Multi-port optical probe for photonic IC characterization and packaging

An end-face, cutting-edge technology, applied in the field of optical coupling, can solve problems such as difficult costs and achieve the effect of eliminating spacing mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

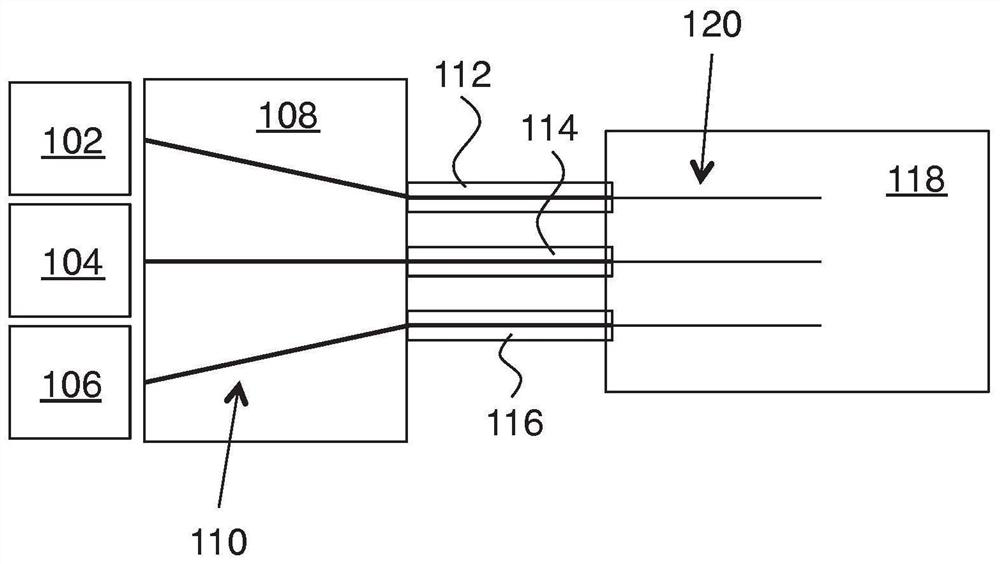

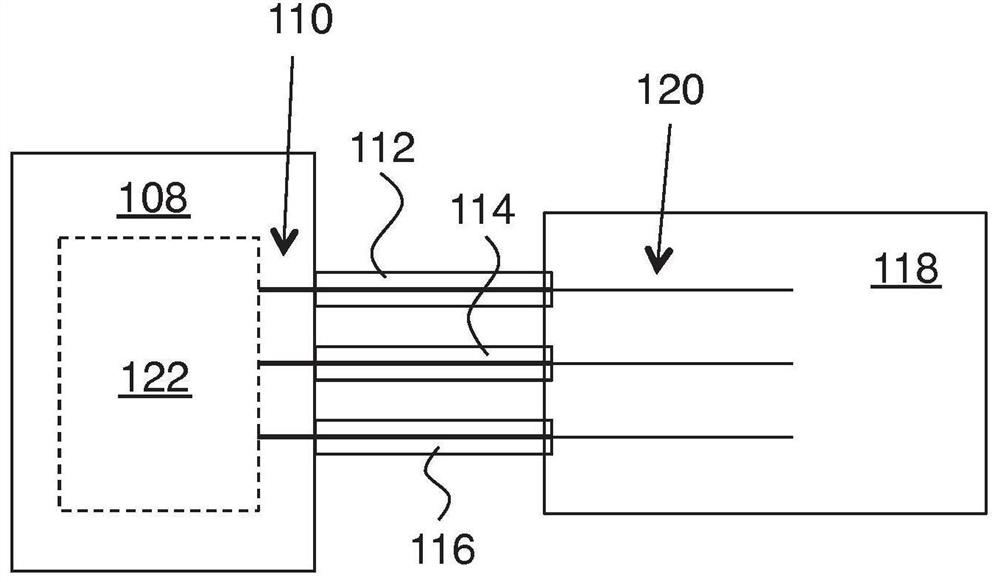

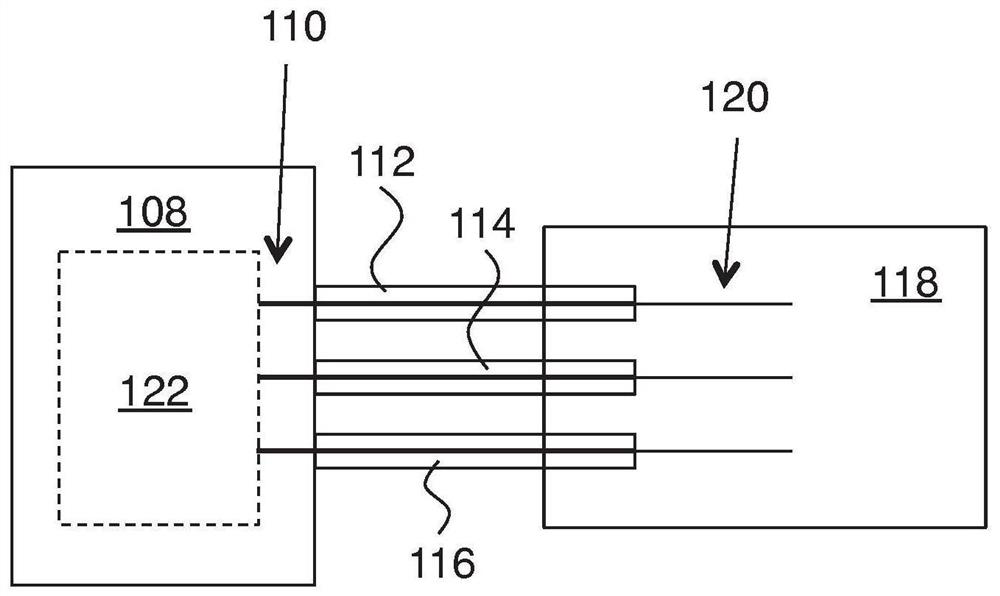

[0037] Figure 1A is a top view of an exemplary embodiment of the invention. In this example, number of optical fibers 102 , 104 , and 106 are optically coupled to photonic integrated circuit chip 118 via interposer unit 108 . Interposer unit 108 includes one or more flexible optical waveguide members, referred to herein as 112 , 114 and 116 . The flexible optical waveguide members each include an optical waveguide. These waveguides are shown here using thick black lines and are referred to as 110 . As shown, the flexible optical waveguide member is configured to be optically coupled between the on-chip optical waveguide 120 of the PIC chip 118 and the interposer unit 108 via the tip of the flexible optical waveguide member.

[0038] exist Figure 1A In the example of , the interposer unit provides the functionality to match the pitch of the array of optical fibers 102 , 104 , and 106 (ie, fiber-to-fiber spacing) to the pitch of the on-chip optical waveguide 120 . It is not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com