Patents

Literature

145 results about "Crown form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

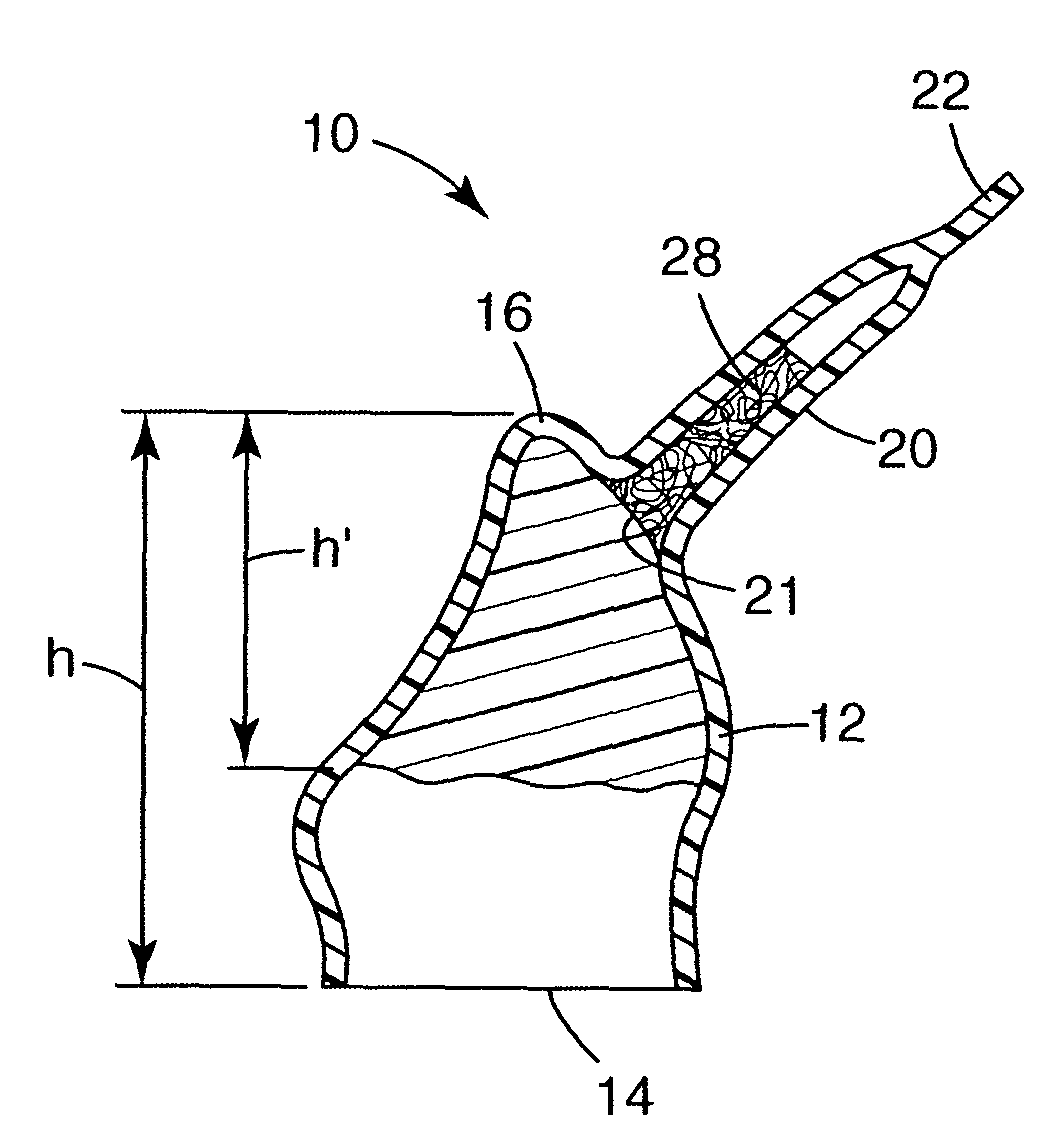

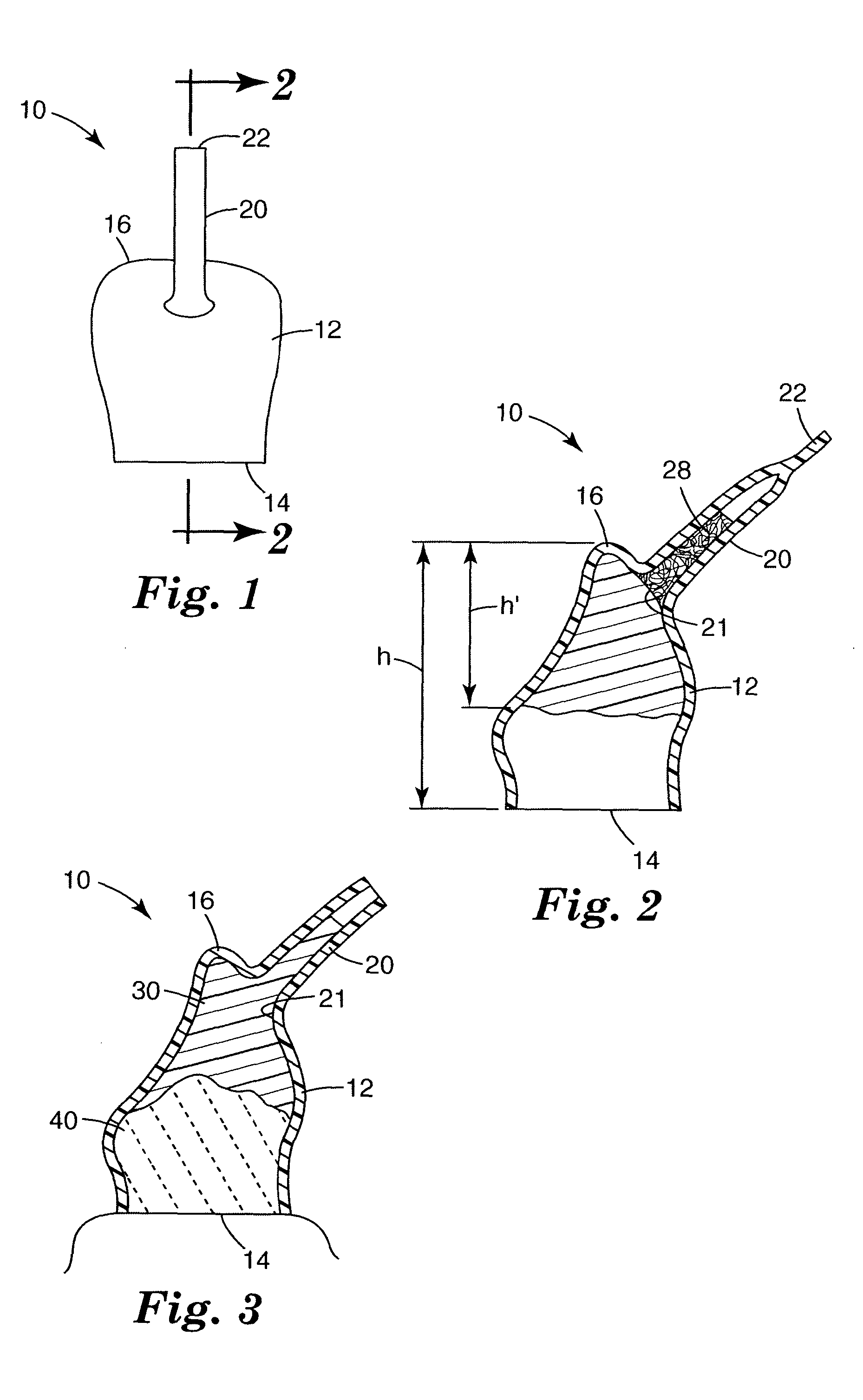

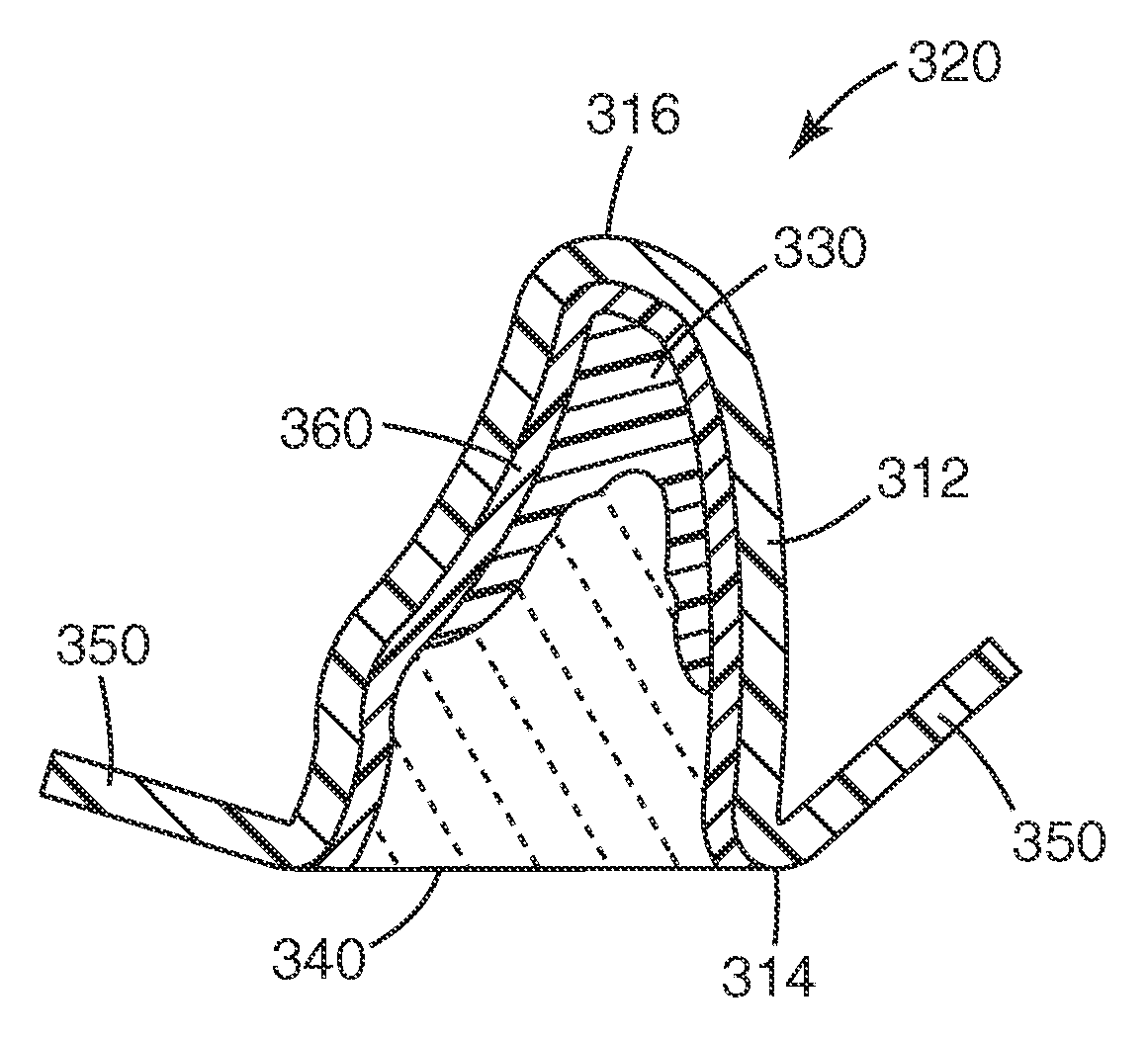

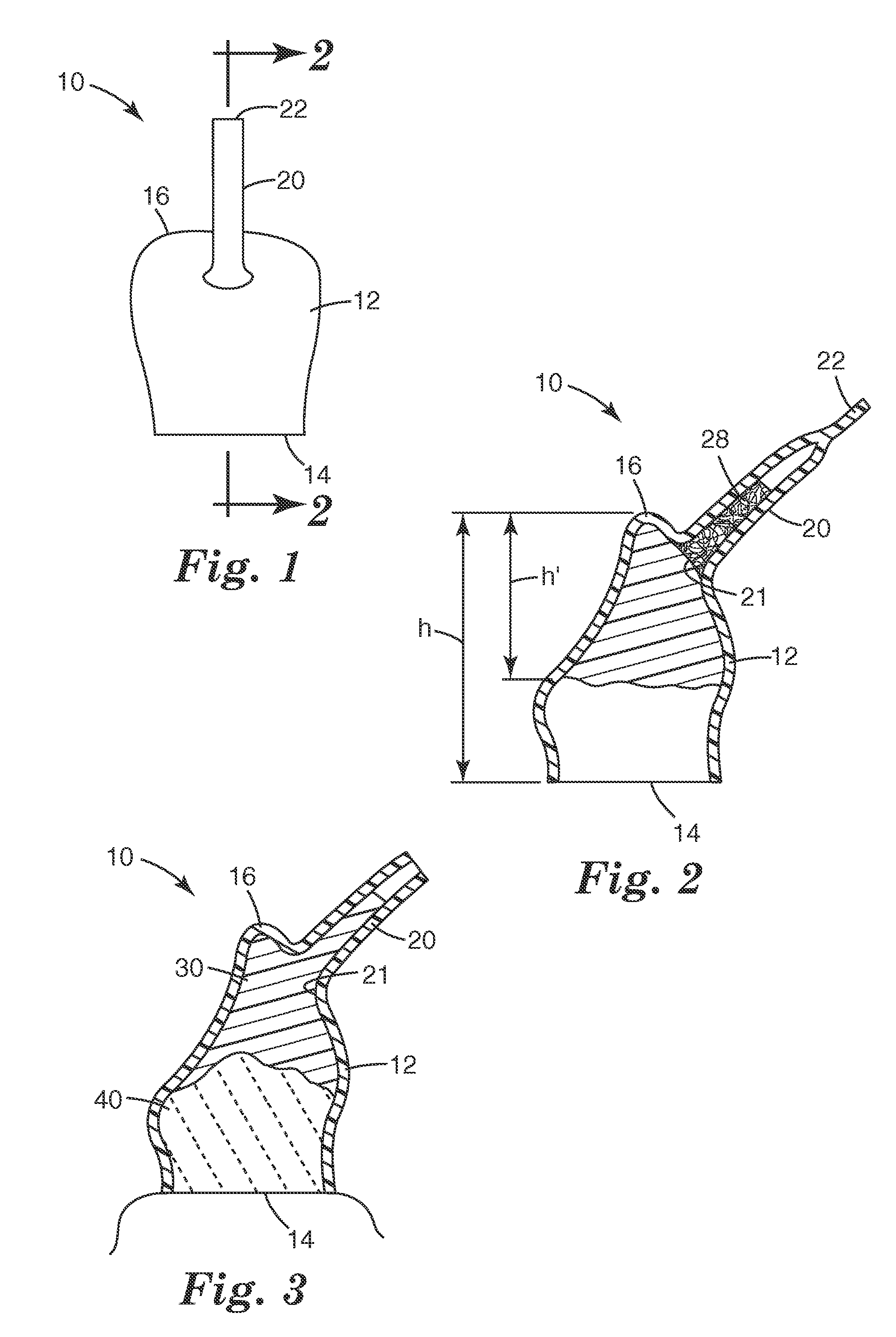

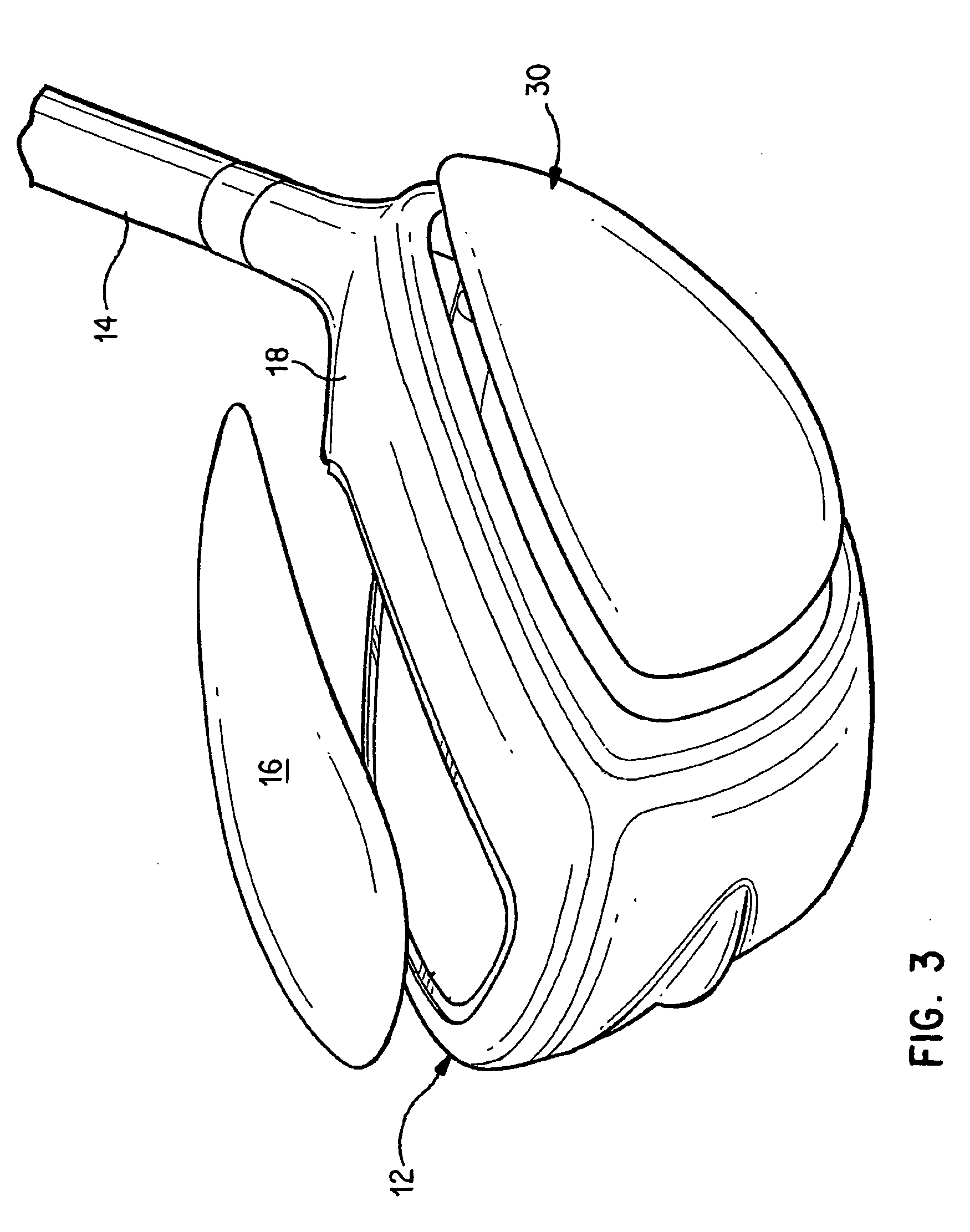

Dental crown forms and methods

Dental crown forms and methods of using them are disclosed. The dental crown forms may include one or more of the following features: a handle attached to the dental crown form at a location removed from the base of the dental crown form; a vented handle through which excess amounts of hardenable dental material can pass during placement of the crown form; and one or more lines of weakness that may be separated to remove a dental crown form from hardenable dental material after placement of the filled crown form. The dental crown forms may also be located in packages with hardenable dental material located within the dental crown forms as packaged.

Owner:3M INNOVATIVE PROPERTIES CO

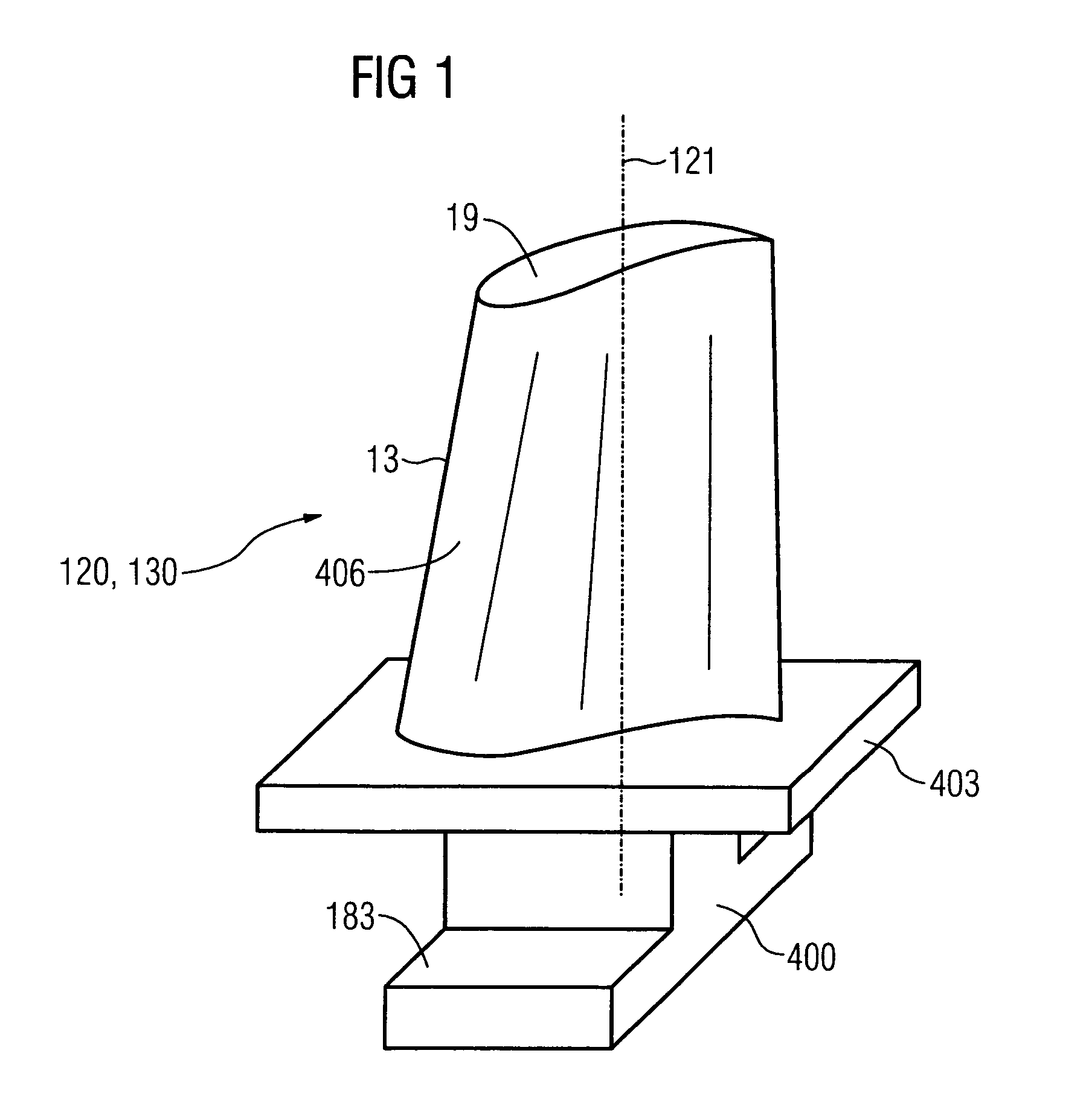

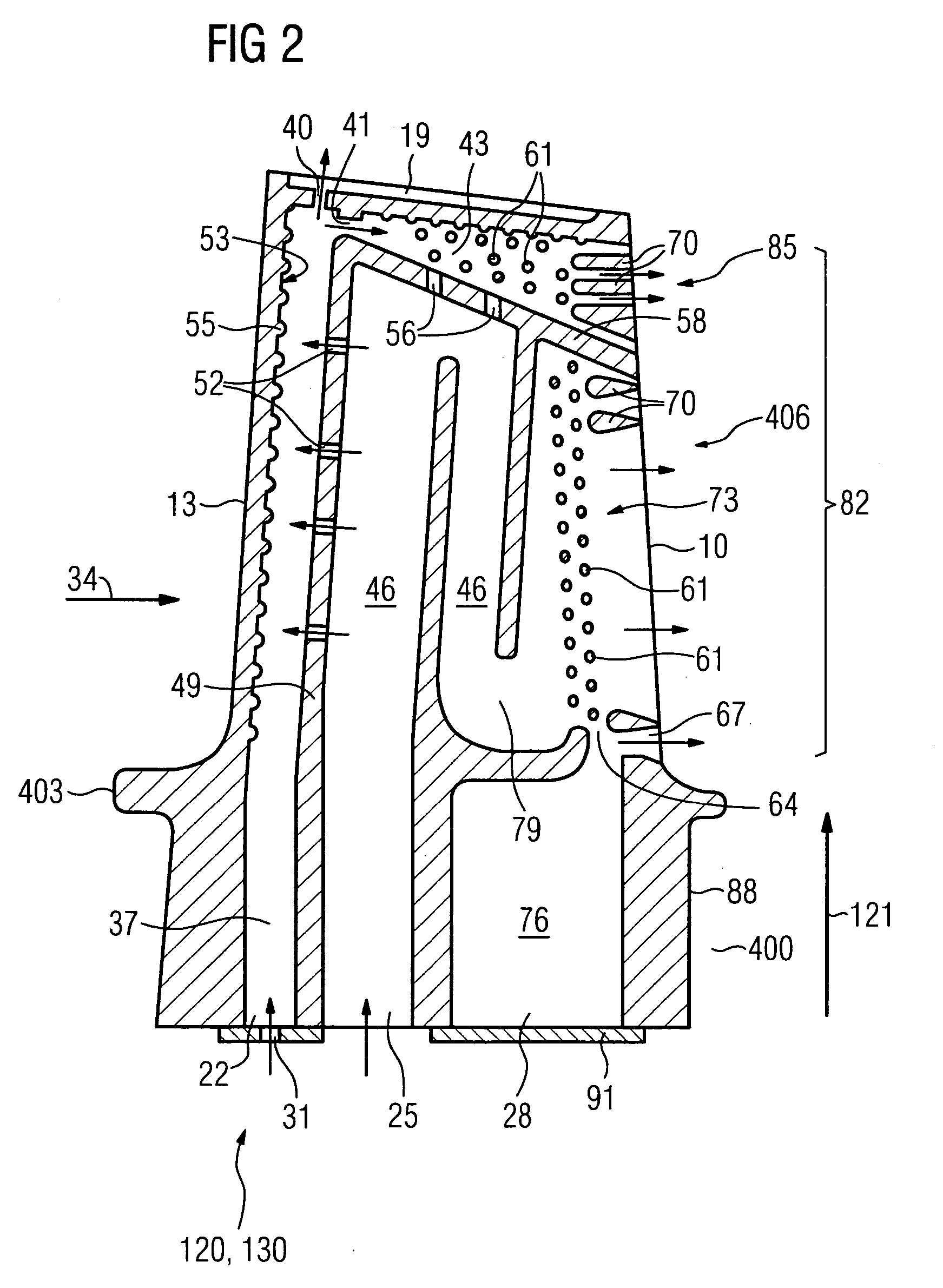

Cooled turbine blade

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

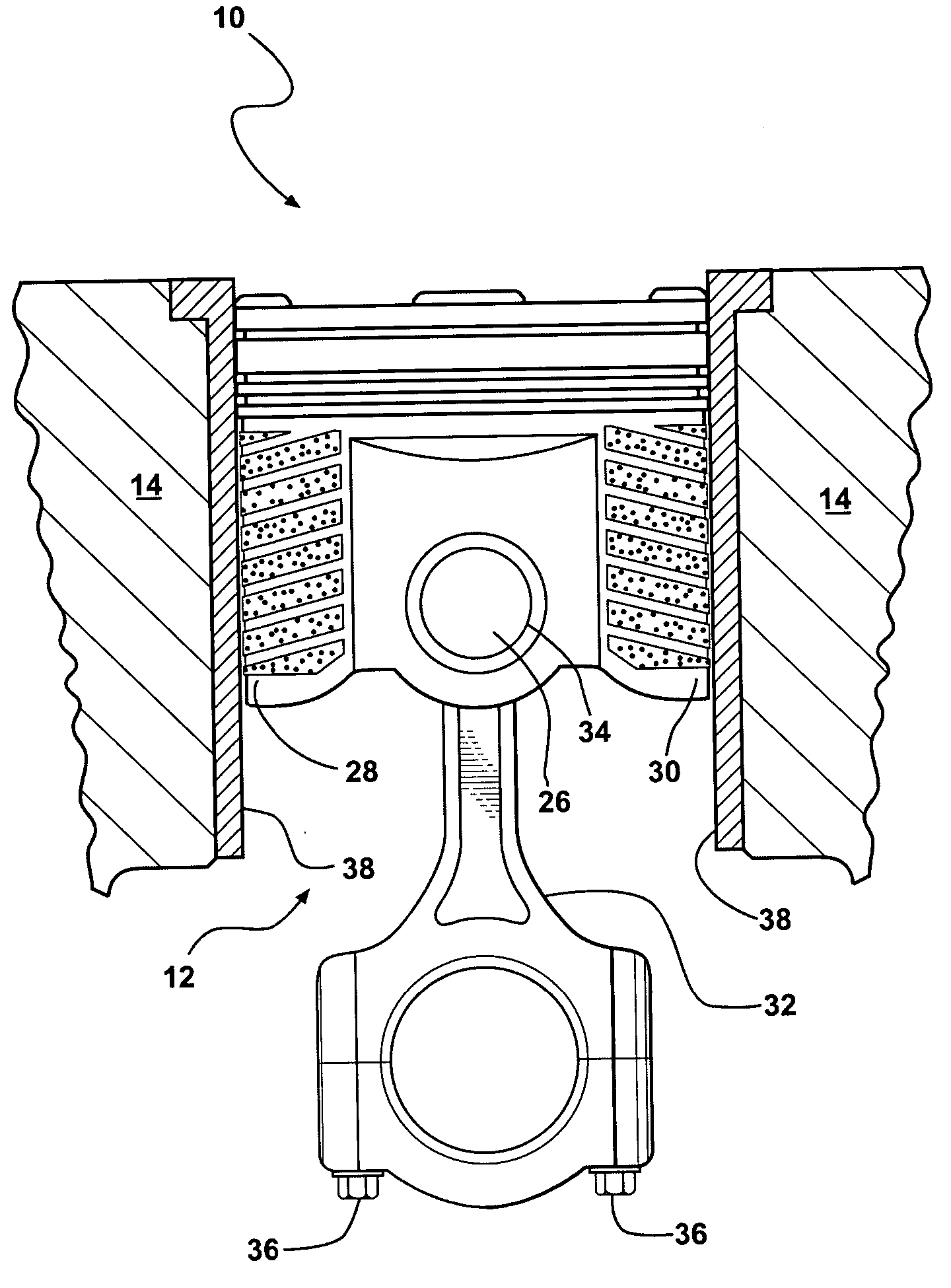

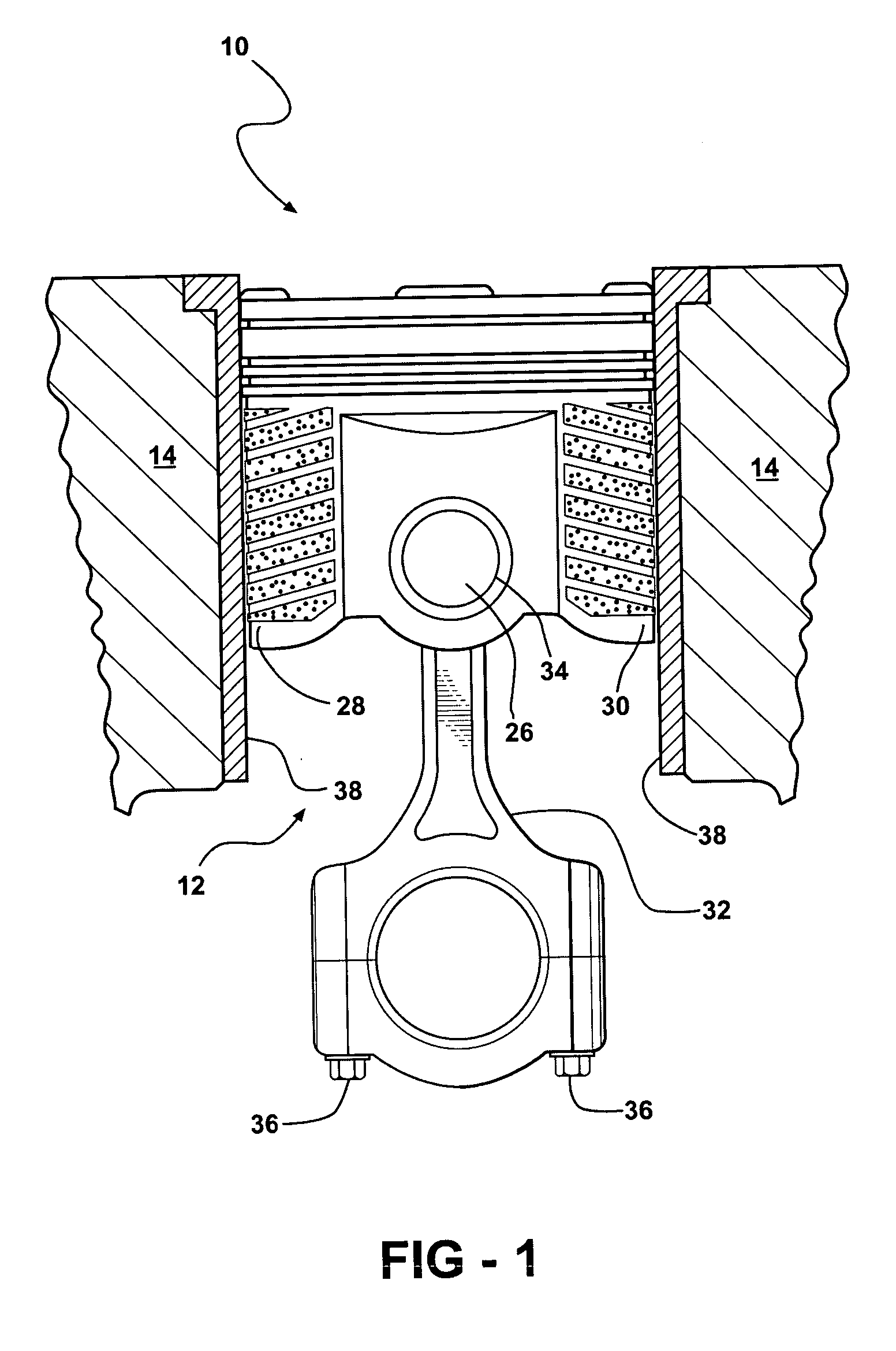

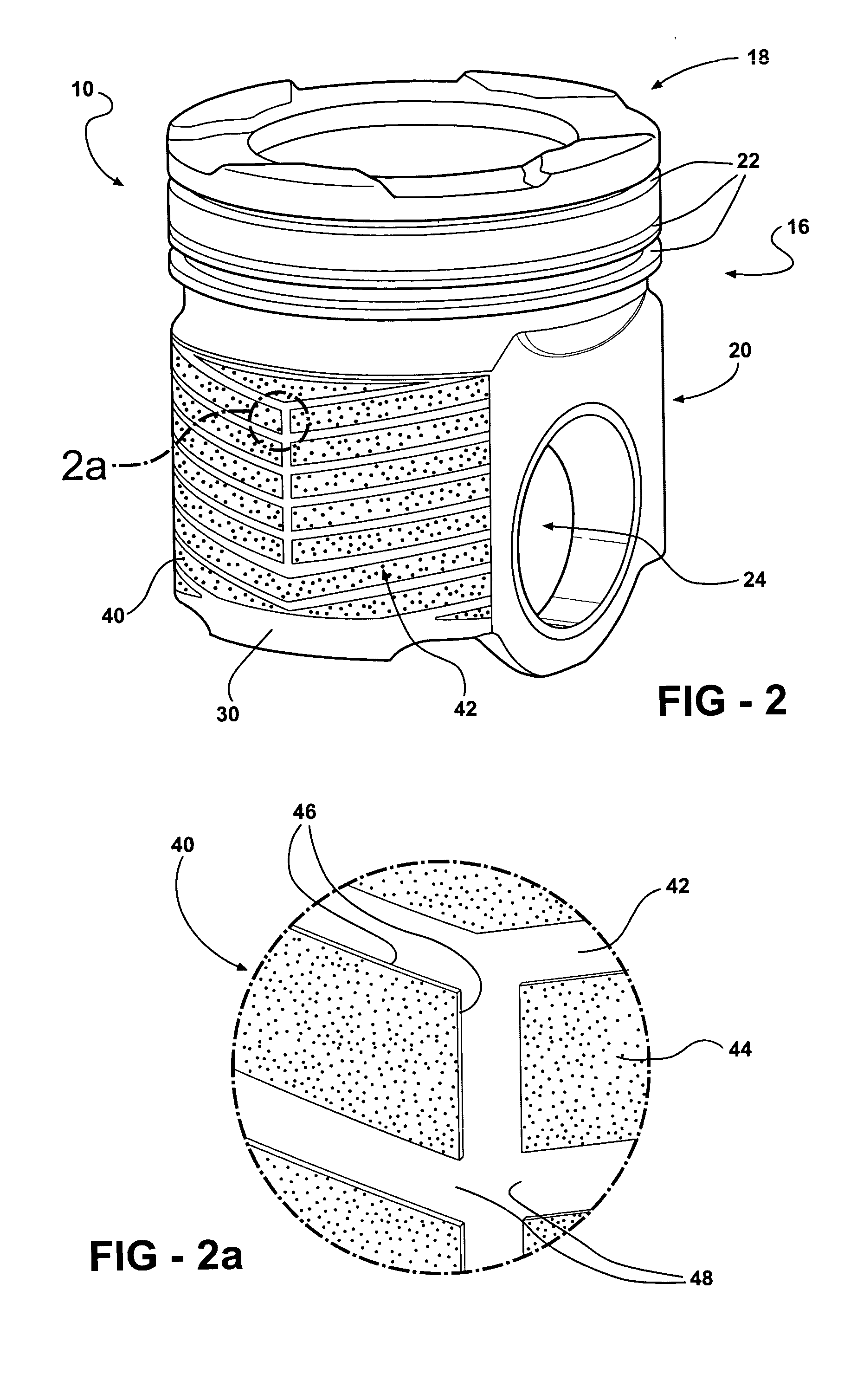

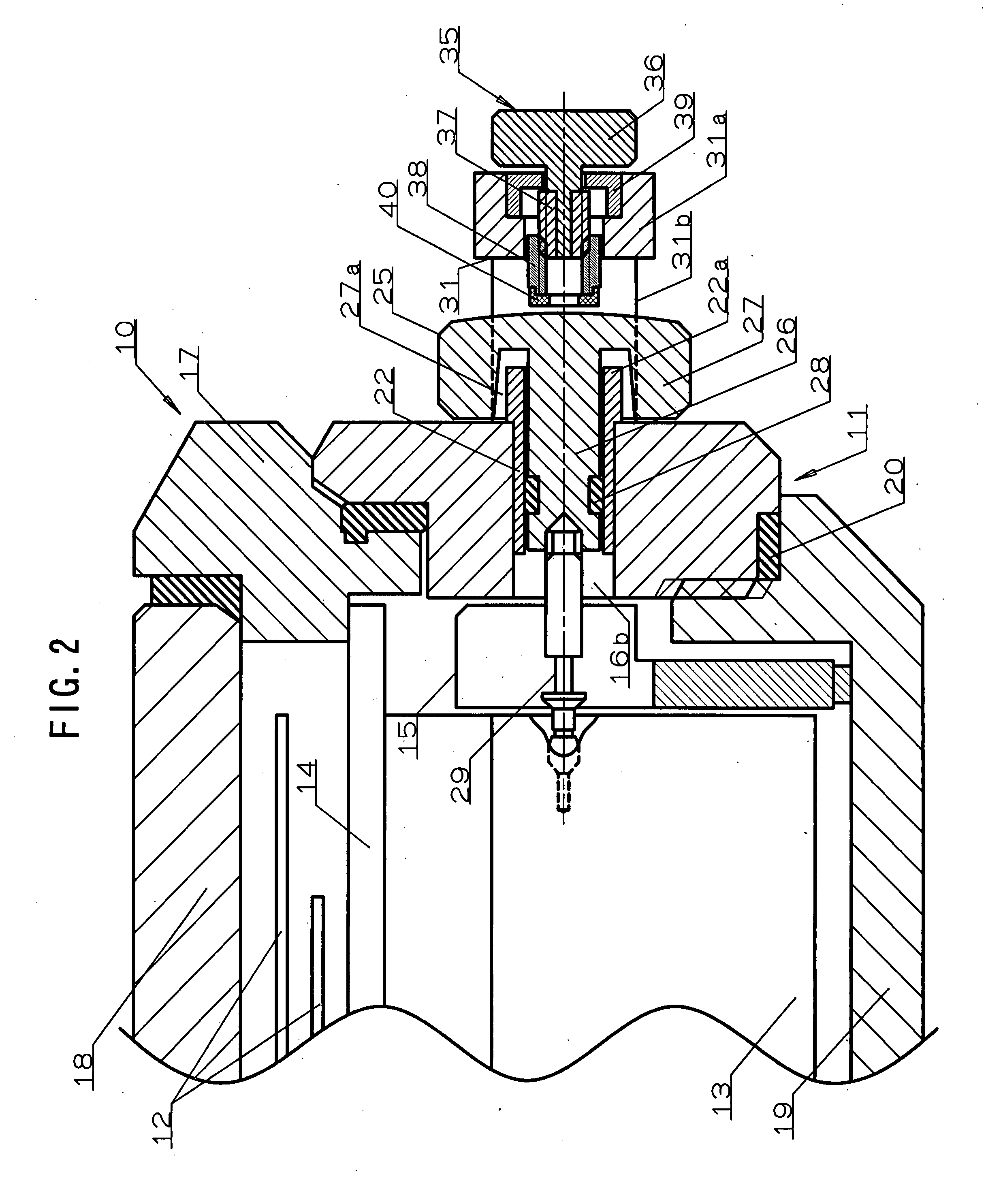

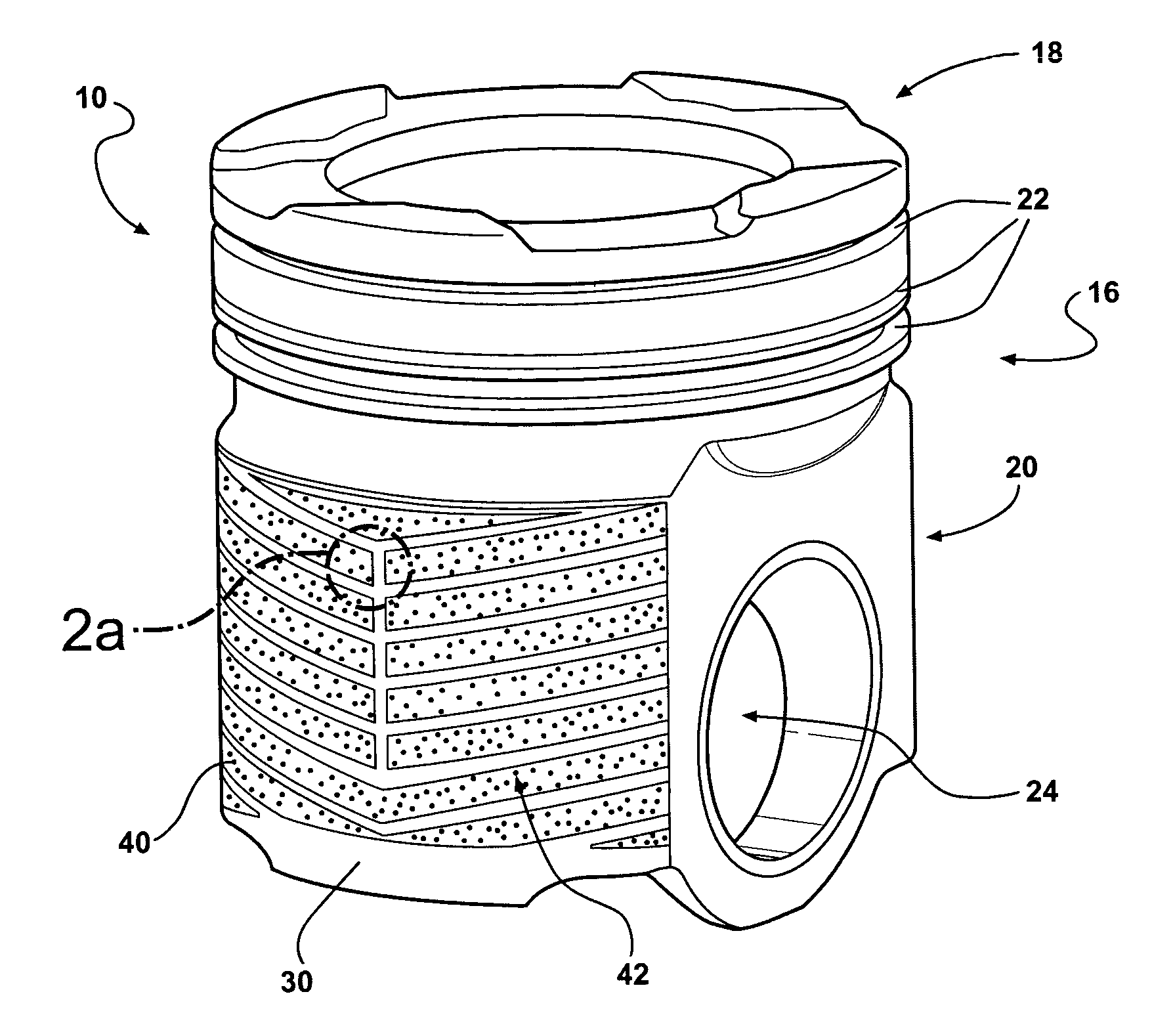

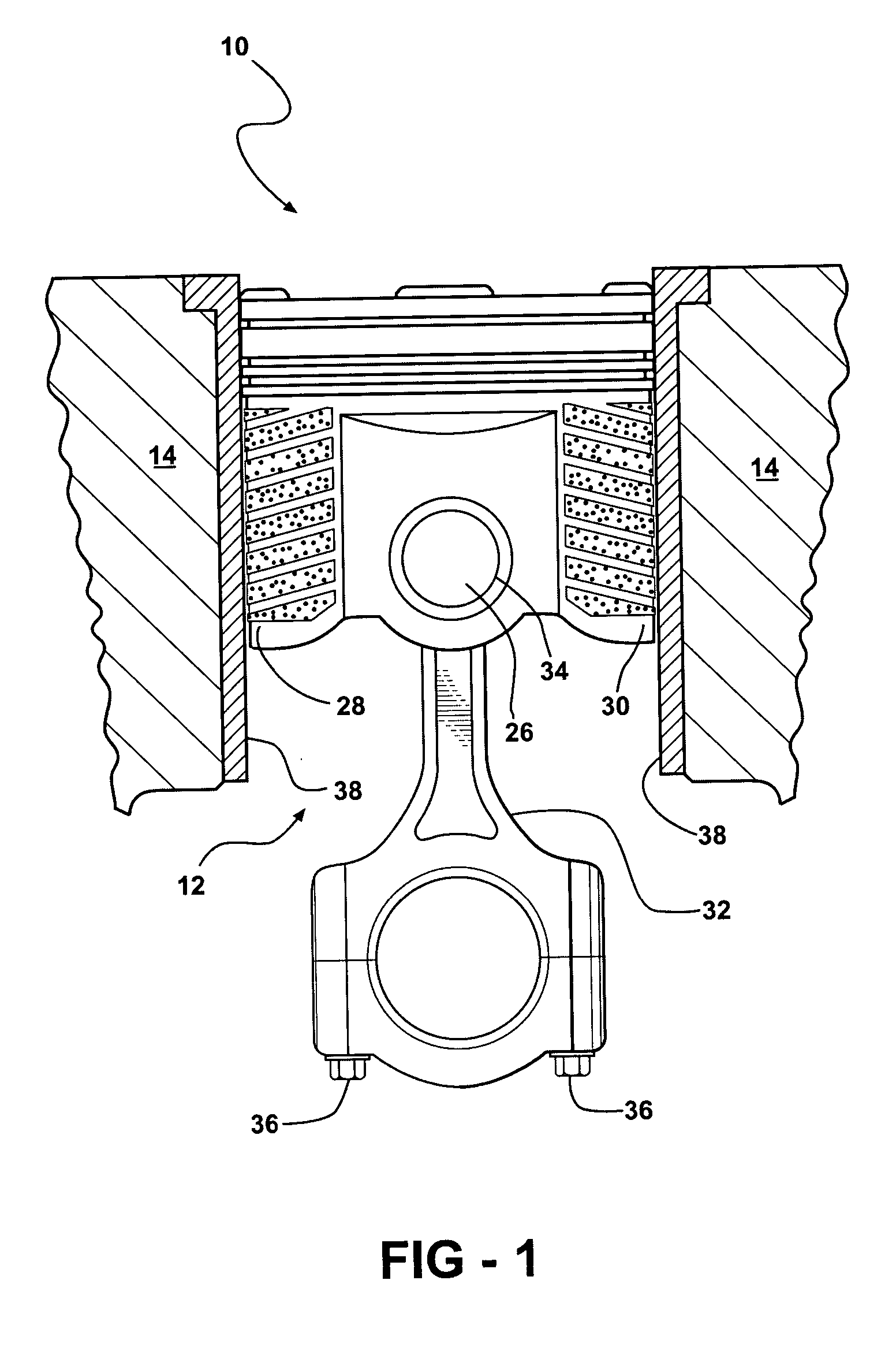

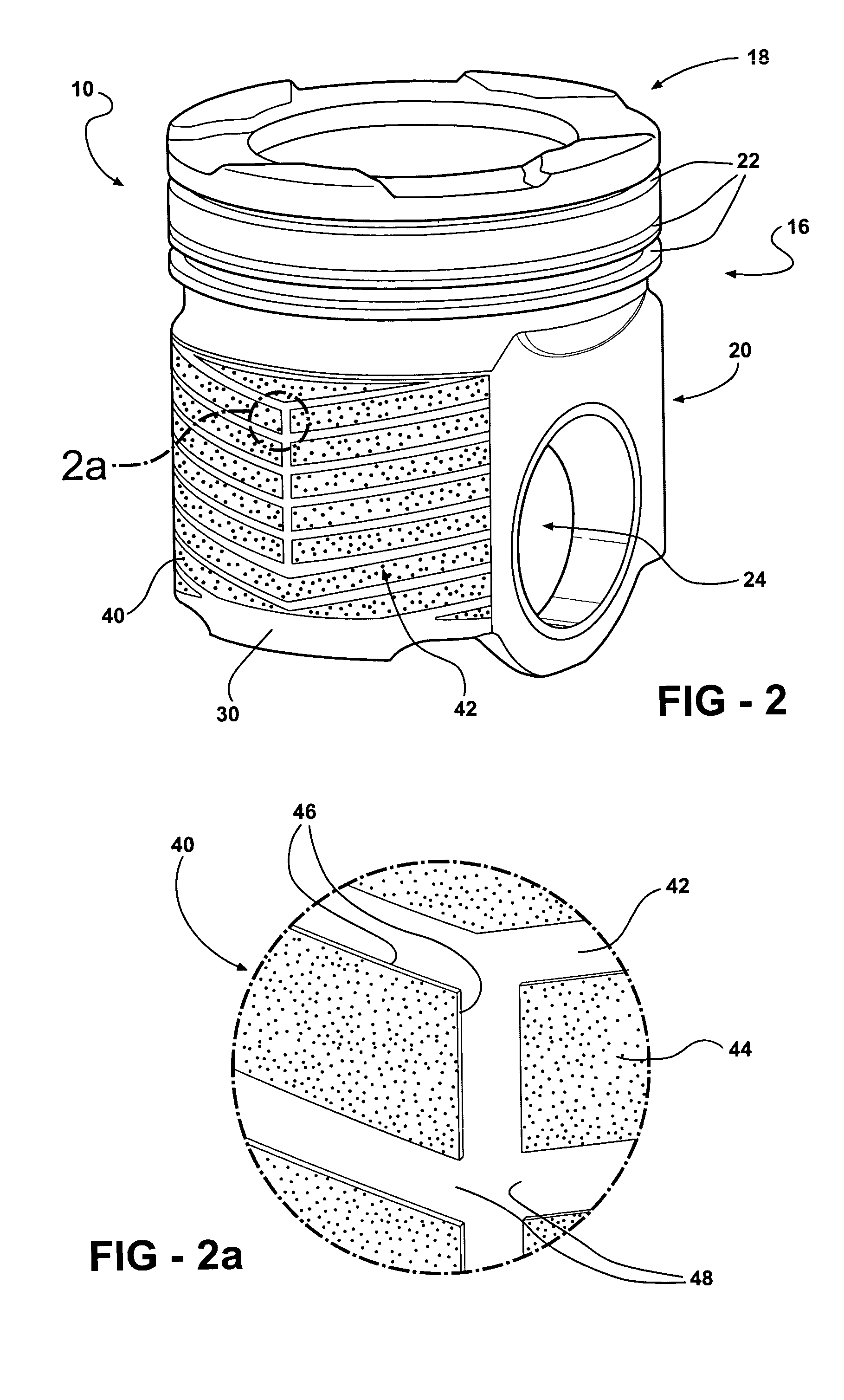

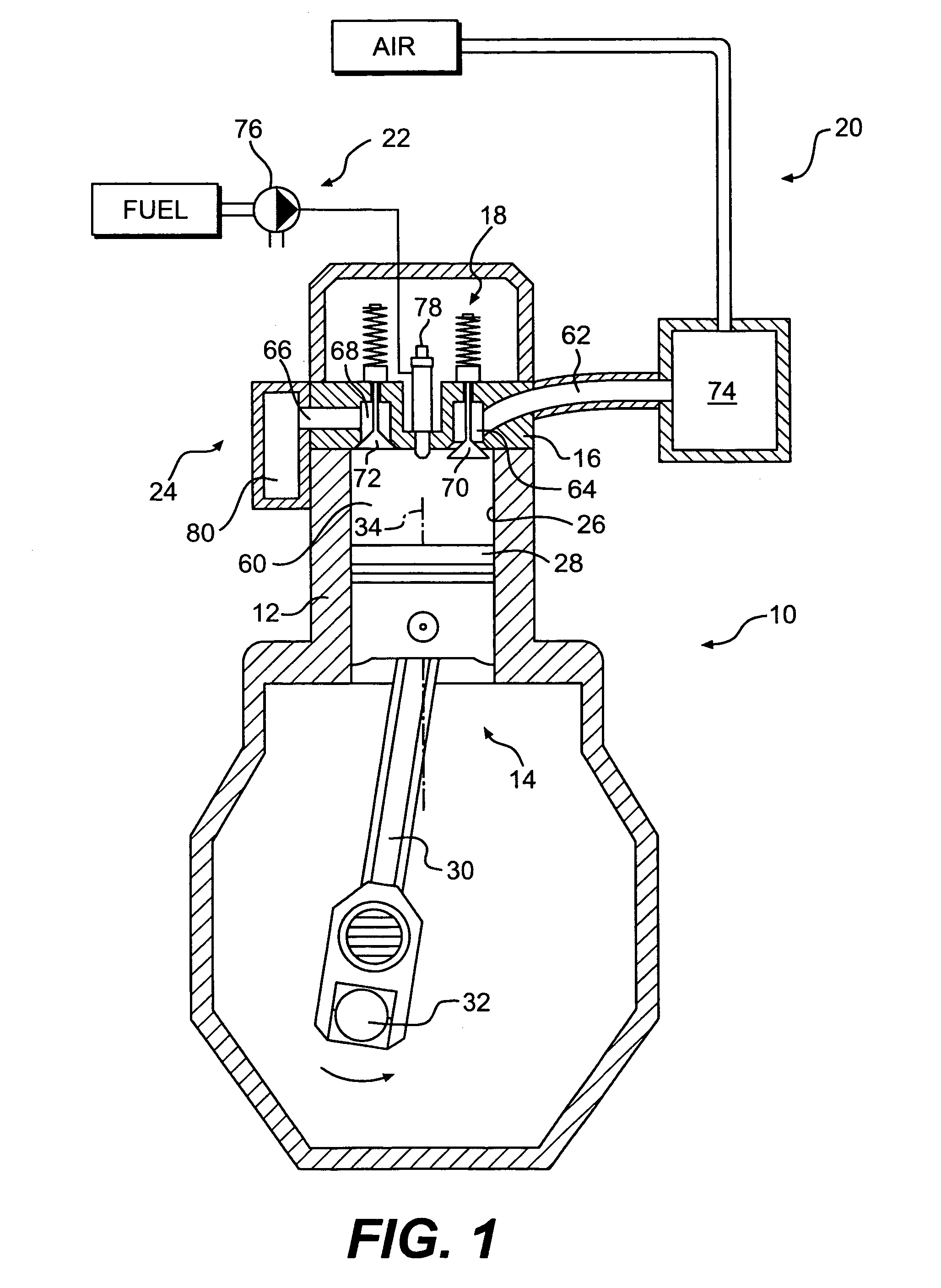

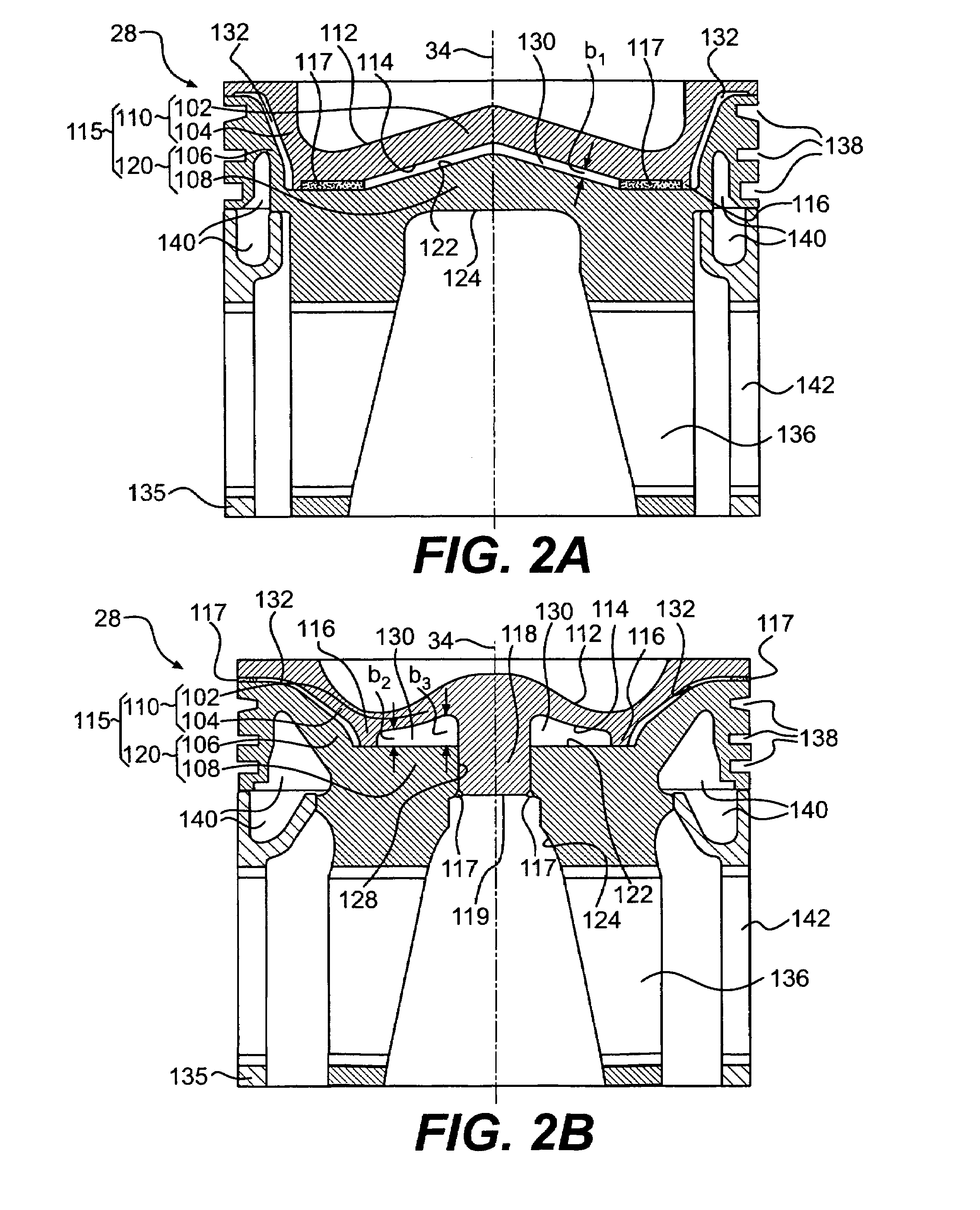

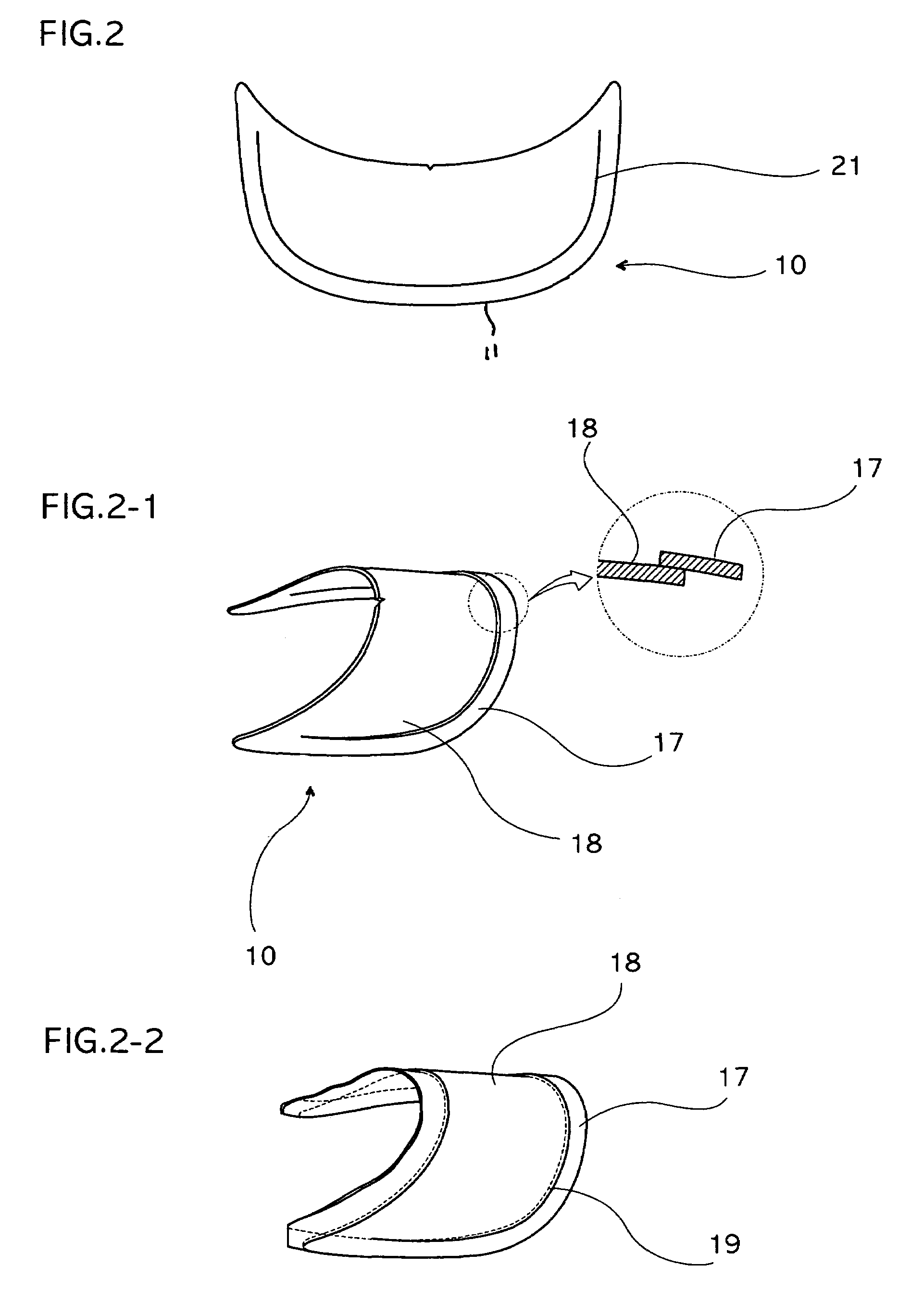

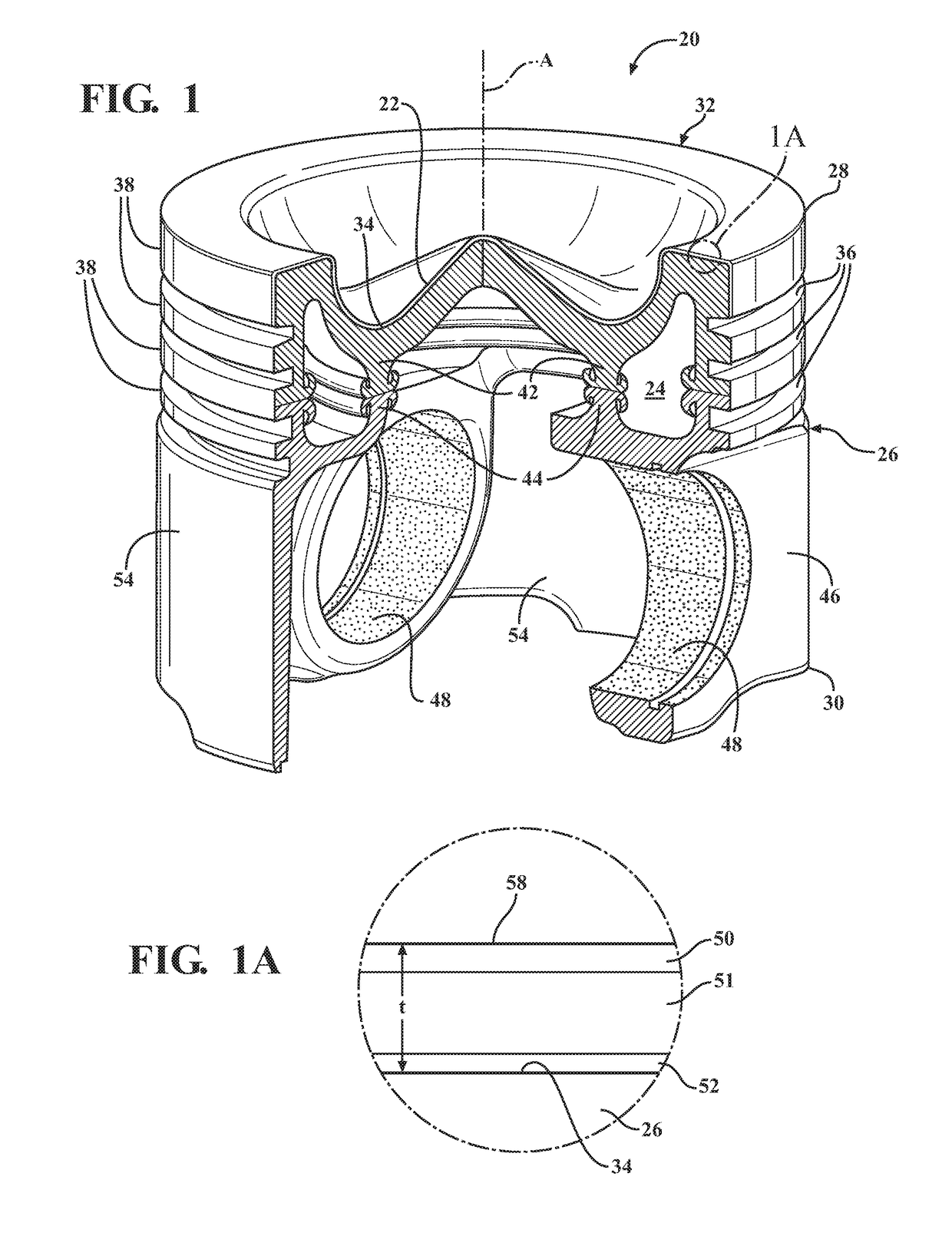

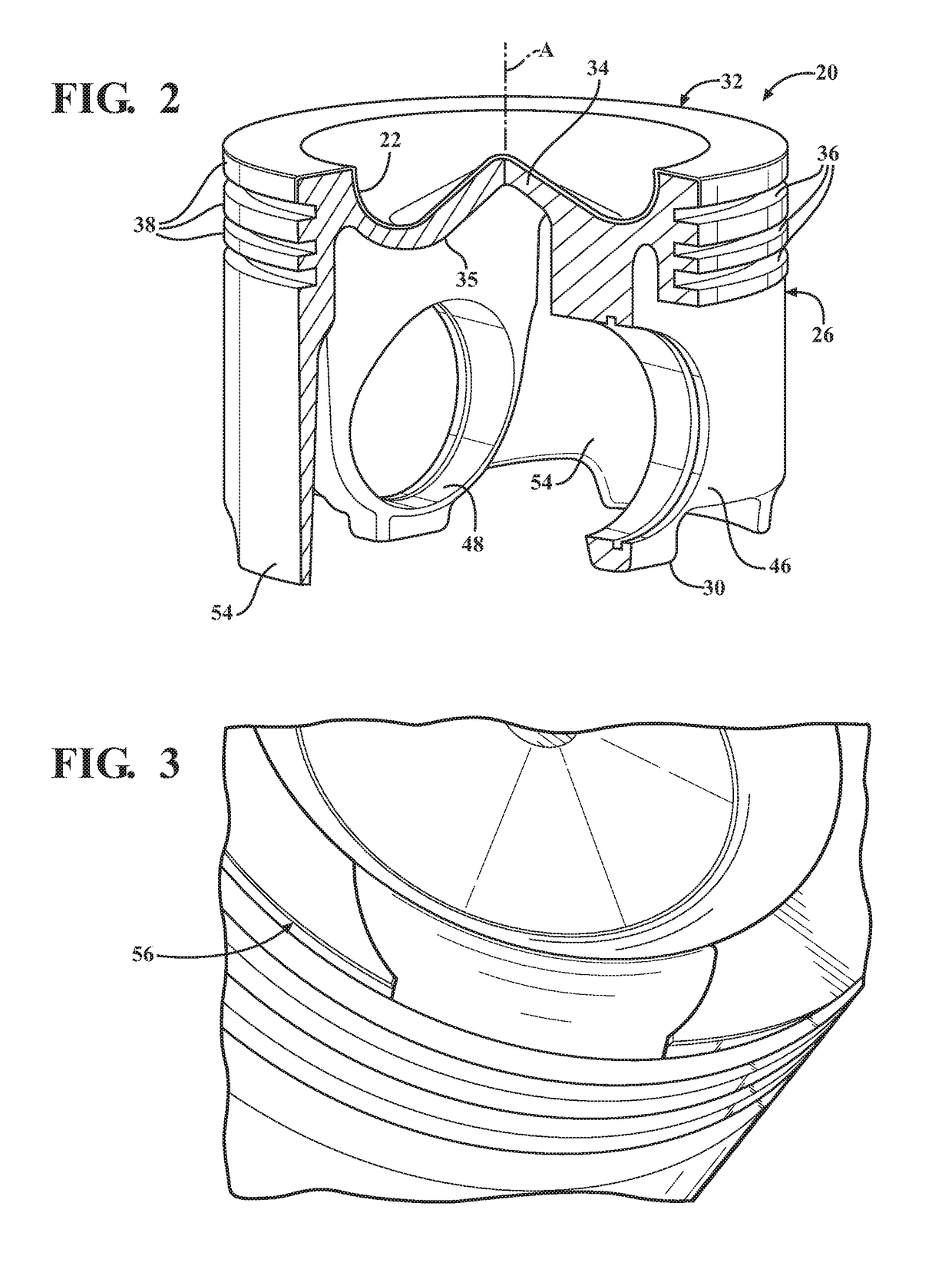

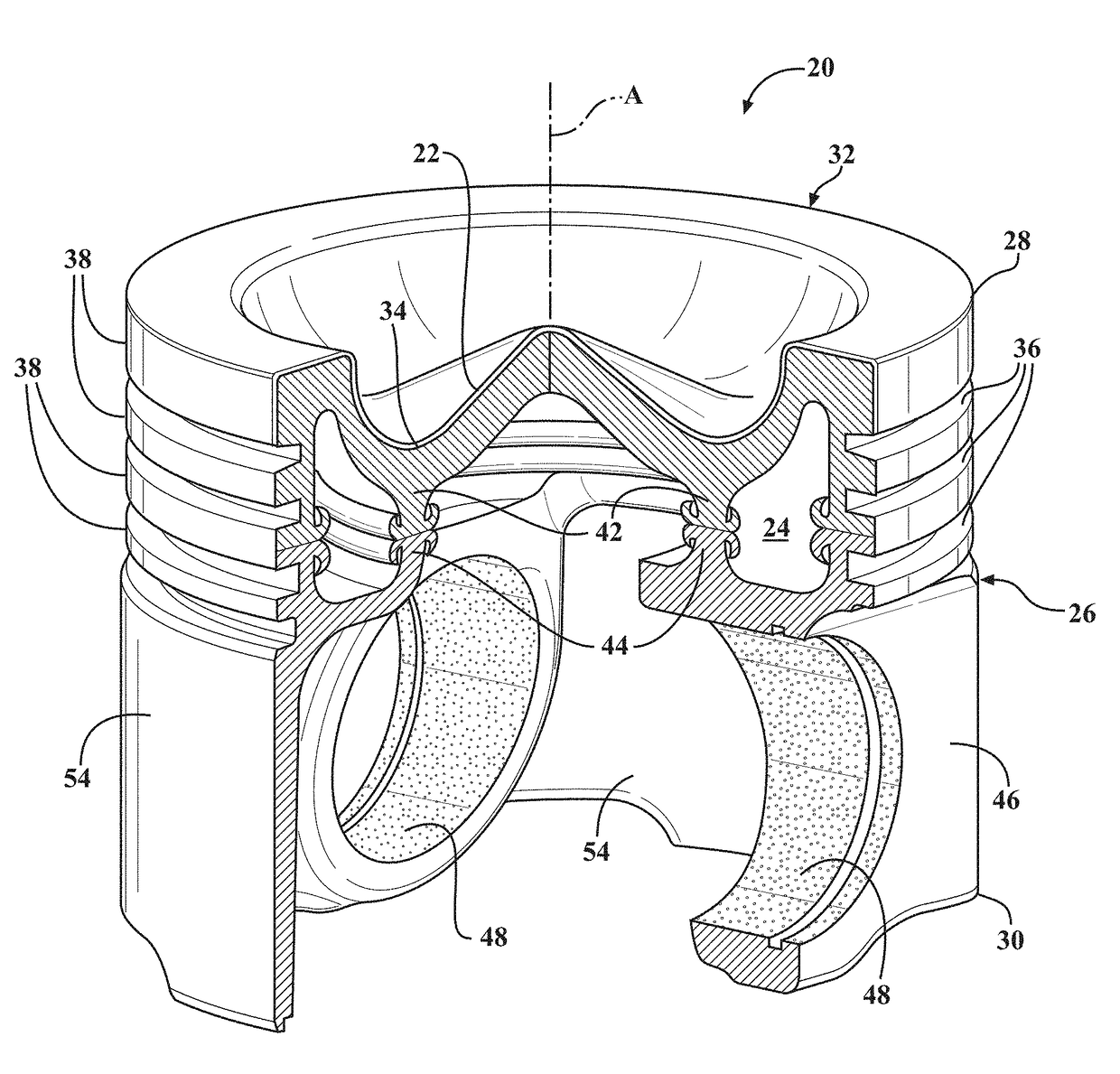

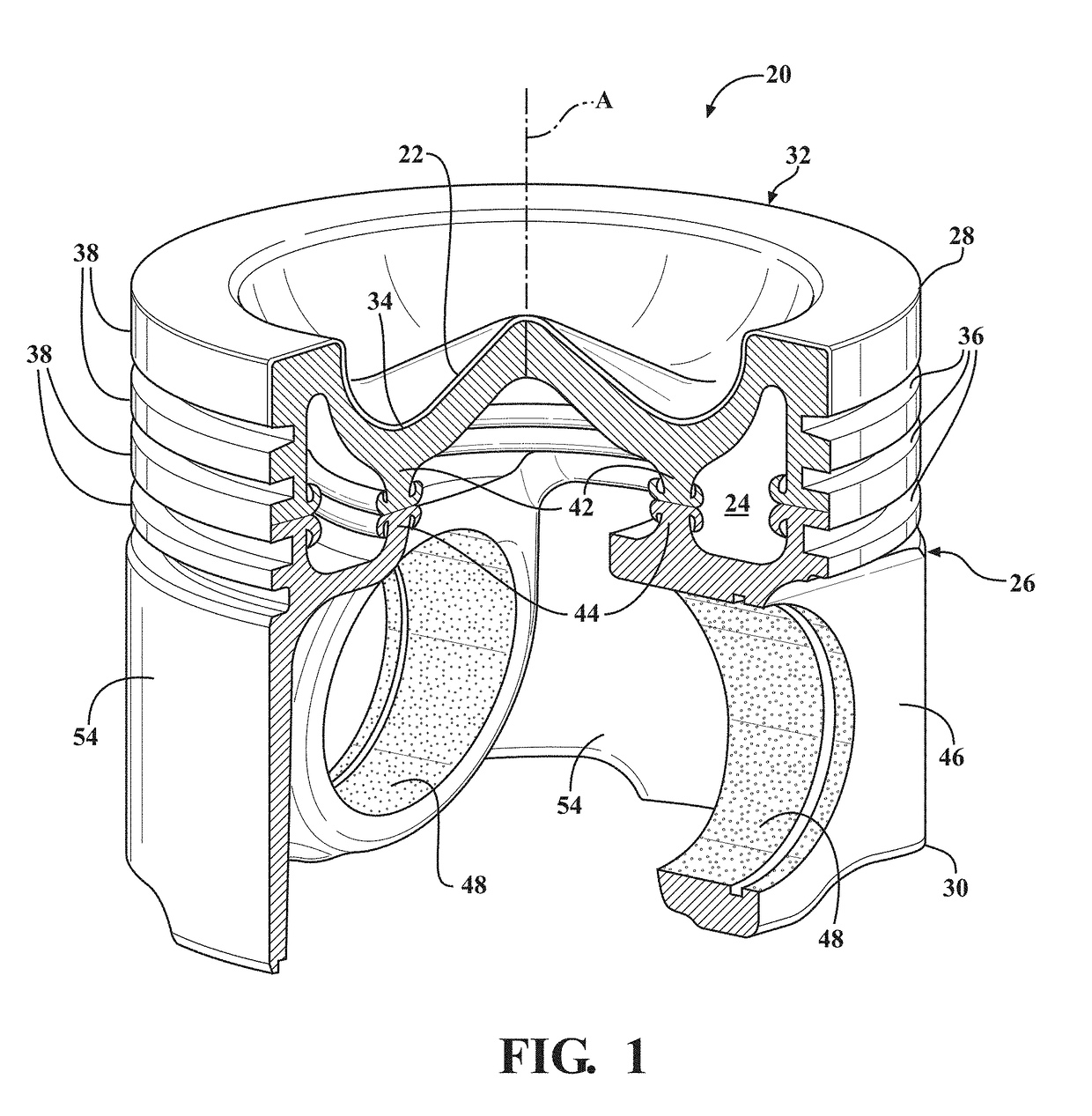

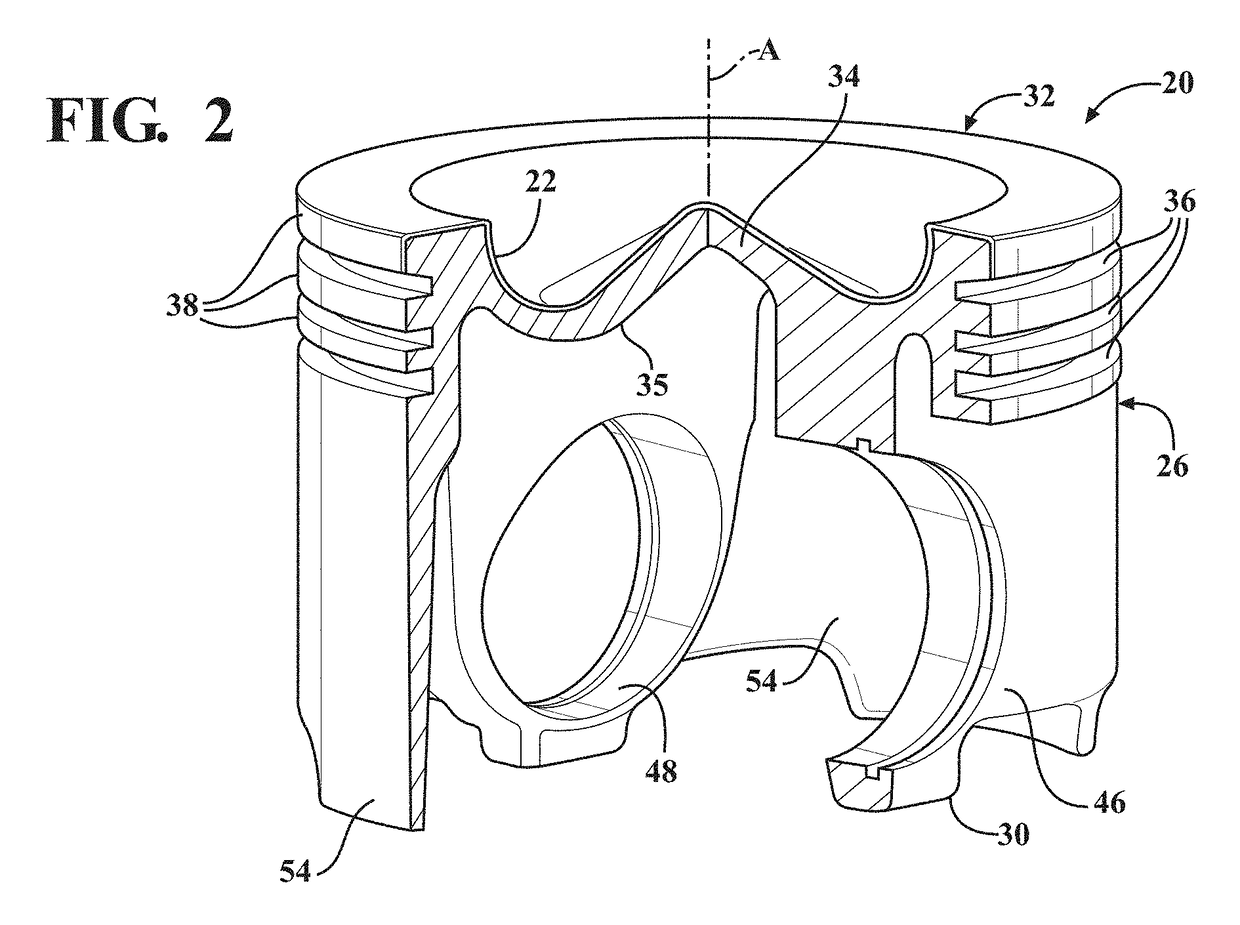

Piston having a patterned coating and method of applying same

ActiveUS20050087166A1Improve propertiesImproved propertyMolten spray coatingPlungersReciprocating motionEngineering

The present invention relates to a piston adapted for reciprocal movement within the cylinders of an internal combustion engine. The piston includes a body having a crown formed at the uppermost margins of the body and a skirt, depending from the crown, adapted for relative sliding motion with respect to the cylinder. The piston further includes a coating bonded to the piston skirt so as to be juxtaposed between the skirt and the cylinder. The coating has a plurality of recesses formed thereon so as to define a predetermined pattern of recesses on the surface of the skirt that retains lubricant between the skirt and the cylinder wall. The coating may also direct lubricant along the outer circumference of the piston skirt during reciprocal movement of the piston within a cylinder. A method of applying the coating to the piston skirt is also disclosed.

Owner:MAHLE TECH

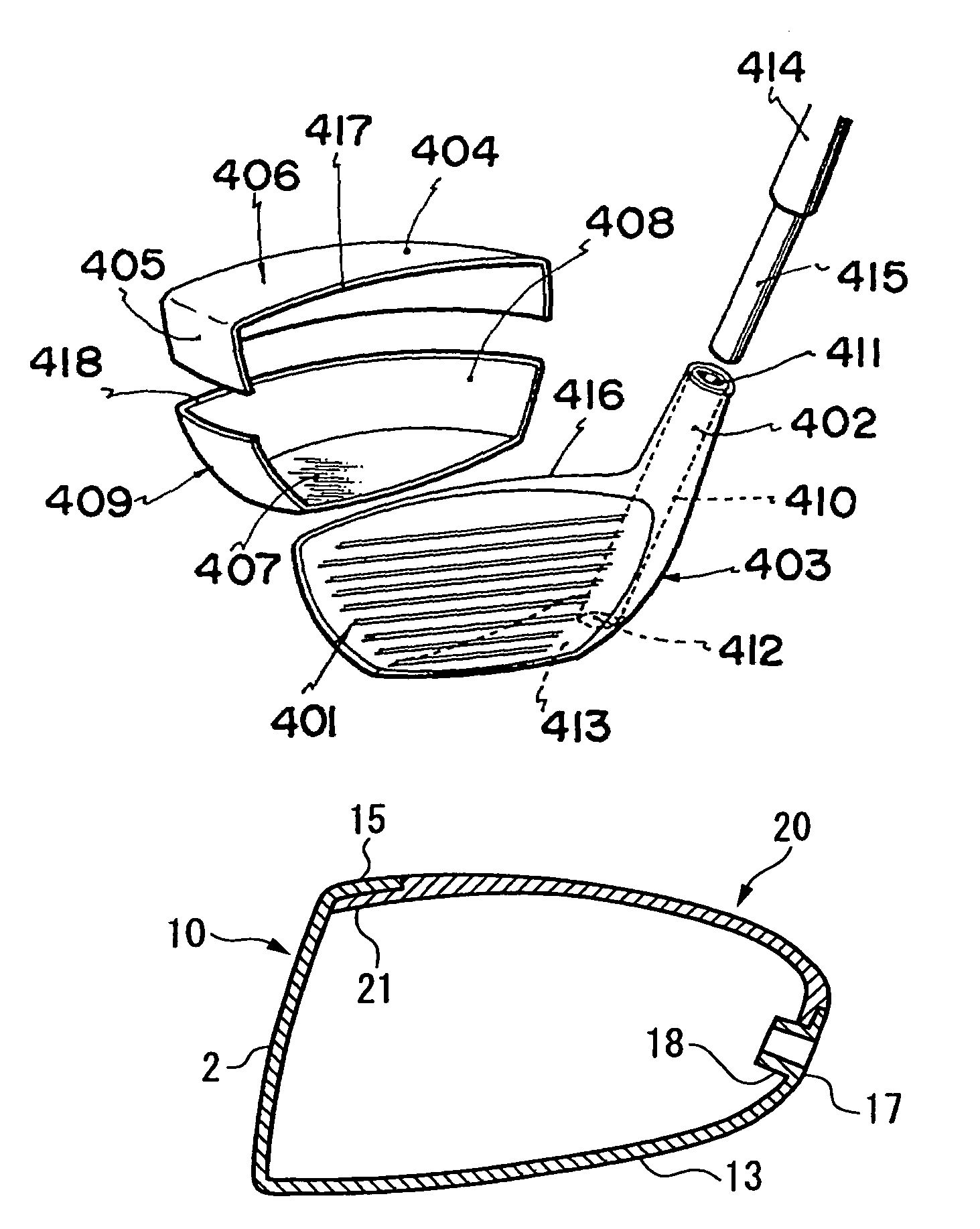

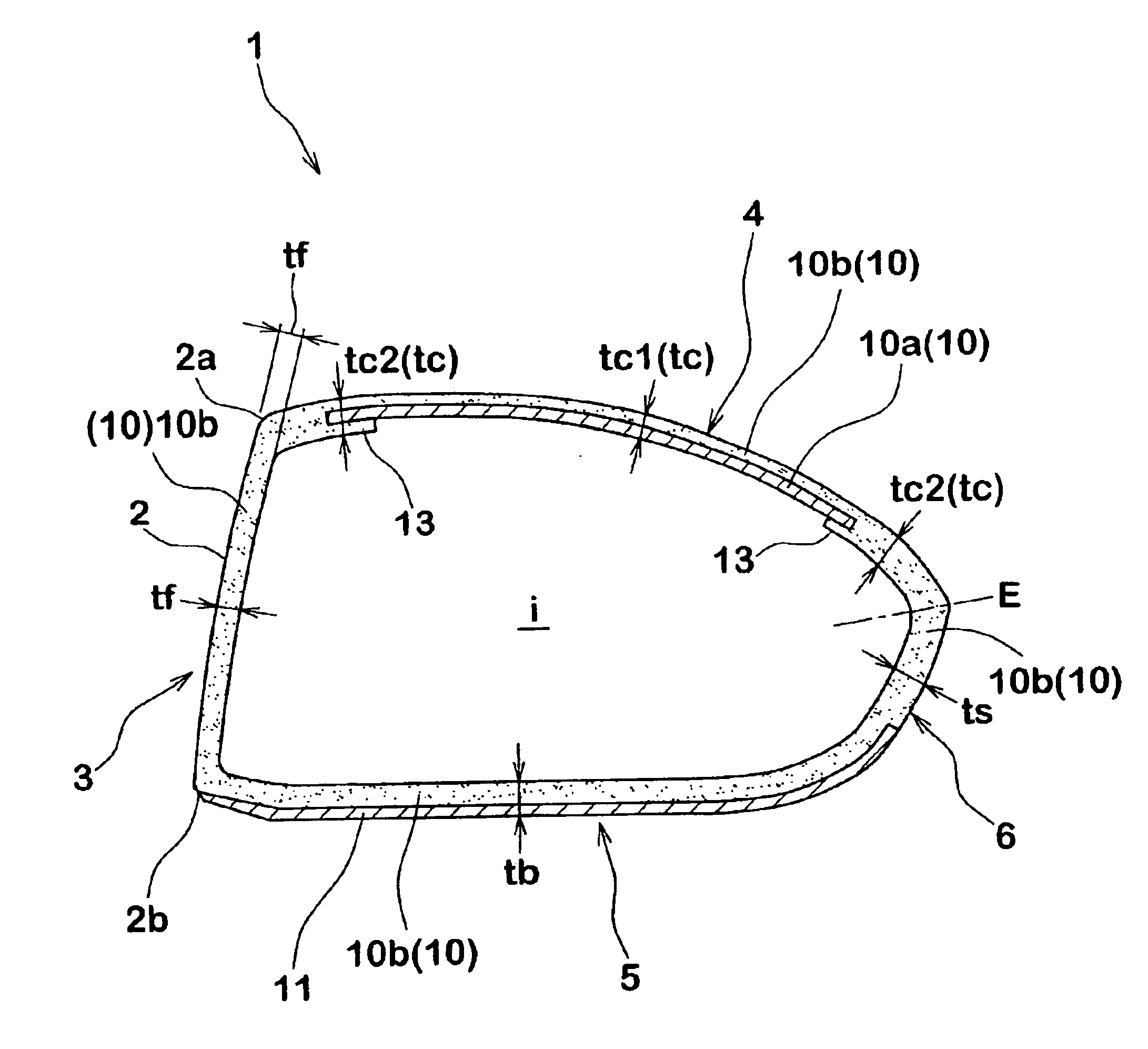

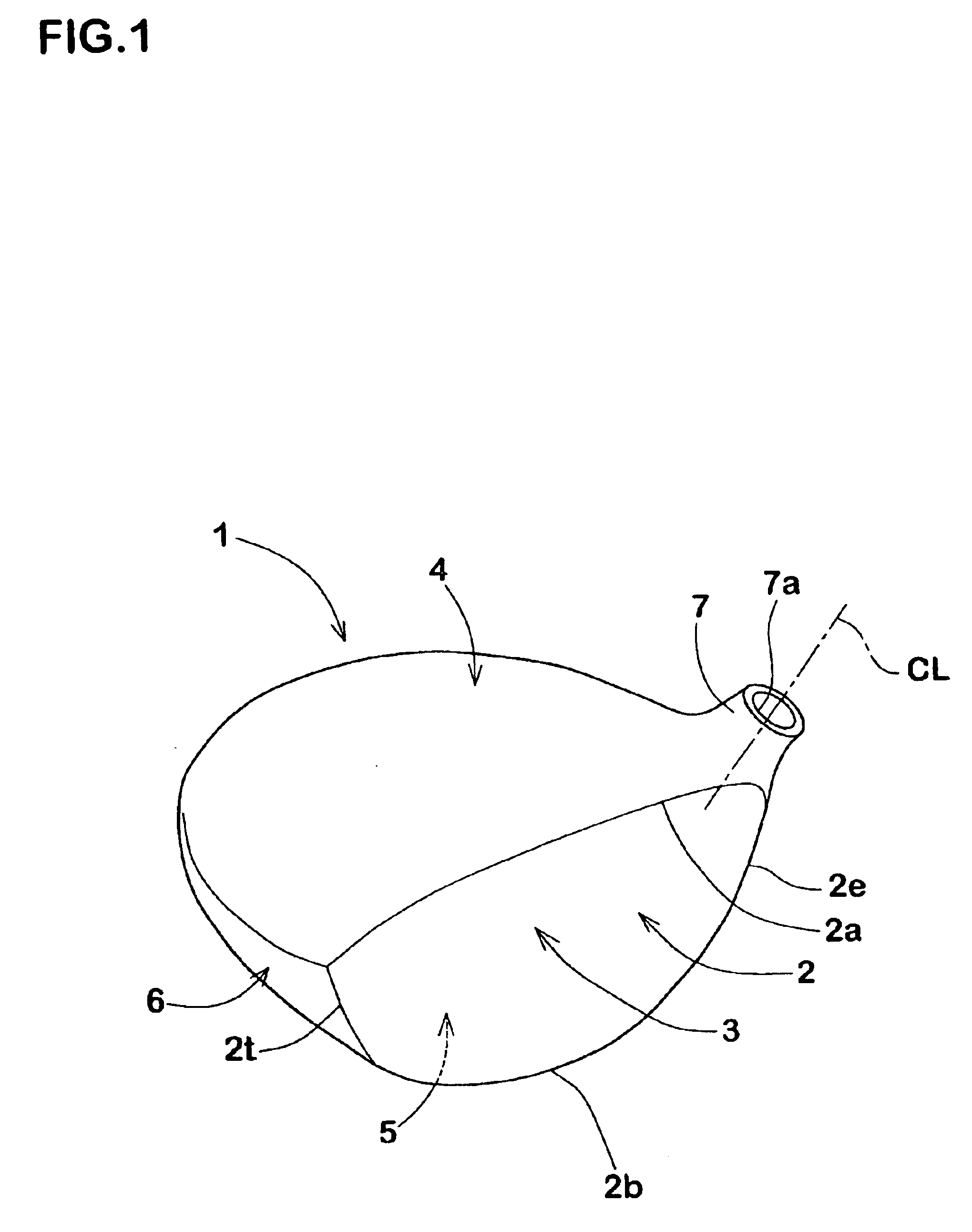

Golf club head

A hollow golf club head has a face portion, a sole portion, a side portion, a crown portion, and a hosel portion. A main portion of the crown portion is made of fiber reinforced plastic. At least the face portion and the front edge portion of the crown portion continuing to the face portion are made of metal. A circumferential edge portion of the crown portion made of fiber reinforced plastic is joined to the rear end surface and the internal surface of the metal front edge portion of the crown portion.

Owner:BRIDGESTONE SPORTS

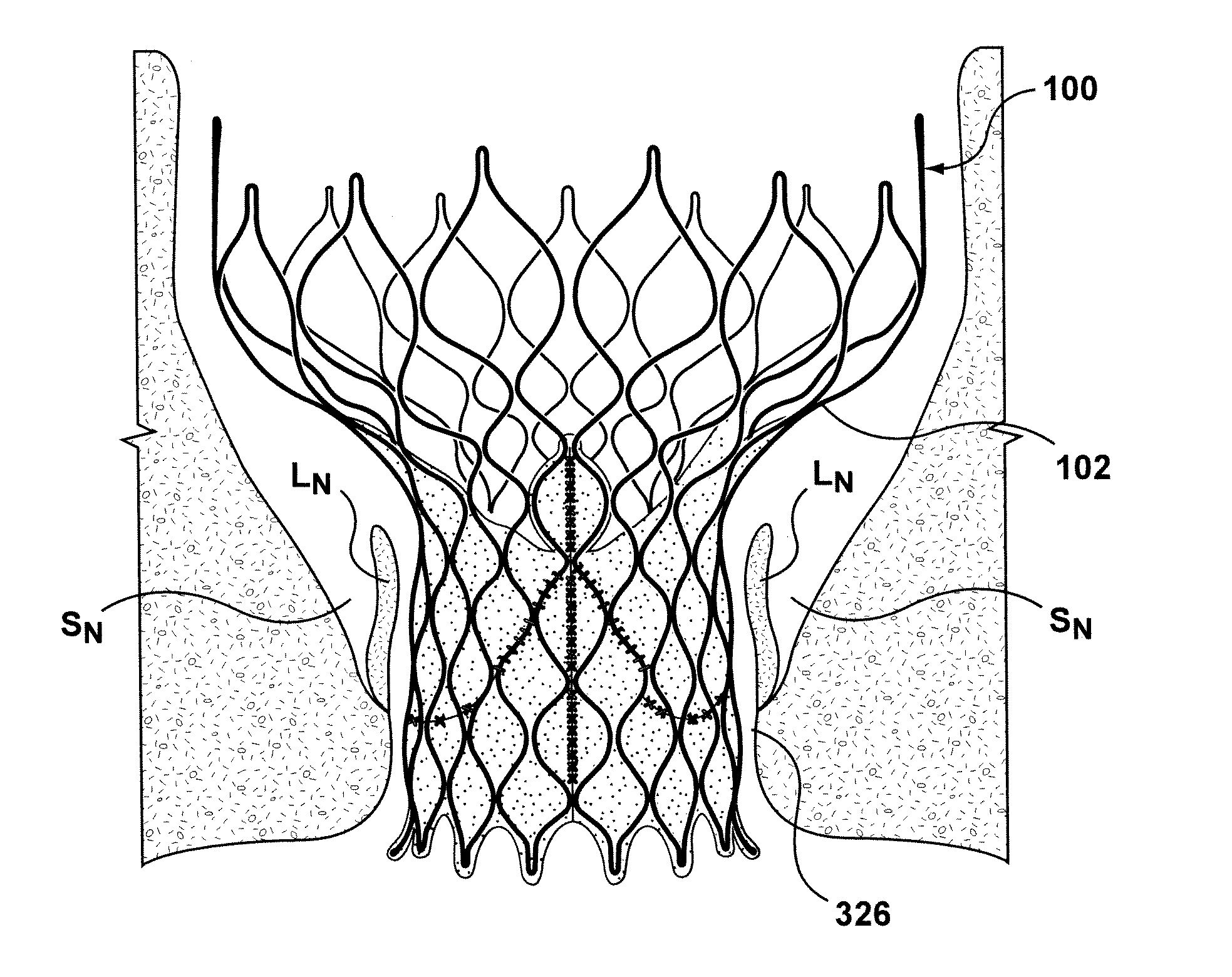

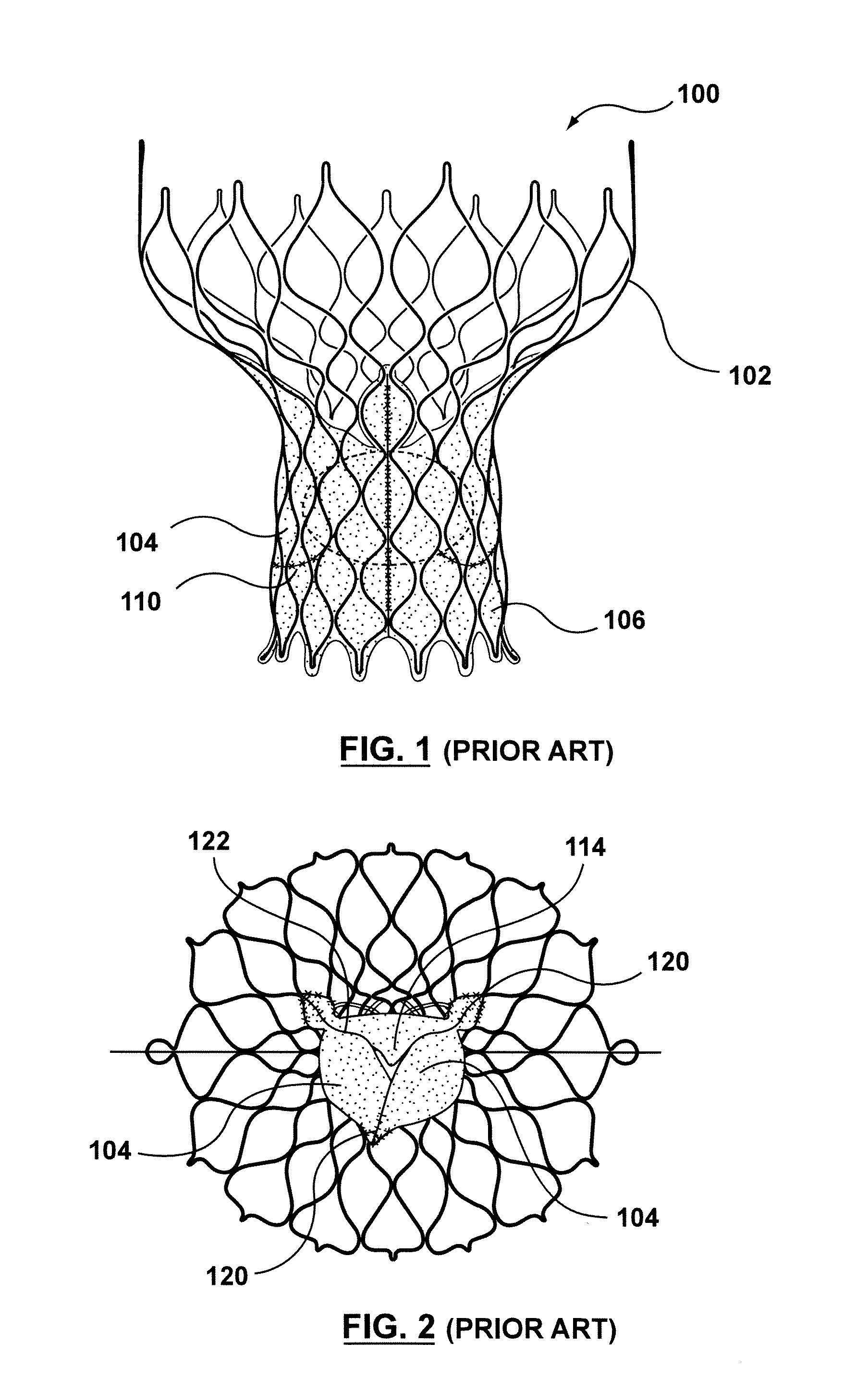

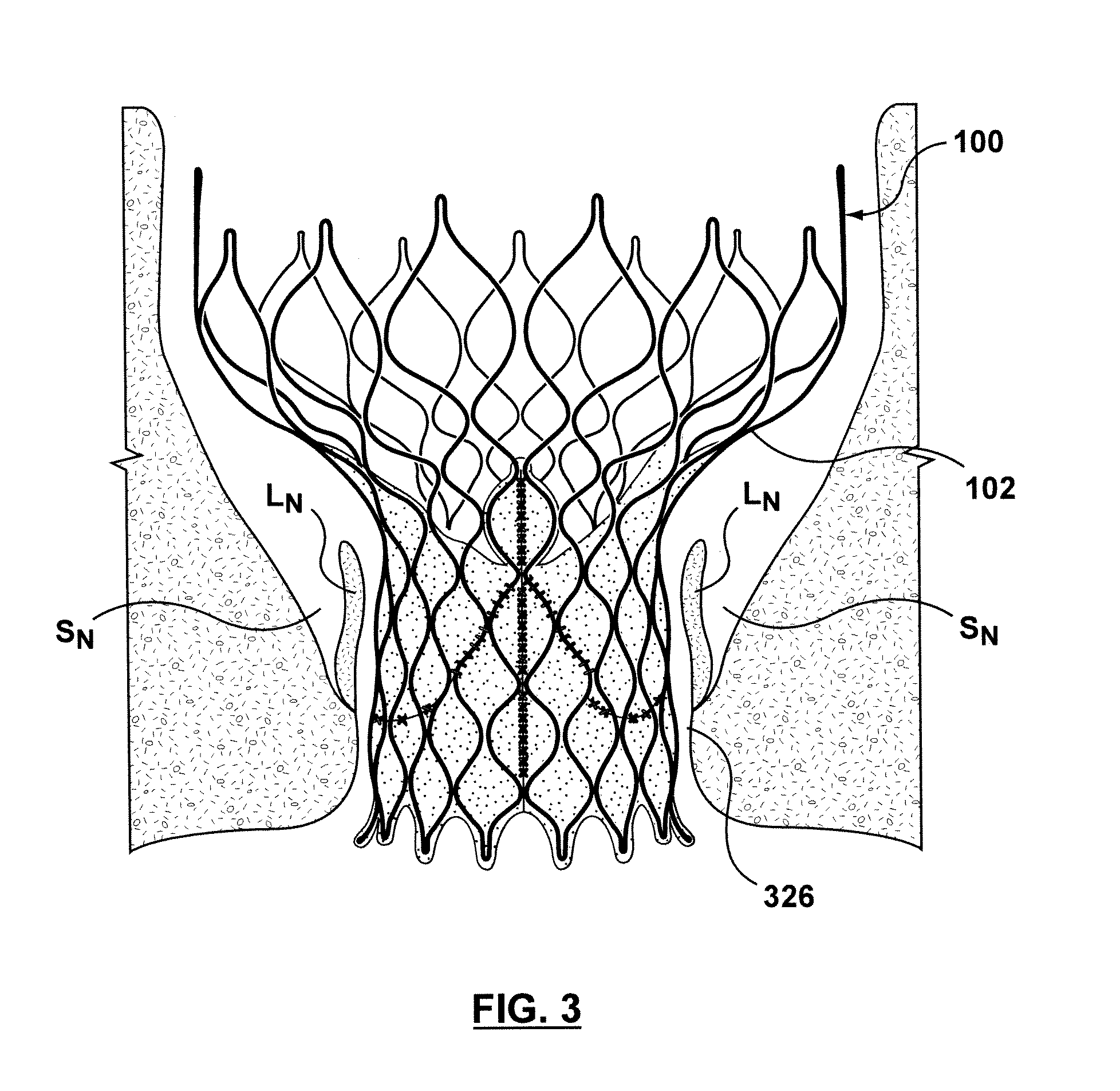

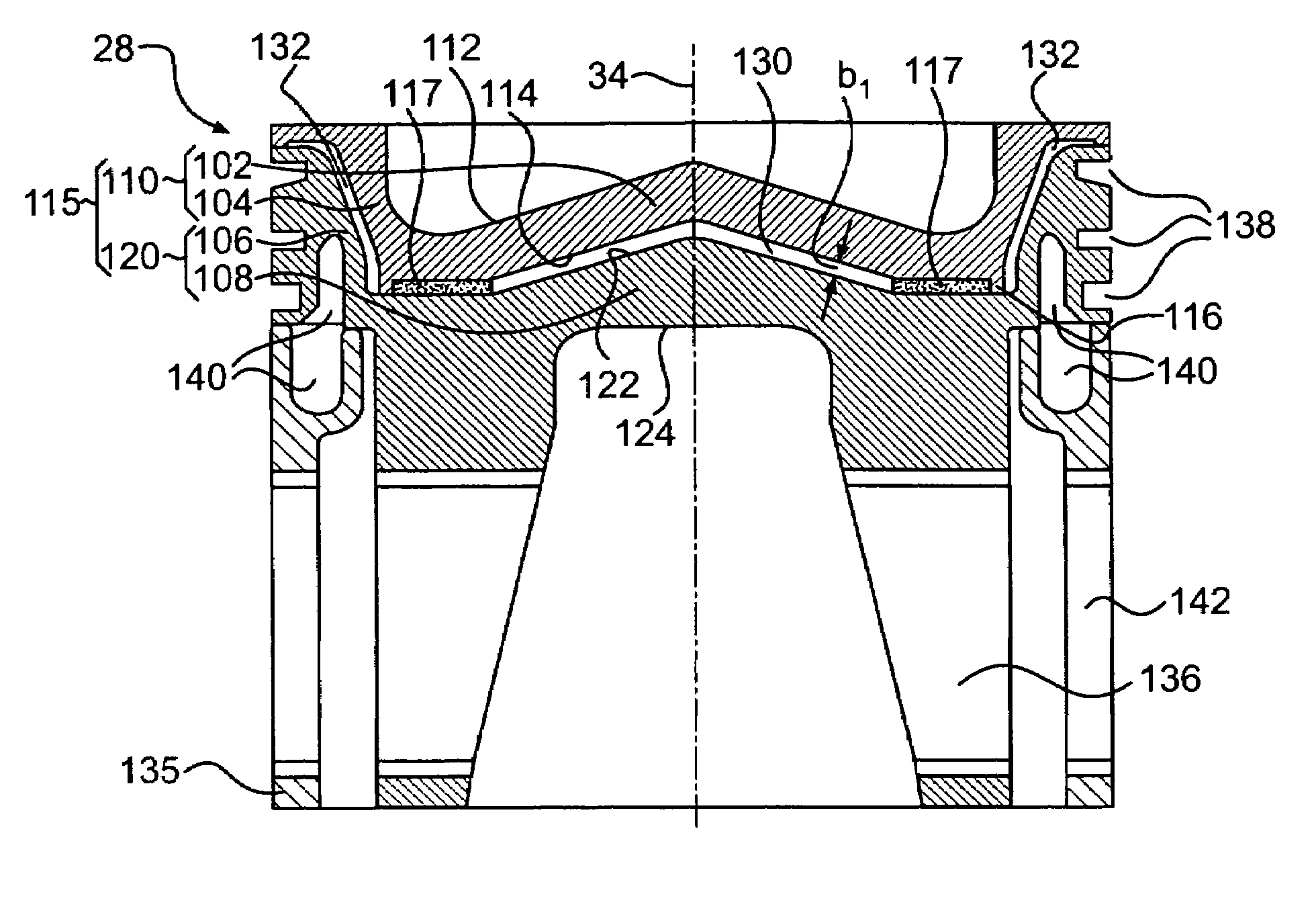

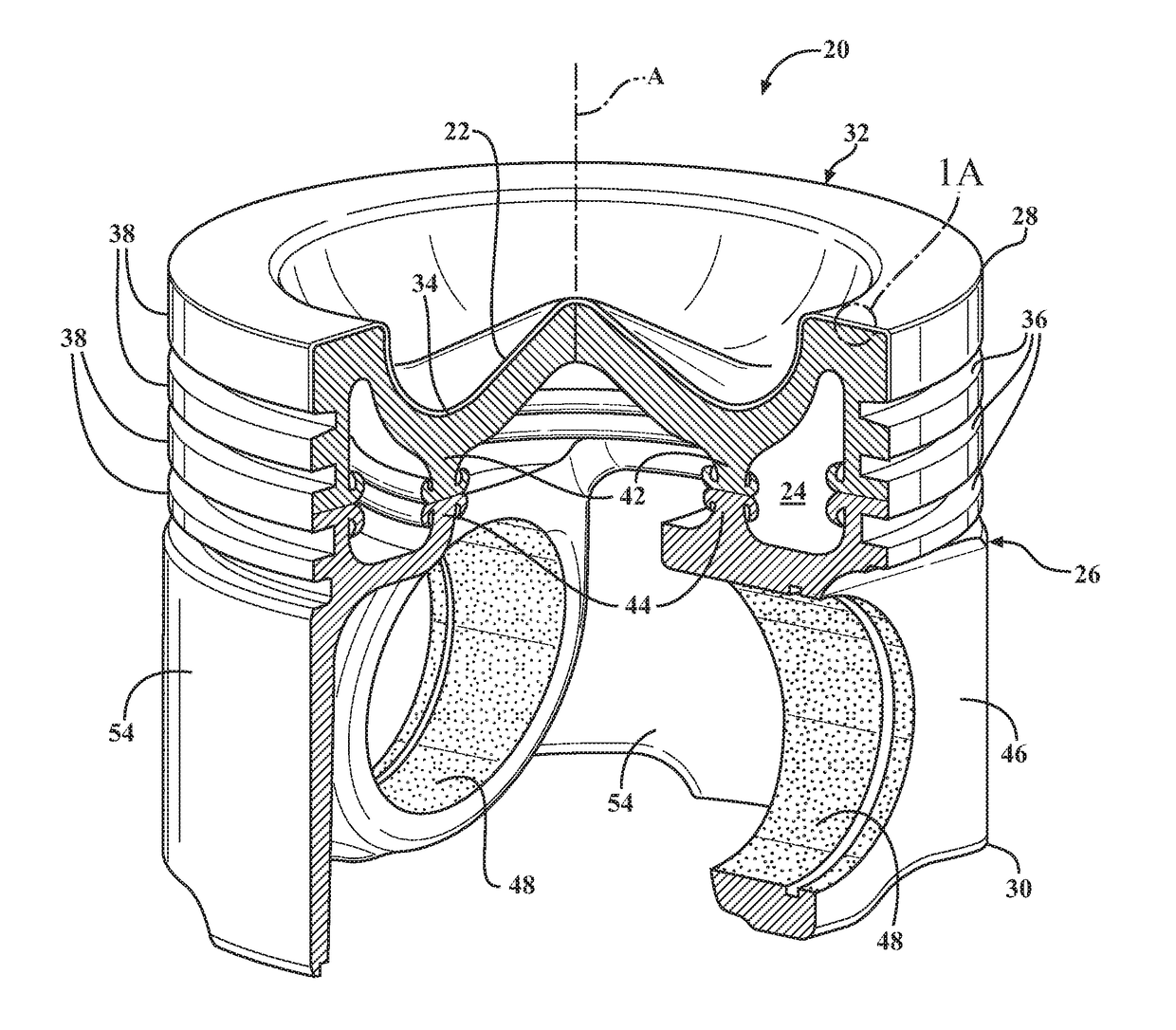

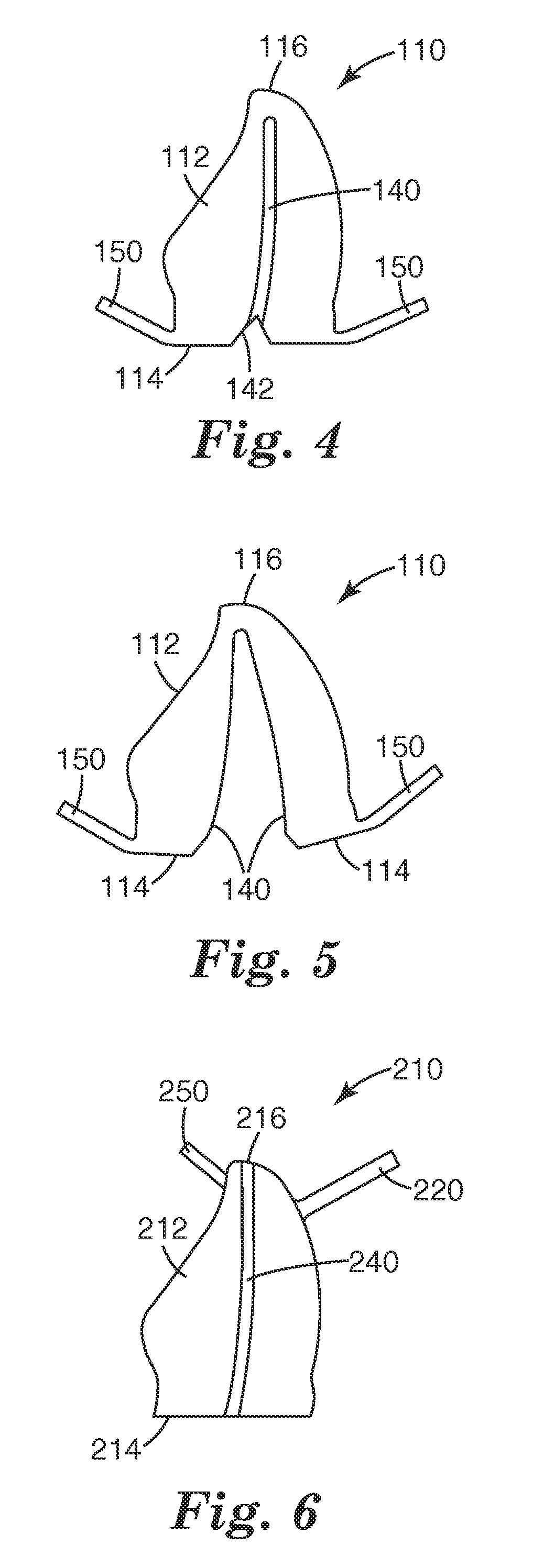

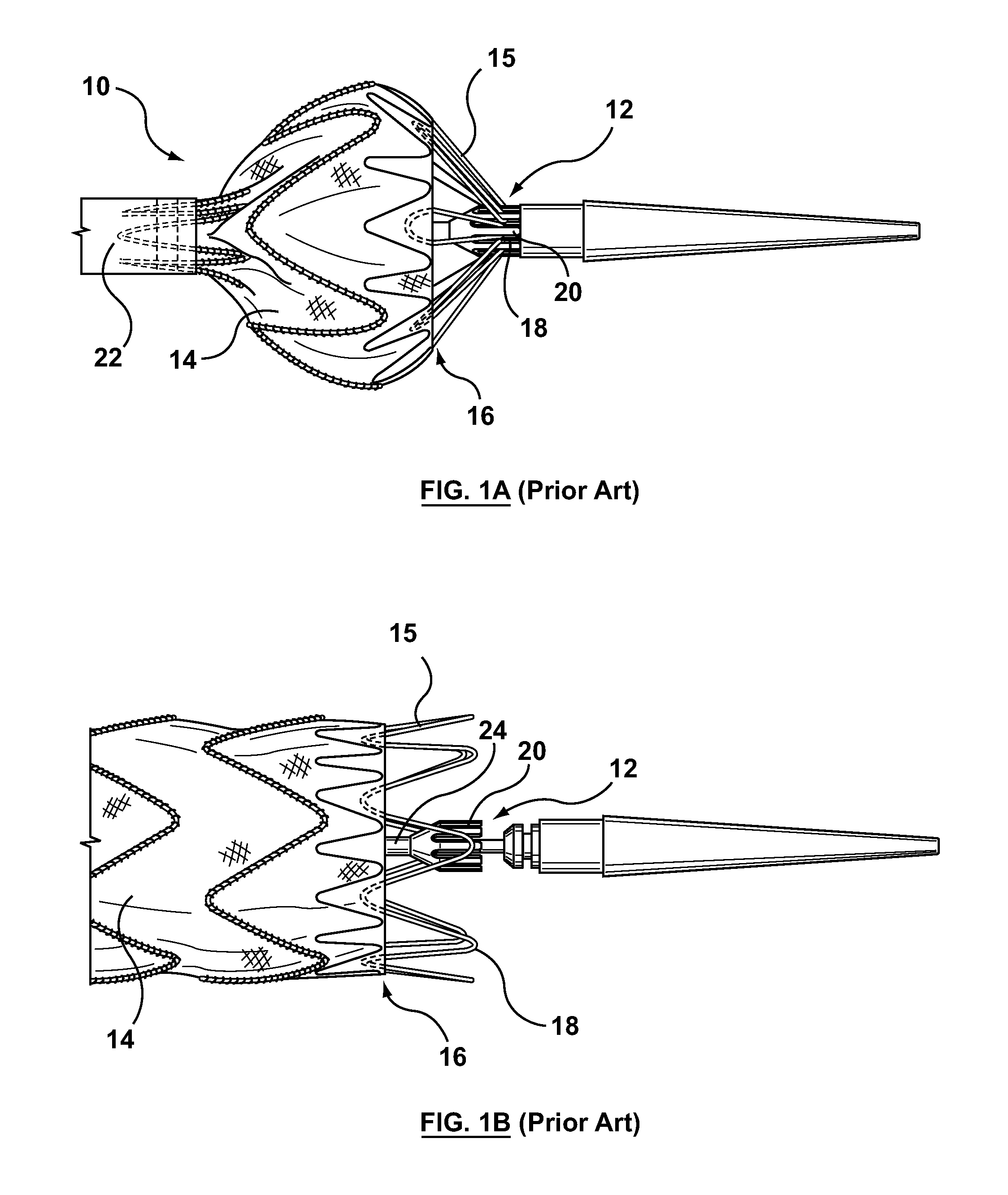

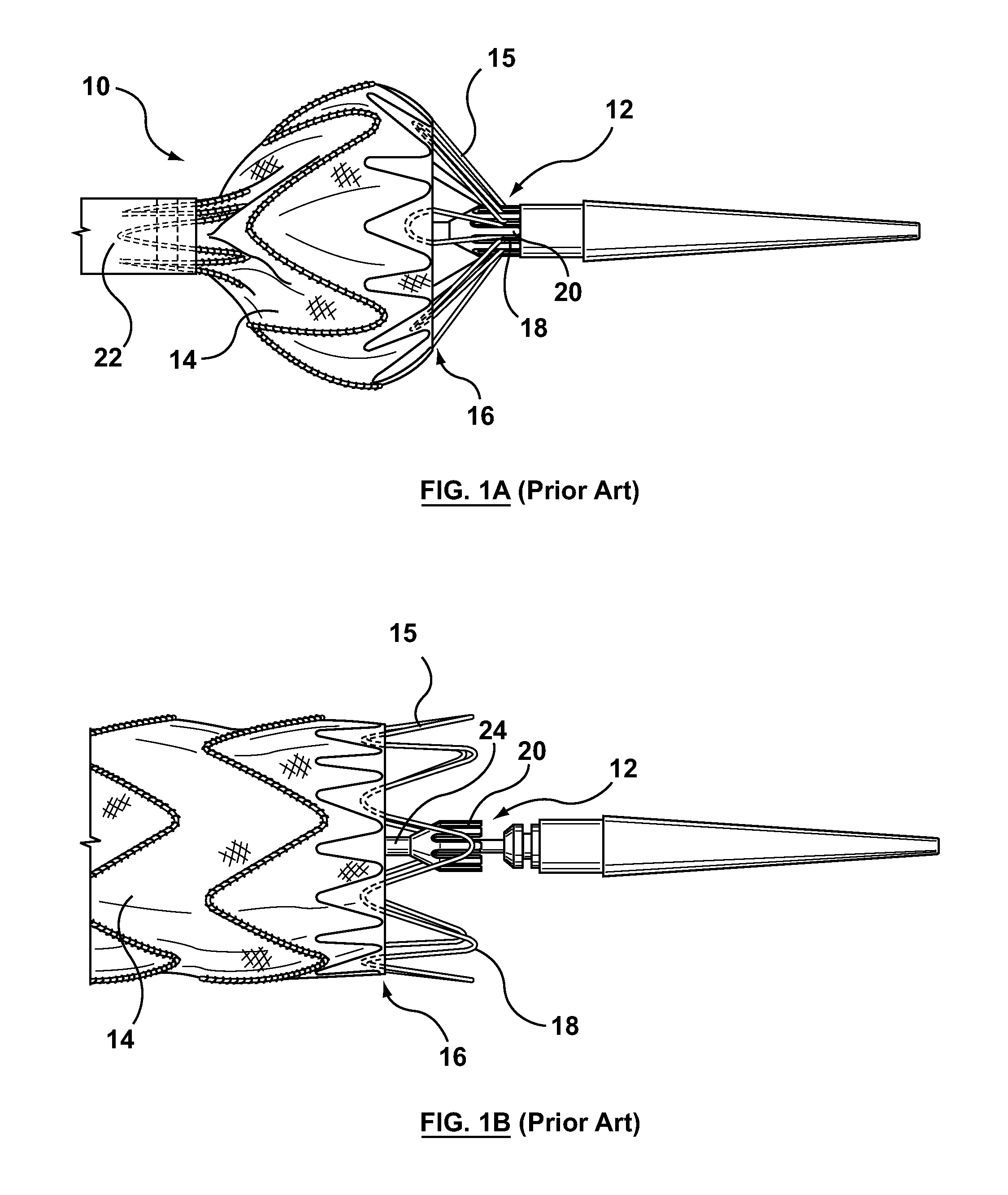

Transcatheter valve prosthesis having an external skirt for sealing and preventing paravalvular leakage

A transcatheter valve prosthesis including a tubular stent includes an interior skirt or skirt portion is coupled to and covers an inner circumferential surface of the stent, and an exterior skirt or skirt portion is coupled to and covers an outer circumferential surface of the stent. A prosthetic valve component is disposed within and secured to the interior skirt or skirt portion. The interior and exterior skirts or skirt portions may overlap to form a double layer of skirt material on the stent, or may be portions of a skirt that do not overlap such that only a single layer of skirt material covers the stent. When the stent is in at least the compressed configuration, at least one endmost crown may be positioned radially inwards with respect to the remaining endmost crowns formed at the inflow end of the stent in order to accommodate the exterior skirt.

Owner:MEDTRONIC VASCULAR INC

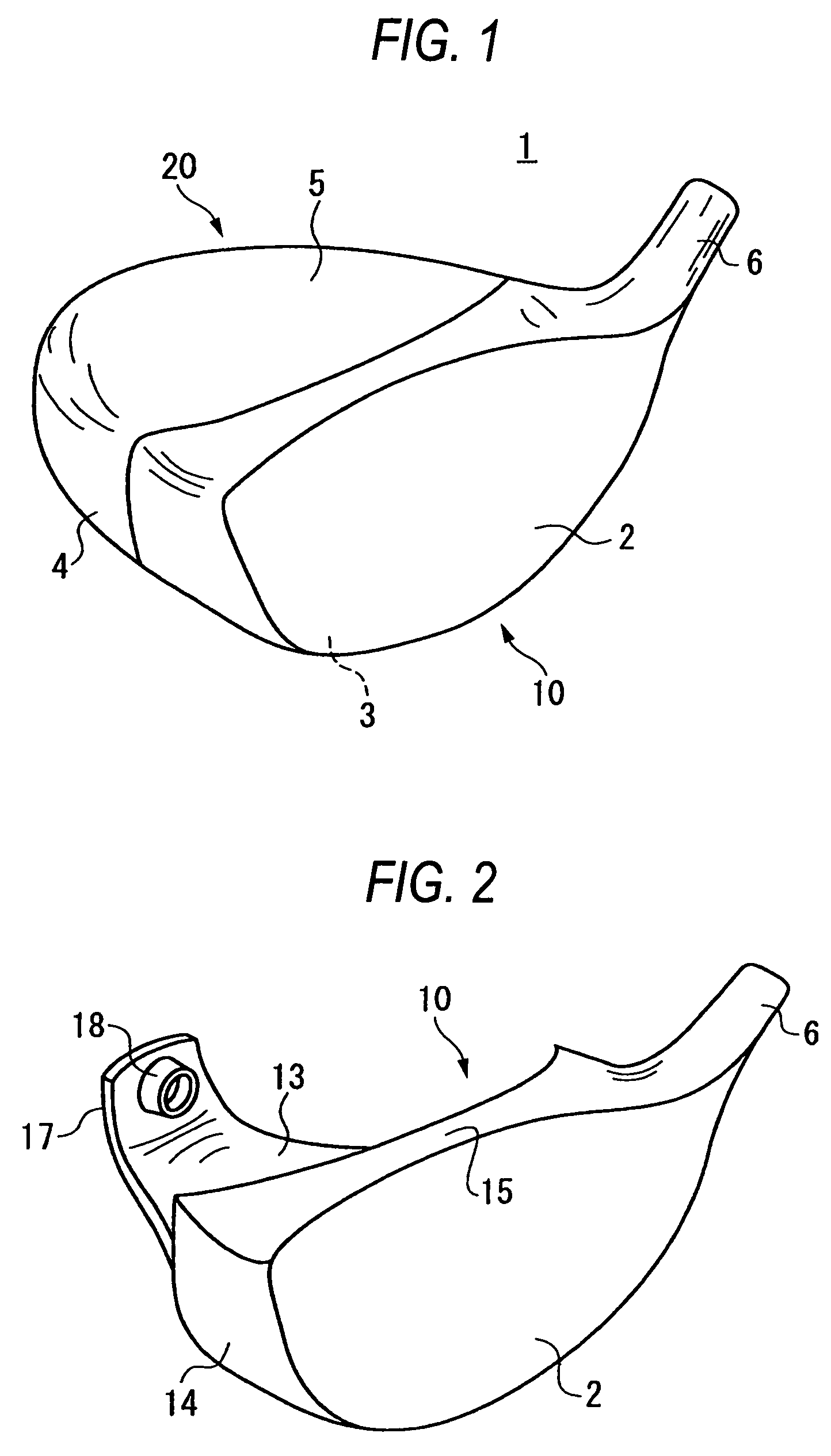

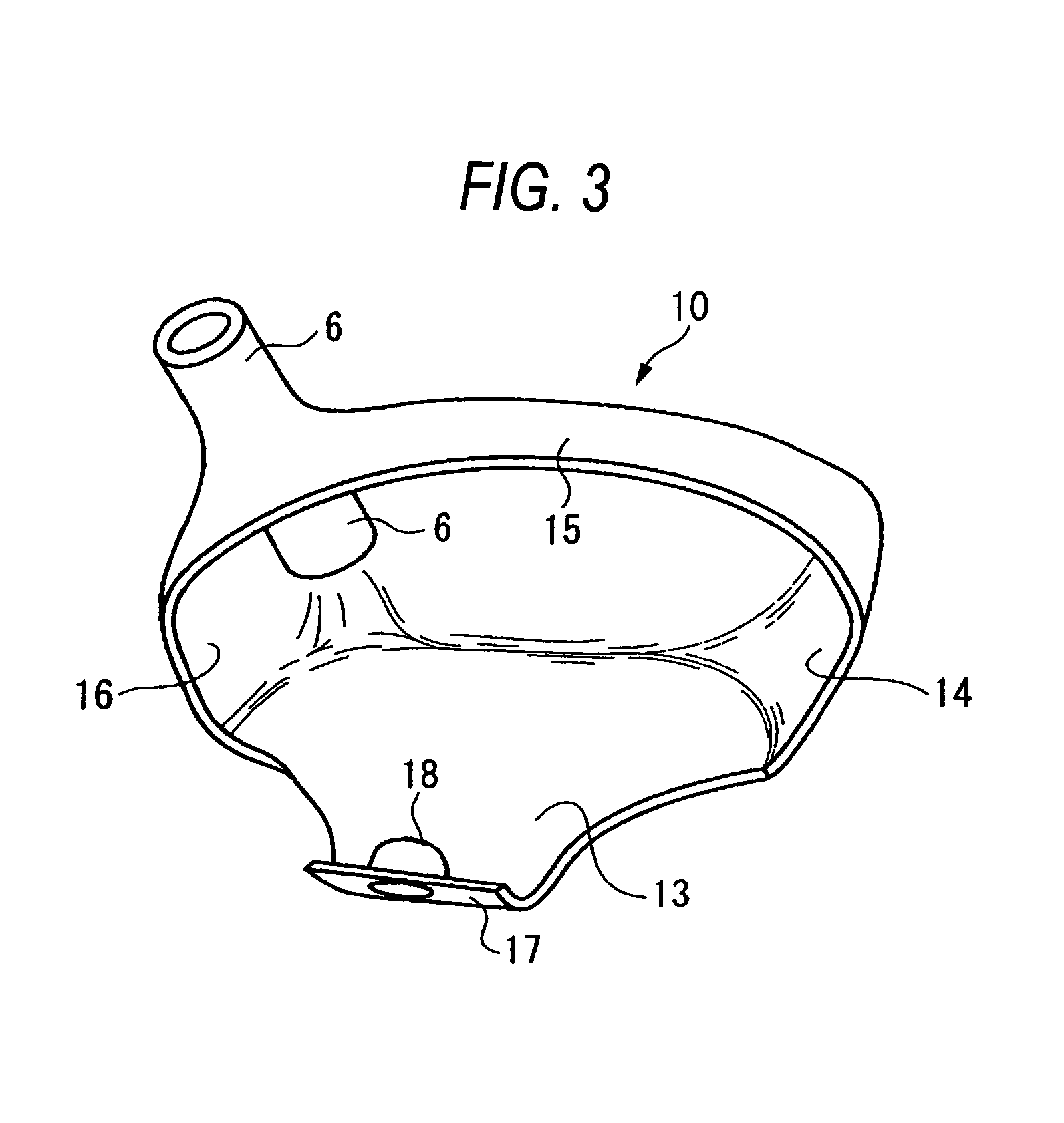

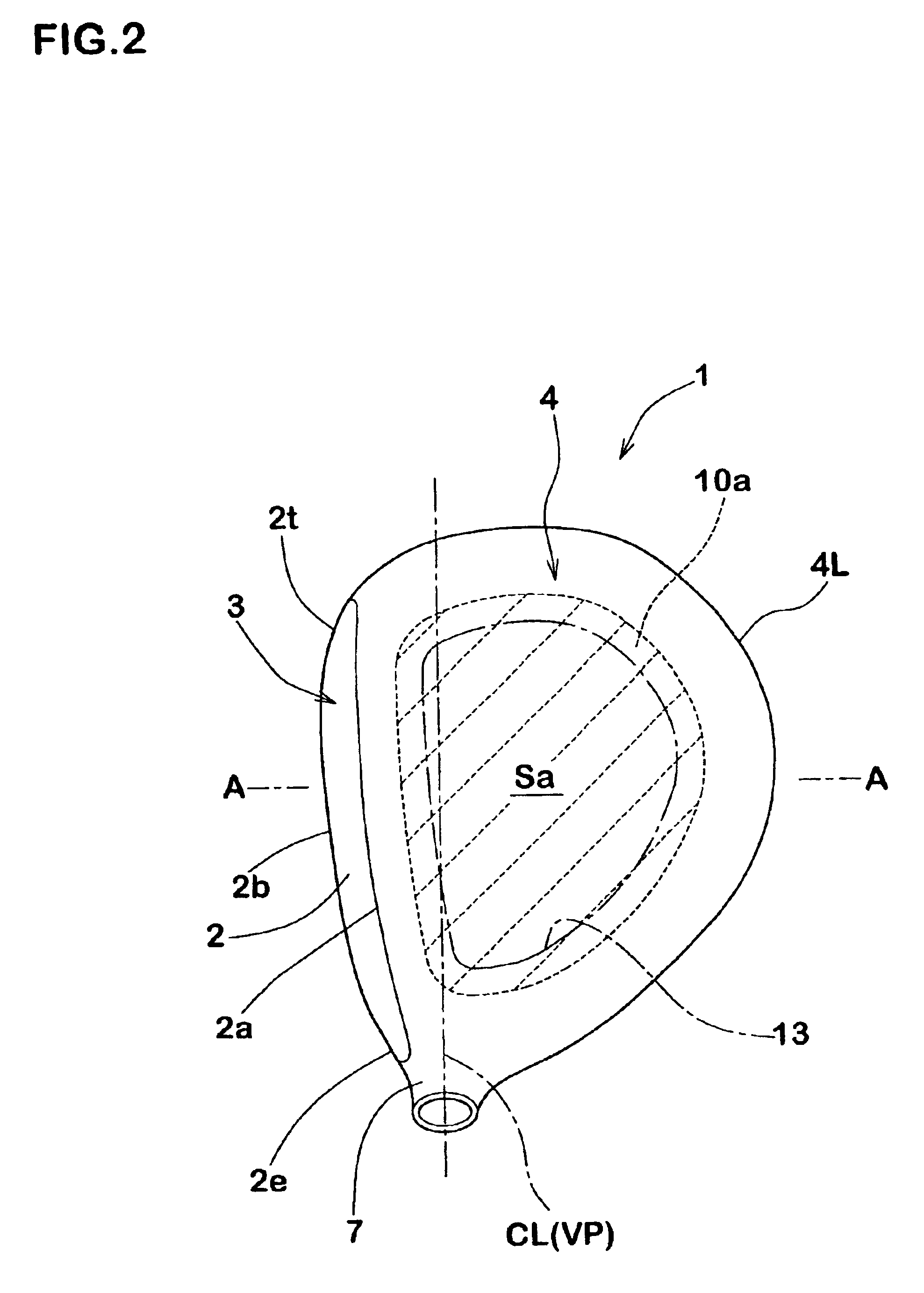

Golf club head

A golf club head made of a fiber reinforced resin, comprising: a face hitting a ball; a crown forming an upper surface of the head; a sole forming a bottom surface of the head; a side extending between the crown and the sole from an edge on a toe side of the face to an edge on a heel side through a back face; and a hosel into which a shaft is inserted, wherein the crown has a thickness of equal to or less than 2.2 mm, and includes at least partially a high elastic part made of a fiber reinforced resin reinforced by at least one kind of fiber having a tensile elasticity modulus between 380 and 900 (GPa), and the hosel is provided with a vibration absorbent having a loss tangent between 0.7 and 1.5 at a temperature of 10° C. in the vicinity thereof.

Owner:DUNLOP SPORTS CO LTD

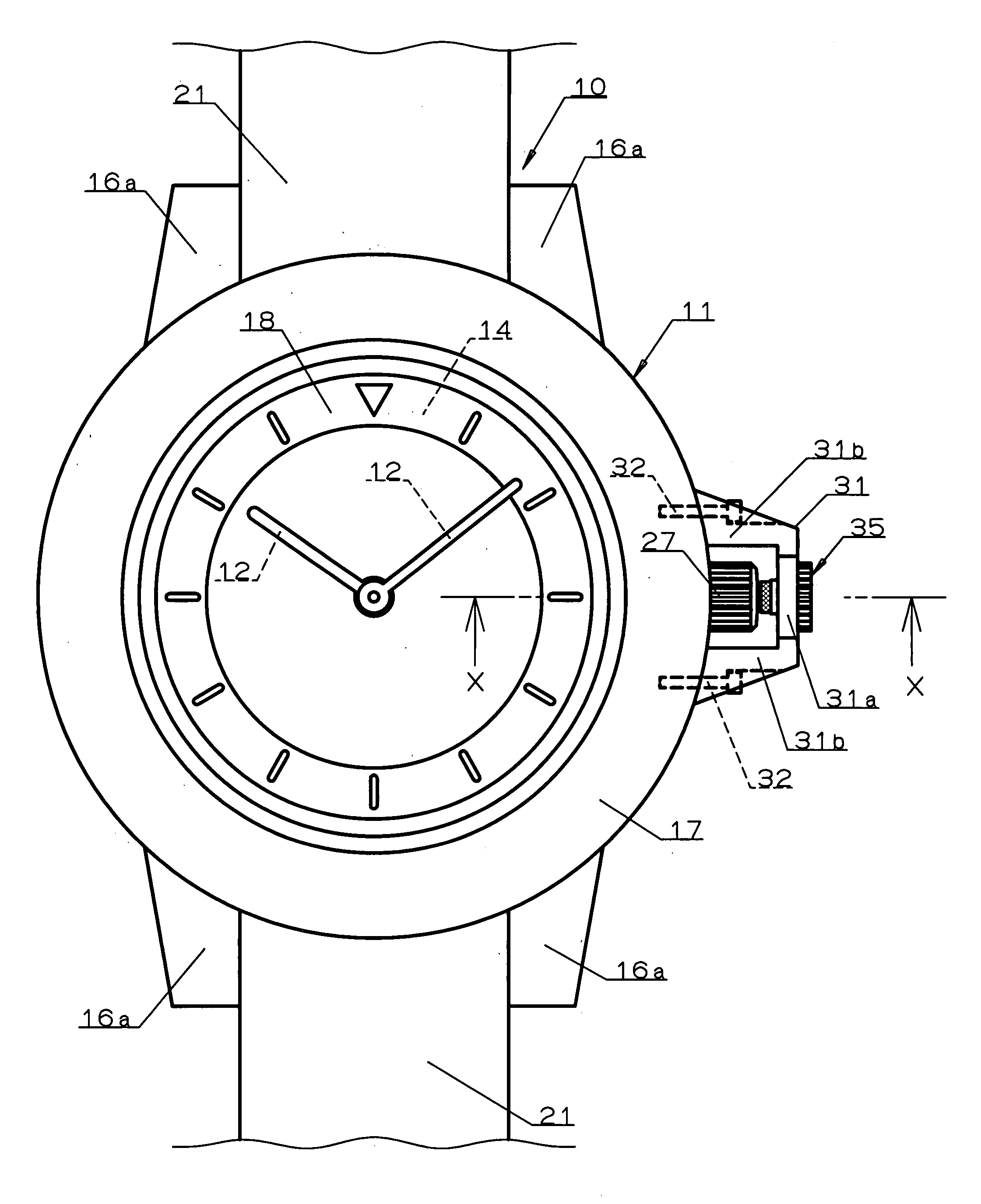

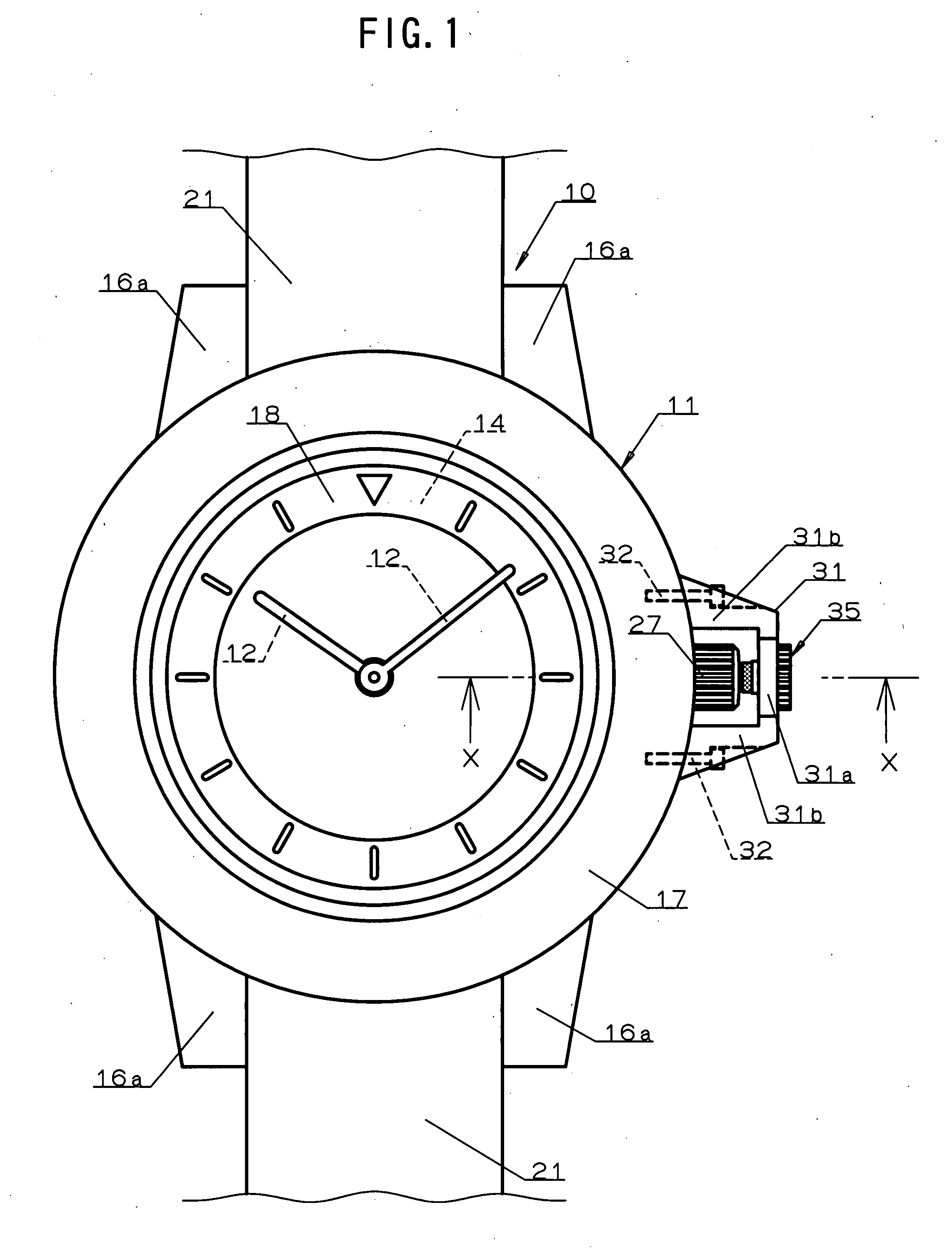

Portable timepiece

ActiveUS20080068934A1Promote recoveryEasy to changeNormal windingClockwork casesLocking mechanismEngineering

Even if a lock member impeding a crown from being excessively pull-moved is carelessly moved, its recovery is easy, and a function for stopping a careless movement of the crown, by the lock member, is maintained for a long period. A wristwatch possesses a case band, a crown, a protector, and a lock mechanism. A winding stem pipe is attached to the case band. The crown has a crown head having non connection relation with the winding stem pipe. This crown is supported to the winding stem pipe so as to be movable in an axial direction of this pipe. The protector is attached to the case band while facing on an end face of the crown head so as to allow an operation of this crown head. The lock mechanism is provided operably in the protector. The lock mechanism has a screw body, and a lock member linearly moving in a direction contacted with and separated from the end face of the crown head by a rotation of the screw body. The lock mechanism moves the lock member between a lock position allowing an operation in which the crown is pull-moved and a lock release position restricting the operation in which the crown is pull-moved.

Owner:SEIKO INSTR INC

Piston having a patterned coating and method of applying same

ActiveUS7171936B2Improve propertiesImprove the lubrication effectMolten spray coatingPlungersReciprocating motionEngineering

Owner:MAHLE TECH

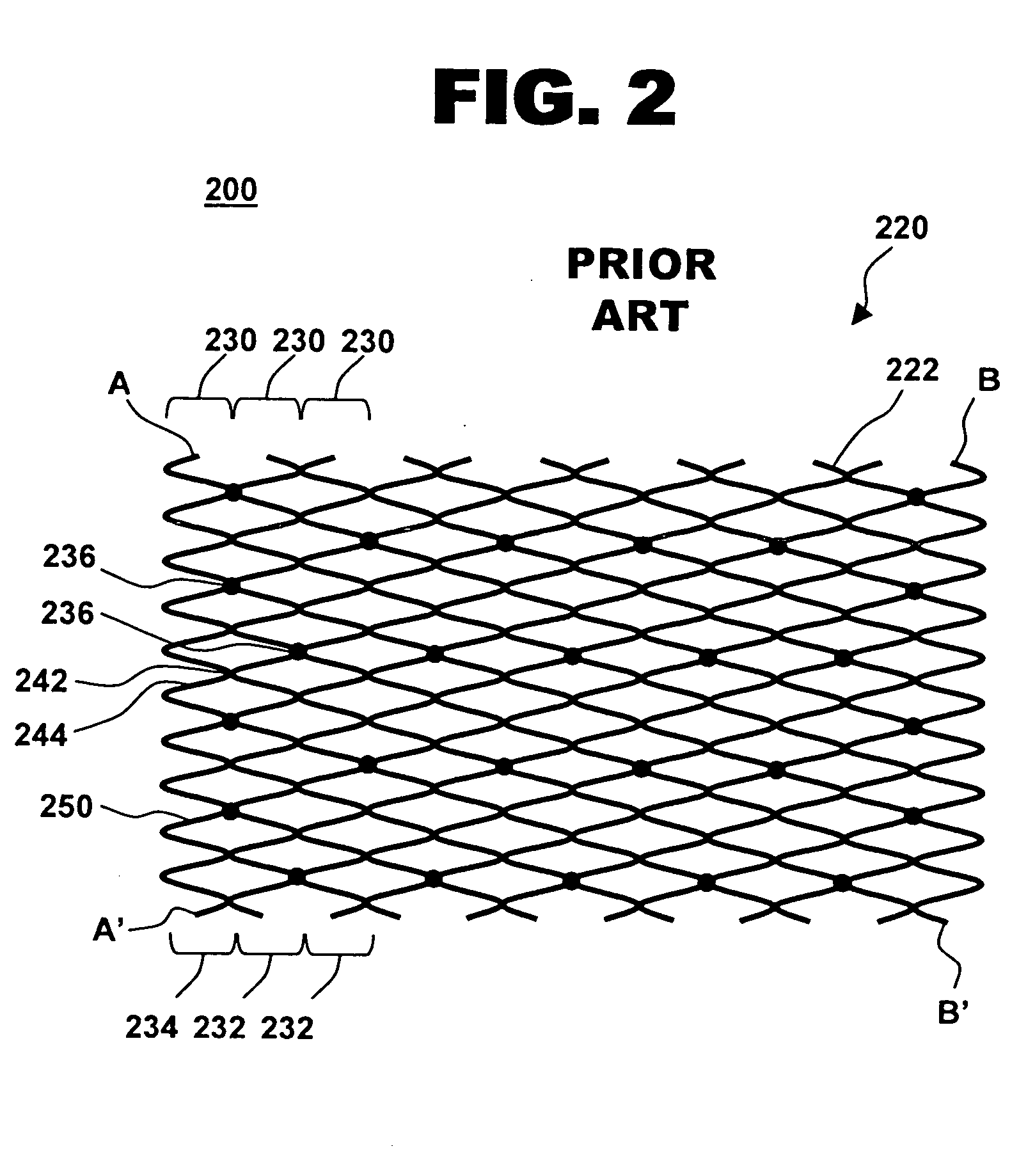

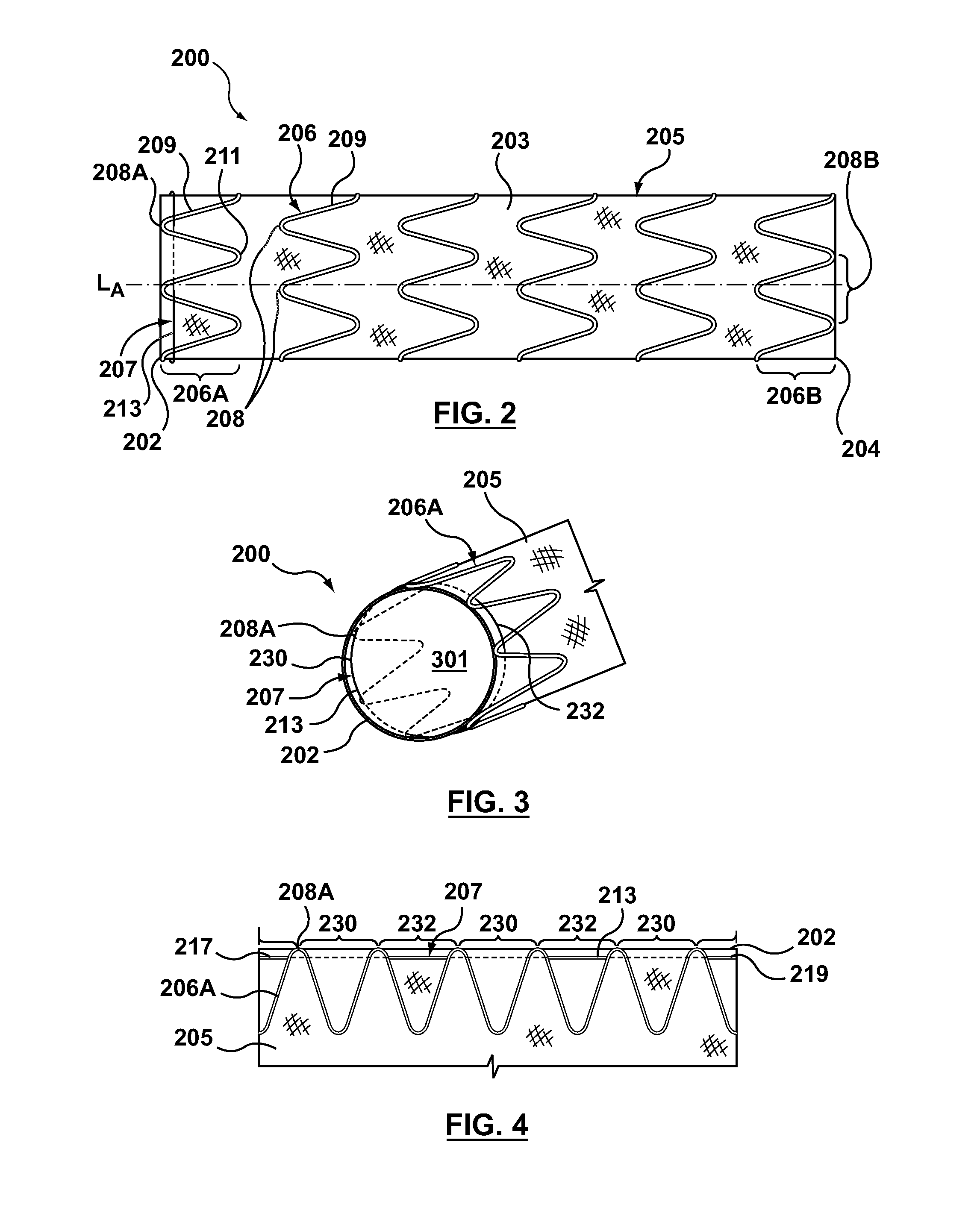

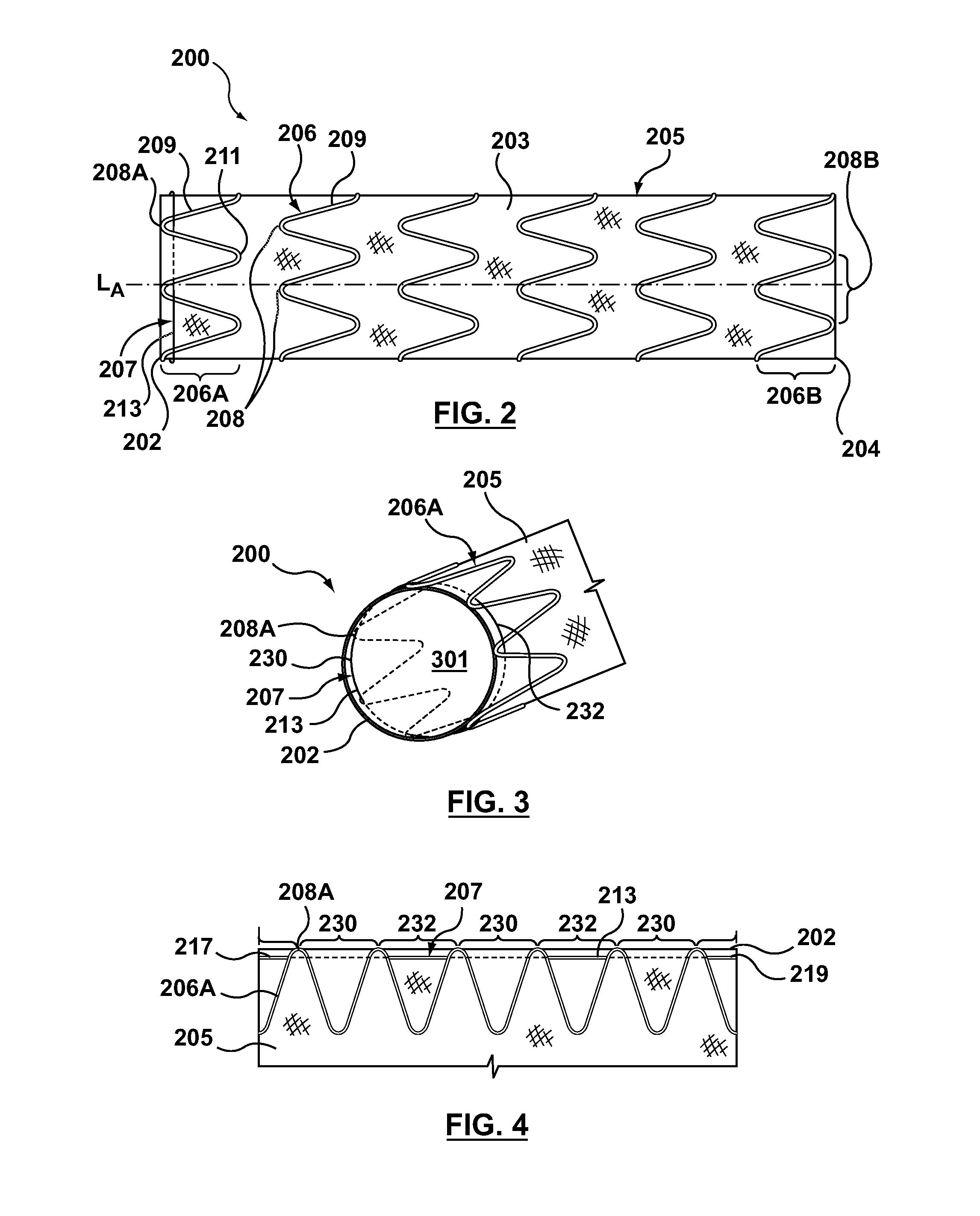

Coated stent having protruding crowns and elongated struts

The present invention provides a stent comprising a stent framework having a plurality of stent framework rings. At least one stent framework ring includes a plurality of interconnected crowns and struts with at least one protruding crown formed by two elongated struts. The protruding crowns of one stent framework ring are connected to corresponding crowns of an adjacent stent framework ring. A system for treating a vascular condition, a method of manufacturing a stent, and a method of reducing polymer bridging within a drug-polymer coated stent are also disclosed.

Owner:MEDTRONIC VASCULAR INC

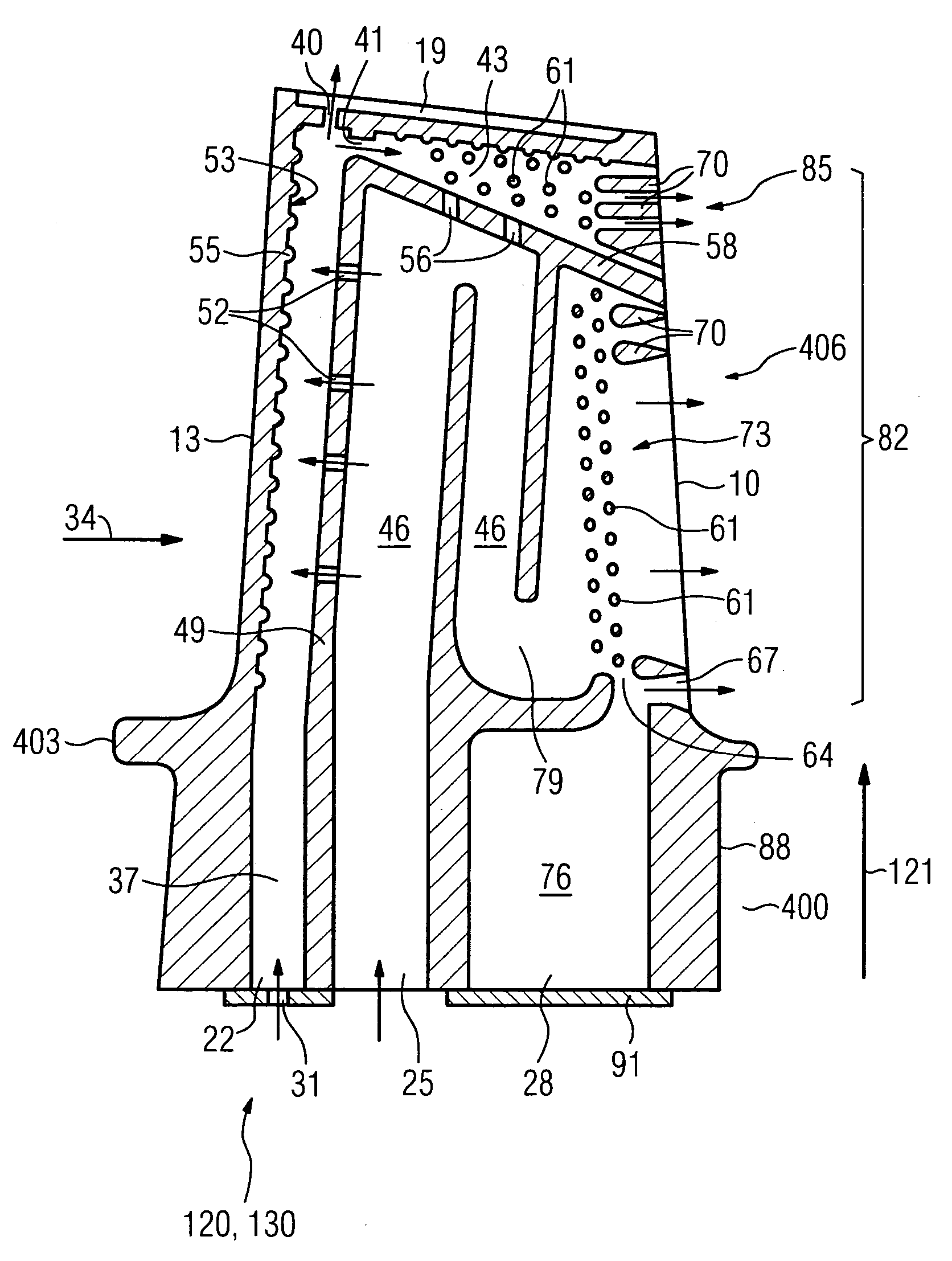

Engine piston having an insulating air gap

A piston for an internal combustion engine has an upper crown with a top and a bottom surface, and a lower crown with a top and a bottom surface. The upper crown and the lower crown are fixedly attached to each other using welds, with the bottom surface of the upper crown and the top surface of the lower crown forming a mating surface. The piston also has at least one centrally located air gap formed on the mating surface. The air gap is sealed to prevent substantial airflow into or out of the air gap.

Owner:CATERPILLAR INC

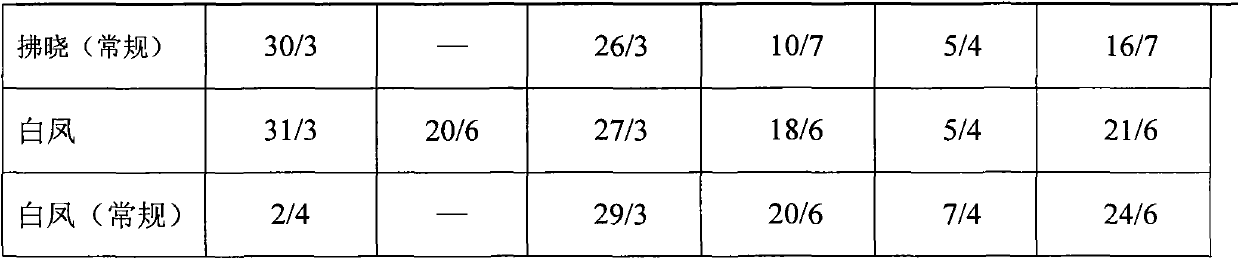

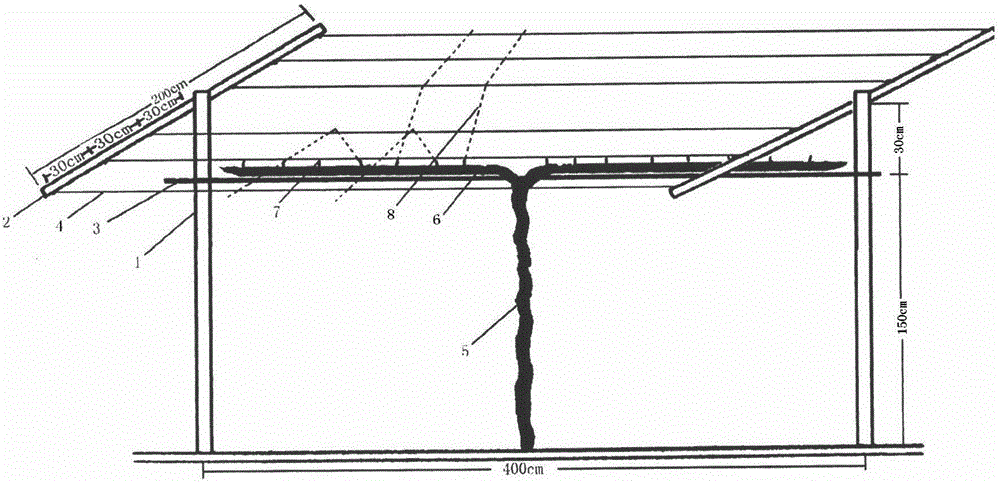

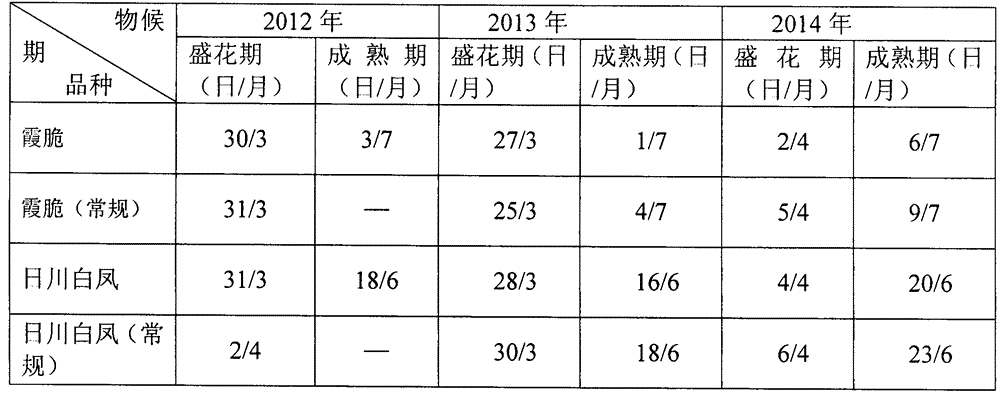

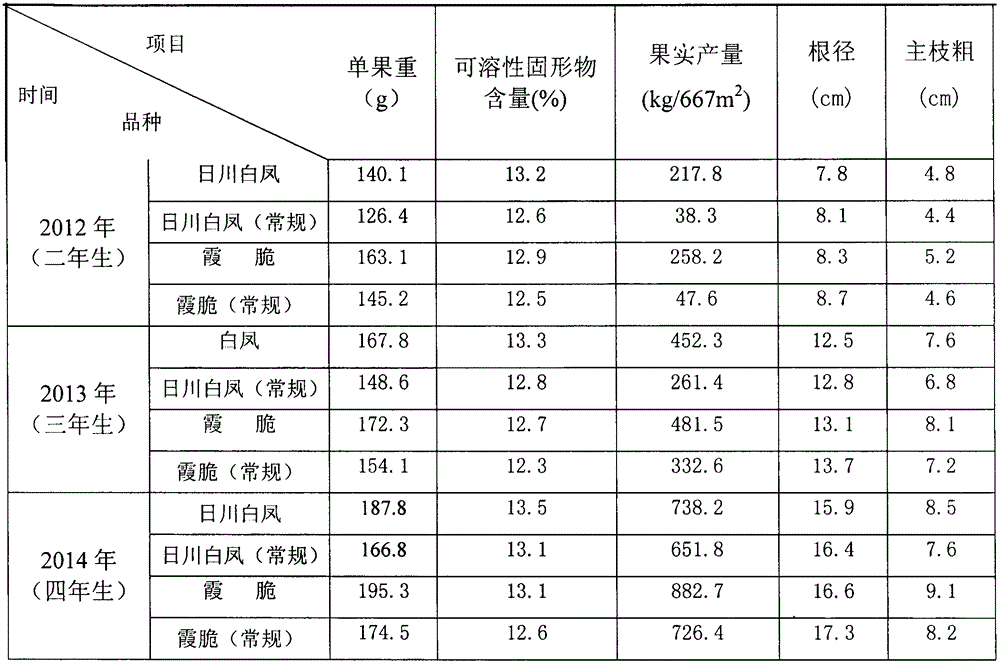

Reshaping and cultivating method for peach tree with single trunk and two main branches

ActiveCN103430804AControlling the Admin WorkspaceFast formingCultivating equipmentsEngineeringCrown form

The invention relates to a reshaping and cultivating method for a peach tree with a single trunk and two main branches. The reshaping and cultivating method specifically comprises the following steps: planting a plantlet at a 1.4m-1.6m position of the height of the trunk; selecting and remaining two strong branches or strong buds which are cultivated into two main branches reversely growing along the rows at a basal angle of 30 degrees; fixing the main braches on a horizontal shed frame when the main branches reach racking points, and inducing the extended branches of the main branches to an inducing rod which forms an 30-degree angle with the shed frame, wherein extended fruiting branch groups which are in parallel arranged and vertically extended into the rows are provided on the main branches; and gently and slowly pushing, binding and fixing the two main branches to the flat shed frame surface in autumn of the next year. The reshaping and cultivating method disclosed by the invention can be used for controlling the dryness advantages of the tree body, is quick in crown forming speed and capable of generally completing the crown structure cultivation 2 years after the planting to begin to enter into an initial fruiting period.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

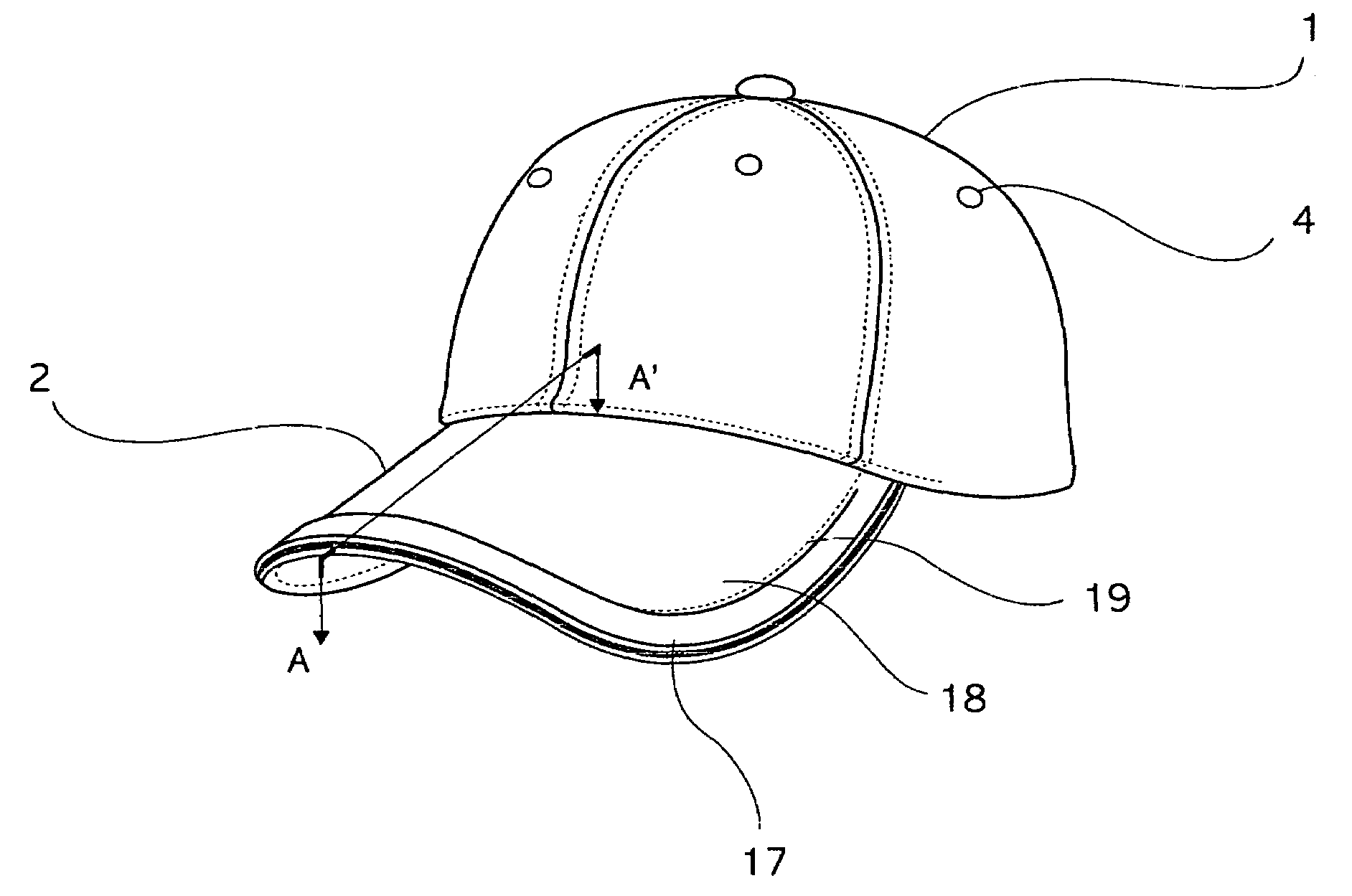

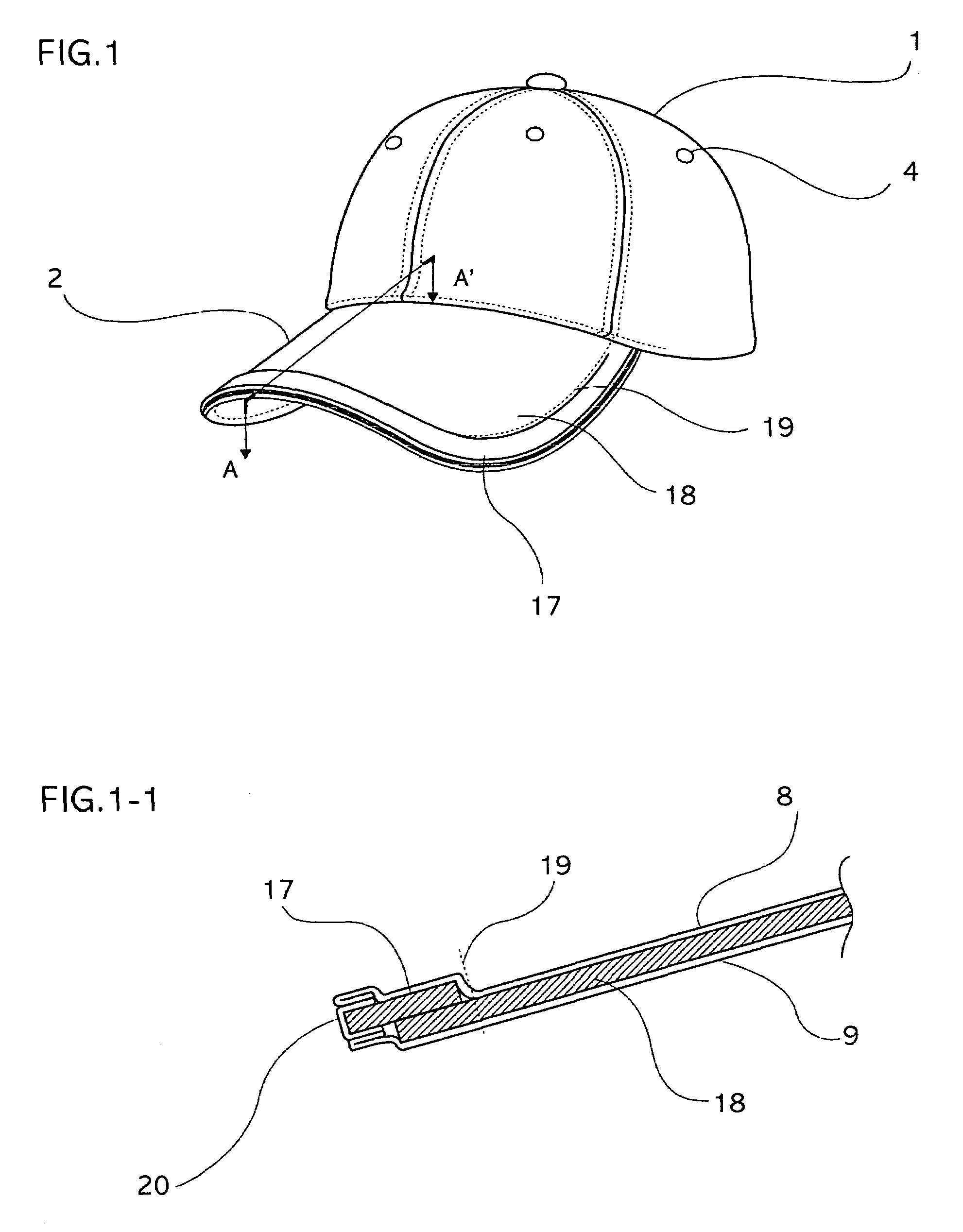

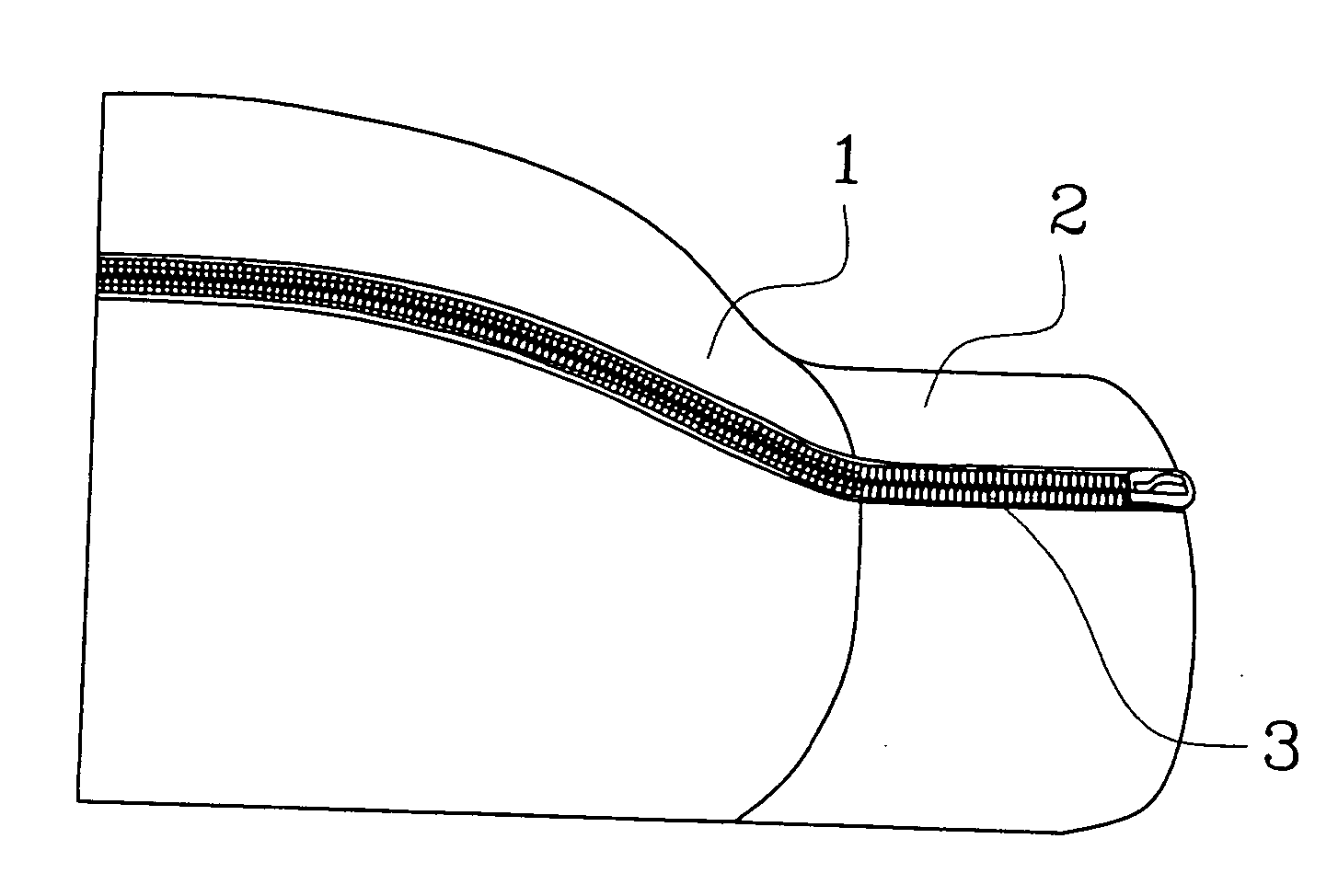

Cap with curved visor

A cap with a curved visor includes a crown formed of a plurality of panels and a visor consisted of a rigid material and inner and outer fabric panels, which covers the rigid material. The visor is secured to a front side of the crown. At least one incision line is made on the rigid material thereby creating a main portion and a strip portion, the main portion is inserted below the strip portion to retain the visor curved. The panels of crown are made out of a common woven fabric material or a stretchable fabric material. The rigid material is a flexible rigid material or a non-flexible rigid material. At least one incision line is made on the rigid material in equal distance from an outer edge of the rigid material along a periphery of the rigid material.

Owner:DADA CO LTD

Thermally insulated steel piston crown and method of making using a ceramic coating

A piston for a diesel engine is provided. The piston includes a thermal barrier coating applied to a crown formed of steel. A layer of a metal bond material is first applied to a combustion surface of the crown, followed by a gradient structure including a mixture of the metal bond material and a ceramic material, followed by a layer of the ceramic material. The ceramic material includes at least one of ceria, ceria stabilized zirconia, yttria stabilized zirconia, calcia stabilized zirconia, magnesia stabilized zirconia, and zirconia stabilized by another oxide. The thermal barrier coating is applied by a thermal spray process or HVOF. The thermal barrier coating has a porosity of 2% by vol. to 25% vol., based on the total volume of the thermal barrier coating, a thickness of less than 1 mm, and a thermal conductivity of less than 1.00 W / m·K.

Owner:TENNECO

Steel piston crown and/or combustion engine components with dynamic thermal insulation coating and method of making and using such a coating

ActiveUS20180128166A1Improved thermal barrier coatingMolten spray coatingMachines/enginesThermal insulationInternal combustion engine

A piston for an internal combustion engine is provided. The piston includes a thermal barrier coating applied to a crown formed of steel. According to one embodiment, a bond layer of a metal is applied to a combustion surface of the crown, followed by a mixed layer of metal and ceramic with a gradient structure, and then optionally a top layer of metal. The thermal barrier coating can also include a ceramic layer between the mixed layer and top layer, or as the outermost layer. The ceramic includes at least one of ceria, ceria stabilized zirconia, yttria, yttria stabilized zirconia, calcia stabilized zirconia, magnesia stabilized zirconia, and zirconia stabilized by another oxide. The thermal barrier coating is applied by thermal spray, HVOF, or wire arc spraying. The thermal barrier coating preferably has a thickness less than 200 microns and a surface roughness Ra of not greater than 3 microns.

Owner:TENNECO

Rolling bearing and bearing unit

In a bearing apparatus which is composed of two bearings each including a crown-shaped retainer and in which a lubricant is filled into its raceways, a preload is applied from the retainer pocket-opening side end face of an inner ring, and also a preload is applied from the retainer counter-pocket-opening side end face of an outer ring.

Owner:NSK LTD

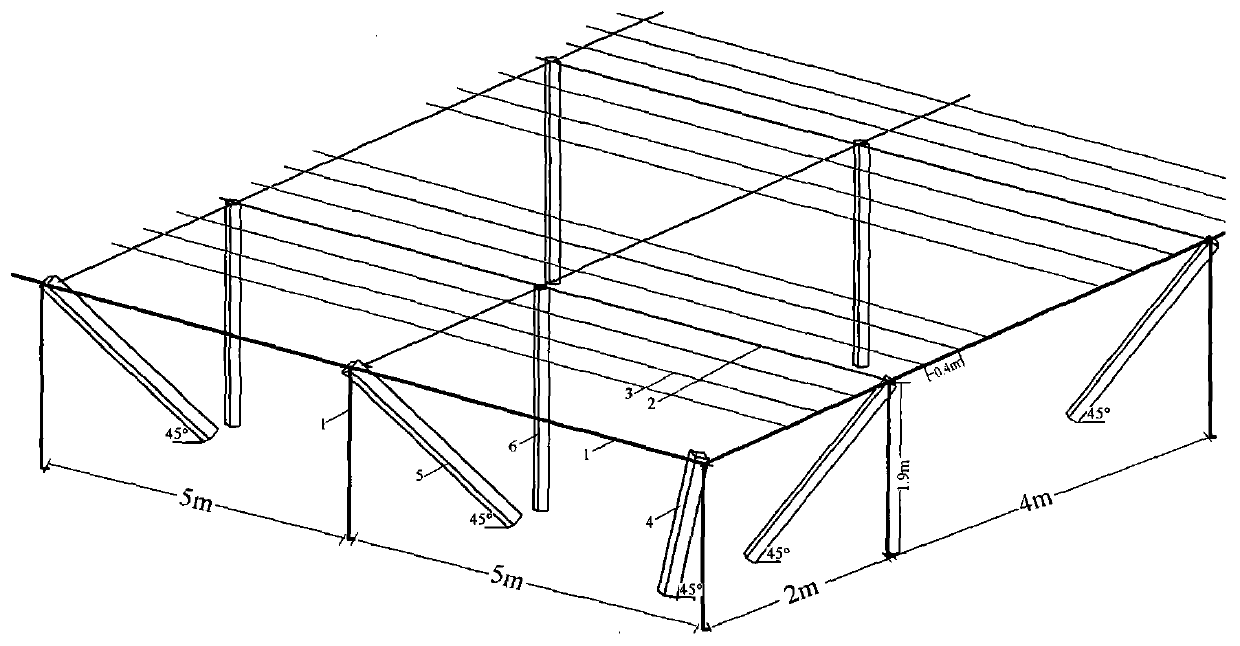

High-quality labor-saving shaping cultivation method for peach tree

InactiveCN105009910AControlling the Admin WorkspaceFast formingCultivating equipmentsHorticultureMain branchShoot

The invention relates to a high-quality labor-saving shaping cultivation method for a peach tree. The method specifically comprises the steps that after field planting is carried out, two strong branches or strong shoots are selected at the position 1.2-1.3 m high of a trunk of a seedling and cultivated into two main branches growing in opposite directions, wherein a base angle of 45 degrees is formed between the two main branches; a frame structure suitable for labor-saving shaping is put up, a cross arm 2 m long is horizontally erected at the upper end of each stand column 1.8 m high from the ground, six pull wires are arranged between the two sides of the cross arms in a pulled mode, a main pull wire is arranged between the positions, 30 cm below the cross arms, of the stand columns in a pulled mode, and the six pull wires and the main pull wire form a frame face together. When reaching the main pull wire, the main branches are fixed to the main pull wire, extending branches of the main branches are lured to luring rods forming a 45-degree angle relative to the main pull wire, and in autumn, the two main branches are pressed downward slowly to be tied and fixed to the main pull wire. According to the method, the branch advantage of a tree body can be controlled, a crown forms fast, crown structure cultivation can be finished in two years generally after the field planting is carried out, and then the tree begins to enter the primary fruit stage.

Owner:句容市白兔镇白枝山生态果园

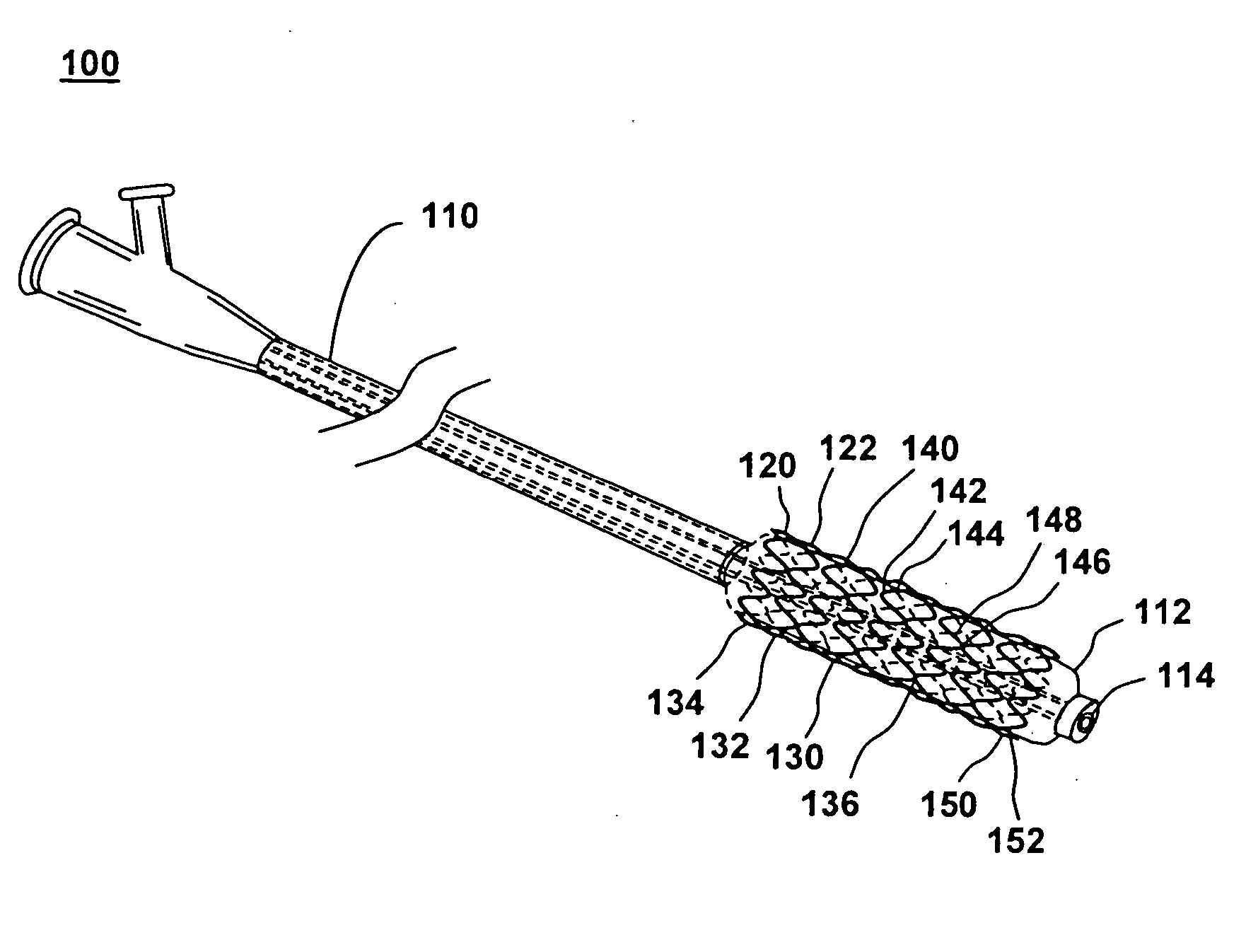

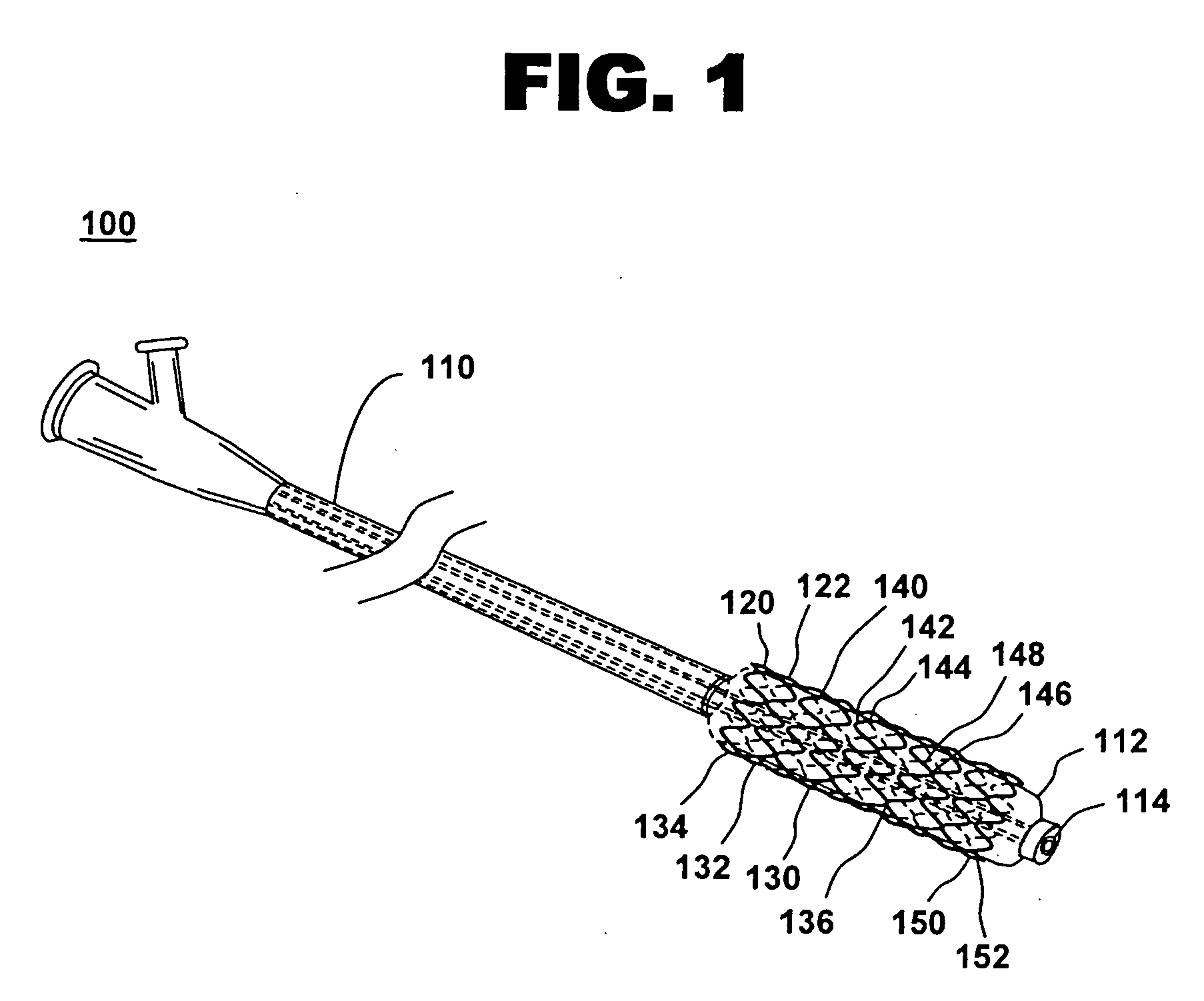

Dental crown forms and methods

Dental crown forms and methods of using them are disclosed. The dental crown forms may include one or more of the following features: a handle attached to the dental crown form at a location removed from the base of the dental crown form; a vented handle through which excess amounts of hardenable dental material can pass during placement of the crown form; and one or more lines of weakness that may be separated to remove a dental crown form from hardenable dental material after placement of the filled crown form. The dental crown forms may also be located in packages with hardenable dental material located within the dental crown forms as packaged.

Owner:3M INNOVATIVE PROPERTIES CO

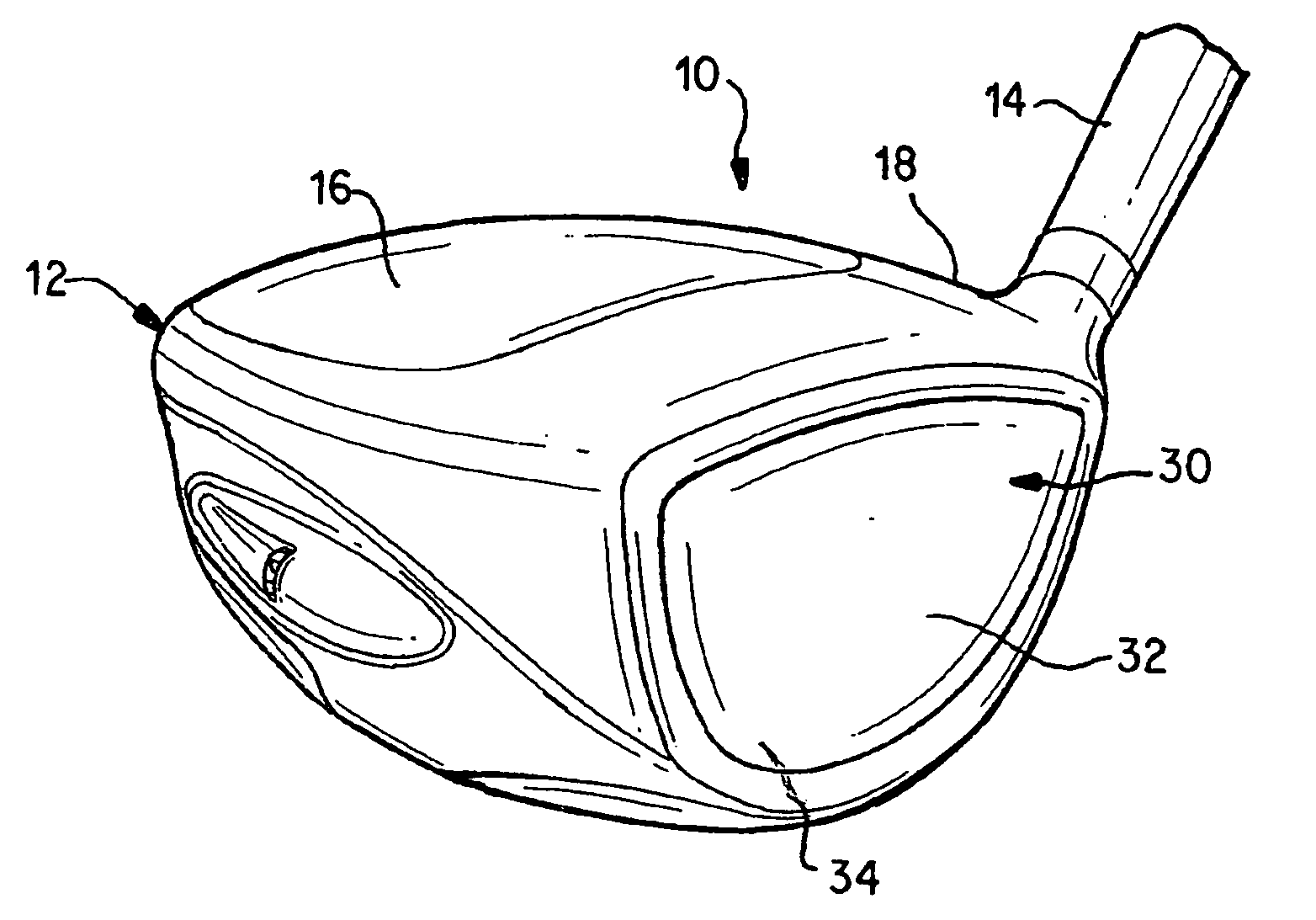

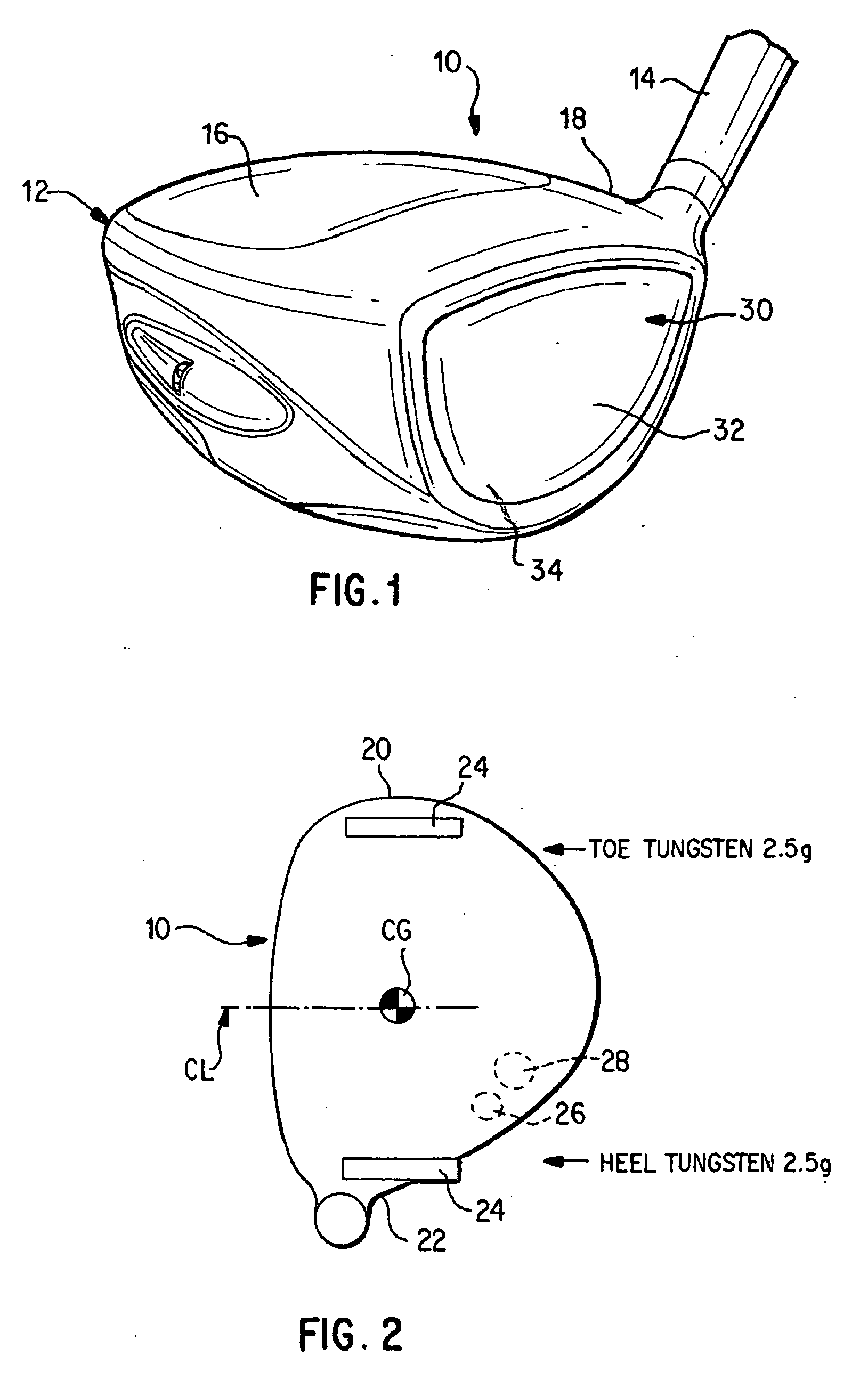

Golf driver having titanium alloy head and flexible shaft

A golf driver has a head which includes an alpha-beta titanium alloy body and a crown formed of a beta titanium plate which is thinner than the body and brazed to the body. The face of the club head comprises a variable-thickness beta titanium faceplate that is plasma welded to the body. Heat generated during the plasma welding causes the thin border region of the faceplate to become even more flexible to enhance the spacing action of the faceplate. Two weights are attached at the toe and heel, respectively, of the body to minimize twisting of the body during an off-center hit. Two additional weights are disposed in the sole of the body in locations causing the center of gravity to be displaced toward the heel and the back side of the club head. A graphite shaft of the driver has at least four sections of different stiffness, defining three bending points, to increase the flex action of the shaft and enable an oversized driver to return to an address position at the moment of impact.

Owner:MACGREGOR GOLF

Production method of precise tapered roller

InactiveCN103821828AHigh precisionRaise the potentialBearing componentsGround rollerSurface roughness

The invention discloses a production method of a precise tapered roller. The method comprises the following steps: 1, preprocessing: carrying out cold heading processing of light tensioned steel wires to form a roller blank; 2, soft buffing processing: carrying out soft buffing of the external diameter of the roller blank, carrying out two-step grinding processing on two centerless grinders, and carrying out soft buffing of the end surfaces of the roller blank; 3, heat treatment and hard grinding: carrying out hard grinding of the external diameter of the surface processed roller on a centerless grinder; 4, base surface: carrying out spherical base surface processing of the fine ground roller on a spherical base grinder; 5, fine finishing: carrying out final grinding of the external diameter on the centerless grinder; and 6, superfinishing: carrying out superfine crown processing of the fine finished roller to obtain the finished tapered roller. A detection result shows that all indexes of the tapered roller obtained in the invention can stably reach national standard (GB / T25767-2010) II level standards, and the rolling surface roughness, the spherical base surface jumping SDW and the circularity of the tapered roller can reach national standard I level standards, and the bus of the external diameter of the roller has a crown form.

Owner:SHANDONG DONGE STEEL BALL GRP

Ring on a closed web stent-graft for use in tip capture

Owner:MEDTRONIC VASCULAR INC

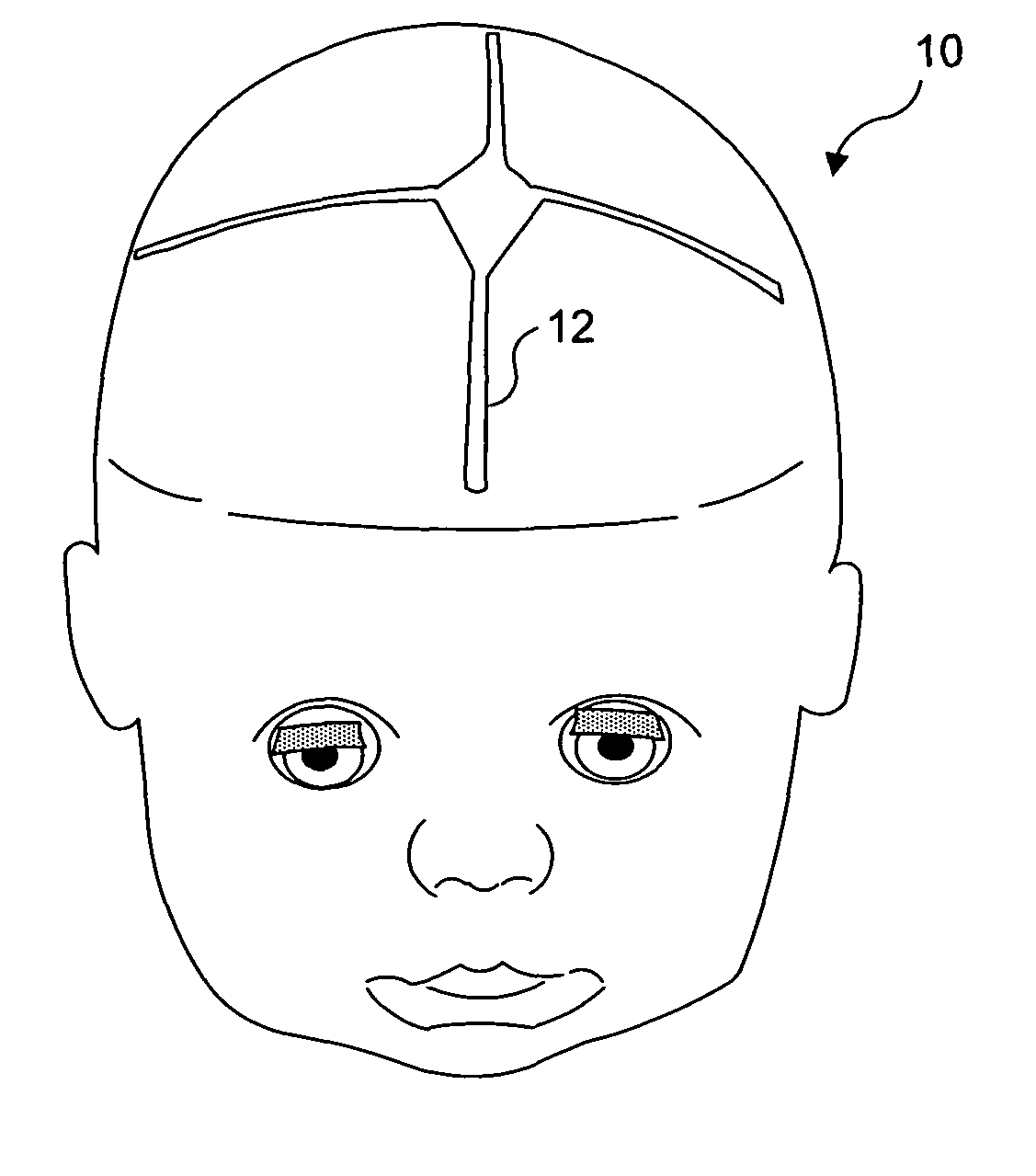

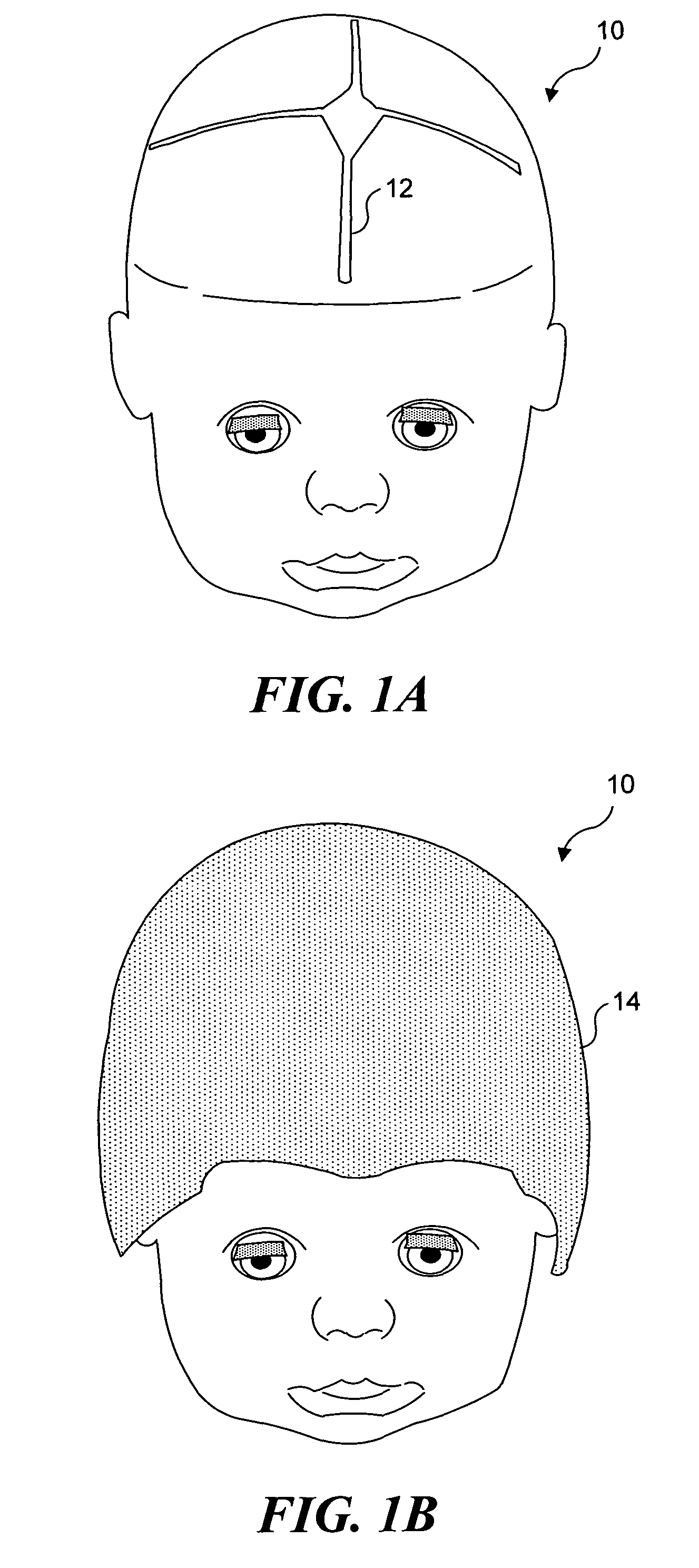

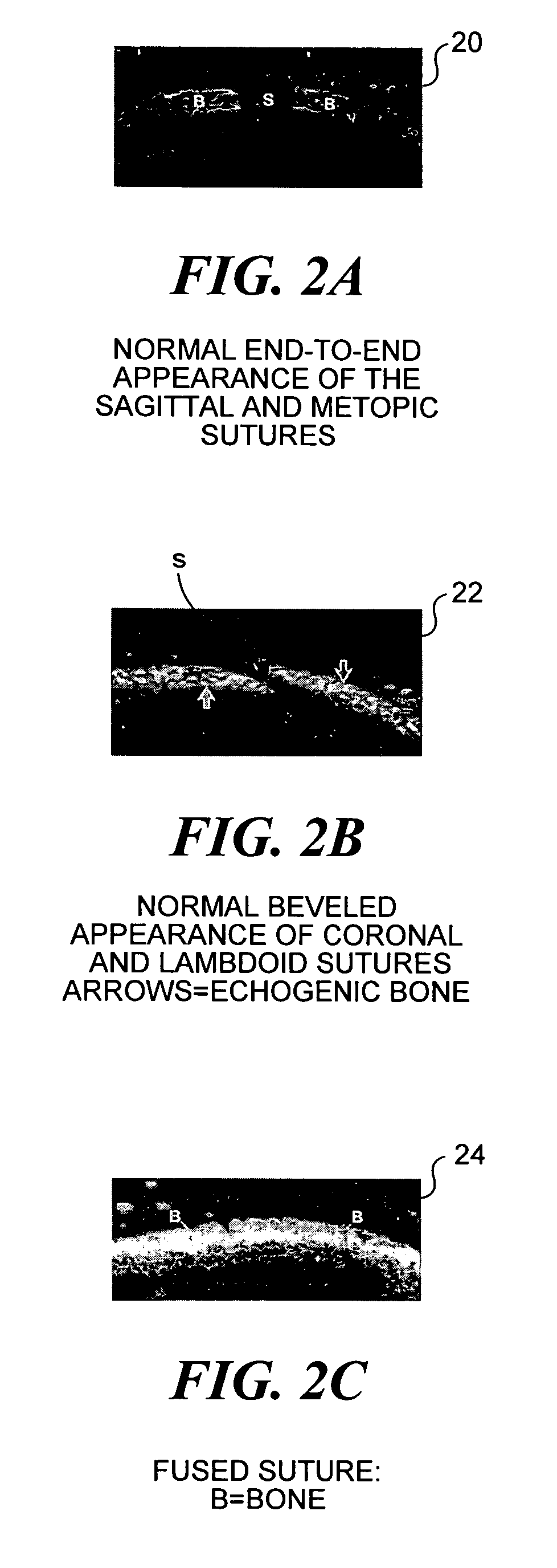

Ultrasound simulator for craniosynostosis screening

InactiveUS7731499B2Easy to distinguishDecrease echogenicityEducational modelsUltrasound imagingSonification

An ultrasound simulator to train radiologists and technologists to locate and recognize patent and fused cranial sutures. The model is formed, for example, using specially fabricated heads or from life-sized plastic doll heads. Simulated suture lines are cut in the heads in anatomically correct positions. The typical end-to-end morphology of the sagittal and metopic sutures and the typical beveled appearance of the paired coronal and lambdoid sutures are created by angling the cutting blade. The hypoechoic appearance of patent sutures in ultrasound images is simulated by filling the gaps that were formed by cutting with a hypoechoic material. Fused echoic sutures are simulated by leaving that portion of the doll's head uncut, or by filling the openings with an echoic material. When imaged using ultrasound, the portions cut and filled with a hypoechoic material are readily distinguishable from uncut portions, and from portions cut and filled with an echoic material.

Owner:UNIV OF WASHINGTON

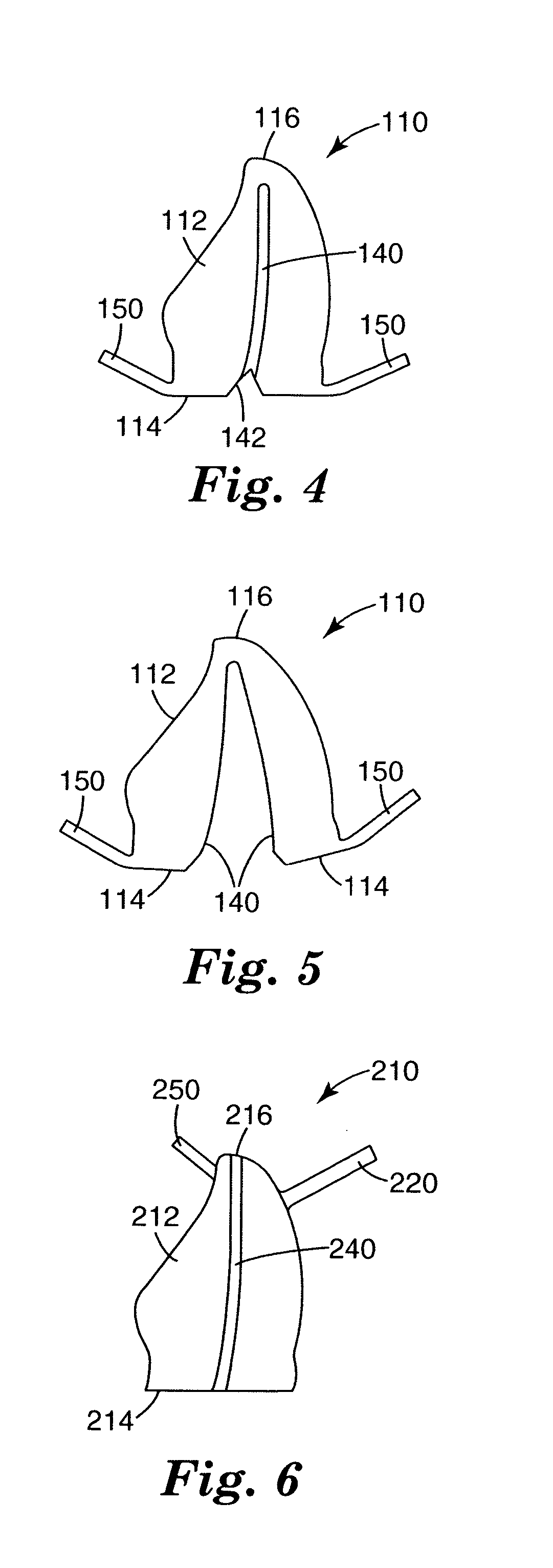

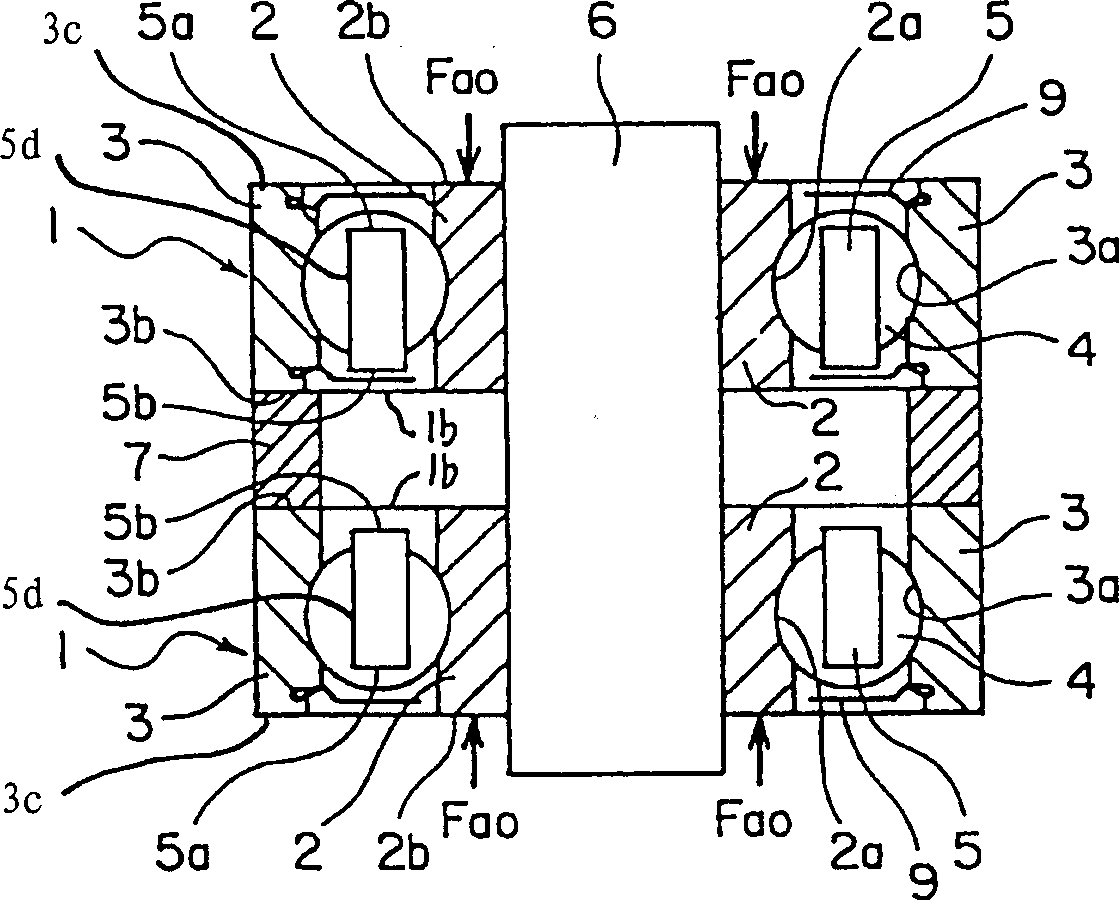

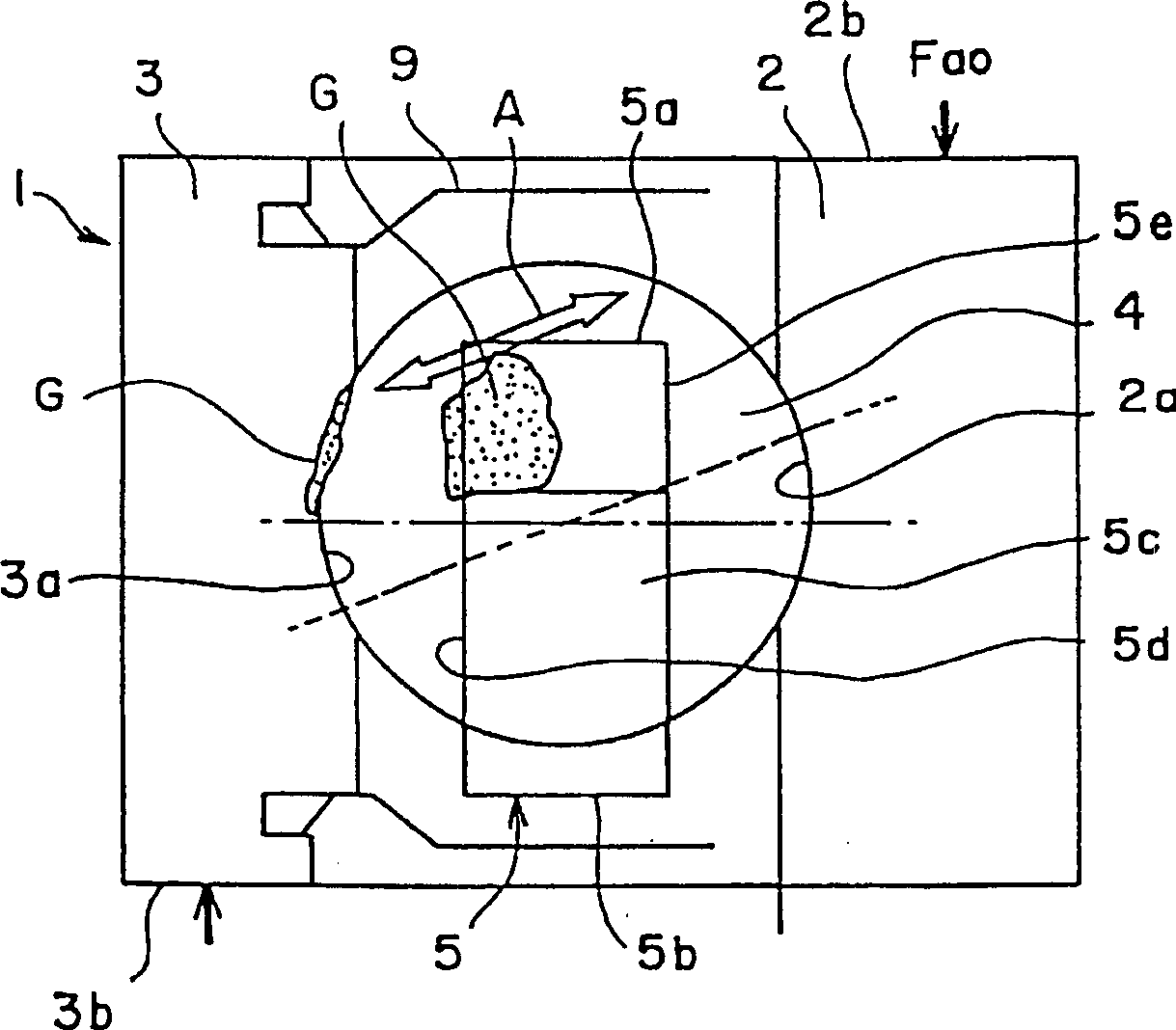

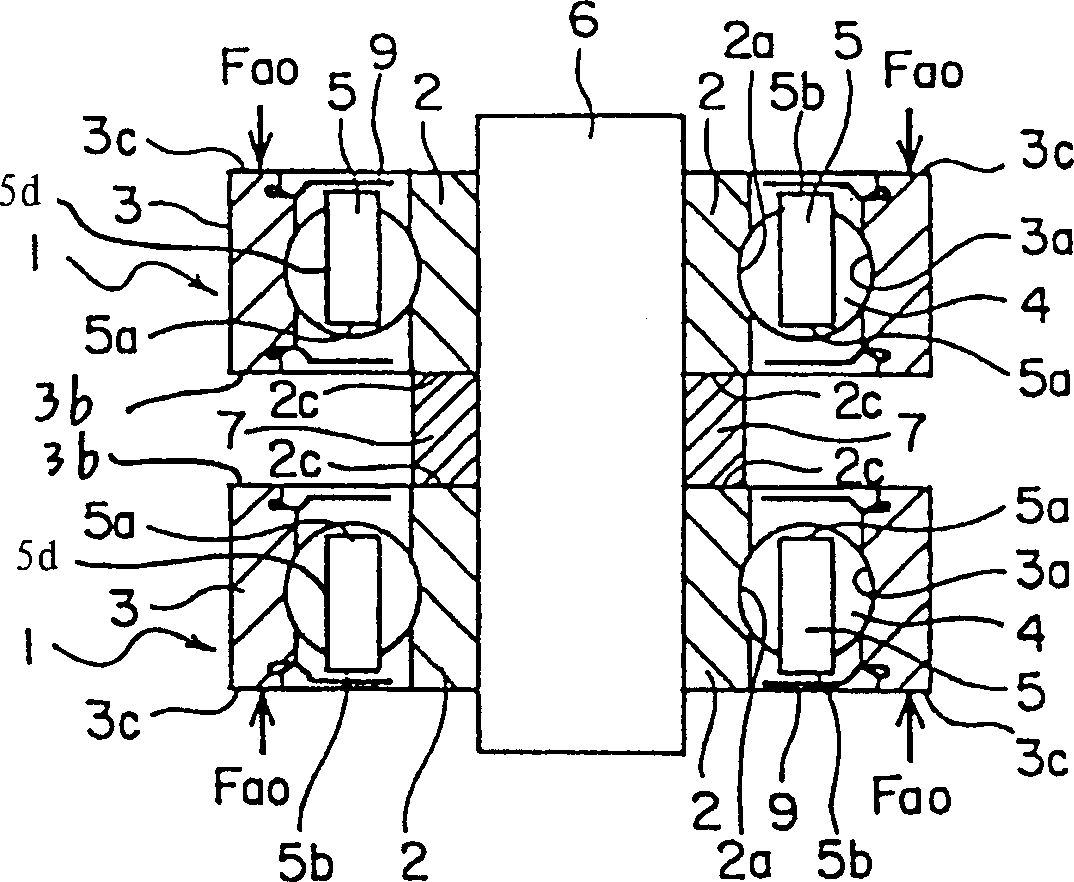

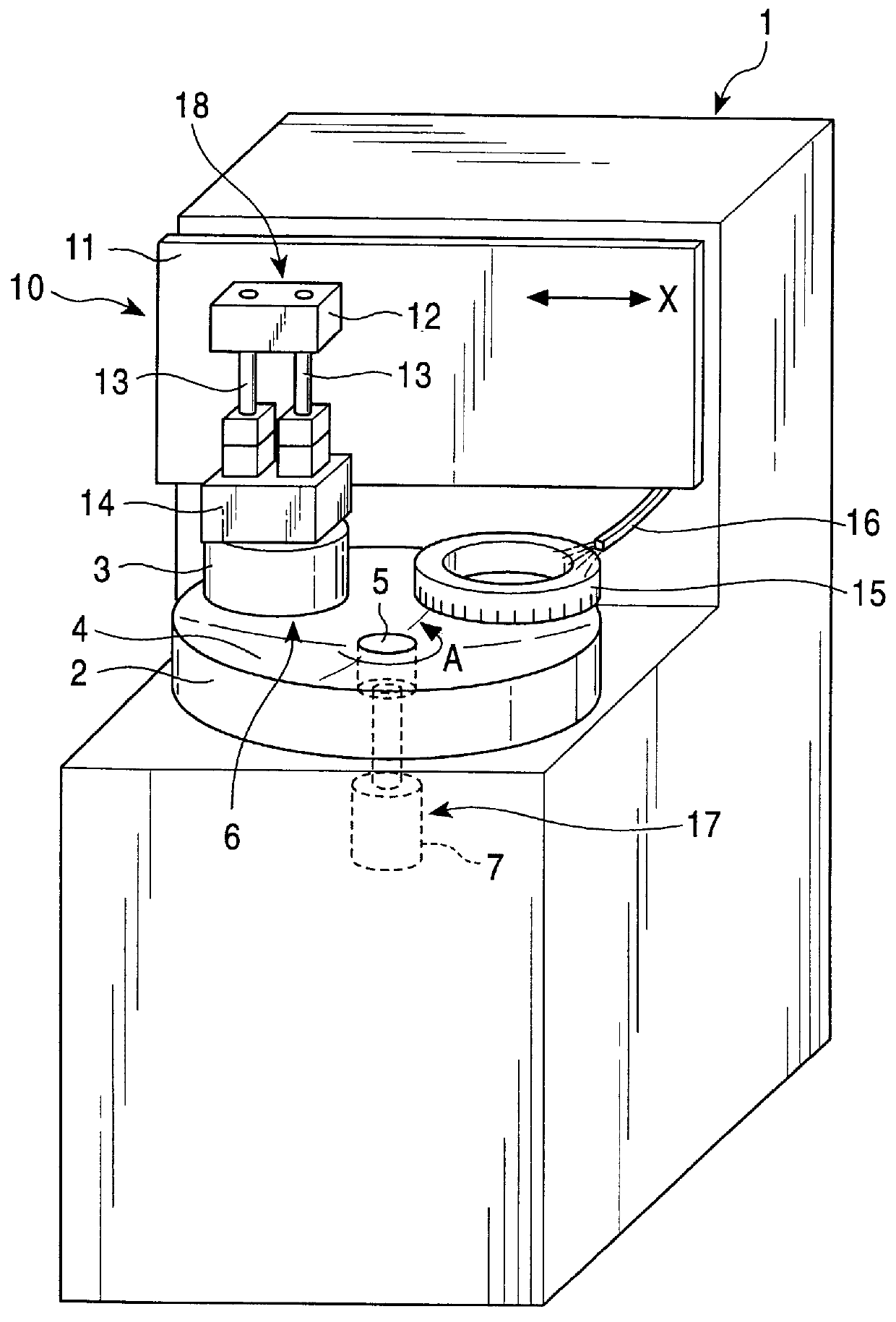

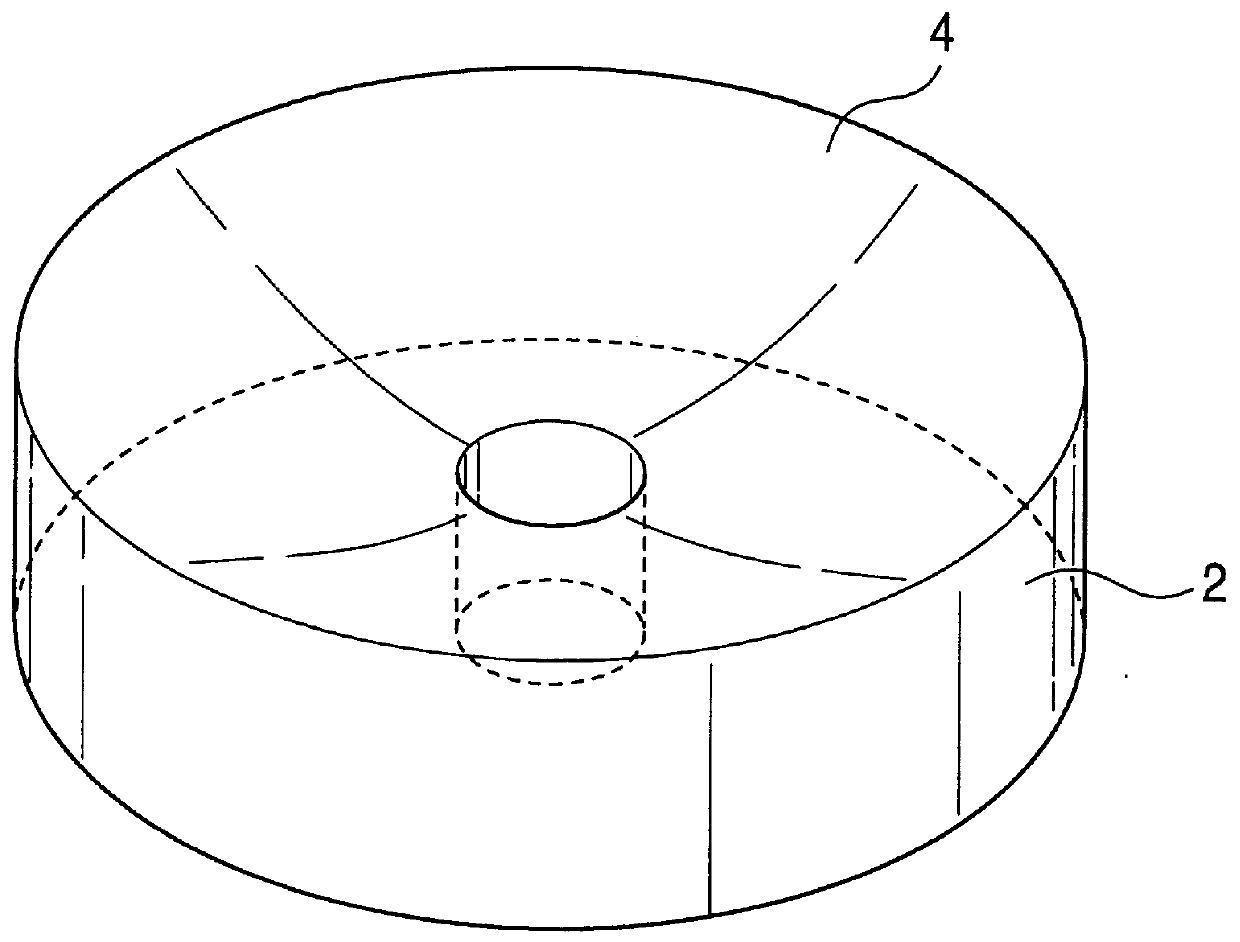

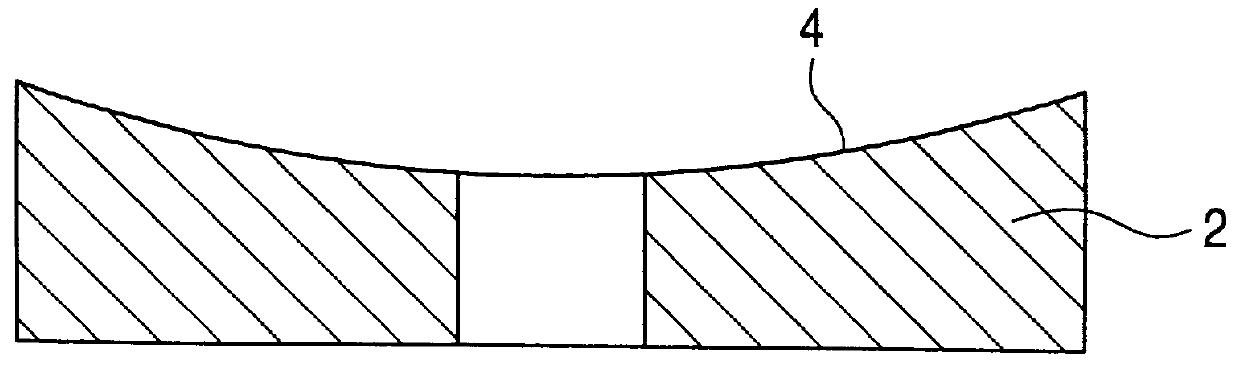

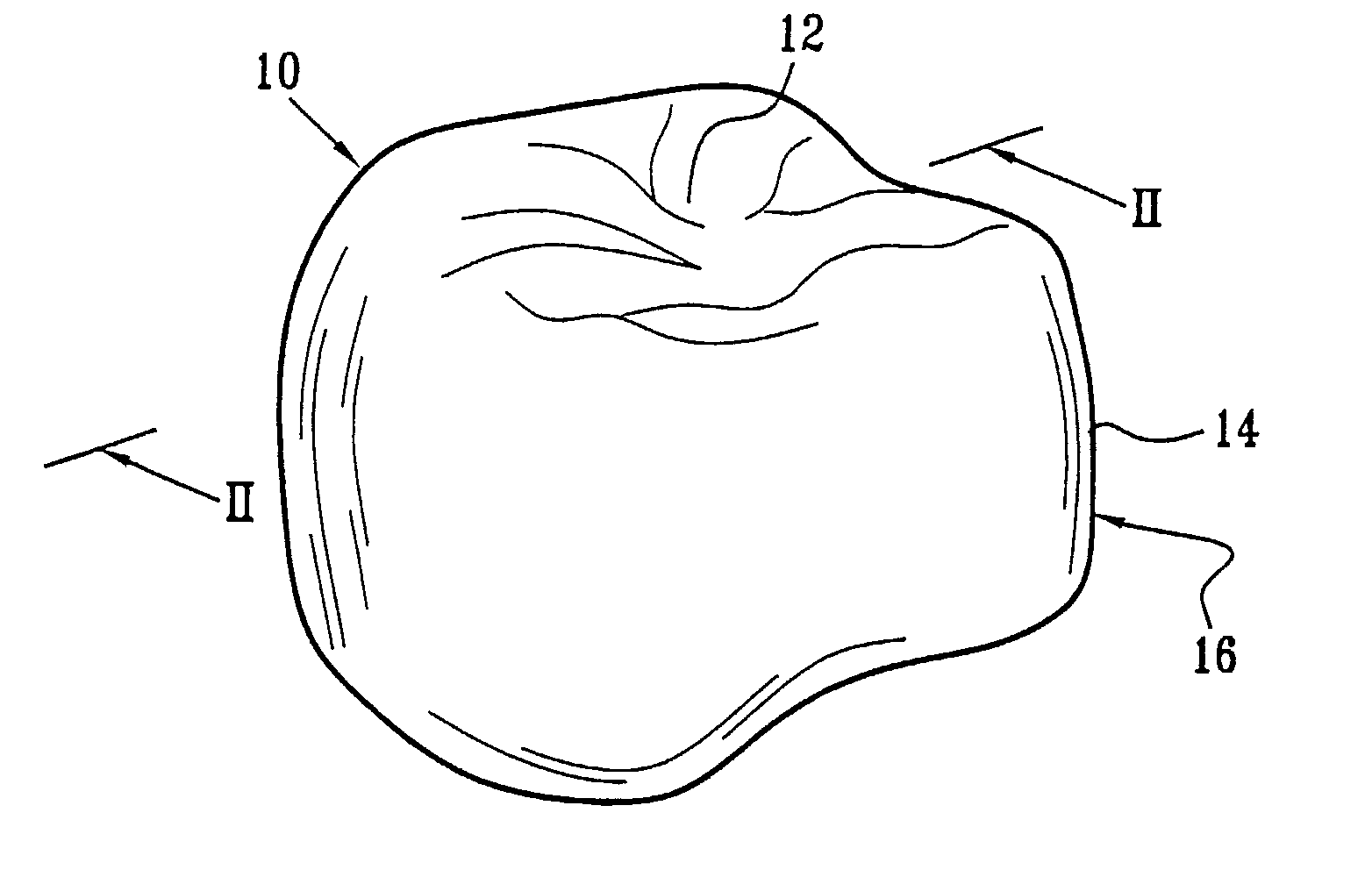

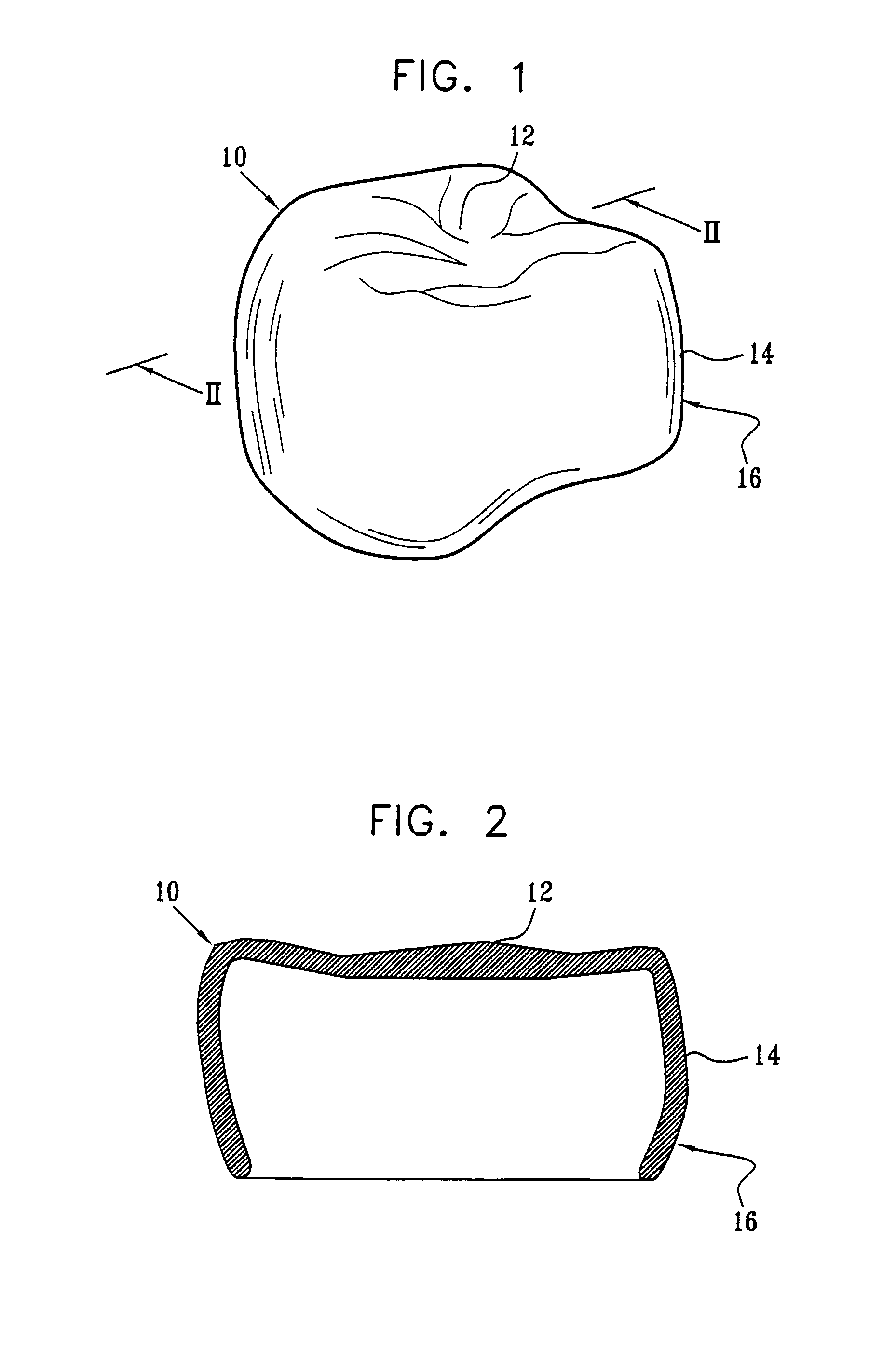

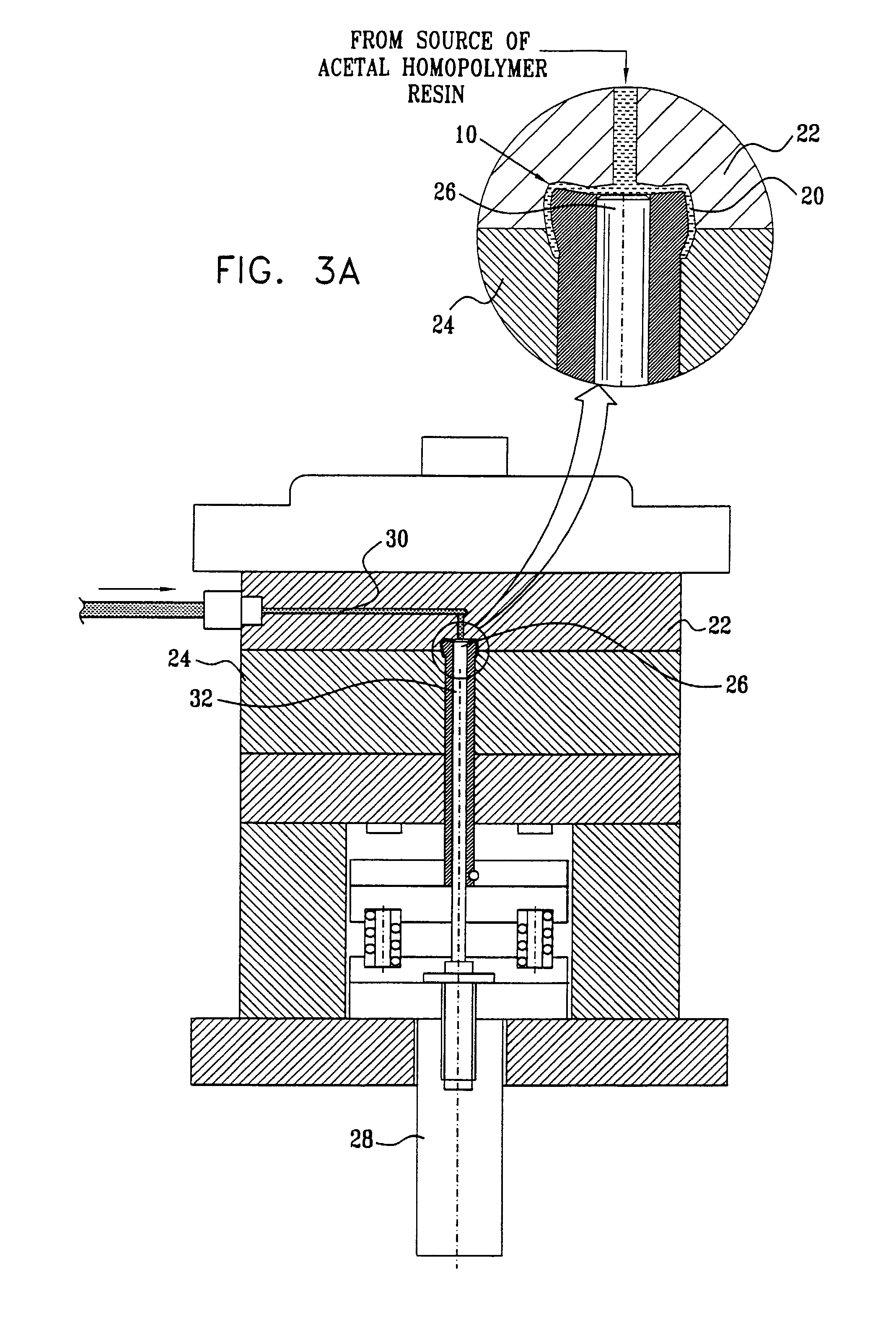

Crown forming apparatus for forming crown floating type magnetic head

InactiveUS6123608AImprove productivityLess amount variationEdge grinding machinesElectrical transducersConvex sidePrism

Employed is a crown forming method of forming a crown on a floating type magnetic head which includes the steps of placing an approximately rectangular-prism-shaped bar, which has magnetic head elements of not less than 1 formed on a side wall thereof in a row, on the convex surface of a jig whose radius of curvature is R1 through an elastic sheet while facing the upper surface (surface to be processed) of the bar to a lapping surface plate having a concave processing surface whose radius of curvature is R2 with the relationship between the radius of curvatures set to R1> / =R2, deforming the bar to an arc shape along the longitudinal direction thereof and bonding it on the convex surface together with the elastic sheet, and lapping the upper surface (surface to be processed) by abutting it against the processing surface and moving the upper surface (surface to be processed) relative to a processing surface.

Owner:TDK CORPARATION

Method for preventing and curing fruit tree diseases and pests by using Vaseline medicine

InactiveCN101642098AExcellent adhesionExtend attachment timeBiocideAnimal repellantsDiseaseFruit tree

The invention relates to a method for preventing and curing fruit tree diseases and pests by using Vaseline medicine, which is characterized in that: common pesticide, bactericide, and gyplure are mixed with Vaseline evenly, preferably the Vaseline can be stuck, and then the mixture is coated on scabs and wound positions of trunks and surface layer of braches by a coating and pouring tool. The invention is mainly used for preventing the wound of pruning and grafting from being intruded by diseases and pests and curing the wound, coating and curing diseased spots, and controlling diseases and pests secondary intrusion hazard; the invention has the effects of sticking and contact poison on the pests, and can block the pests (or disease germs) from migrating to the tree crown form the groundto harm the trees; and the invention can intensively prevent and cure pests sensitive to gyplure. The invention has the advantages that Vaseline is strong in adhesive force, durable for rain water washing, windy and sunny weather, long in adhesive time, and can maintain long-time release of the pesticide. The operation of evenly mixing Vaseline and pesticide is simple and convenient, so that laborinvestment is reduced.

Owner:刘学平

Dental crowns

InactiveUS20100297587A1Eliminate needPrevent fallingTooth crownsDentistry preparationsCrown formDental crowns

The present invention provides a dental crown formed of an elastically thermoplastic polymer material, said crown comprising: a tooth shaped top surface; and flexible side surfaces, at least one of which includes inwardly directed bottom portion.

Owner:URI DENT LTD

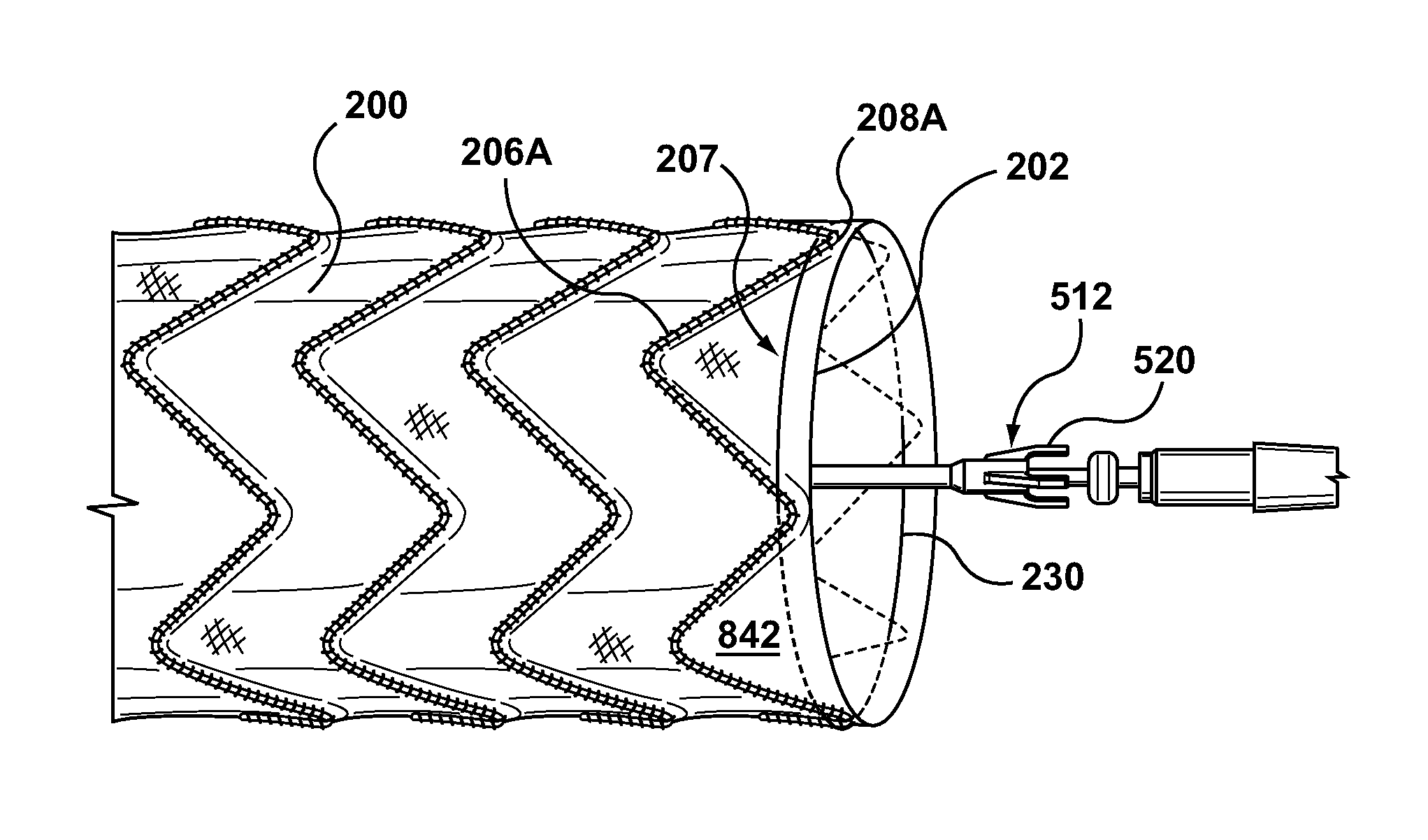

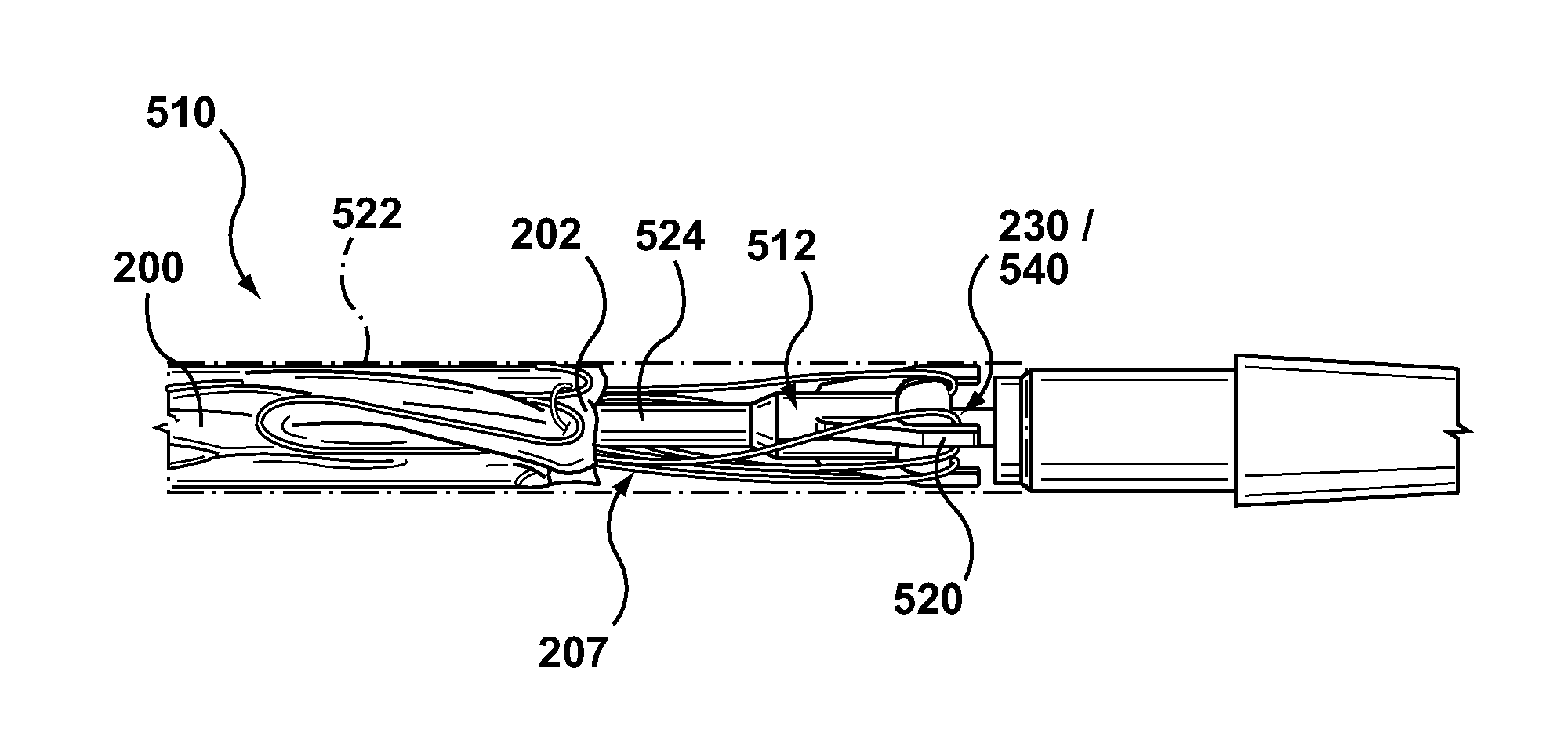

Ring on a closed web stent-graft for use in tip capture

A stent-graft has a closed web end configuration in which endmost stent crowns do not extend beyond an end or edge of a tubular graft. In order to couple the stent-graft to tip capture fingers or prongs of a delivery system, the stent-graft includes a ring woven between the endmost crowns of an end stent. When end stent is in a compressed delivery configuration, sections of the ring between adjacent endmost crowns form attachment loops that longitudinally extend beyond the end of the tubular graft for engaging the tip capture fingers of a delivery system. When the end stent is in an expanded fully deployed configuration, the attachment loops retract back to the stent so that the ring is a circular band having a diameter substantially equal to the expanded diameter of the stent.

Owner:MEDTRONIC VASCULAR INC

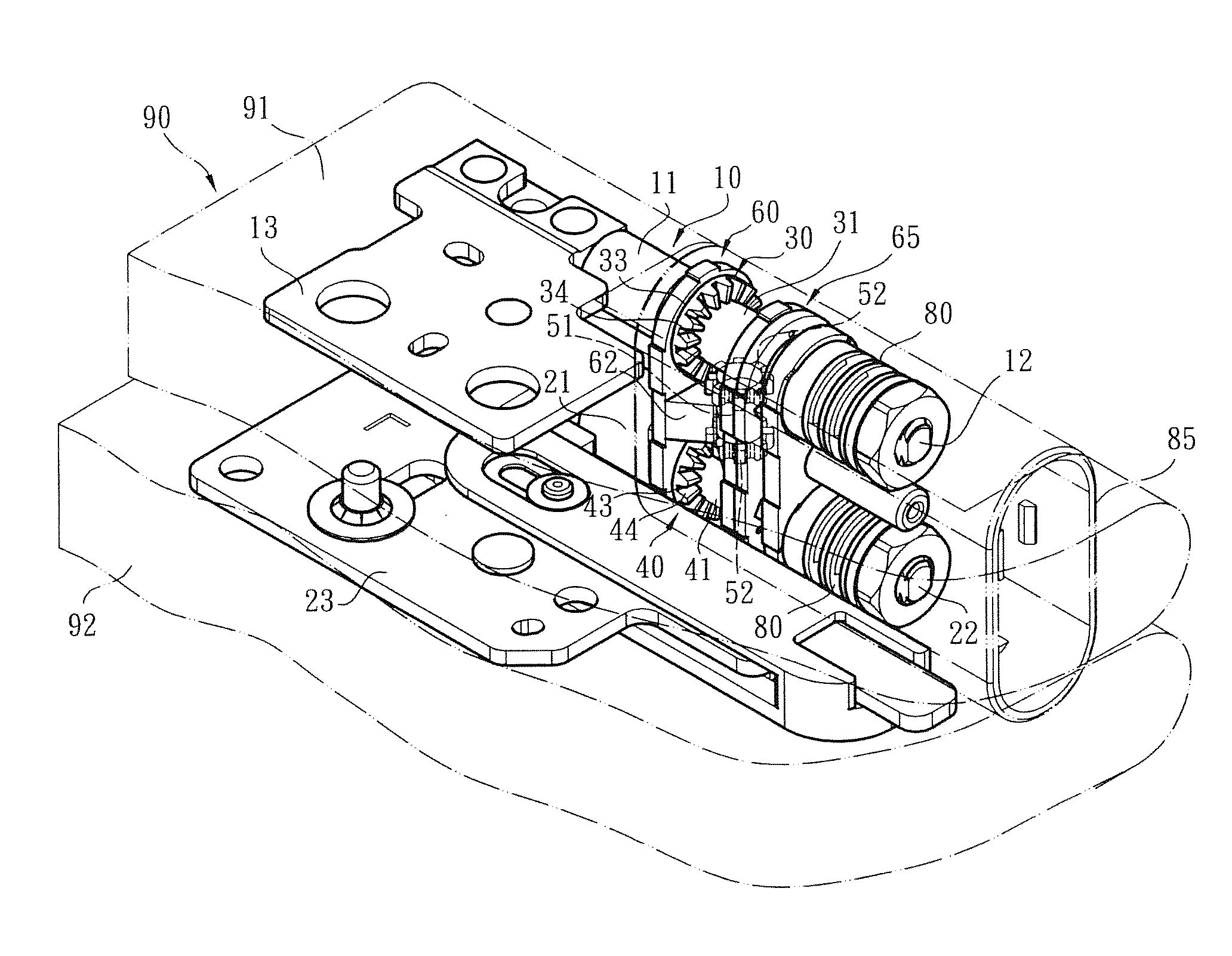

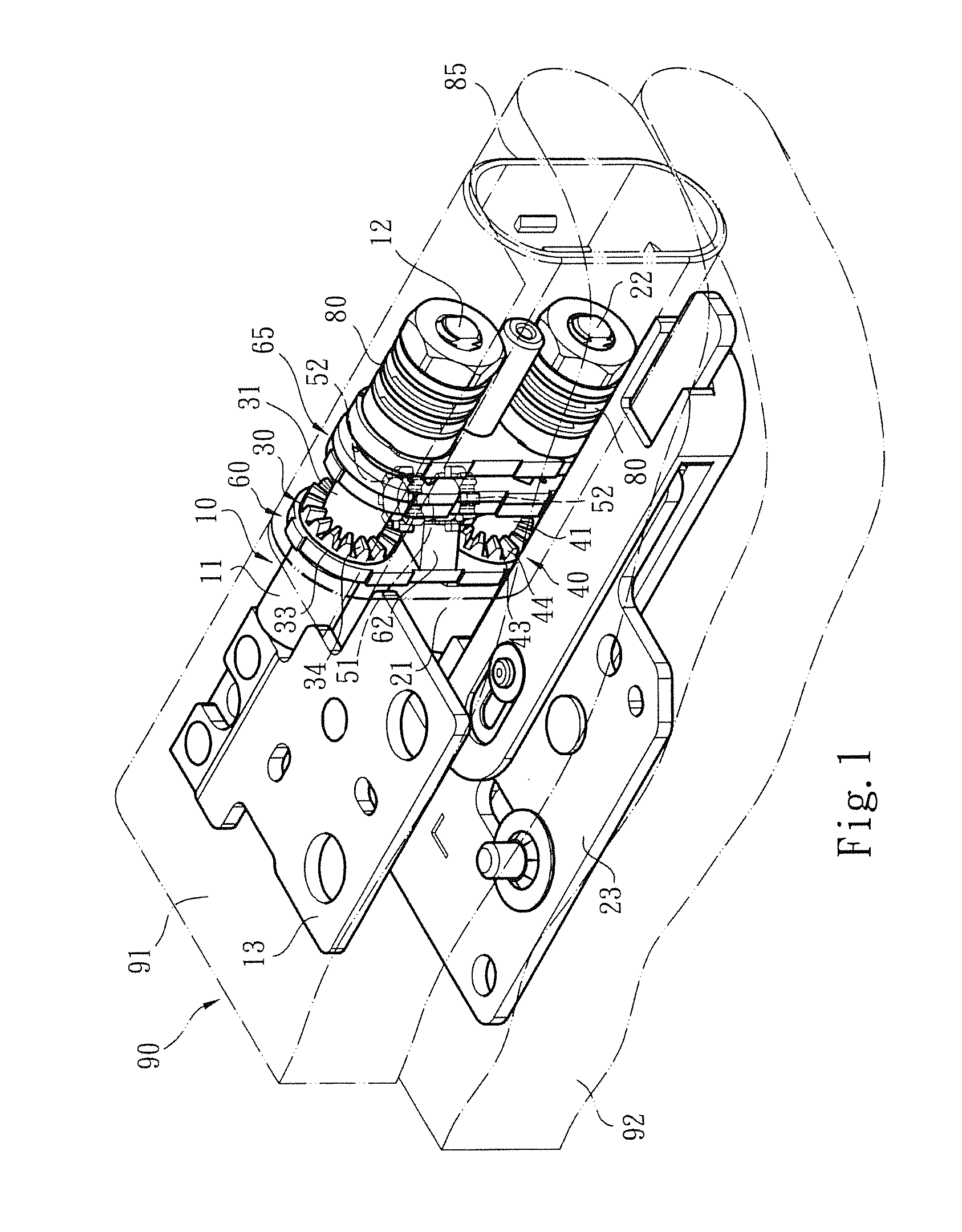

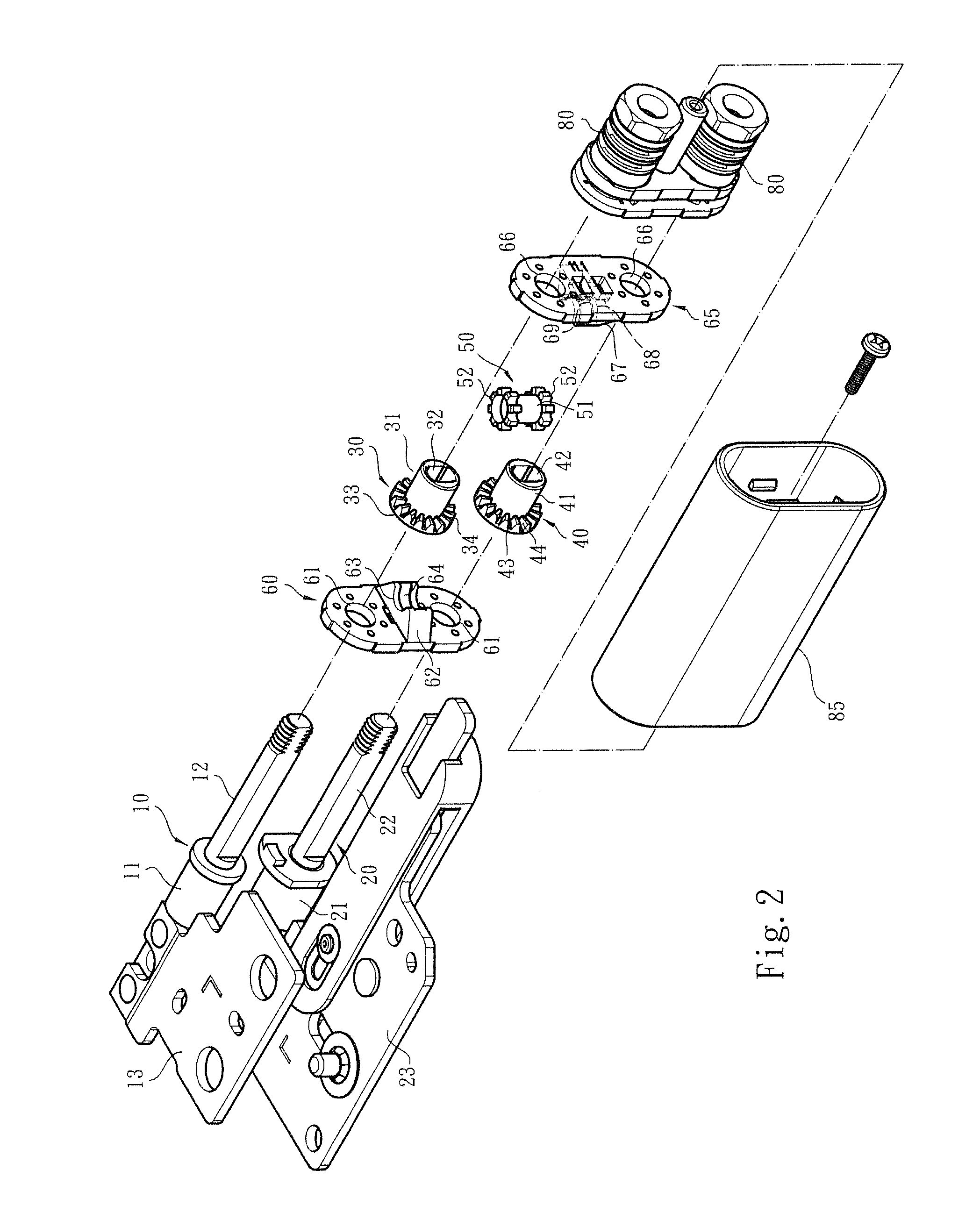

Dual-shaft synchronous transmission device

ActiveUS9310849B2Smooth rotationDigital data processing detailsWing accessoriesGear wheelEngineering

A dual-shaft synchronous transmission device is applied to an electronic apparatus. The distance between the two shafts of the dual-shaft synchronous transmission device is shortened so that the electronic device can be thinned and lightweight. The dual-shaft synchronous transmission device includes a driver and a reactor respectively disposed on a first shaft and a second shaft and a link unit. Spur gear structures or crown gear structures are respectively disposed on the driver and the reactor. Crown gear structures or spur gear structures are respectively disposed at two ends of the link unit correspondingly engaged with the spur gear structures or crown gear structures of the driver and the reactor. When the first shaft and the driver are rotated, the driver rotates the link unit to drive the reactor and the second shaft to synchronously rotate in a direction reverse to the rotational direction of the driver.

Owner:FIRST DOME

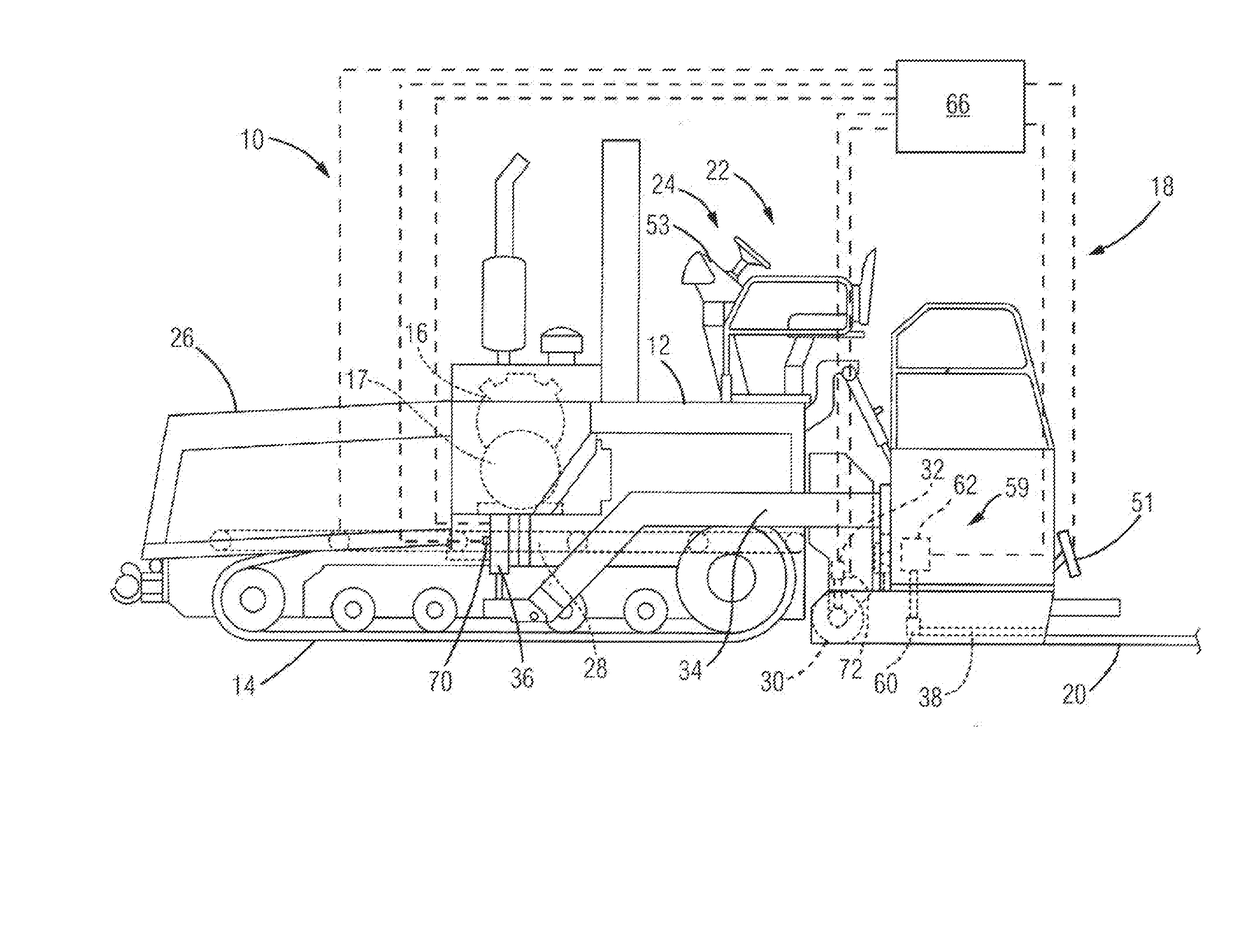

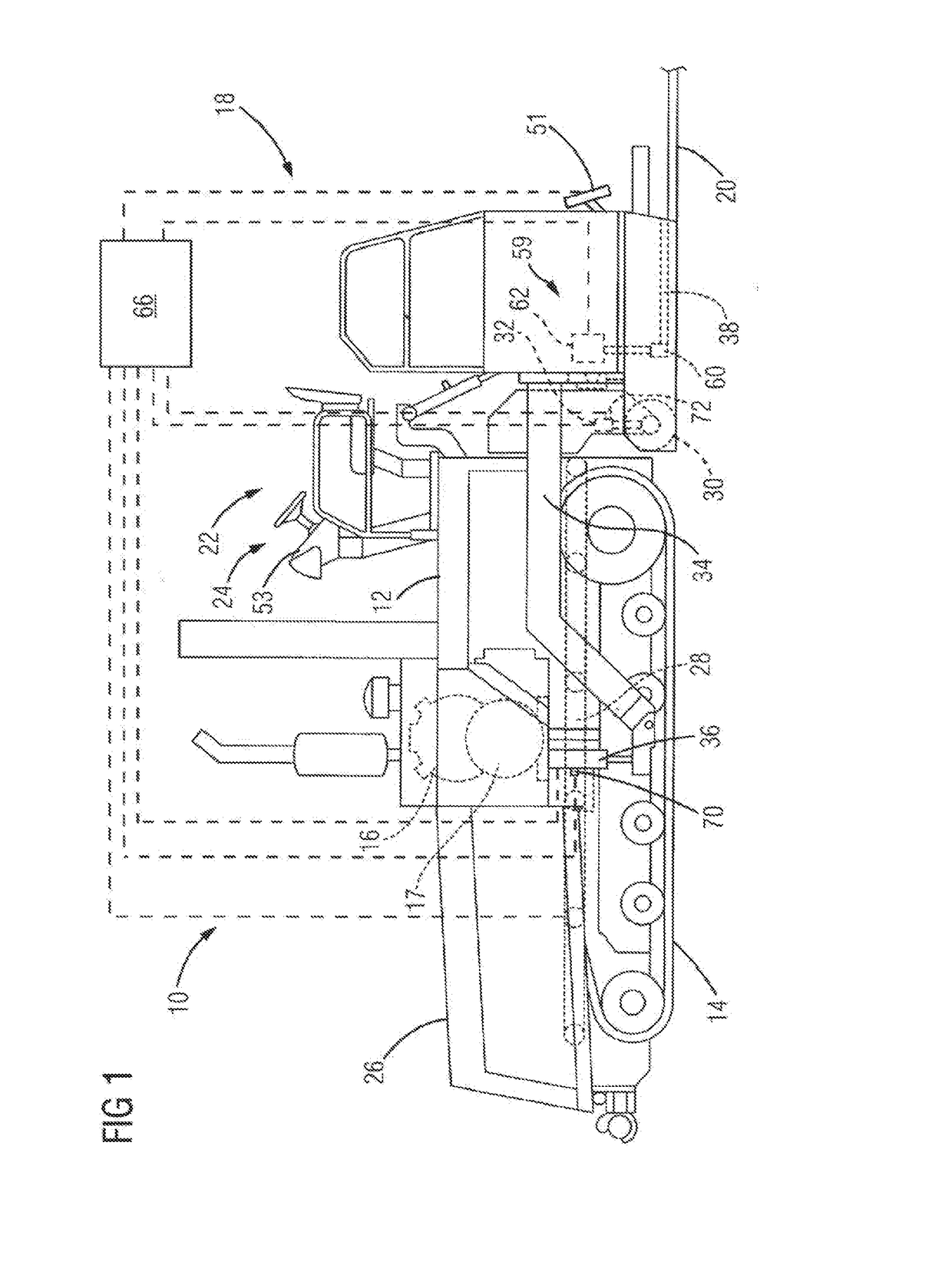

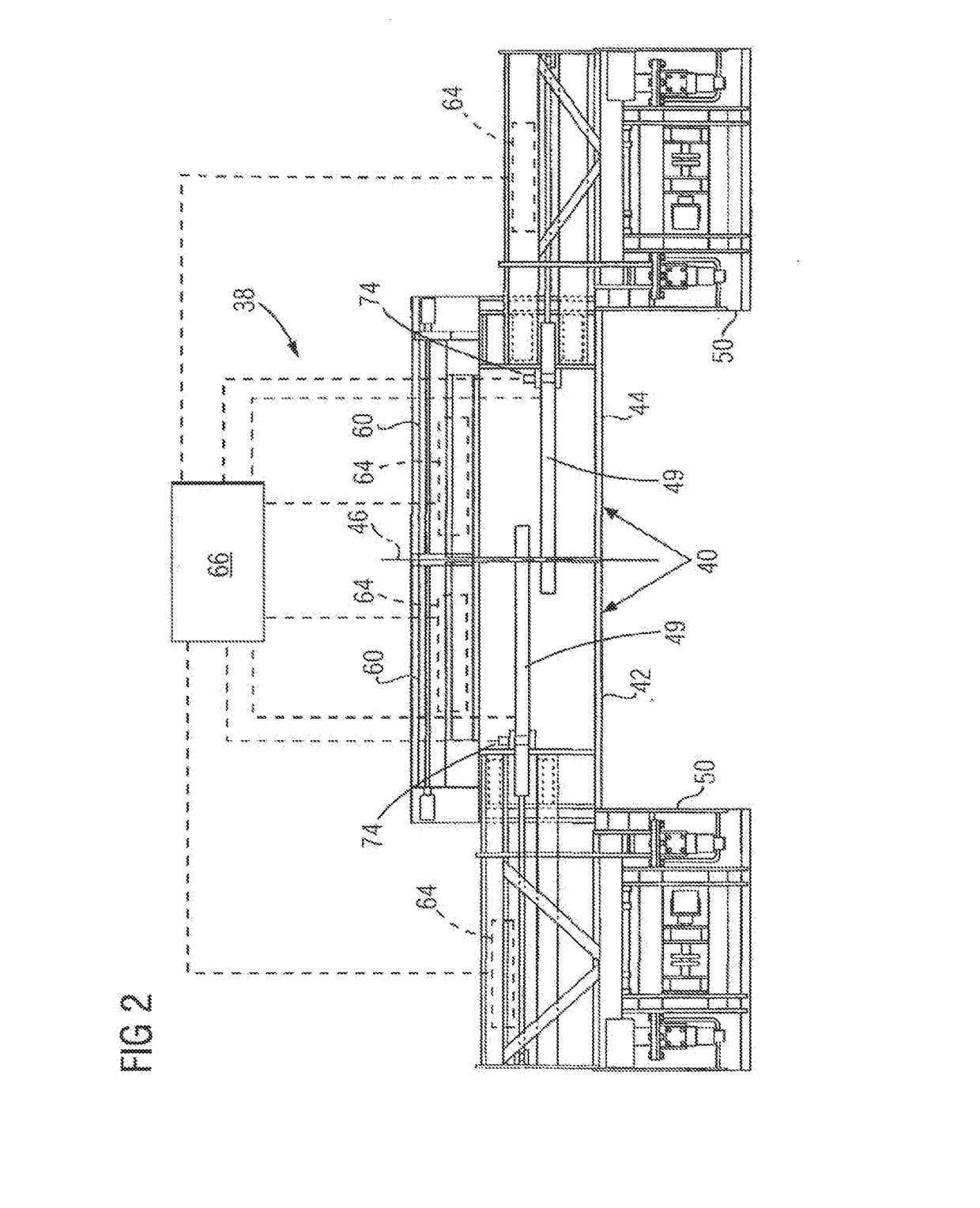

Paving machine for applying varying crown profiles

A paving machine is disclosed. The paving machine may have a screed assembly having a left screed section and a right screed section. The paving machine may also have a crown actuator configured to pivot the left and right screed sections about the centerline. The paving machine may have a crown profile sensor configured to detect the crown profile (DP), and a cross slope sensor configured to detect a cross slope (QNL*, QNR*) of the screed assembly. Further, the paving machine may have a controller configured to determine the crown profile (DP) and a cross slope (QNL*, QNR*) of the screed assembly. The controller may calculate a left cross slope (QNL) of the left screed section and a right cross slope (QNR) of the right screed section based on the determined crown profile (DP) and the determined cross slope (QNL*, QNR*), and display the crown profile on the display device.

Owner:CATERPILLAR PAVING PROD INC +1

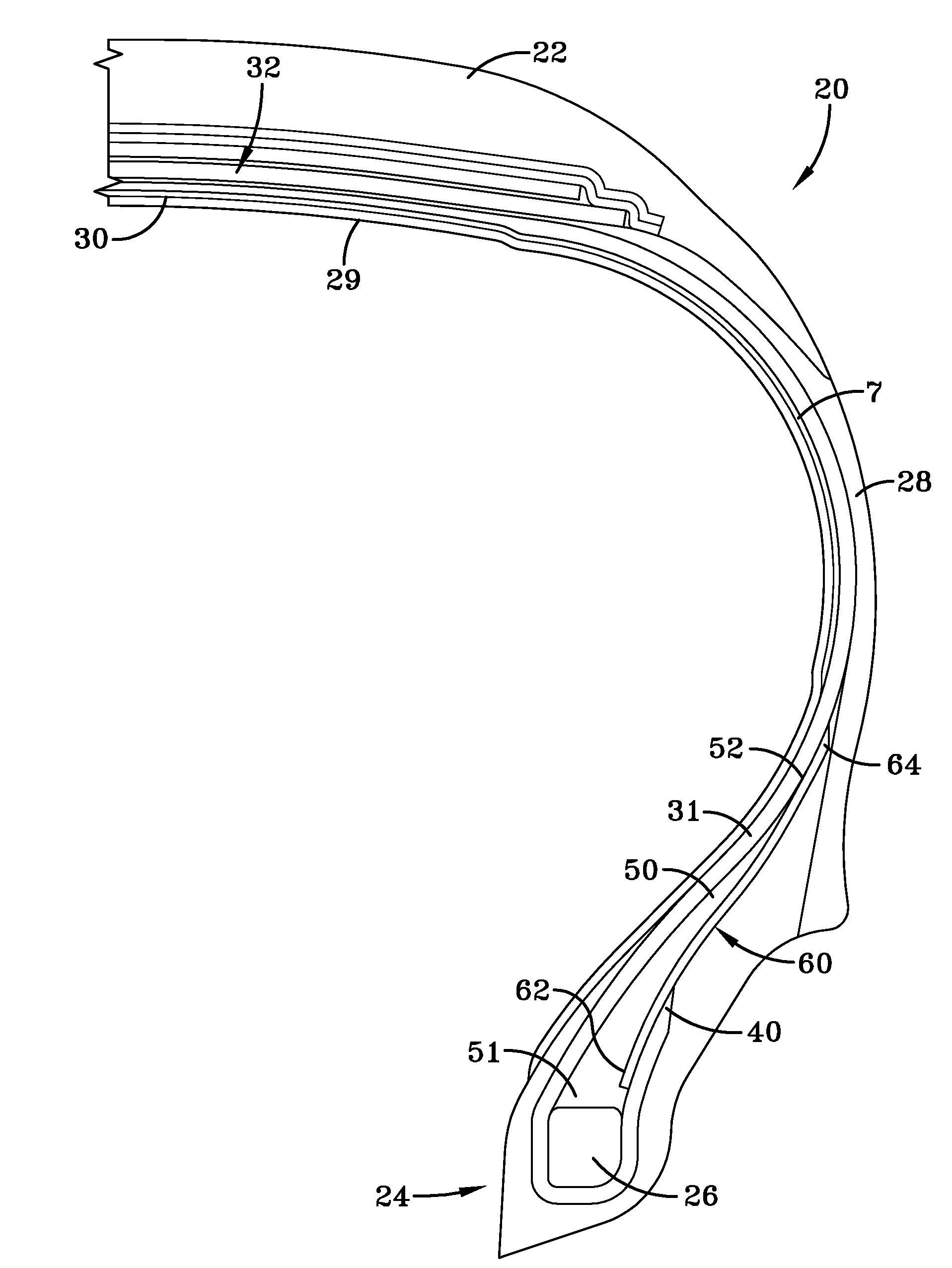

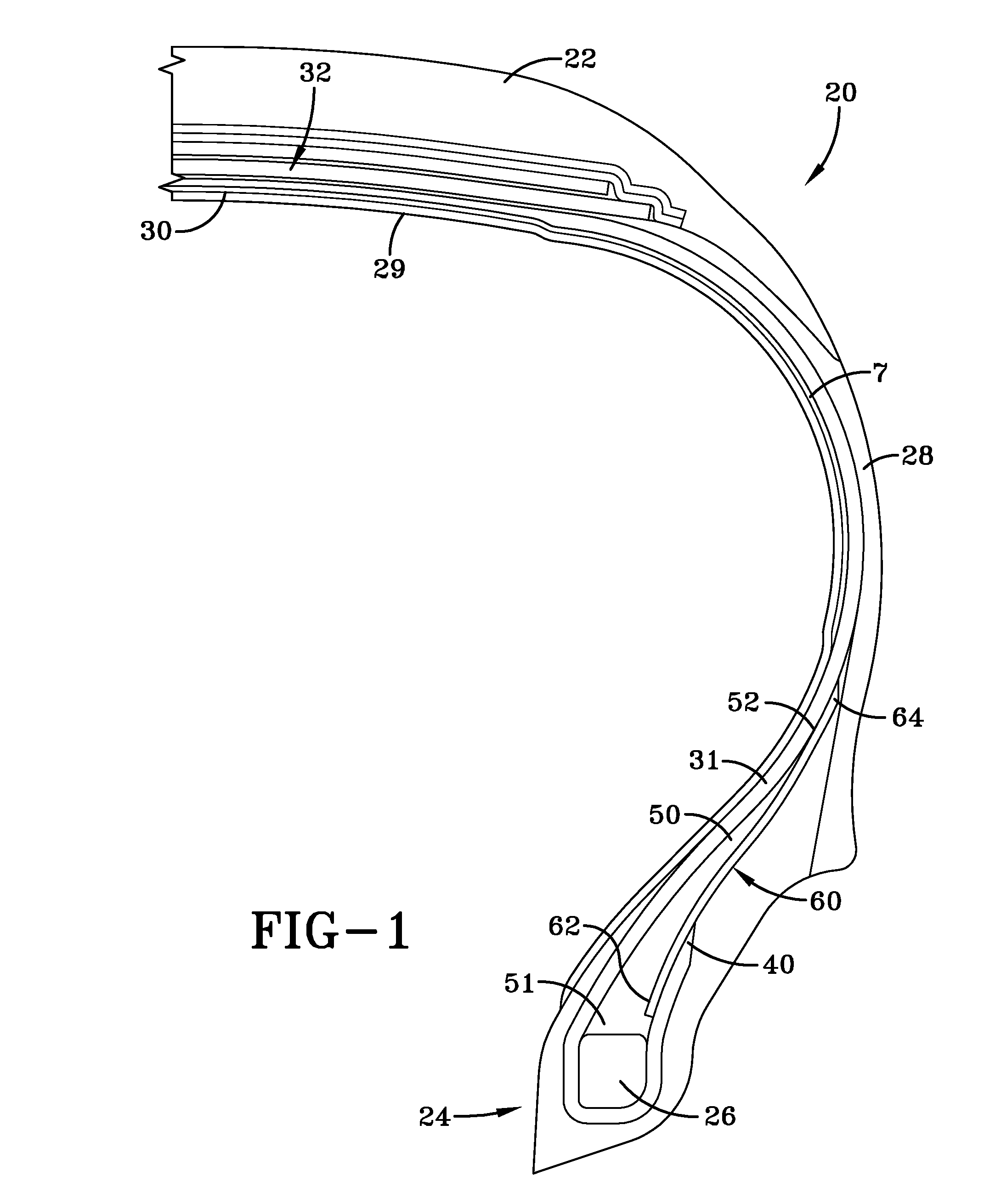

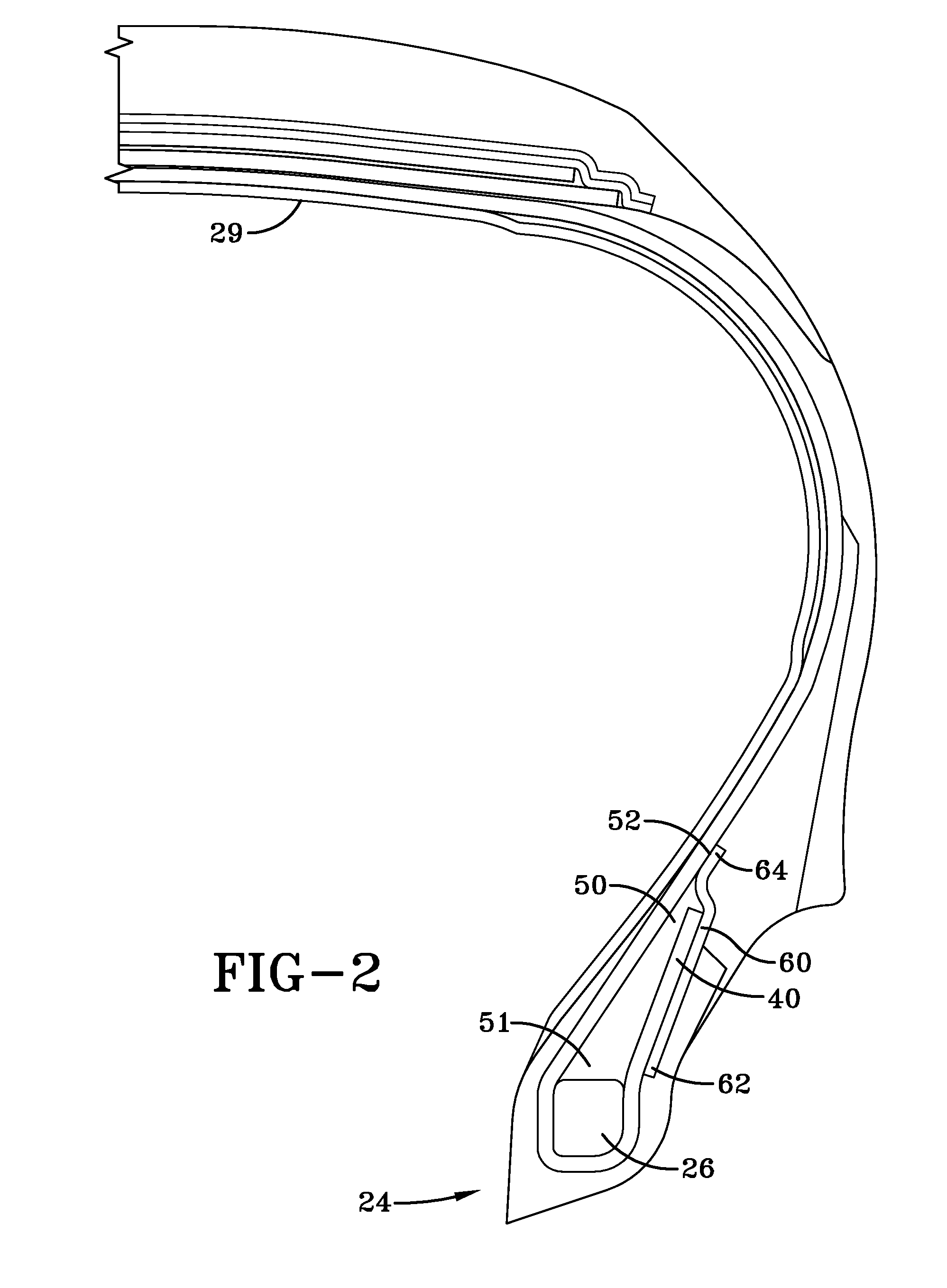

Pneumatic tire

Owner:FELTES SERGE GUILLAUME +2

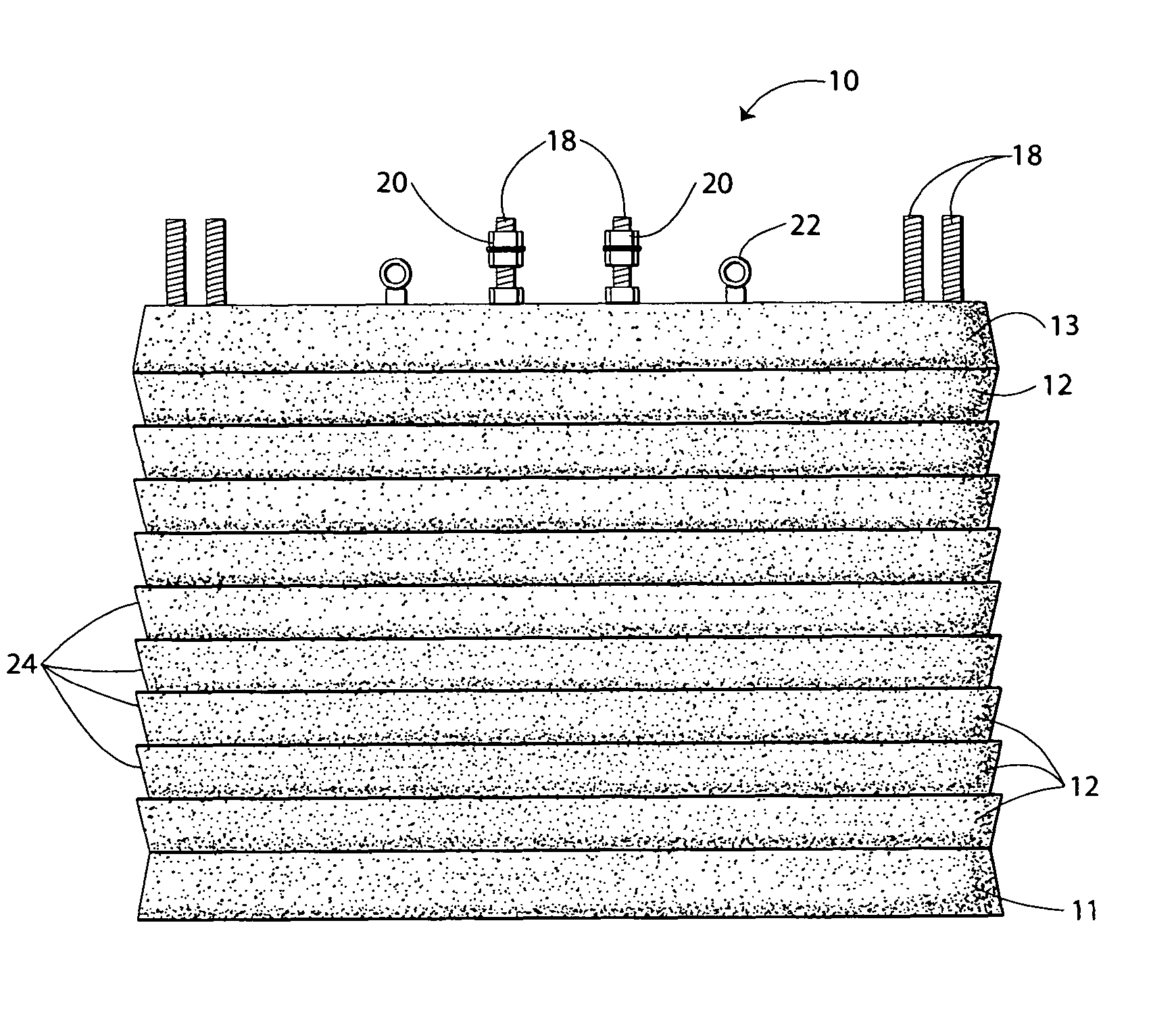

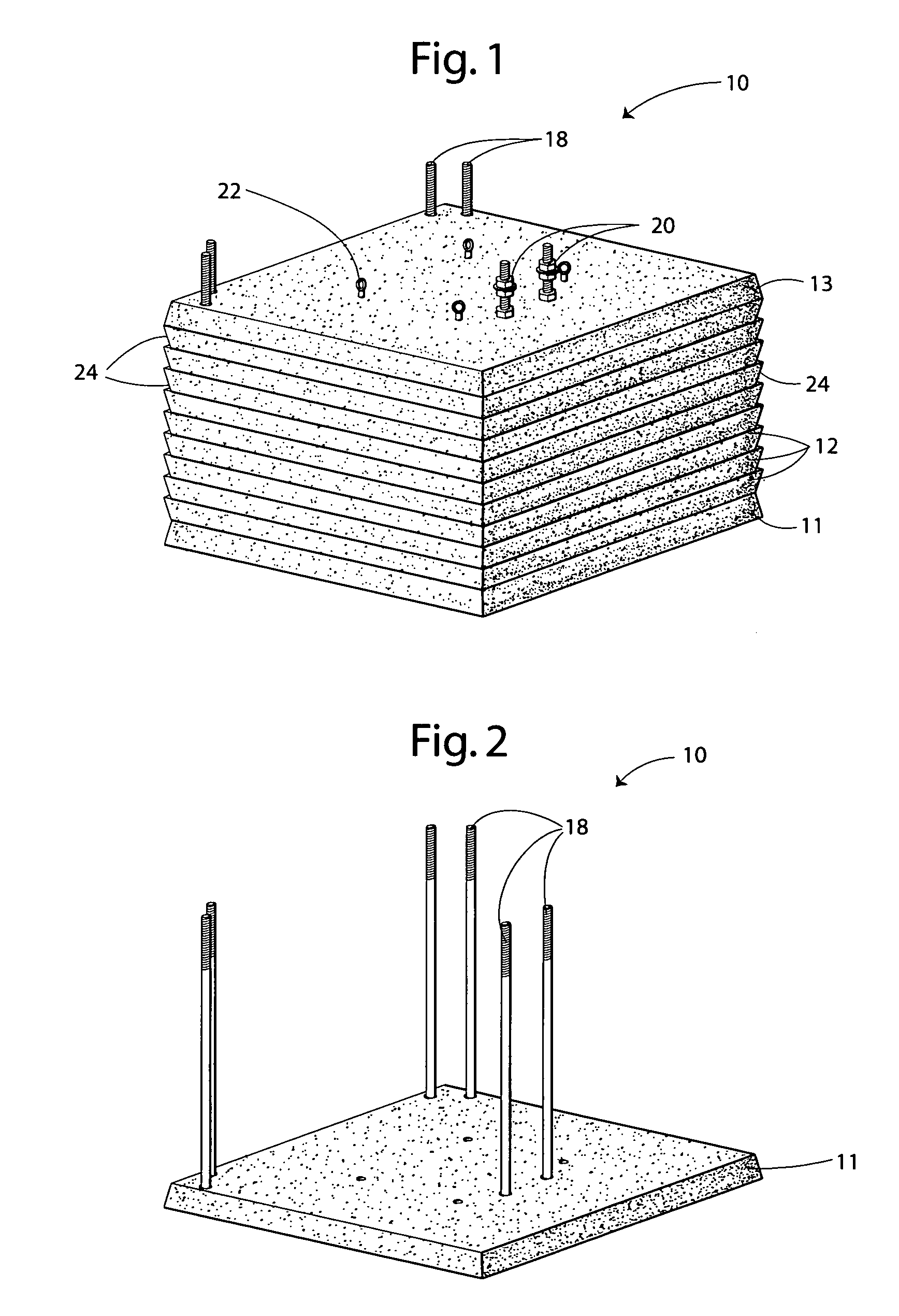

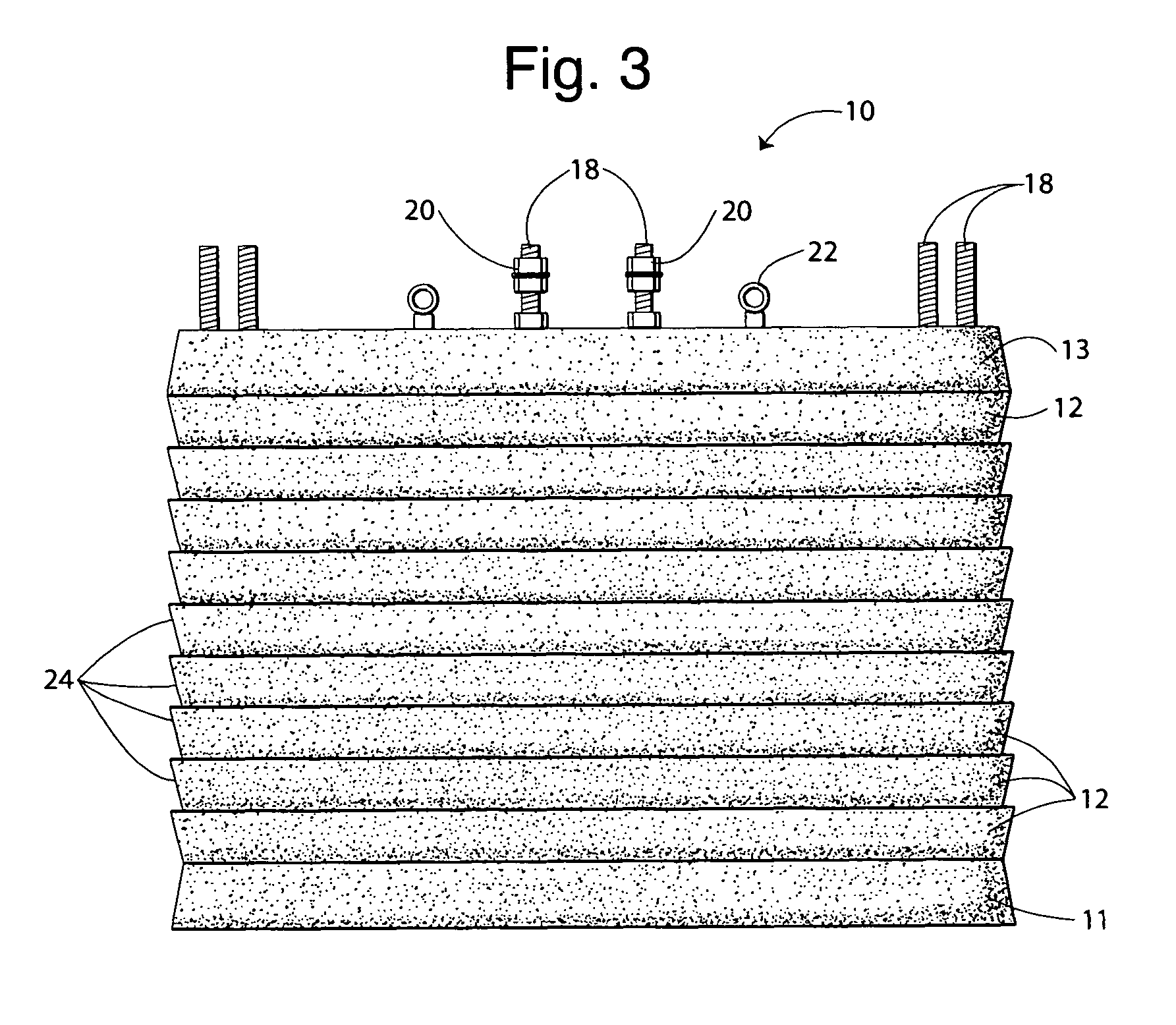

Tower foundation

A tower foundation (10) comprises a base slab (11), a plurality of pillar slabs (12), and a crown stab (13). The base slab (11), pillar slabs (12) and crown slab (13) are all retained in position by six steel guide rods (18) that extend upwardly from the base slab (11). The six guide rods (18) have externally threaded ends configured to receive internally threaded mounting bolts (20). The guide rods are arranged in a generally triangular pattern. The pillar slabs are rectangular with their sides being undercut or sloping outwardly from the bottom surface to the top surface, i.e., the sidewalls diverge outwardly as they extend upwardly. The outwardly sloping sidewalls aid in preventing the foundation from tilting over time.

Owner:DIXIE PRECAST

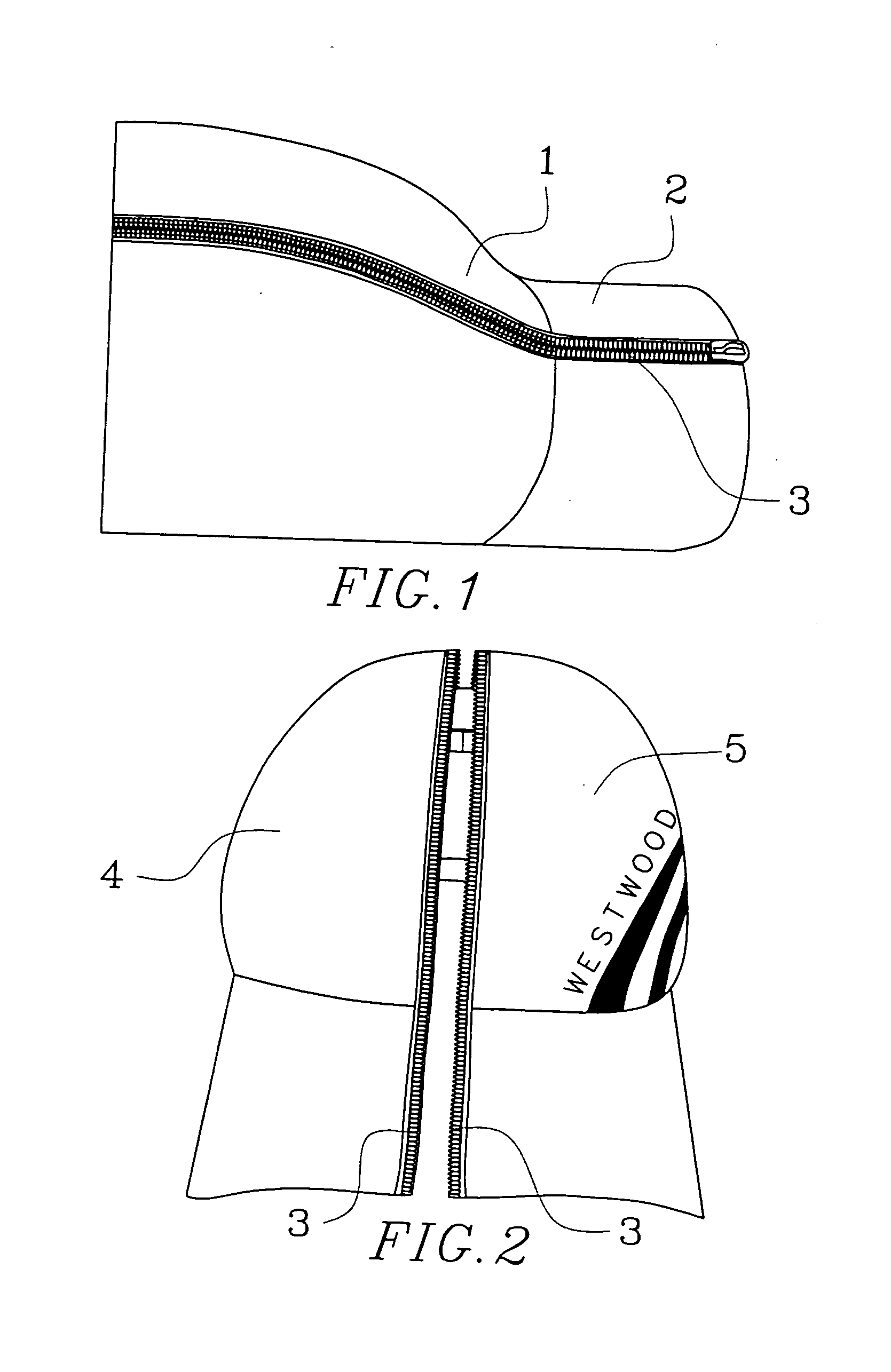

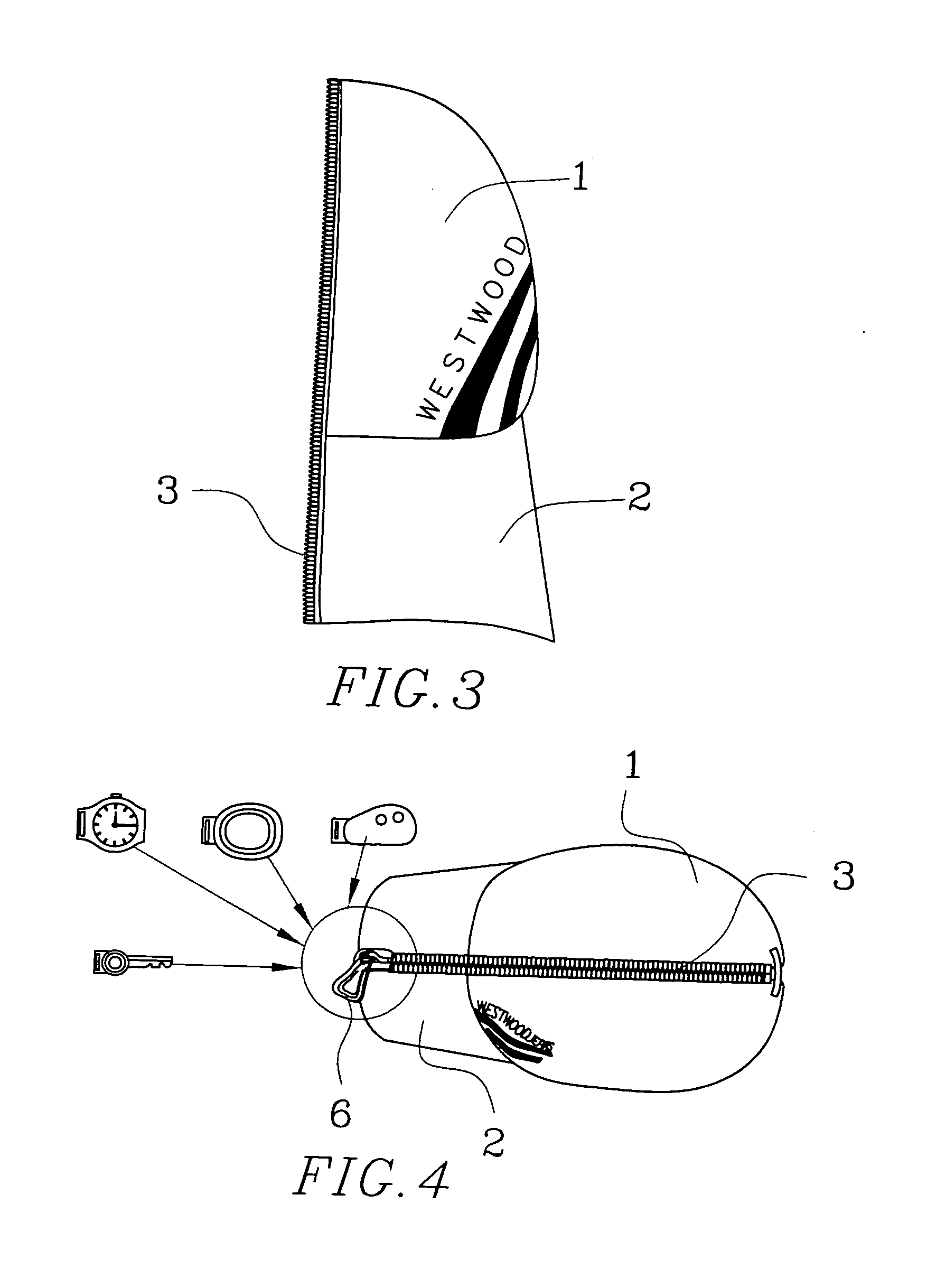

Hat

InactiveUS20120174288A1Function increaseExtended consumer possibilityHatsHeadwear capsCrown formMechanical engineering

Owner:KOVALOV OLEKSII

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com