Golf driver having titanium alloy head and flexible shaft

a technology of titanium alloy and golf balls, applied in the field of titanium alloy golf balls, can solve the problems of unfavorable directional accuracy, ball to hook or slide, undeadly deadening the sound of impact, etc., and achieve the effect of less flexibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

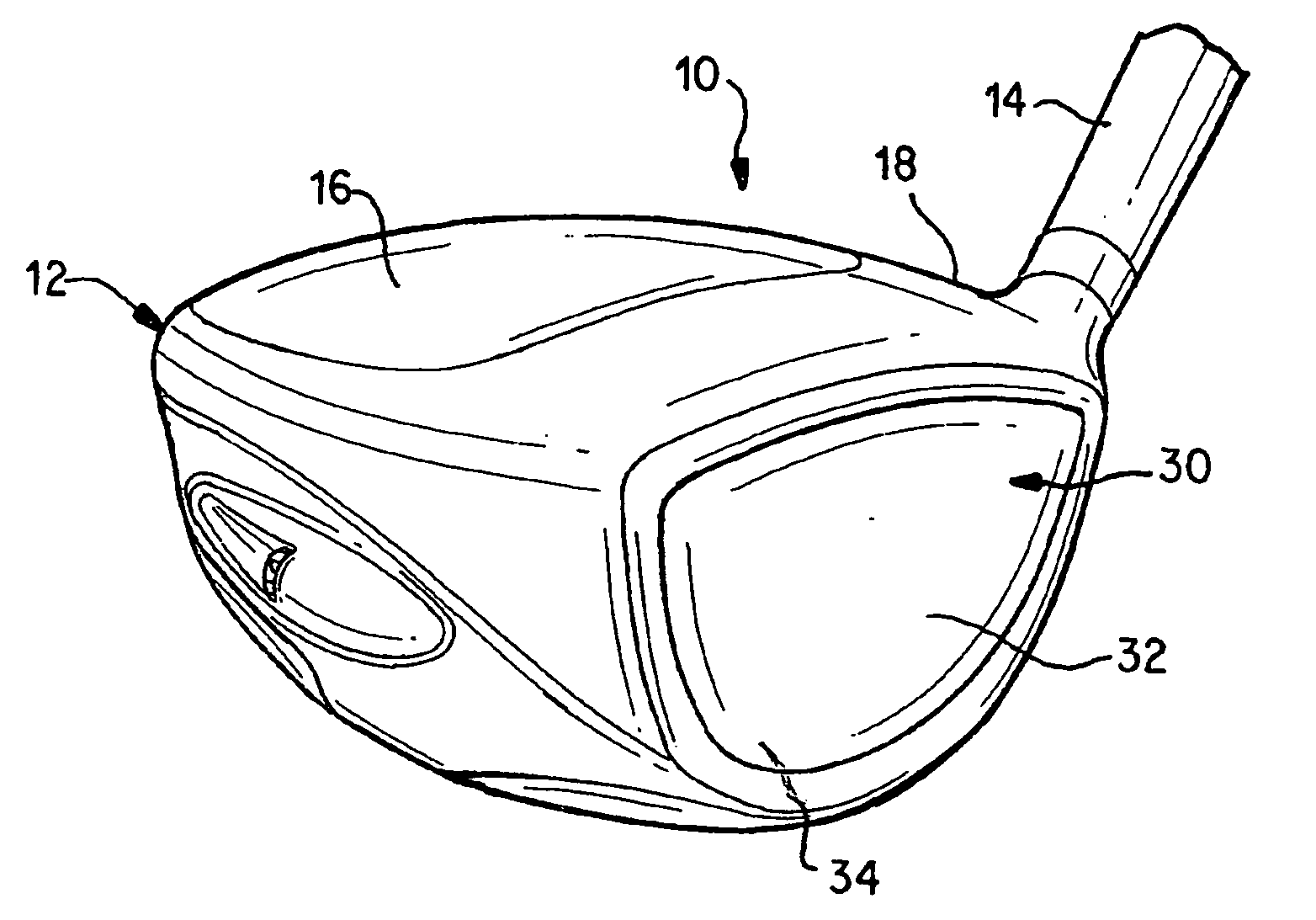

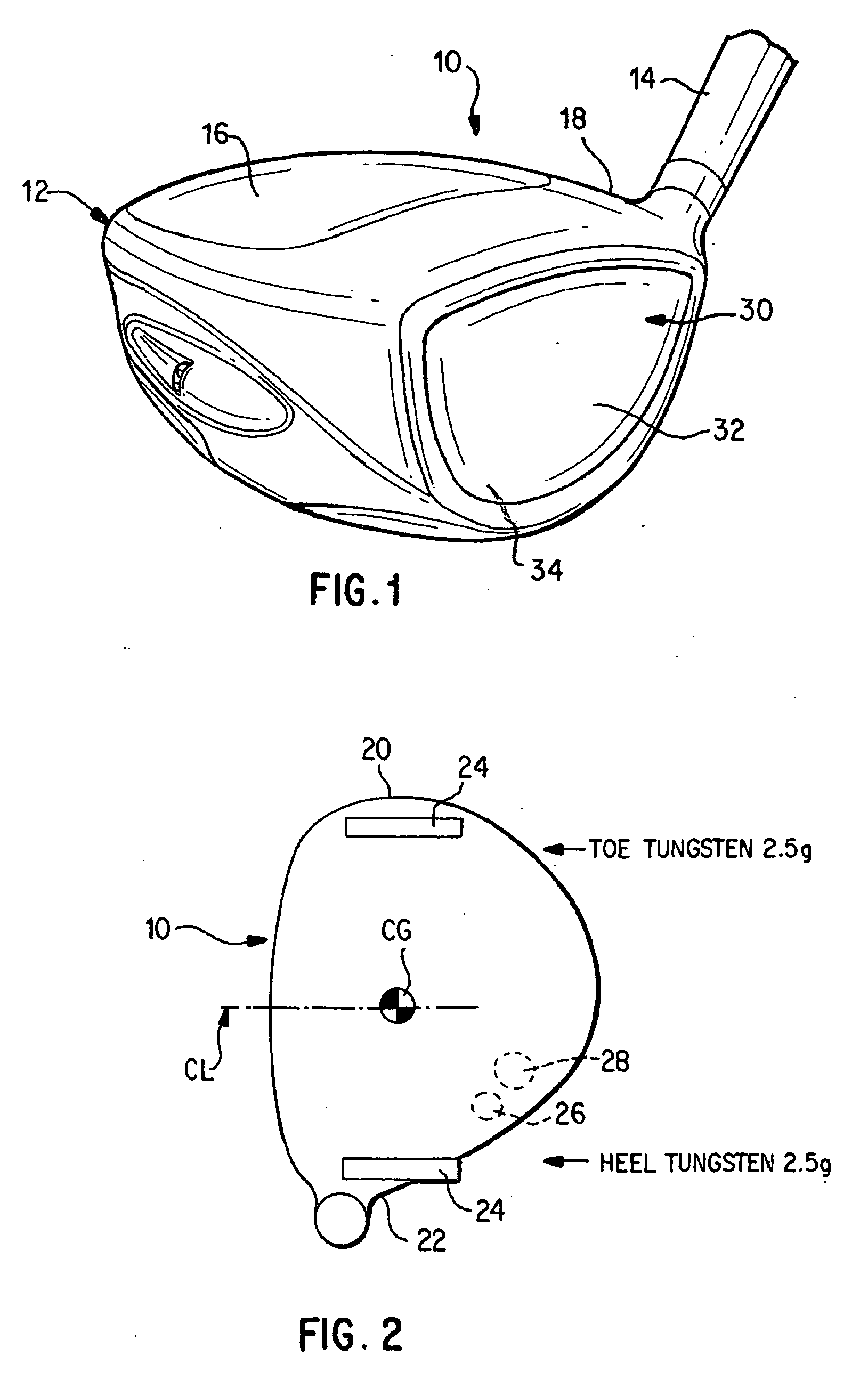

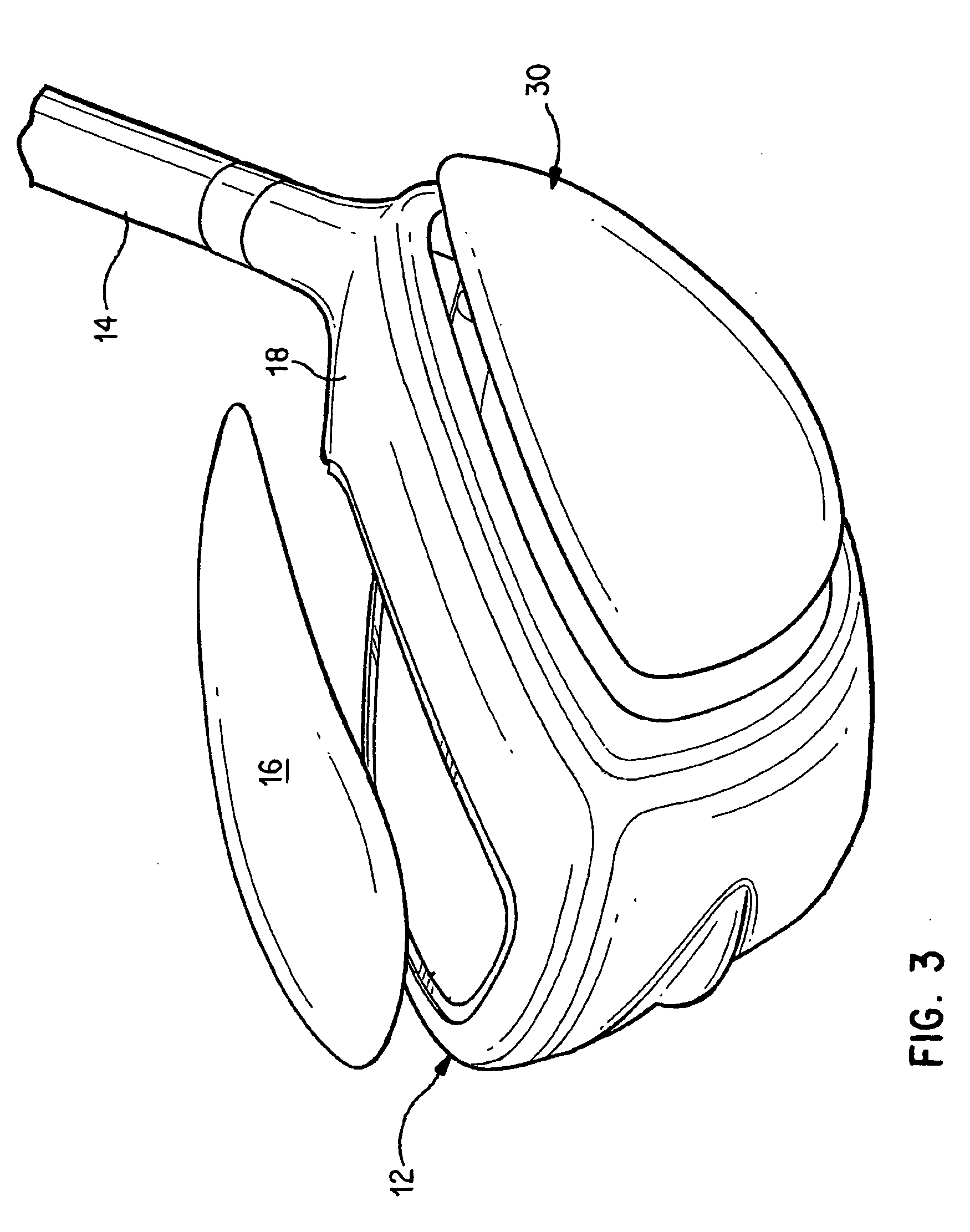

[0025] A golf driver 10 depicted in FIGS. 1-4 includes a head 12 and a shaft 14. At least a major portion of the crown of the head is formed by a thin plate 16 that is attached to a body 18 of the head.

[0026] Both the body 18 and the crown 16 are formed of different respective titanium alloys. The titanium alloy of the crown 16 is stronger than the titanium alloy of the body 18, enabling the crown 16 to be considerably thinner and thus of lighter weight than would have been the case if the crown were instead formed of the same material and thickness as the body.

[0027] Preferably, the body 16 is formed of an alpha-beta titanium alloy, most preferably 6-4 ti, and the crown is preferably formed of a beta-titanium alloy, most preferably 15-3-3-3 ti. The crown thickness is can be on the order of 0.4 mm, as compared to a typical thickness of 1.0-1.5 mm for the body 18, e.g. the crown can be less than one-half the thickness of the body 18.

[0028] The crown is adhered to the body by brazi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com