Anti-noise wind-powered generator

A technology for wind turbines and mechanical devices, which is applied in the directions of wind turbines, control of wind turbines, motors, etc., can solve problems such as the inability to guarantee compliance with the standard of the maximum noise level of wind turbines, reliability problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

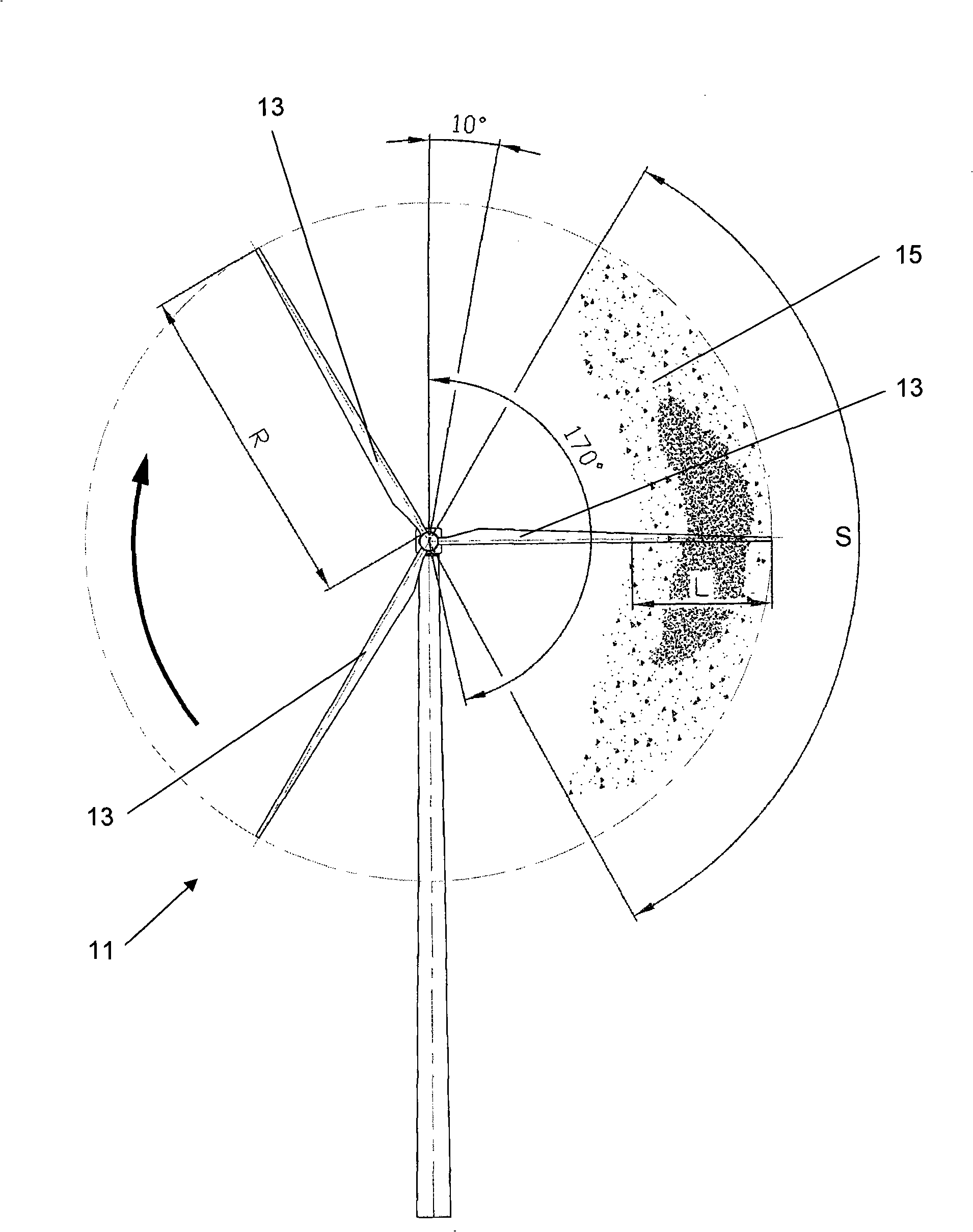

[0016] The wind turbine 11 according to the invention comprises a rotor with at least one blade 13 having an aerodynamic profile on the leading and trailing edges, combined into a cyclic control system that allows the lift of each blade 13 to be adjusted. The azimuthal distribution over its radius R or only over a portion of its length L from the tip can be achieved by various mechanical means as described below.

[0017] Because the wind turbine has these characteristics, the measurement according to the Sirocco project implementation method can effectively reduce the noise emission. The noise caused by the wind turbine 11 is mainly generated in the area 15 on the fan-shaped part S defined by the rotor plane between the two hypothetical radii, According to the direction of blade rotation, the blade reaches the maximum height at the assumed radius of 10° to 170°, so the control method is to reduce the lift force of the blade in this region only (especially in the noisy sector o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com