Pipe bending apparatus

A bending processing and bending technology, which is applied in the field of bending processing devices, can solve the problems of unusability and inability to correct the rotation angle, and achieve the effects of good precision, easy shape change, and reliable precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be described in detail based on an illustrated embodiment.

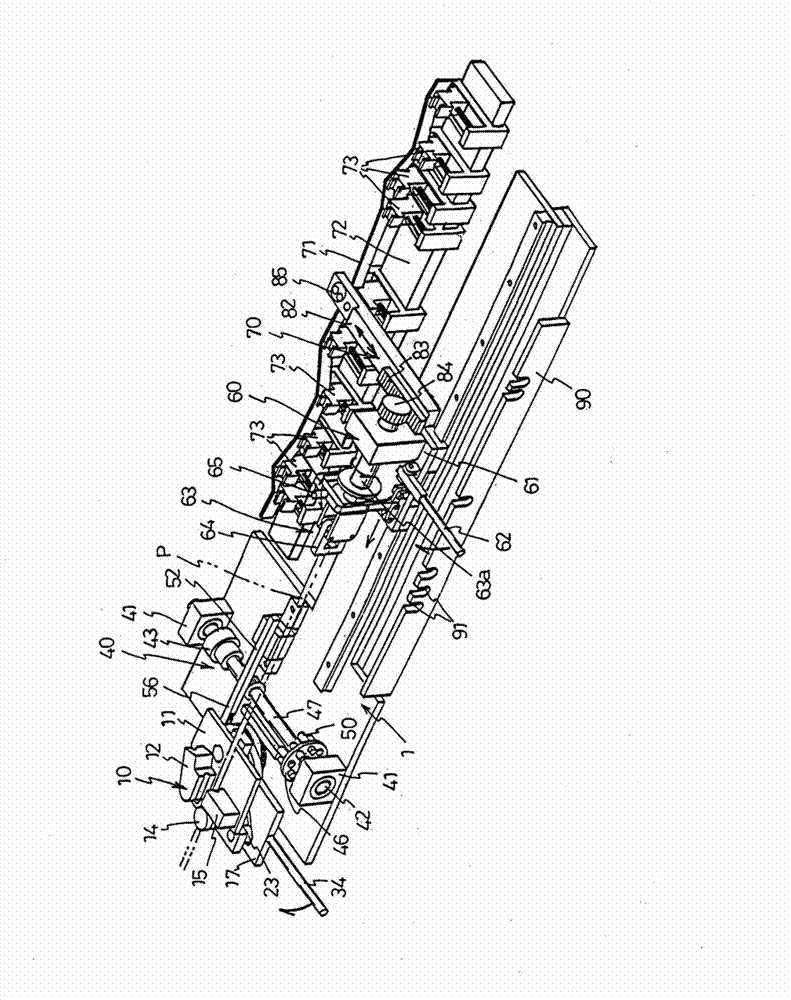

[0035] The illustrated pipe bending device includes a bending unit 10 that bends a pipe P at a predetermined angle, a transport unit 60 that supports and advances the pipe P, and a rotation unit 70 that rotates the pipe P by a predetermined amount.

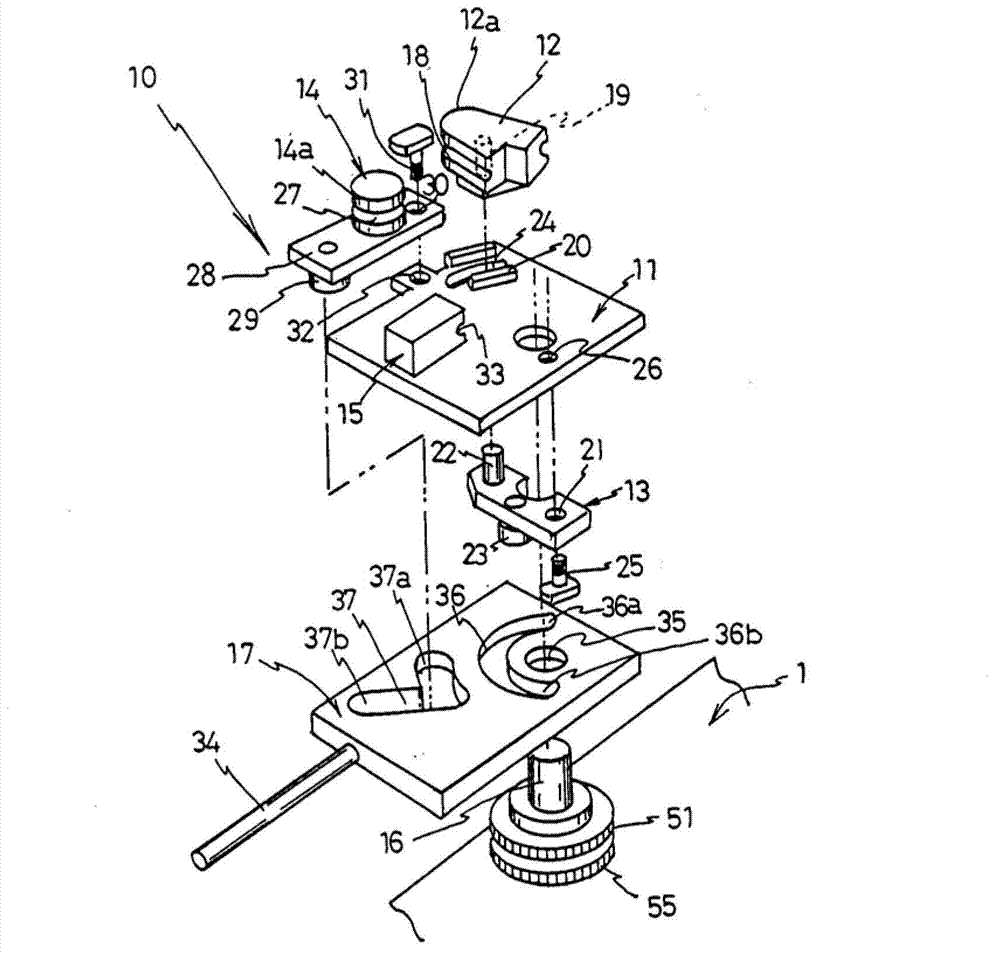

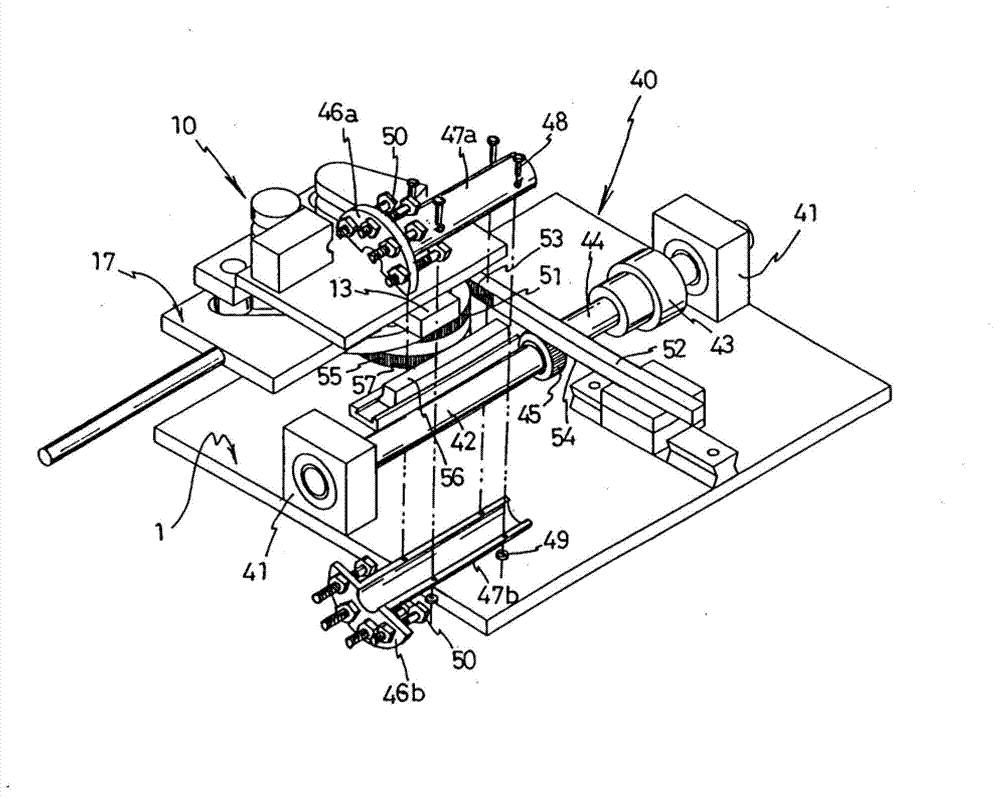

[0036] In the bending unit 10 , a substrate 11 is provided above the device frame 1 with an appropriate gap therebetween. On the substrate 11, as figure 2 As shown, a bending die 12 , a bending die work piece 13 , a presser 14 , and a clamping device 15 are respectively provided, and a shaft 16 is rotatably supported between the frame 1 and the base plate 11 . Furthermore, one end portion of the operation plate 17 is integrally provided on the shaft 16 .

[0037] The bending die 12 has a partially arc-shaped peripheral surface 12a, and an arc-shaped groove 18 having a substantially semicircular cross-section for housing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com