Welding work platform with mobile fixture

A technology for moving fixtures and welding platforms, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. to avoid high-temperature deformation damage, smooth sliding, and convenient sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

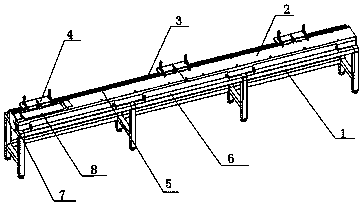

[0029] Such as figure 1 As shown, a welding work platform with a movable fixture includes a frame body 1, a welding platform 2 and a slide rail 3 arranged on the frame body 1, a gap of 100 mm is provided in the middle of the frame body 1, and the gap holds the frame The body is divided into two parts; the welding platform 2 and the slide rail 3 are respectively arranged on both sides of the gap, and a plurality of moving fixtures 4 are arranged on the side of the welding platform 2 close to the slide rail 3; One side of the slide rail 3 is embedded with a scale 5, and the other side is connected with a plurality of welding rod storage boxes 6; the product 8 to be welded is fixed on the welding platform with a mobile fixture 4, and one end of the product 8 to be welded is close to the welding Positioning backer 7 on platform 2.

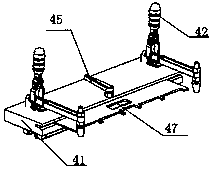

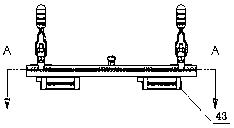

[0030] The moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com