Toothbrush having pressure relief unit and method of producing the same

A release unit, toothbrush technology, applied in the direction of brushes, brush bodies, household components, etc., can solve the problems of increasing head area, toothbrush hair falling off, injection molding machine not running, etc., to reduce thickness and maximize productivity , solve the effect of head fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The toothbrush of the present invention includes a pressure relief unit (r) having a plate shape and a size sufficient to cover bristles disposed in the head of the toothbrush.

[0041] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings.

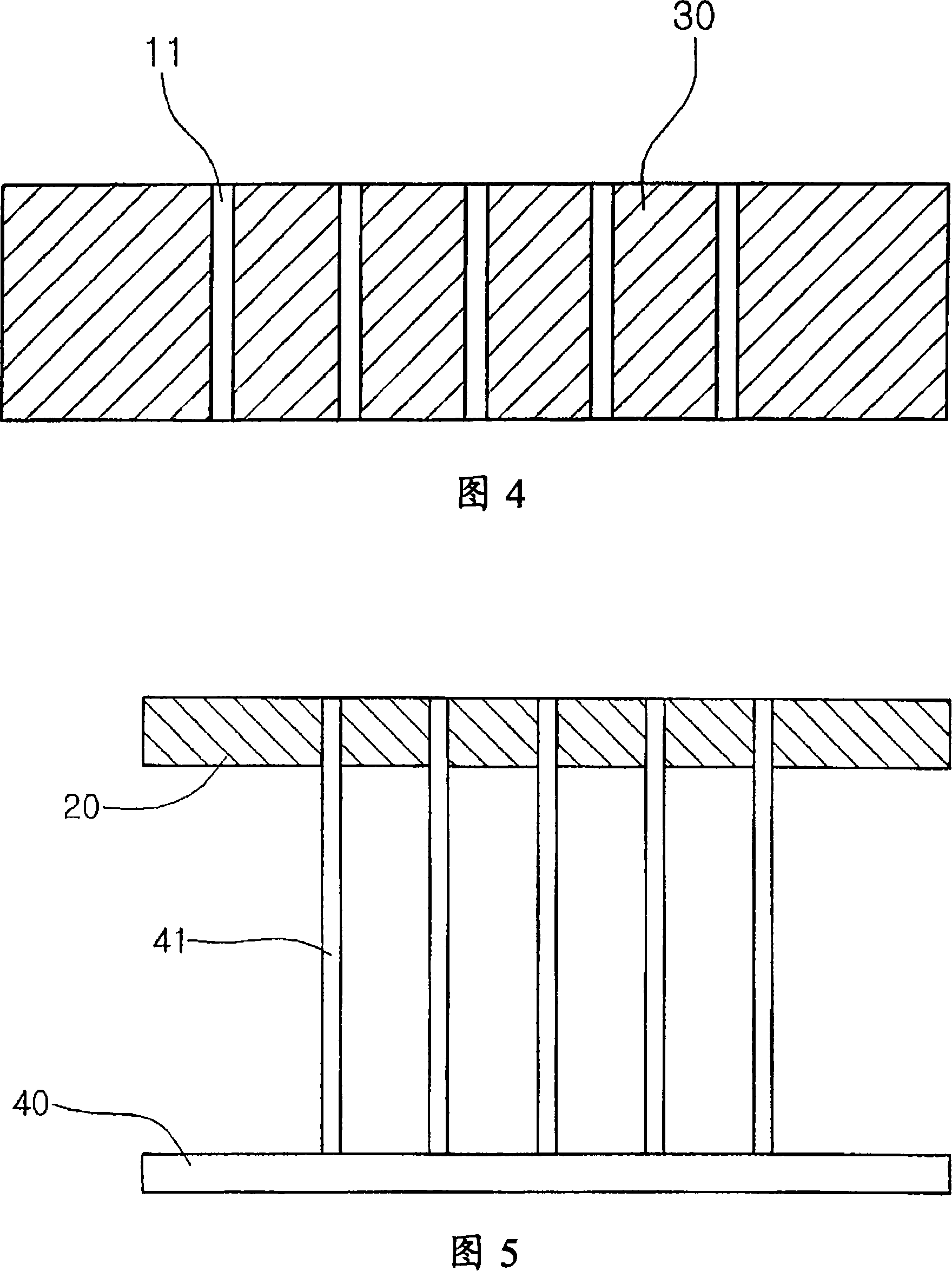

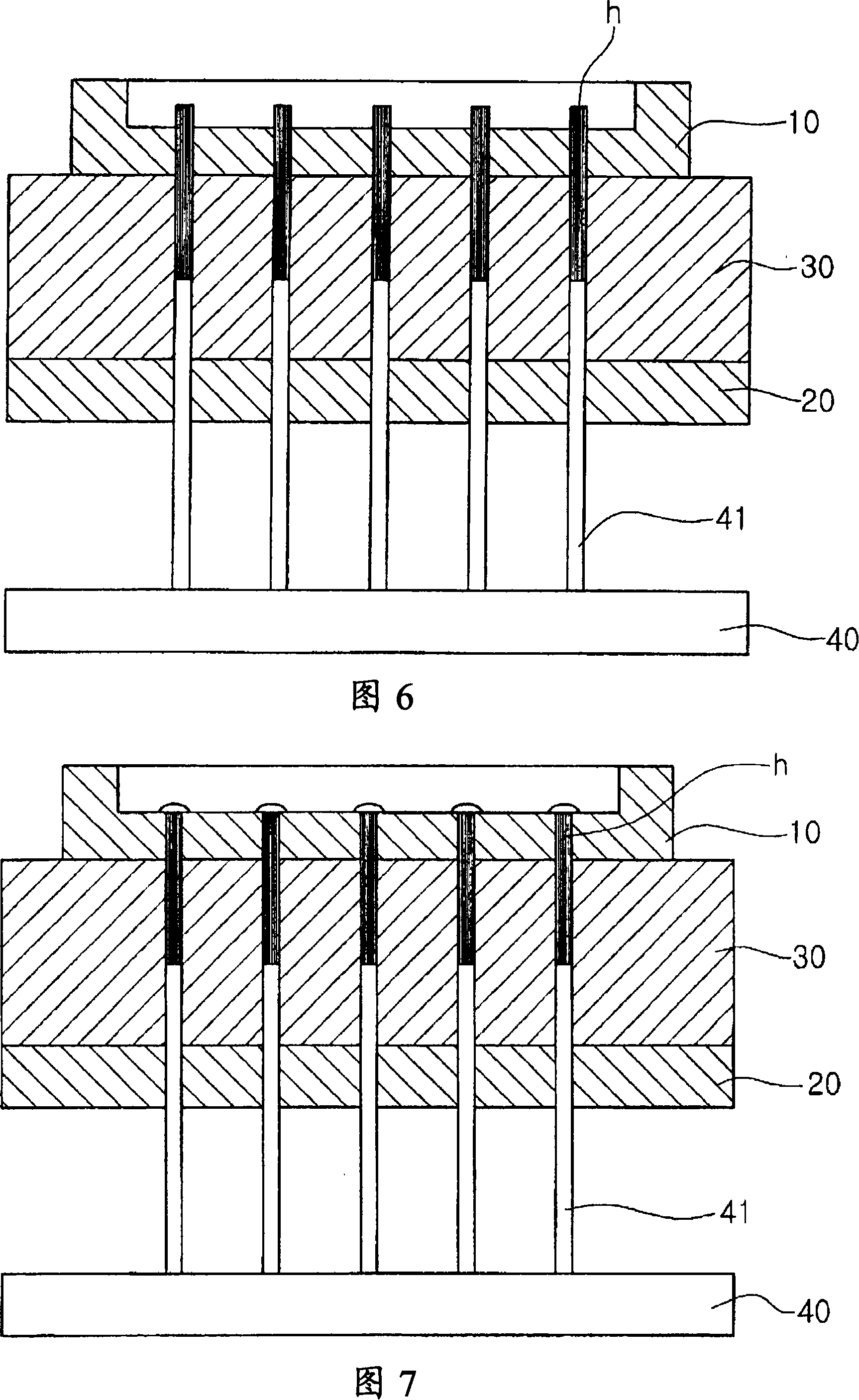

[0042] Figure 2 is a perspective view of the head insert 10 used in the present invention. The head insert 10 is made of plastic and has a thickness ranging from 1.5 mm to 3.0 mm. If the thickness of the head insert 10 is smaller than the above range, the head insert 10 may be undesirably bent during the heat welding process. If the thickness of the head insert 10 is greater than the above range, the toothbrush head will be too thick.

[0043]The head insert 10 has a through hole 11 therein so that toothbrush bristles can be seated in the through hole 11 . Unlike conventional techniques using filaments, the vias 11 can have different sizes. In other words, the size and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com