Multi-component reflector for light module of a motor vehicle headlight

A technology of optical modules and headlights, which is applied in the field of optical modules, can solve the problems of increasing the cost of materials, and achieve the effects of reducing structural space, reducing tolerance chains, and low material input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

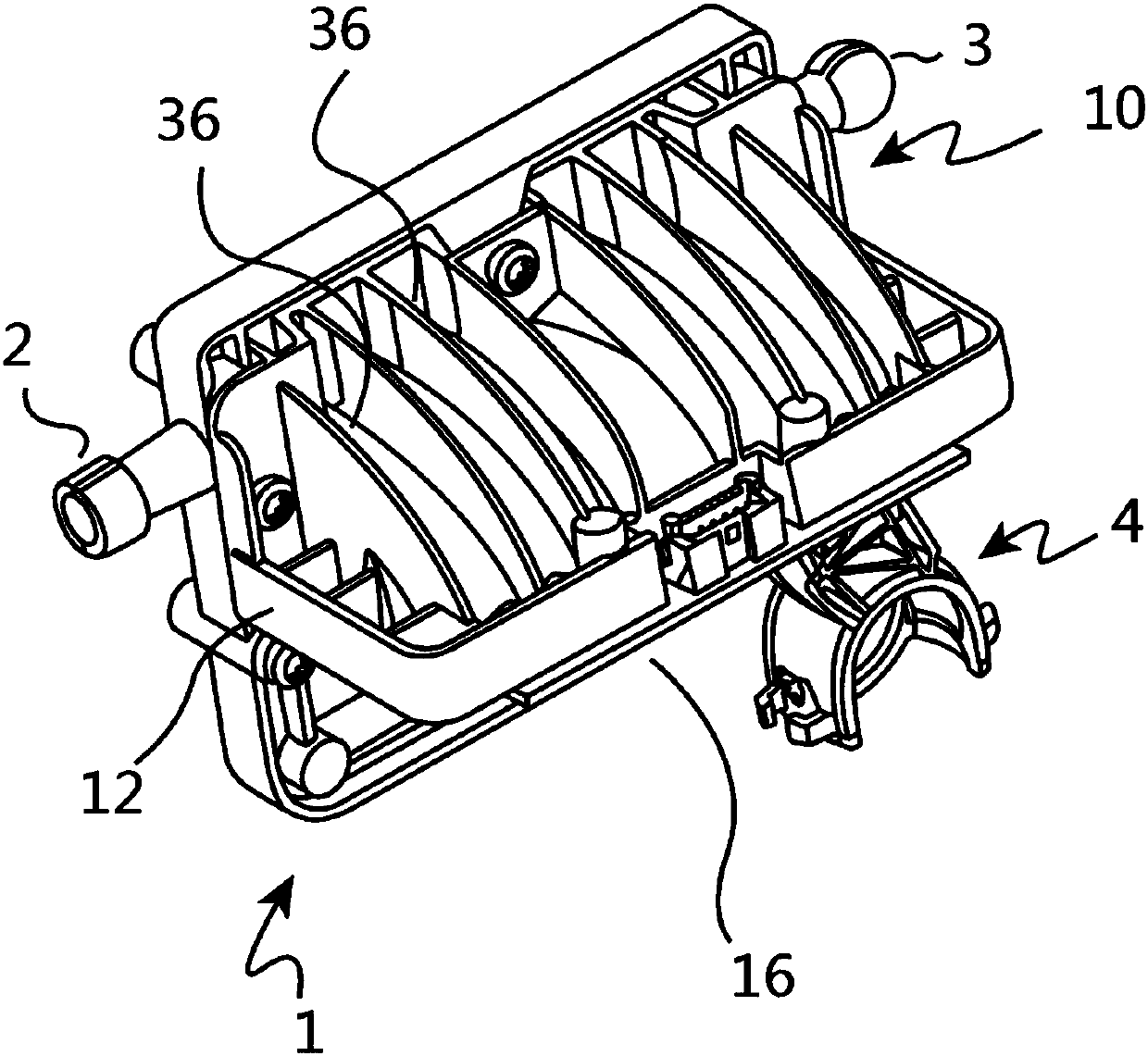

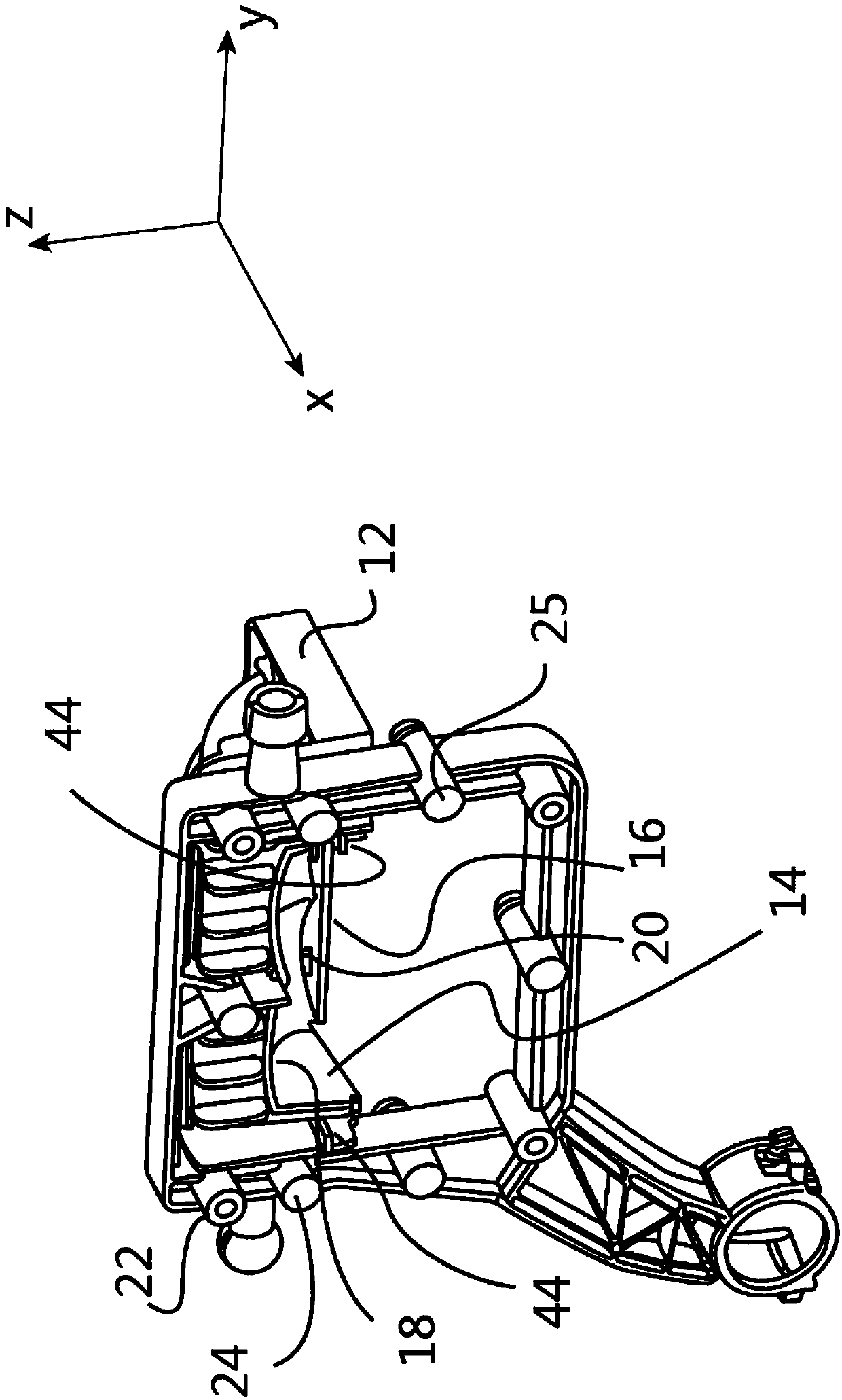

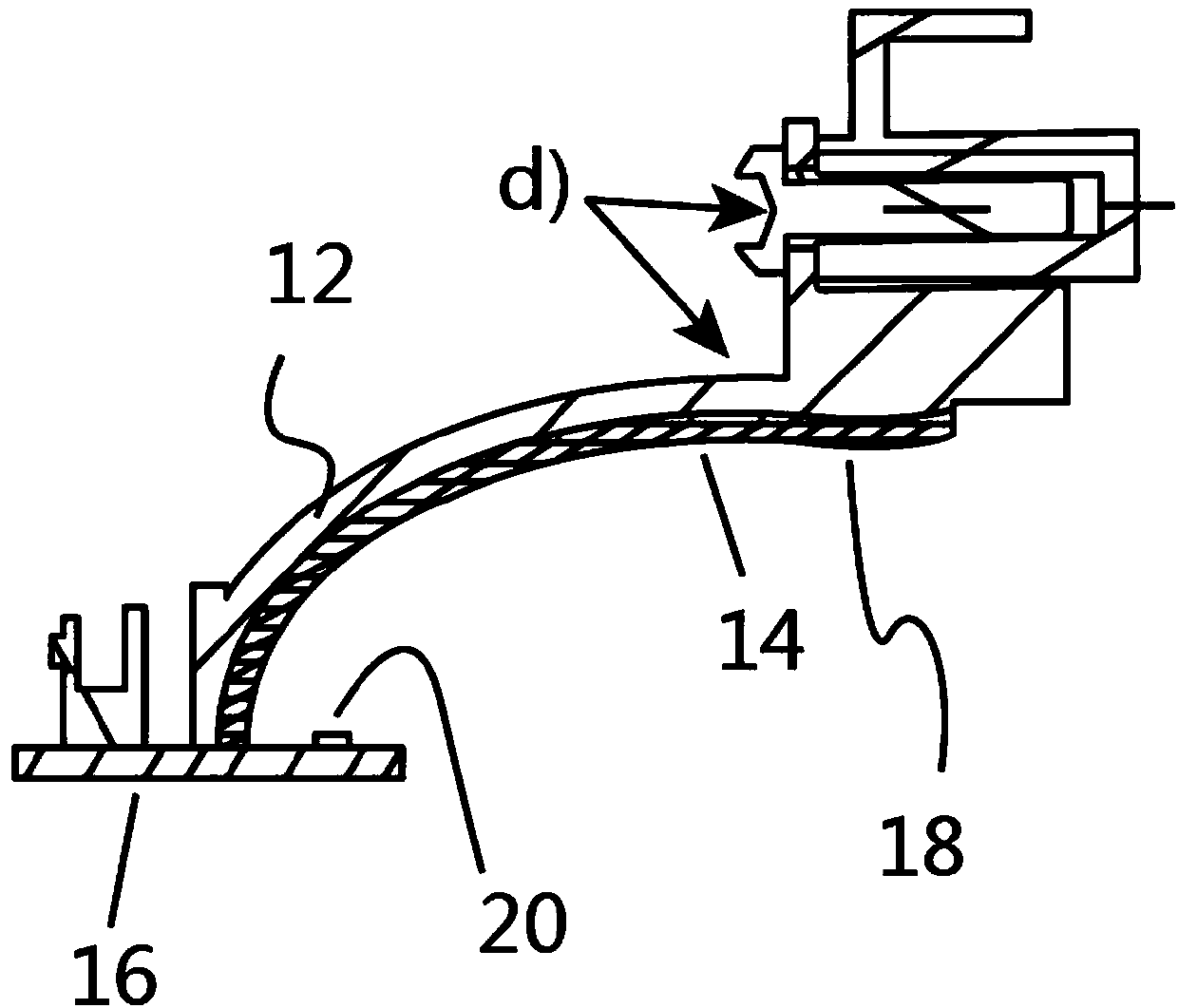

[0031] figure 1 and figure 2 A pivot frame 1 of a motor vehicle headlight, which is a component of an exemplary embodiment of a light module 10 according to the invention, is shown in detail. For this, figure 1 shows a perspective view of the rear side of the swing frame 1 and the light module 10, while figure 2 A perspective view of the front side of the swing frame 1 and the light module 10 is shown.

[0032] In the exemplary embodiment shown, the pivot frame 1 has a cylindrical bearing pin 2 , a spherical bearing pin 3 and a receptacle 4 for the spherical bearing pin. The bearing pins 2 , 3 and the receptacles form an articulated structure by means of which the pivot frame is mounted pivotably in the housing of the motor vehicle headlight during its conventional use in the motor vehicle headlight. The cylindrical bearing pin 2 together with the spherical bearing pin 3 defines a pivot axis for the lighting width adjustment, and the spherical bearing pin 38 together wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com