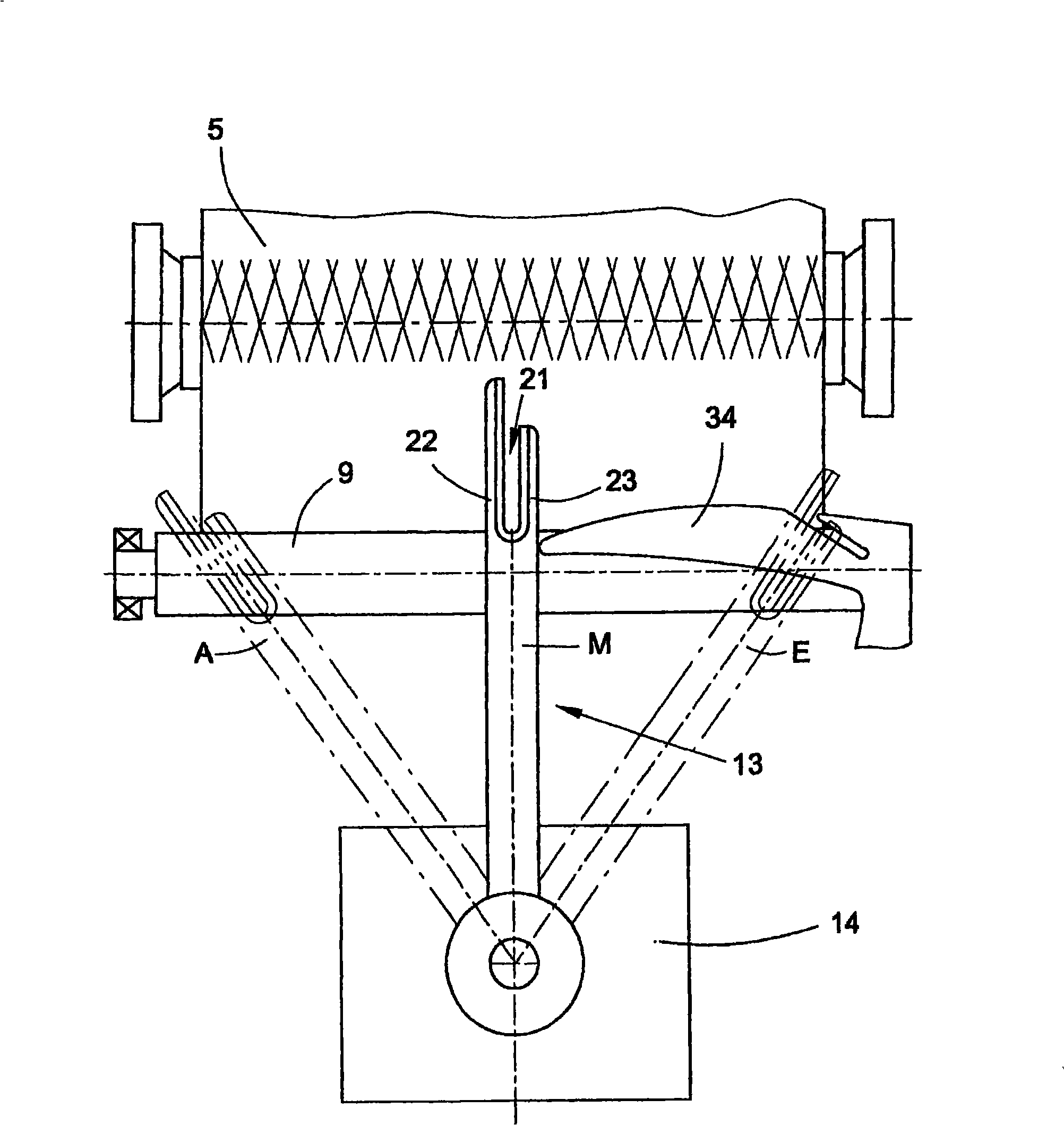

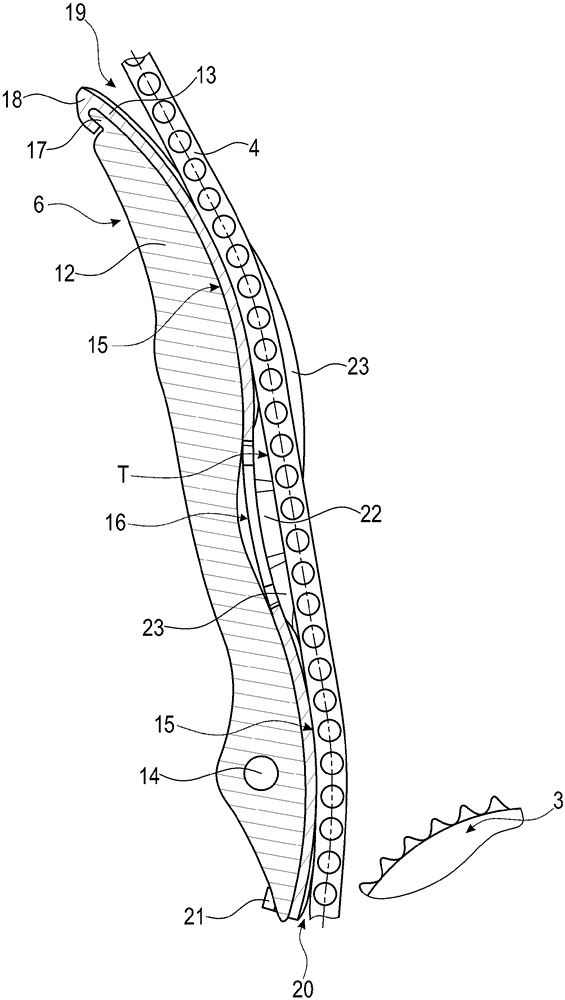

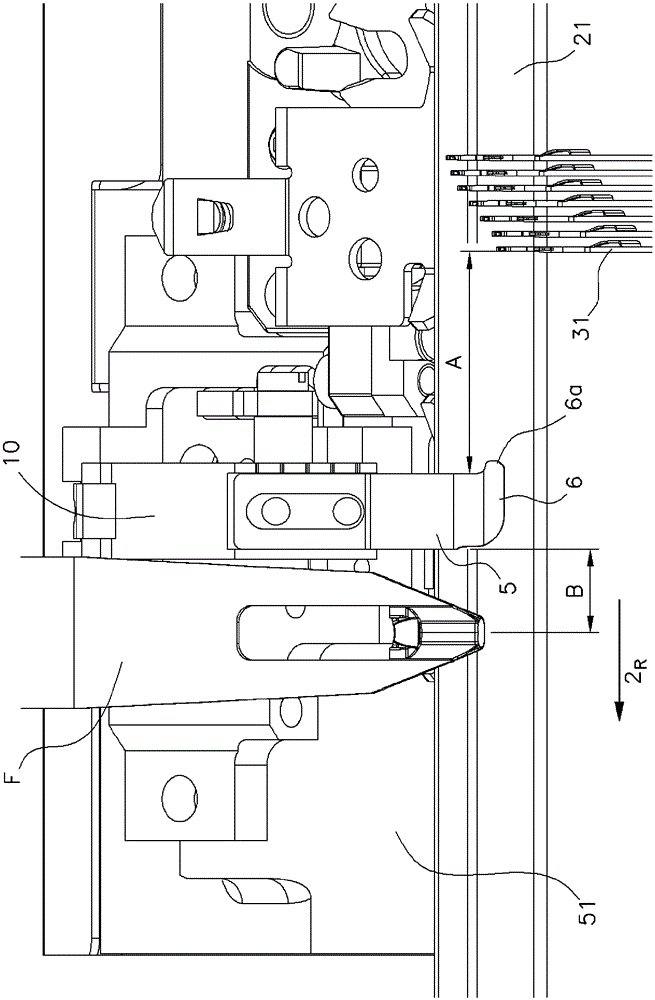

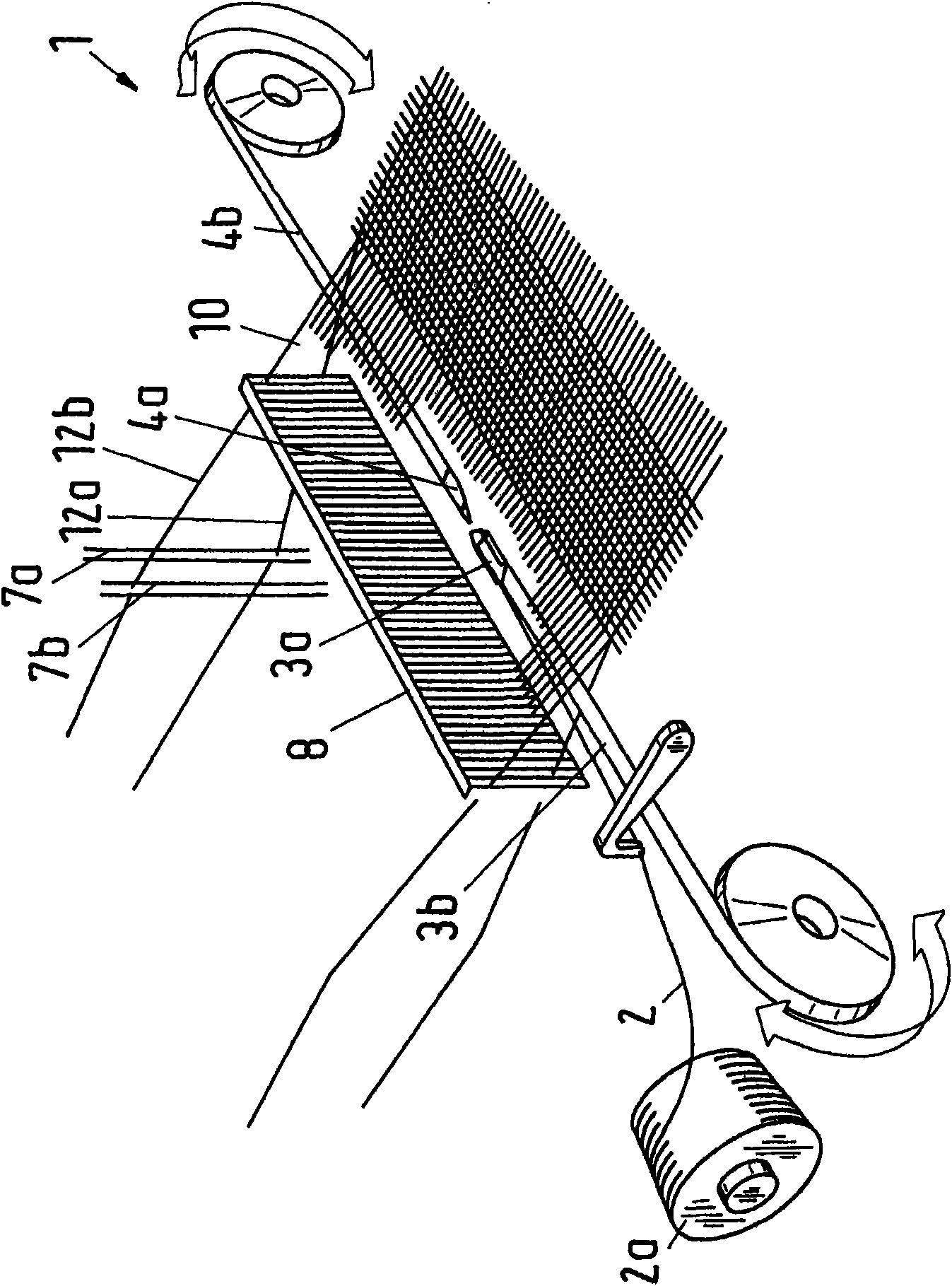

Device for melt-spinning and winding synthetic threads

ActiveCN101680119AFully automatedCompact structureNew-spun product collectionArtificial thread manufacturing machinesWinding machineEngineering

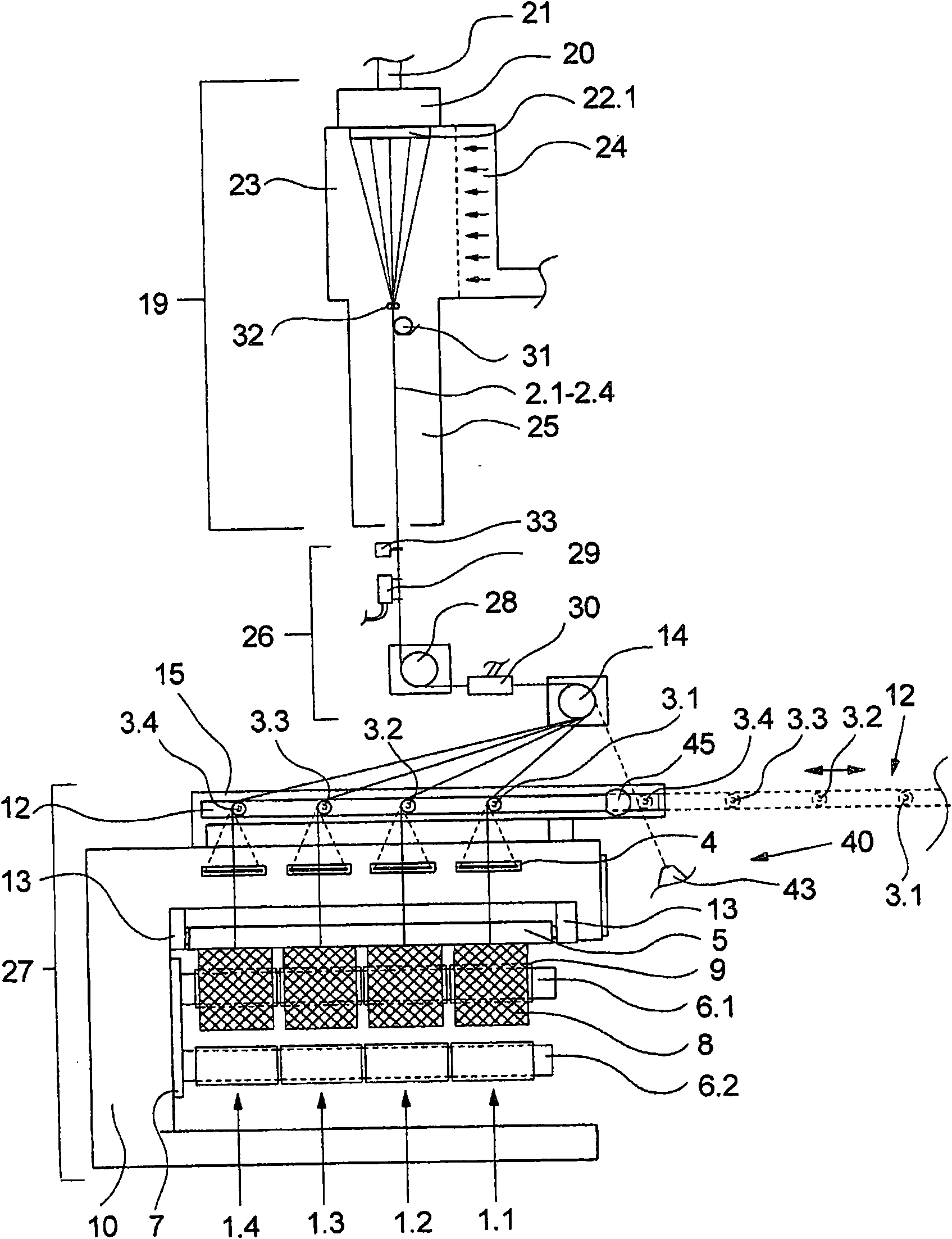

The invention relates to a device for melt-spinning and winding synthetic threads, comprising a spinning device, a treatment device and a winding machine. The treatment device is provided with a take-off godet for guiding the threads before the threads are fed and distributing the threads to a plurality of winding points in the winding machine. The take-off godet is disposed above the winding machine and guides the threads on the circumference such that the threads run parallel next to each other. The take-off godet is arranged transversely to a winding spindle, above the winding machine. Thewinding machine is equipped with a plurality of top thread guides, which are mounted upstream of the winding points and are located in a feeding plane. In order to improve the application process regarding the distribution of the filaments on the individual winding points when starting the process or pausing the process, the take-off godet and the group of the top thread guides for applying the threads into the winding points of the winding machine are designed to be moveable relative to each other according to the invention.

Owner:OERLIKON TEXTILE GMBH & CO KG

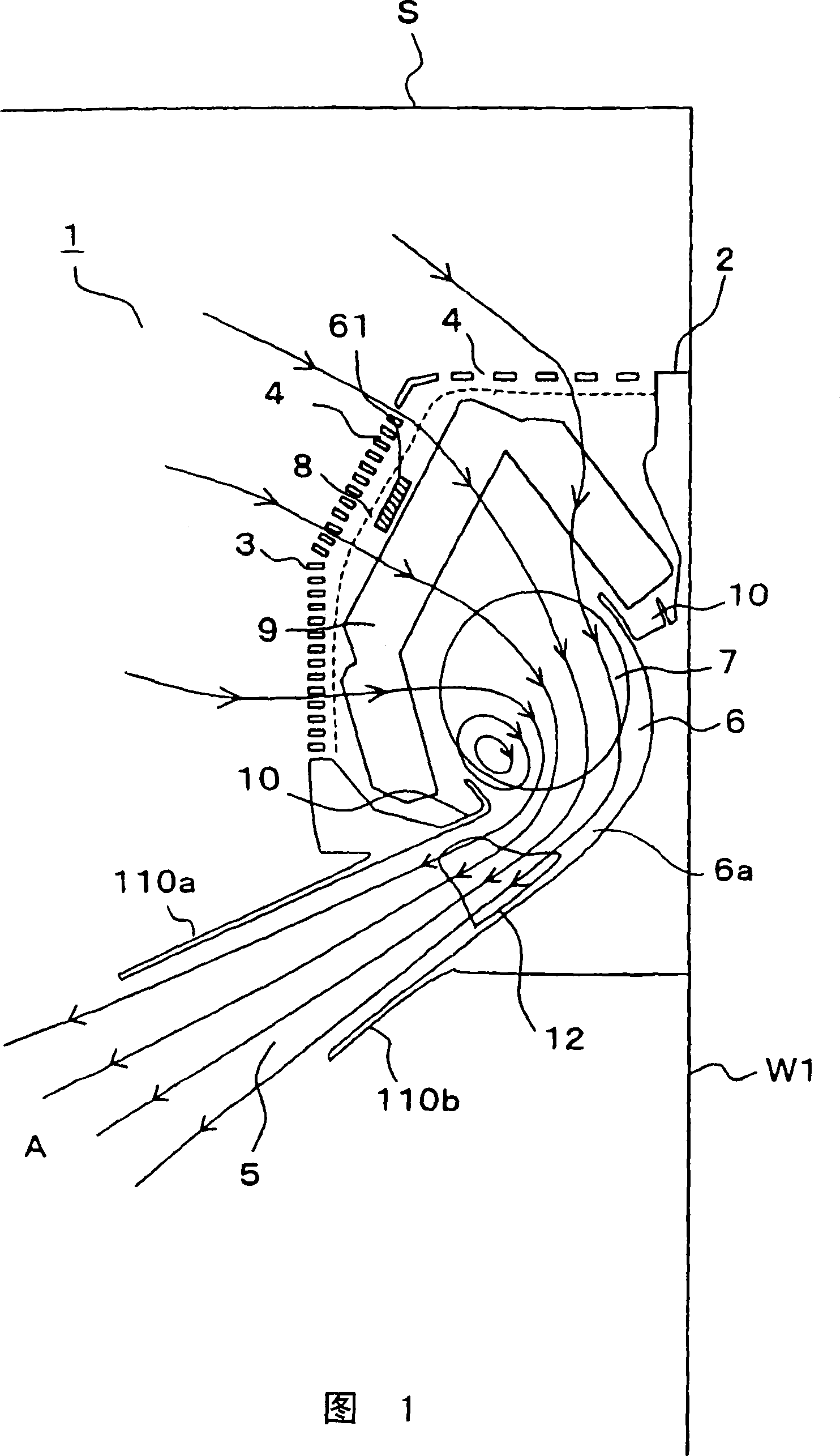

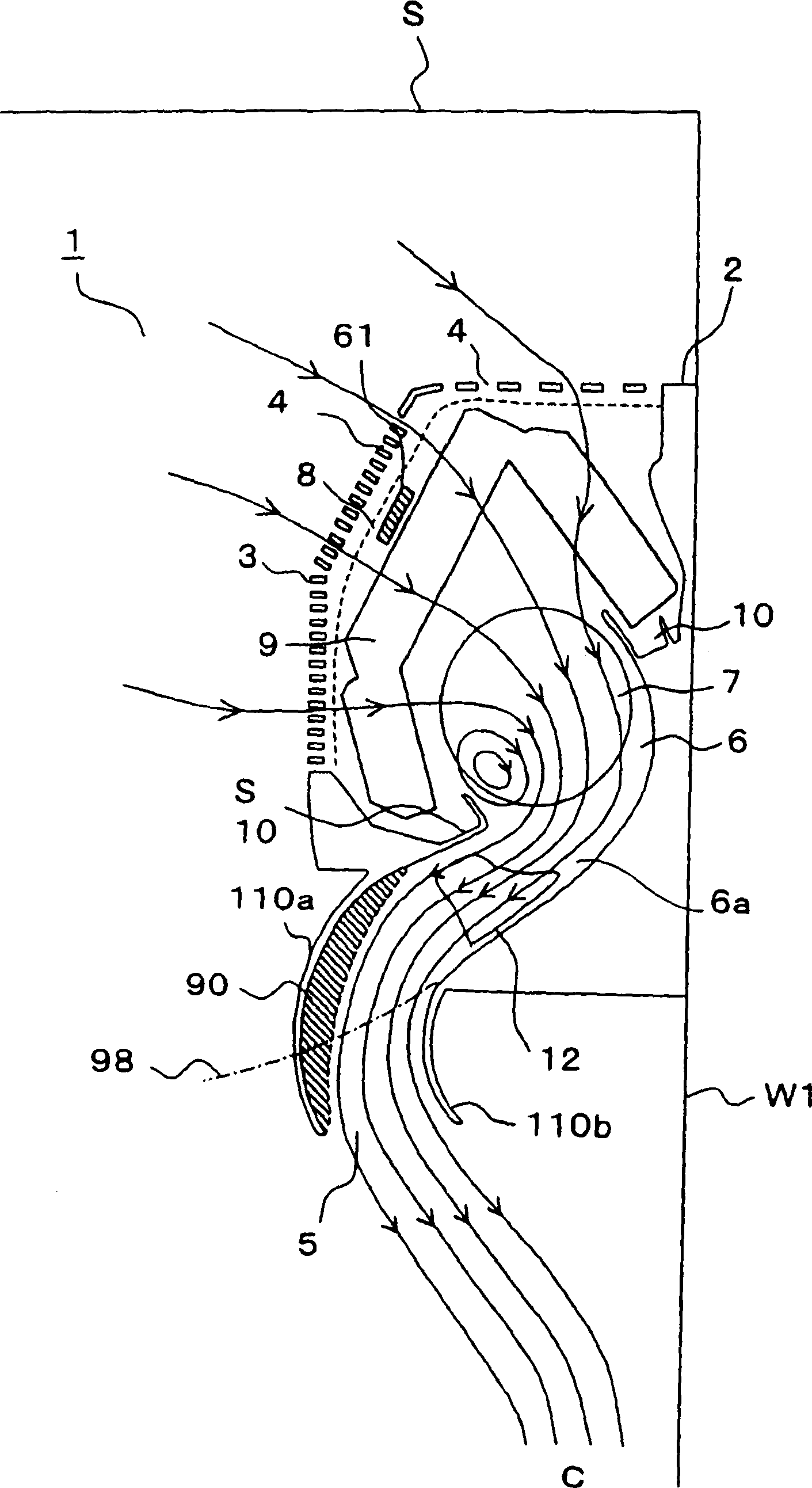

Air conditioner

ActiveCN1906447AEasy to change the wind directionSmall pressure lossDucting arrangementsLighting and heating apparatusEngineeringAir conditioning

Owner:SHARP KK

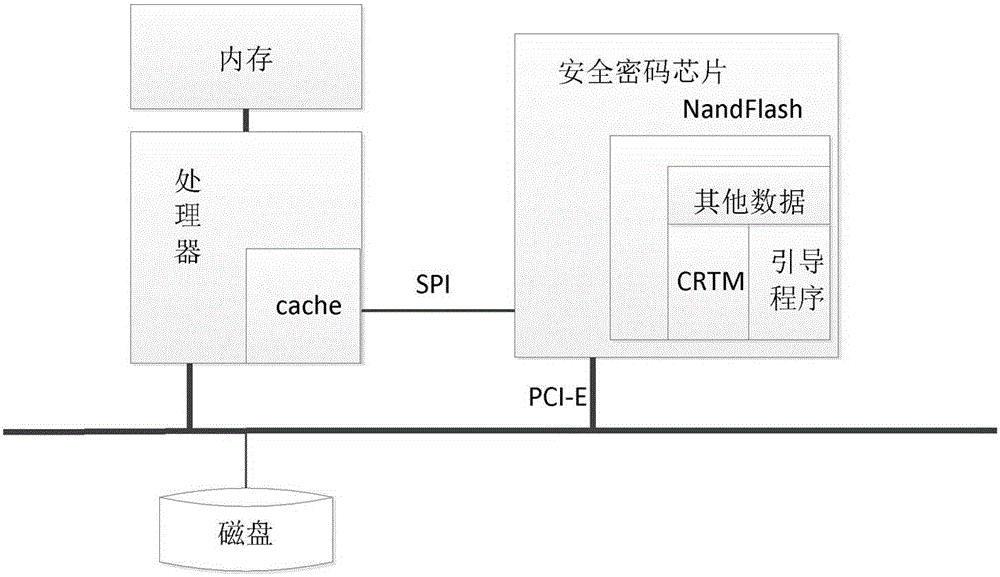

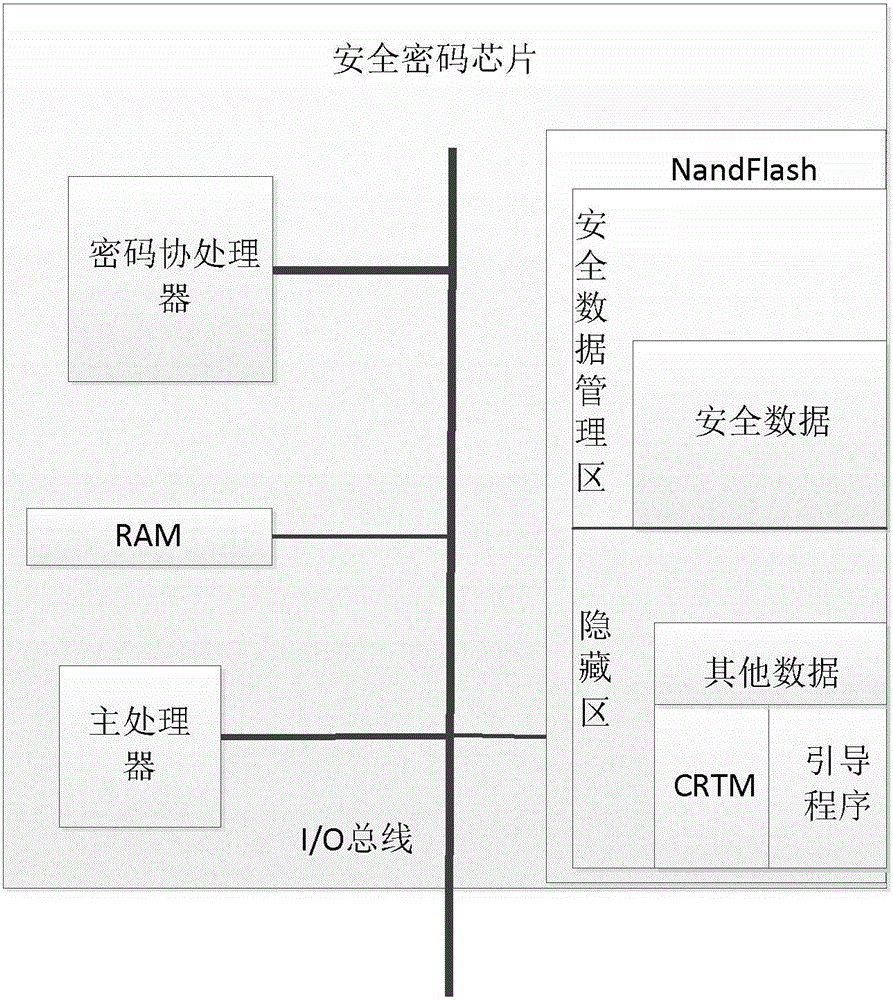

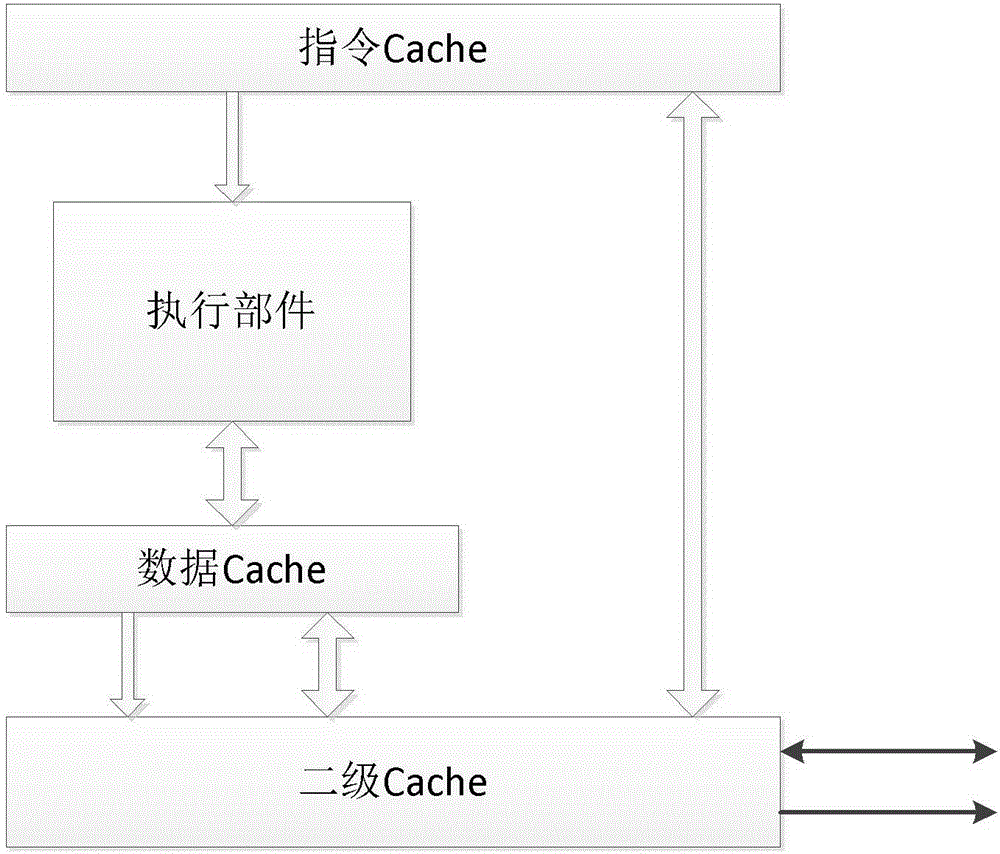

Trusted computer system based on safe password chip and trusted guiding method thereof

InactiveCN105205401ASecure and Trusted BootSecure bootPlatform integrity maintainanceInternal memoryOperational system

The invention relates to a trusted computer system based on a safe password chip and a trusted guiding method thereof. The system comprises a main platform and the safe password chip. The main platform comprises a main processor, an internal memory, an external memory, a bus and an external device. The main processor comprises a command cache unit, a data cache unit, an executing unit and a second-level cache unit. According to the trusted computer system and the trusted guiding method, when the system is started, the safe password chip runs before the main processor runs, pushes a CRTM to the command cache unit and awakes the main processor; the main processor performs execution from the CRTM, measures and loads a guide program, an operating system, an application program and the like through the safe password chip and builds a trusted chain; the safe password chip participates in the whole trusted guiding process and can not be bypassed; the CRTM is retained inside the safe password chip, other programs running on the main processor can not meet the CRTM and can also not analyze and distort the CRTM, the safer effect is achieved, and the system is more stable.

Owner:THE PLA INFORMATION ENG UNIV

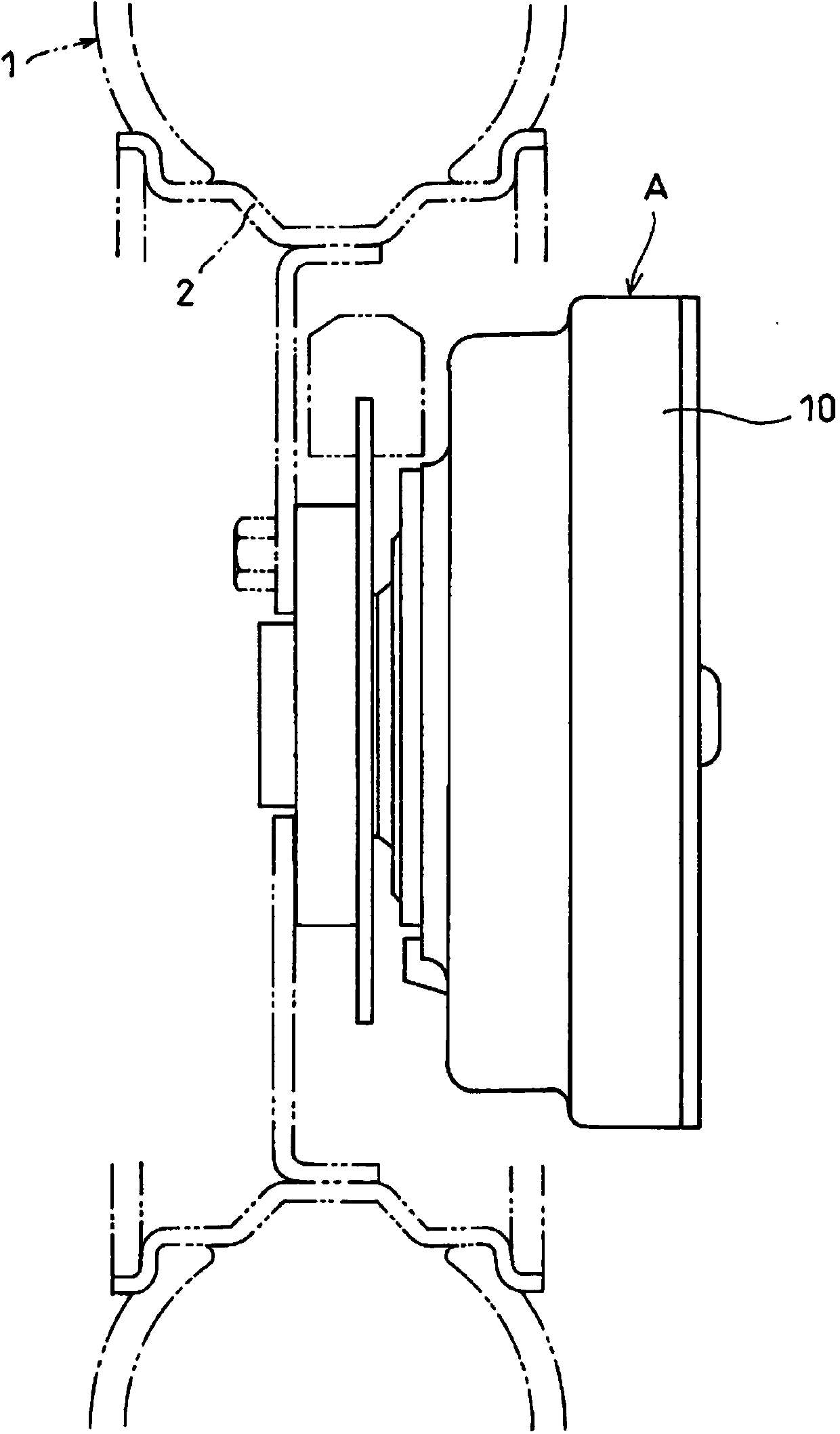

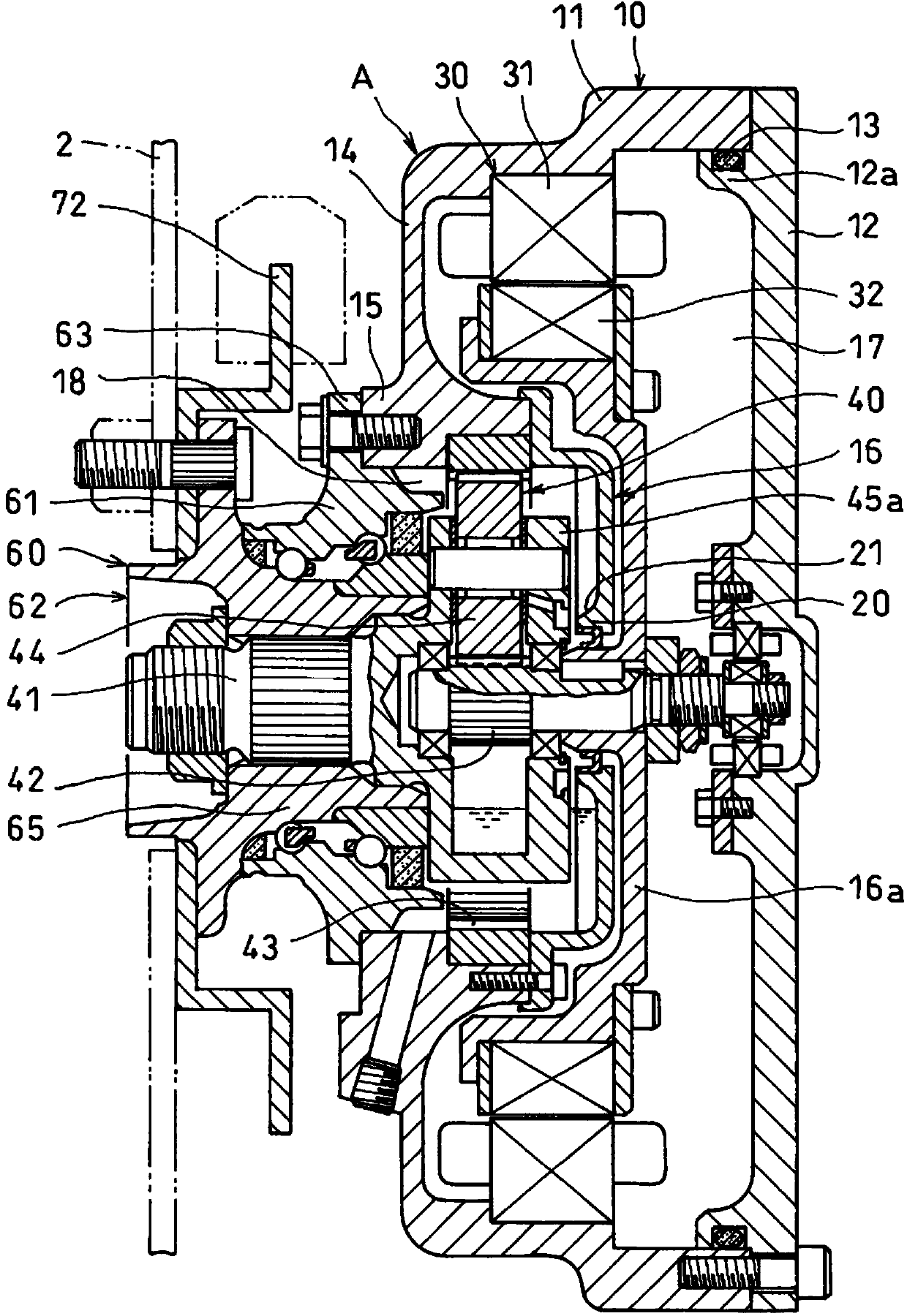

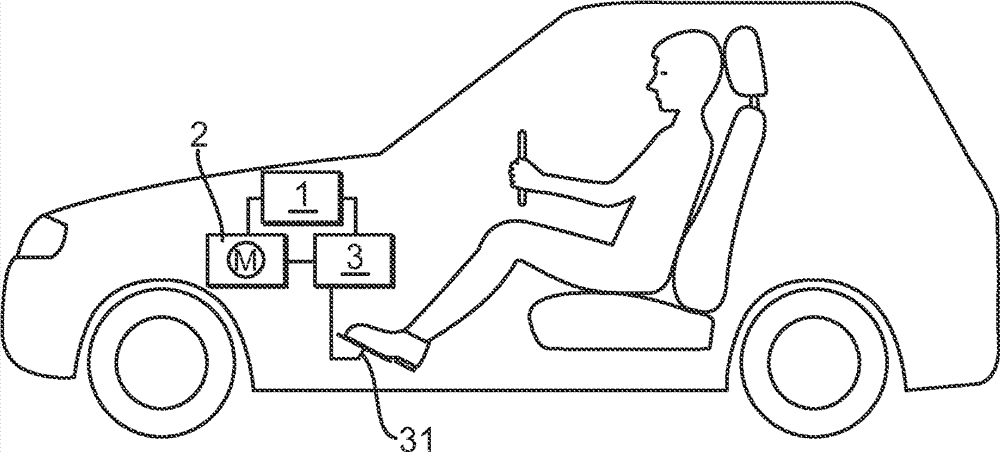

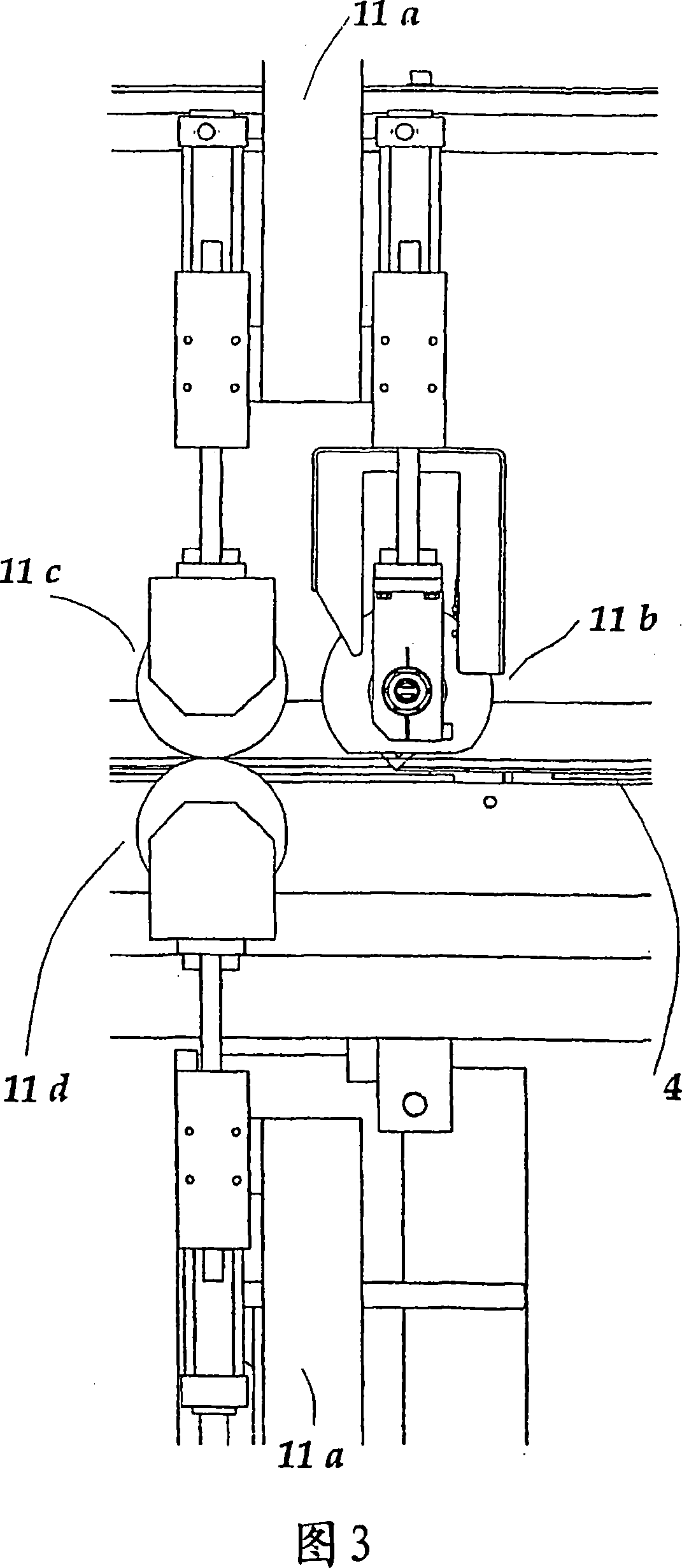

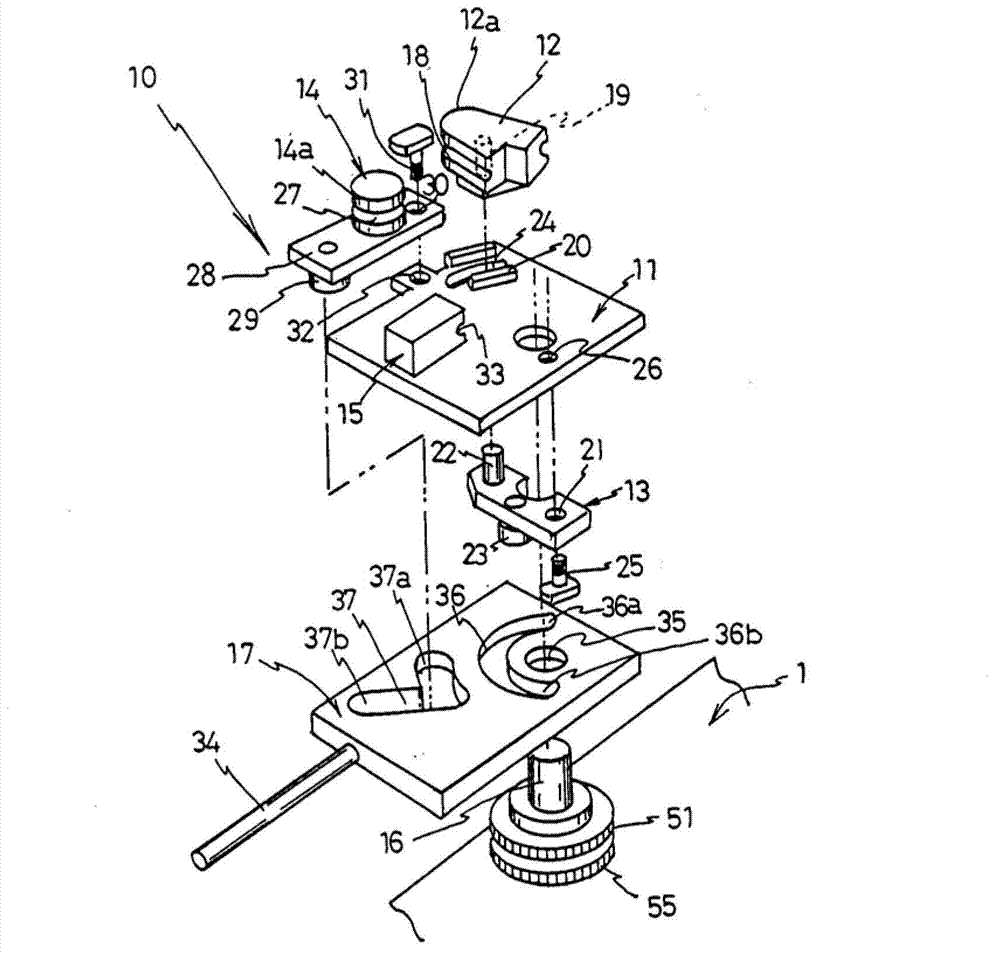

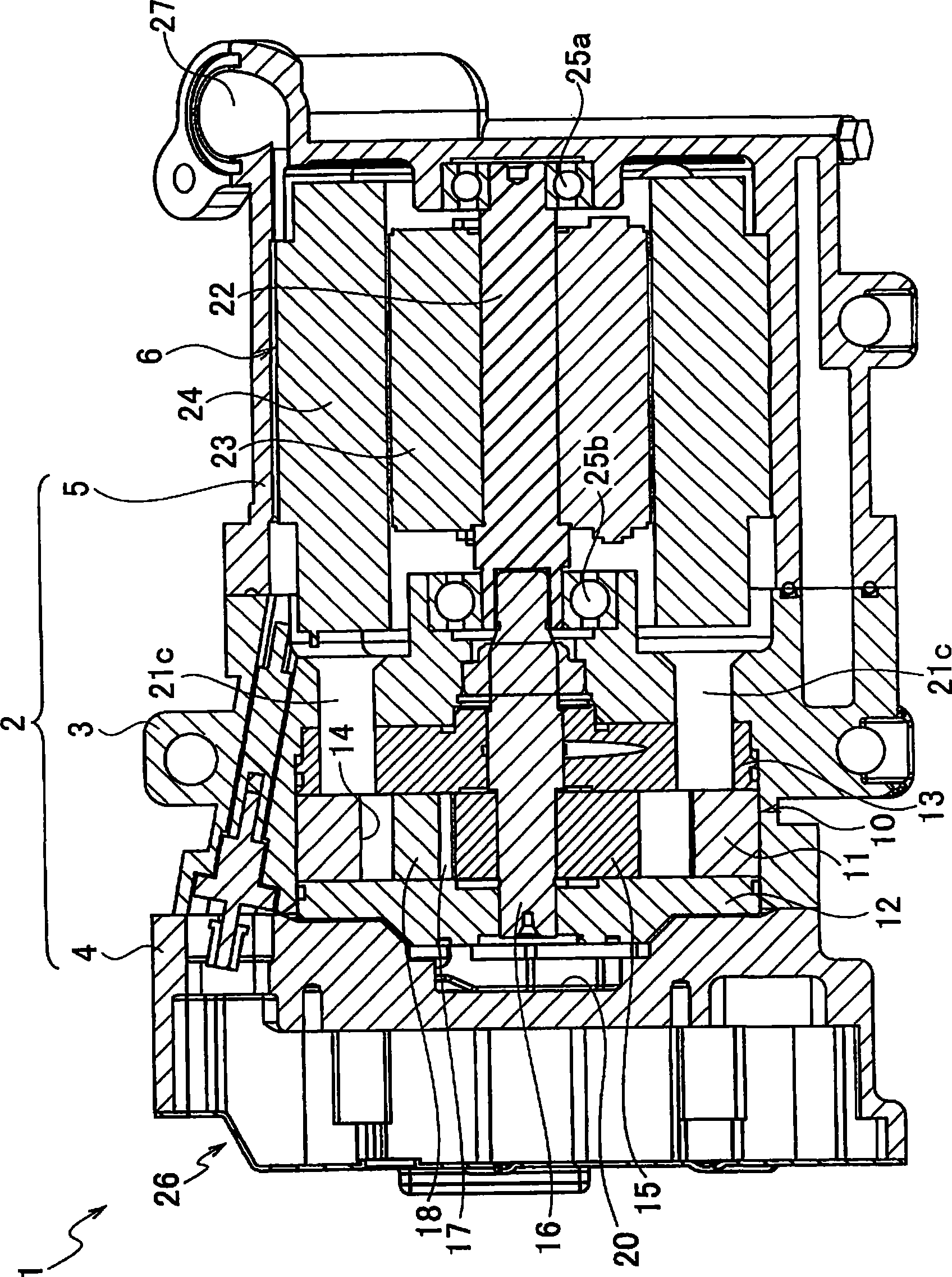

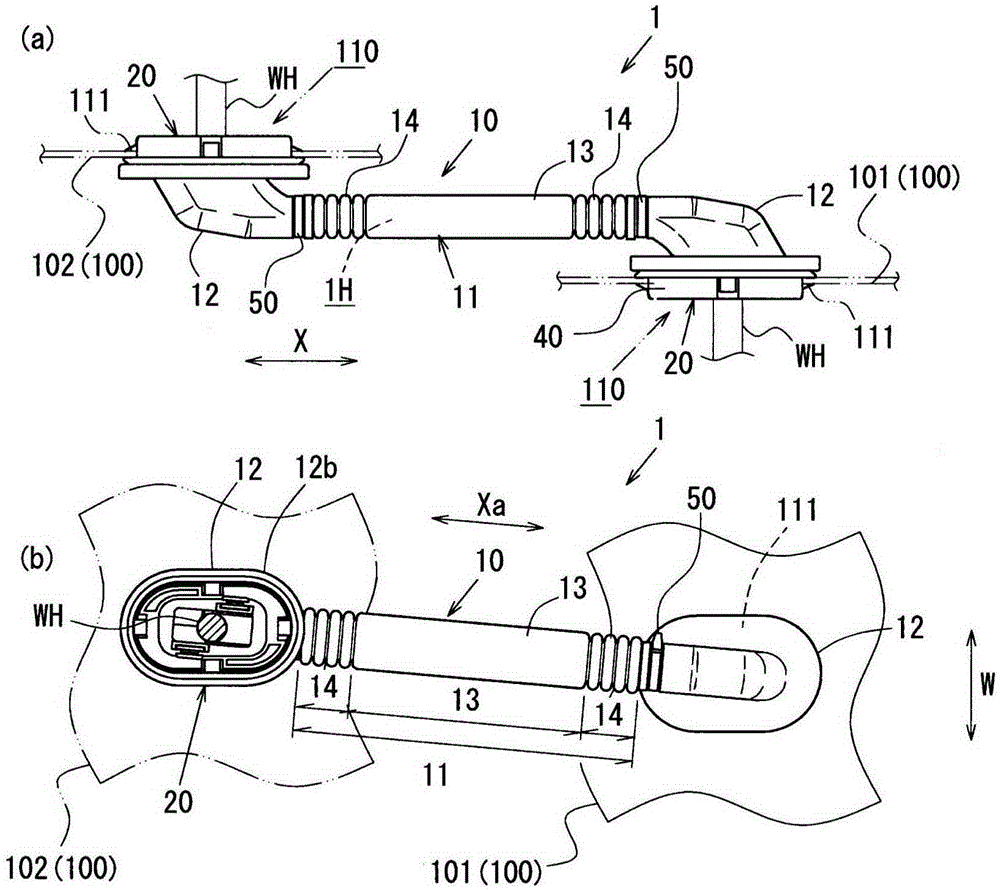

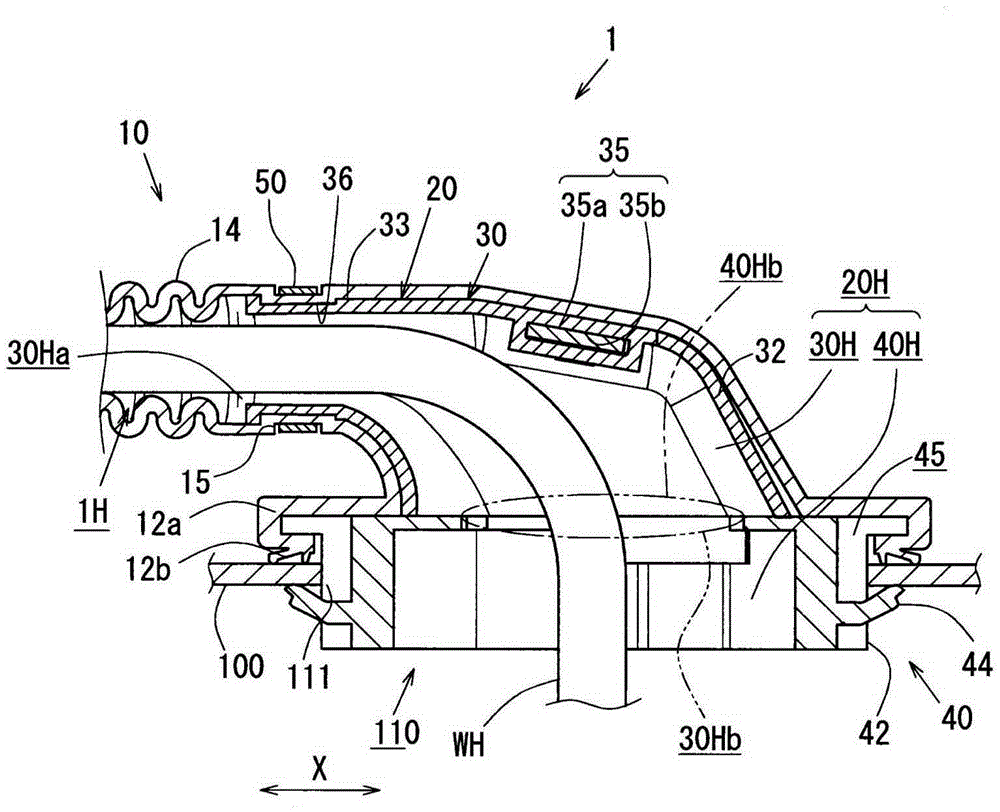

In-wheel motor drive device

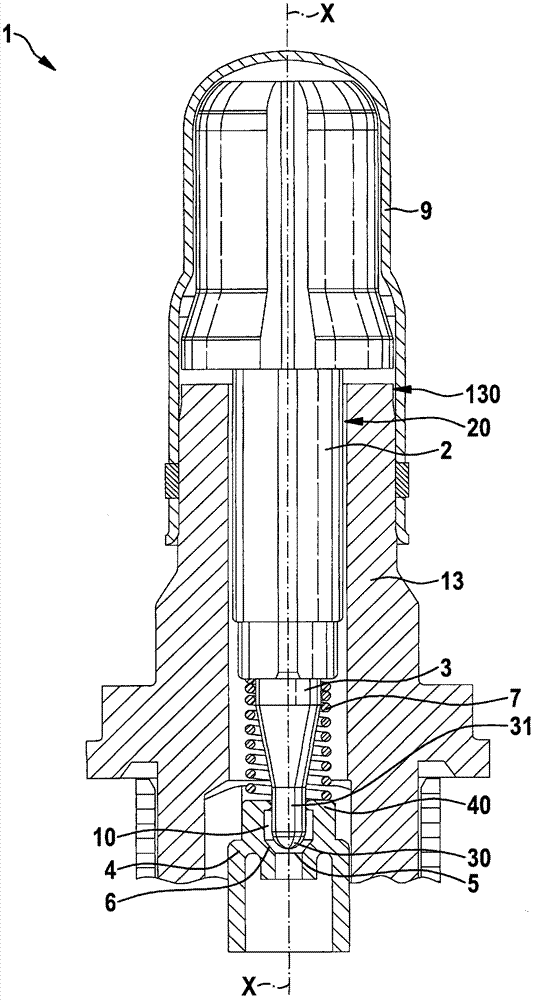

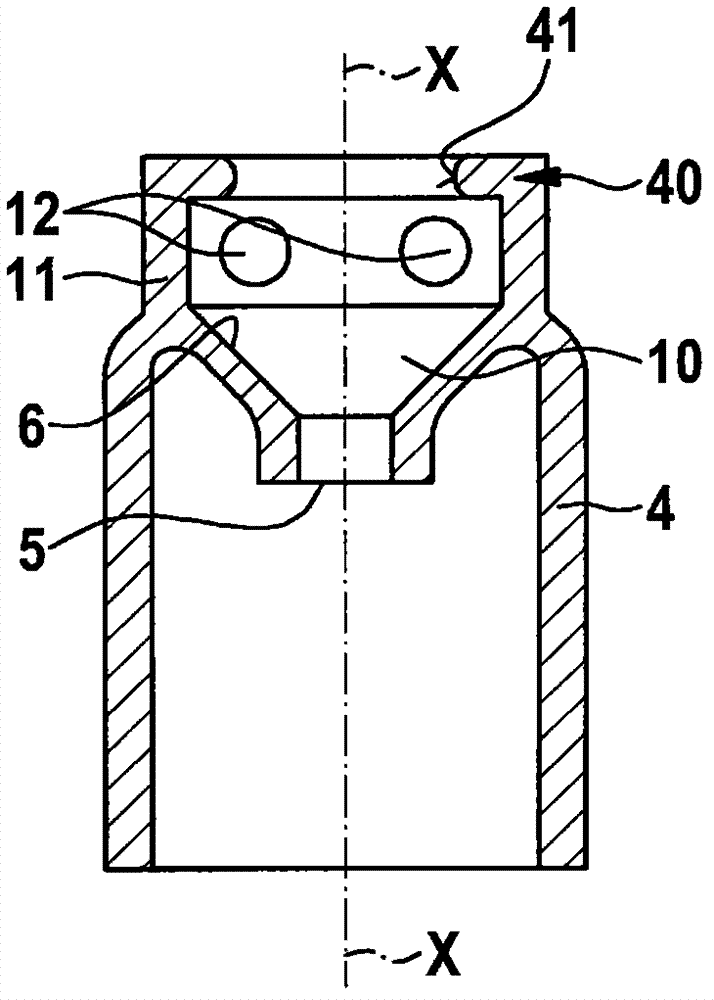

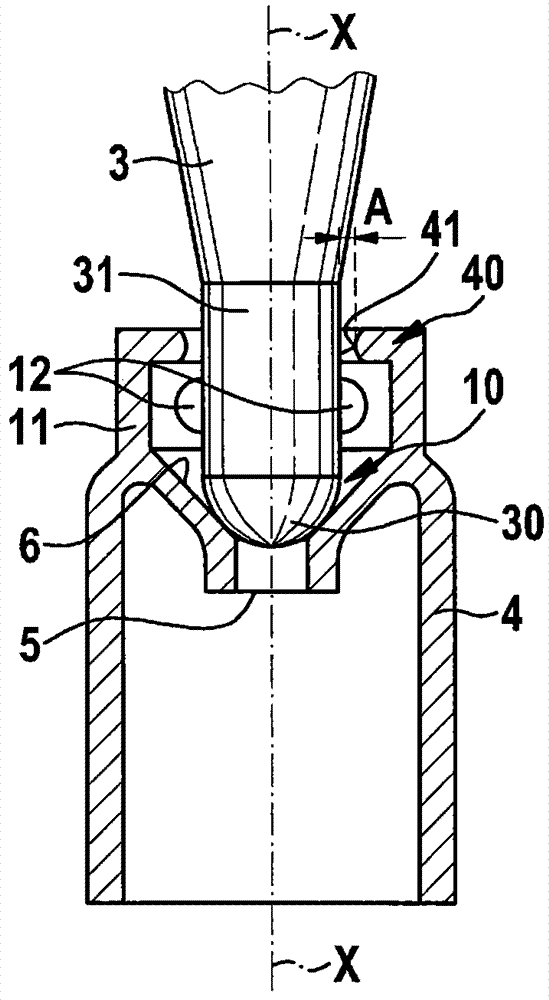

InactiveCN103874871AEffective lubricationReliable bootSpeed controllerElectric devicesMotor driveElectric motor

An in-wheel motor drive assembly is provided of which a reduction mechanism and a bearing supporting a rotor shaft can be reliably lubricated with oil. The assembly includes a motor case (10) defining a motor chamber (17) and a reduction mechanism chamber (18) provided on one side of and isolated from the motor chamber by a partition wall (16). An electric motor (30) is mounted in the motor chamber (17). A planetary gear type reduction mechanism (40) is mounted in the reduction mechanism chamber (18), and is adapted to reduce the rotation of the electric motor (30) and output the reduced rotation to a hub ring (65). The reduction mechanism (40) is lubricated by lubricating oil stored in the reduction mechanism chamber (18). A tapered oil guide surface (21) is formed at the center of the inner surface of the partition wall (16) facing the reduction mechanism chamber (18). The oil guide surface (21) guides lubricating oil splashed up by the rotating reduction mechanism and flowing down along the inner surface of the partition wall (16), onto the rotor shaft (34) of the electric motor (30), thereby lubricating bearings (47) mounted on the rotor shaft (34).

Owner:NTN CORP

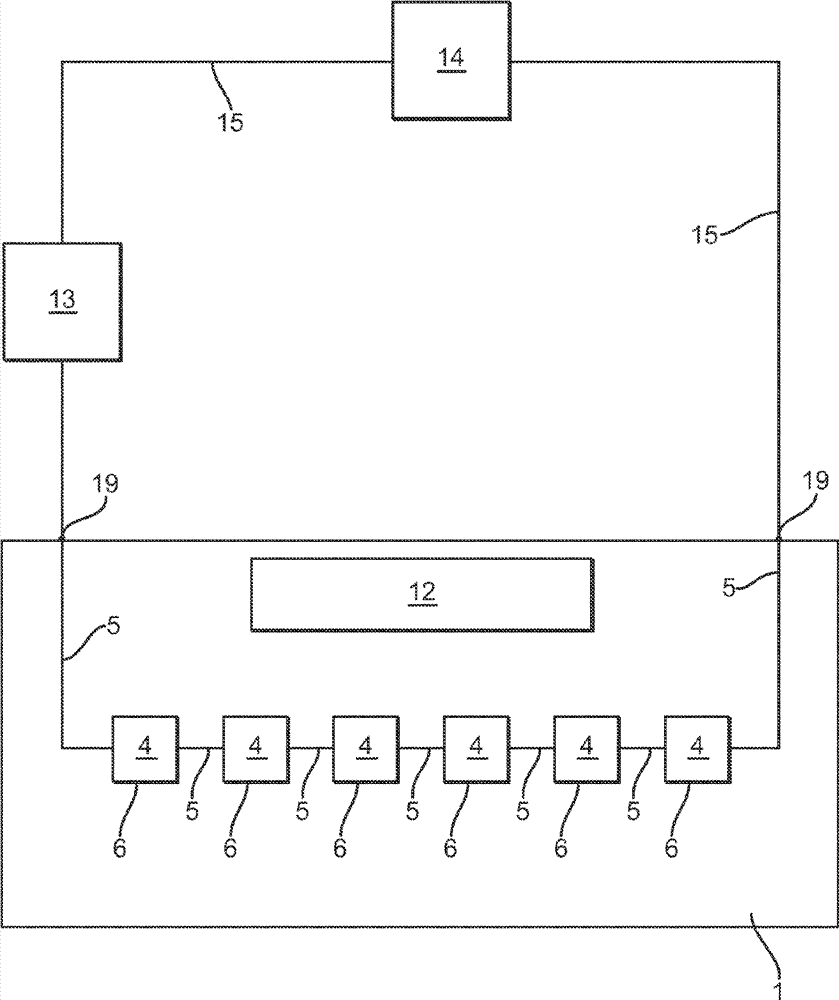

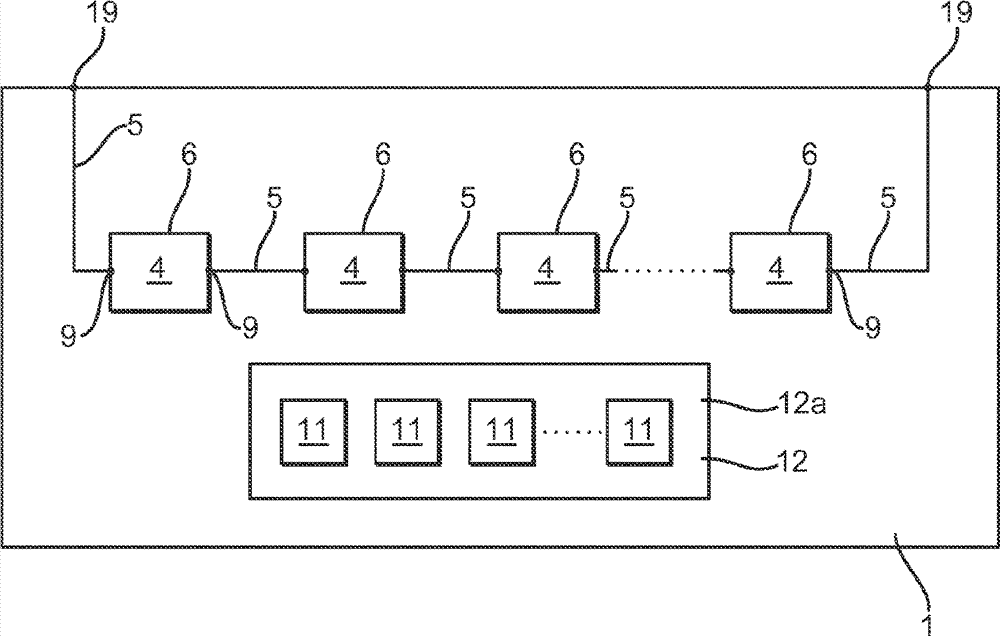

High-current battery system and method for controlling a high-current battery system

InactiveCN102742066AAvoid short circuitNo short circuitCircuit monitoring/indicationIndicating/monitoring circuitsElectricityComputer module

The present invention relates to a high-current battery system (1) in which a high operating current flows, in particular for vehicle drives. The high-current battery system (1) has a battery system monitoring electronics unit (12) and a plurality of battery modules (4), each module including at least one rechargeable battery cell (10) and being electrically connected in series by means of an operating current line (5) such that an operating current flows through the operating current line (5) during operation. At least one of the battery modules (4) is designed as a bypass battery module (6) which comprises a bypass switch (7) and a bypass line (8), which are designed and disposed such that the battery module (6) is electrically bridged by the bypass line (8) after the bypass switch (7) is switched from a normal operating position into a bypass position, so that the operating current flows through the bypass line (8). For each bypass battery module (6), the battery system monitoring electronics unit (12) incorporates a module monitoring unit (11) which monitors the associated battery module (6) and detects a fault state of the module (6). Upon detection of a fault state of a battery module (6) by one of the module monitoring units (11), the battery system monitoring electronics unit (12) measures the current flow in the operating current line (5) and switches the bypass switch (7) of the battery module (6) in question from the normal operating position into the bypass position at a time at which the current flow in the operating current line (5) is less than a predetermined limit value.

Owner:INNOLITH ASSESTS AG

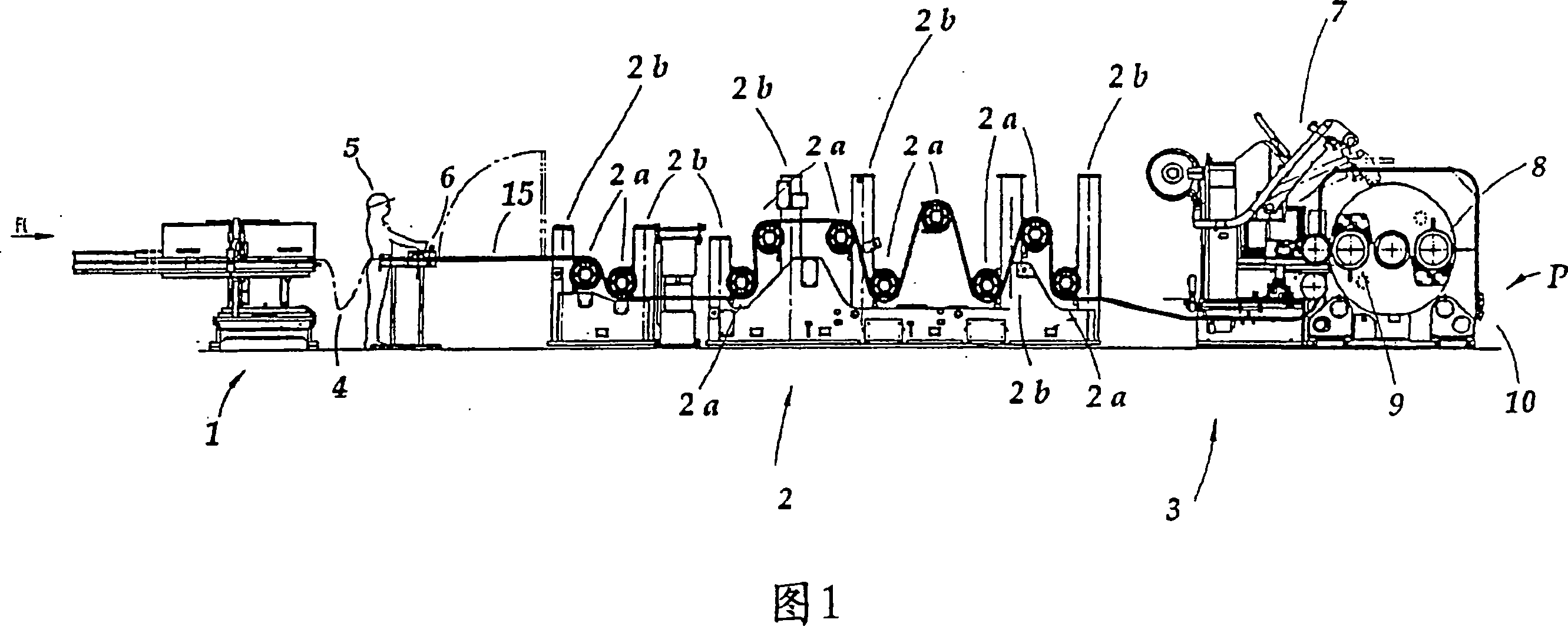

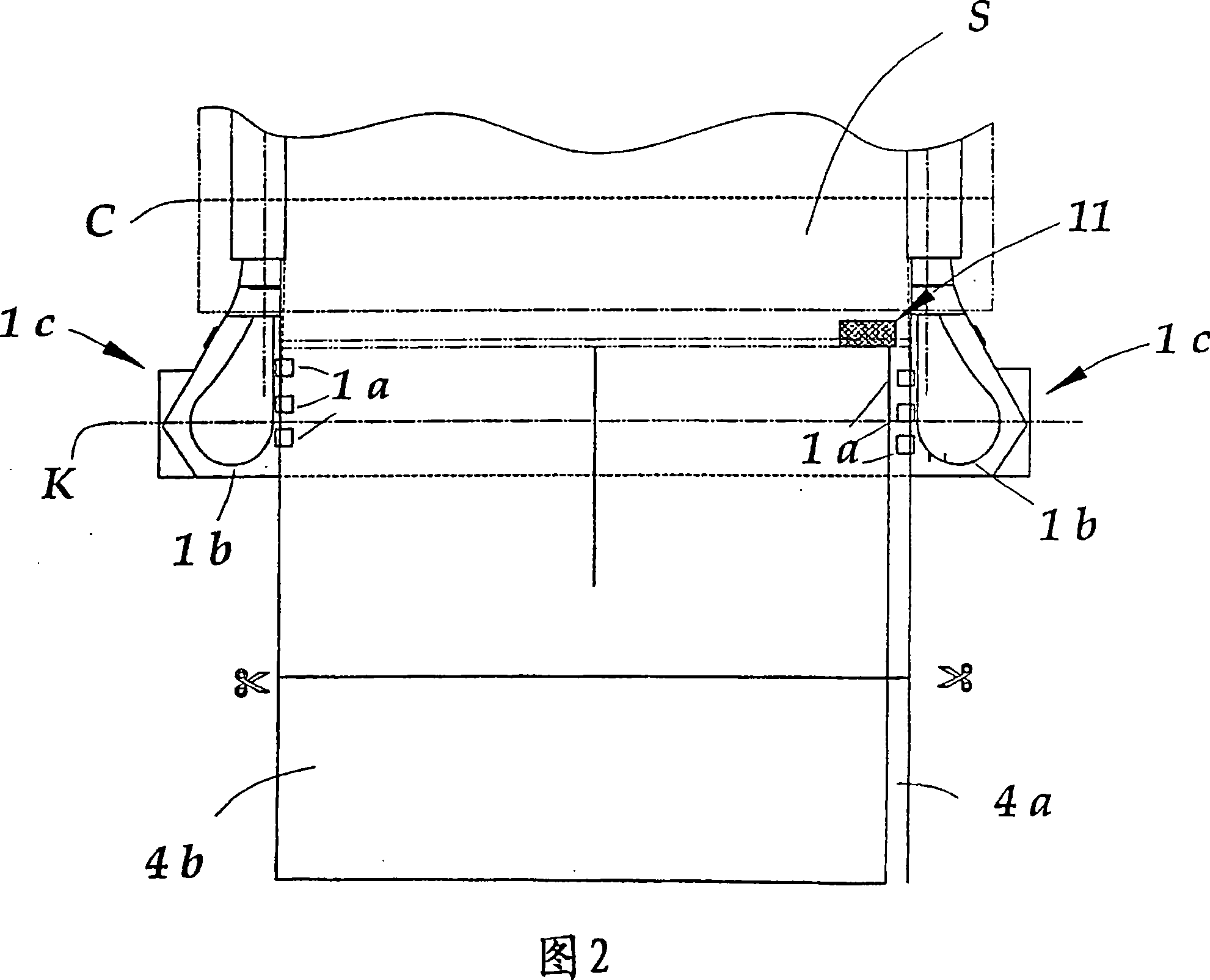

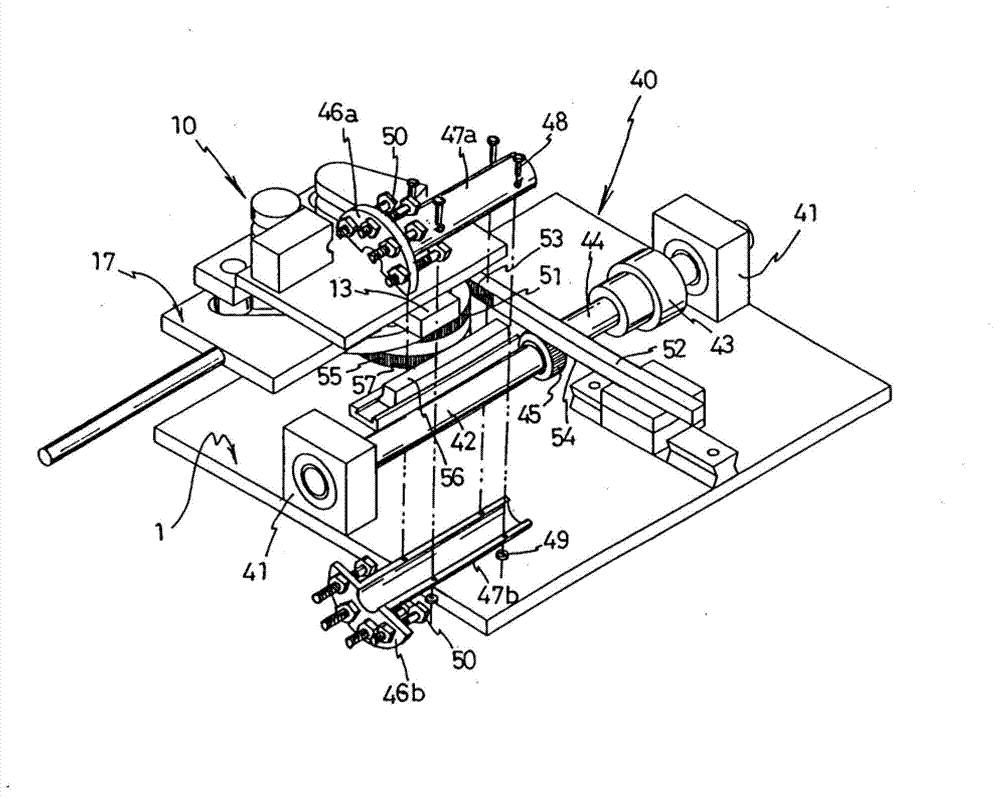

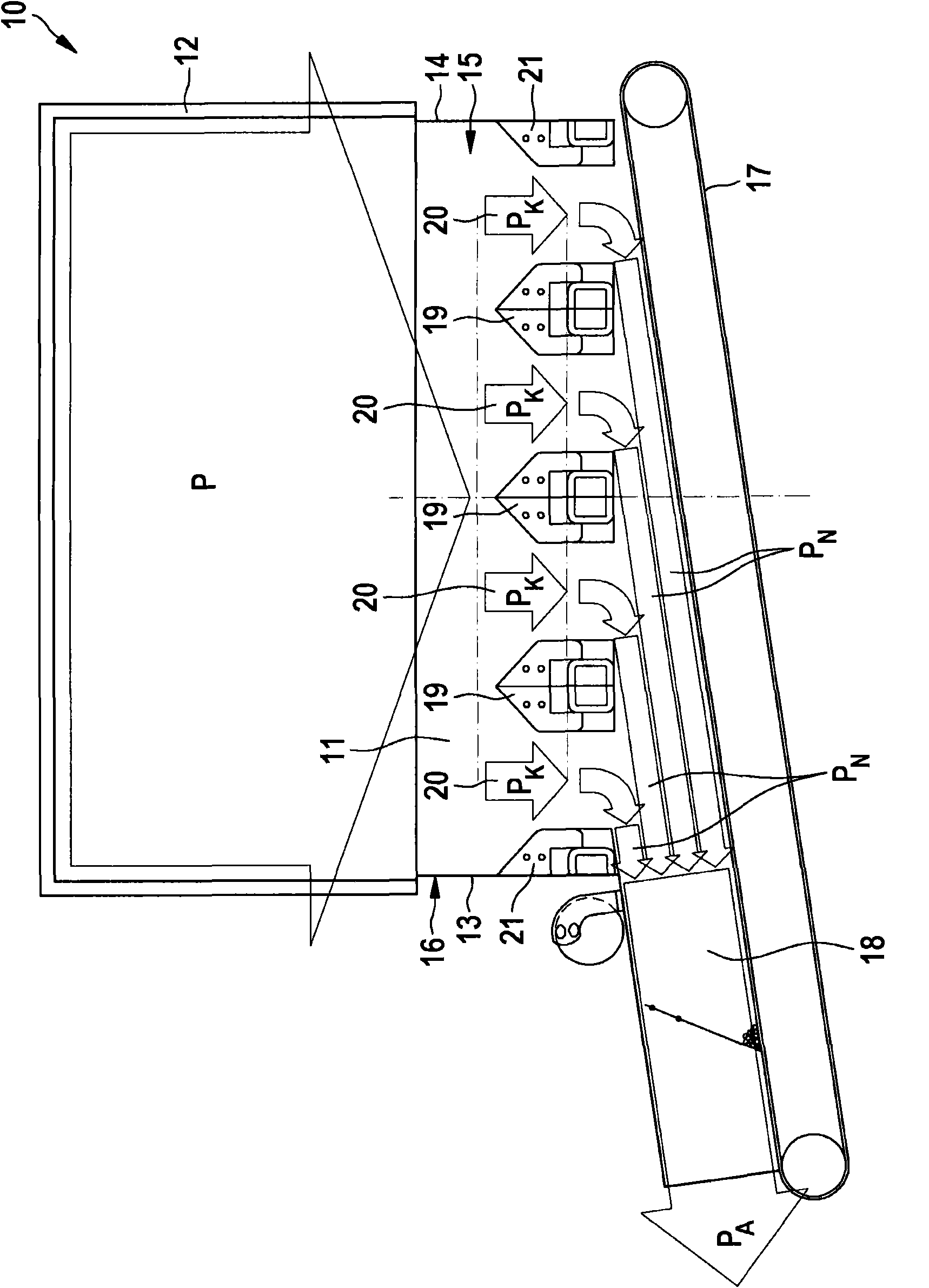

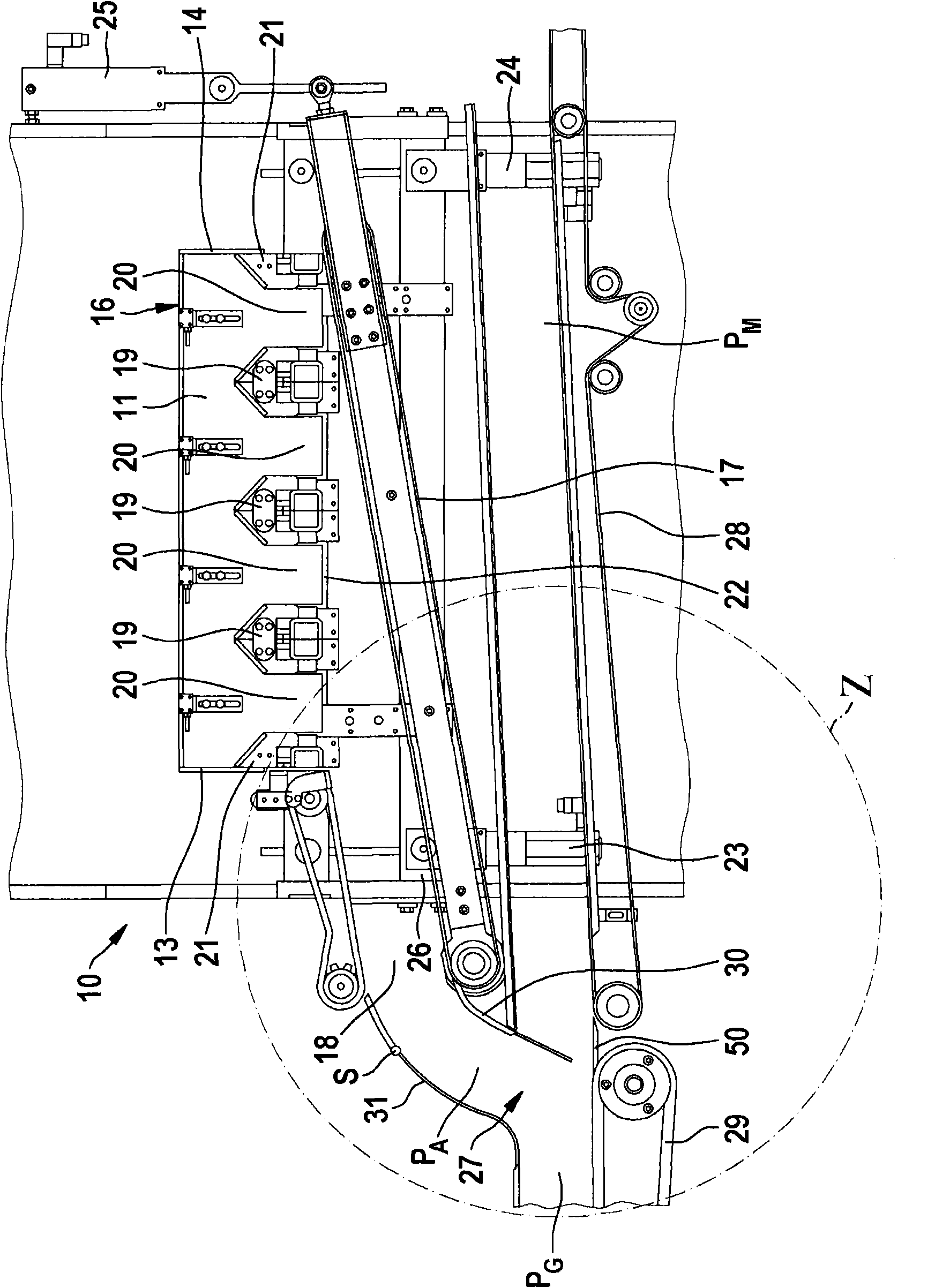

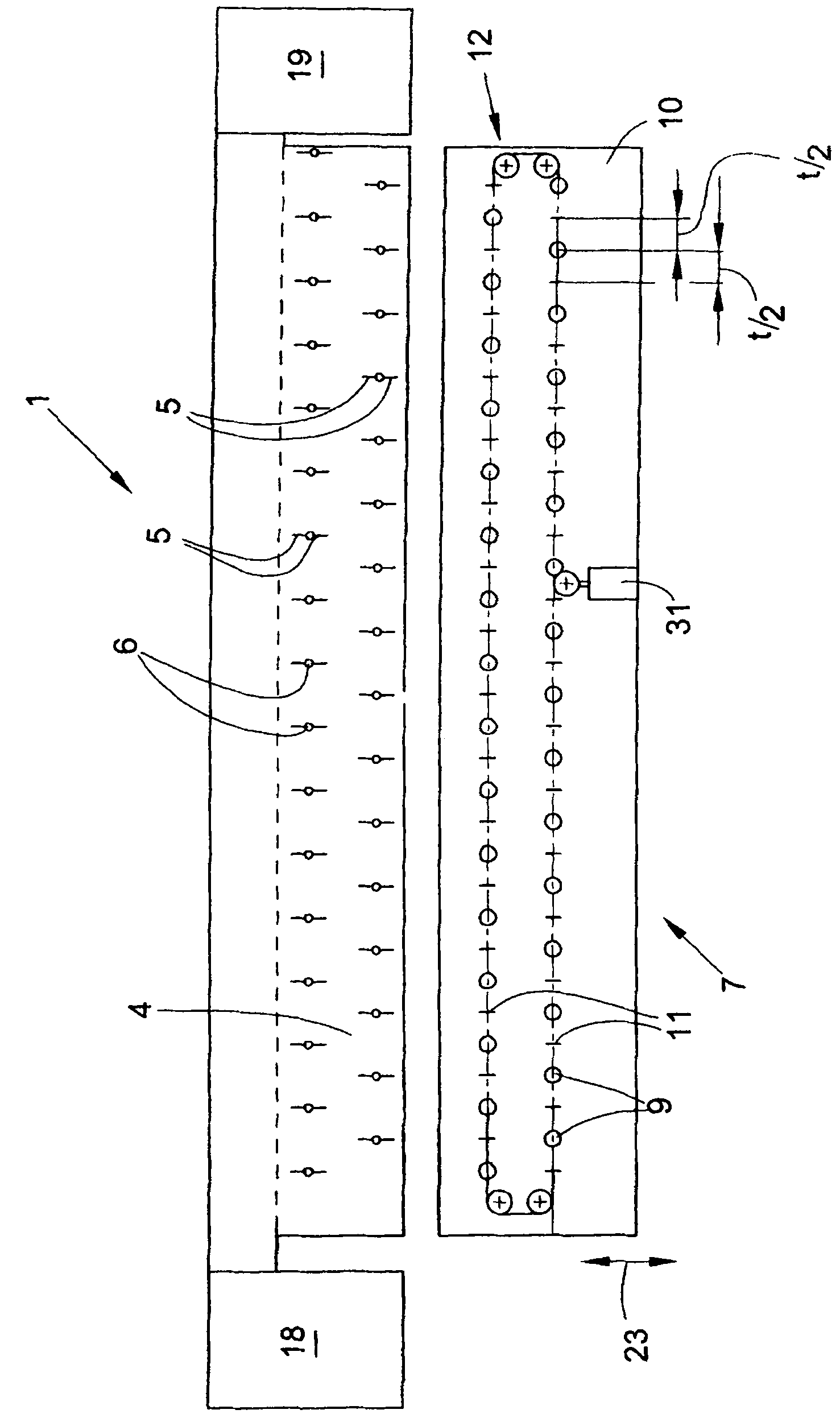

Process and device for processing a film web

InactiveCN1930069AReliable bootReliable startAdhesivesWebs handlingEngineeringMechanical engineering

An improved process for processing a film web (4) has the following steps: the film web (4) is cut in the longitudinal direction, forming a marginal strip (4a) and a remaining film web (4b) with a width reduced by the width of the marginal strip (4a); the marginal strip (4a) is transferred to a movable film-drafting device (10) on which is arranged a gripper; the remaining film web (4b) is separated entirely or partially by cutting and also possibly by tearing; the film-drafting device (10) is moved along one side of a roller arrangement (2), threading the film web (4) into the roller arrangement (2); the film-drafting device (2) is moved along one side of a winding device (3) comprising at least one winding roller (8) up to a release or end position (P); and the film-drafting device (10) is opened at the end position (P) to release the marginal strip (4a).

Owner:BRUECKNER MASCHB

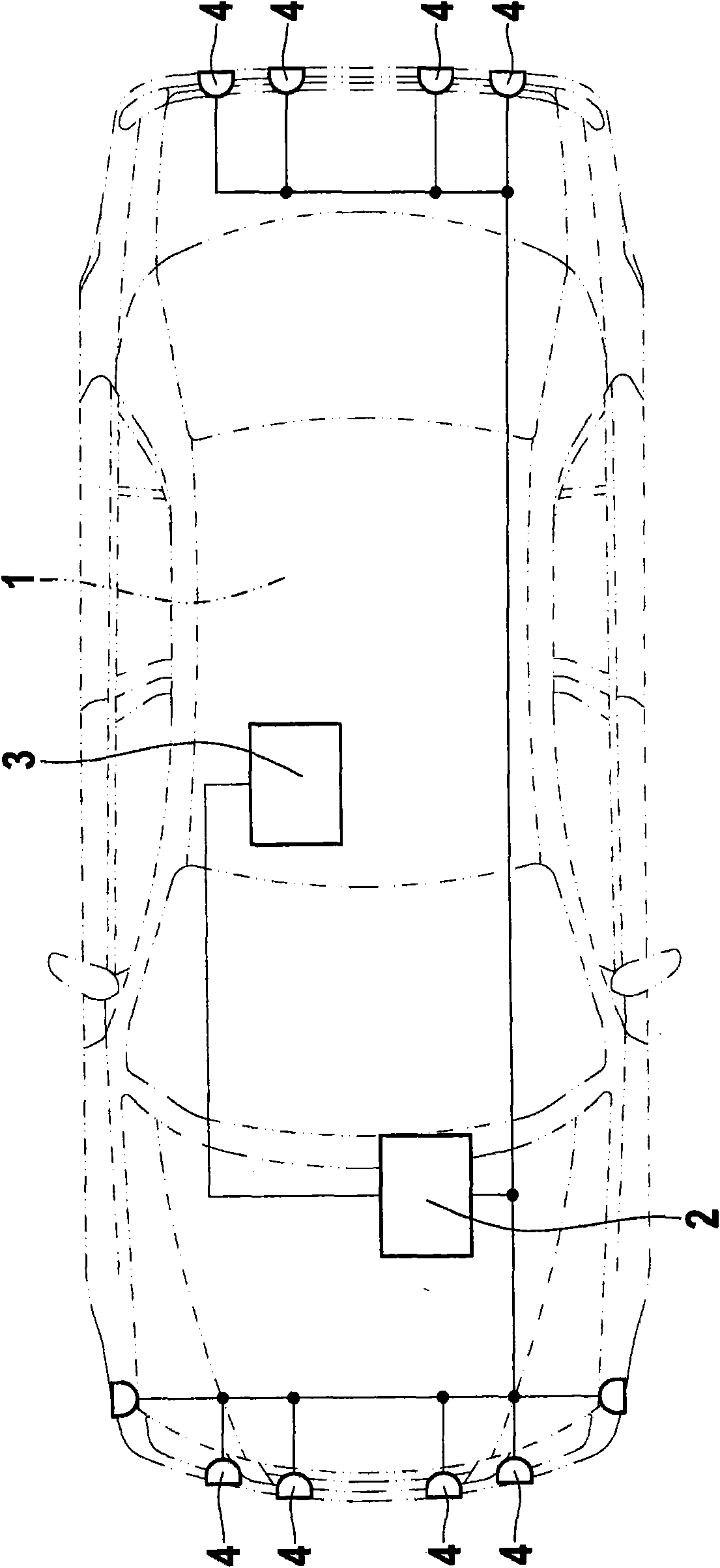

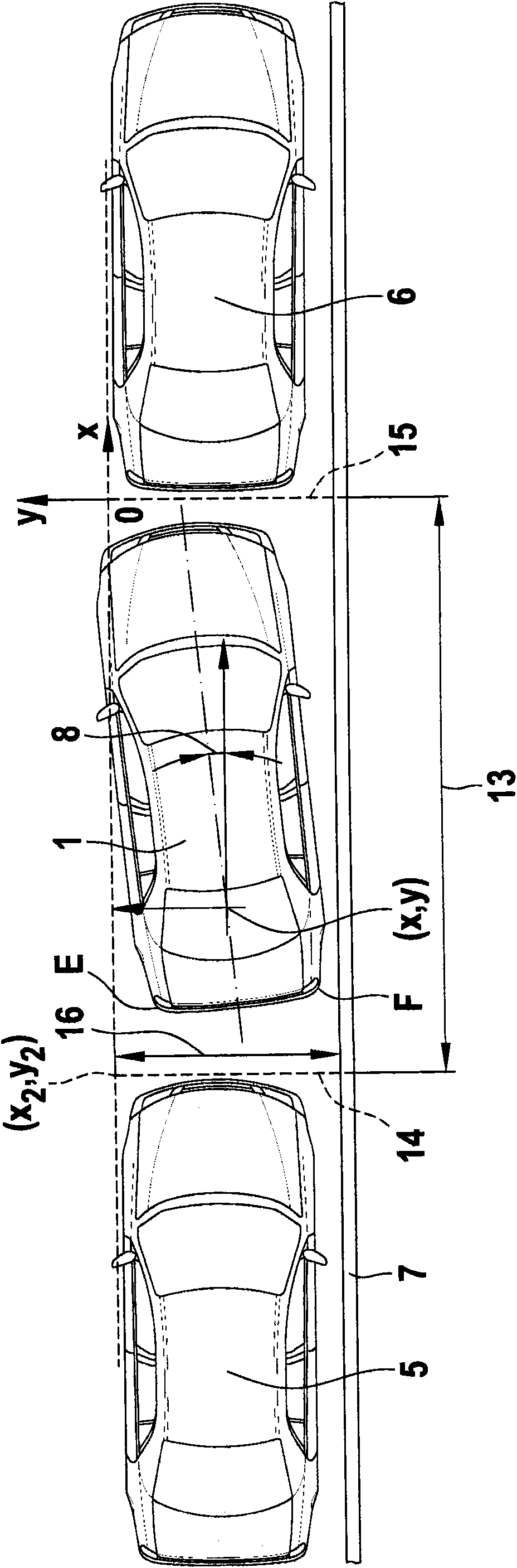

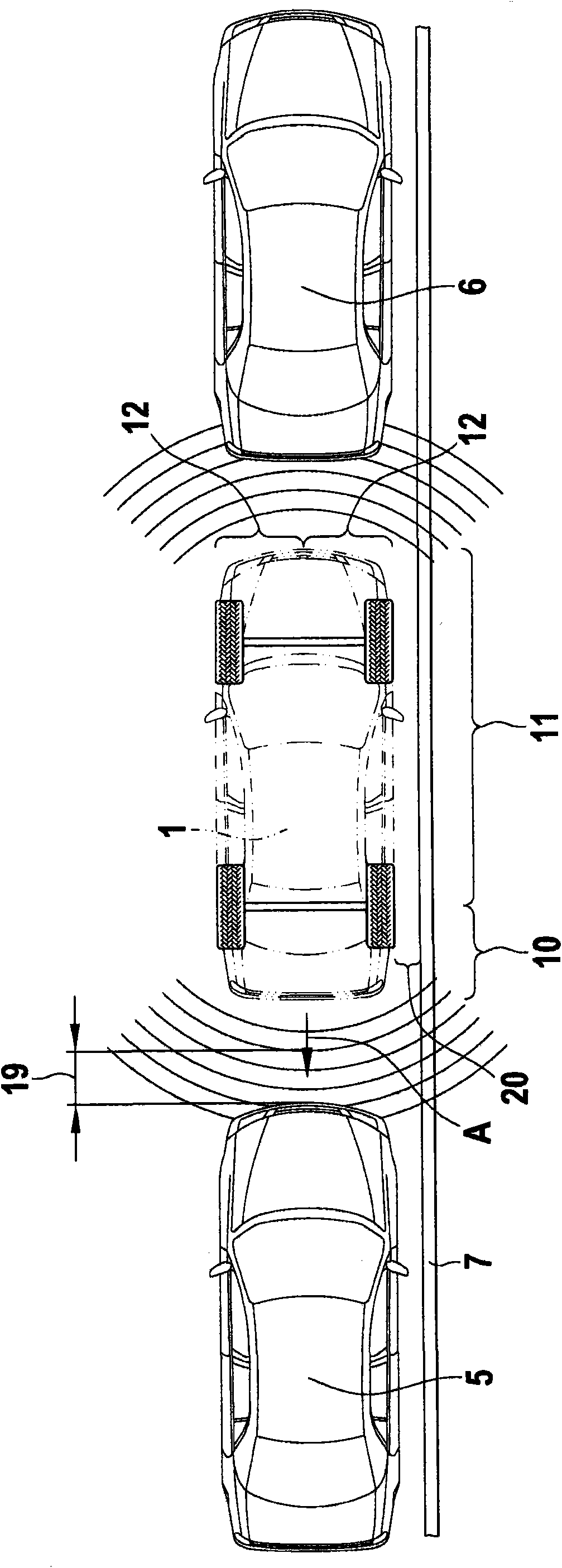

Method and device for supporting the process of leaving a parking space of motor vehicles

InactiveCN101772446ABroadly determinedHigh precisionAnti-collision systemsSteering partsParking spaceParking pawl

The invention relates to a method for supporting the process of leaving a parking space and to a corresponding device. The method relates to methods for supporting the processes of leaving parking spaces of motor vehicles, wherein data of different board sensors is used for determining a collision-free process of leaving a parking space, comprising the following steps: a) Determining sensor data during parking for modeling the physical surroundings of the motor vehicle, b) calculating data for describing the surroundings, c) storing the data, d) retrieving the stored data for determining the physical surroundings of the motor vehicle relevant for the process of leaving a parking space, e) checking the stored data for plausibility, f) releasing the data and g) using the data for calculating a collision-free path for leaving the parking space. The invention further relates to a device for the execution of a method for leaving a parking space.

Owner:ROBERT BOSCH GMBH

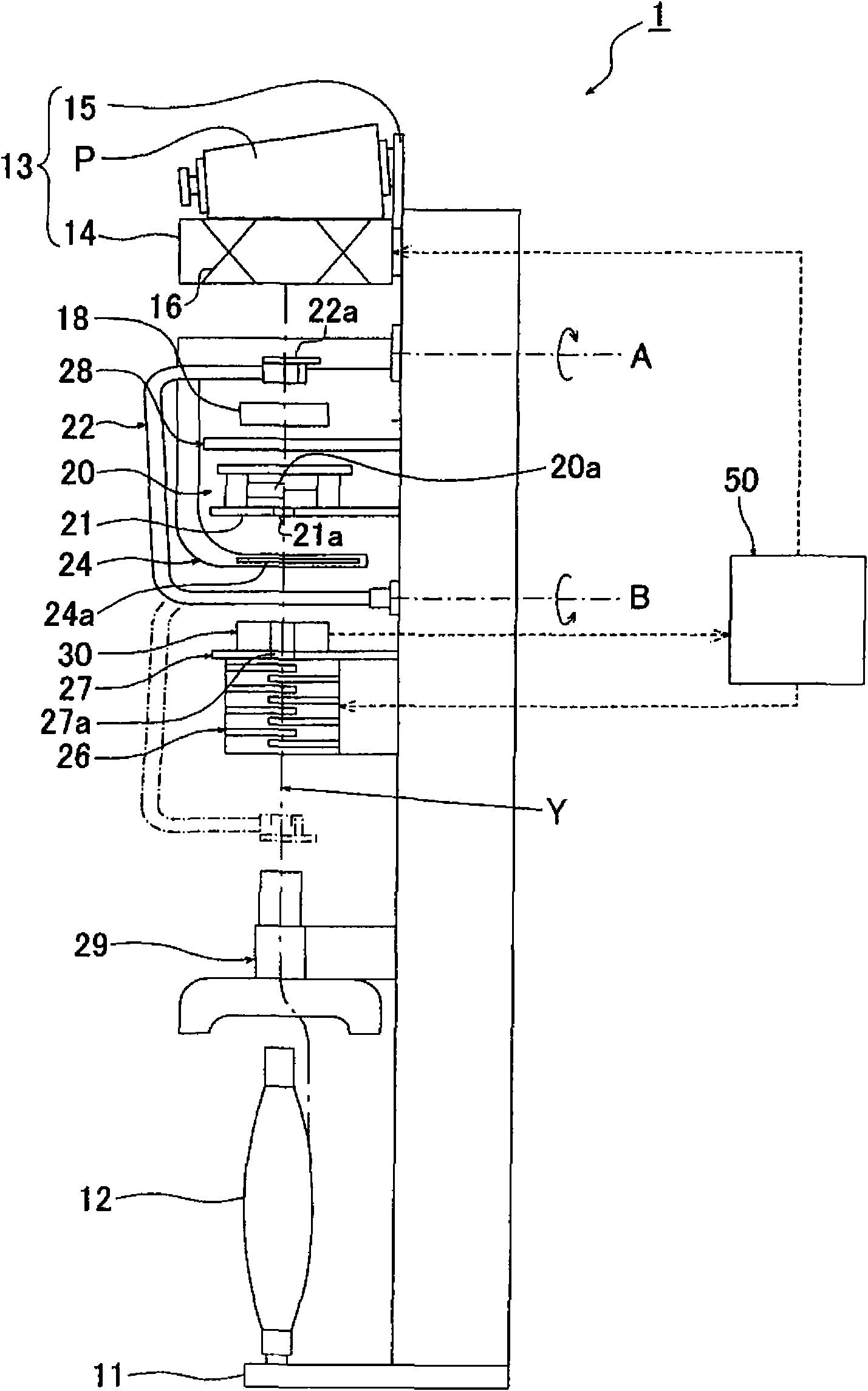

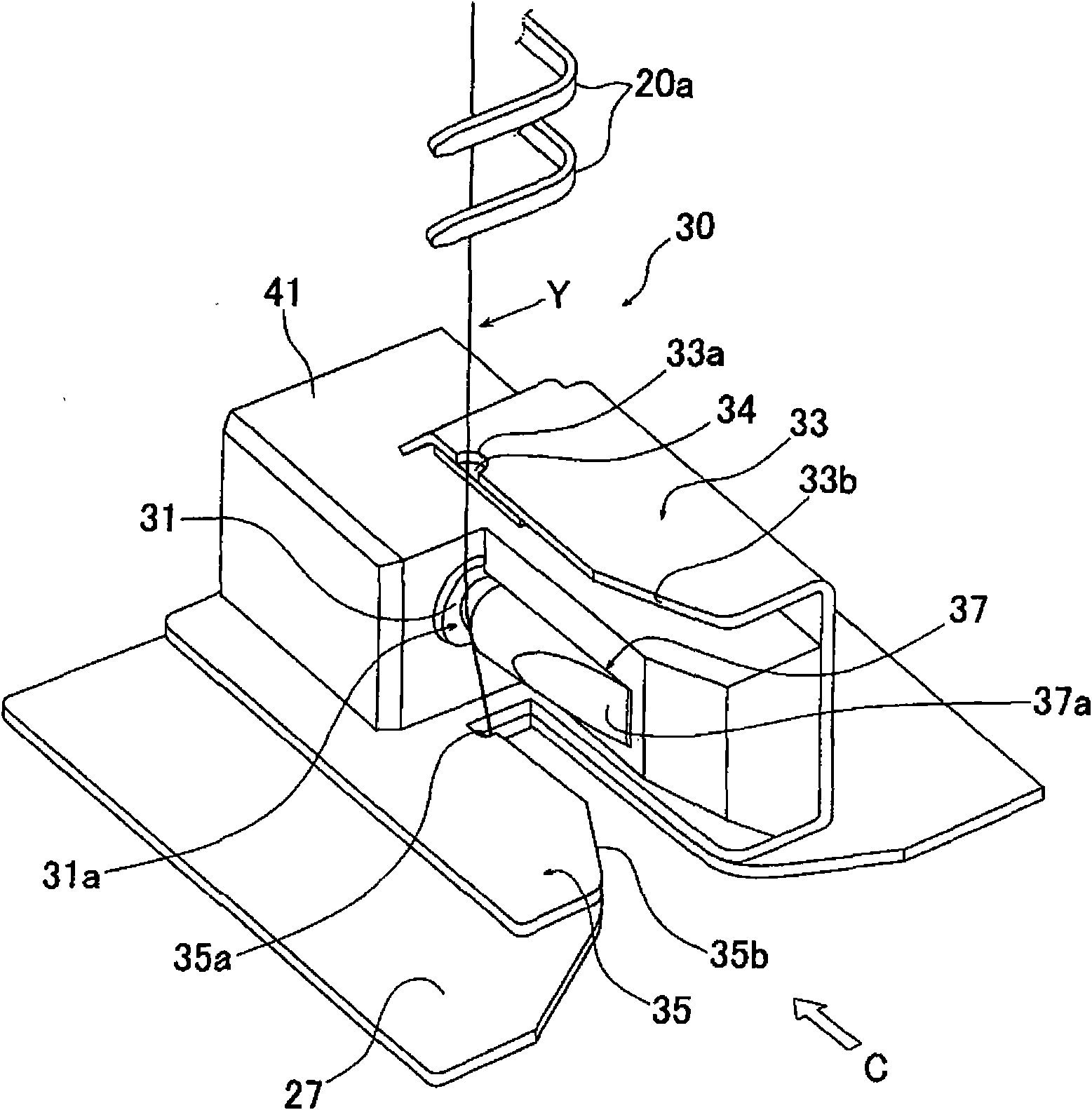

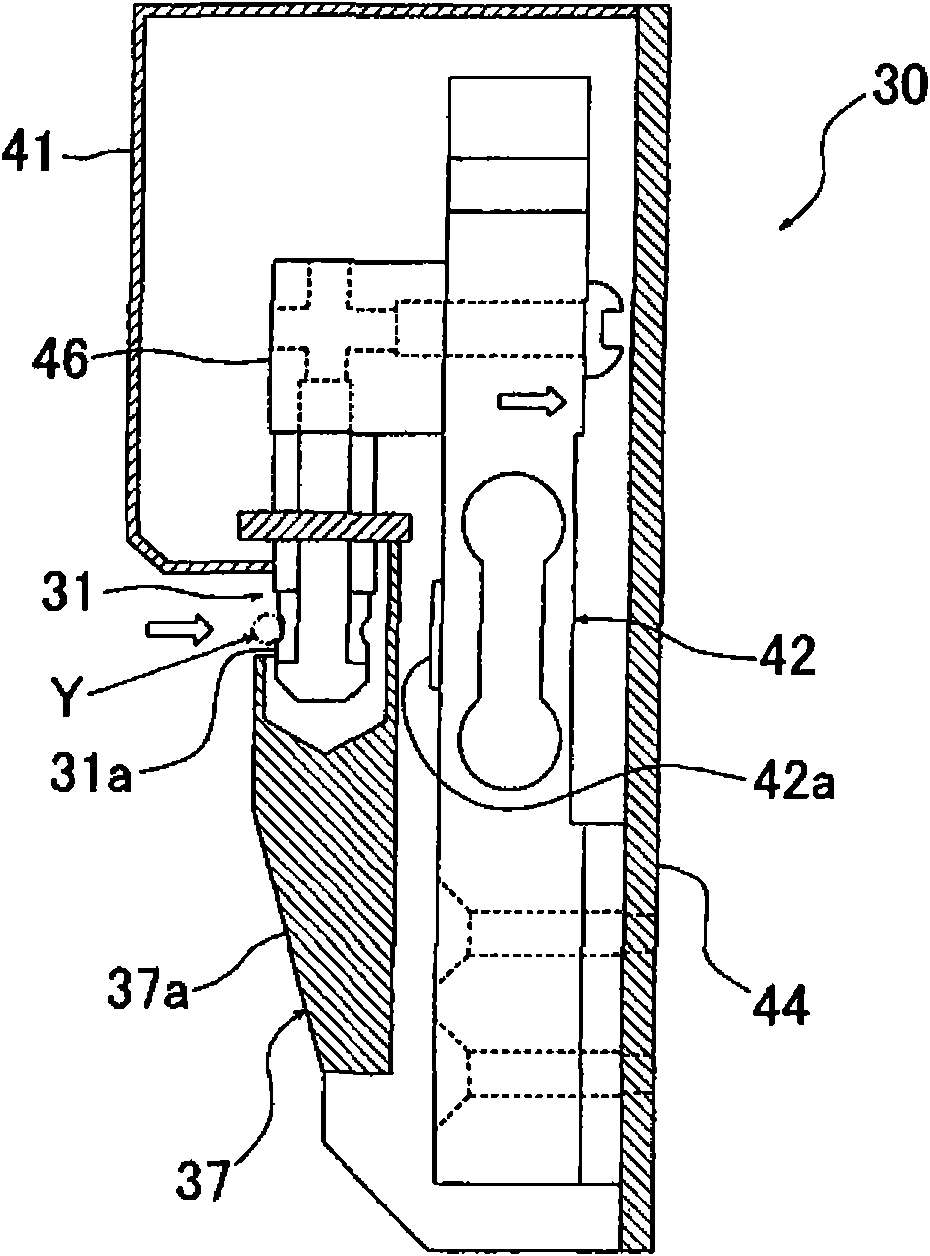

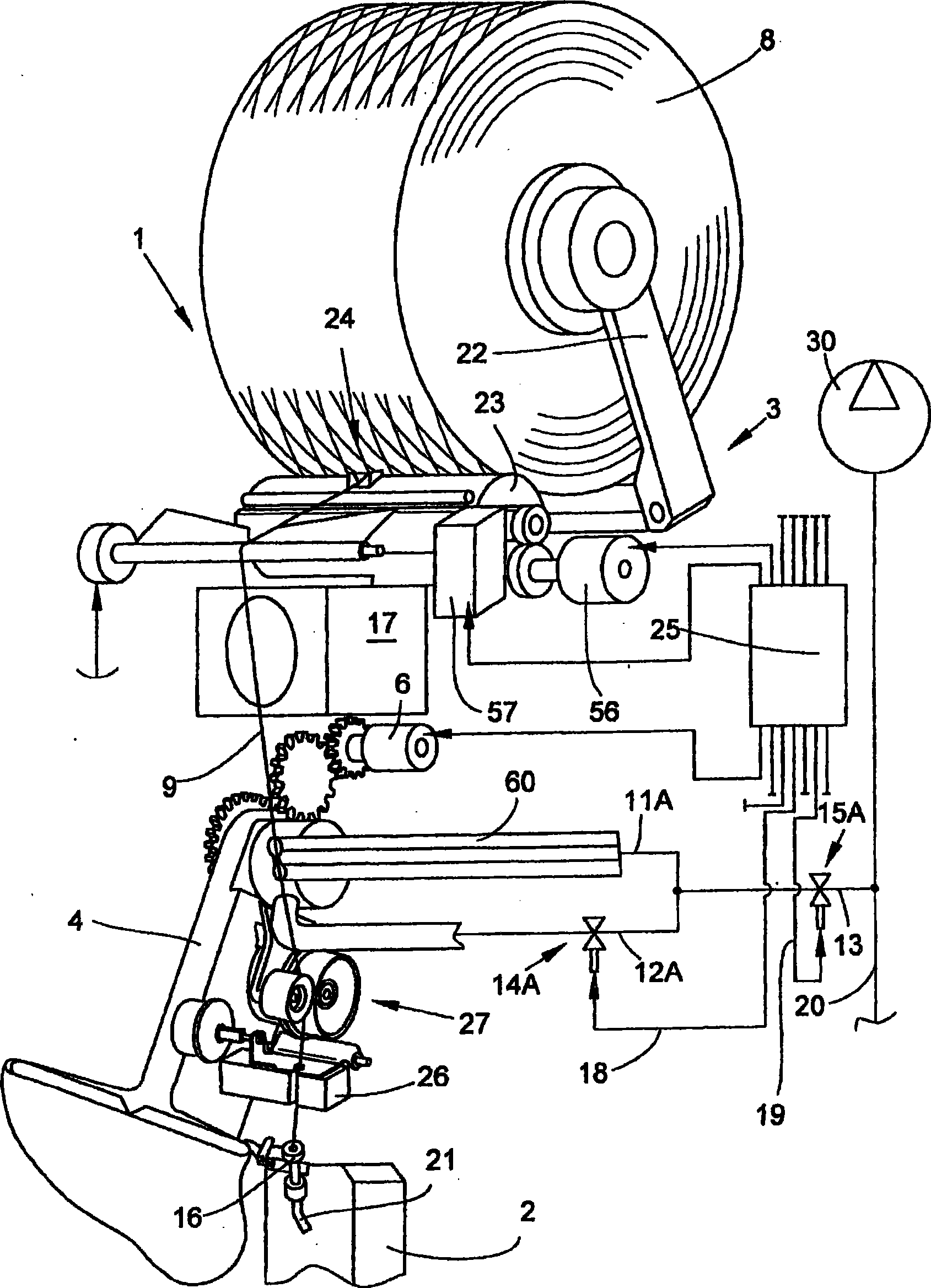

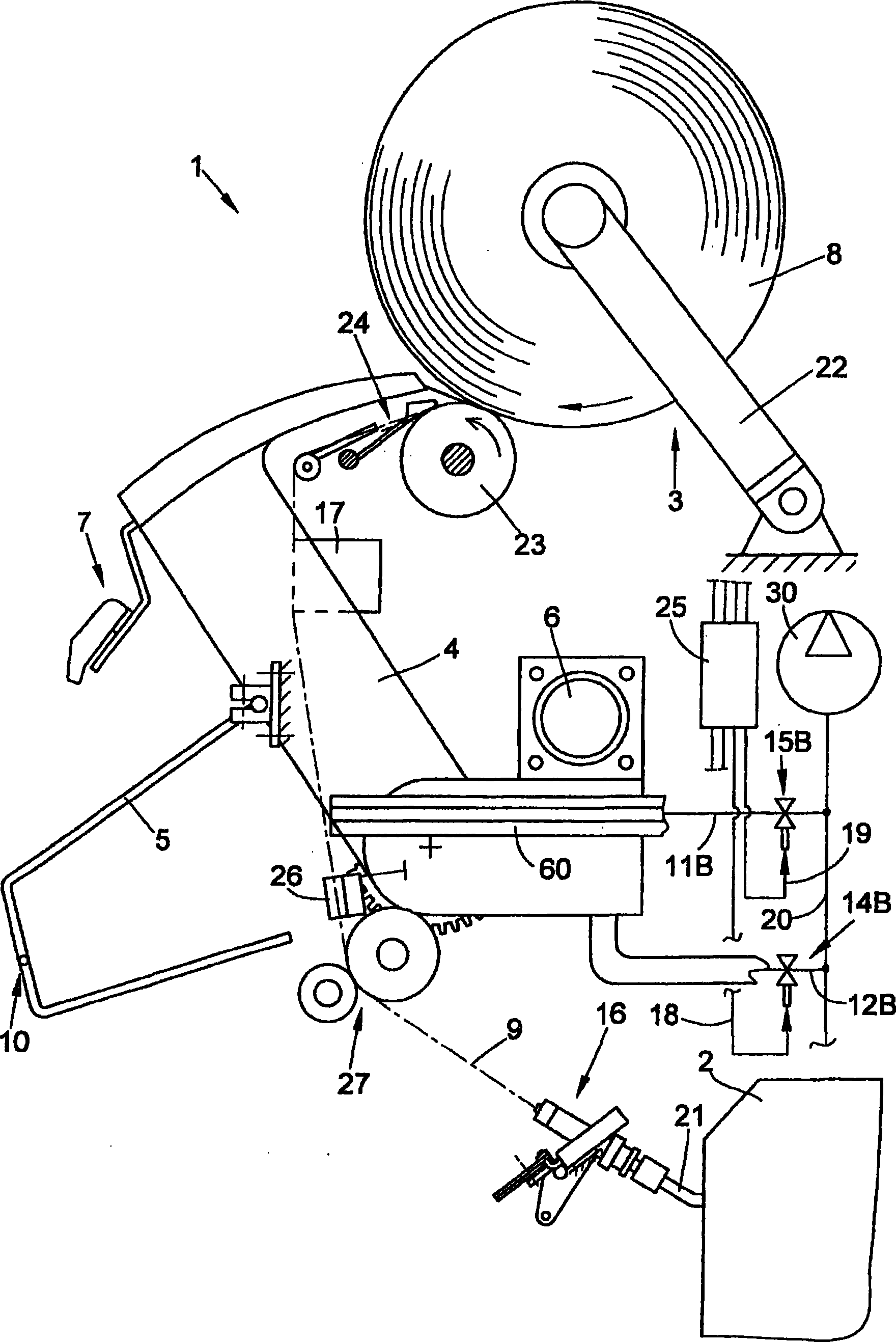

Automatic winder

The invention provides an automatic winder, comprising a gate tensioner (26) capable of enduing the tension on the yarn to be winded on a pony roll (P) after being unwound from a bobbin (12), a tension sensor (3) for detecting the tension of the yarn and mounted on the yarn passage (Y) over the gate tensioner (26). The automatic winder can directly detect the unwinding tension of the bobbin (12),the unwinding tension of the yarn unwinding auxiliary device, the tension endued by the gate tensioner (26), free from the tension variance infection due to the other factors. Thus the automatic winder not only directly detects the generation of the abnormal tension when the abnormal tension generates, but also easily determines the generation cause, thereby preventing the end broke due to abnormal tension or bad pony roll winding shape from generating.

Owner:MURATA MASCH LTD

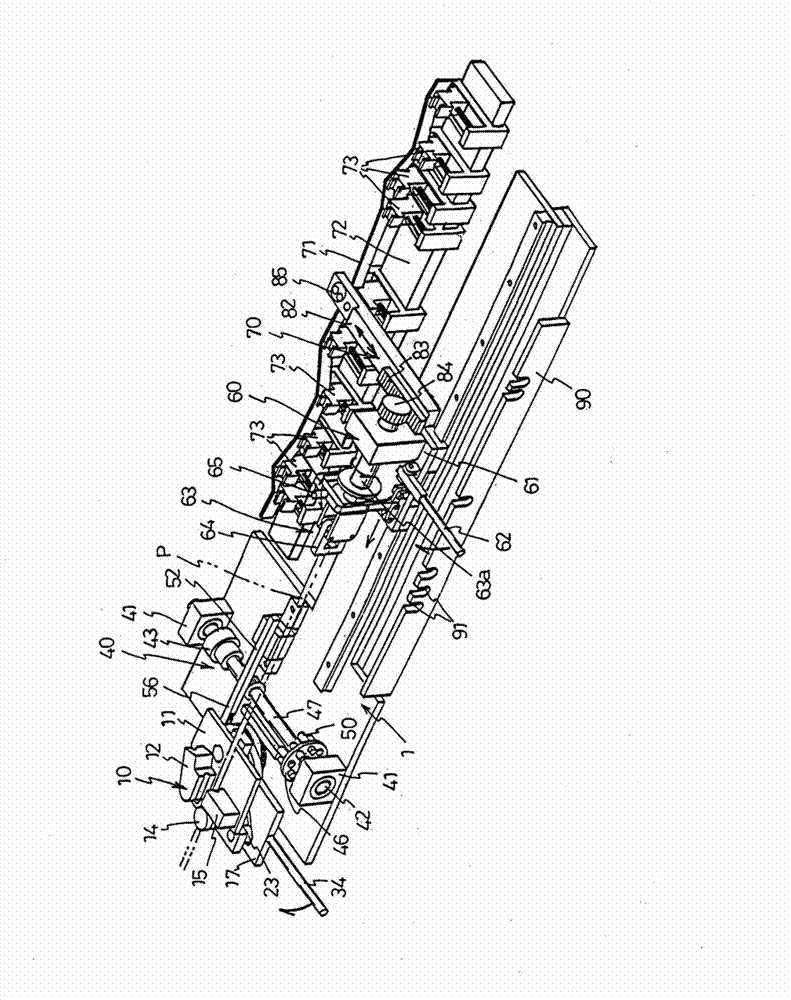

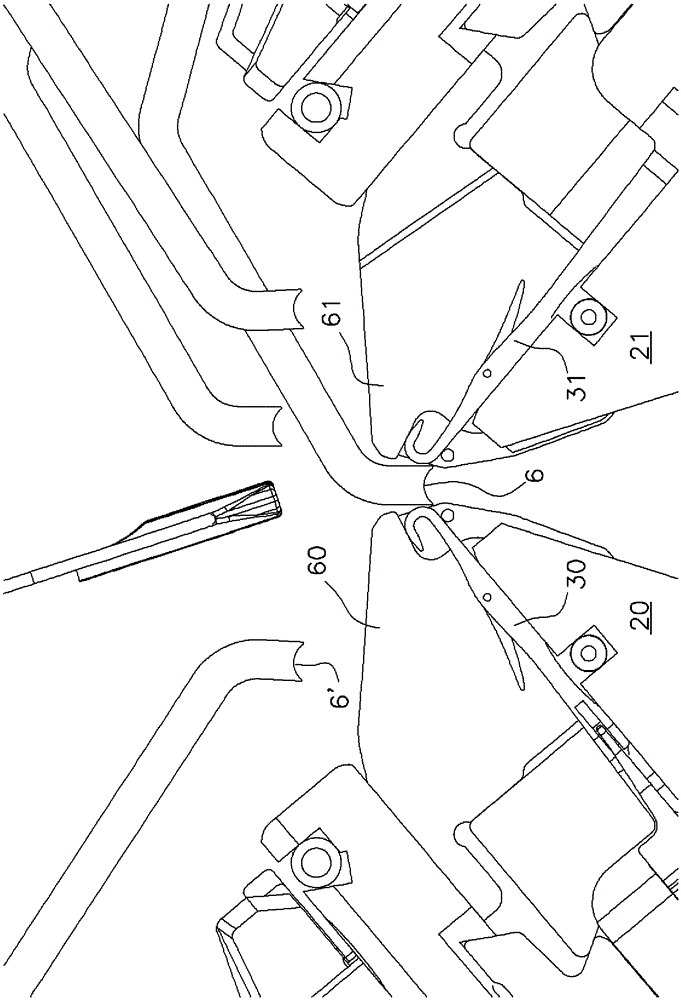

Pipe bending apparatus

The purpose of the present invention is to provide a pipe bending apparatus comprising a turning means that can be easily implemented at low cost and can be used for bending pipes in different directions and in different shapes. In order to achieve this purpose, in the pipe bending apparatus of the present invention, a pipe feeding base (61) is disposed so as to be movable in the feeding direction of a pipe (P), a feeding means (60) is configured by rotatably disposing a chuck (63) on the feeding base to support the pipe, a cam (71) formed by bending a long plate or rod is disposed substantially parallel with the movement direction of the feeding base, a cam follower (86) is disposed on the feeding base so as to be movable in a direction perpendicular to the axis of the pipe, a turning means (70); is configured by engaging the cam follower with the cam and also connecting the cam follower to the chuck, and, together with an operation which moves the feeding base forward, the cam follower follows the cam and moves, and the motion of the cam follower is transmitted to the chuck so as to turn the chuck.

Owner:SANOH IND CO LTD

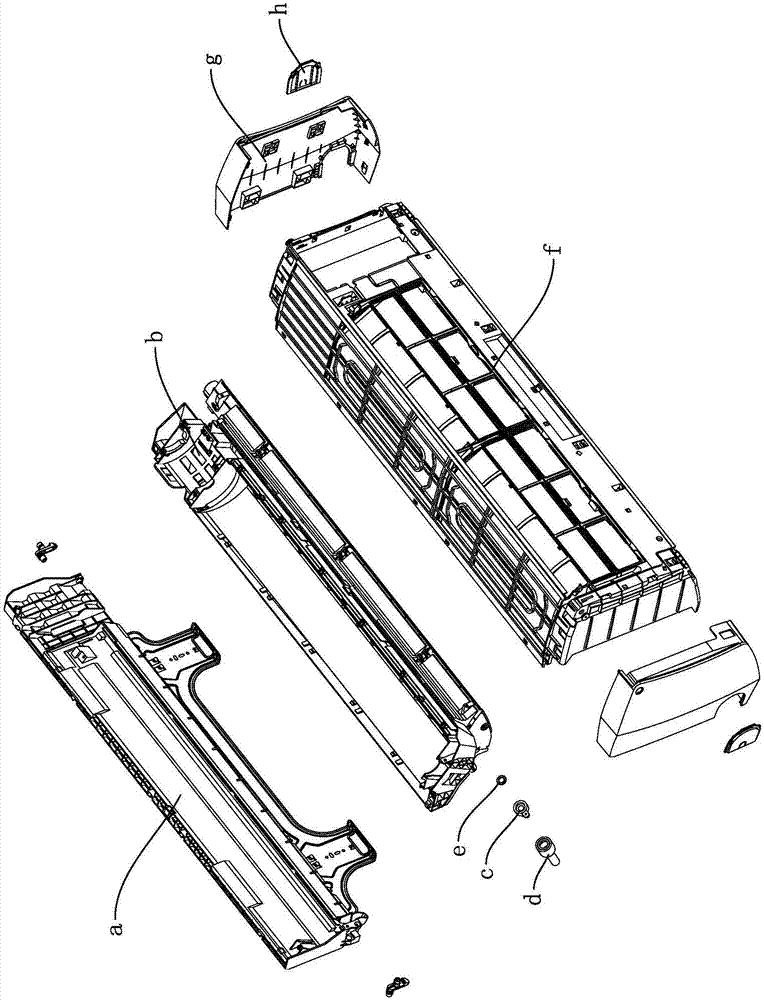

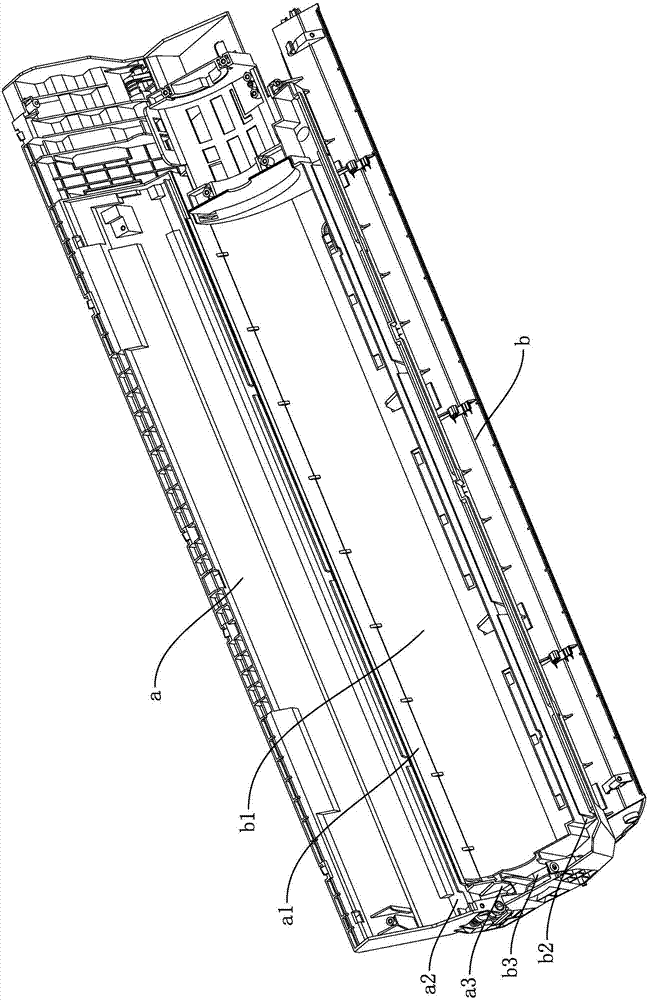

Wall-mounted air conditioner with detachable bases

ActiveCN107084432AReliable drainageSmooth connectionCondensate preventionLighting and heating apparatusWall mountAir channel

The invention discloses a wall-mounted air conditioner with detachable bases. The wall-mounted air conditioner comprises the upper base and the lower base which are detachably connected. An air guide wall is arranged between the upper base and the lower base. The air guide wall comprises an upper air guide wall body and a lower air guide wall body. The upper air guide wall body and the lower air guide wall body are arranged on the upper base and the lower base correspondingly. Due to the fact that the air guide wall comprises the upper air guide wall body and the lower air guide wall body and the upper air guide wall body and the lower air guide wall body are arranged on the upper base and the lower base correspondingly, the upper base and the lower base can be demounted at the position of an air channel formed by the air guide wall and air conditioner blades, when the air channel of the wall-mounted air conditioner is cleaned, an evaporator, the blades, a motor and other parts of the air conditioner do not need to be demounted, and convenience is brought to cleaning of the air conditioner.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

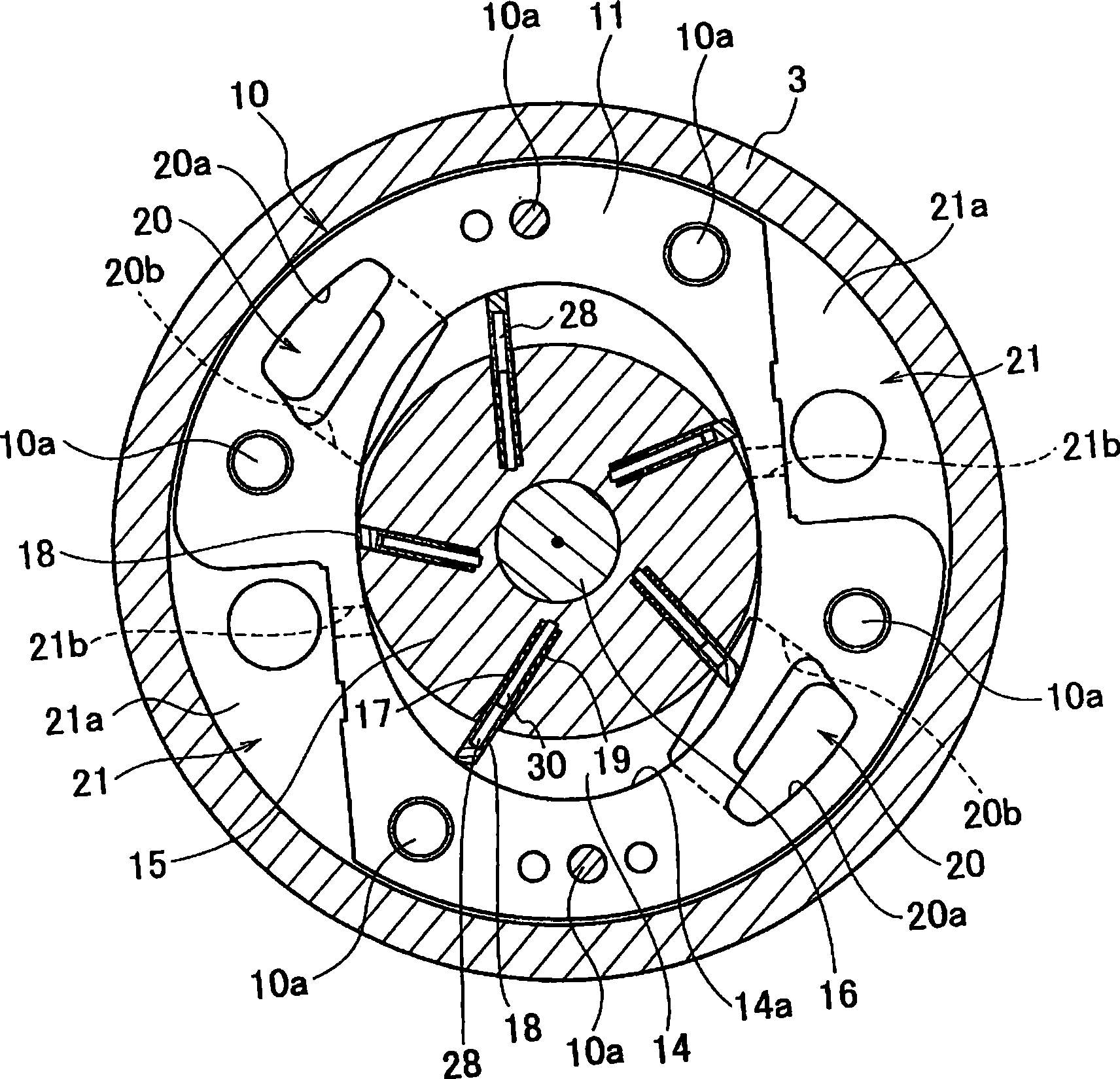

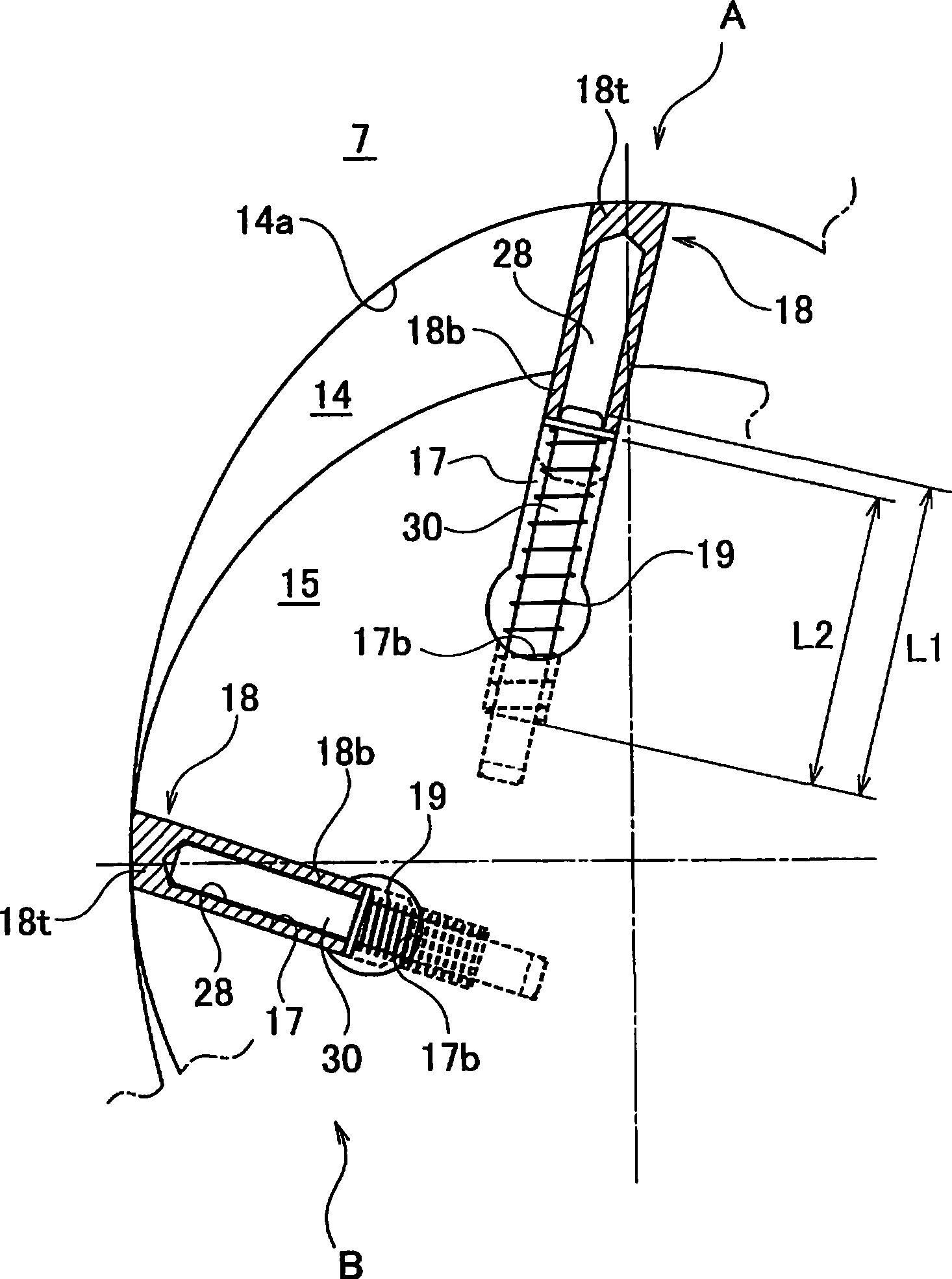

Vane-type compressor

InactiveCN101469707APrevent increase in the number of partsAvoid cost increasesRotary piston pumpsRotary piston liquid enginesCylinder blockEngineering

A vane-type compressor includes: a cylinder block; a rotor rotating within the cylinder block; vane slots provided on the rotor; vanes each provided slidably within each of the vane slots; coil springs provided within the vane slots for pushing the vanes; guide pins each provided along each of the coil springs and directly fixed on the vanes or the rotor; and guide holes each provided for each of the guide pins and formed on the rotor or the vane. The guide holes are formed on the vanes in case where the guide pins are directly fixed on the rotor. Alternatively, the guide holes are formed on the rotor in case where the guide pins are directly fixed on the vanes. The compressor prevents chattering of the vanes and also prevents a complex structure and cost rise.

Owner:CALSONIC KANSEI CORP

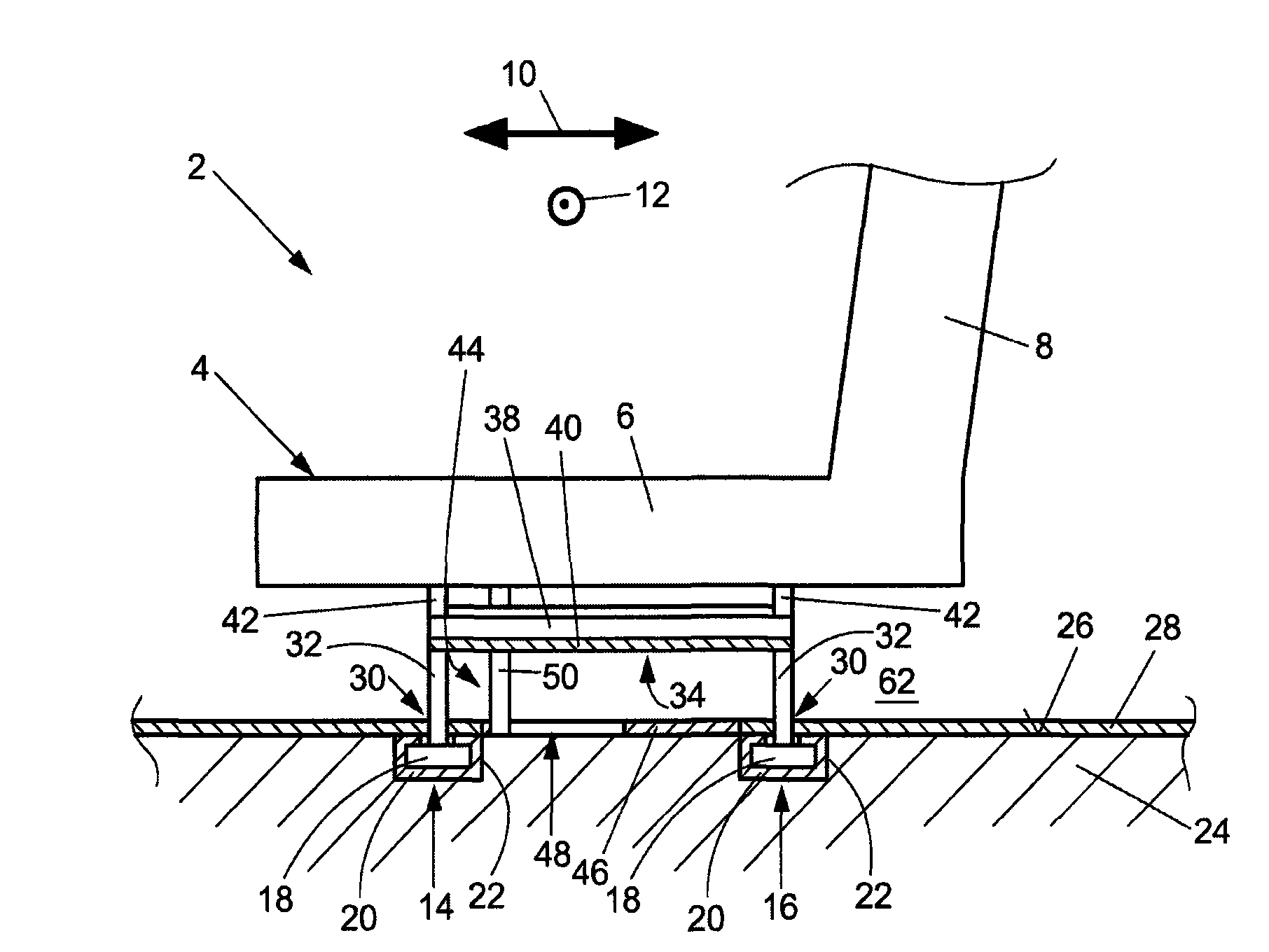

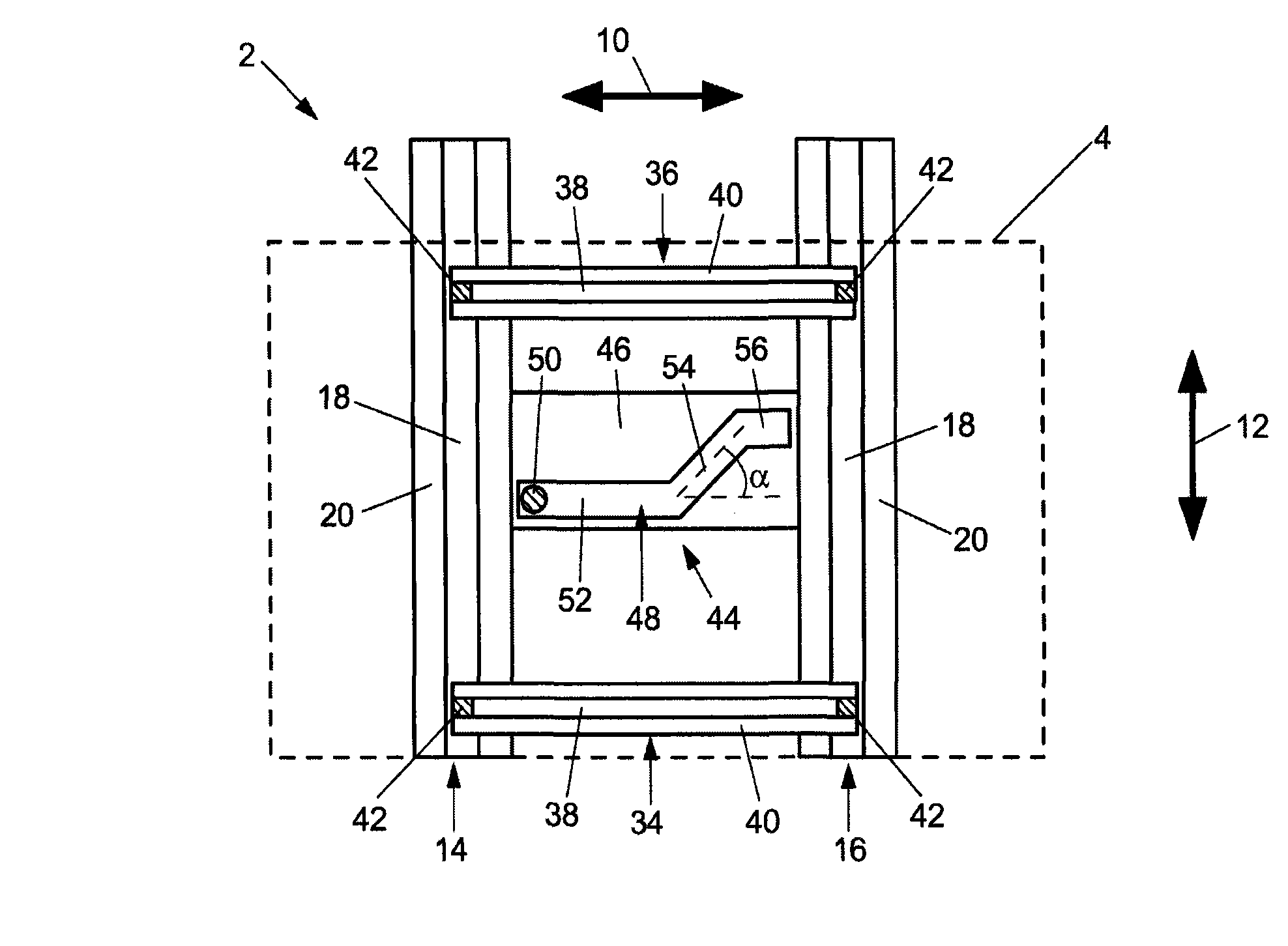

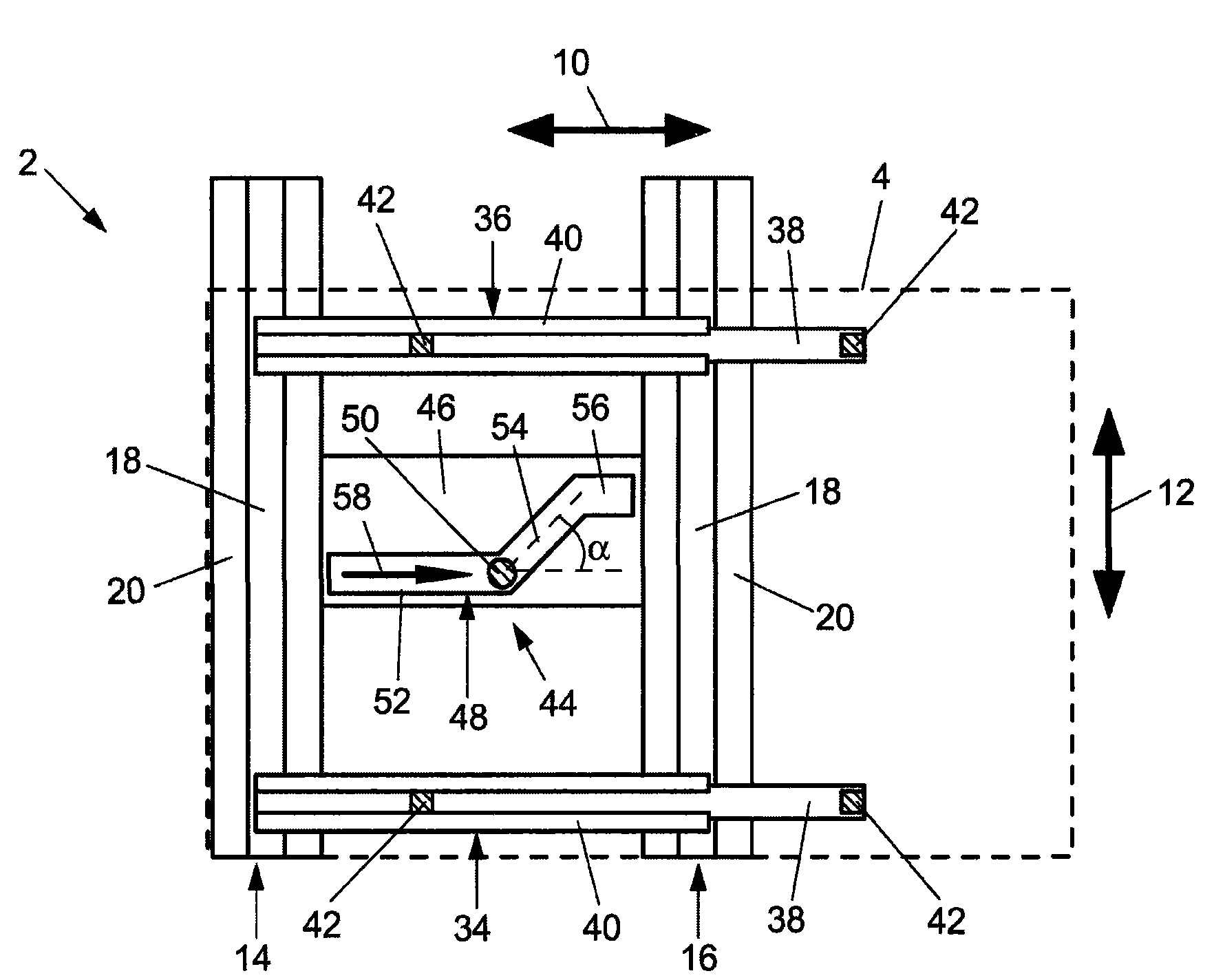

Seat arrangement with forced guide rail

InactiveCN101537805AMobile stable and reliableMove preciselyMovable seatsEngineeringMechanical engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

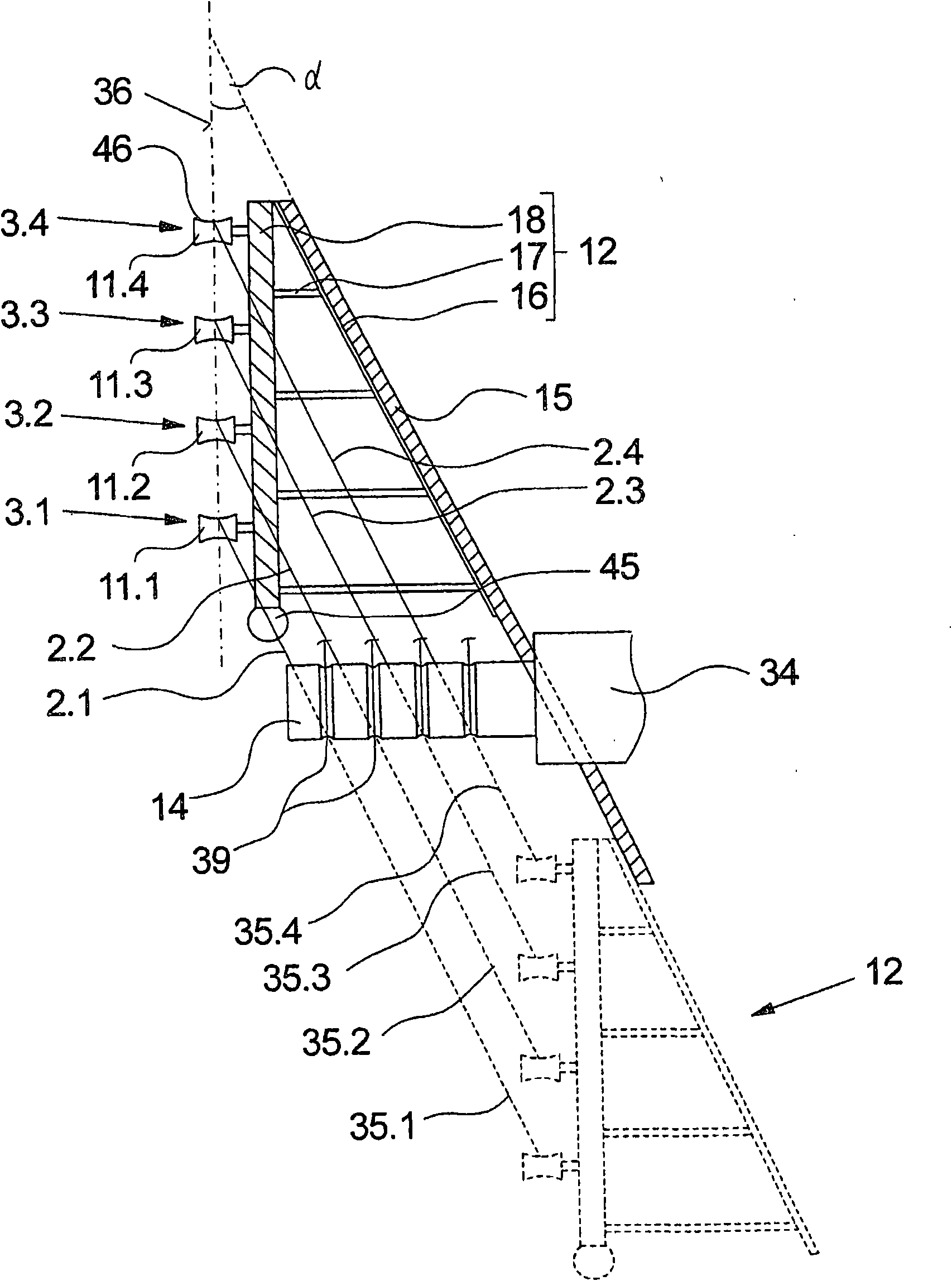

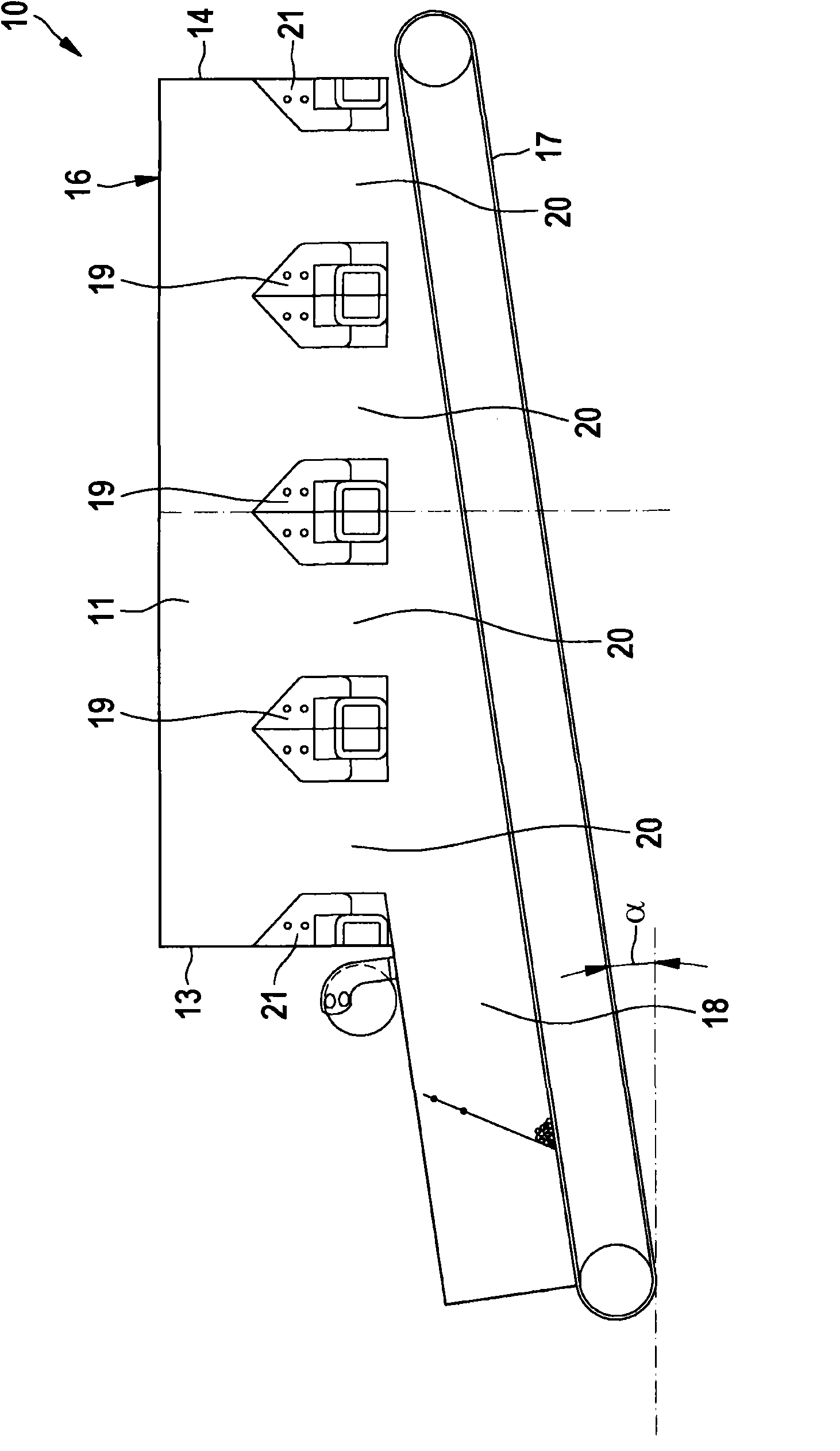

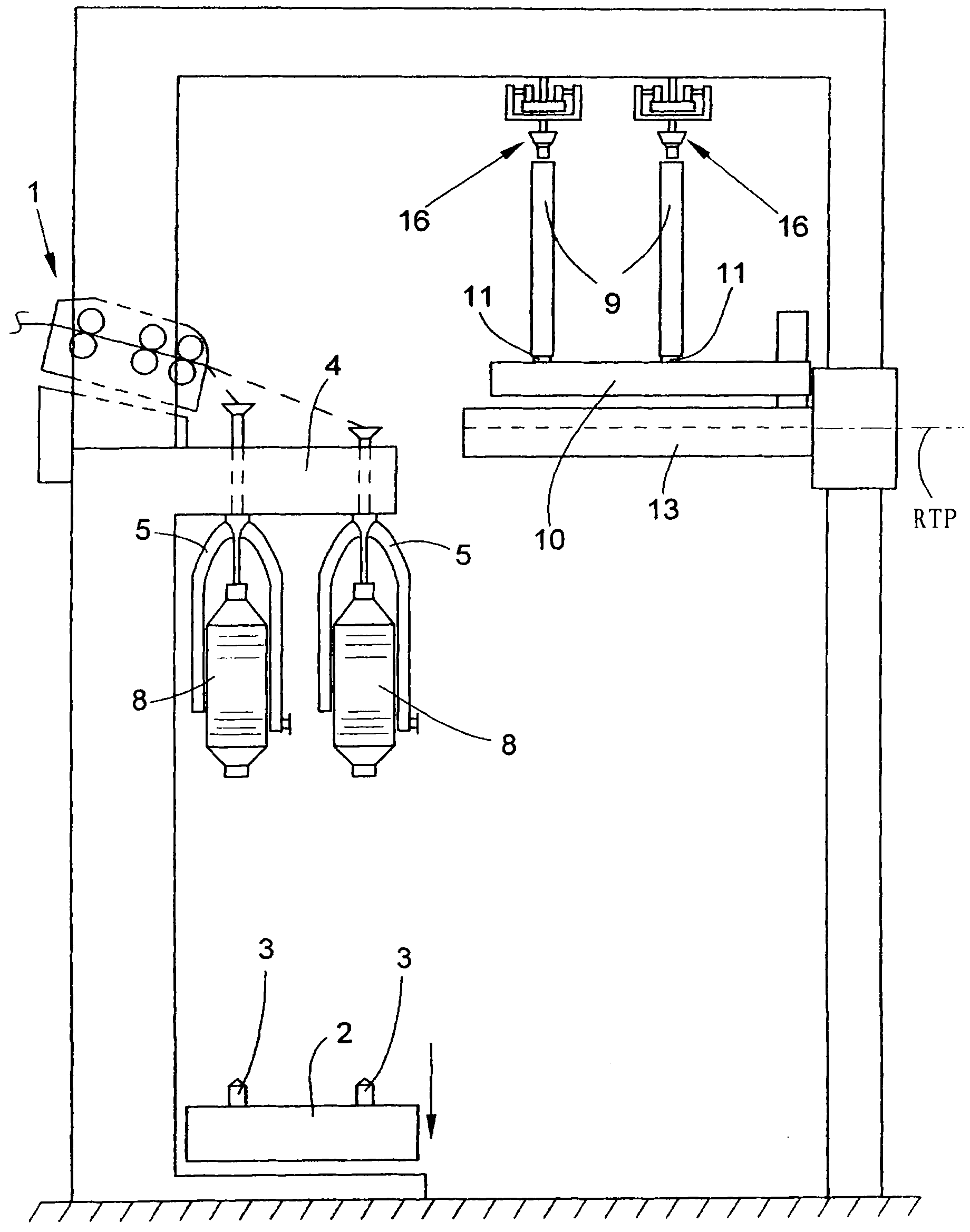

Emptying cartridge, method for emptying chamfers filled with rod-shaped objects and device for bringing together mass flows, in particular for an emptying cartridge

ActiveCN102058158AIncreased functional reliabilitySimple structureMeasurement devicesPackaging cigaretteAngle alphaMechanical engineering

The invention relates to an emptying cartridge, a method for emptying chamfers filled with rod-shaped objects and a device for bringing together mass flows, in particular for an emptying cartridge. The emptying cartridge comprises: a receiving space (11) for receiving the rod-shaped objects from the chamfer, wherein the receiving space is opened upwards along the chamfer direction and limited downwards by a conveying element (17) for conveying the products and formed by one canal (18); at least one flow controlling element (19, 21), wherein the distance between each flow controlling element and the conveying element is adjustable, characterized in that: the conveying element (17) for forming the canal and for conveying the products is arranged in an inclined way and according to the product diameter, the distance between the inclined angle Alpha and the conveying element (17) and each flow controlling element (19,21) is adjusted when keeping the product figure by the adjustability of each flow controlling element (19,21) and / or conveying element (17).

Owner:KOERBER TECH GMBH

Workstation of a textile machine

The invention relates to a workstation of a textile machine comprising an open-end spinning device for the production of a thread, a cone winding device for winding the thread into a cross-wound bobbin, a pivotably mounted suction nozzle connected to a low-pressure network of the textile machine for receiving the thread from the surface of the cross-wound bobbin, and a storage nozzle connected to the low-pressure network for the temporary storage of a thread excess created in the form of a thread loop during the startup of the workstation. According to the invention, it is provided that the suction nozzle (4), which has a relatively high suction air consumption, and the storage nozzle (60), which has significantly lower suction air consumption, are connected to the low-pressure network (20) of the textile machine such that the suction nozzle (4) can be decoupled from the low-pressure network (20), if necessary, independently of the storage nozzle (60).

Owner:SAURER GERMANY GMBH & CO KG

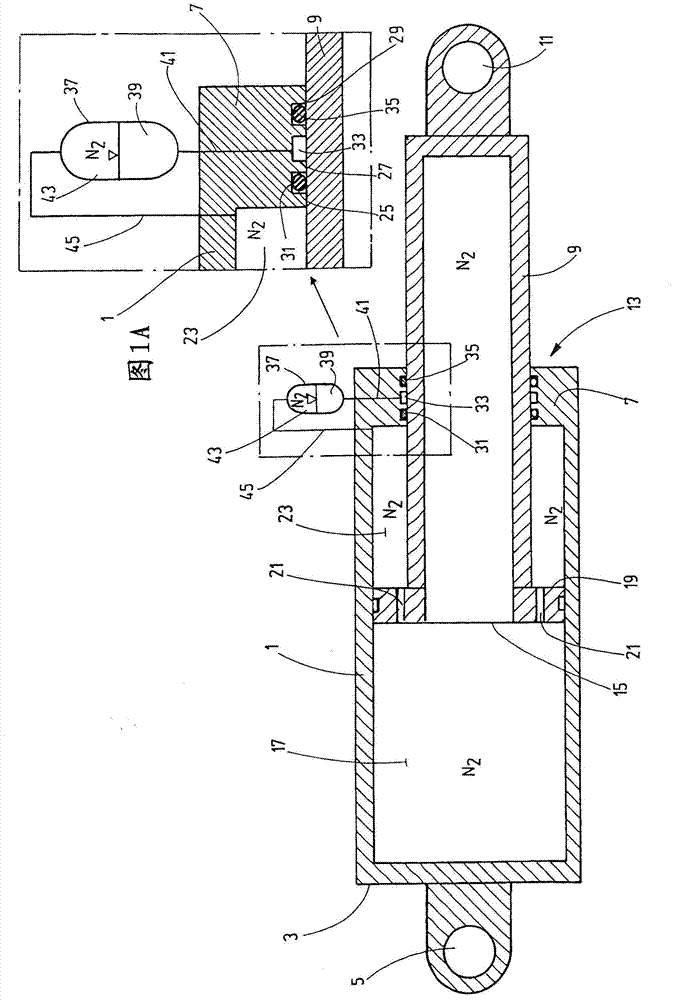

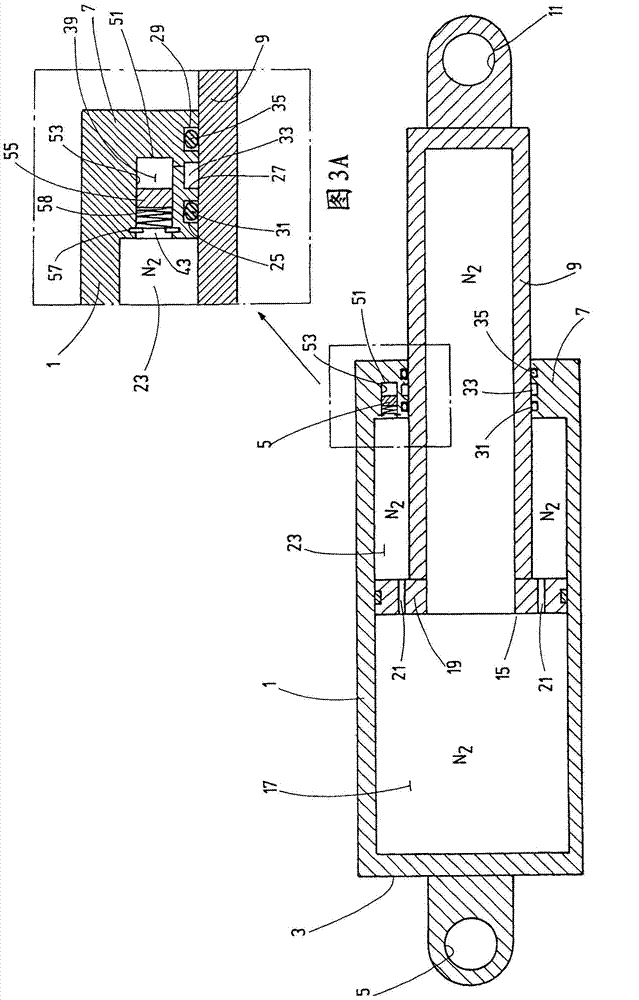

Gas cylinder, in particular high-pressure gas cylinder

The invention relates to a gas cylinder, in particular a high-pressure gas cylinder, the cylinder tube (1) of which has a piston rod (9) that is passed through a sealing arrangement (13) by which the gas pressure prevailing in the pressure chamber (23) of the cylinder tube (1) is sealed off against the ambient pressure. The invention is characterized in that the sealing arrangement (13) has a compressed oil chamber (33) between at least one sealing element (31) adjacent to the pressure chamber (23) and at least one more sealing element further away from the pressure chamber (23), into which oil chamber oil can be pressed in by means of a supply device (51) at a pressure that is equal to or higher than the respective gas pressure prevailing in the pressure chamber (23) of the cylinder tube (1).

Owner:HYDAC TECH GMBH

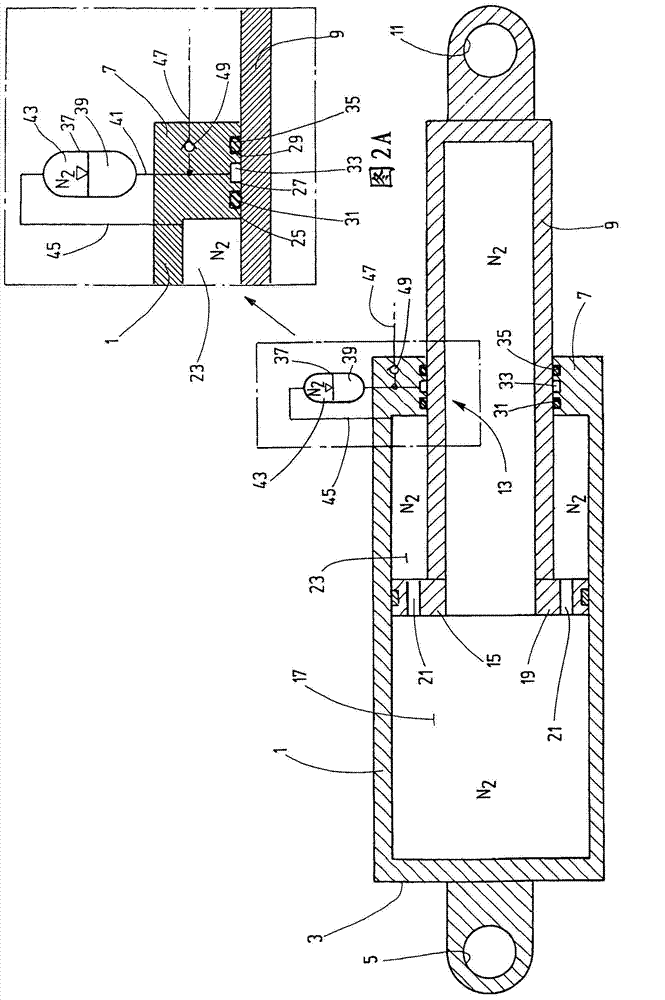

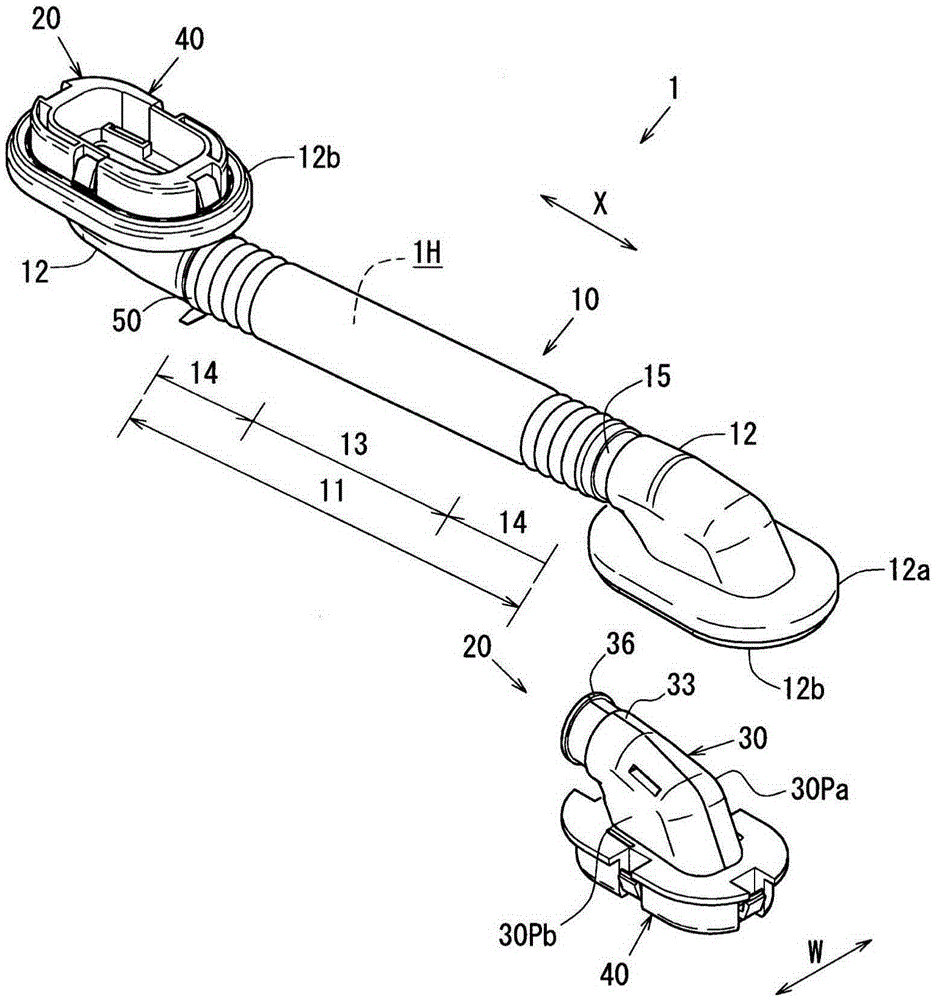

Conduit

Owner:FURUKAWA ELECTRIC CO LTD +2

Method for melt spinning, stretching and winding multifilament thread and device for carrying out same

InactiveCN102131965AReached temperatureDesired temperatureArtificial thread manufacturing machinesArtificial filament heat treatmentPolymer sciencePlastic materials

The invention relates to a method for melt spinning, stretching and winding a multifilament thread to form an FDY yarn, and a device for carrying out the method. First, a plurality of filaments made from a thermoplastic melt are extruded, cooled to a temperature below the glass transition temperature of the plastic material, and combined to form a filament bundle with no addition of a preparation fluid. Then, the filament bundle is drawn off at a speed of greater than 1500 m / min, heated to a temperature above the glass transition temperature of the thermoplastic material and stretched at a stretching speed of greater than 4000 m / min. The filament bundle is led through a hot air atmosphere of a heating tube for providing non-contact heating. Then, the filament bundle is prepared with a preparation fluid and the thread is wound into a coil. In the device according to the invention, the preparation device is disposed downstream of the heating means in the thread direction, wherein the heating means, which is a heating tube with a hot air atmosphere for non-contact heating of the filament bundle, is disposed between the drawing-off galette and the stretching galette.

Owner:OERLIKON TEXTILE GMBH & CO KG

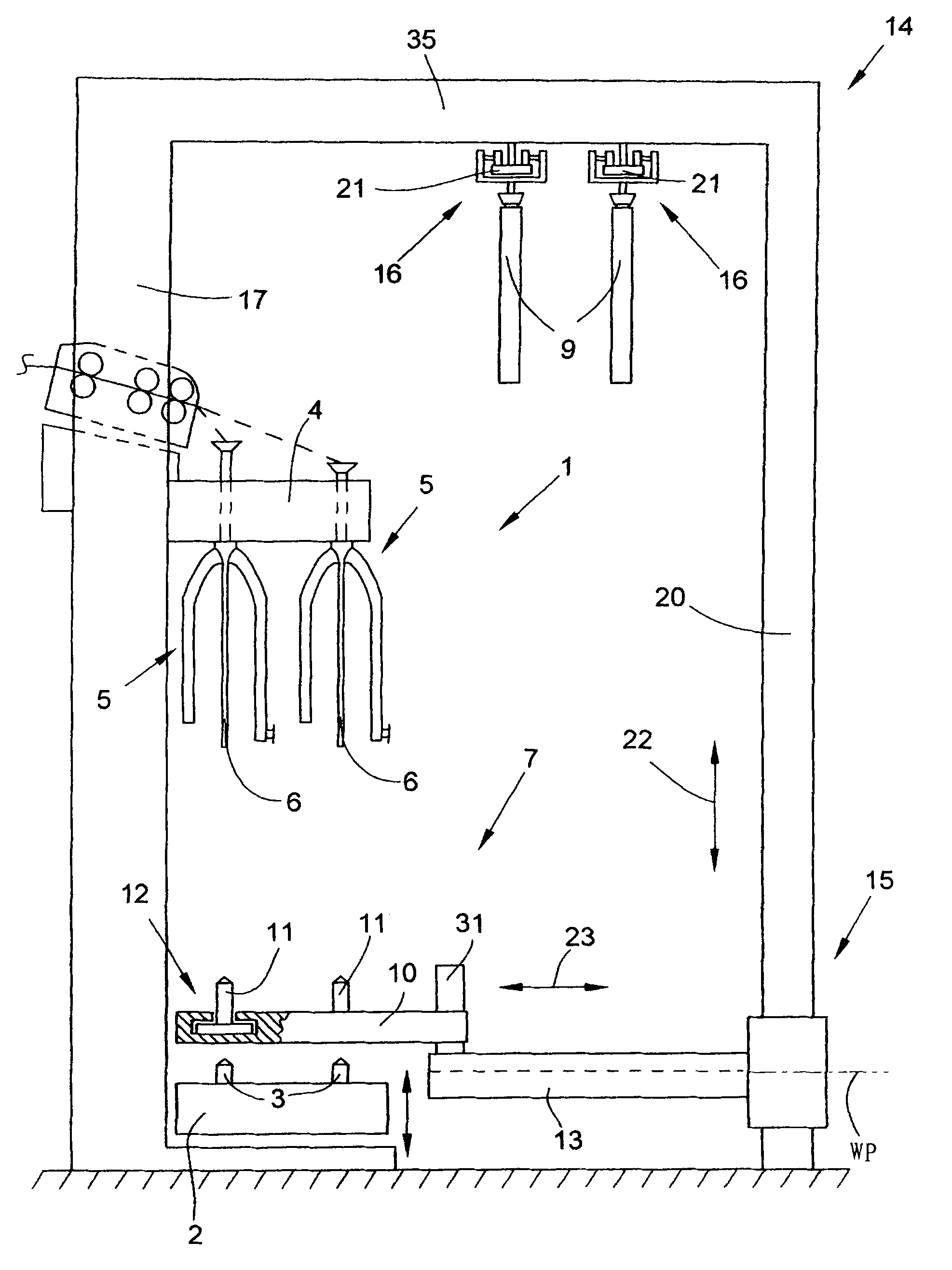

Roving machine with reel change mechanism

ActiveCN101988225APrecise positioningReliable bootFilament handlingTextiles and paperBobbinCentral spindle

The present invention relates to a roving machine with a bobbin rail, a flyer rail and a reel change mechanism. The bobbin rail can be equipped with movably in a vertical direction. The flyer rail is equipped fixedly. All flyers of the flyer rail are respectively provided with a central spindle. The reel change mechanism is connected with a frame structure which bestrides the roving machine. The reel change mechanism is provided with a base component which is movable in a vertical direction relatively to the adjustment height. The base component is provided with a change platform which is equipped movably in a horizontal direction. According to the invention, the change platform (10) is provided with a conveying device (12) which is provided with a case carrier (11) for receiving roving reels (8) or empty bobbins (9). Furthermore the conveying device (12) can be positioned in an area of the roving machine (1) such that empty case carriers (11) or case carriers (11) provided with the empty bobbins (9) are alternatively positioned exactly below central spindles (6) of a flyer (5) of the flyer rail (4).

Owner:SAURER GERMANY GMBH & CO KG

Solenoid valve for controlling fluid

InactiveCN102758948AShorten the tolerance chainSteer tight and preciseOperating means/releasing devices for valvesBraking systemsSolenoid valveEngineering

A solenoid valve for controlling a fluid comprising an armature, a valve member which has a dome-shaped end region and which is connected to the a mature and is movable jointly with the armature, a first guidance region being provided on the armature, and a valve body with a valve seat, with a through orifice, the valve member opening and closing the through orifice on the valve seat, and with a guide element which defines a second guidance region for guiding the valve member and which guides the valve member when the solenoid valve is open, the guide element being formed in one piece with the valve body.

Owner:ROBERT BOSCH GMBH

Method for threading in a thread

The present invention relates to a method for threading a thread (16) into a guide slot (21) of an individually driven, finger-shaped thread guide (13) of a textile machine, which thread guide (13) guides the thread (16) parallel to the spool axis via an oscillating stroke width in order to transfer a thread (16) on a rotating spool (5), wherein the thread guide (13) is transferred into an initial position (A) before the beginning of the threading operation; the thread guide (13) is then transferred into a threading position (E) and drives the thread (16) which is to be threaded in; a relative movement is generated here between the thread guide (13) and the thread (16), in order to thread the thread (16) into the thread guide (16); and the thread (16) is held with tension for the threading operation.

Owner:SAURER GERMANY GMBH & CO KG

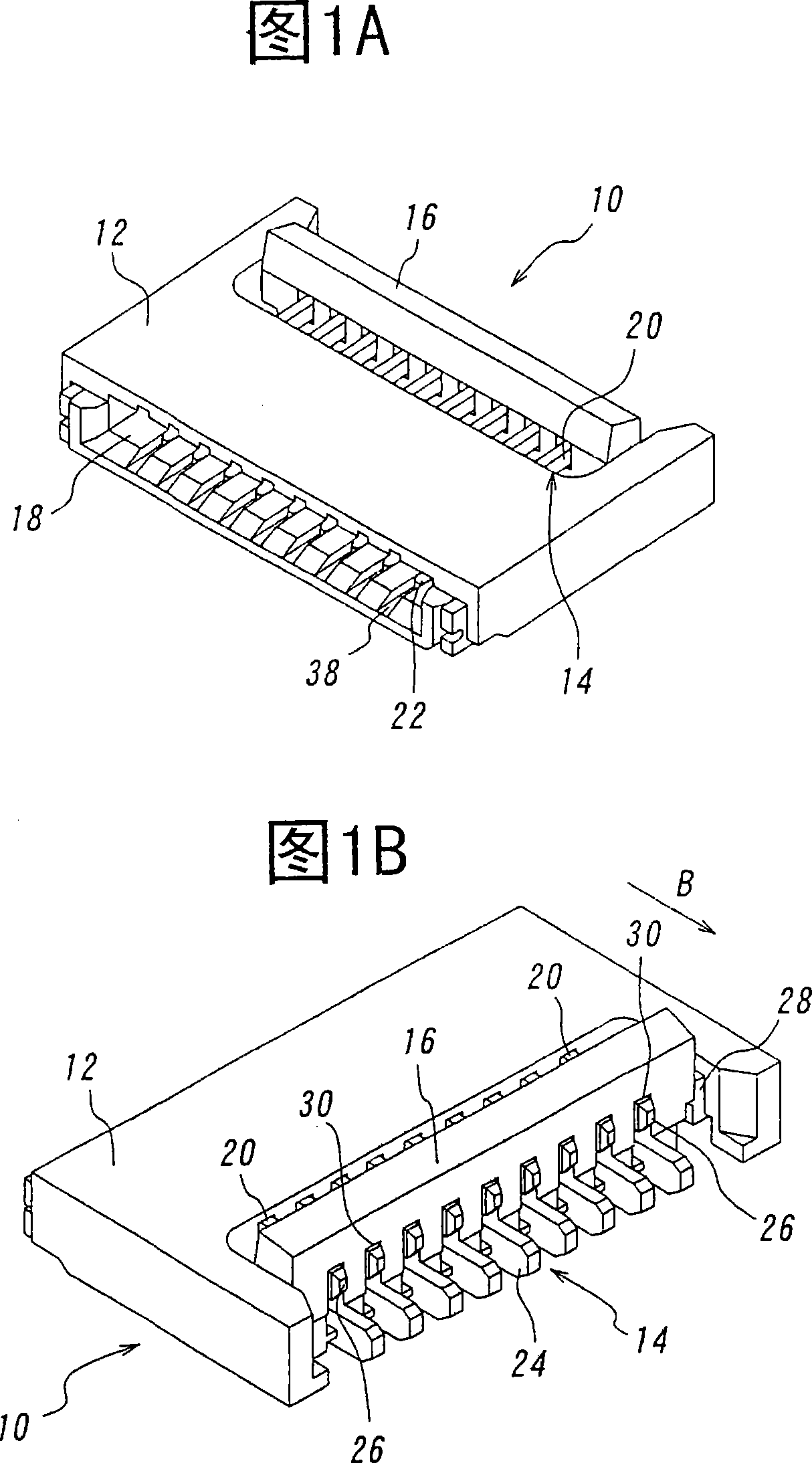

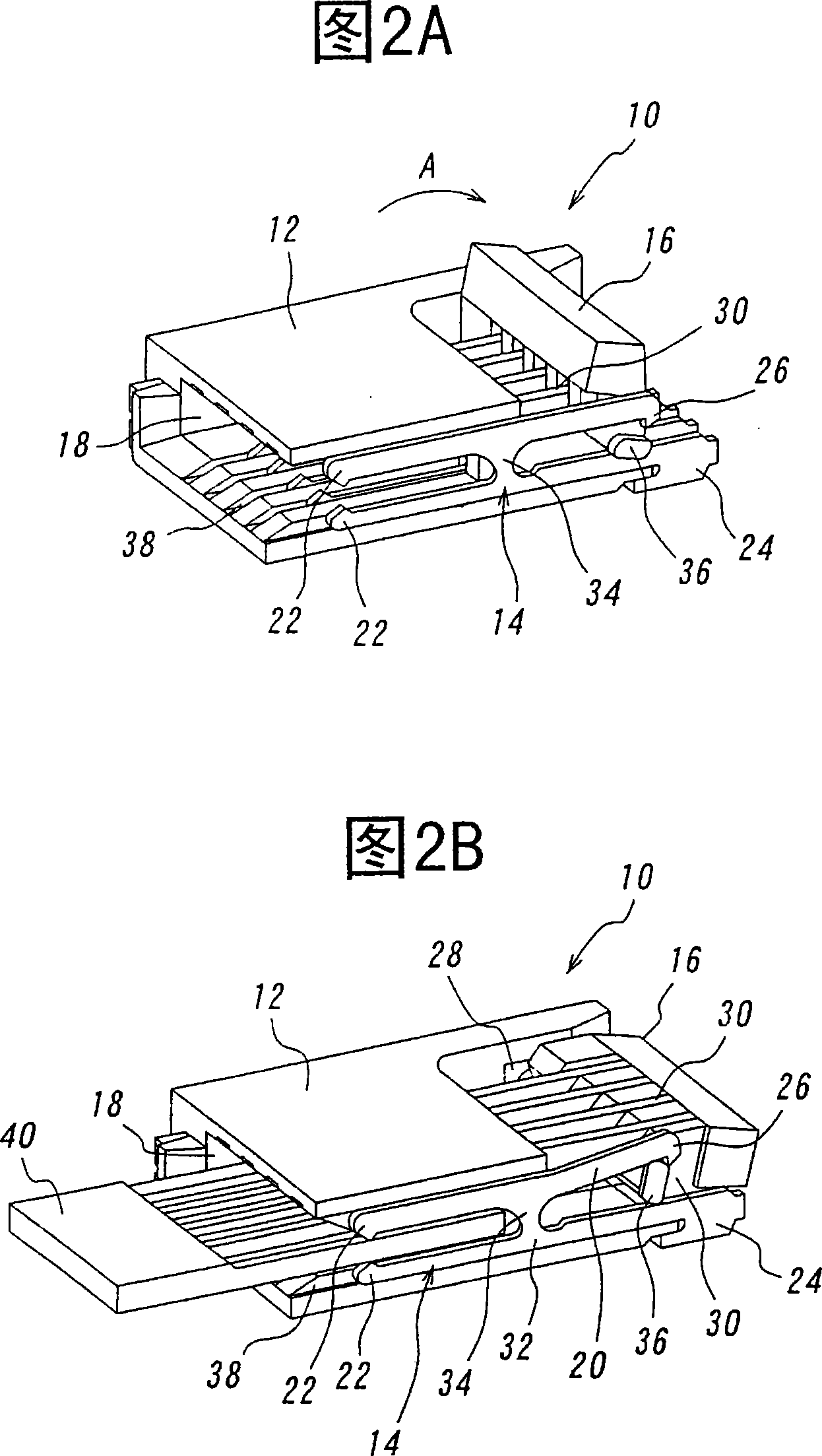

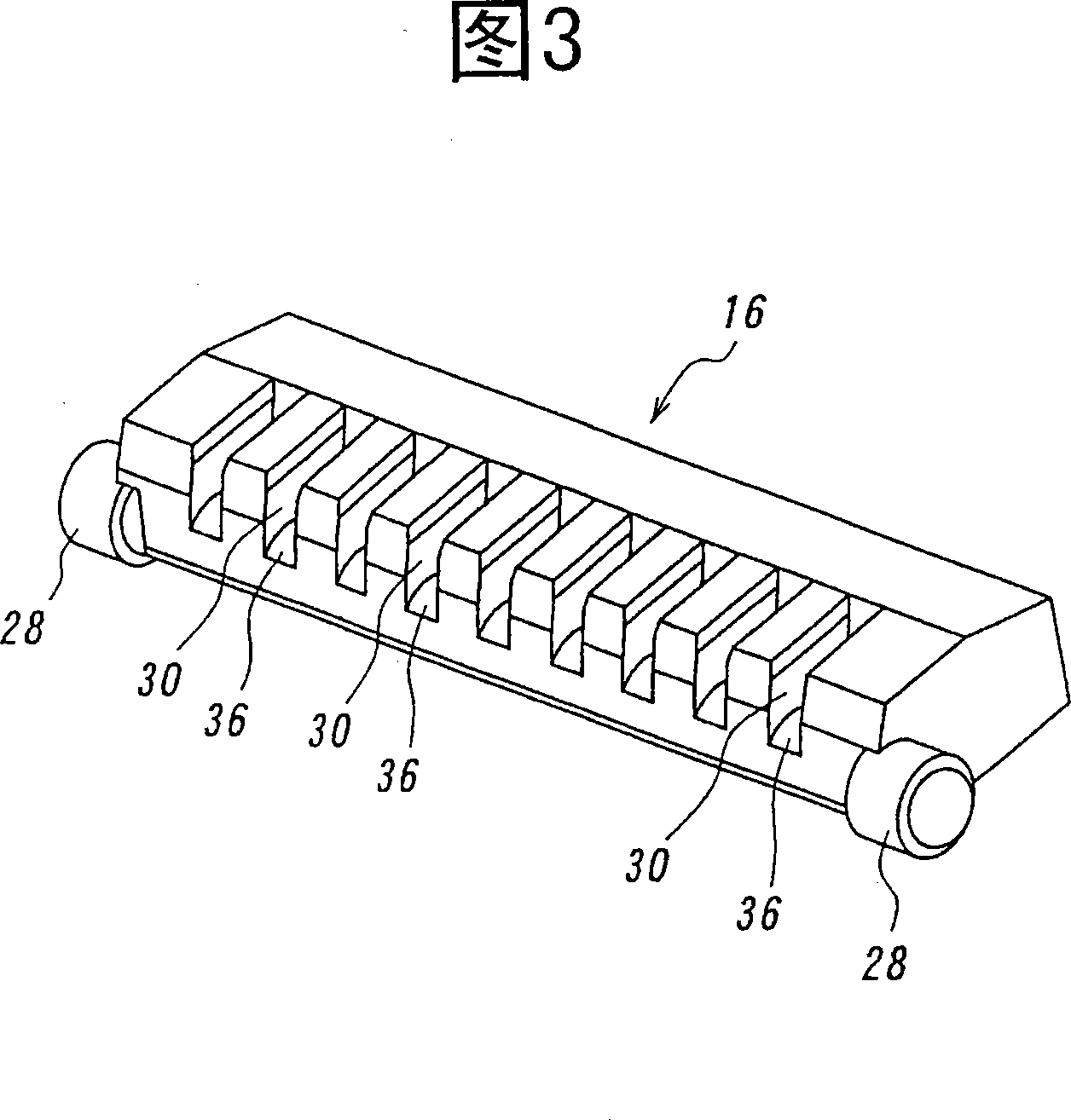

Connector

InactiveCN101090182ALock firmlyReduce thicknessEngagement/disengagement of coupling partsTwo-part coupling devicesMiniaturizationEngineering

A connector includes contacts each having a contact portion, an elastic portion and a fulcrum portion between the contact portion and a connection portion, and a pressure receiving portion; a housing fixing the contacts; and a slider having urging portions pivotally moved between the connection and pressure receiving portions of the contacts to urging the contact portions against the circuit board, thereby achieving reliable connection and miniaturization of the connector. In an aspect, the housing is formed on the side of a board insertion opening with a recessed portion for conducting the board. In another aspect, the contact includes upper and lower contact portions one above the other arranged alternately staggered so as to be connected to a circuit board having contact portions alternately staggered, so that no defective connection occurs, even if the circuit board is inserted erroneously upside down. In a further aspect, the connector further includes locking members having an engaging portion which engages an anchoring portion of the circuit board to prevent the circuit board from being removed. In one aspect, contacts of two kinds are inserted into the housing from opposite sides, respectively so that these contacts of the two kinds are into contact with the contact portions on respective surfaces of the circuit board. In a further aspect, moreover, a plate-shaped piece is provided in opposition to the contact portions of the contacts to prevent the housing from being deformed.

Owner:DDK LTD

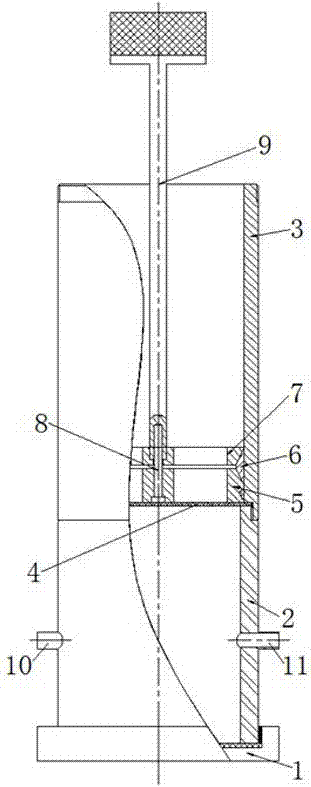

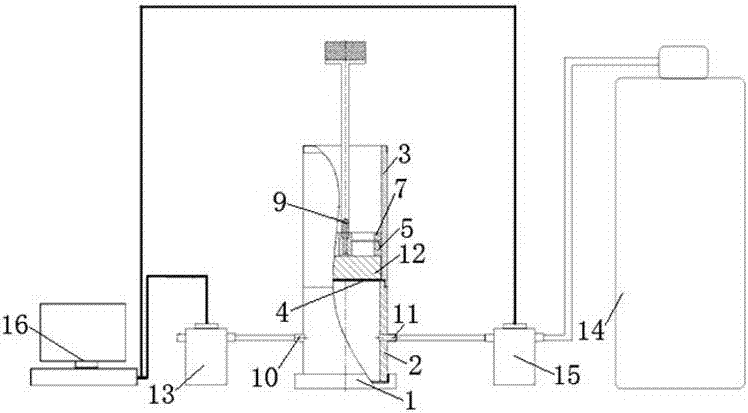

Measuring instrument for flow resistance of porous sound absorption material

InactiveCN106918442ADoes not affect the flow effectImprove convenienceHydrodynamic testingMeasuring instrumentDifferential pressure

The invention discloses a measuring instrument for the flow resistance of a porous sound absorption material, which comprises a specimen tube, wherein one end of the specimen tube is of a closed structure, the other end of the specimen tube is of an open structure, and the tube wall, which is close to the closed end, of the specimen tube is at least provided with a differential pressure measuring joint and an air inlet joint. The measuring instrument is characterized in that a grid plate is supported in the radial direction at the inner wall of the middle part of the specimen tube, the outer surface of the grid plate is used for placing a specimen material, the specimen material is mainly limited in the axial direction by an annular sealing assembly which his arranged in the specimen tube and located at the outer side of the grid plate, the annular sealing assembly is provided with an air flow channel, and the annular sealing assembly is closely matched with the inner wall of the specimen tube. The measuring instrument is conducive to improving and ensuring the accuracy and the reliability of flow resistance measurement of the porous sound absorption material effectively and reliably, and is high in practicability.

Owner:中国测试技术研究院声学研究所

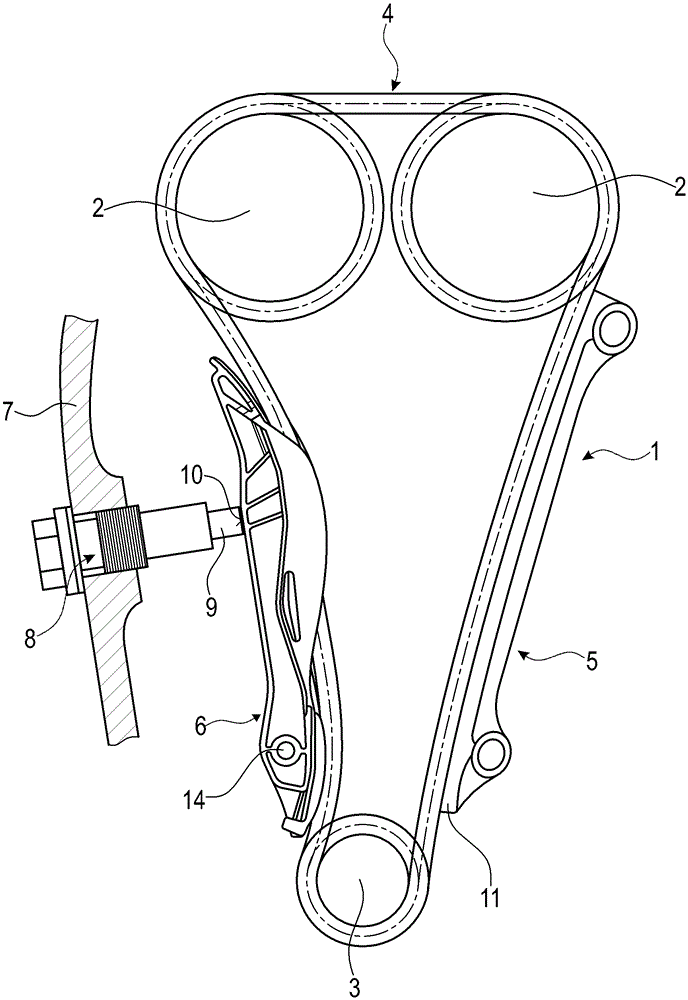

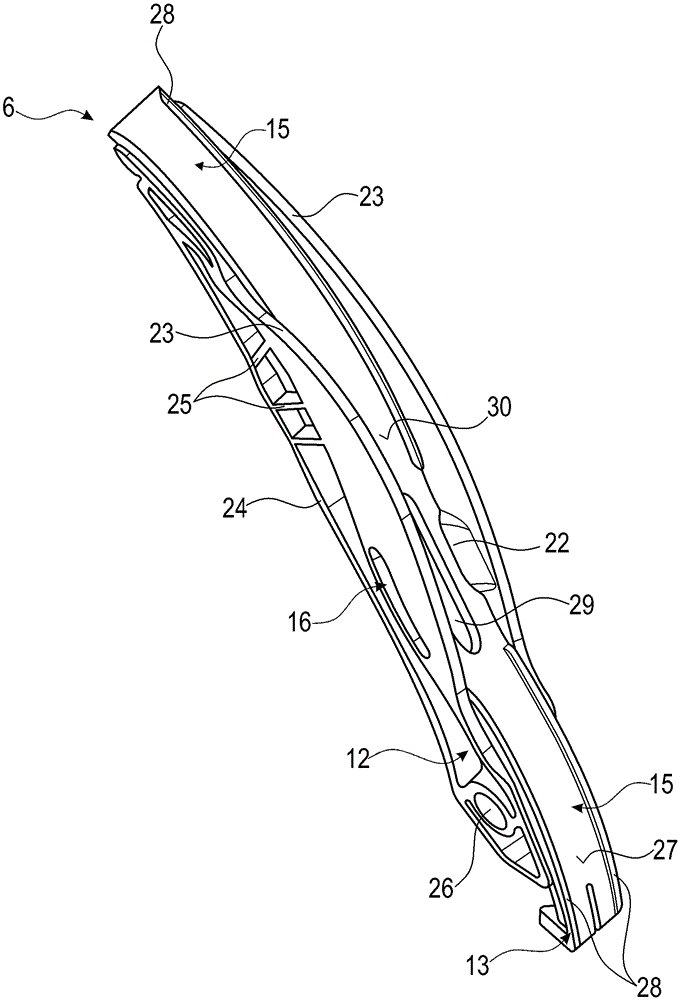

Tensioning or guide rail having a continuous recessed sliding body

InactiveCN105485274AReduce generationReduce frictional resistanceGearingEngineeringInternal combustion engine

The invention provdies a tensioning or guide rail having a continuous recessed sliding body. A tensioning or guide rail for a drive chain, in particular for a chain drive of an internal combustion engine, comprises a carrier body with at least two chain guide sections and with at least one recessed section. The at least one recessed section is arranged between two chain guide sections and recessed relative to a tangent connecting the adjoining chain guide sections, the at least two chain guide sections having each a sliding-contact surface for contacting the drive chain. A continuous sliding body is arranged on the carrier body along the at least two chain guide sections and the at least one recessed section, the sliding body defining the sliding-contact surfaces of the at least two chain guide sections and a surface of the at least one recessed section, the surface facing the drive chain.

Owner:IWIS MOTORSYSTEME GMBH & CO KG

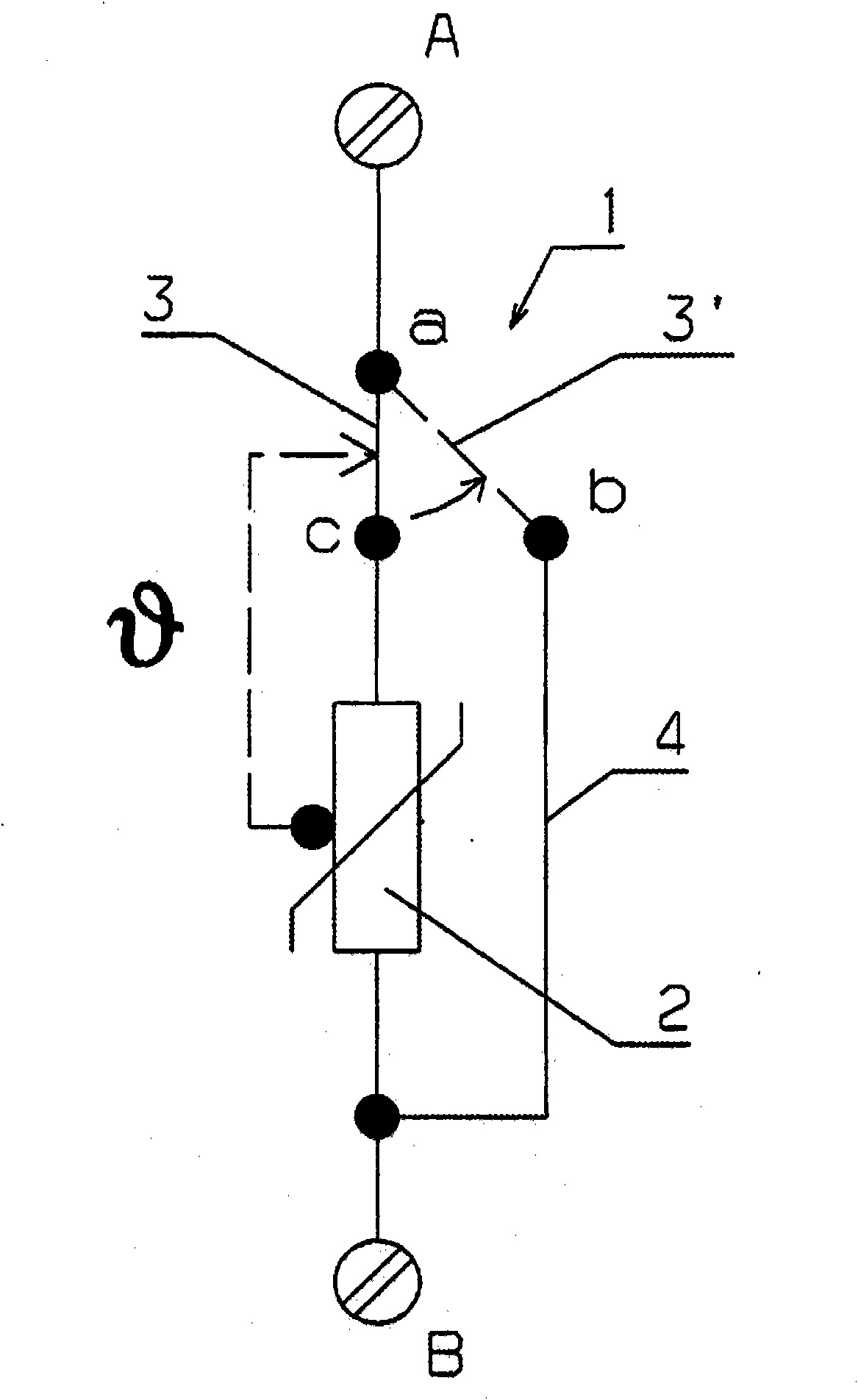

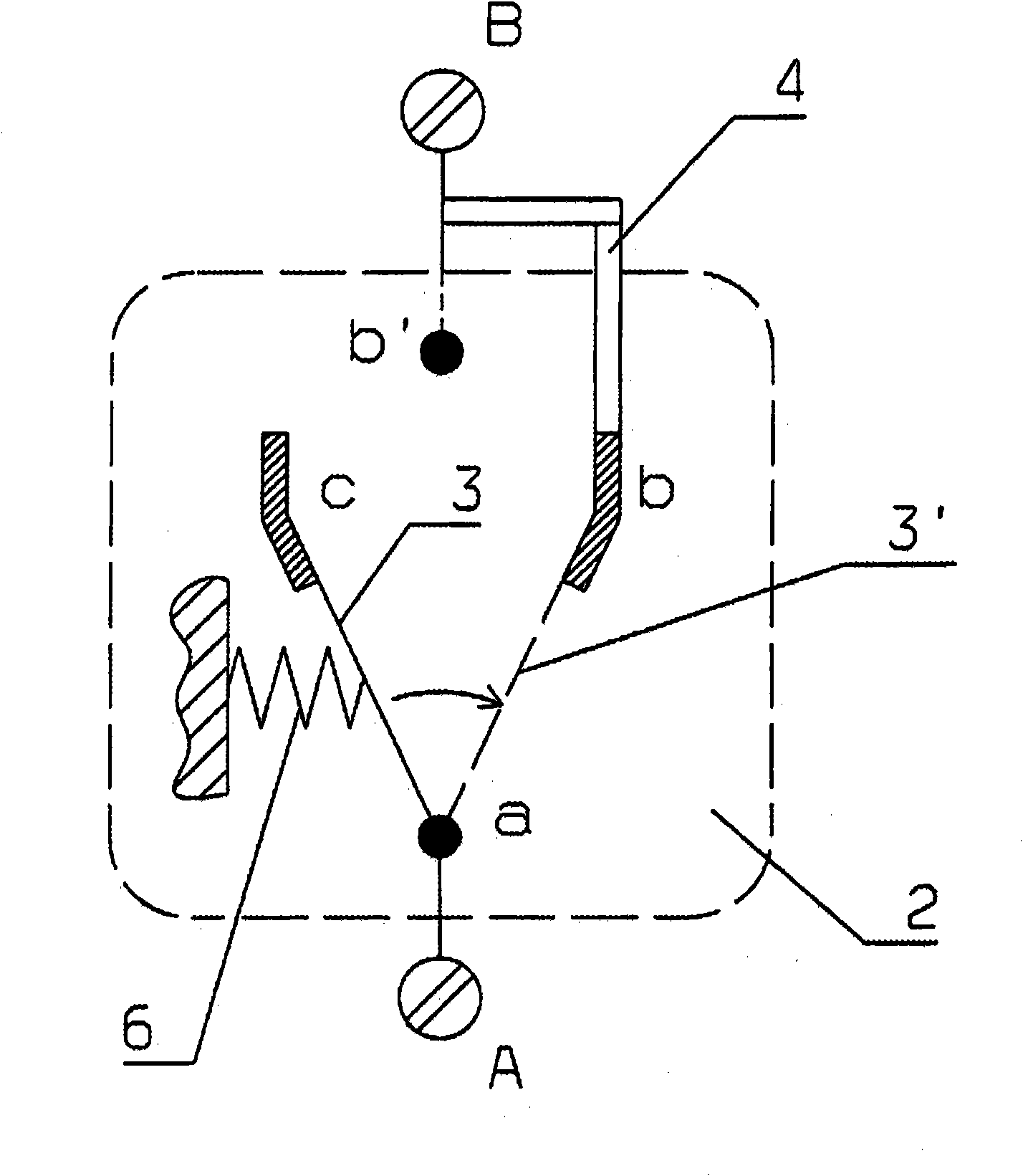

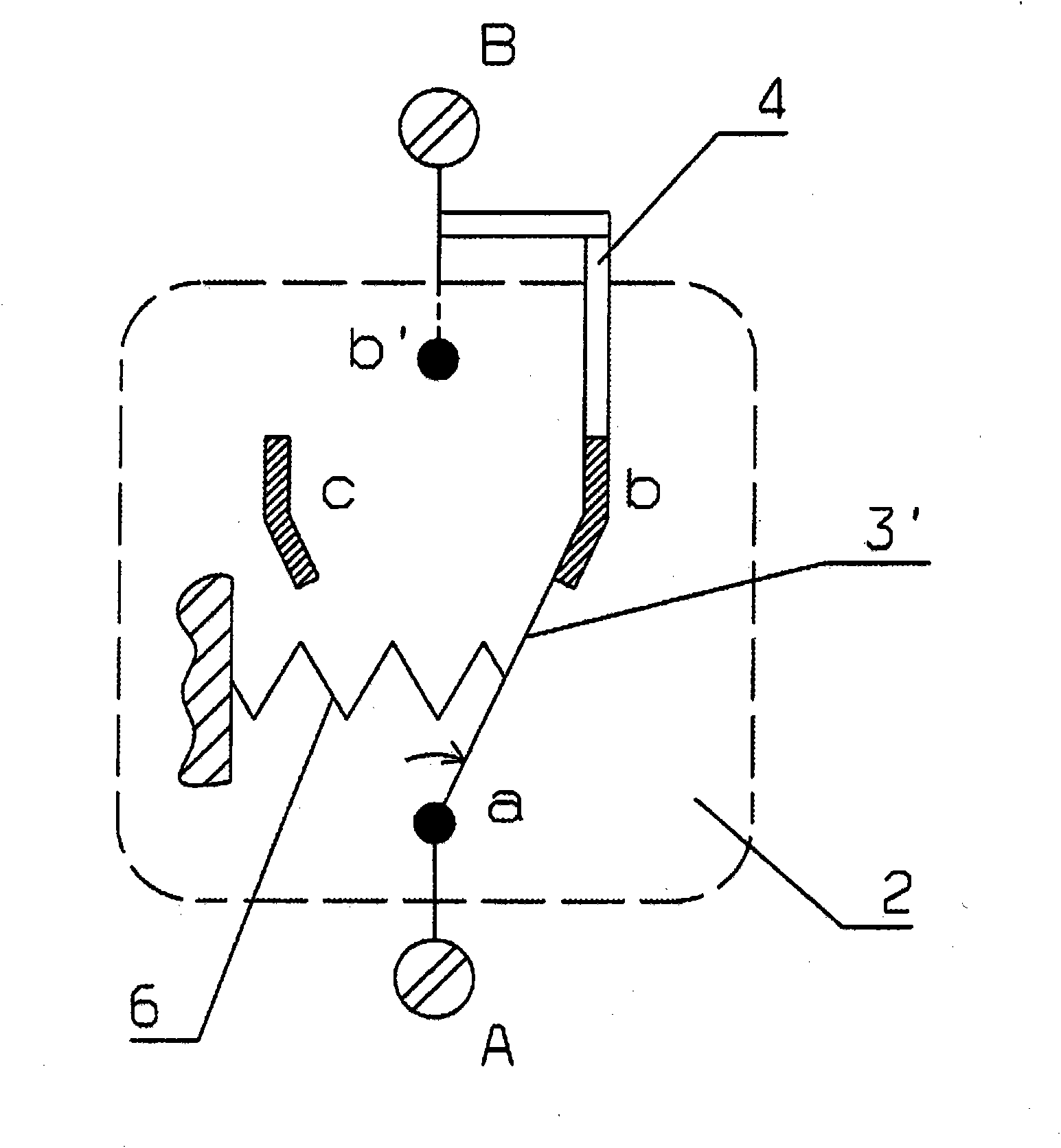

Surge arrester having a housing and having at least one arresting element

The invention relates to a surge arrester having a housing (10) and at least one arrester element and a disconnection device, in order to disconnect the arrester element or elements from the mains, the disconnection device comprising a junction (14), which is incorporated in the electrical terminal path (A; B) inside the arrester, a movable conductor section (3) being connected via the junction to the arrester element on the one hand and the conductor section on the other hand, using a first electrical outer terminal of the arrester under over voltage protection, and comprising a means which generates a pre-load force, the force vector in this regard acting indirectly or directly via a movable disconnection bracket (13) on the conductor section or the bridge in the disconnection direction. According to the invention, a conductive element (4; 7) is disposed in the movement path of the conductor section, the first end of the conductive element coming into contact with the conductor section if the disconnection device is triggered, the second end of the element being connected to a second electrical outer terminal, and the conductive element comprising a switching unit or being implemented as a switching unit.

Owner:デーンエスエープルスツェオーカーゲー

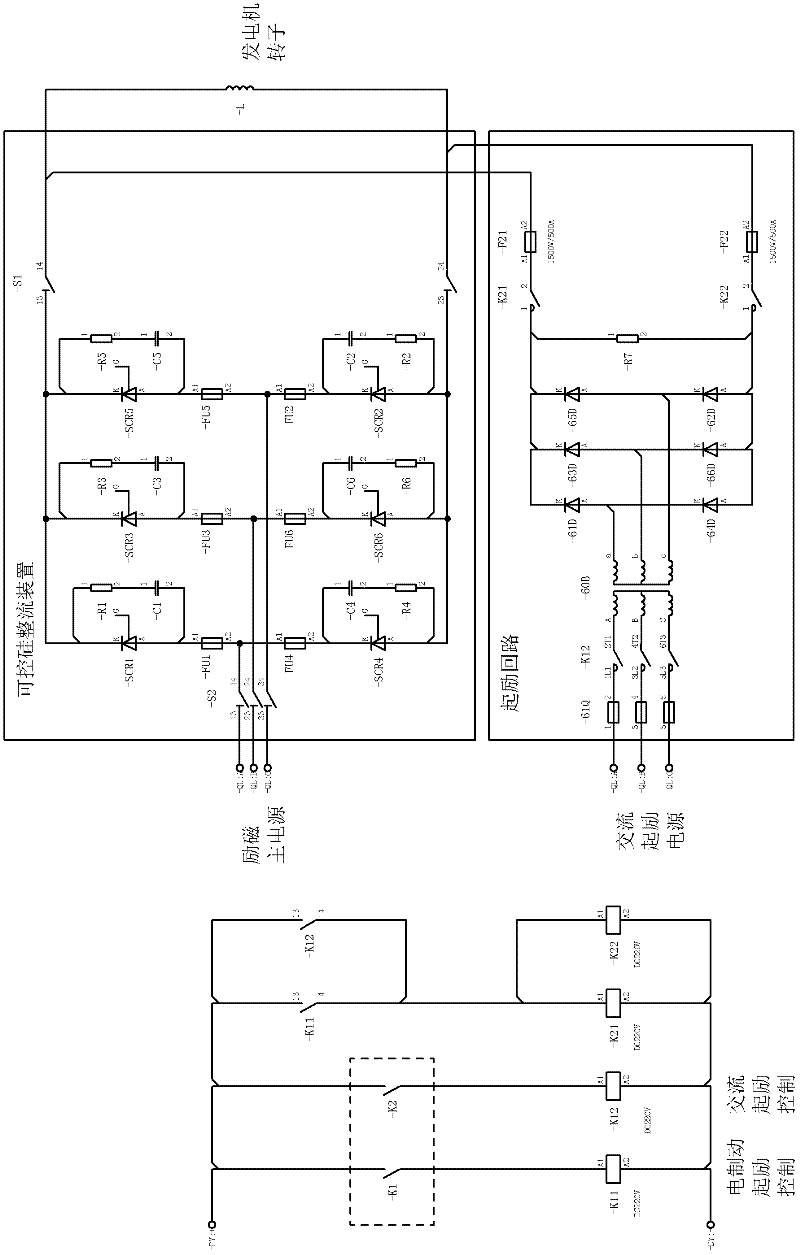

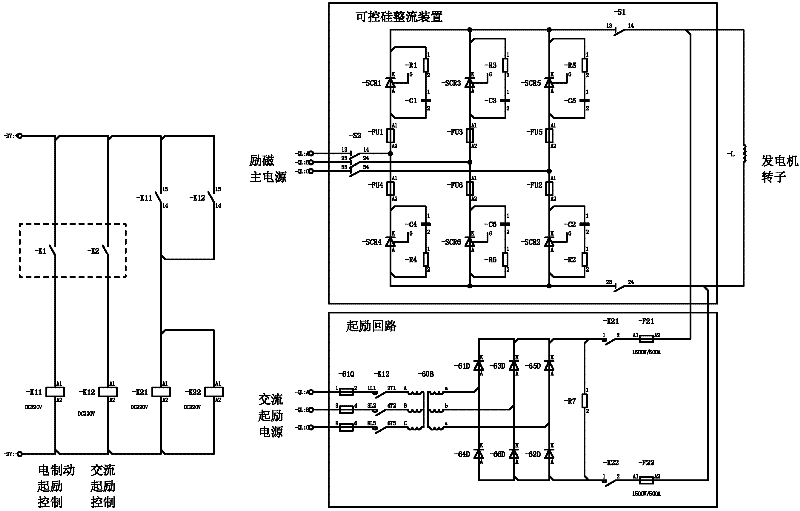

Flexible electric braking exciting loop of self-exciting hydraulic generator and exciting method thereof

ActiveCN102340276AEnsure safetyReliable bootGenerator control by field variationElectricityAlternating current

The invention discloses a flexible electric braking exciting loop of a self-exciting hydraulic generator and an exciting method thereof. The flexible electric braking exciting loop of the self-exciting hydraulic generator comprises a diode rectifier bridge exciting loop with an alternating-current side contactor and a direct-current side contactor, and the diode rectifier bridge exciting loop is connected in parallel at two ends of a rotor of the generator. The flexible electric braking exciting loop of the self-exciting hydraulic generator is characterized in that a diode rectifier bridge output side of the diode rectifier bridge exciting loop is connected in parallel with a resistor. The exciting loop provided by the invention not only can be used for carrying out alternating-current control excitation when the generator is subjected to self-exciting electricity generation, but also can be used for the excitation when the generator is subjected to flexible braking startup simultaneously.

Owner:NARI TECH CO LTD +1

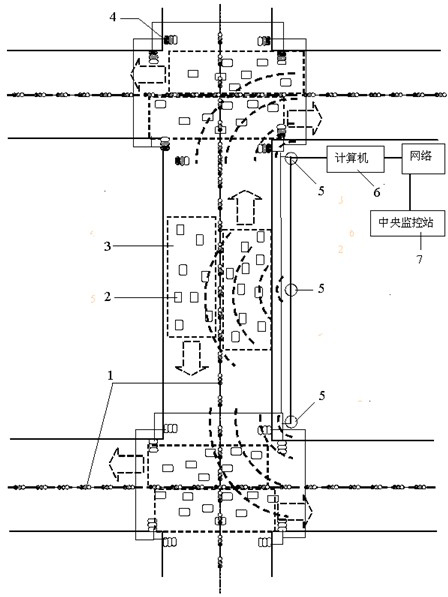

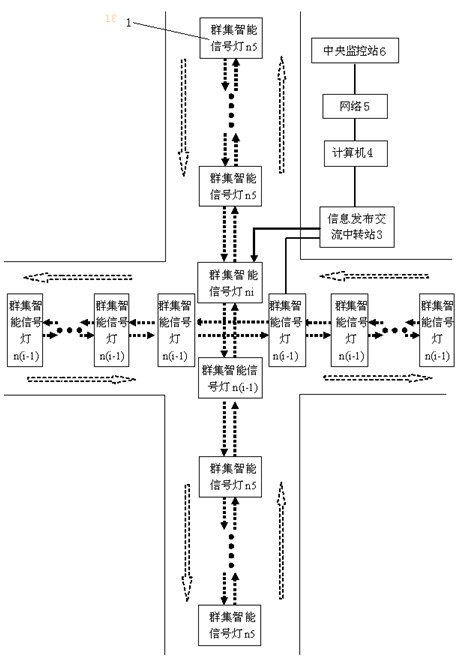

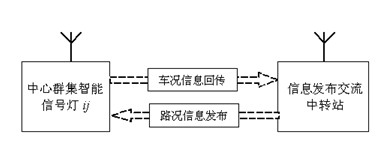

Green wave induction control method and system of traffic flow through intelligent cluster signal lamps

InactiveCN102592463AImprove traffic congestionEffective guidanceControlling traffic signalsWireless transmissionWireless data

The invention relates to a green wave induction control method and a system of traffic flow through intelligent cluster signal lamps, belonging to the technical field of intelligent traffic. The method comprises the steps of: setting intelligent signal lamps along a road and at intersections for sensing vehicle movement and wireless transmission and processing vehicle information, clustering single signal lamps to proper clusters to form lamp clusters by utilizing an intelligent cluster preprogram through information communication, performing communication and negotiation among the lamp clusters to form flowing green wave bands or green wave band lamp clusters so as to realize cluster flow and green wave flow traffic induction of the intelligent signal lamps. The system comprises intelligent signal lamps and red and green signal lamps arranged along the road and at intersections, an information communication transfer station and a central monitoring station, wherein an intelligent chips, a vibration sensor, a wireless data transmitter, a power supply and a three-color LED (light emitting diode) lamp are built in each intelligent signal lamp, the intelligent signal lamps are in wireless connection, and the intelligent signal lamps and the information communication transfer station are in wireless connection, and the central monitoring station is connected with the information communication transfer station through a network. The method and the system, disclosed by the invention, have the advantages of reliable system and good traffic flow control effect, etc.

Owner:KUNMING UNIV OF SCI & TECH

Flat knitting machine with weft yarn, warp yarn and/or float yarn clearing and stitch pressing means

ActiveCN105714466AAvoid hittingGuaranteed to guide the yarnFlat-bed knitting machinesWeft yarnIndustrial engineering

The invention relates to a flat knitting machine with at least one needle bed (20,21) and carriages (50,51) capable of moving along the needle bed (20,21), and at least one looping system on the carriage, wherein the means (10) for clearing weft yarn, warp yarn and / or float yarn and / or stitch pressing into knitwear and / or holding the knitwear during the looping process, and the yarn contact area of the means (10) is aranged on one end of the looping system and outside the looping system.

Owner:KARL MAYER STOLL R&D GMBH

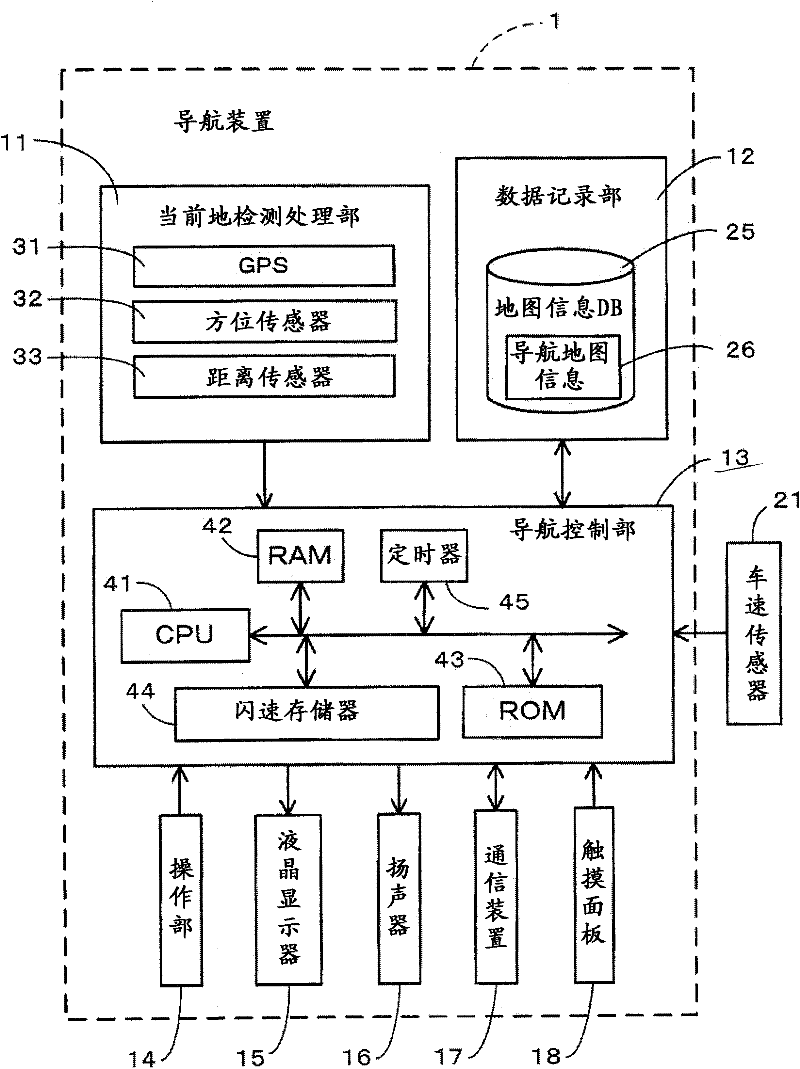

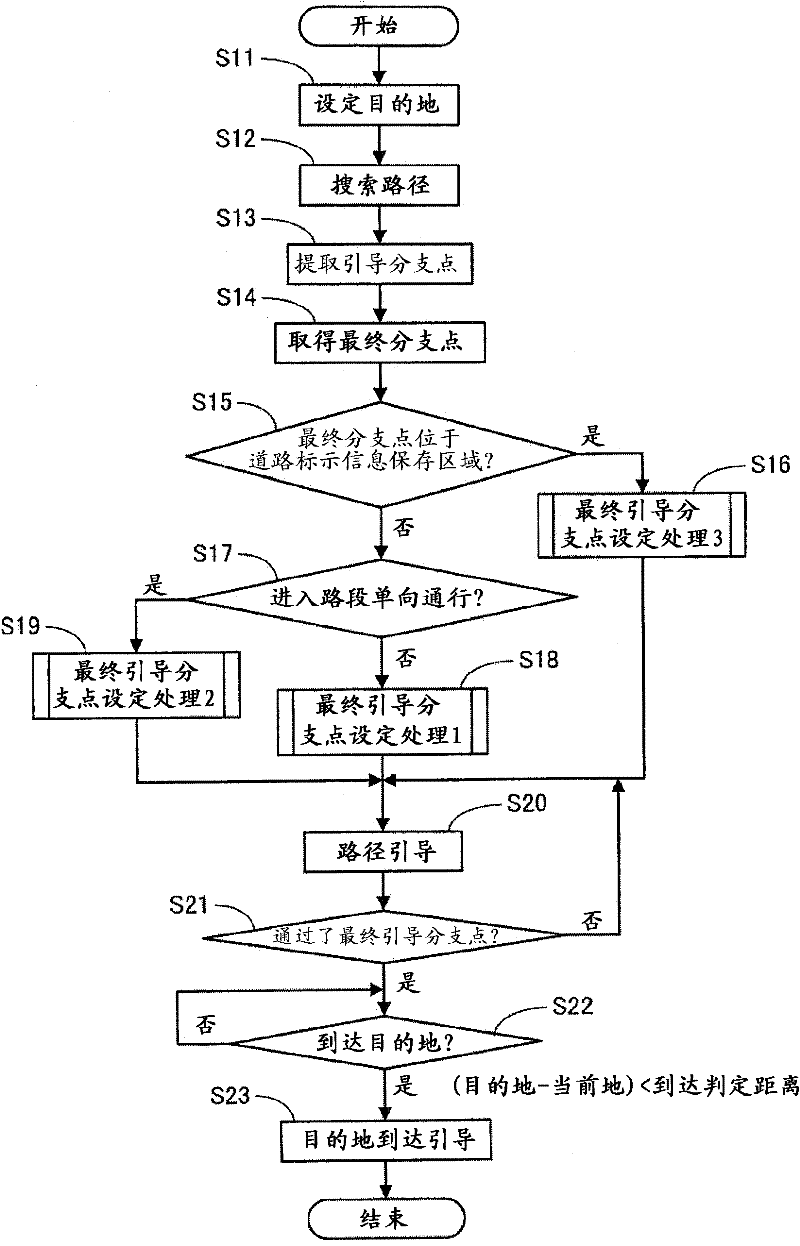

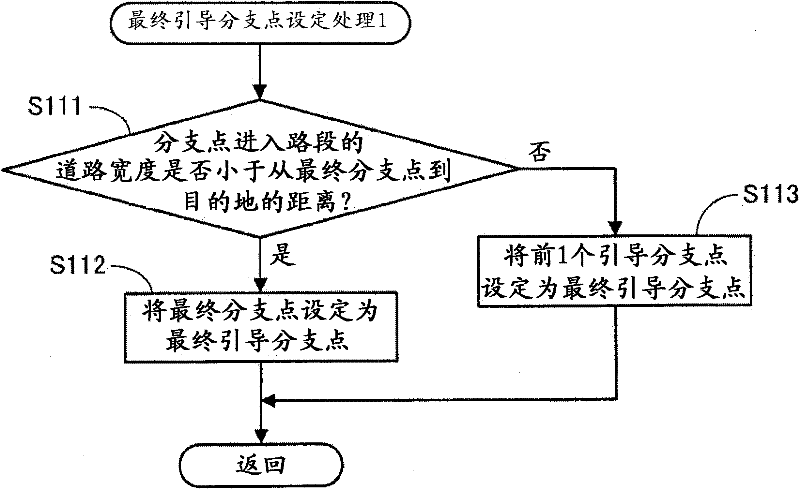

Navigation device, navigation method, and program

InactiveCN102568241ASmooth bootReliable bootInstruments for road network navigationRoad vehicles traffic controlRoute searchInformation searching

The invention provides navigation devices capable of guiding in a way of finding a destination out successfully, navigation methods and programs. The navigation devices comprise: a vehicle location acquisition unit for acquiring a vehicle location, a map information storage unit for storing map information including road width information, a destination setting unit configured to set a destination, a route search unit for searching for a route to the destination based on the map information, a route guidance unit for performing route guidance based on the route; and a last branch point acquisition unit for acquiring a last branch point on the route, wherein based on a road width of an entering link entering the last branch point and a distance from the last branch point to the destination, the route guidance unit determines a point at which last guidance to the destination is to be given.

Owner:AISIN AW CO LTD

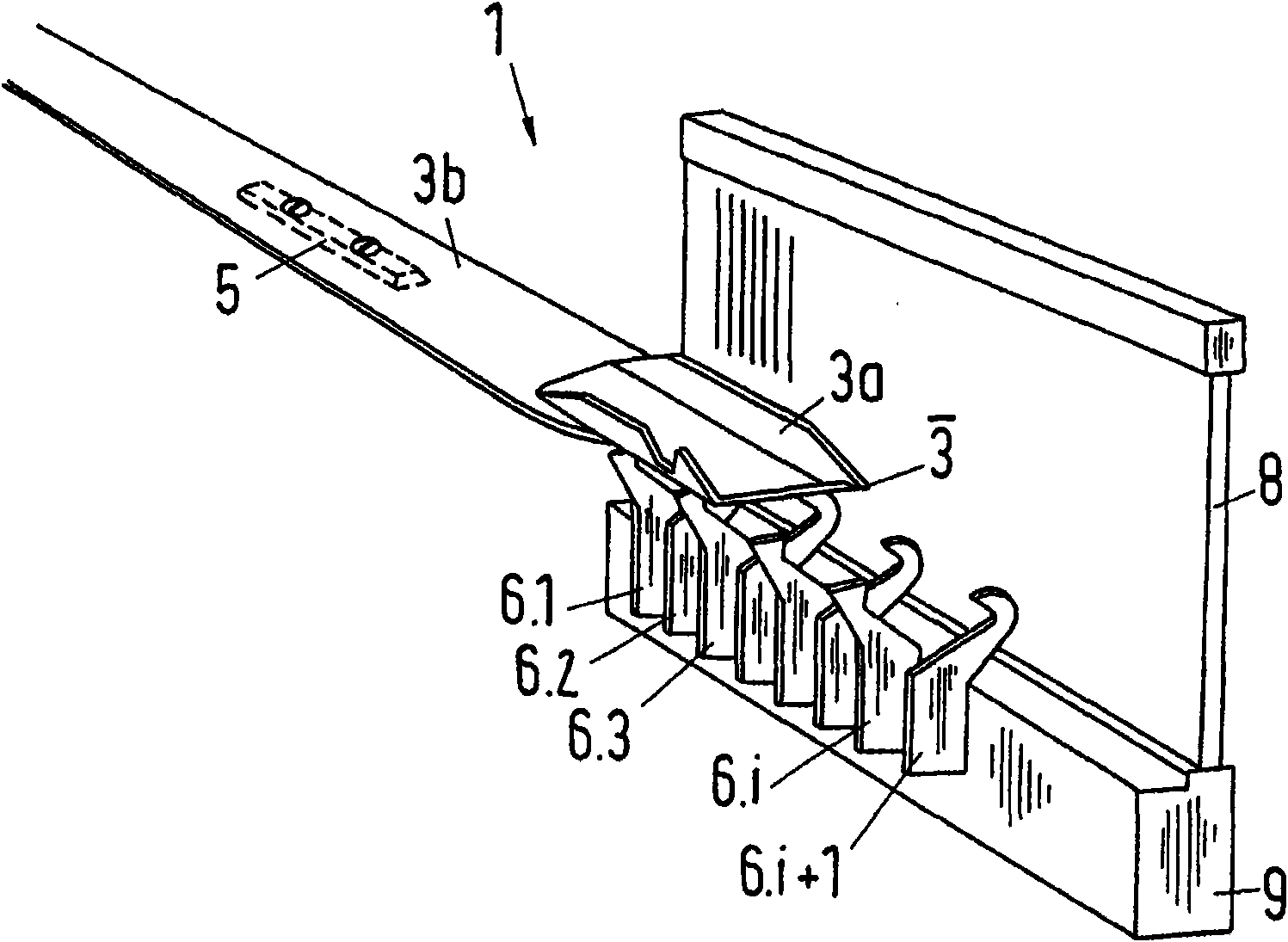

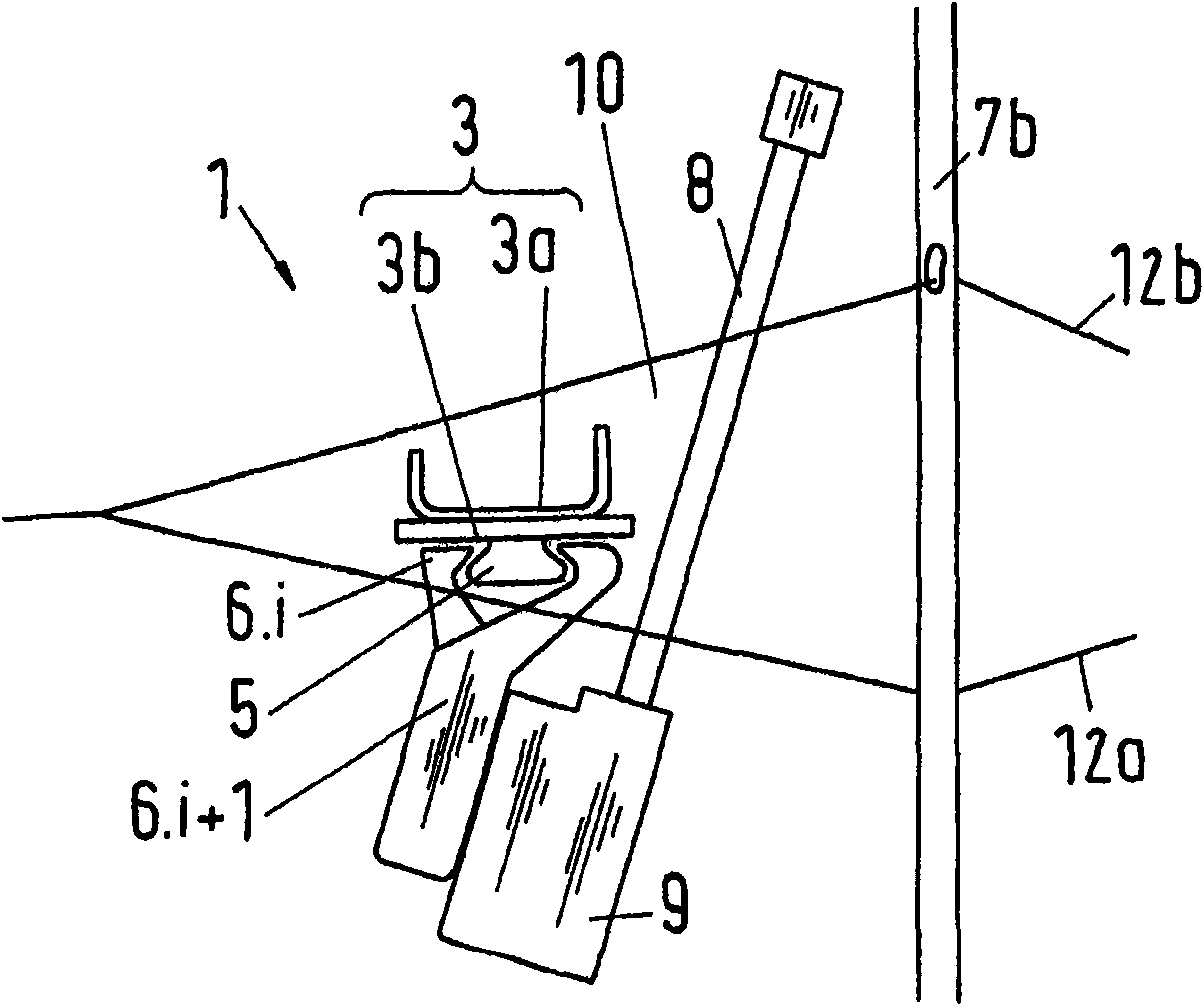

Method and device for inserting weft thread in a gripper loom

An apparatus (1) is presented for the insertion of a weft thread (2) into a shed (10) of a rapier weaving machine. The apparatus (1) includes a rapier tape (3b) movable in the insertion direction, a rapier head (3a) at the same and at least one guide part (5) which is provided at the rapier tape or at the rapier head as well as a plurality of guide elements (6.1-6.i+1) which cooperate with the guide part to guide the rapier tape or the rapier head in the shed, wherein the start of the guidance of the guide part by the guide elements is delayed until the rapier tip ( 3) is at a distance of at least 14 cm in the shed.

Owner:埃特马(瑞士)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com