Golf club head

a golf club and head technology, applied in the field of golf club head, can solve the problems of poor feeling low sound of hitting the ball, and inability to leave reverberant sound, etc., and achieve the effect of improving feeling and excellent performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

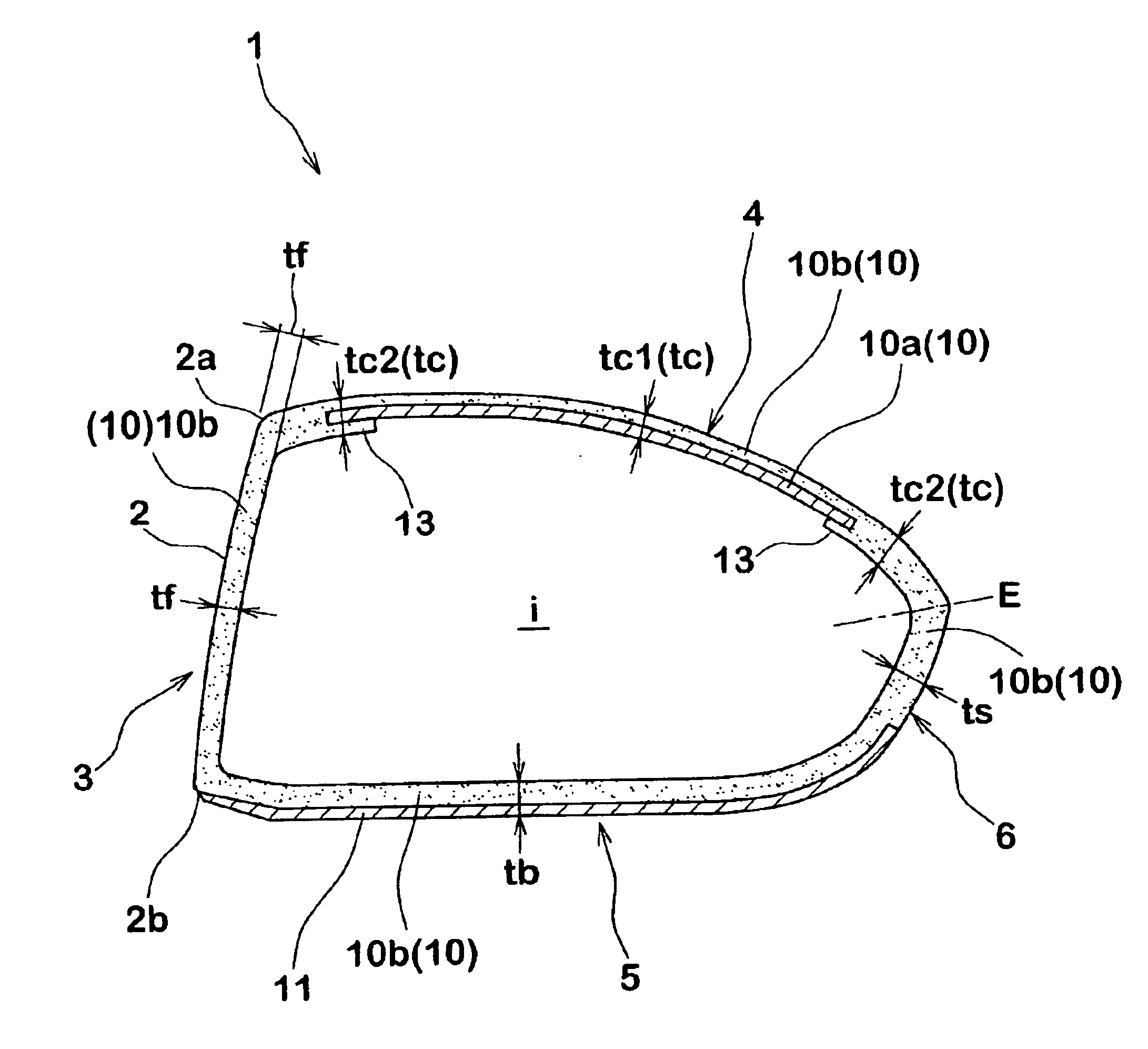

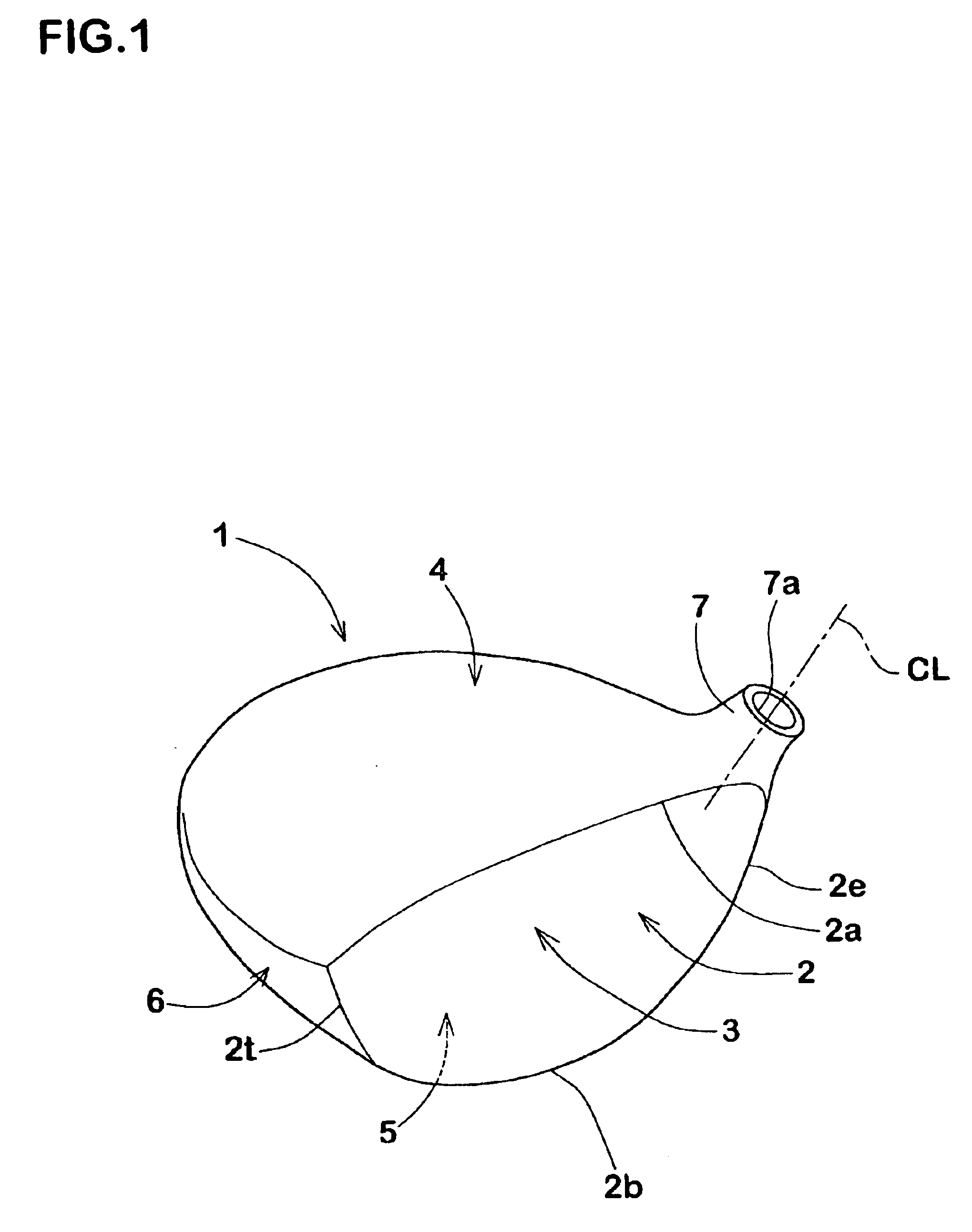

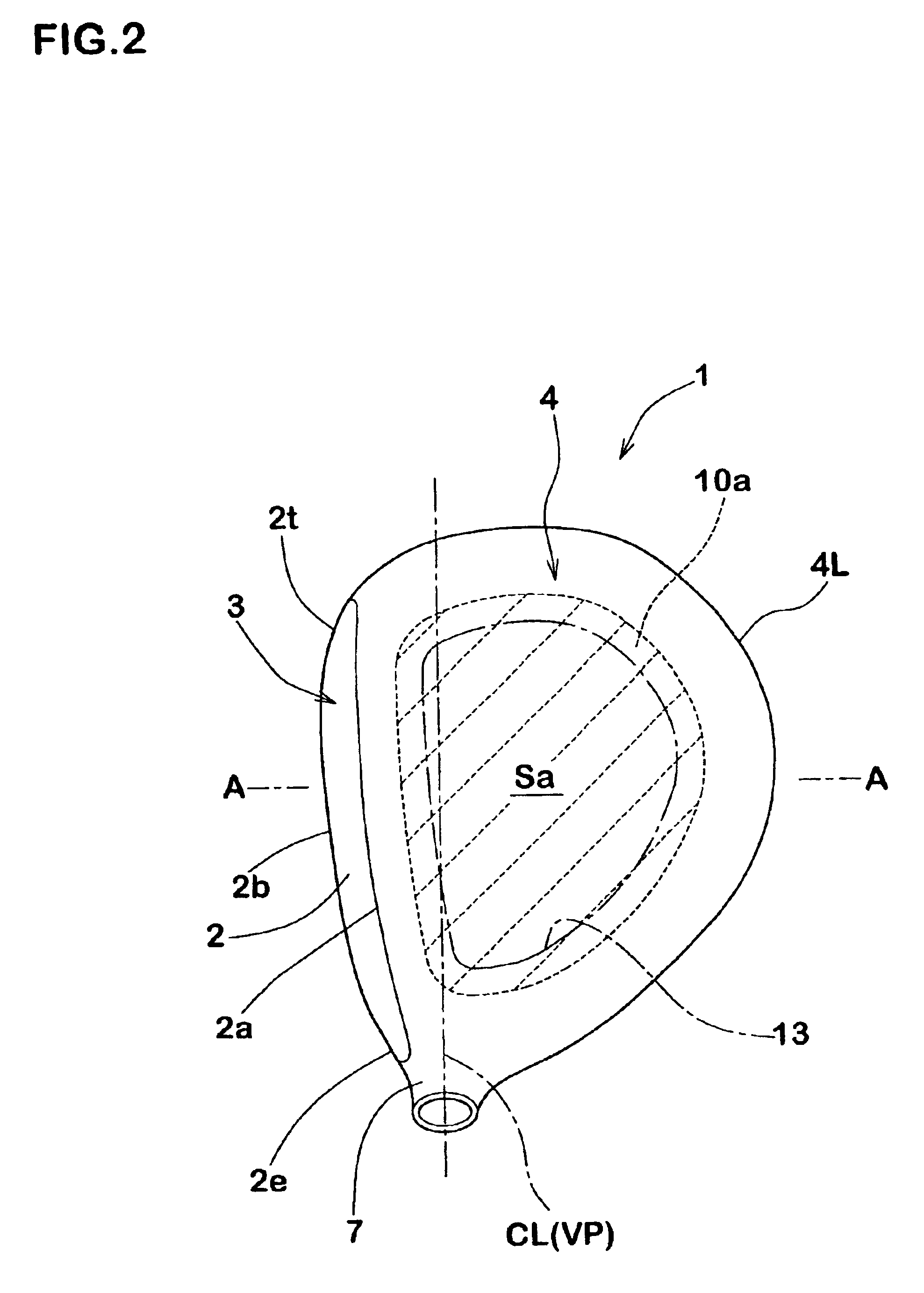

A golf club head having the basic aspect shown in FIGS. 1 to 3 and having a head volume of 360 cm3 was manufactured by way of trial on the basis of the specification shown in Table 1, and the ball hitting sound (high or low of the sound) and the ball hitting feeling (large or small of the vibration transmitted to the hands) were evaluated. Herein, the main part of the head was manufactured by attaching the prepreg to the outer peripheral surface of the bladder and hot pressing within the metal mold. Herein, the vibration absorbent was arranged inside the side by inserting into the position between the prepreg layers forming the side and the position shown in FIG. 8.

Further, the ball hitting sound and the vibration at a time of hitting the ball (the impact absorbability) were evaluated on the basis of a five-point method (the larger the numeric value is, the higher the sound is and the lower the vibration applied to the arms is) in accordance with a sensory test of each of fifty gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com