Conveyors for folding machines for folding fabrics

A technology of conveying device and folding equipment, applied in the direction of folder, washing device, folding thin material, etc., can solve the problem of not being the best

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

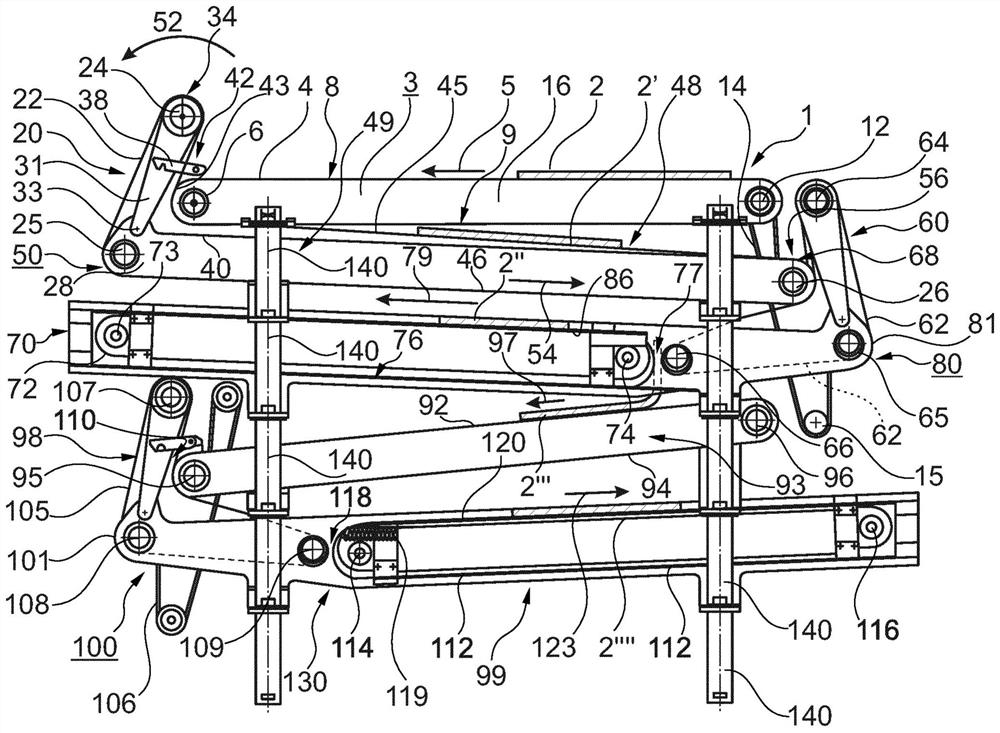

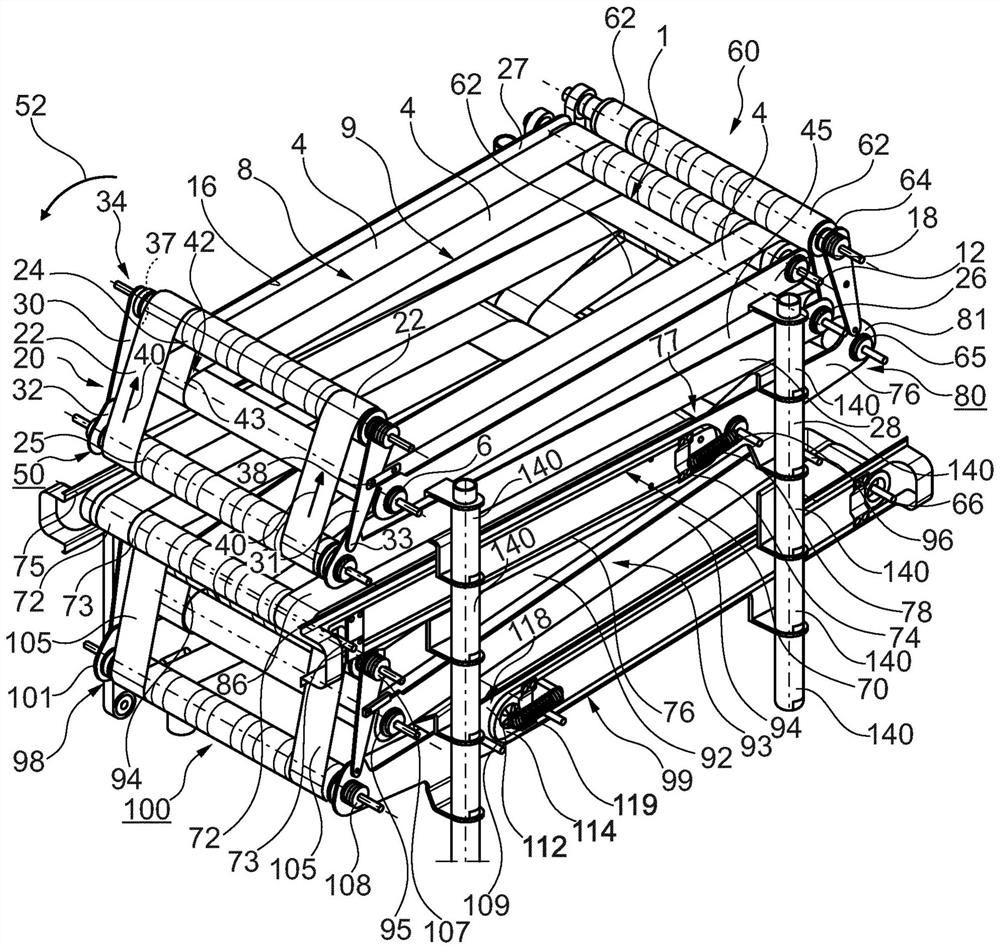

[0025] figure 1 with figure 2 is a side view and a perspective view of a first embodiment of a conveyor for a folding apparatus for folding fabrics according to the invention. The transfer device has a function for the fabric 2 (in figure 1 is only schematically shown as a supply or introduction area 1 for flat laundry). A first belt conveyor 3 with a conveyor belt or conveyor belt (hereinafter collectively referred to as “conveyor belt”) 4 conveys the laundry 2 in the direction of the arrow 5 . Here, a single conveyor belt 4 or a plurality of conveyor belts 4 can be provided, which revolve on deflection rollers 6 , on the first conveyor plane 8 formed by the upper side of the conveyor belt 4 . The bottom returns in an approximately parallel plane 9 and deflects around a driven deflection roller (drive roller) 12 . The drawing schematically shows the drive of the drive roller 12 via a drive belt 14 by a drive 15 of a drive motor, not shown in greater detail. In this case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com