Solenoid valve for controlling fluid

A technology for controlling fluids and solenoid valves, applied in the field of solenoid valves, can solve problems such as damage, deformation of valve elements, damage or change of valve functions, etc., and achieve the effect of large guide length, simple guide, and shortened tolerance chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

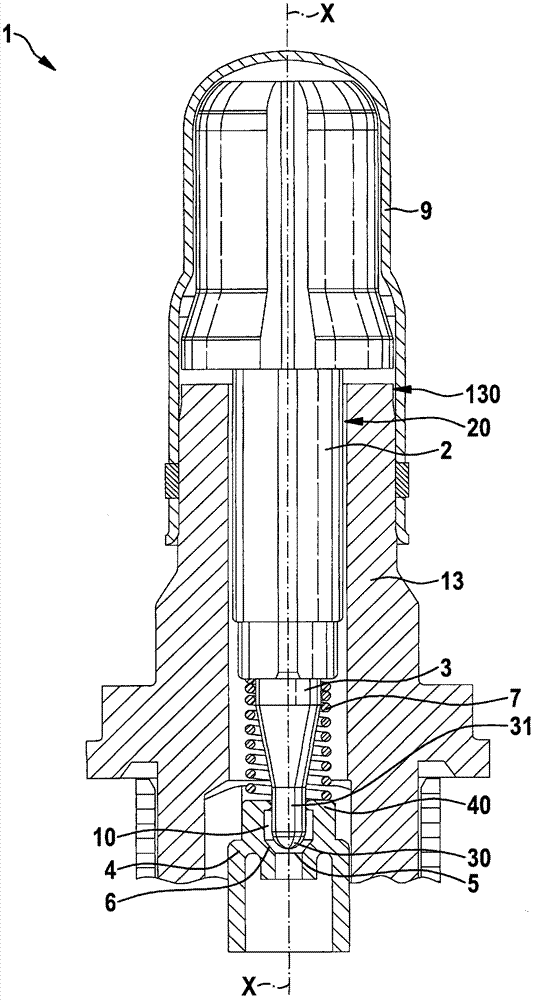

[0019] Refer to the following Figure 1 to Figure 5 A solenoid valve for controlling fluid according to a preferred embodiment of the present invention is described in detail.

[0020] figure 1 A schematic cross-sectional view of a solenoid valve 1 for controlling fluids according to a preferred embodiment of the present invention is shown.

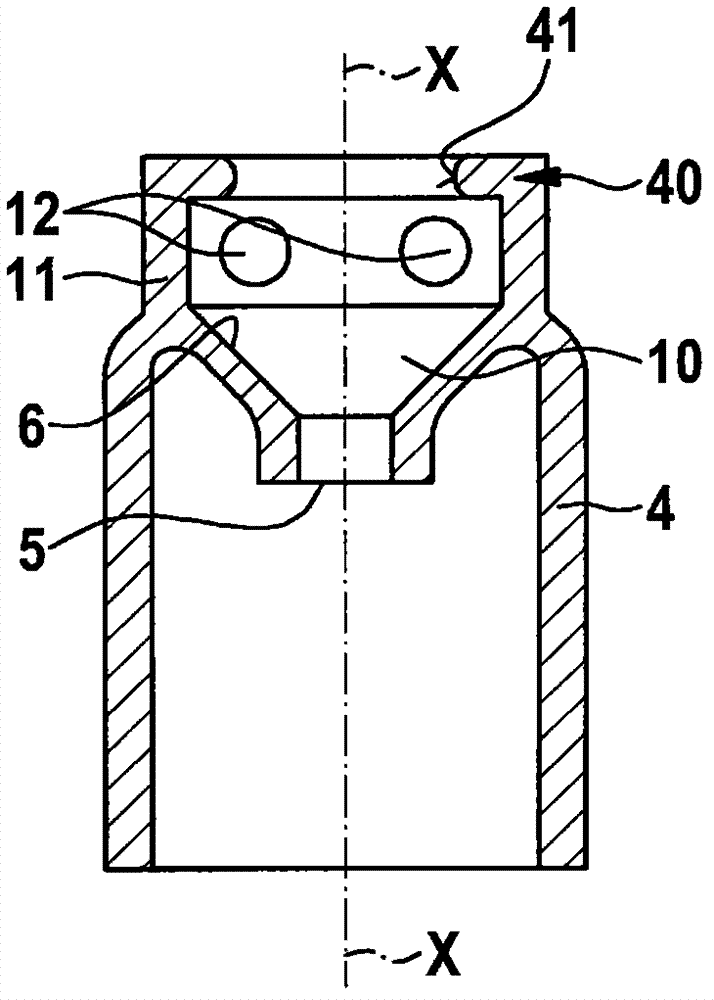

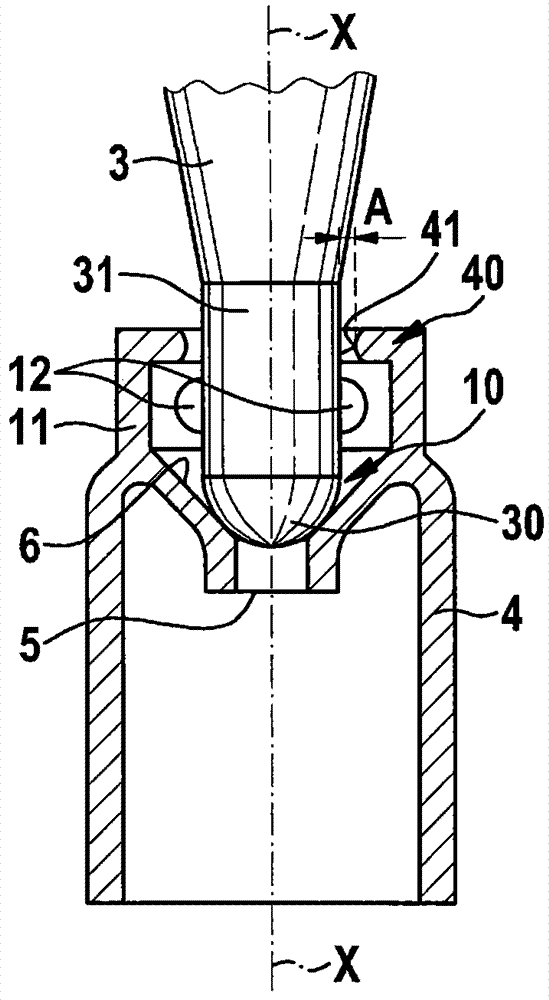

[0021] The solenoid valve 1 comprises an armature 2 , a valve element 3 and a valve body 4 which are arranged coaxially with the axis X-X in the pole housing 9 or in a housing 13 connected thereto. The armature 2 is installed here both in the pole housing 9 and in the housing 13 . The valve element 3 is connected to the armature 2 and is movable together with said armature. A first guide region 20 for guiding the armature 2 is provided on the armature 2 at the level of the first end region 130 of the housing 13 . The valve element 3 has a spherical end region 30 and a cylindrical guide section 31 directly connected to the spherical en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com