Circulating feeding mechanism

A feeding mechanism and circular conveying technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low working efficiency and slow product output speed of laminators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the technical solution of the present invention, a preferred embodiment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

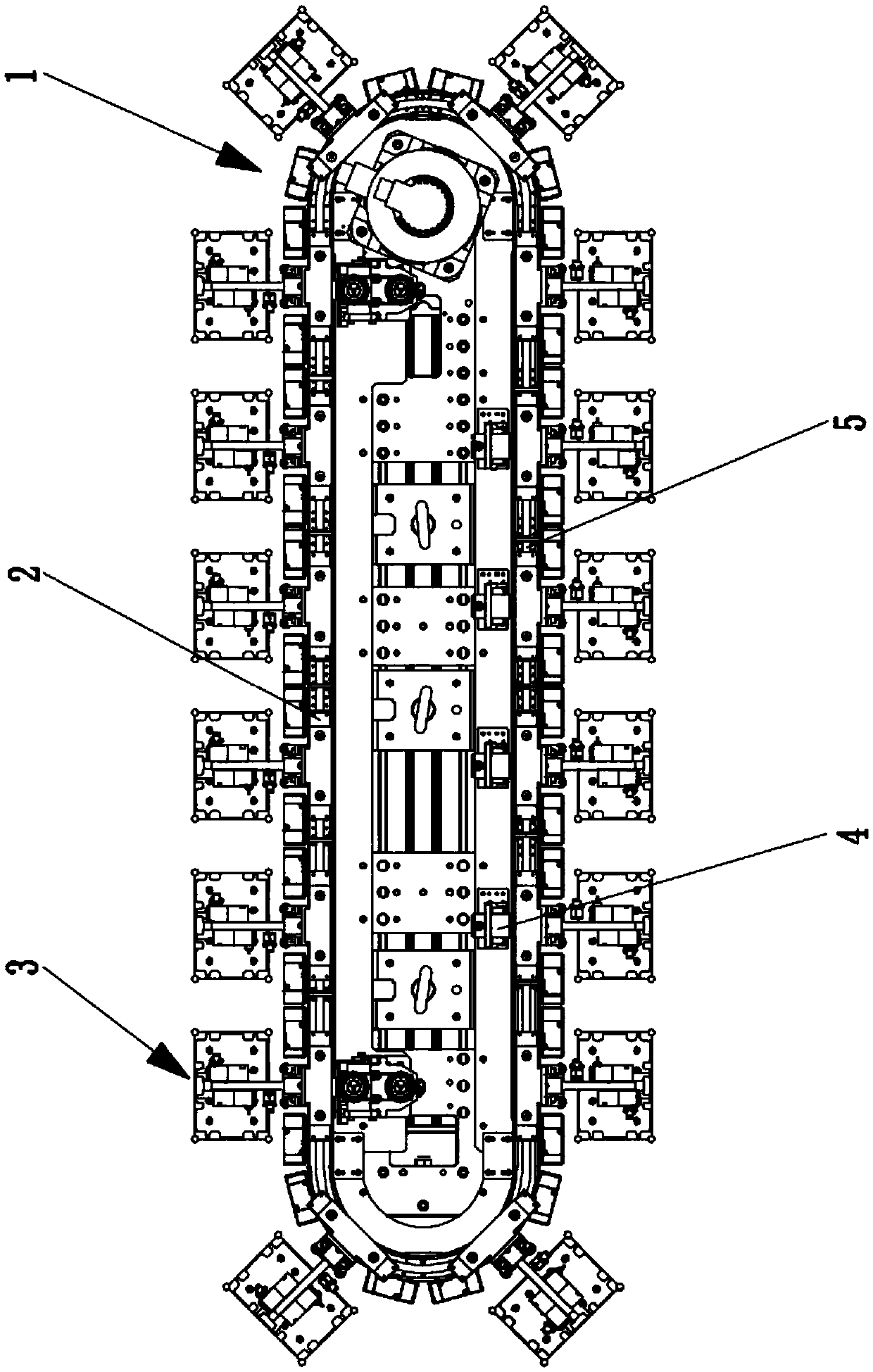

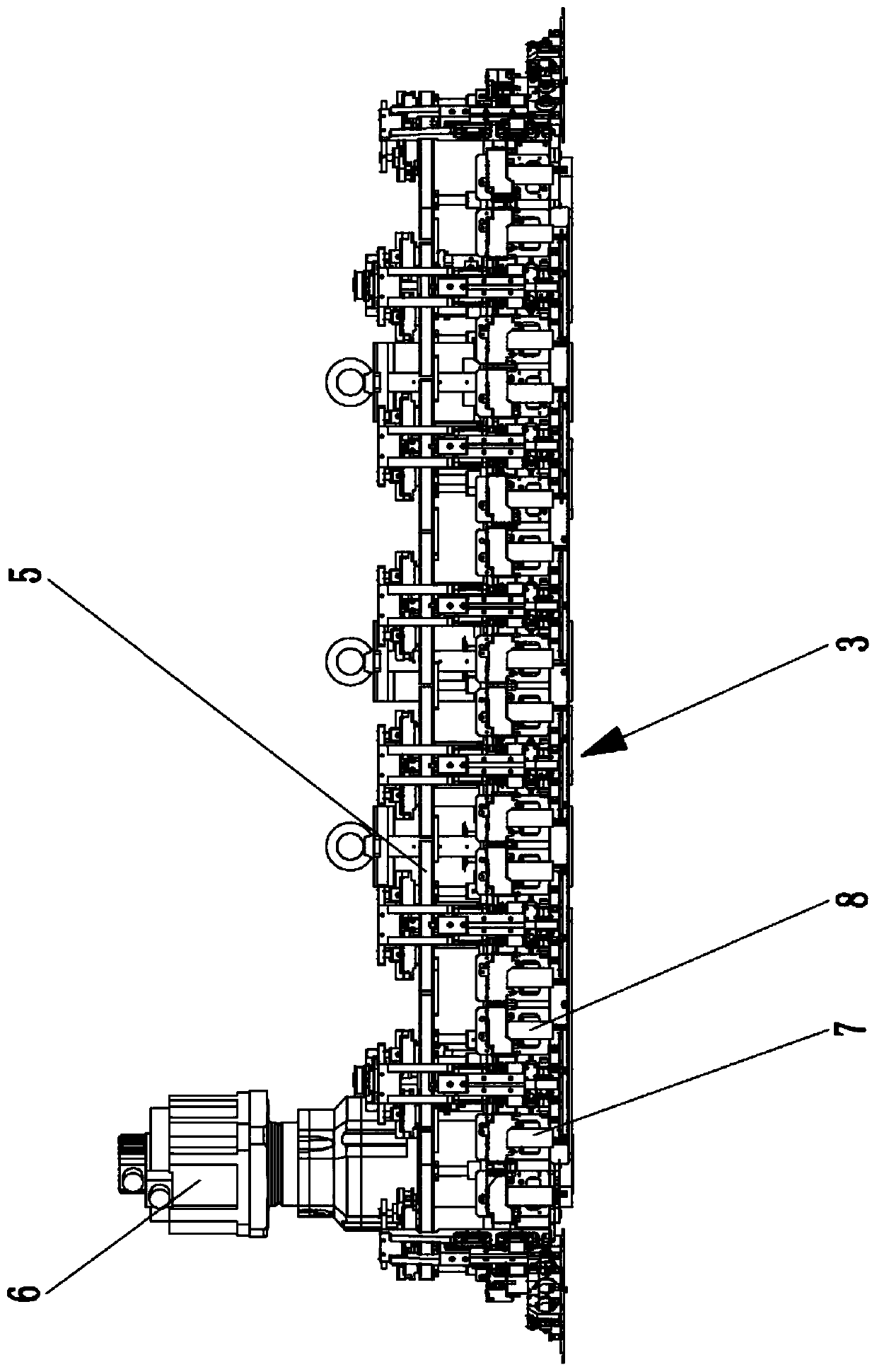

[0014] Such as figure 1 A circular feeding mechanism shown includes an annular conveying device 1, a pressing device 4, a workpiece pick-and-place device 3, a current collector 2, and an electrified track 5. The pressing device 4 is fixed on the annular conveying device 1, and the electrified track 5 Fixed on the circular conveying device 1, the circular conveying device 1 is connected with the workpiece pick-and-place device 3, the collector 2 is fixed on the workpiece pick-and-place device 3, and the collector 2 is connected with the electrified track 5.

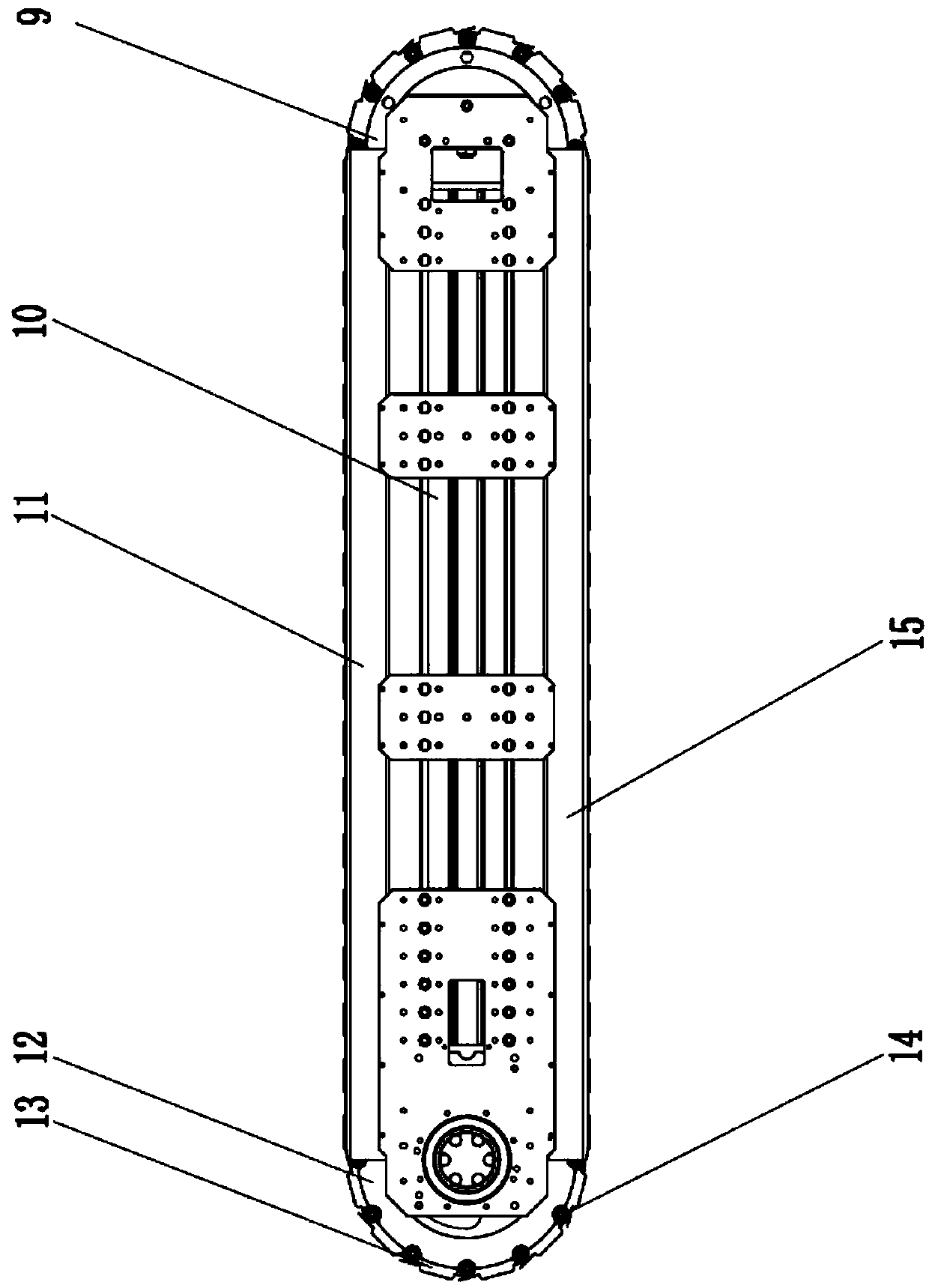

[0015] Such as image 3 The shown circular conveying device comprises a main board 10, a driving device 6, a driving wheel 12, a driven wheel 16, a first track 11, a second track 15, some chain link ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com