Patents

Literature

41 results about "Beta-titanium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beta-titanium is an alloy of titanium.

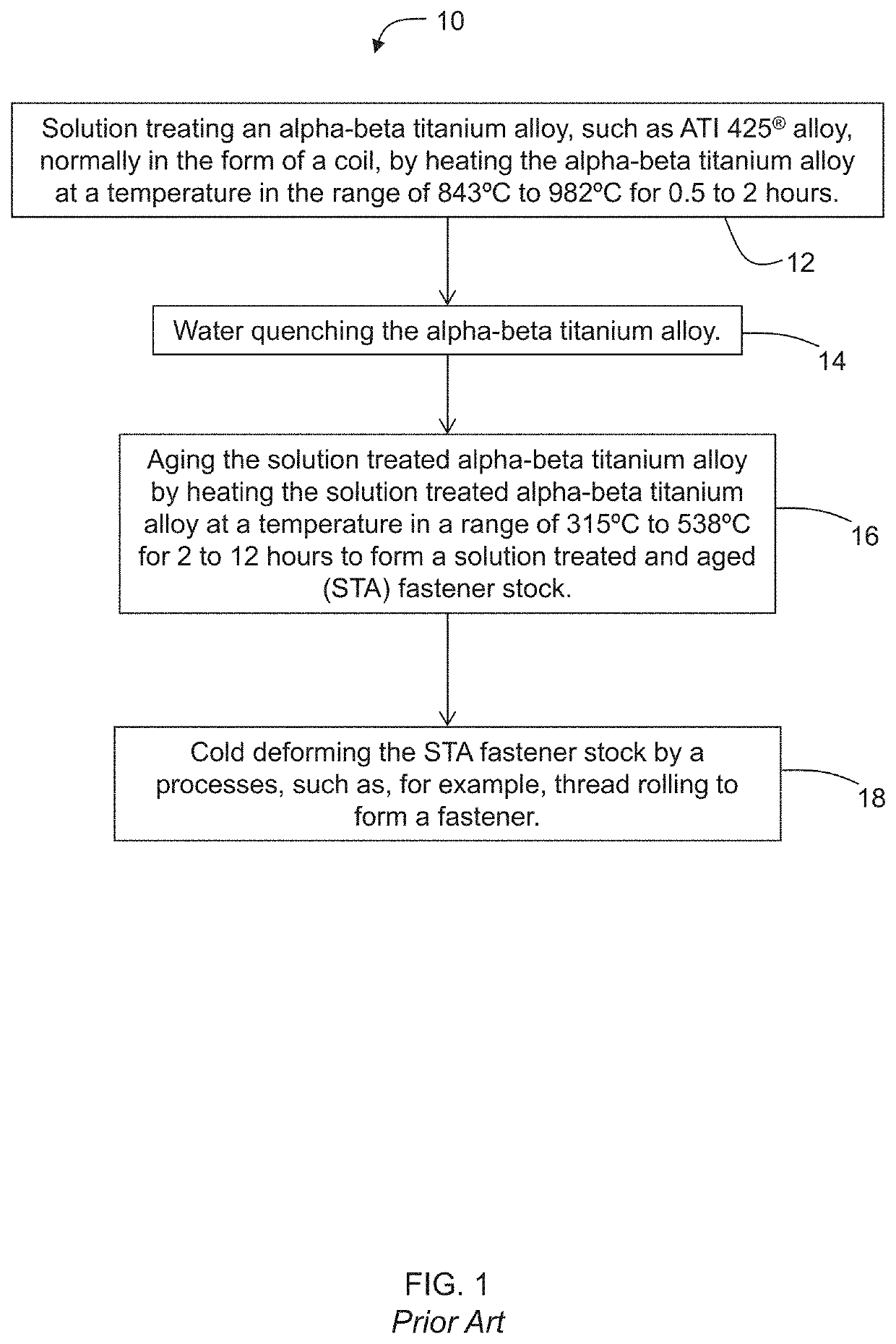

Processing of titanium-aluminum-vanadium alloys and products made thereby

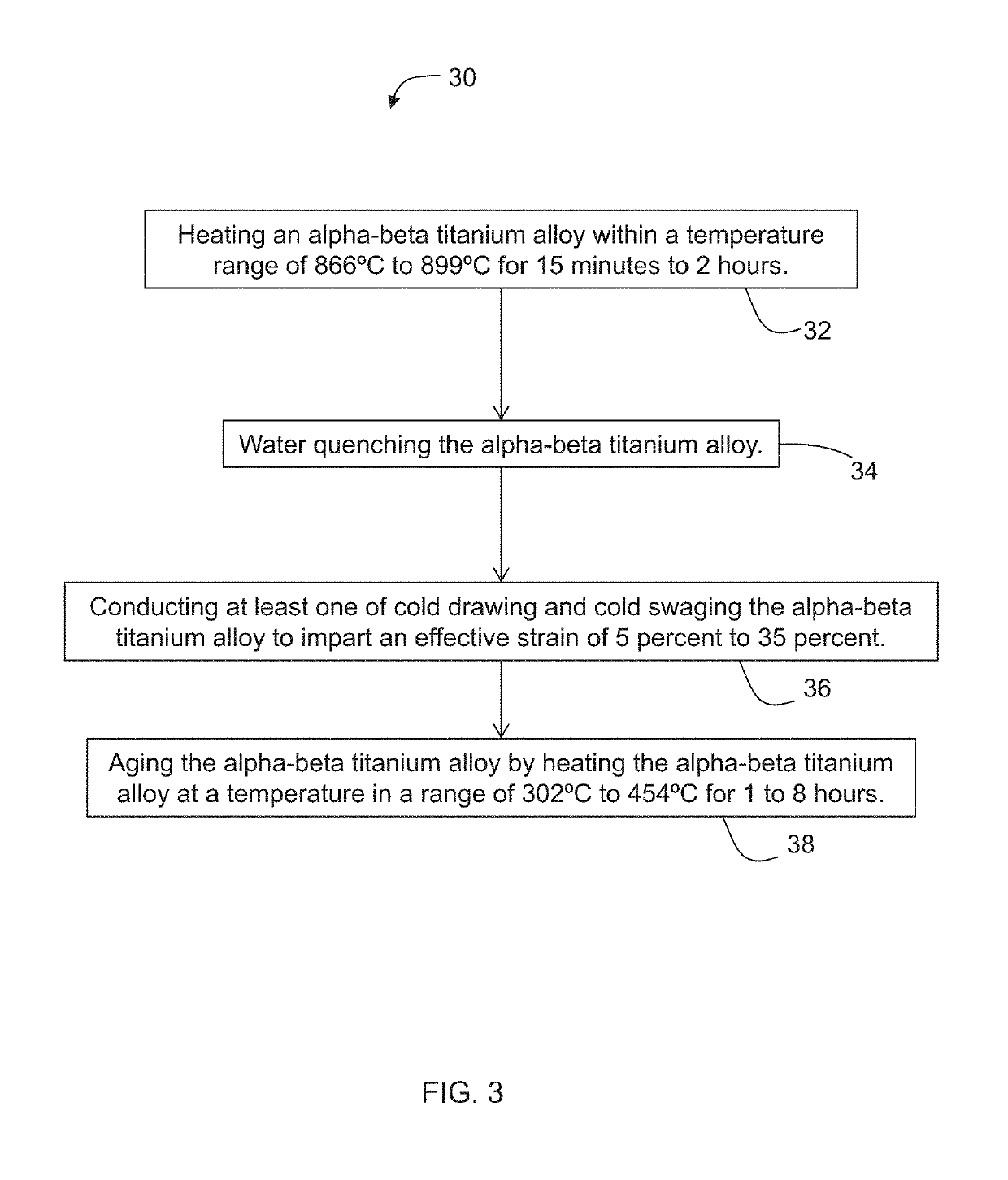

InactiveUS20040221929A1Expensive to produceHigh energy input requirementMetal rolling arrangementsNitrogenTitanium

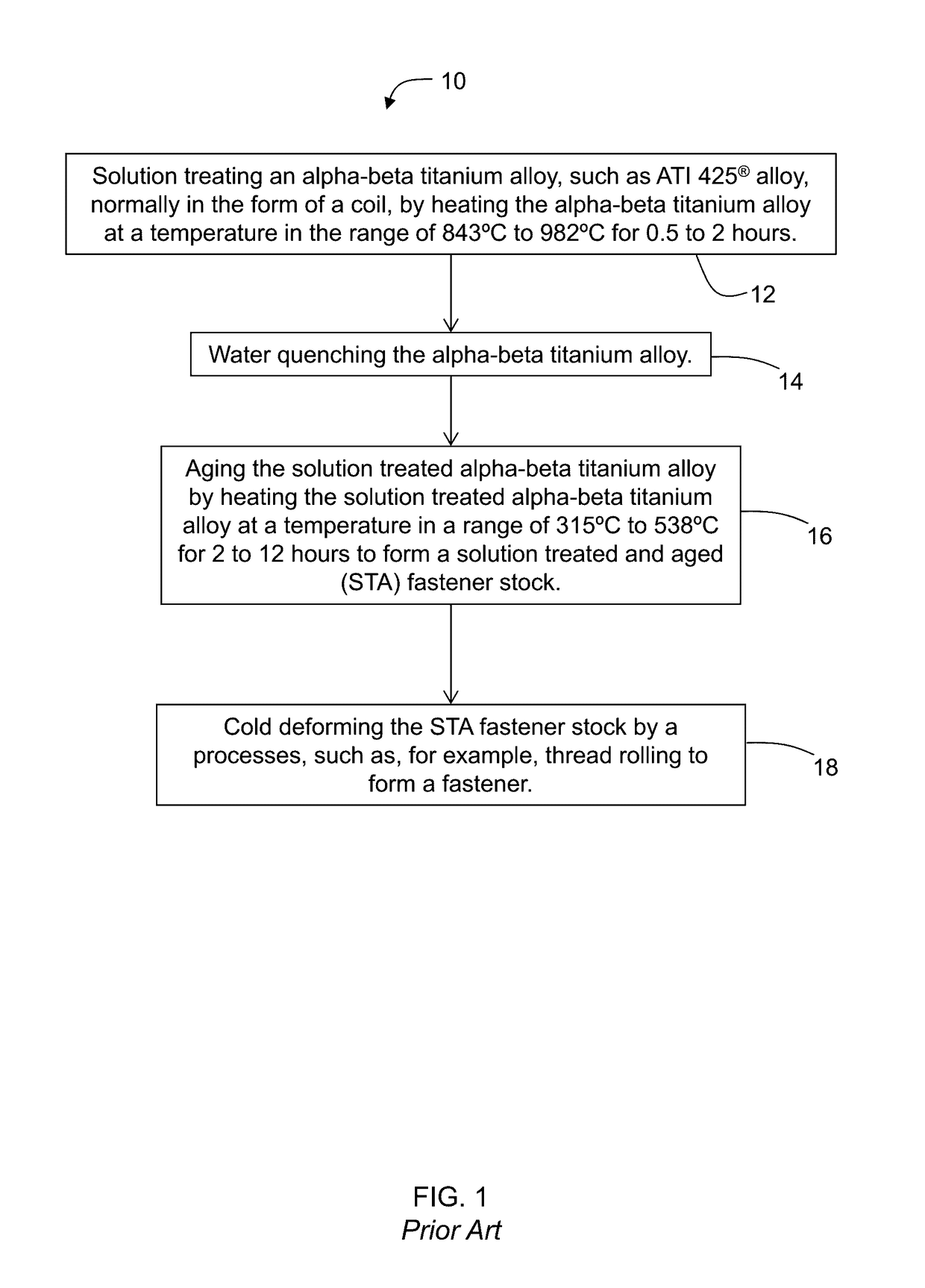

A method of forming an article from an alpha-beta titanium including, in weight percentages, from about 2.9 to about 5.0 aluminum, from about 2.0 to about 3.0 vanadium, from about 0.4 to about 2.0 iron, from about 0.2 to about 0.3 oxygen, from about 0.005 to about 0.3 carbon, from about 0.001 to about 0.02 nitrogen, and less than about 0.5 of other elements. The method comprises cold working the alpha-beta titanium alloy.

Owner:ATI PROPERTIES

Process for preparing biomedical beta-titanium alloy

InactiveCN101724764AImprove performanceHigh strengthImpression capsFurnace typesMaterials processingQuenching

The invention discloses a process for preparing a biomedical beta-titanium alloy. The process comprises the following steps: A) alloy preparation; B) surface coating; C) hot forging and cogging; D) hot rolling; E) cold rolling and molding; and F) heat treatment. In the process, the material is manufactured to a 2mm plate after the beta-titanium alloy is subjected to high vacuum electric arc melting, repeated stirring, casting, phase transformation point measuring, homogenization under the protection of vacuum and argon, coating, hot forging, hot rolling, cold rolling, solid solution, water quenching, artificial aging and water cooling so as to prepare the biomedical beta-titanium alloy with excellent comprehensive performance. The process is a biomedical beta-titanium preparation process capable of improving the material strength, abrasion resistance and corrosion resistance, reducing the elasticity modulus of the material, and maintaining excellent manufacturing and molding performance of the material.

Owner:CENT SOUTH UNIV

Method for manufacturing fully dense metal sheets and layered composites from reactive alloy powders

InactiveUS20040096350A1Improve mechanical propertiesReduce residual porosityIncreasing energy efficiencyWelding/cutting media/materialsTi 6al 4vVolumetric Mass Density

The method is suitable for the manufacture of flat or shaped titanium aluminide articles and layered metal matrix composites such as lightweight plates and sheets for aircraft and automotive applications, thin cross-section vanes and blades, composite electrodes, heat-sinking lightweight electronic substrates, bulletproof structures for vests, partition walls and doors, as well as for sporting goods such as helmets, golf clubs, sole plates, crown plates, etc. The method includes the following steps: (a) forming a porous preform of the reactive powder alloy or a porous multi-layer composite preform consisting of reactive powder metals and alloys by consolidation using at least one method selected from low-temperature loose sintering in vacuum, high-temperature loose sintering in vacuum, low-pressure sintering in an inert gas, cold pressing, direct powder rolling, isostatic or die pressing, and other means of room temperature and warm temperature consolidation, and / or combination thereof, to provide the density not less than 25% from the theoretical density of said reactive alloy; (b) hot consolidating by hot pressing said preform, hot rolling, hot isostatic pressing, or hot extrusion to obtain the density of 98-100% from the theoretical density of said reactive alloy; (c) additional sintering and / or annealing at the temperature being at least 900° C. to decrease the residual porosity, control the microstructure, and improve the mechanical properties, especially ductility and / or plasticity of the resulting metal sheets or layered composites. The hot pressing is carried out at the temperature ranging 950-1700° C., preferably at 1250-1450° C., and at pressure ranging 50-350 kg / cm<2>. The HIP is carried out at the temperature ranging 1250-1350° C. and at pressure ranging 15000-40000 psi. The layered composite preform is manufactured by individual loose sintering, one layer of the composite at a time, and assembling them in the desired order. The composite consists of layers of titanium and / or titanium hydride, Ti-6Al-4V alloy, alpha-titanium aluminide alloy, beta-titanium aluminide alloy, and gamma-titanium aluminide alloy in any combinations.

Owner:ADVANCED MATERIALS PRODS

Metastable beta-titanium alloys and methods of processing the same by direct aging

Owner:ATI PROPERTIES LLC

Metastable beta-titanium alloys and methods of processing the same by direct aging

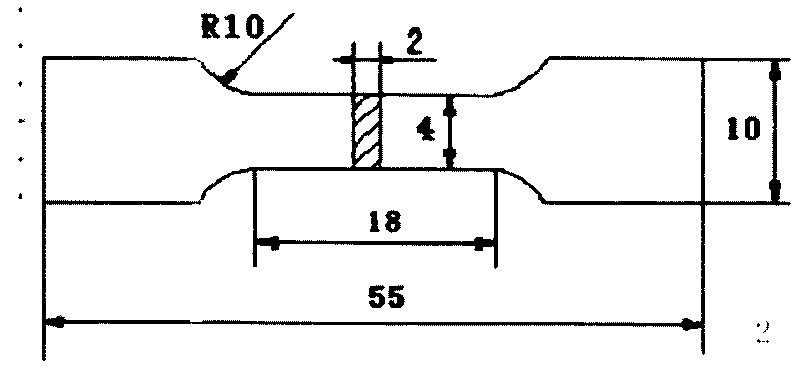

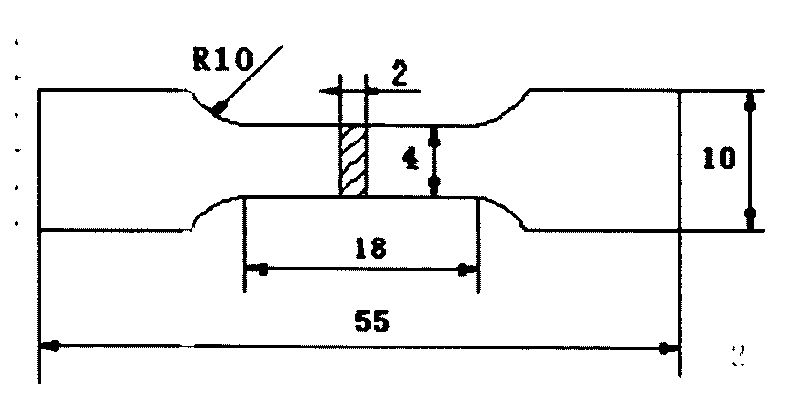

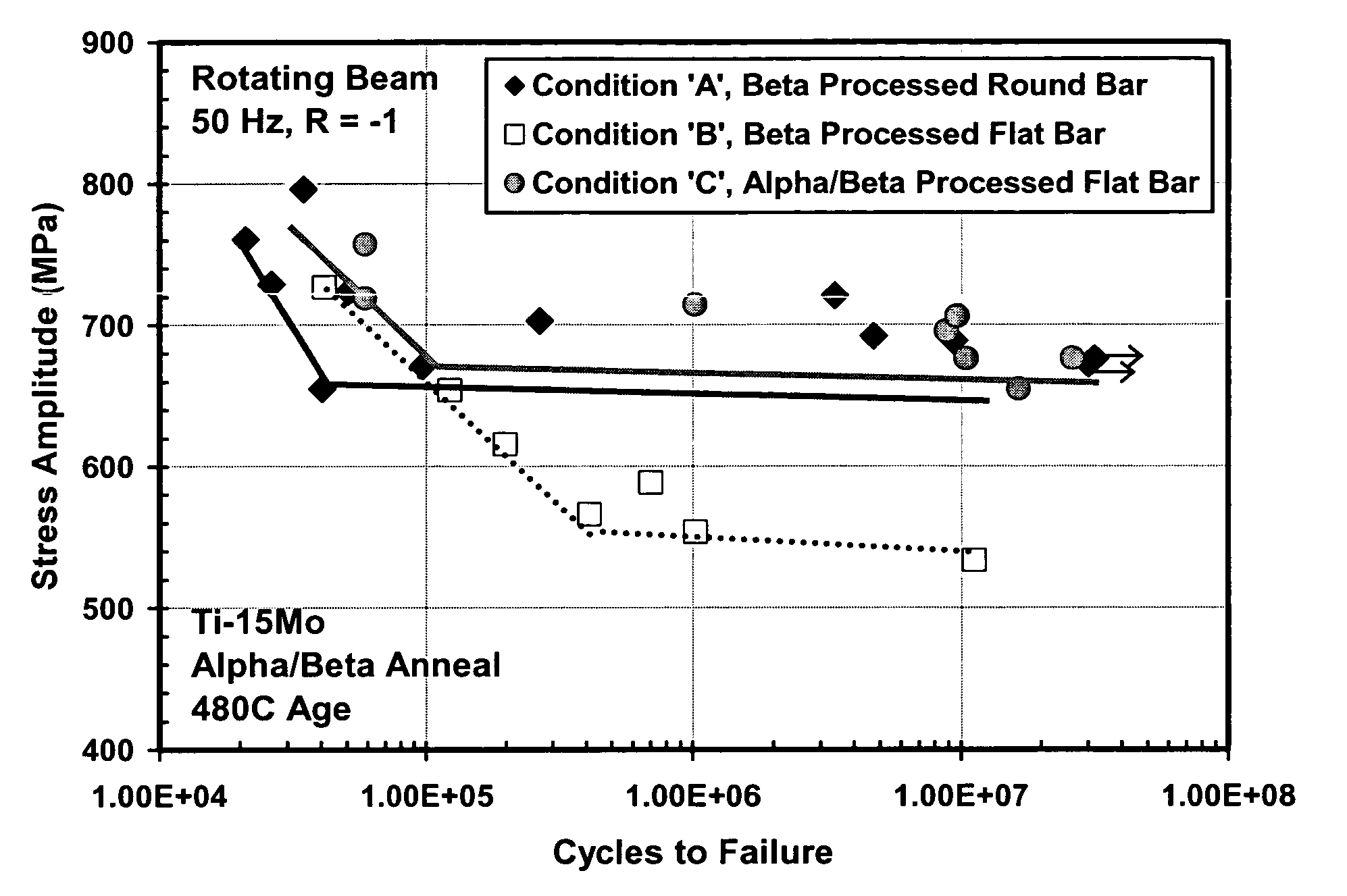

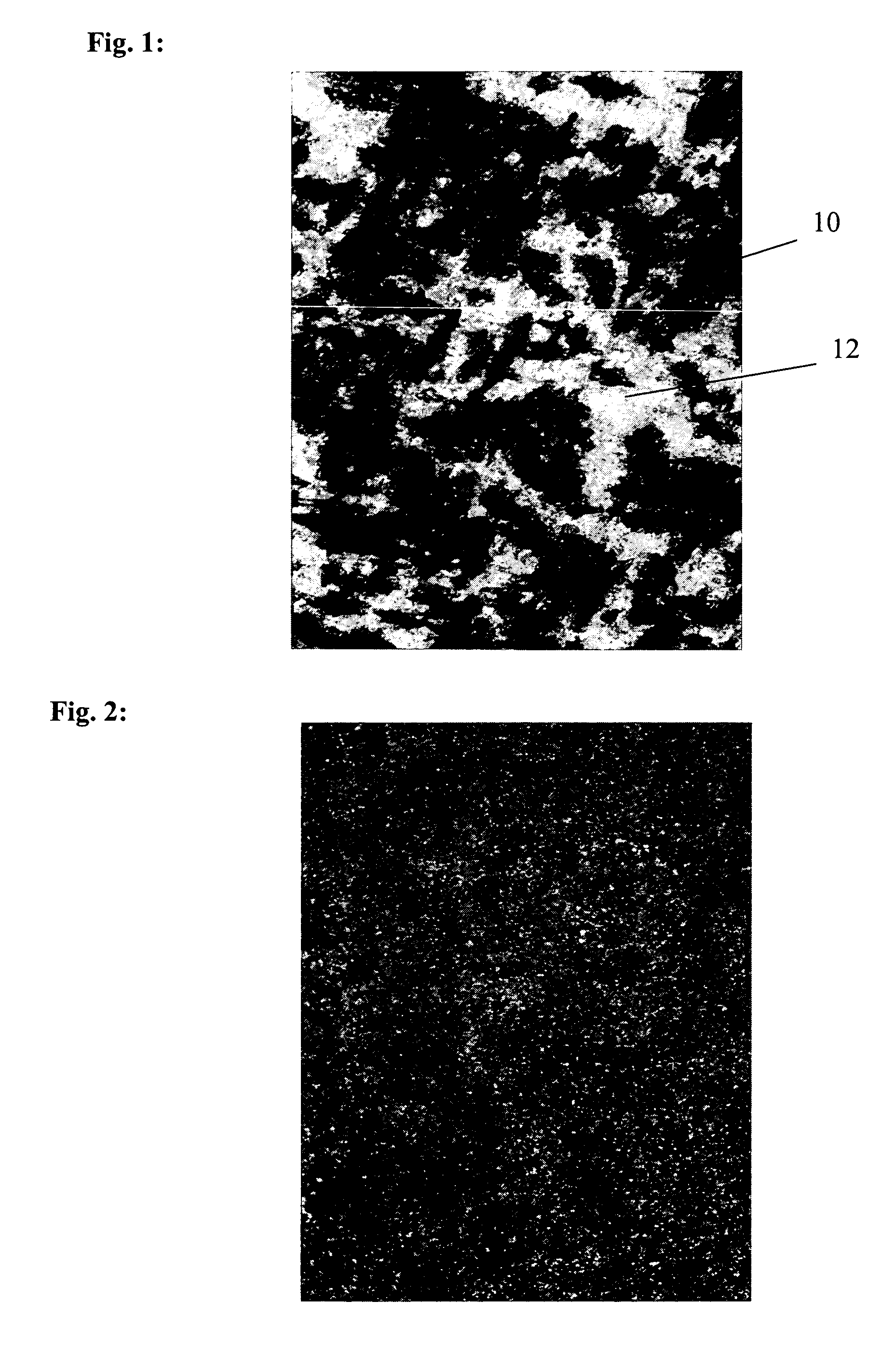

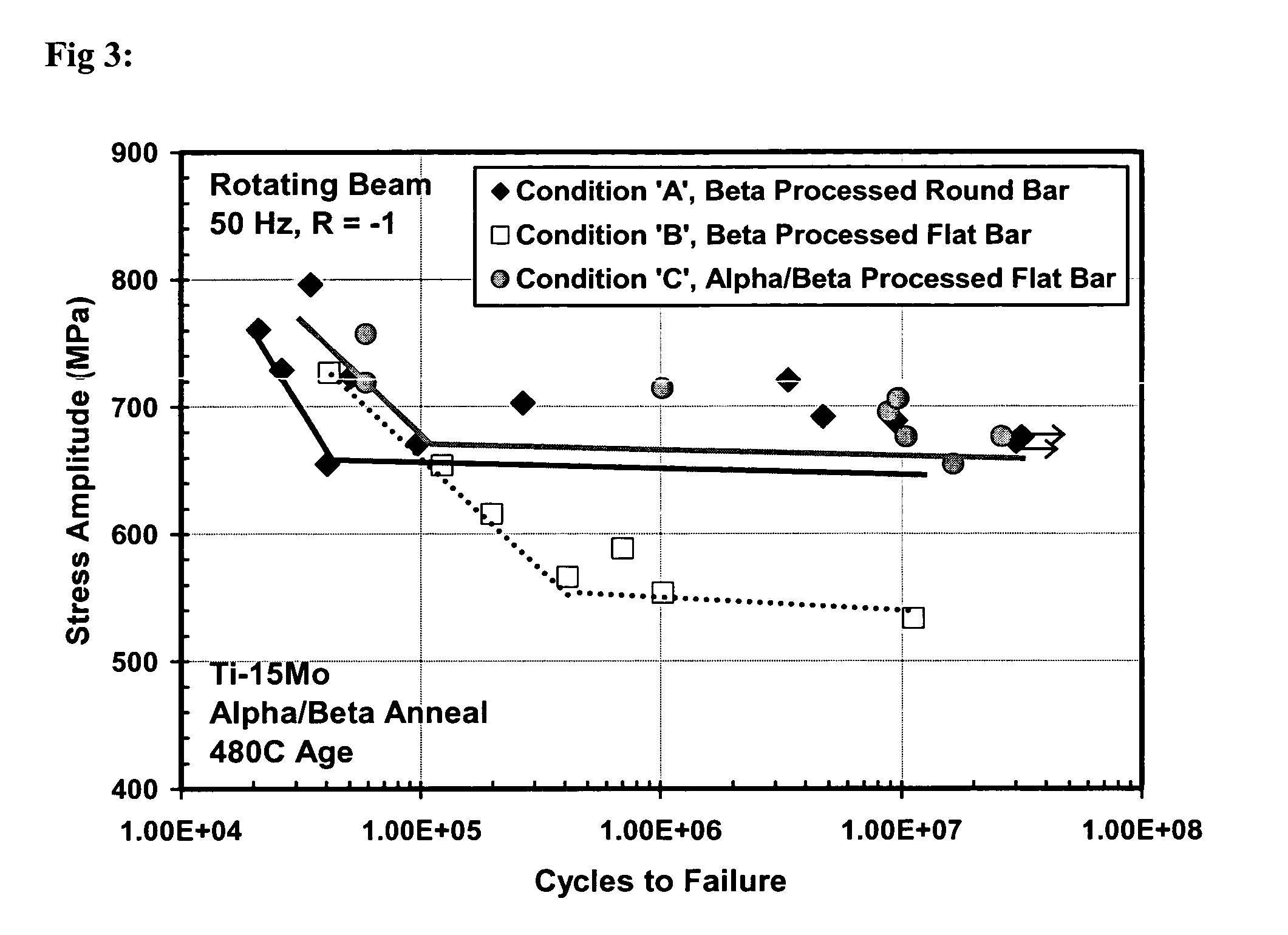

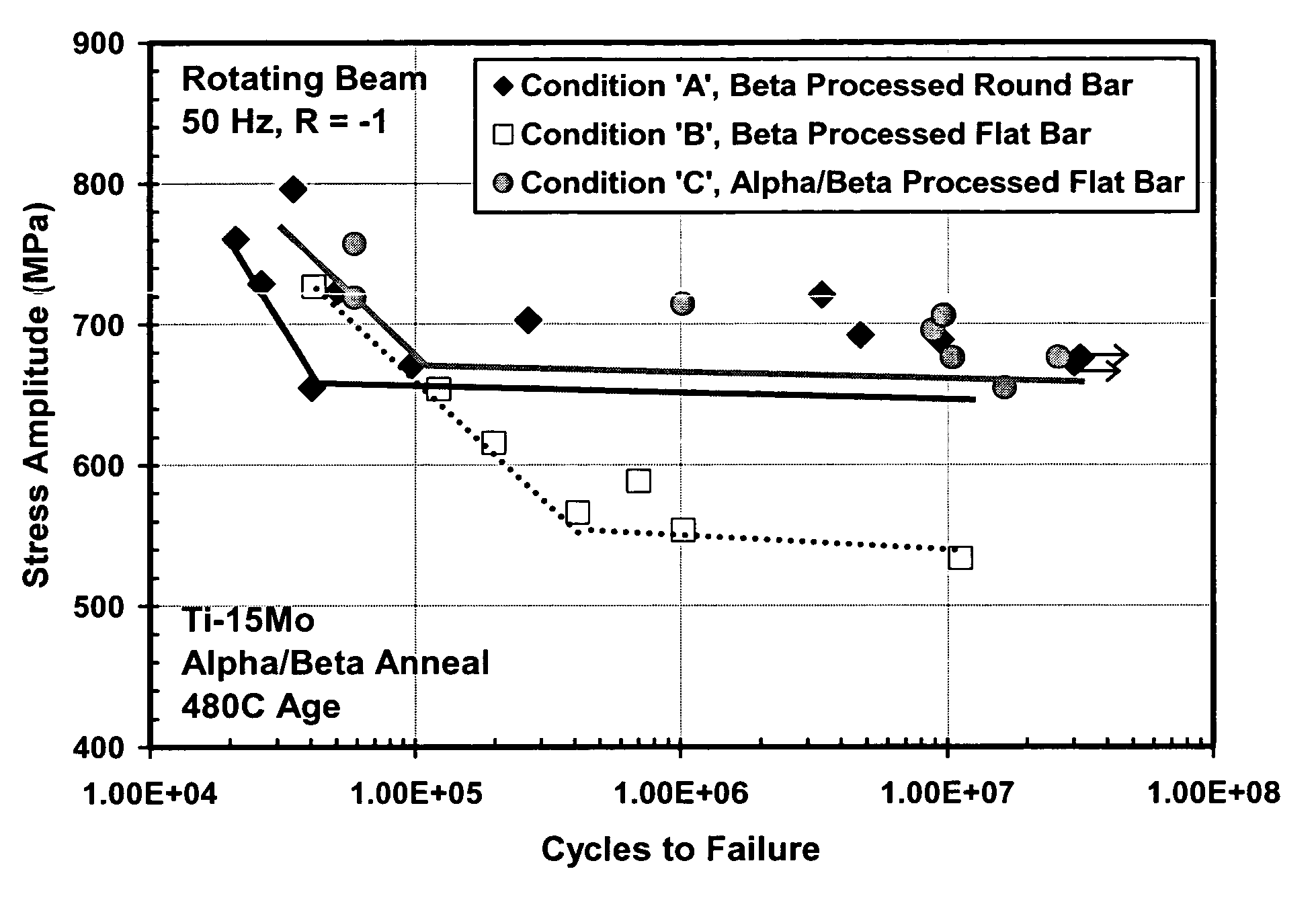

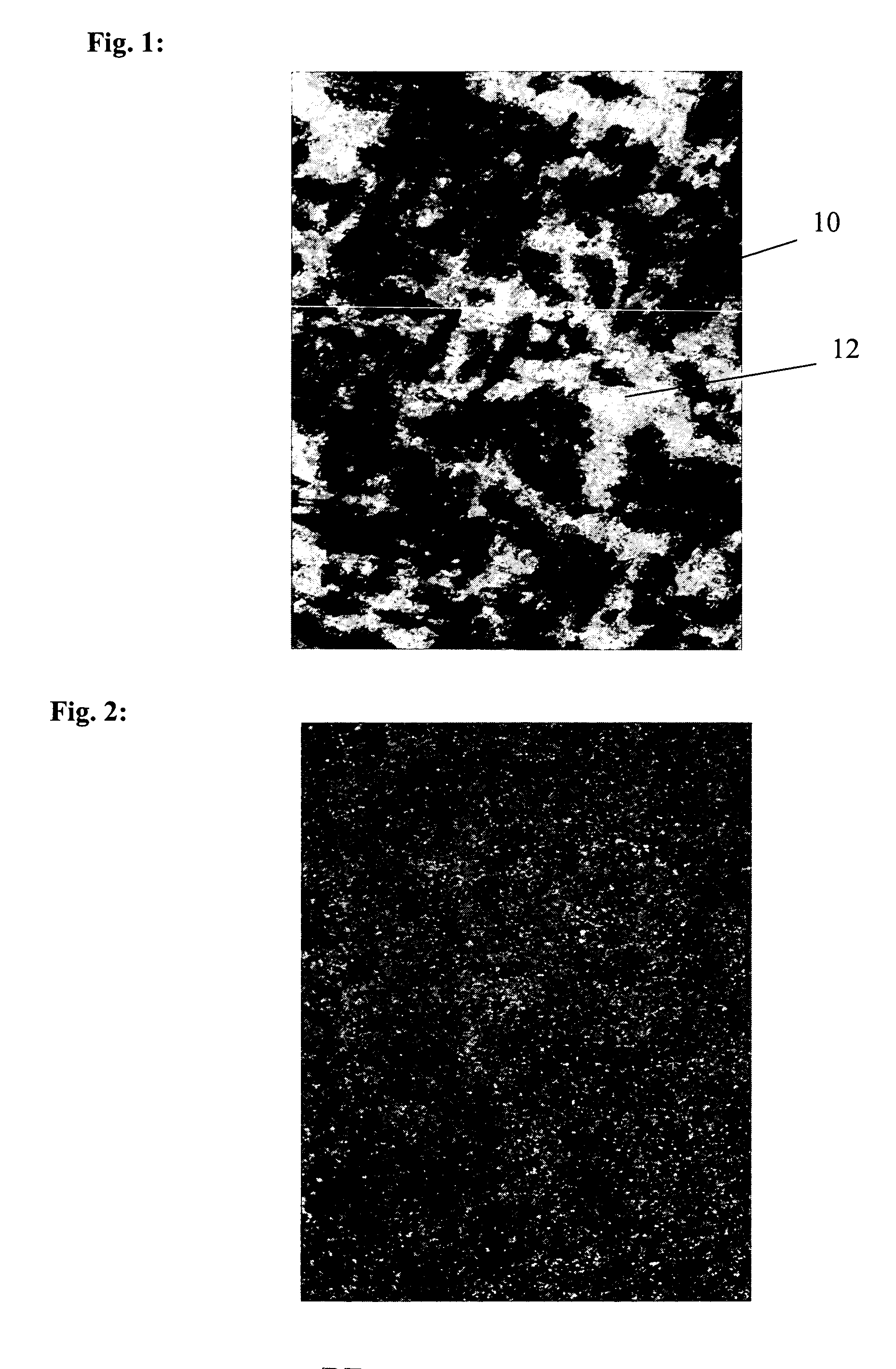

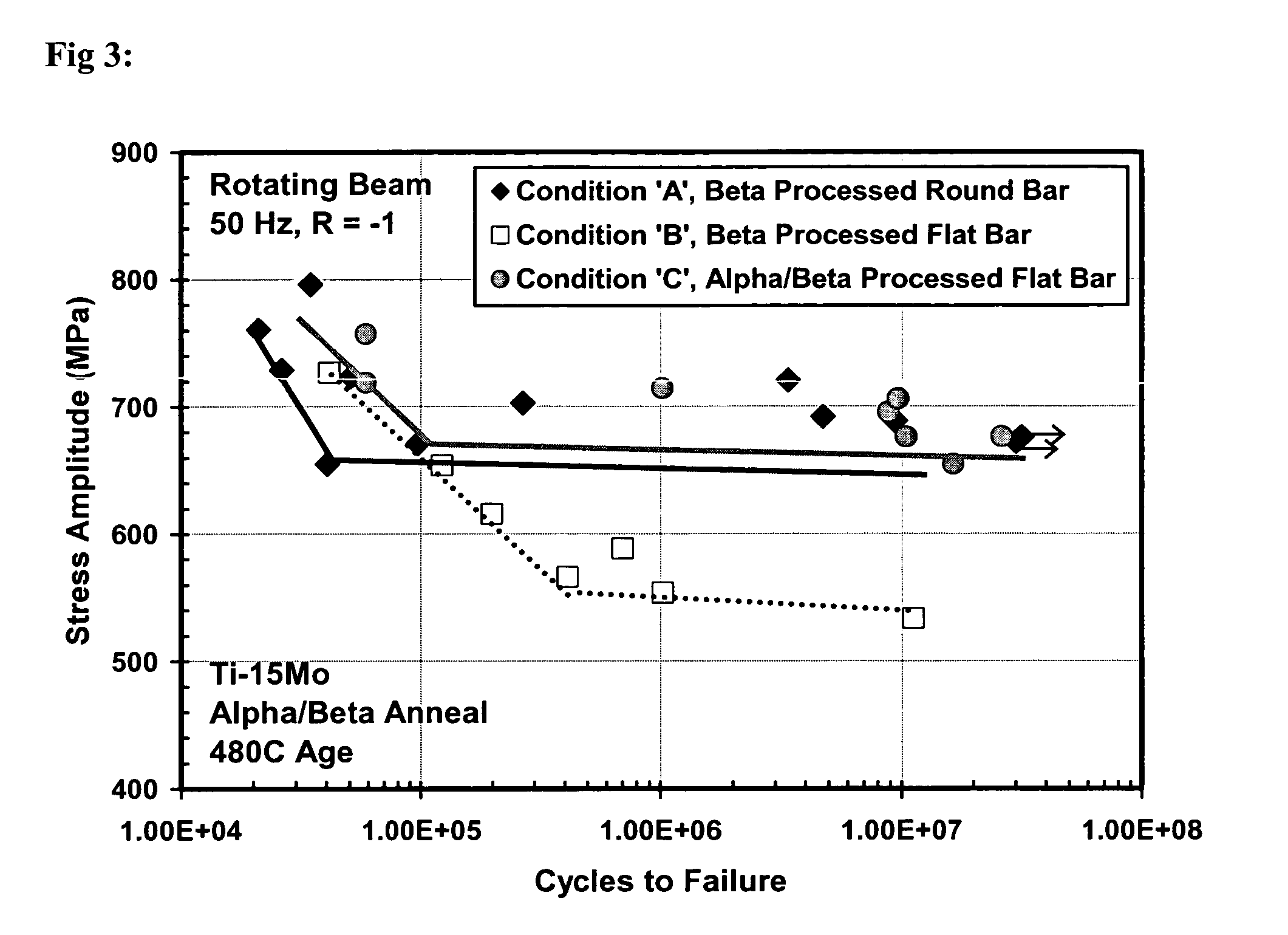

Metastable beta titanium alloys and methods of processing metastable β-titanium alloys are disclosed. For example, certain non-limiting embodiments relate to metastable β-titanium alloys, such as binary β-titanium alloys comprising greater than 10 weight percent molybdenum, having tensile strengths of at least 150 ksi and elongations of at least 12 percent. Other non-limiting embodiments relate to methods of processing metastable β-titanium alloys, and more specifically, methods of processing binary β-titanium alloys comprising greater than 10 weight percent molybdenum, wherein the method comprises hot working and direct aging the metastable β-titanium alloy at a temperature below the β-transus temperature of the metastable β-titanium alloy for a time sufficient to form α-phase precipitates in the metastable β-titanium alloy. Articles of manufacture comprising binary β-titanium alloys according to various non-limiting embodiments disclosed herein are also disclosed.

Owner:ATI PROPERTIES LLC

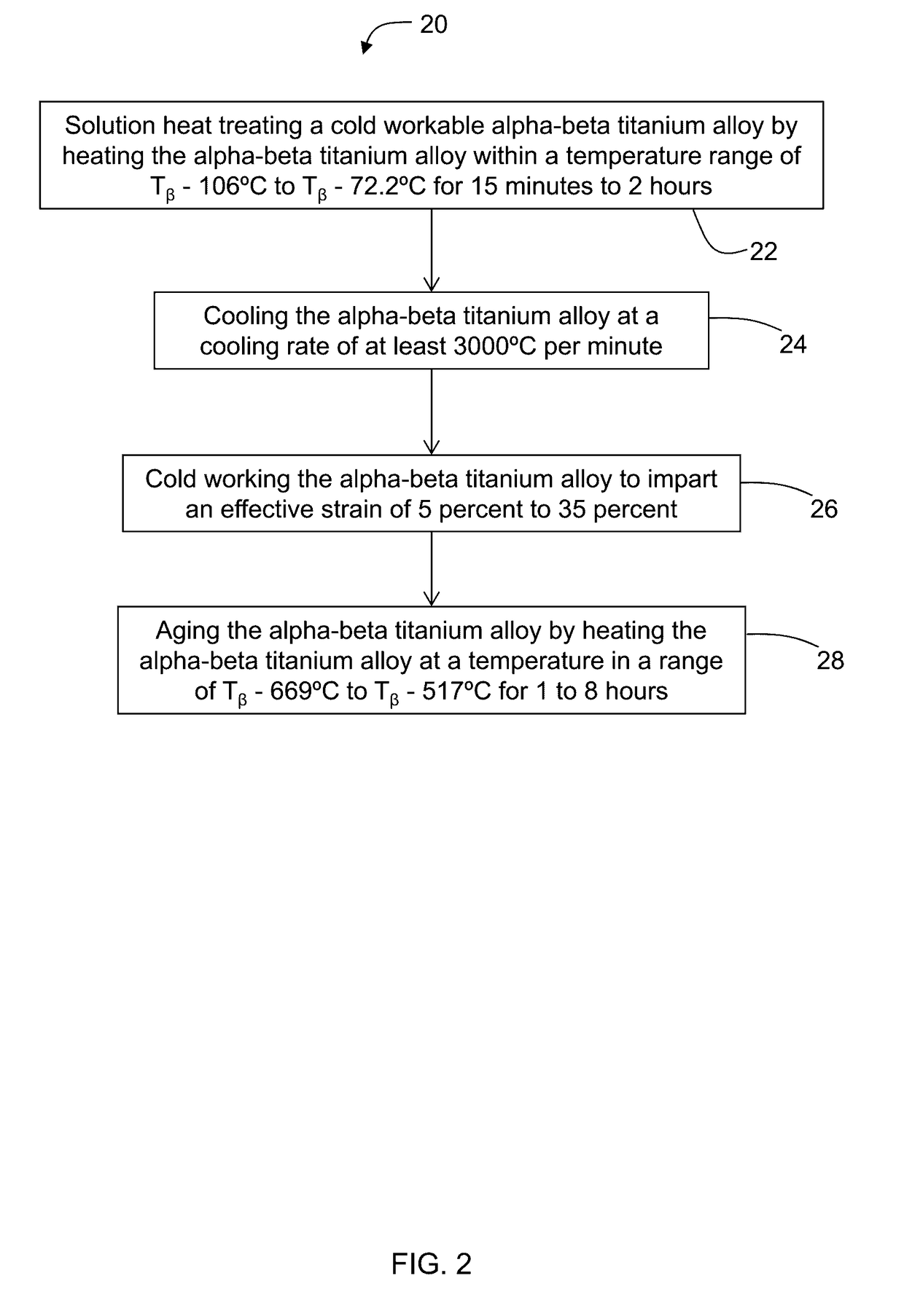

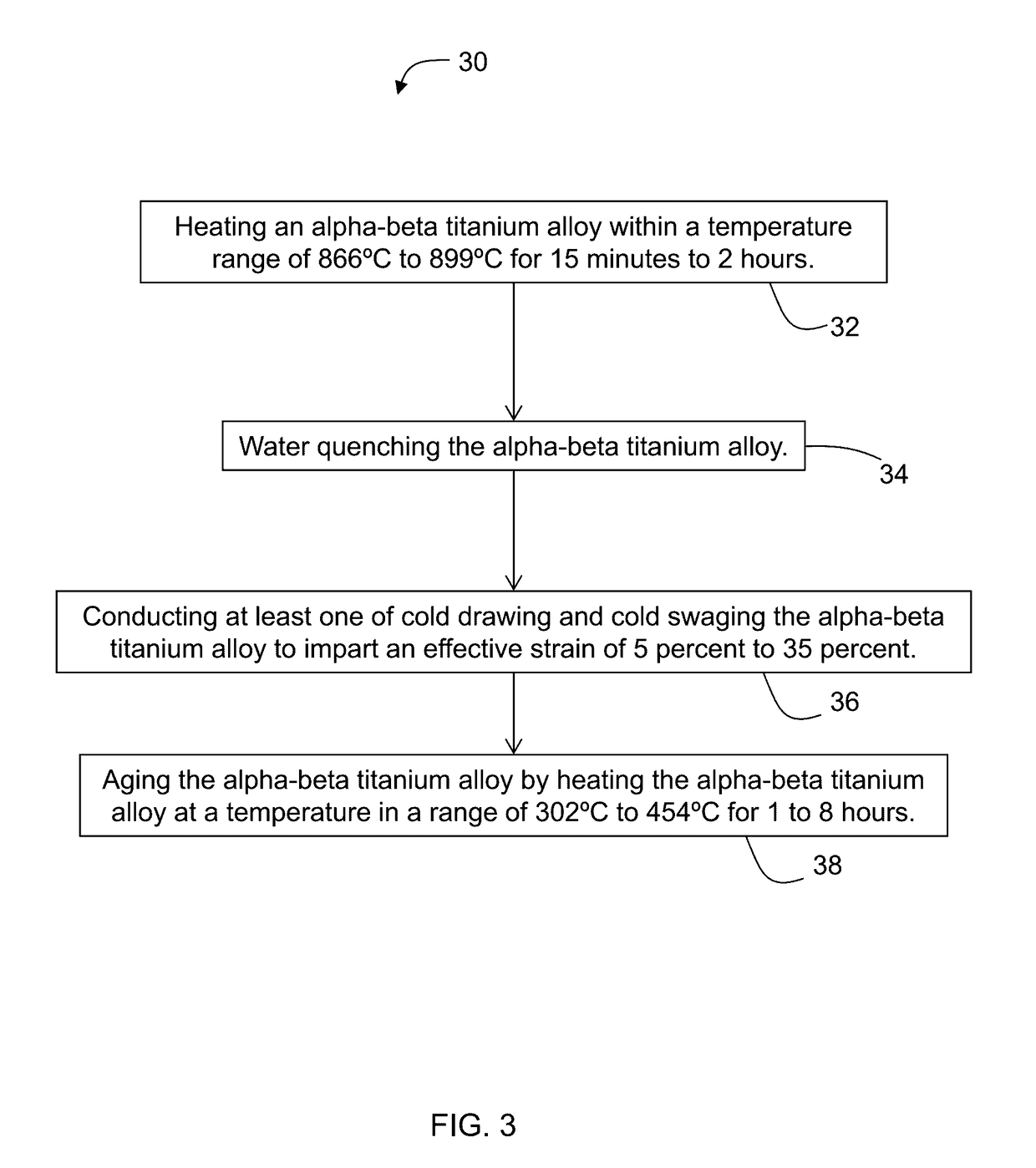

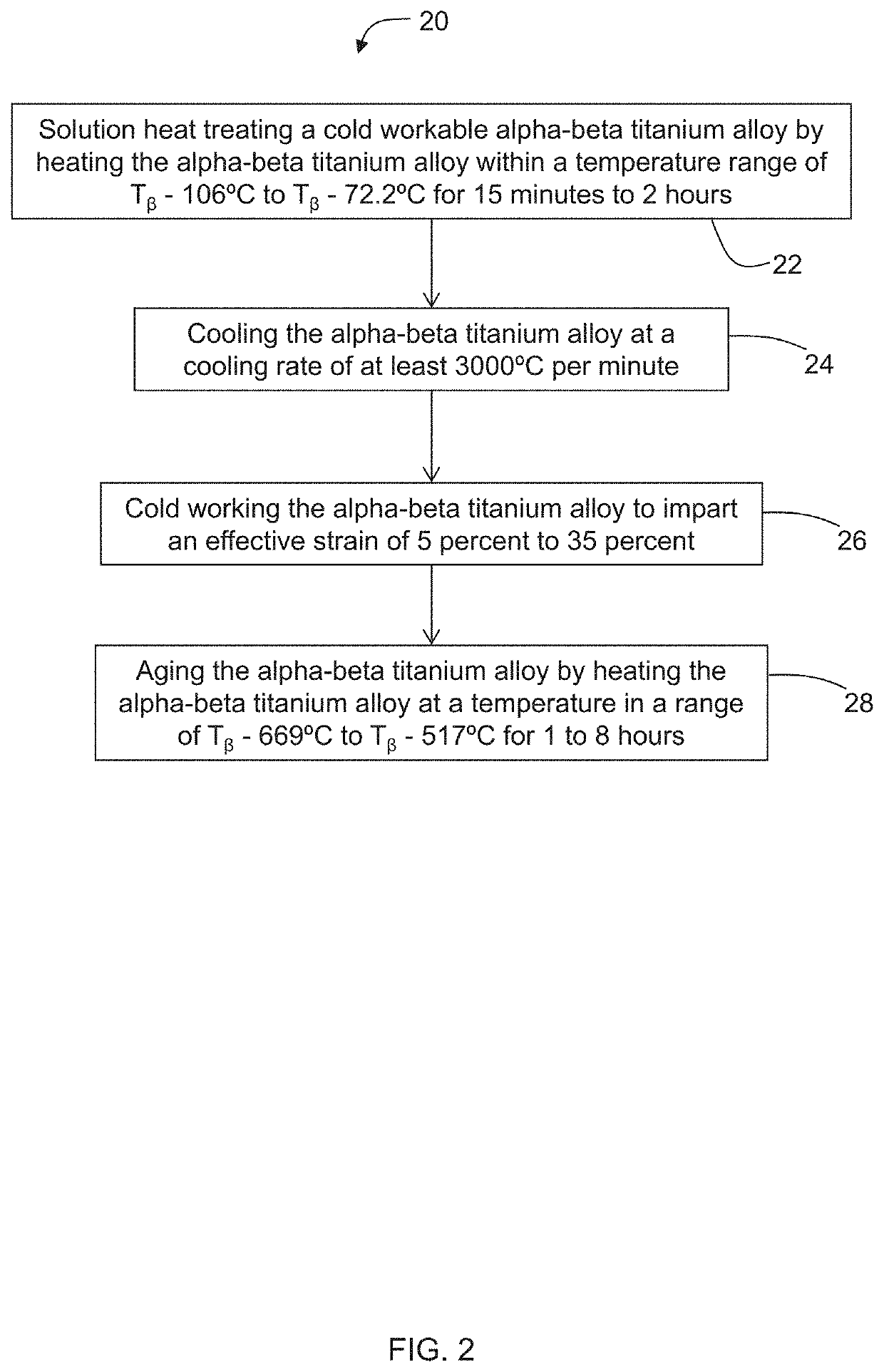

Processing of alpha-beta titanium alloys

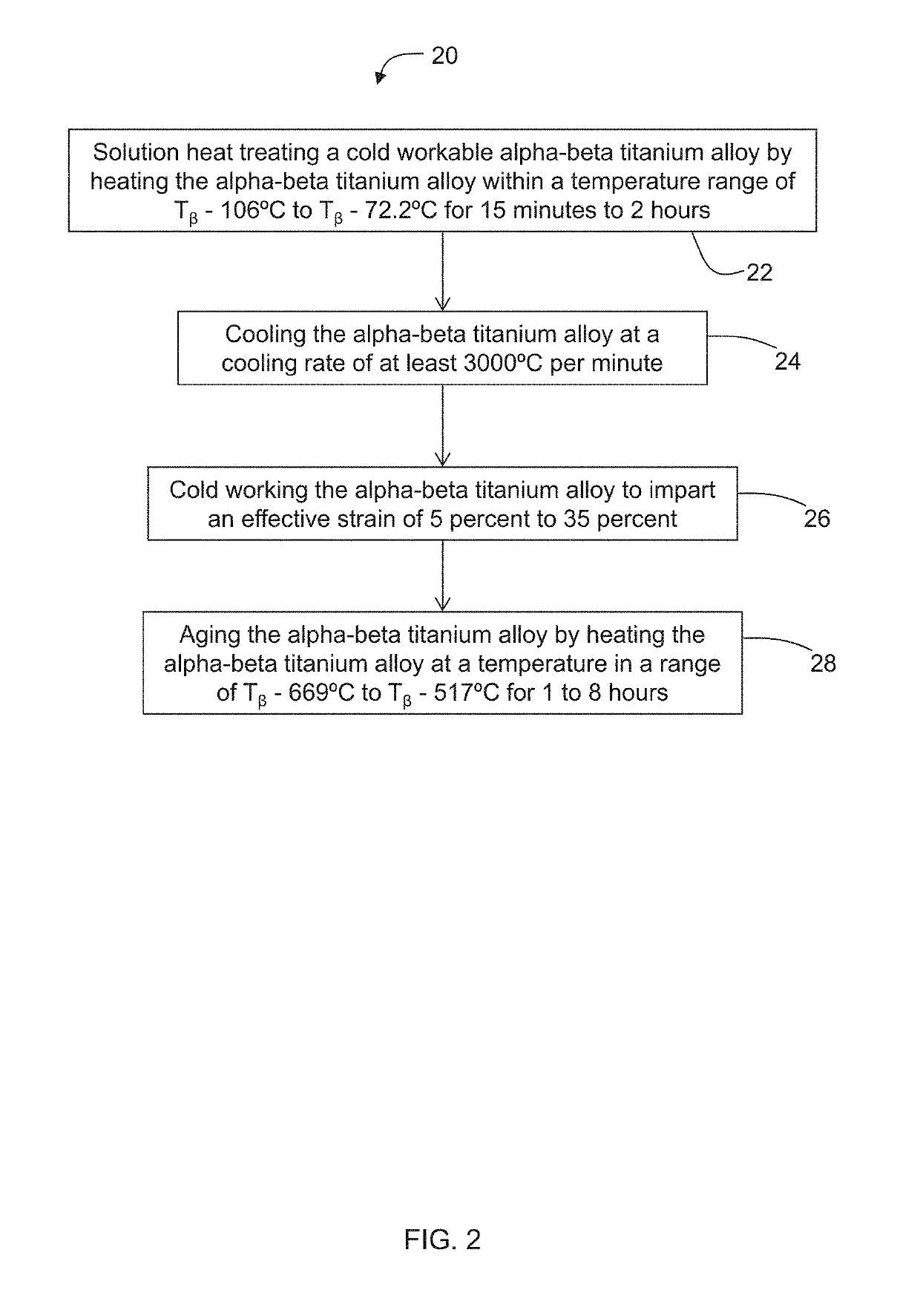

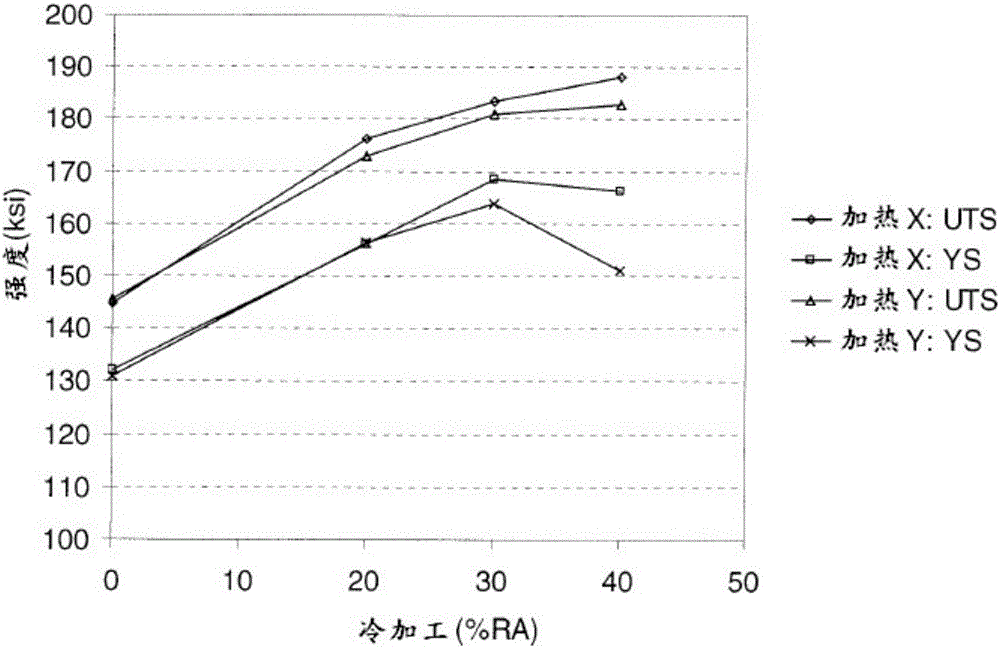

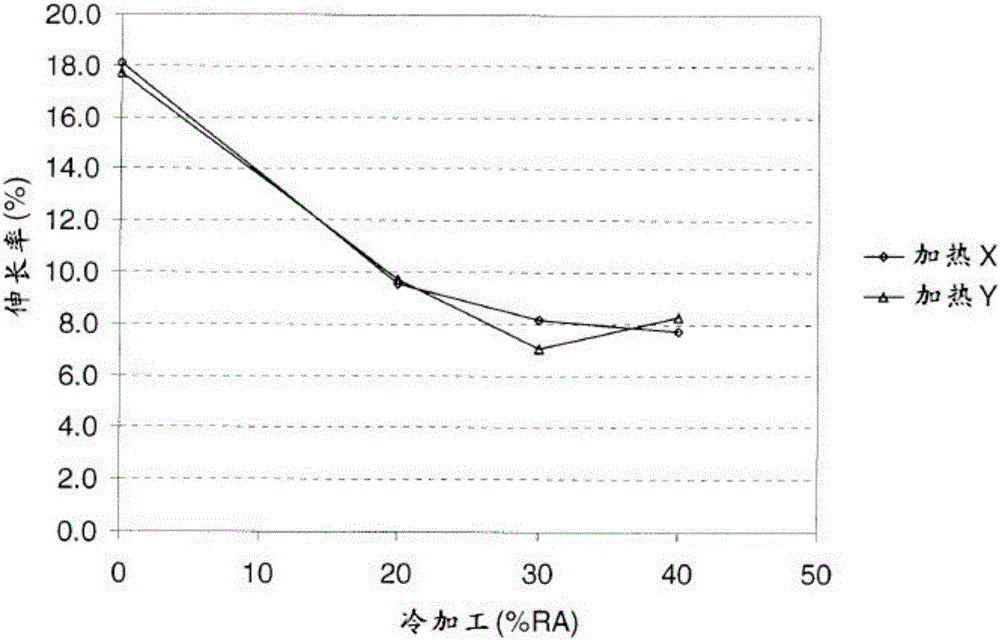

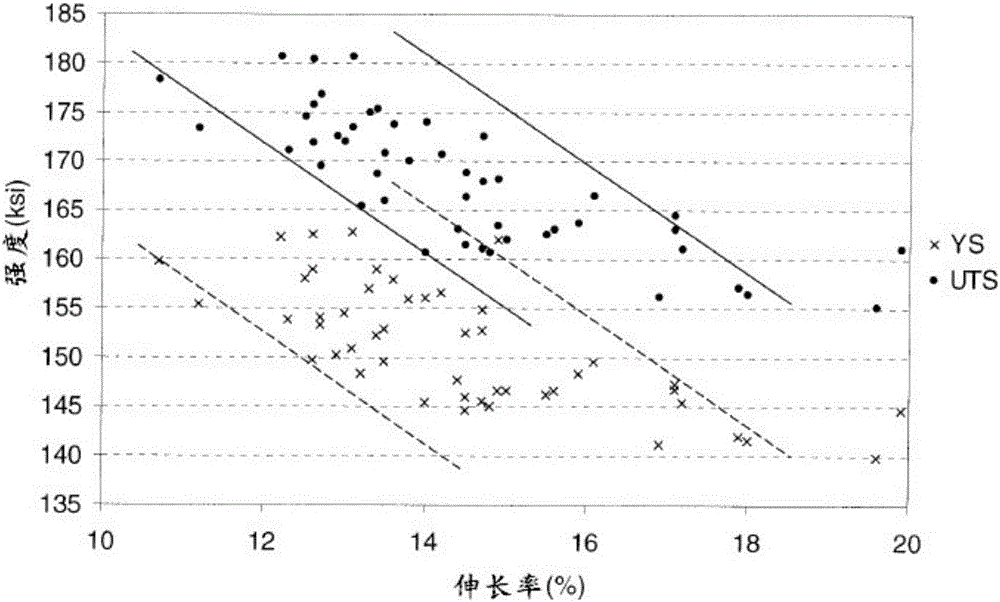

A method for increasing tensile strength of a cold workable alpha-beta titanium alloy comprises solution heat treating a cold workable alpha-beta titanium alloy in a temperature range of Tβ-106° C. to Tβ-72.2° C. for 15 minutes to 2 hours; cooling the alpha-beta titanium alloy at a cooling rate of at least 3000° C. / minute; cold working the alpha-beta titanium alloy to impart an effective strain in the range of 5 percent to 35 percent in the alloy; and aging the alpha-beta titanium alloy in a temperature range of Tβ-669° C. to Tβ-517° C. for 1 to 8 hours. Fastener stock and fasteners including solution treated, quenched, cold worked, and aged alpha-beta titanium alloys are also disclosed.

Owner:ATI PROPERTIES LLC

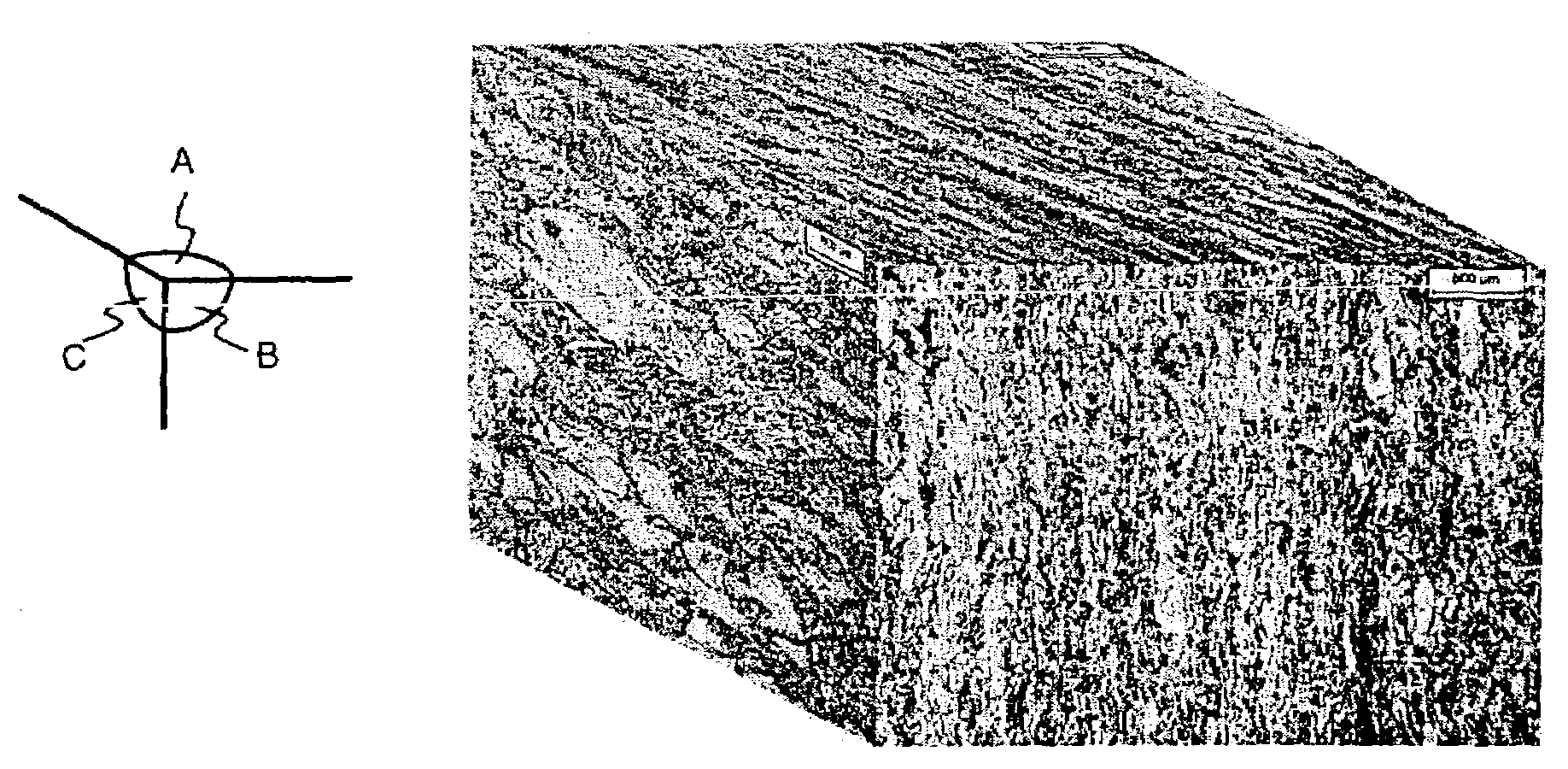

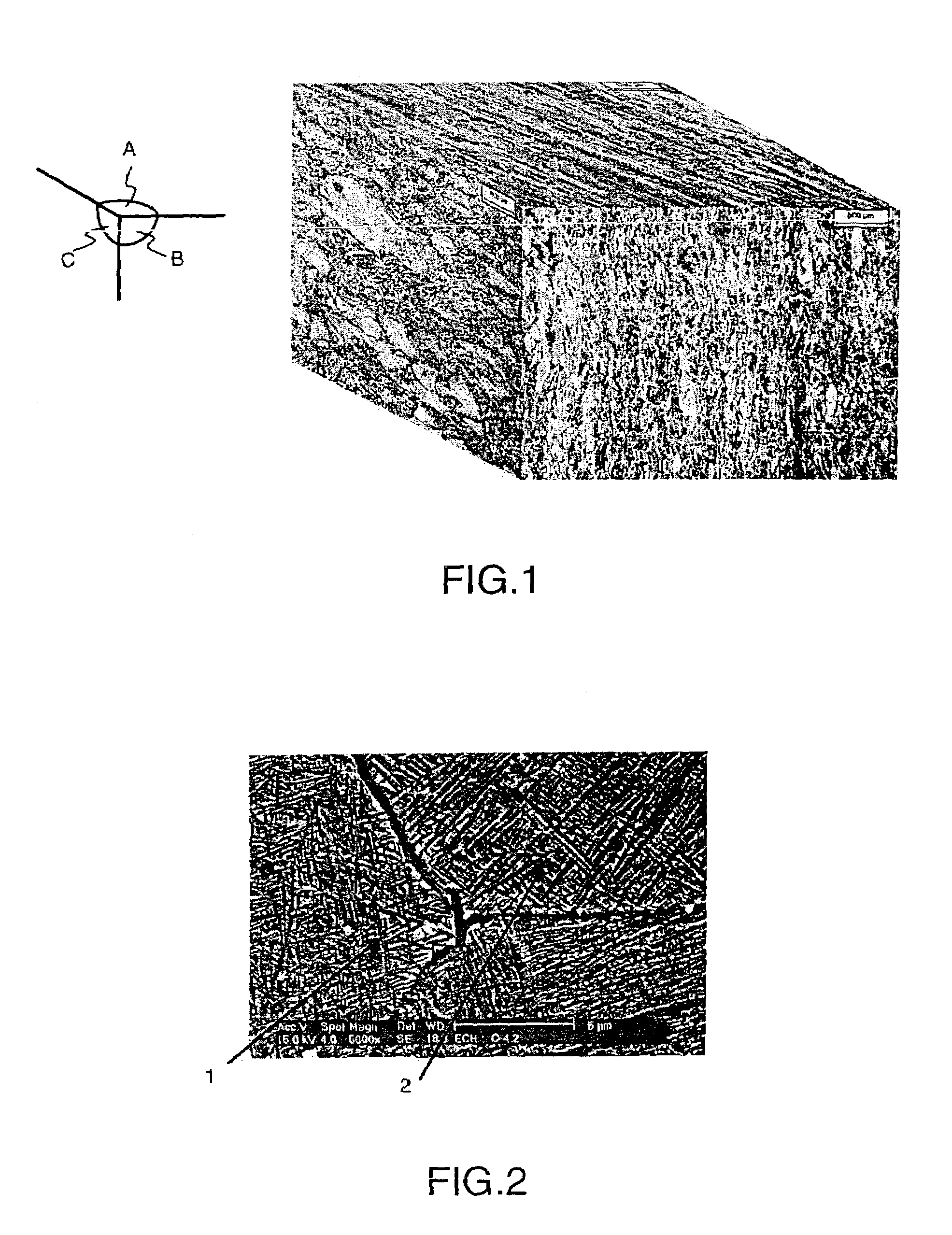

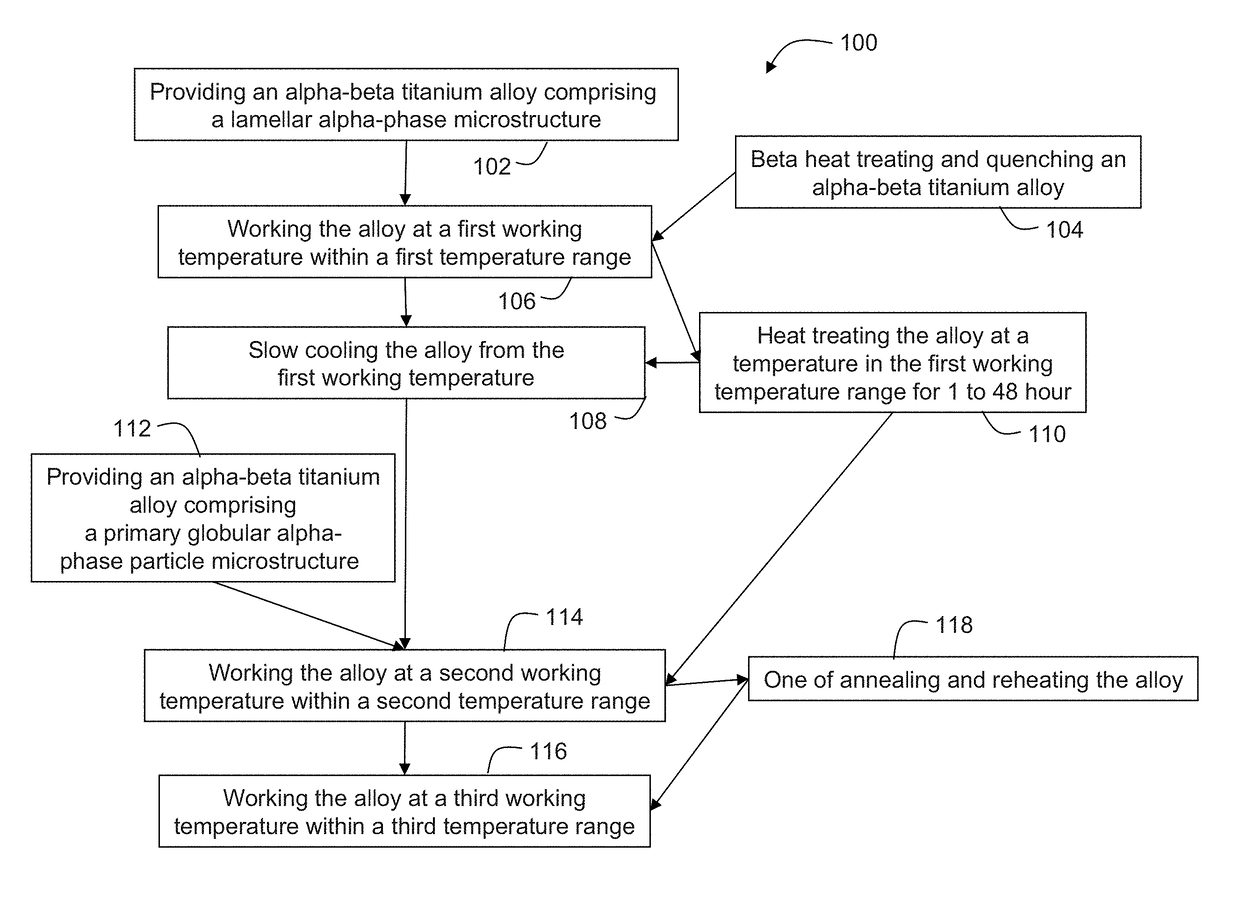

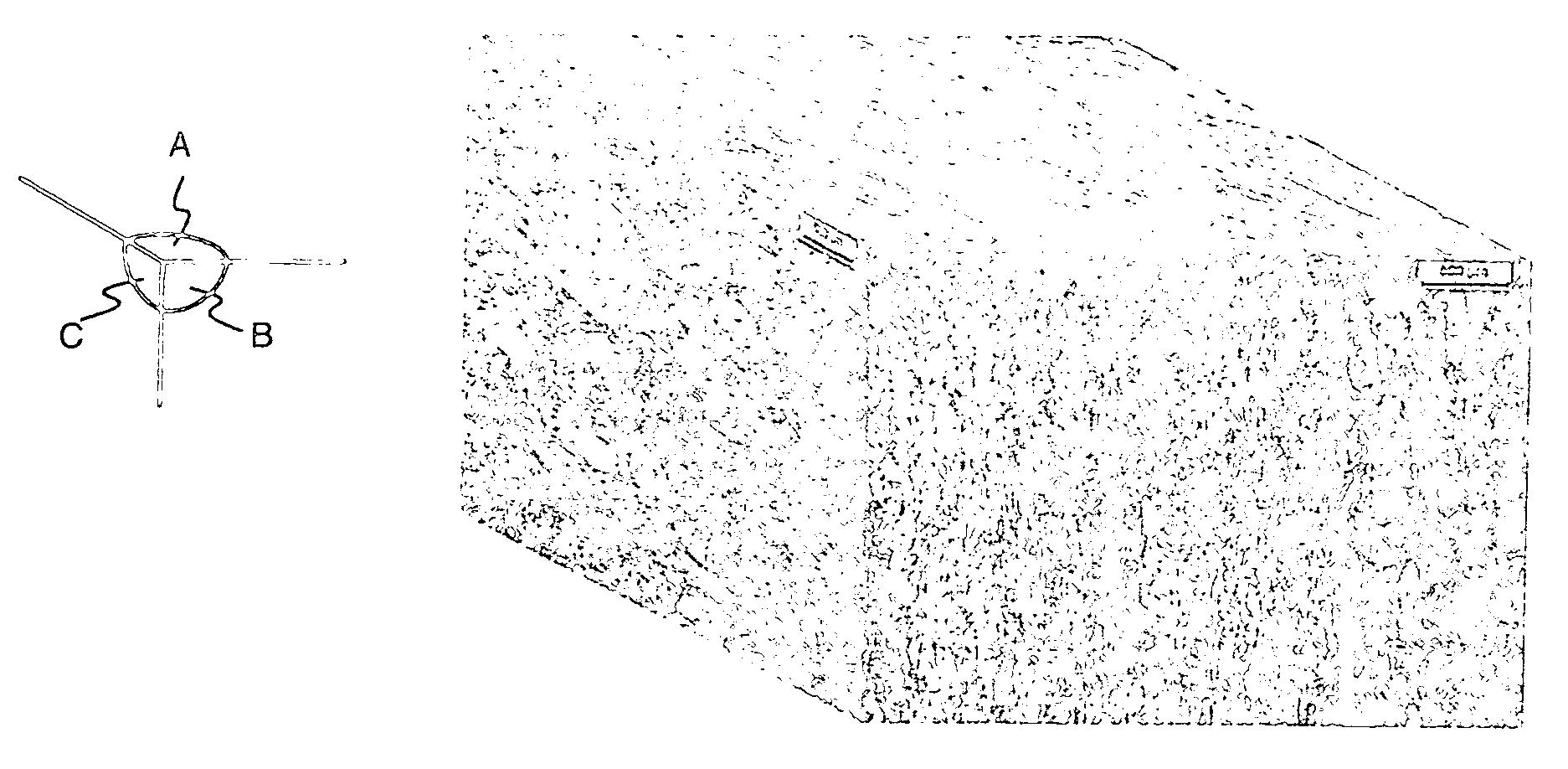

Thin parts made of beta or quasi-beta titanium alloys; manufacture by forging

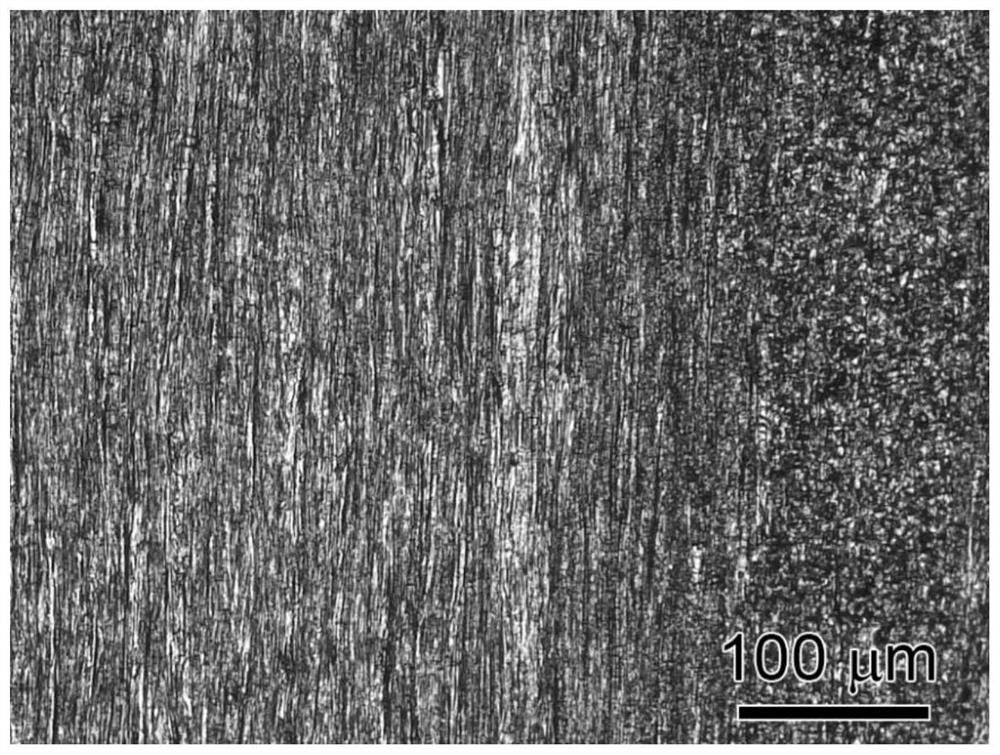

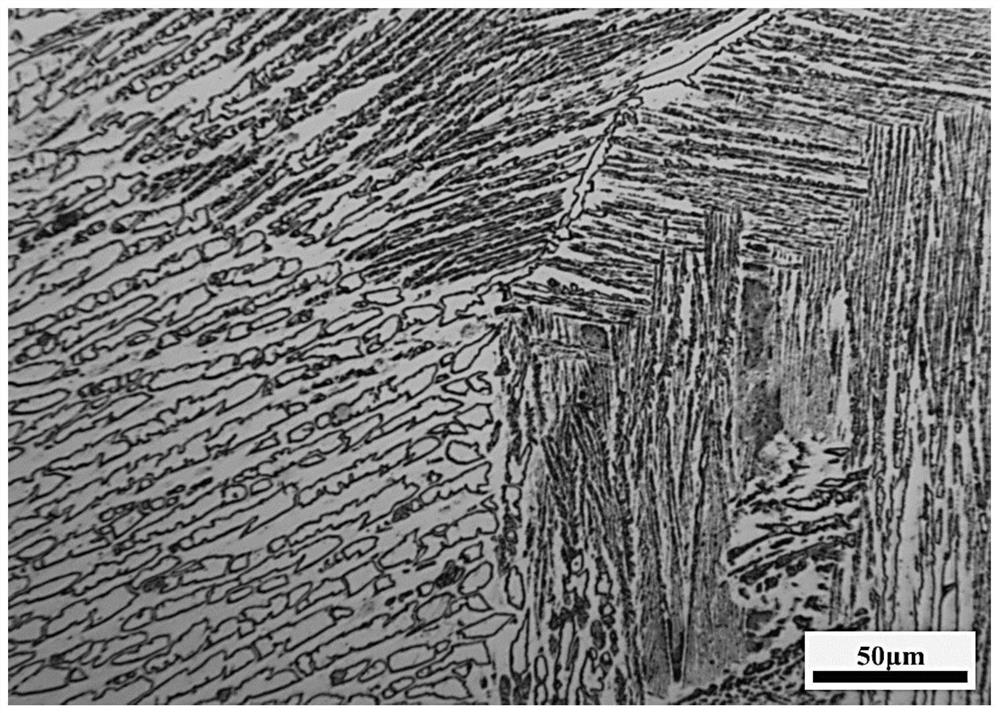

The present invention provides non-axially symmetrical manufactured parts of thickness less than 10 mm, made of β or quasi-β titanium alloy, having a core microstructure constituted by whole grains presenting a slenderness ratio greater than 4 and an equivalent diameter lying in the range 10 μm to 300 μm. The invention also provides a method of manufacturing the parts by forging.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

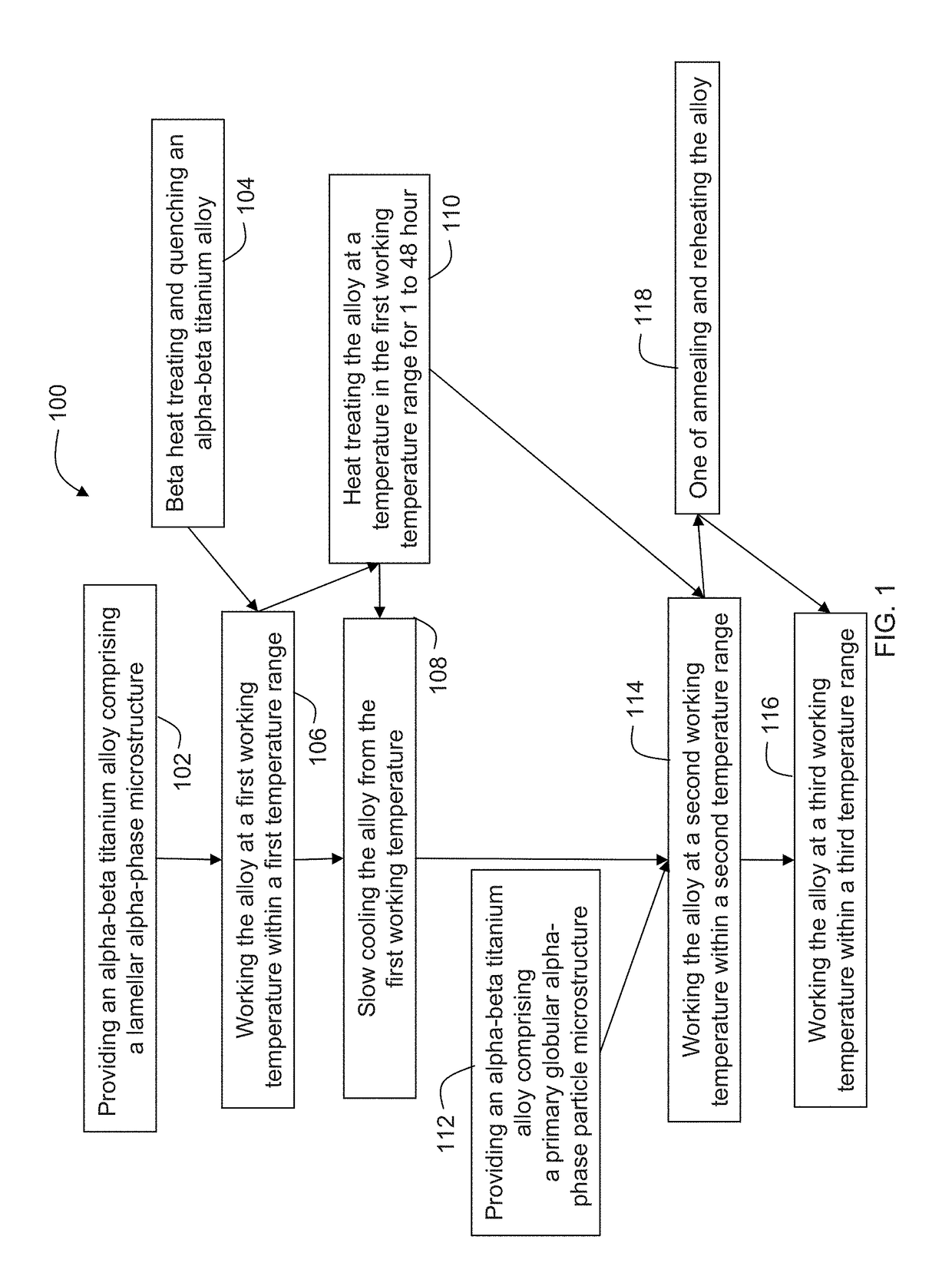

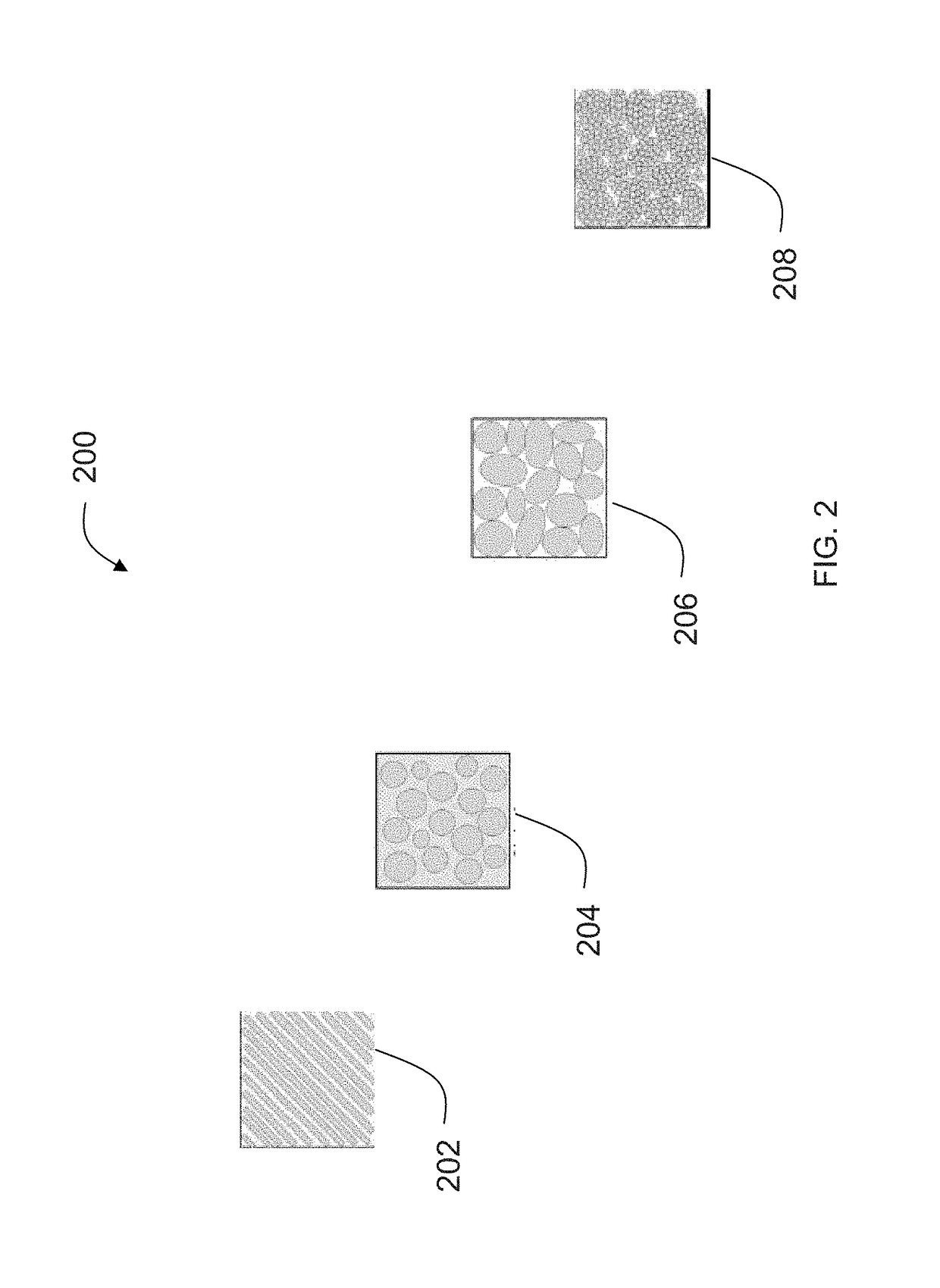

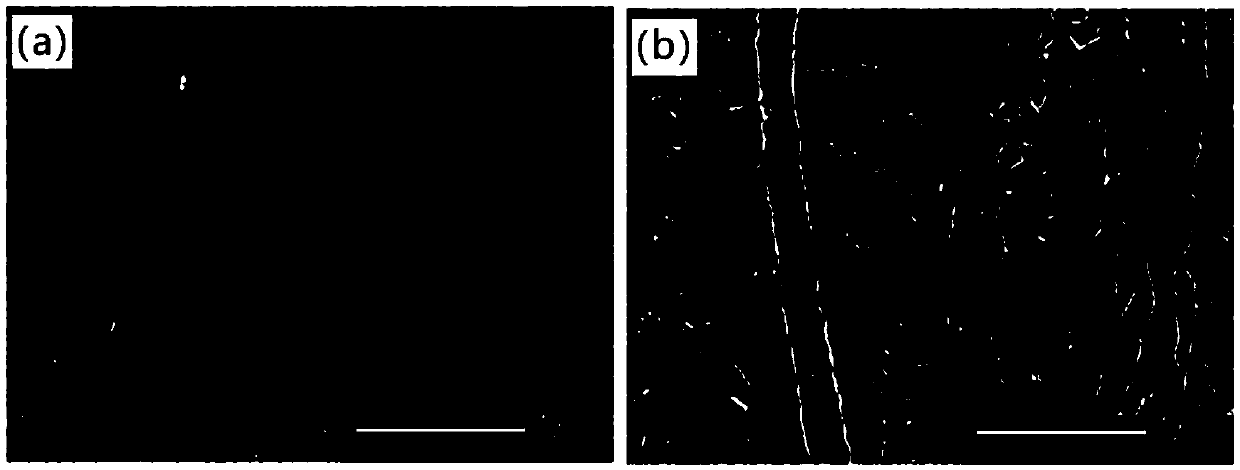

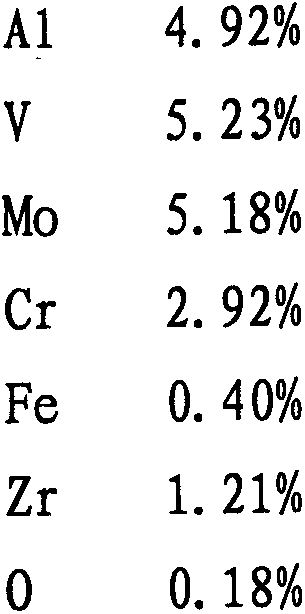

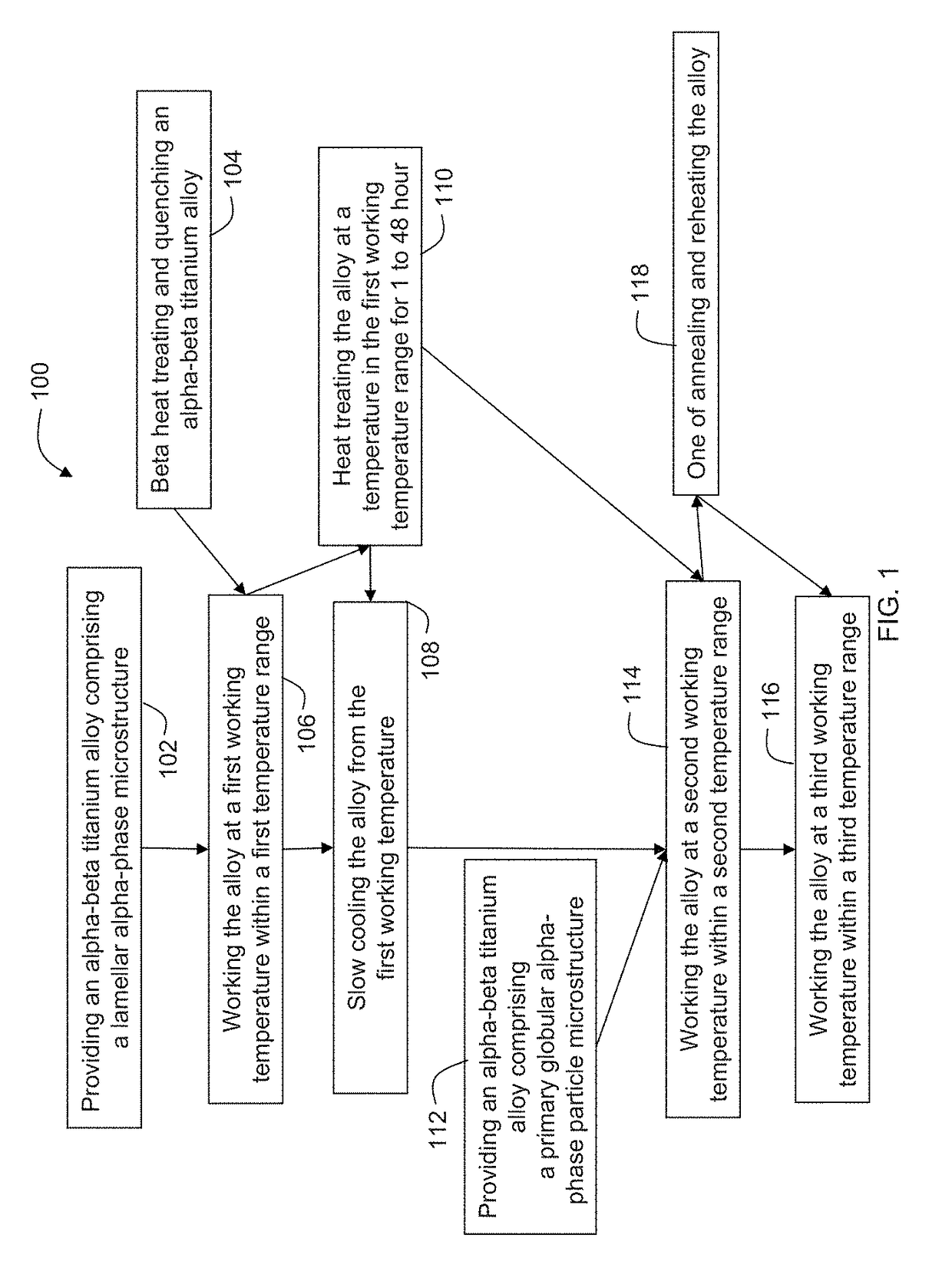

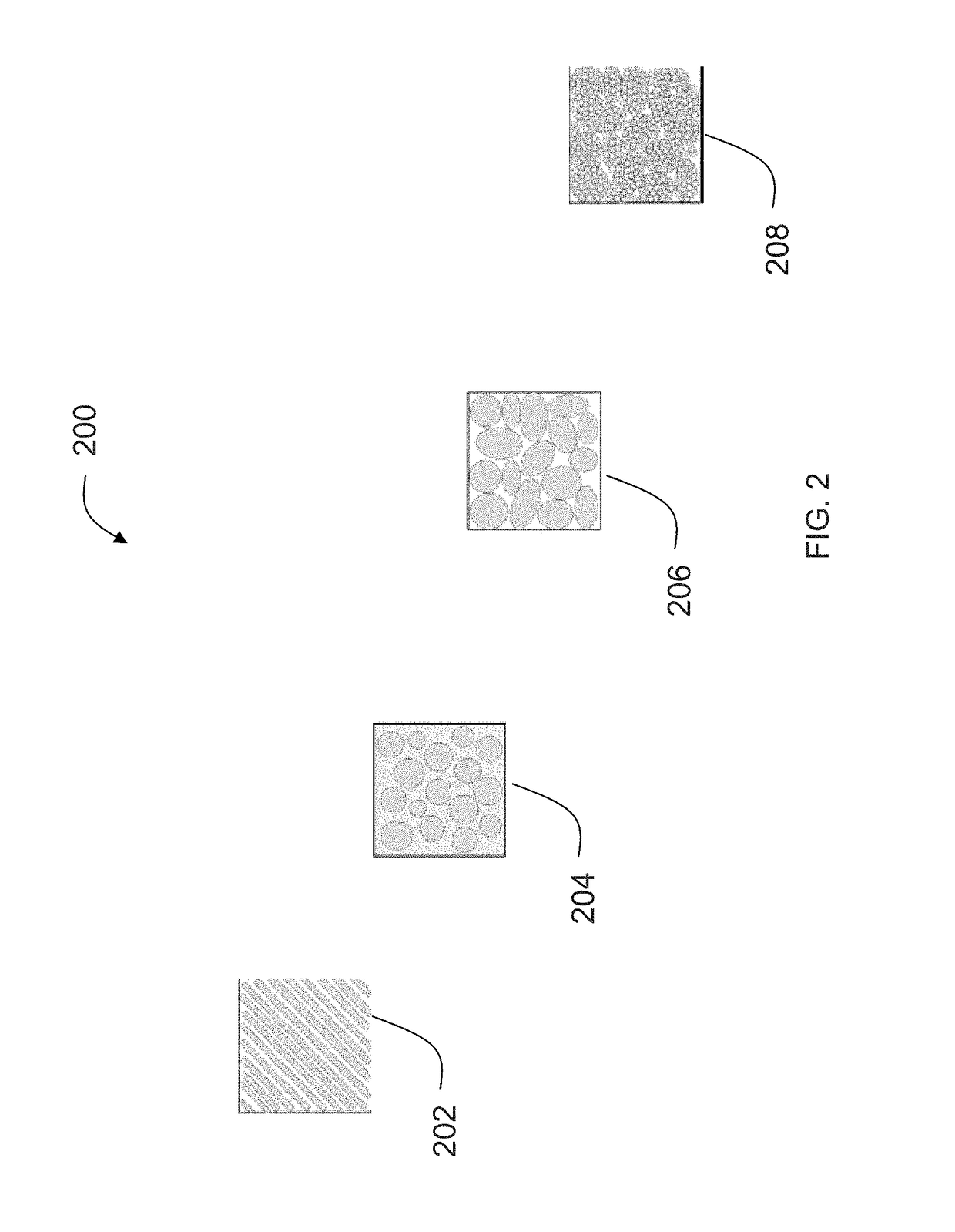

Thermomechanical processing of alpha-beta titanium alloys

One embodiment of a method of refining alpha-phase grain size in an alpha-beta titanium alloy comprises working an alpha-beta titanium alloy at a first working temperature within a first temperature range in the alpha-beta phase field of the alpha-beta titanium alloy. The alloy is slow cooled from the first working temperature. On completion of working at and slow cooling from the first working temperature, the alloy comprises a primary globularized alpha-phase particle microstructure. The alloy is worked at a second working temperature within a second temperature range in the alpha-beta phase field. The second working temperature is lower than the first working temperature. The is worked at a third working temperature in a third temperature range in the alpha-beta phase field. The third working temperature is lower than the second working temperature. After working at the third working temperature, the titanium alloy comprises a desired refined alpha-phase grain size.

Owner:ATI PROPERTIES LLC

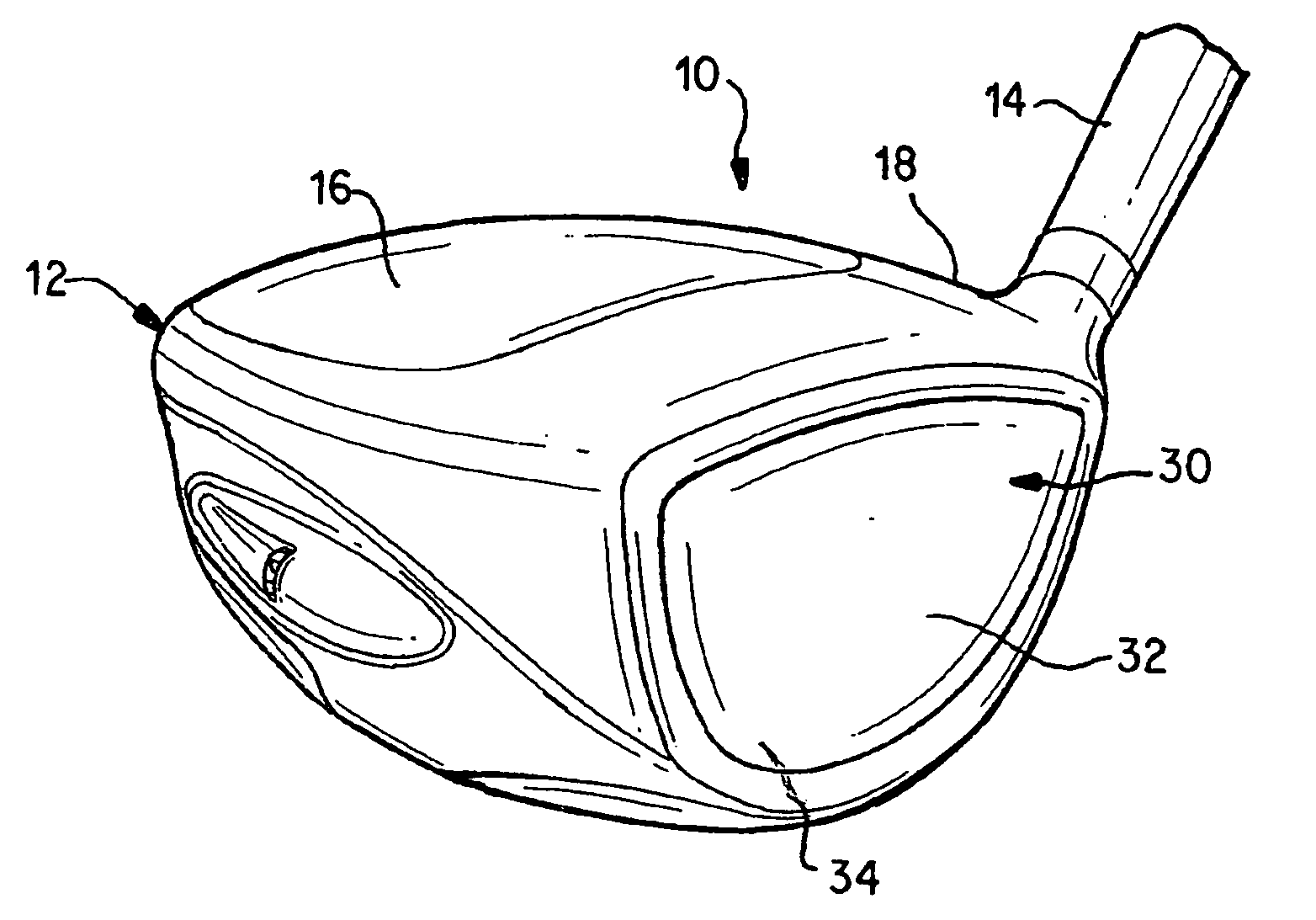

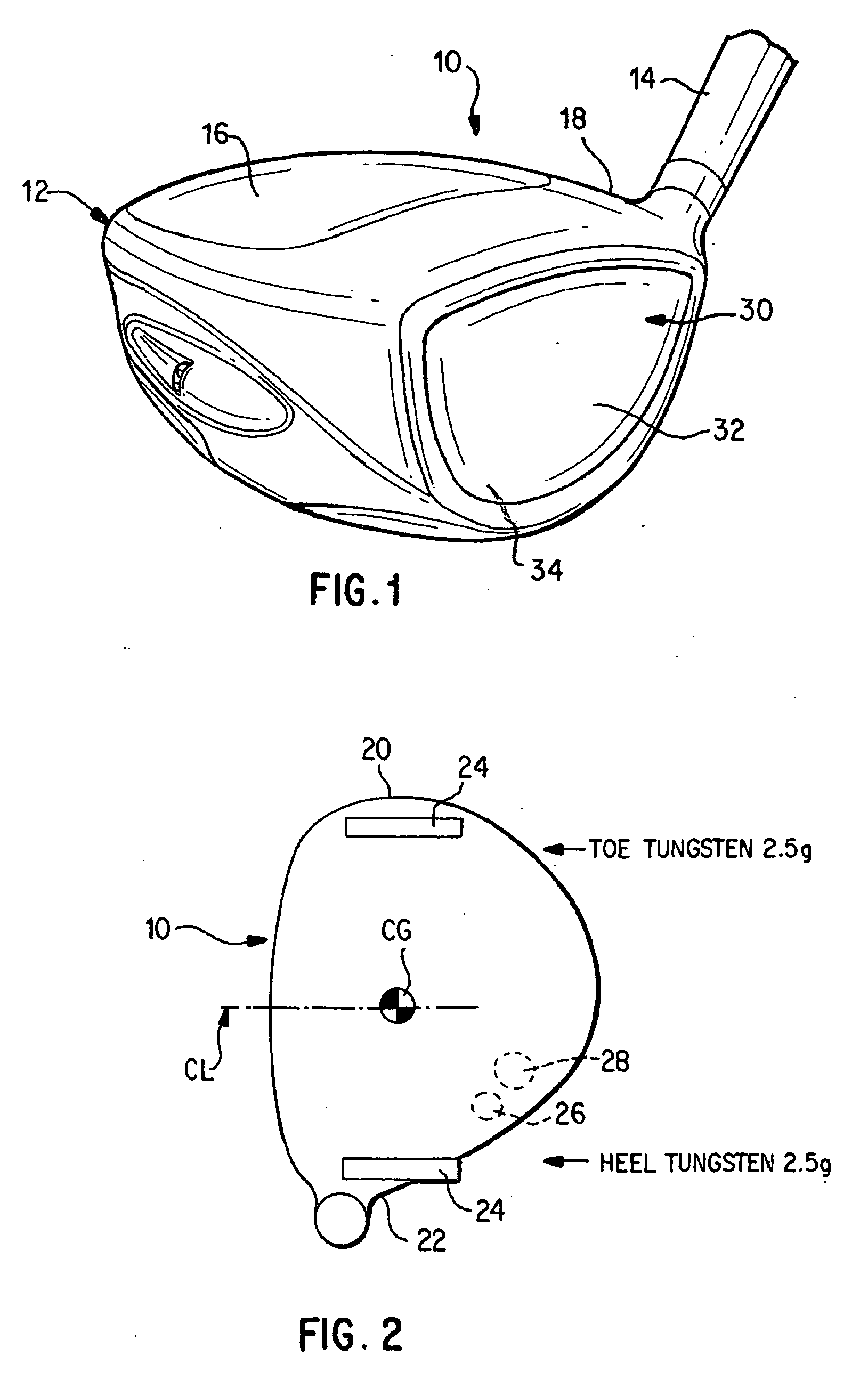

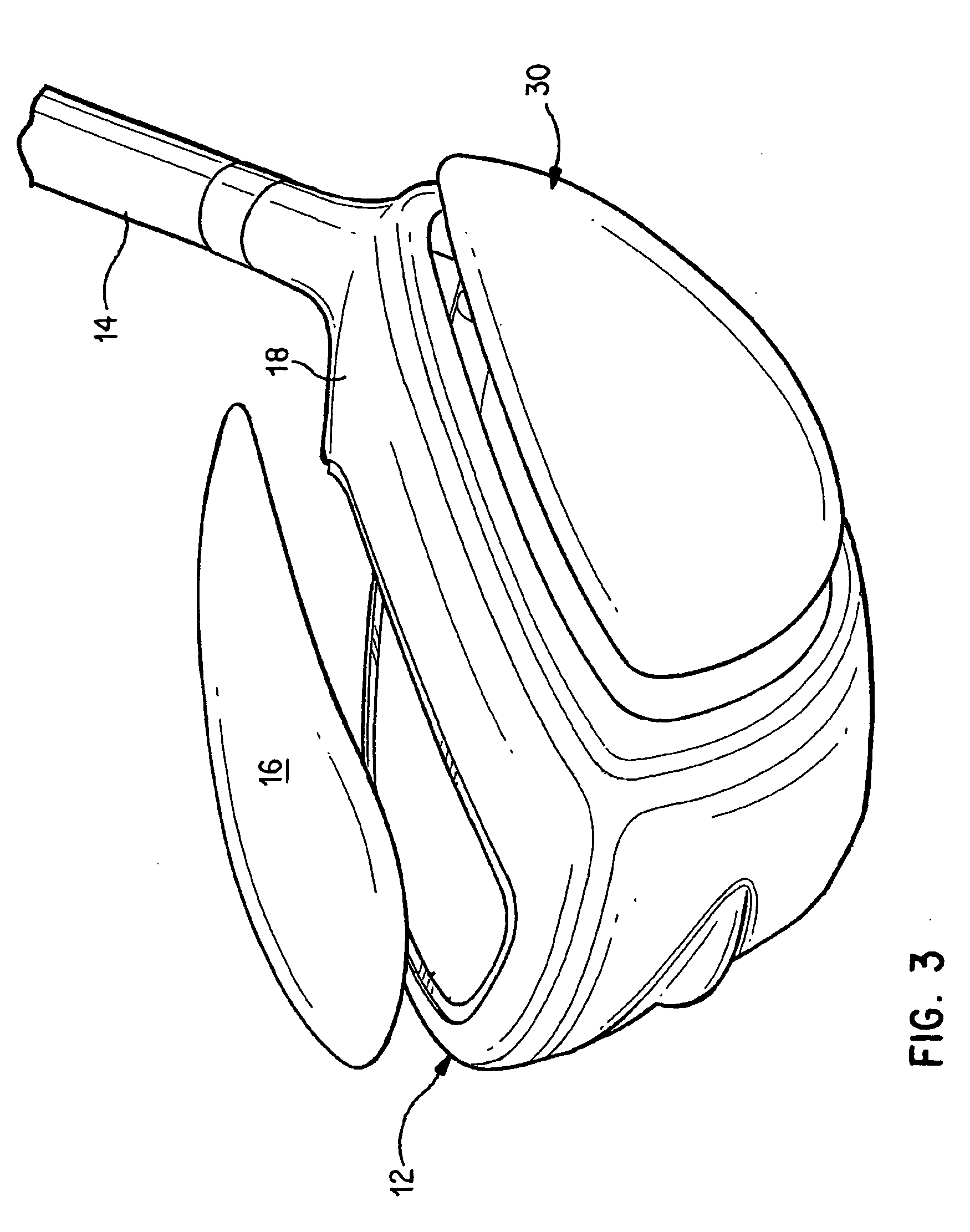

Golf driver having titanium alloy head and flexible shaft

A golf driver has a head which includes an alpha-beta titanium alloy body and a crown formed of a beta titanium plate which is thinner than the body and brazed to the body. The face of the club head comprises a variable-thickness beta titanium faceplate that is plasma welded to the body. Heat generated during the plasma welding causes the thin border region of the faceplate to become even more flexible to enhance the spacing action of the faceplate. Two weights are attached at the toe and heel, respectively, of the body to minimize twisting of the body during an off-center hit. Two additional weights are disposed in the sole of the body in locations causing the center of gravity to be displaced toward the heel and the back side of the club head. A graphite shaft of the driver has at least four sections of different stiffness, defining three bending points, to increase the flex action of the shaft and enable an oversized driver to return to an address position at the moment of impact.

Owner:MACGREGOR GOLF

Online non-oxidation heat treatment method for beta titanium alloy wire

The invention discloses an online non-oxidation heat treatment method for a beta titanium alloy wire, which relates to a titanium alloy processing method and comprises the following steps: performing cold treatment on beta titanium alloy; performing surface pretreatment; and performing heat preservation for 3-10min under controlling the temperature of a protective tube-type furnace to be within a temperature range which is 0-100 DEG C higher than the phase transformation point of the alloy in an Ar (argon) atmosphere protection environment to finally obtain the bright beta titanium alloy wire with low deformation resistance and high deformability. The method is suitable for any beta titanium alloys. For example, the alloy contains 14.0-16.0 percent of vanadium, 2.5-3.5 percent of chromium, 2.5-3.5 percent of stannum, 2.5-3.5 percent of aluminum and the balance titanium by weight. Excellent mechanical properties that the tensile strength is 780MPa, the yield strength is 730MPa, the elongation is 21.5 percent and the reduction of section is 72 percent are obtained by the alloy wire through non-oxidation heat treatment performed after the cold treatment. The processing method is suitable for large-scale production modes.

Owner:西安赛特金属材料开发有限公司

Processing method for beta titanium alloy wires used for glass frames

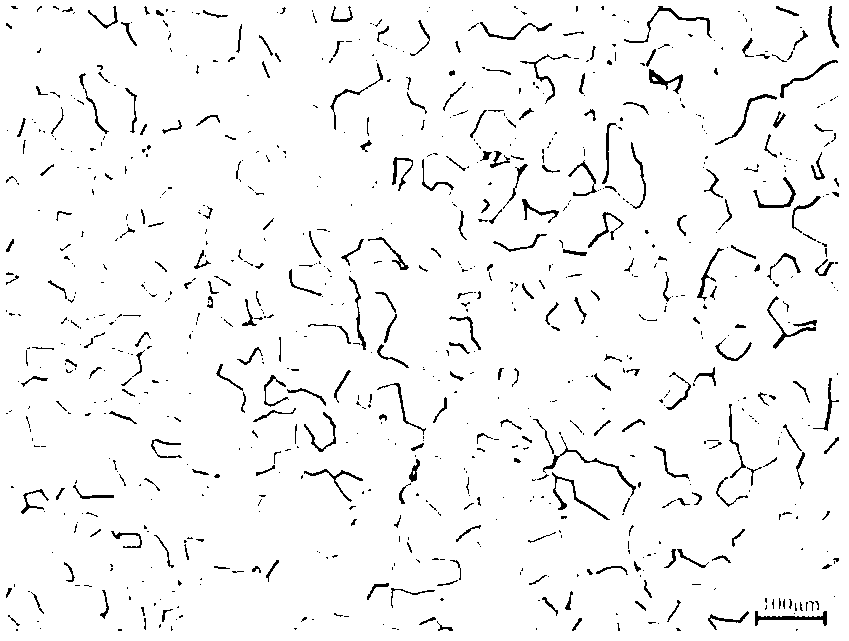

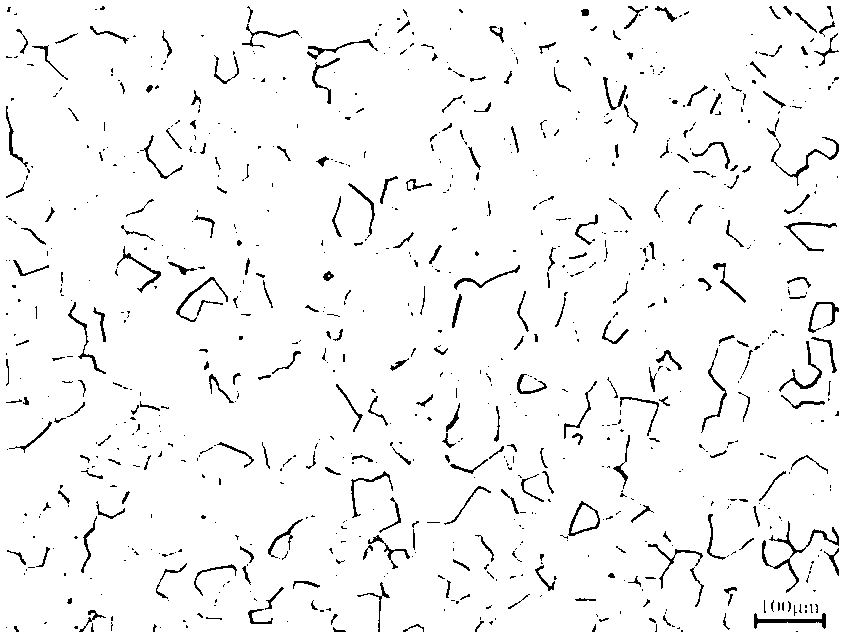

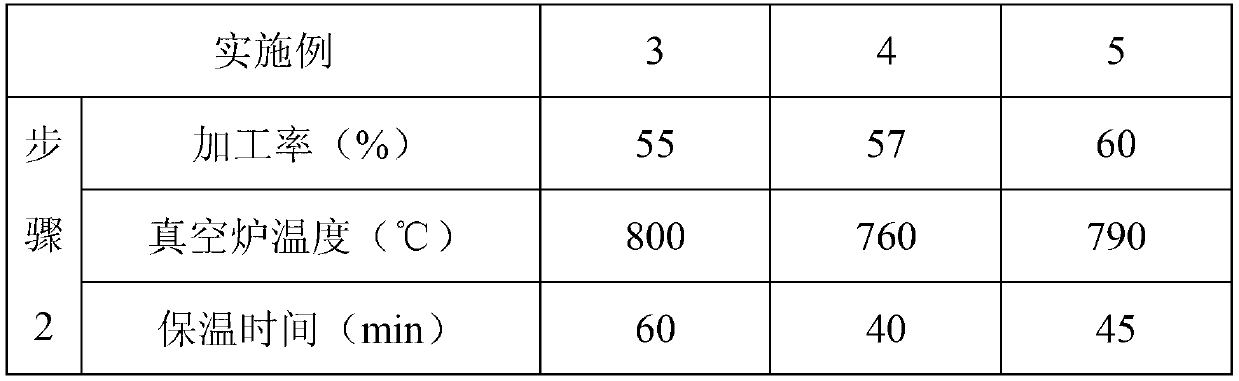

InactiveCN103203390AIncrease productivityEase of mass productionExtrusion cleaning devicesSolution treatmentBeta titanium alloy

The invention discloses a processing method for beta titanium alloy wires used for glass frames. The processing method includes performing cold drawing on beta titanium alloy wire blanks after surface treatment, performing center vacuum annealing after cleaning when processing rate is 50-60%, then carrying out cold drawing until the diameter is phi2.0-phi5.0, performing solution treatment, polishing, and finally obtaining the beta titanium alloy wires used for the glass frames. With the processing method, production efficiency is high, mass manufacturing is easy to realize, the beta titanium alloy wires are not oxidized during the whole processing procedure, acid and alkali treatment is omitted, and pollution on environment is avoided. The beta titanium alloy wires obtained from the processing procedure are high in accuracy, excellent in surface quality, high in elasticity and good in cold processing performances, and can completely meet the requirements on beta titanium wire used for the glass frames; the glass frames prepared with the beta titanium wires have the advantages of corrosion resistance, light weight, high elasticity and excellent weldability.

Owner:西安思维智能材料有限公司

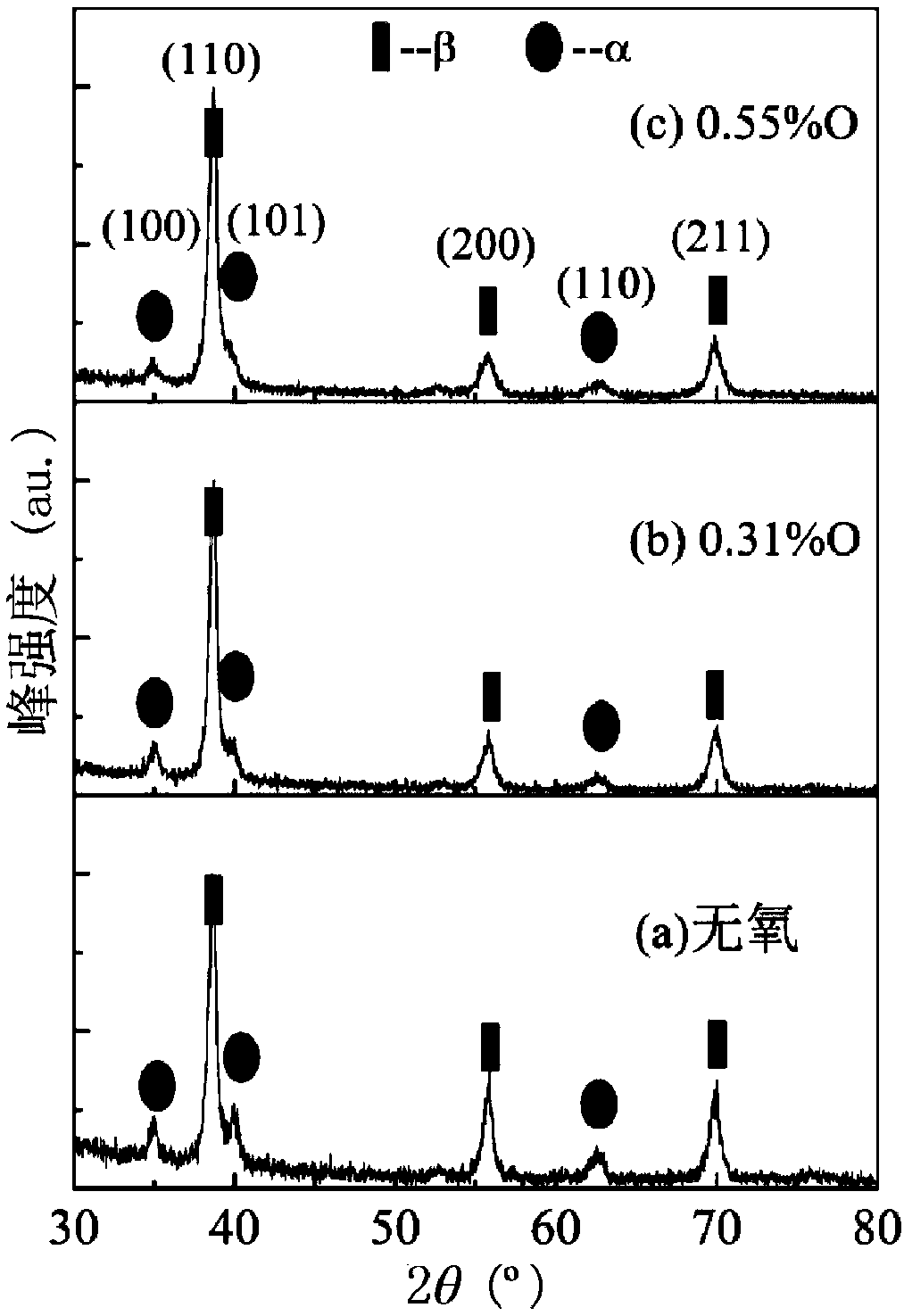

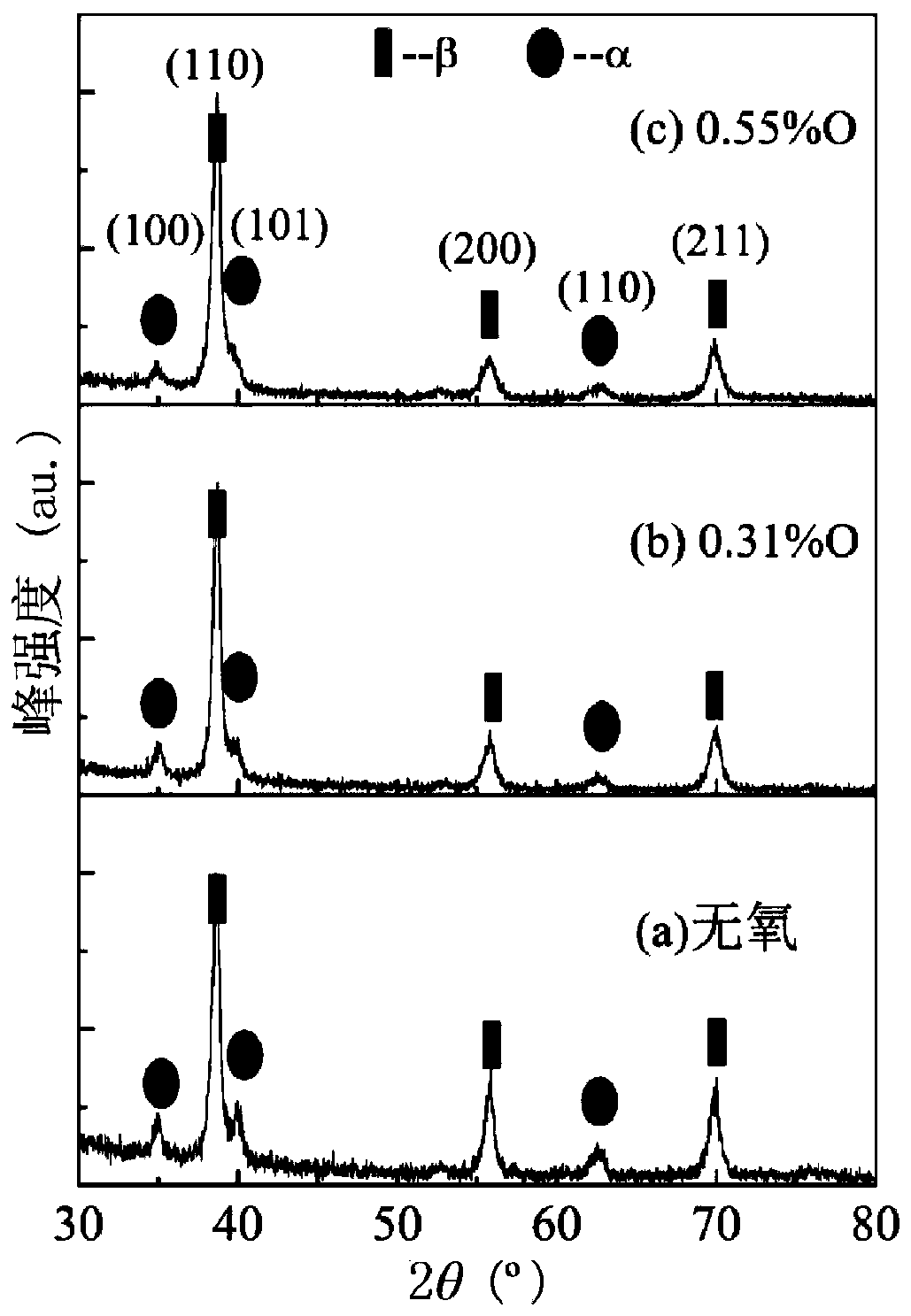

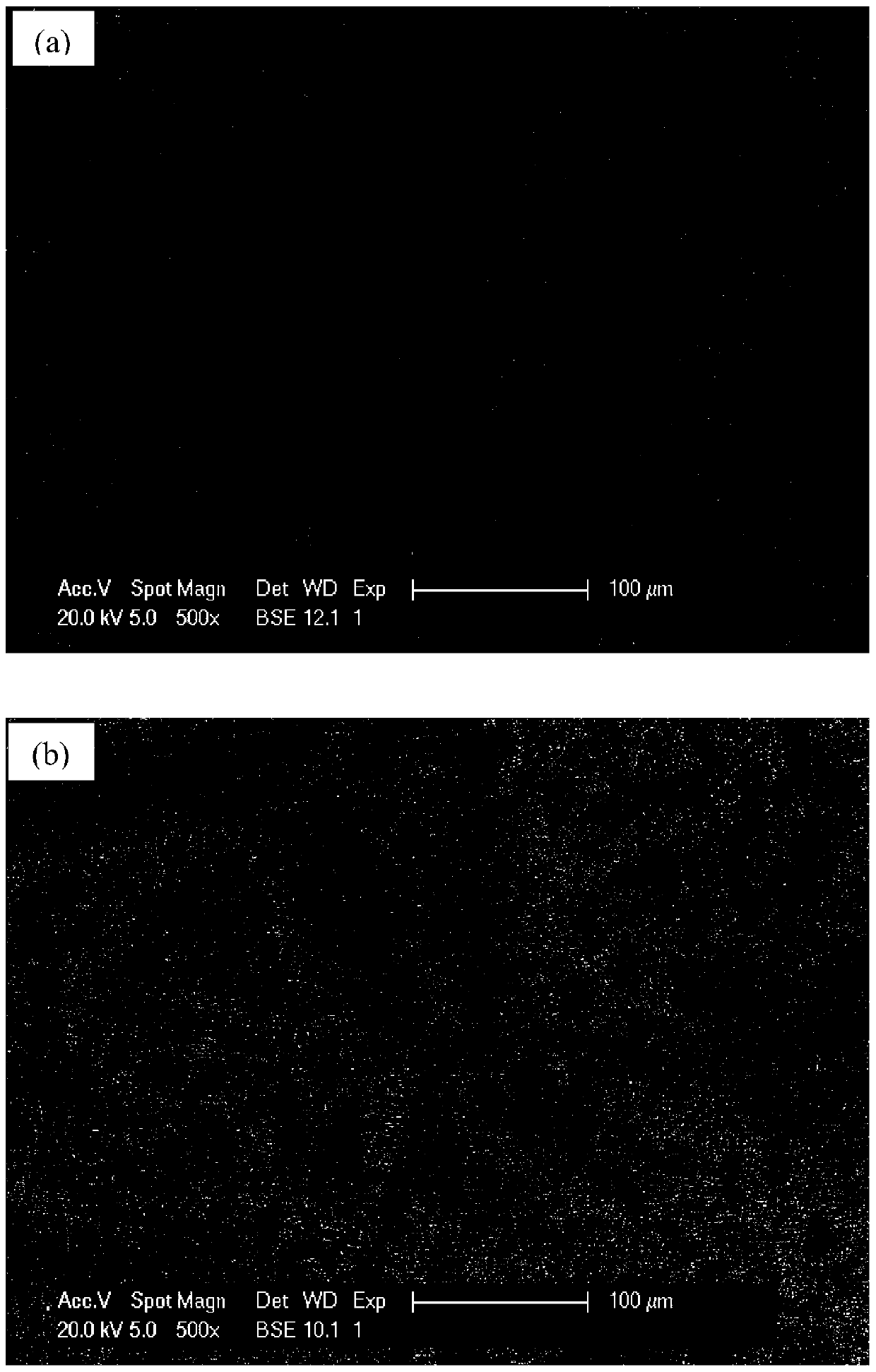

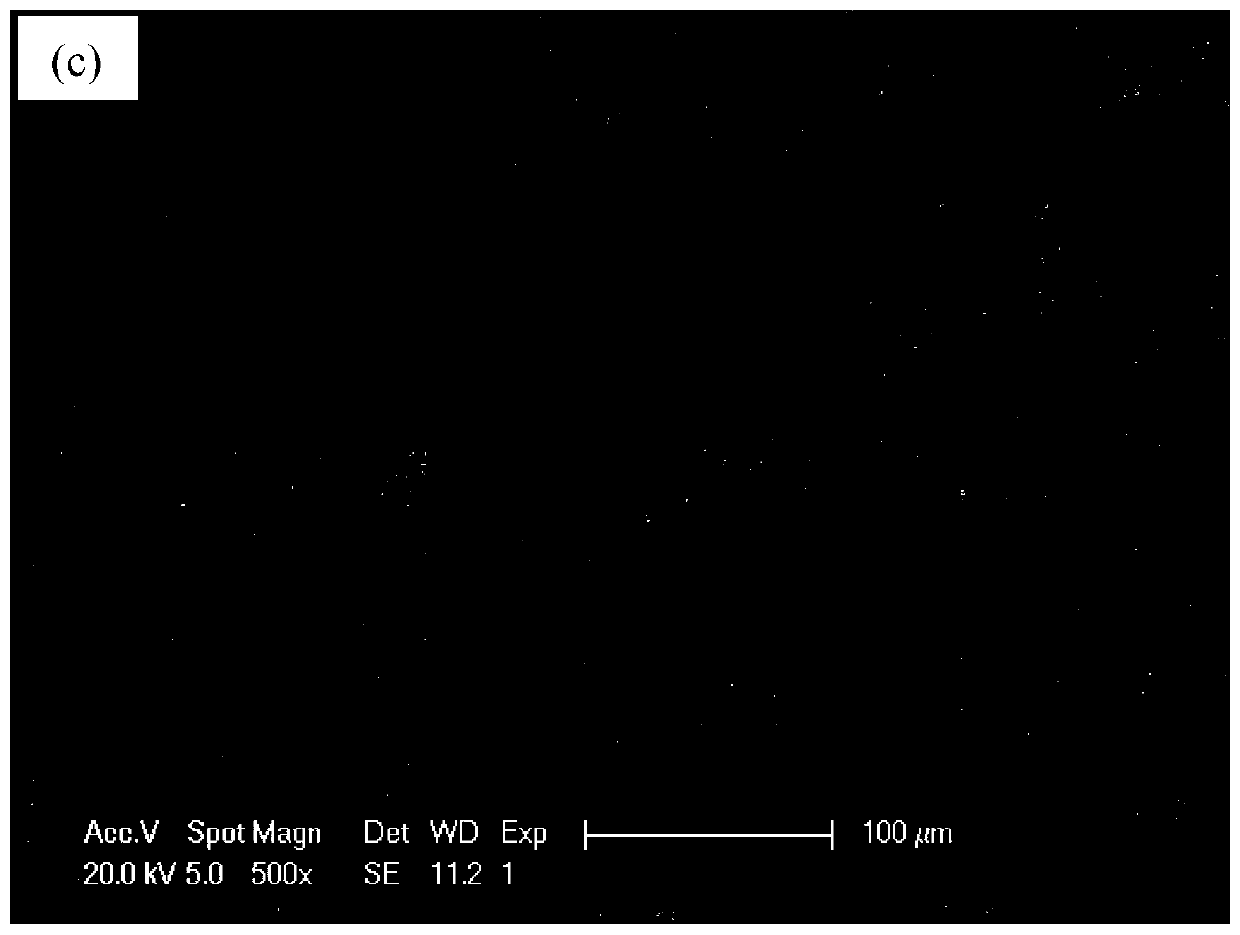

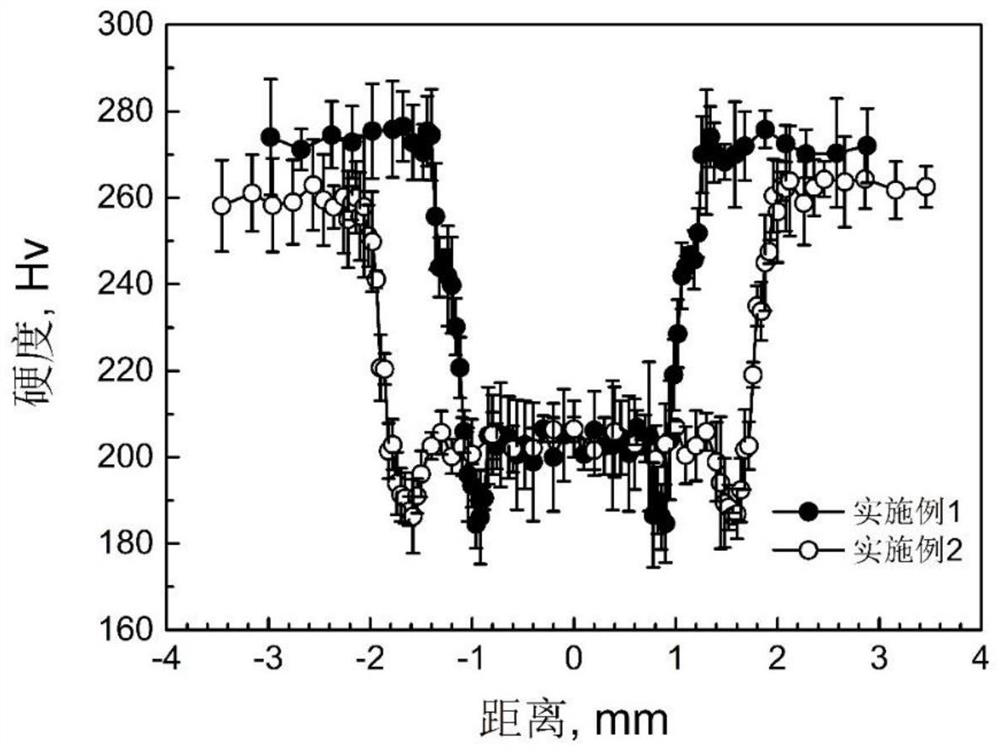

High strength high elasticity titanium alloy and preparation method

The invention relates to a high strength high elasticity titanium alloy and a preparation method. The alloy comprises the following components in percentages by weight: 31-33wt% of Nb, 4-8wt% of Zr, 2-4wt% of Sn, 0.30-0.55wt% of O (0.3wt% endpoint value is not contained) and the balance of Ti. The preparation method of the alloy comprises the follow specific steps: adopting a vacuum nonconsumableelectric-arc furnace to smelt to obtain a uniform alloy ingot, performing solution treatment at 850-950 DEG C after hot forging of a rod, and performing water cooling to room temperature; then performing cold rolling deformation processing, wherein the deformation is 80-90%; and finally, performing ageing thermal treatment, wherein the heating temperature is 400-500 DEG C and the insulating time is 1-24h. The titanium alloy provided by the invention has high strength and relatively low elasticity modulus. The elastic deformability is superior to those of various beta-titanium alloys high in elasticity. The titanium alloy is quite suitable for preparing ultralight small-sized elastic parts in the fields of aerospace, machinery and the like, and also can be applied to preparing biomedical implants.

Owner:SOUTHEAST UNIV

High strength high elasticity heatproof titanium alloy and preparation method thereof

The invention relates to a high strength high elasticity heatproof titanium alloy and a preparation method thereof. The alloy comprises Ti, Nb, Zr, V, and O, wt%Nb=35wt%-1.5wt%V, wt%Nb represents weight percentage of Nb, wt%V represents weight percentage of V, V: 0 wt%<V<=4.0 wt%, Zr: 1.8-2.2 wt%, O: 0.29-0.31 wt%, and the balance being Ti. The preparation method comprises following steps: carrying out smelting in a vacuum non-consumable electric arc furnace to obtain uniform alloy ingots; carrying out hot forging to obtain rods, performing a solution treatment at a temperature of 900-1000 DEGC, cooling to the room temperature; carrying out cold rolling and deformation processing, wherein the deformation amount is 80-90%; and finally carrying out an aging heat treatment, wherein the heating temperature is 490 to 510 DEG C, and the holding time is 8-10 hours. The titanium alloy has the advantages of high strength and low elastic modulus, the elastic deformation capacity (the ratio of yield strength to elastic modulus) is better than those of various high elasticity beta-titanium alloys, and thus the titanium alloy is very suitable for preparing light, heatproof, and high elasticityparts in the fields of aviation, aerospace, and machinery.

Owner:SOUTHEAST UNIV

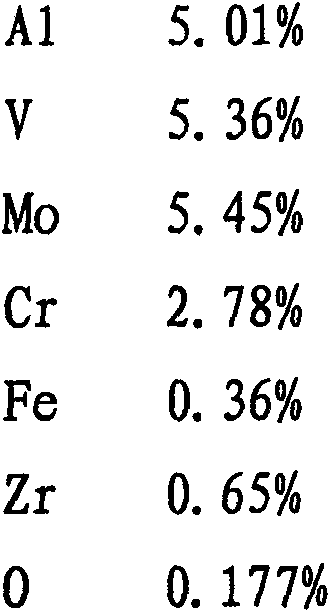

Method for melting a pseudo beta-titanium alloy comprising (4.0-6.0)% Ai-(4.5-6.0)% Mo-(4.5-6.0)% v-(2.0-3.6)% Cr, (0.2-0.5)% Fe-(0.1-2.0)% Zr

The invention relates to the field of nonferrous metallurgy, and specifically to the production of pseudo beta-titanium alloys comprising titanium and also the following alloying elements: molybdenum, vanadium, chromium, zirconium, iron and aluminium. The proposed alloy comprises the following components: 25-27% by mass of molybdenum; 25-27% by mass of vanadium; 14-16% by mass of chromium; 9-11% by mass of titanium; aluminium as the base, and iron and zirconium in the form of technically pure metals. The technical result of the invention is the possibility of producing a pseudo beta-titanium alloy with a highly homogeneous chemical composition, which is alloyed with high-melting elements, has a less than or equal to 6% content of aluminium and has stable high-impact properties in combination with high-impact strength.

Owner:OTKRYTOE AKTSIONERNOE OBSHCHESTVO KORPORATSIJA VSMPO AVISMA

Thermomechanical processing of alpha-beta titanium alloys

Owner:ATI PROPERTIES LLC

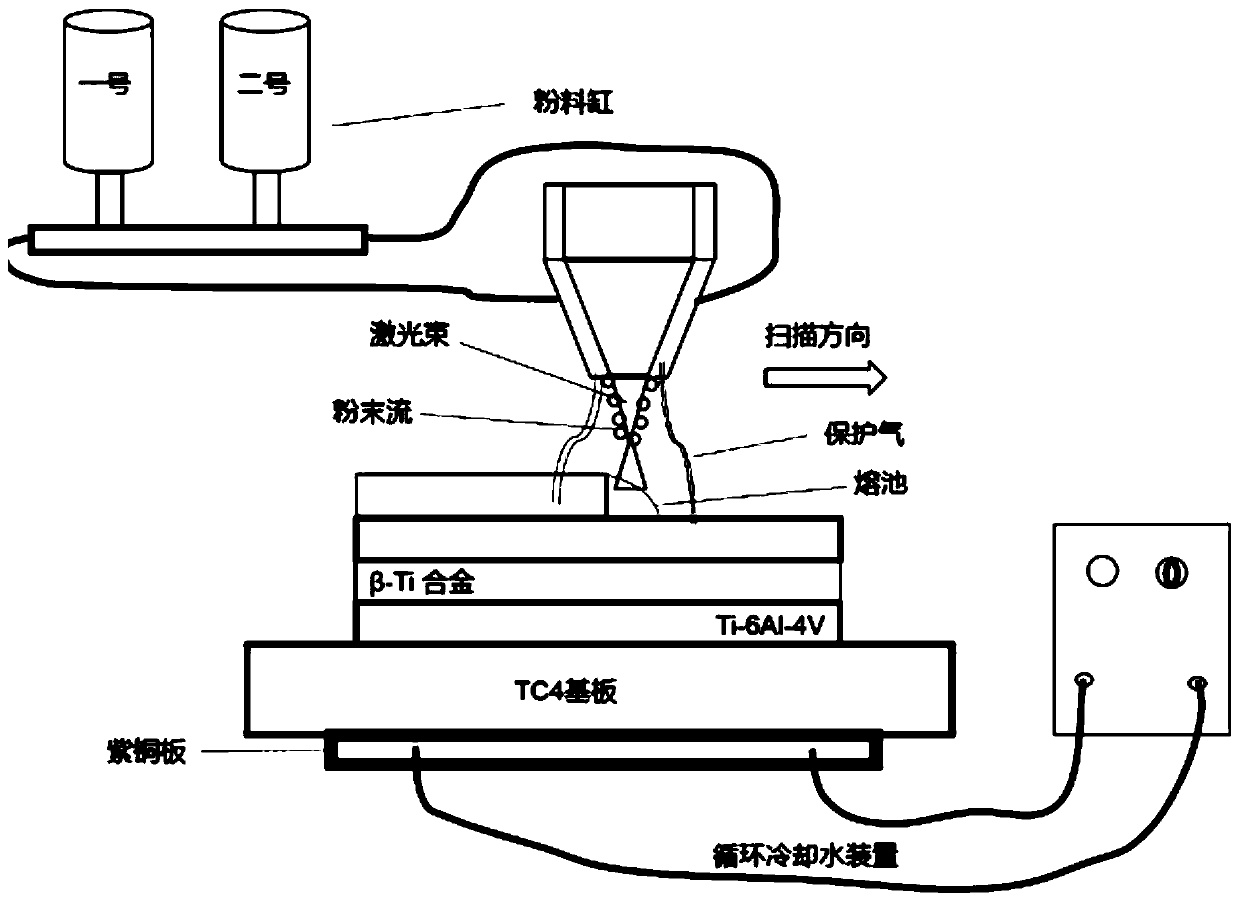

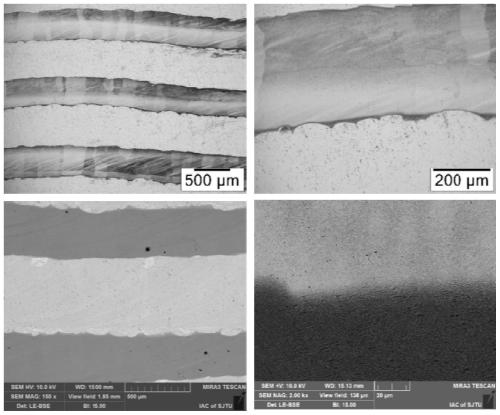

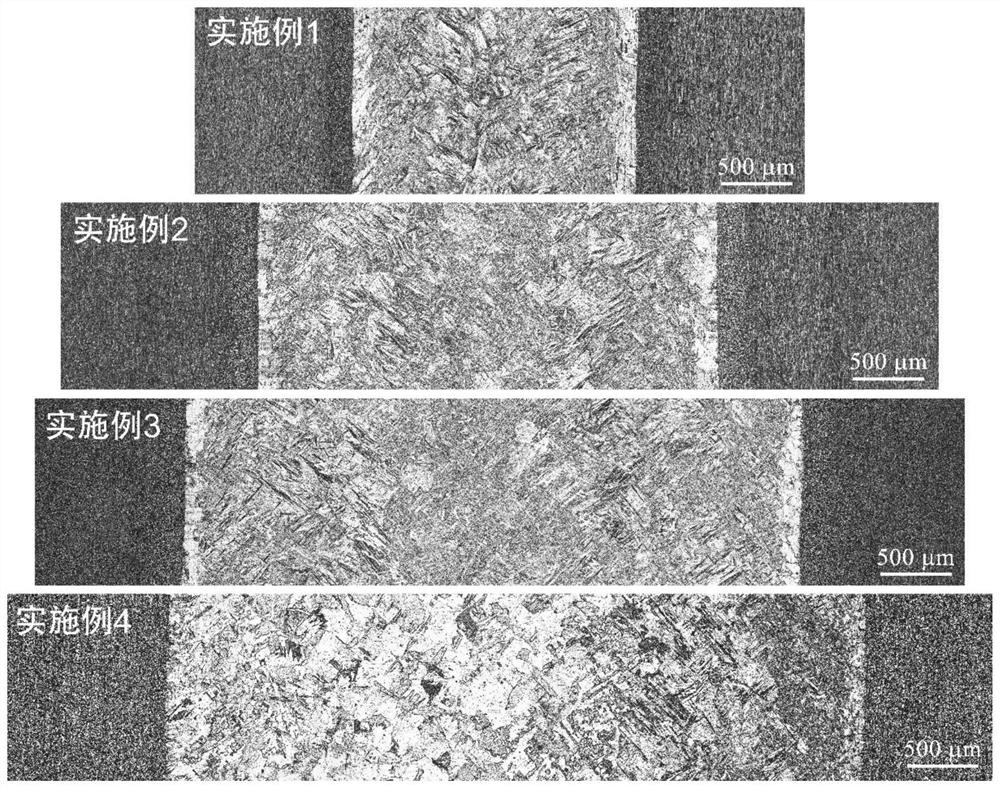

Additive manufacturing method of low-modulus titanium/titanium stratified material

ActiveCN111069600ALow modulusImprove plasticityAdditive manufacturing apparatusIncreasing energy efficiencyTitaniumBeta titanium alloy

The invention provides an additive manufacturing method of a low-modulus titanium / titanium stratified material. According to the additive manufacturing method, alternating deposition is carried out oncommercial TC4 powder and beta titanium alloy powder through coaxial powder feeding laser deposition equipment to obtain a laminar composite. The additive manufacturing method specifically comprisesthe following steps of taking and feeding Ti-6Al-4V powder and the beta titanium alloy powder into two powder tanks of the direct laser deposition equipment; and carrying out alternating cladding on the two kinds of titanium alloy powder under a protective atmosphere to obtain a molded sample piece. The TC4 / beta titanium alloy laminar composite with the good metallurgical bonding performance can be prepared through the additive manufacturing method. The advantages of the TC4 / beta titanium alloys are integrated, and the high-strength and low-modulus composite titanium alloy material is obtained.

Owner:SHANGHAI JIAO TONG UNIV +1

Processing of alpha-beta titanium alloys

A method for increasing tensile strength of a cold workable alpha-beta titanium alloy comprises solution heat treating a cold workable alpha-beta titanium alloy in a temperature range of Tβ−106° C. to Tβ−72.2° C. for 15 minutes to 2 hours; cooling the alpha-beta titanium alloy at a cooling rate of at least 3000° C. / minute; cold working the alpha-beta titanium alloy to impart an effective strain in the range of 5 percent to 35 percent in the alloy; and aging the alpha-beta titanium alloy in a temperature range of Tβ−669° C. to Tβ−517° C. for 1 to 8 hours. Fastener stock and fasteners including solution treated, quenched, cold worked, and aged alpha-beta titanium alloys are also disclosed.

Owner:ATI PROPERTIES LLC

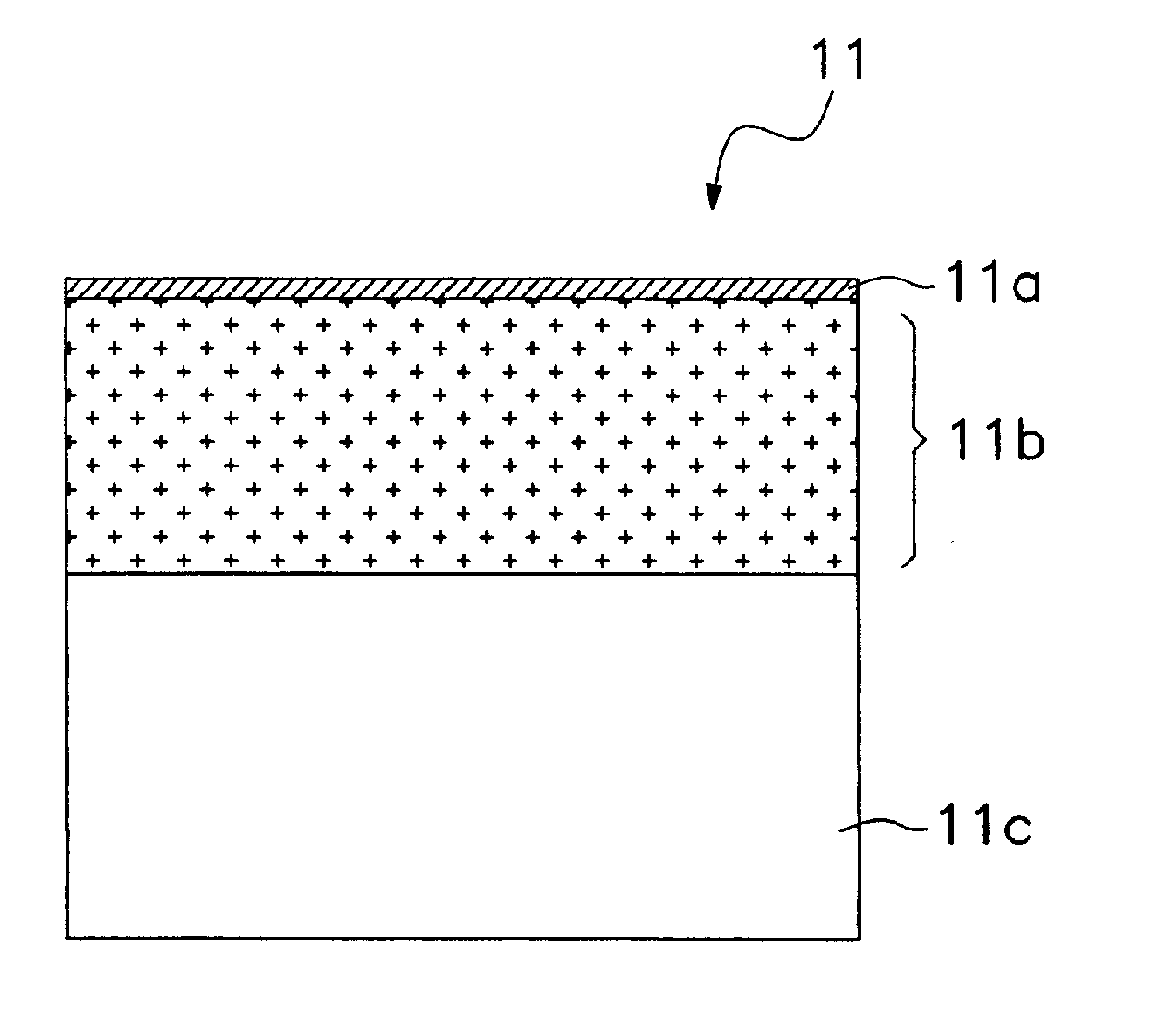

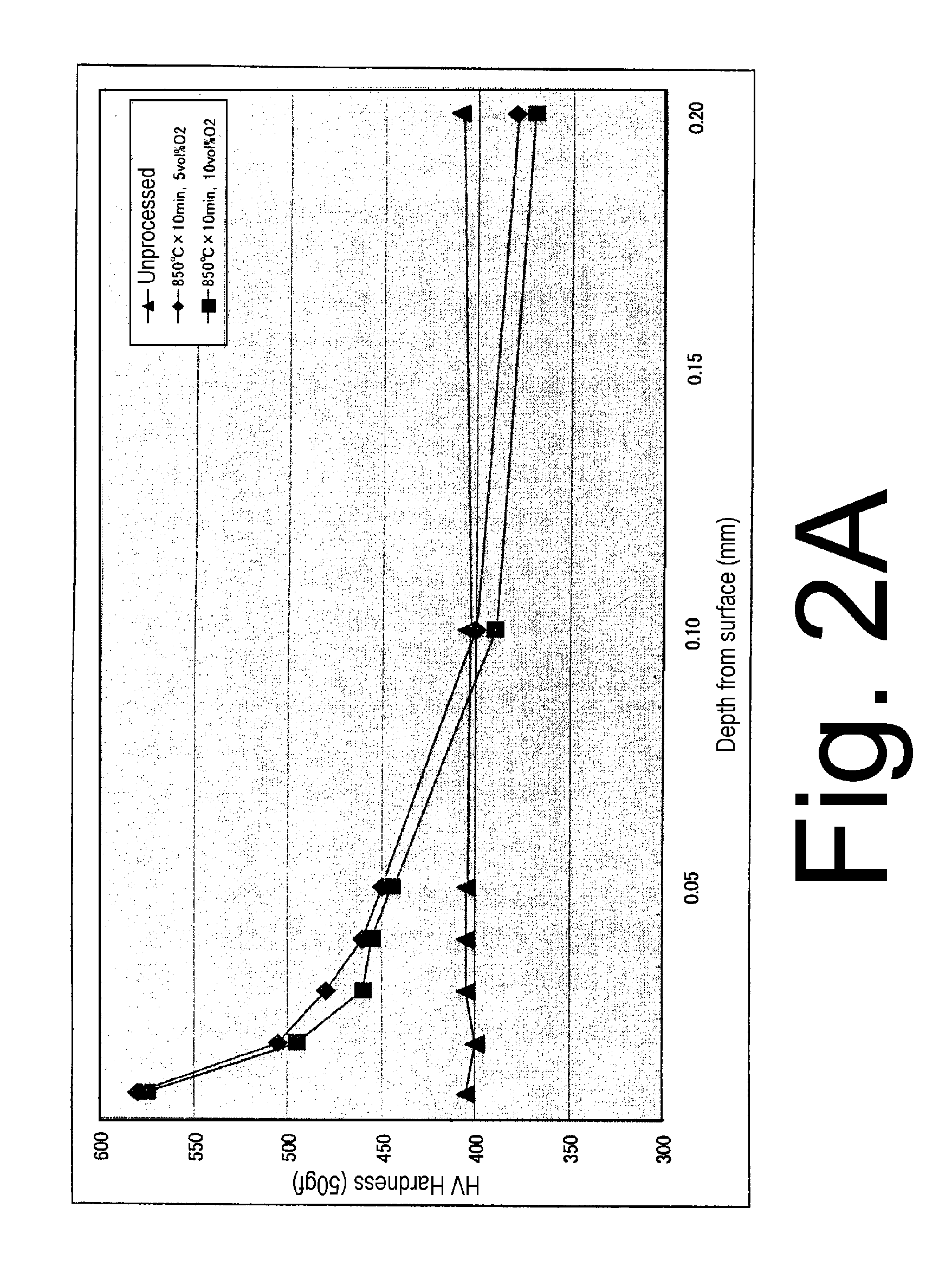

Method of hardening a beta titanium member

A method of hardening the surface of a beta titanium member comprises the step of heating the beta titanium member in a gas mixture consisting essentially of an inert gas and oxygen.

Owner:SHIMANO INC

Method for manufacture of wrought articles or near-beta titanium alloys

This invention relates to nonferrous metallurgy, namely to thermomechanical treatment of titanium alloys and can be used for manufacture of structural parts and components of high-strength near-beta titanium alloys for the aerospace application, mainly landing gear and airframe application.The method for thermomechanical treatment of titanium alloy consists of multiple heating operations to a temperature that is above or below beta transus temperature (BTT), hot working with the specified strain, and cooling.A technical result of this method is manufacture of near-net shape forgings with stable properties having sections with thickness 100 mm and over and length over 6 m with the following mechanical properties:1. Ultimate tensile strength over 1200 MPa with fracture toughness, κ1C, not less than 35 MPa√m.2. Fracture toughness, κ1C, over 70 MPa√m with ultimate tensile strength not less than 1100 MPa.

Owner:OTKRYTOE AKTSIONERNOE OBSHCHESTVO KORPORATSIJA VSMPO AVISMA

Thin parts made of beta or quasi-beta titanium alloys; manufacture by forging

The present invention provides non-axially symmetrical manufactured parts of thickness less than 10 mm, made of β or quasi-β titanium alloy, having a core microstructure constituted by whole grains presenting a slenderness ratio greater than 4 and an equivalent diameter lying in the range 10 μm to 300 μm. The invention also provides a method of manufacturing the parts by forging.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Processing of alpha-beta titanium alloys

A method for increasing tensile strength of a cold workable alpha-beta titanium alloy comprises solution heat treating a cold workable alpha-beta titanium alloy in a temperature range of Tβ-106° C. to Tβ-72.2° C. for 15 minutes to 2 hours; cooling the alpha-beta titanium alloy at a cooling rate of at least 3000° C. / minute; cold working the alpha-beta titanium alloy to impart an effective strain in the range of 5 percent to 35 percent in the alloy; and aging the alpha-beta titanium alloy in a temperature range of Tβ-669° C. to Tβ-517° C. for 1 to 8 hours. Fastener stock and fasteners including solution treated, quenched, cold worked, and aged alpha-beta titanium alloys are also disclosed.

Owner:ATI PROPERTIES LLC

Method for preparing ceramics capable of repeatedly storing heat

The invention discloses a method for preparing ceramics capable of repeatedly storing heat. The method is characterized in that titanium oxide black blue powder and pottery clay are weighed according to a weight percentage, raw materials are injected into a ball mill after being mixed, and are ground after water is added; well ground slurry subsides; supernatant liquid is pumped out after subsiding, precipitates are taken out to be placed on the clean ground to be dried in the sun; the dried soil is placed into a pugmill to be pugged, and the air in the soil is discharged. Well pugged mud is made into corresponding green bodies and is dried, and the dried green bodies are put into a fire ceramic body to be calcined, and a ceramic product which can repeatedly store heat can be obtained after natural cooling. The ceramic product capable of repeatedly storing heat is placed in an illumination position, titanium oxide can be converted into lambda-titanium oxide, can store heat, and is converted into beta-titanium oxide to release heat under definite conditions, then the beta-titanium oxide is converted into lambada-titanium oxide after the ceramic product is heated, and the ceramic product can continuous to absorb and store heat.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP +1

A kind of high-strength high-elasticity titanium alloy and preparation method thereof

The invention relates to a high strength high elasticity titanium alloy and a preparation method. The alloy comprises the following components in percentages by weight: 31-33wt% of Nb, 4-8wt% of Zr, 2-4wt% of Sn, 0.30-0.55wt% of O (0.3wt% endpoint value is not contained) and the balance of Ti. The preparation method of the alloy comprises the follow specific steps: adopting a vacuum nonconsumableelectric-arc furnace to smelt to obtain a uniform alloy ingot, performing solution treatment at 850-950 DEG C after hot forging of a rod, and performing water cooling to room temperature; then performing cold rolling deformation processing, wherein the deformation is 80-90%; and finally, performing ageing thermal treatment, wherein the heating temperature is 400-500 DEG C and the insulating time is 1-24h. The titanium alloy provided by the invention has high strength and relatively low elasticity modulus. The elastic deformability is superior to those of various beta-titanium alloys high in elasticity. The titanium alloy is quite suitable for preparing ultralight small-sized elastic parts in the fields of aerospace, machinery and the like, and also can be applied to preparing biomedical implants.

Owner:SOUTHEAST UNIV

GOLF CLUB HEAD ALLOY AND METHOD FOR manufacturing SAME

The invention discloses a golf club head alloy and a method for manufacturing same. The method for manufacturing the golf club head alloy comprises the steps of: providing an alloy blank comprising 0.1 to 10 parts by weight of zirconium and 77 to 99.9 parts by weight of titanium; hot rolling the alloy blank at 850 to 950 DEG C to form the golf club head alloy, wherein a crystal phase compositionof the golf club head alloy comprises an equiaxed crystal duplex structure, and the equiaxed crystal duplex structure comprises an alpha titanium phase and a beta titanium phase. The golf club head alloy manufacturing method of the present invention can be used to manufacture a golf club head alloy having a low Young's modulus, and the golf club head alloy can be used to increase the spring effect of the hitting face of the golf club head, thereby increasing the hitting distance.

Owner:O TA PRECISION IND

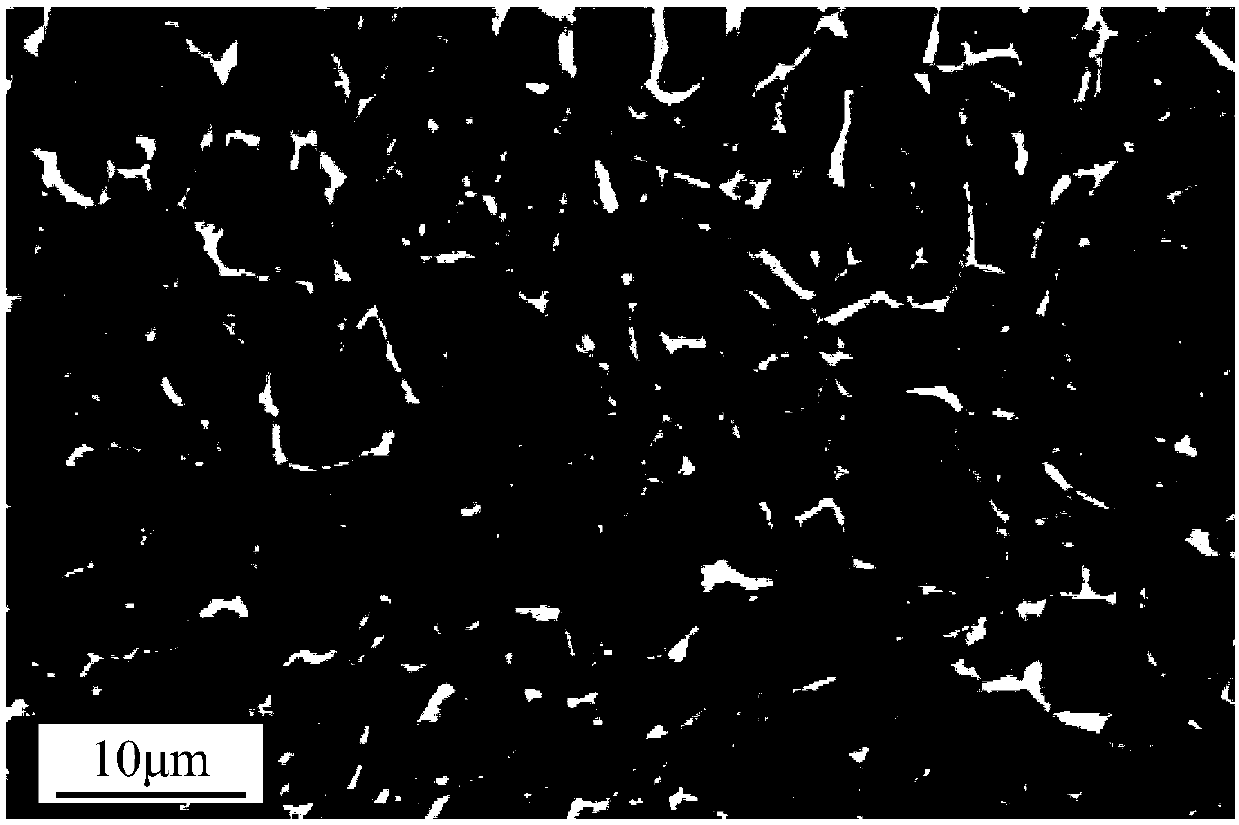

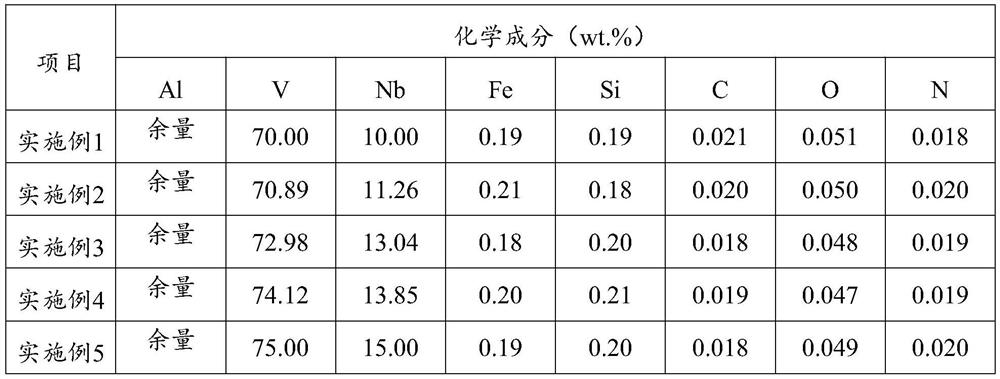

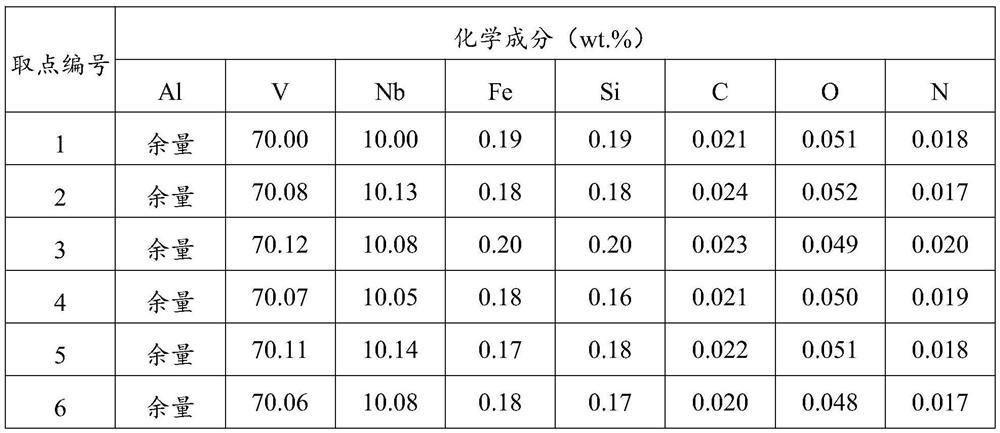

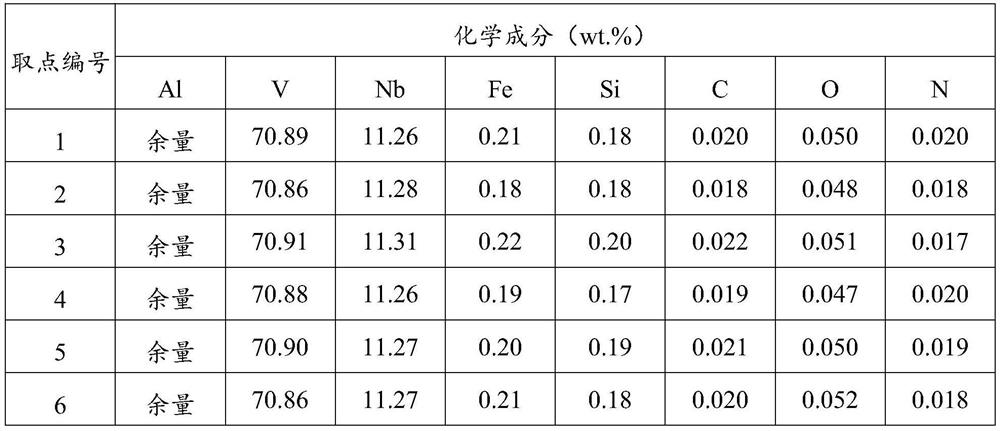

Aluminum-vanadium-niobium intermediate alloy, aluminum-vanadium-niobium-titanium intermediate alloy and preparation methods of aluminum-vanadium-niobium intermediate alloy and aluminum-vanadium-niobium-titanium intermediate alloy

InactiveCN113355577AMeet production requirementsImprove uniformity and stabilityMetallic materialsSolid solution strengthening

The invention provides an aluminum-vanadium-niobium intermediate alloy, an aluminum-vanadium-niobium-titanium intermediate alloy and preparation methods of the aluminum-vanadium-niobium intermediate alloy and the aluminum-vanadium-niobium-titanium intermediate alloy, and belongs to the field of metal materials. The invention provides the aluminum-vanadium-niobium intermediate alloy and the aluminum-vanadium-niobium-titanium intermediate alloy. Aluminum is the most important strengthening element in titanium alloy, has a remarkable solid solution strengthening effect and can remarkably improve the high-temperature mechanical performance of the titanium alloy, and meanwhile, the aluminum also has a relatively low density and is beneficial for improving the specific strength of the titanium alloy; vanadium has the effect of strengthening the titanium alloy, and when a certain proportion of vanadium is added into the titanium alloy, the alloy has good ductility, corrosion resistance, formability and other excellent performance. Niobium can be subjected to infinite solid solution in beta titanium, the solid solution strengthening effect is achieved, when the alloy strength is improved, the thermal stability of the alloy can also be effectively improved, and good plasticity is maintained. According to the invention, by controlling components and content, the aluminum-vanadium-niobium and aluminum-vanadium-niobium-titanium intermediate alloys are uniform in component and small in segregation, and during titanium alloy smelting, titanium alloy component homogenization is facilitated, and component segregation is prevented.

Owner:CHENGDE TIANDA VANADIUM IND

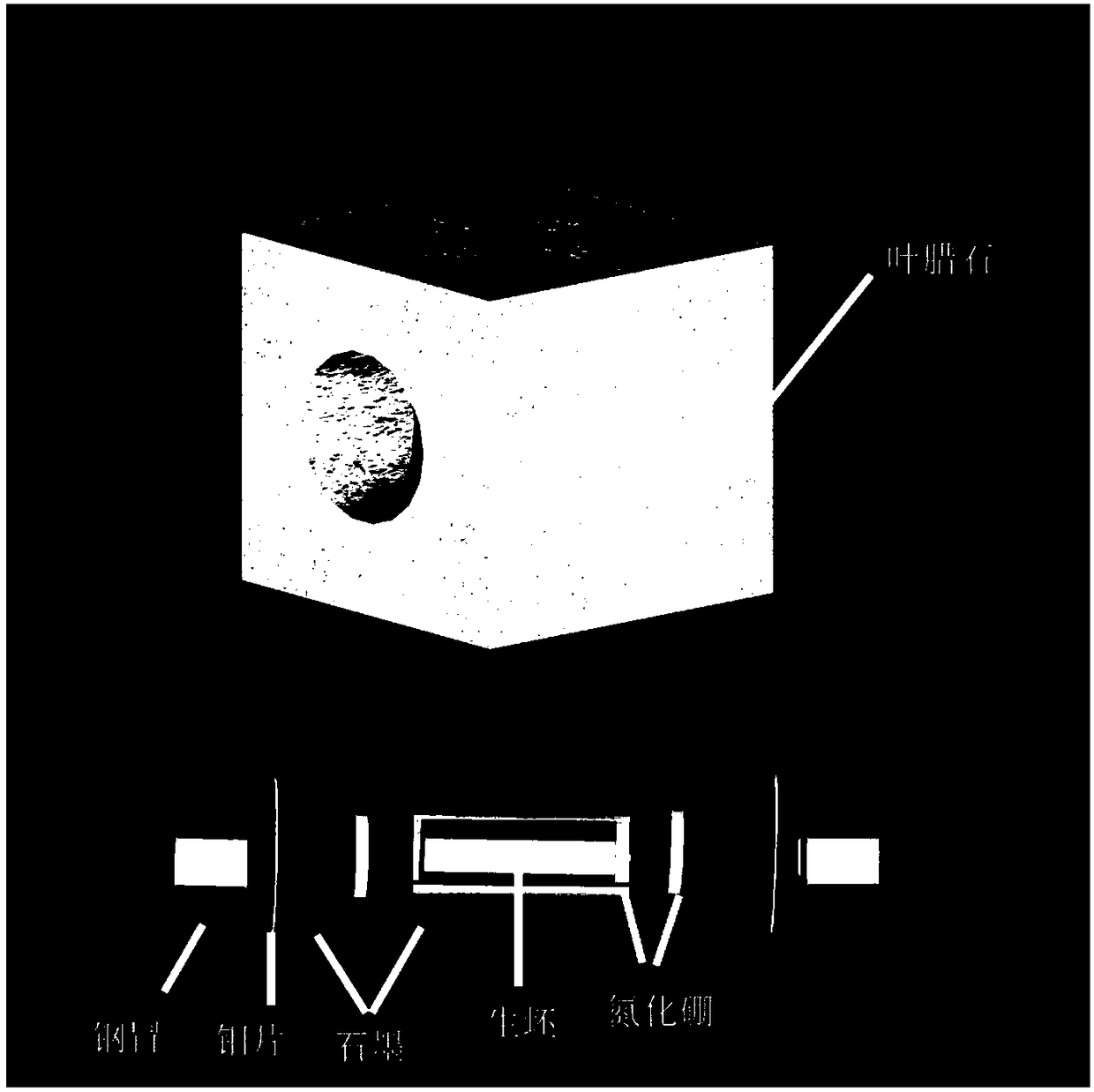

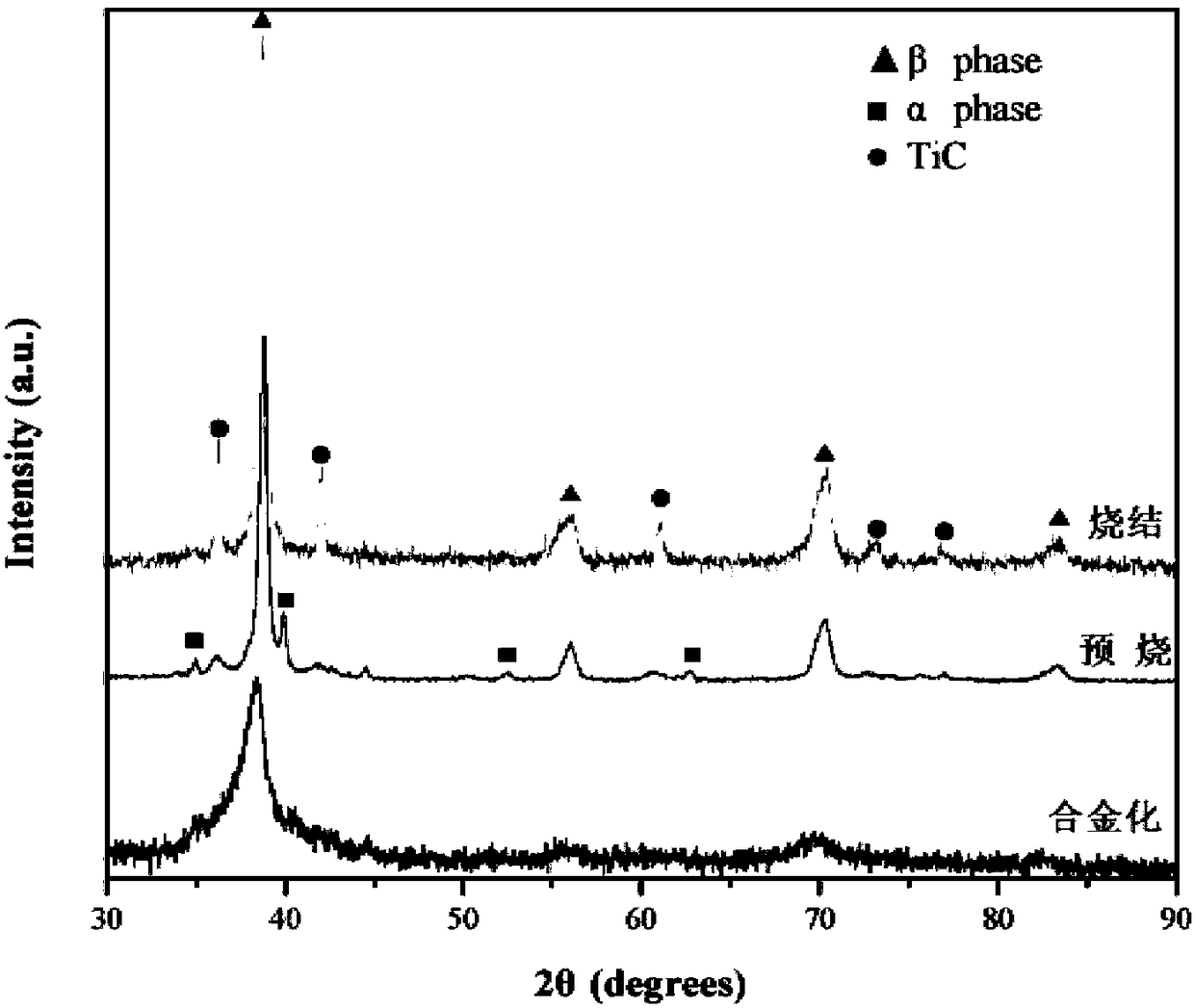

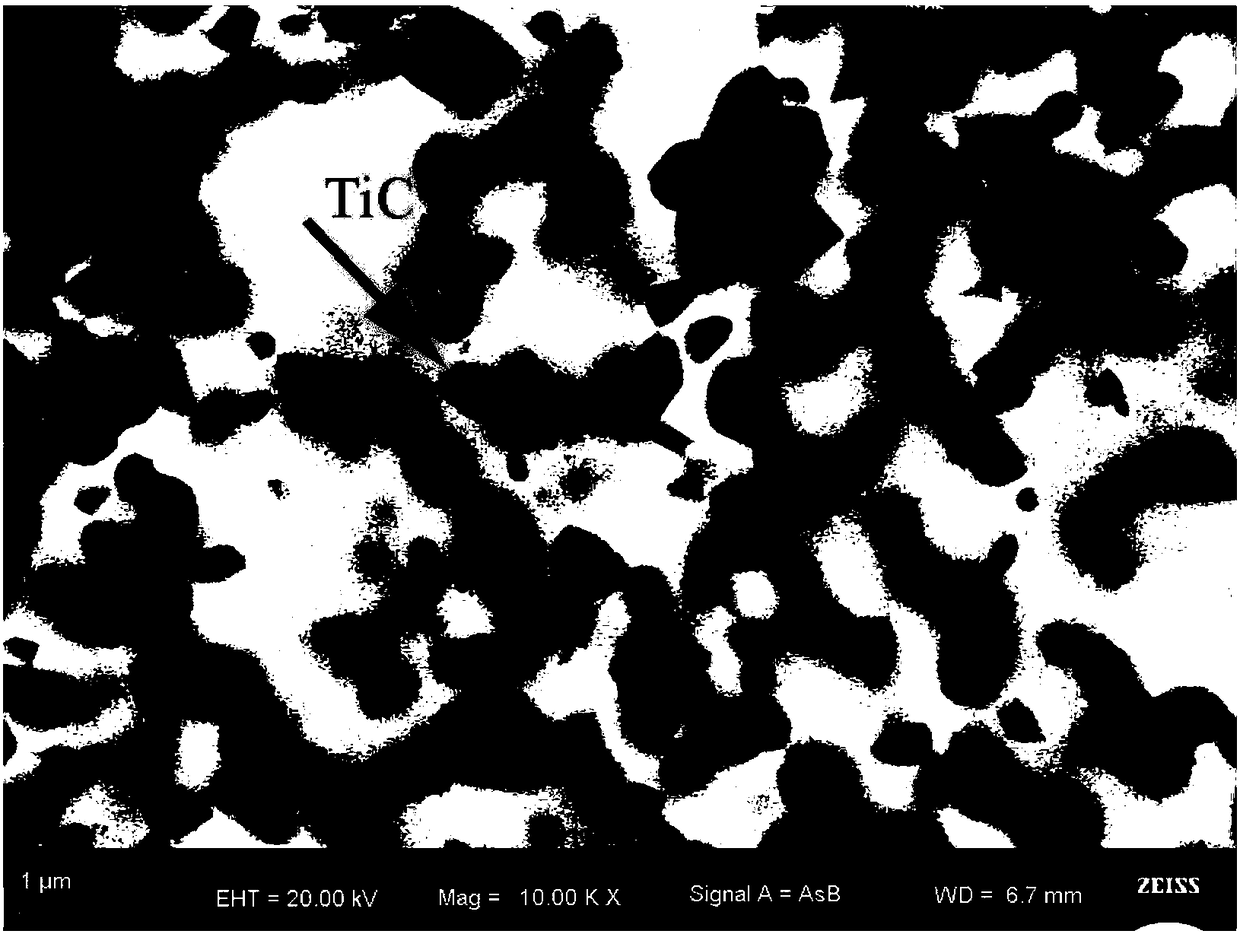

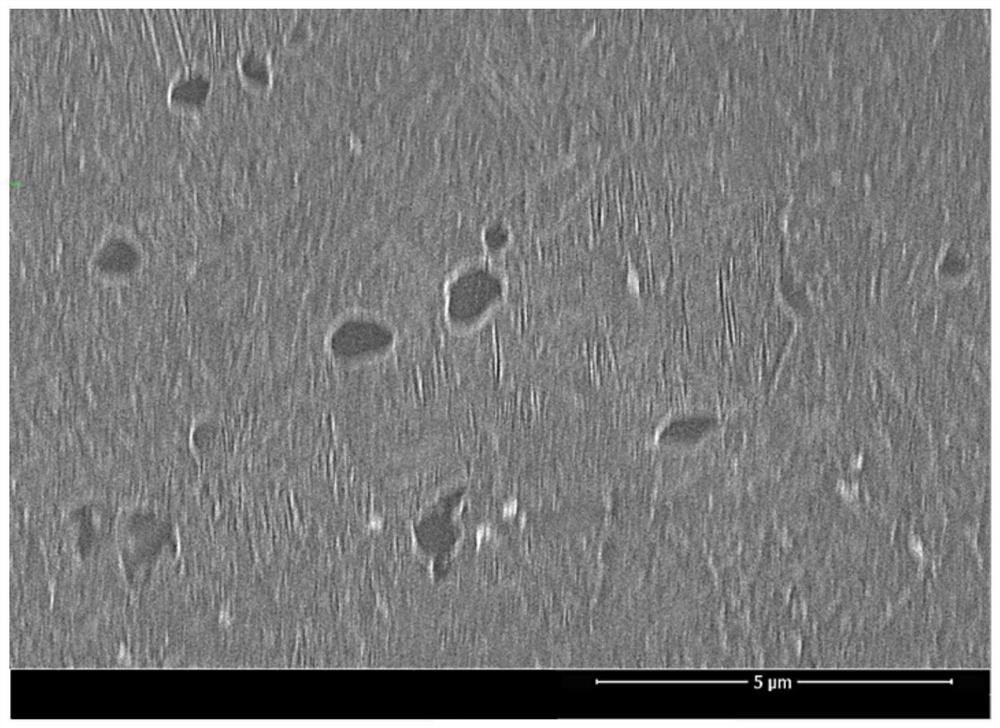

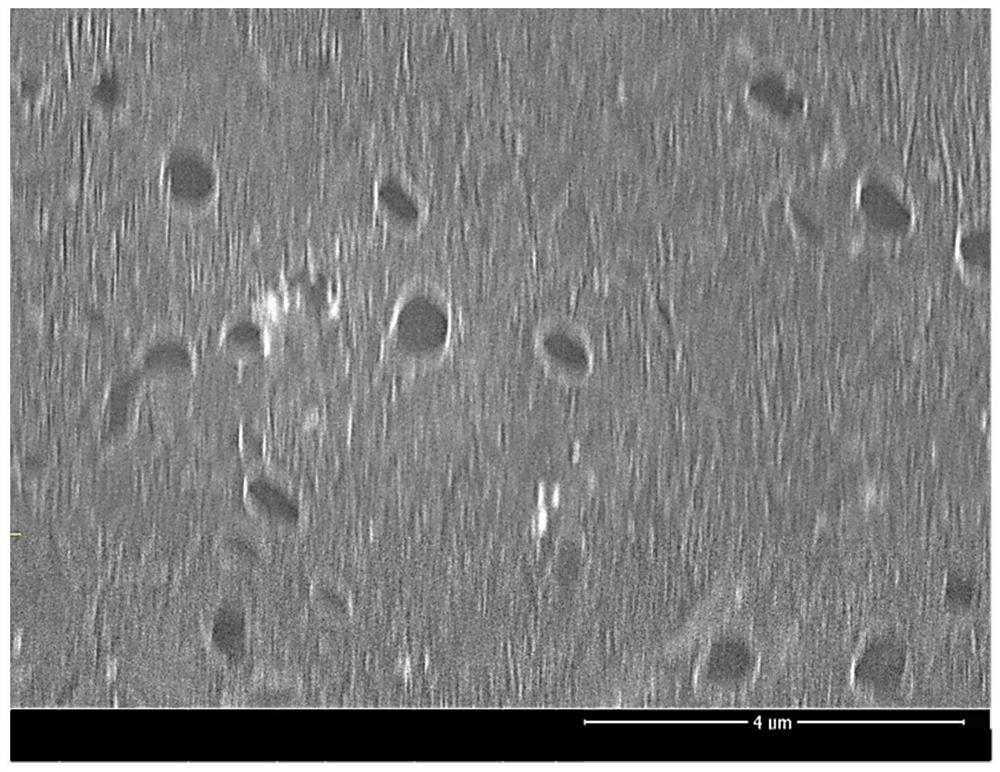

A kind of preparation method of TIC reinforced ultra-fine grain β titanium niobium matrix composite material

The invention discloses a preparation method for a TiC reinforced ultra-fine grain beta titanium and niobium based composite material. According to the preparation method, pure Ti powder and pure Nb powder serve as raw materials, a carbon and hydrogen containing process control agent serves as a carbon source for in-situ synthetic TiC and a process control agent, alloy powder is obtained through ball milling, the alloy powder is subjected to vacuum pre-sintering to remove gas and stress, then, the alloy powder is prepared into green bodies, units are subjected to assembling and sintering, and finally the TiC reinforced ultra-fine grain beta titanium and niobium based composite material is obtained through high-temperature ultrahigh pressure sintering. According to the preparation method, the process control agent serves as the carbon source for in-situ synthetic TiC, powder agglomeration and ball sticking and wall sticking situations in the ball-milling process are effectively relieved, the process control agent plays a role in refining the powder and increasing the powder yield, meanwhile TiC generated through low-temperature pre-burning is combined with high-temperature ultrahigh pressure sintering, the growth of grains is effectively restrained, the prepared TiC reinforced ultra-fine grain beta titanium and niobium based composite material is uniform in reinforcement body, fine in grain and high in density and meanwhile has the beneficial effects of being high in strength and plasticity and resistant to abrasion.

Owner:XIANGTAN UNIV

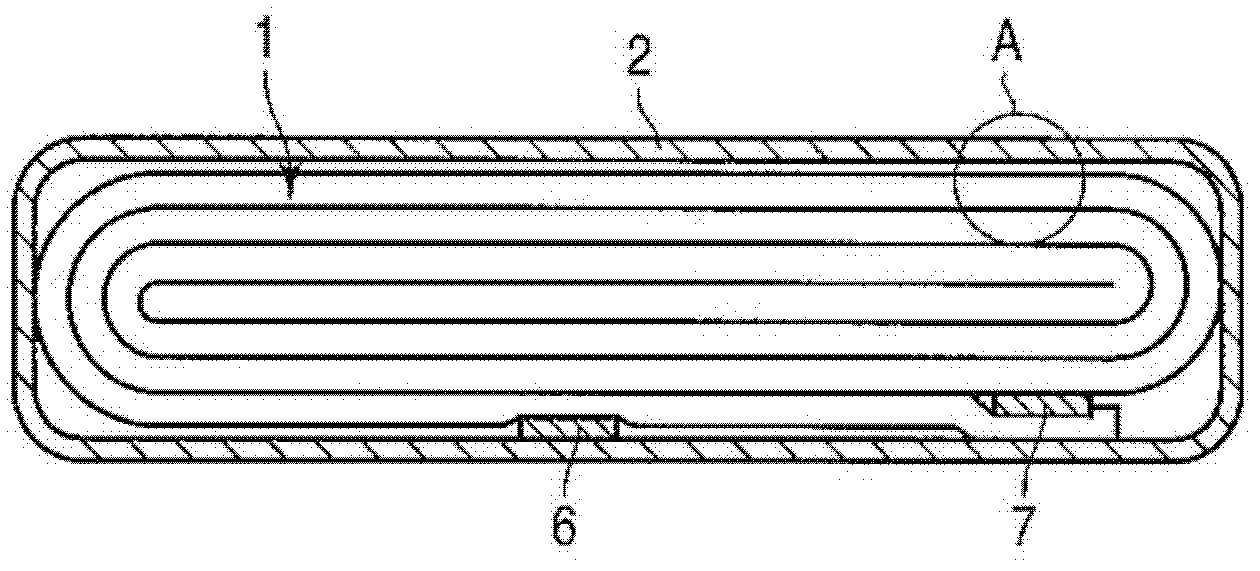

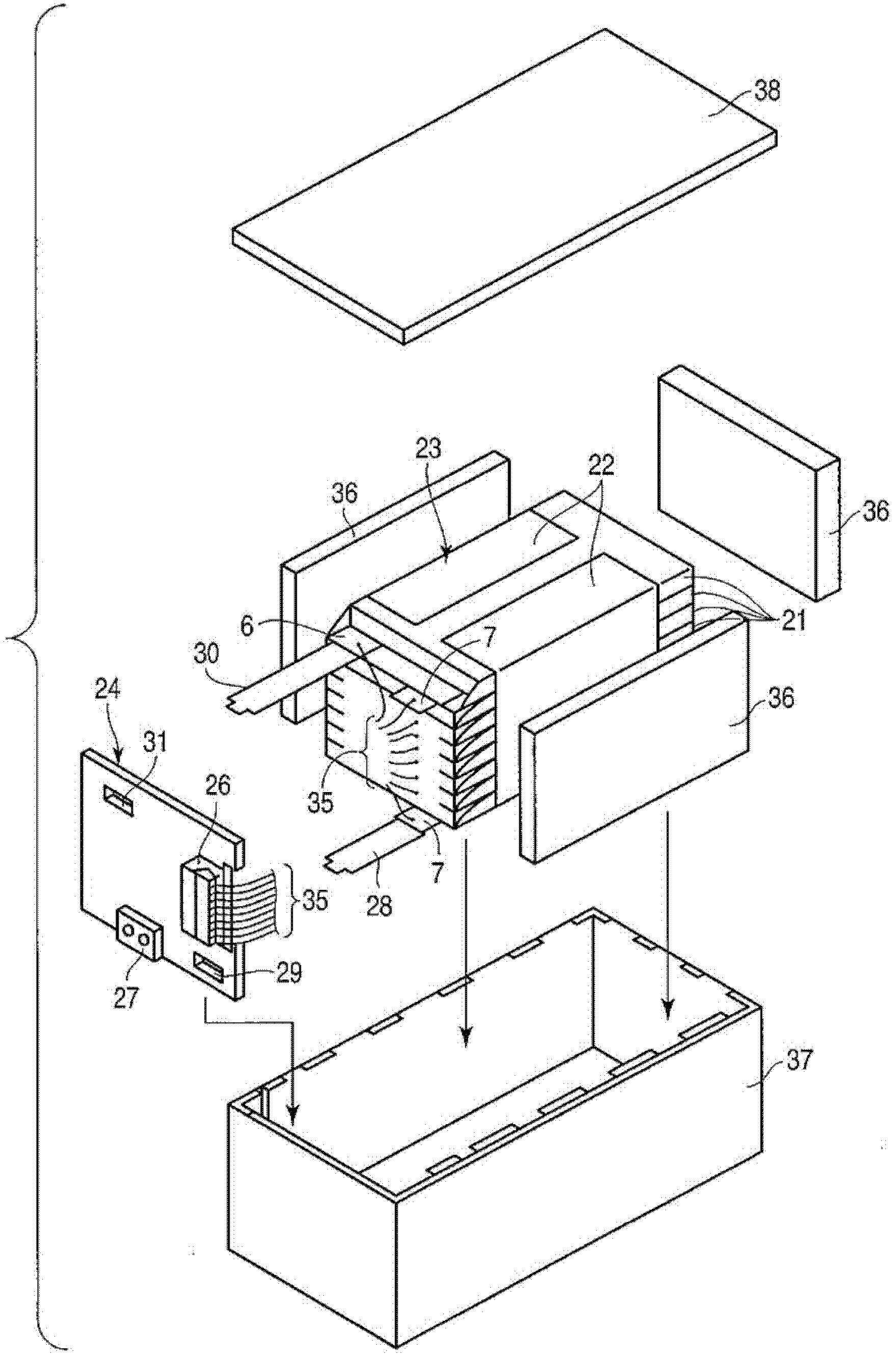

Active material for cell, nonaqueous electrolyte cell and cell pack

ActiveCN102414881AIncrease capacityExcellent high current characteristicsAlkali titanatesCell electrodesX-rayBattery cell

A nonaqueous electrolyte cell is provided with an exterior material, a positive electrode housed in the exterior material, a negative electrode housed in the exterior material spatially apart from the positive electrode and containing an active material containing a monoclinic beta titanium composite oxide, and a nonaqueous electrolyte filled in the exterior material. Regarding the crystallite diameter of the monoclinic beta titanium composite oxide, which is calculated by a wide-angle X-ray diffraction method using a CuKa line as an X-ray source, when the crystallite diameter calculated from a peak at which 2? is in the range of 48-49 DEG is taken as X and the crystallite diameter calculated from a peak at which 2? is in the range of 24-26 DEG is taken as Y, X is larger than Y.

Owner:KK TOSHIBA

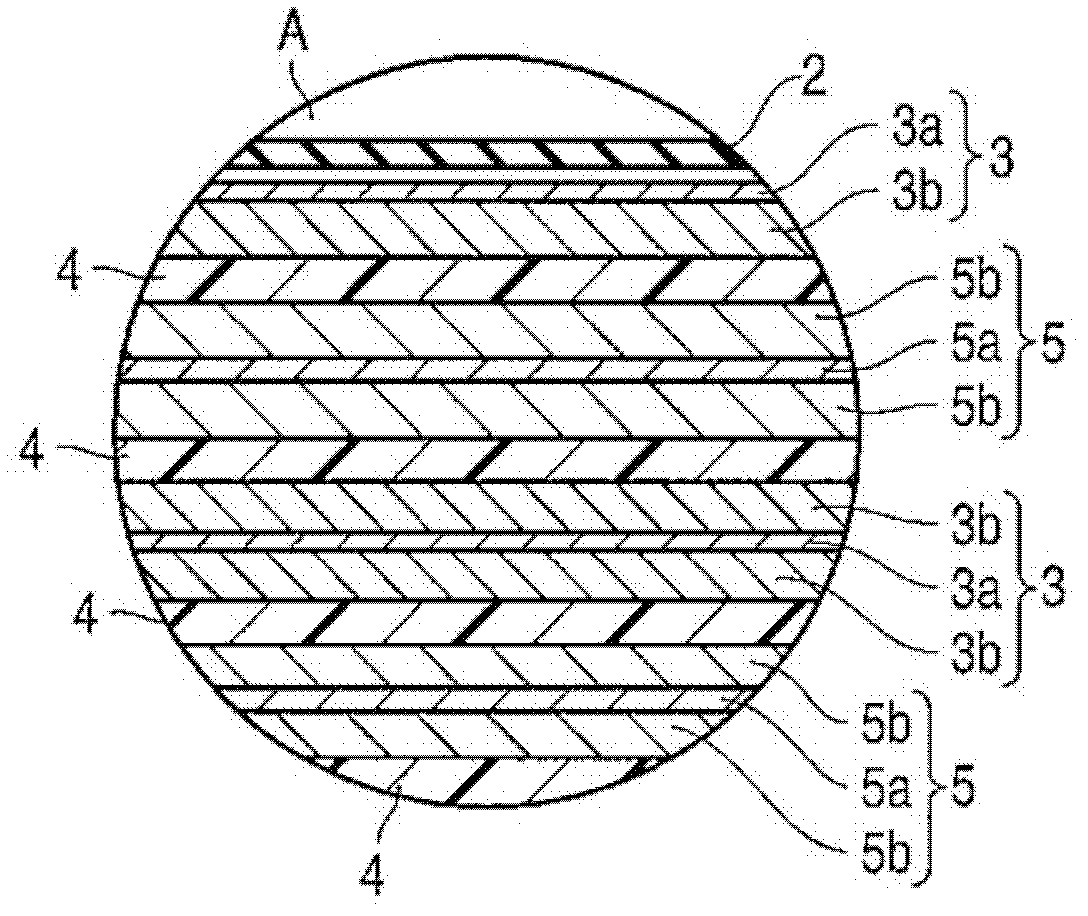

Multi-layer double-phase cross-scale structure pure titanium and preparation method thereof

ActiveCN114411074ASolving the problem of multilayer dual-phase cross-scale pure titaniumDo not destroy strength advantageHigh energy electron beamElectron bunches

The invention discloses multi-layer double-phase cross-scale structure pure titanium and a preparation method thereof. The multi-layer double-phase cross-scale structure is composed of nanocrystalline alpha titanium, fine grain alpha titanium and coarse grain beta titanium. The preparation method of the multi-layer double-phase cross-scale structure pure titanium comprises the following steps that 1, a titanium plate is subjected to multi-pass rolling at the room temperature, and nanocrystalline alpha pure titanium is obtained; 2, carrying out recovery annealing on the nanocrystalline alpha pure titanium obtained in the step 1; and 3, the nanocrystalline alpha pure titanium obtained in the step 2 is subjected to etching heat treatment in a vacuum environment through a high-energy electron beam, and the multi-layer double-phase nanocrystalline alpha titanium-fine grain alpha titanium-coarse grain beta titanium cross-scale structure is obtained. According to the method, the problem that the pure titanium with the cross-scale uneven structure is obtained from the nanocrystalline pure titanium is solved, the obtained multi-layer double-phase pure titanium with the cross-scale structure can be used as a biological implant bearing structure material, the preparation process is simple and efficient, and large-scale production can be achieved. In addition, the preparation method disclosed by the invention can also be applied to the fields of surface modification of nanocrystalline materials and the like.

Owner:SICHUAN UNIV

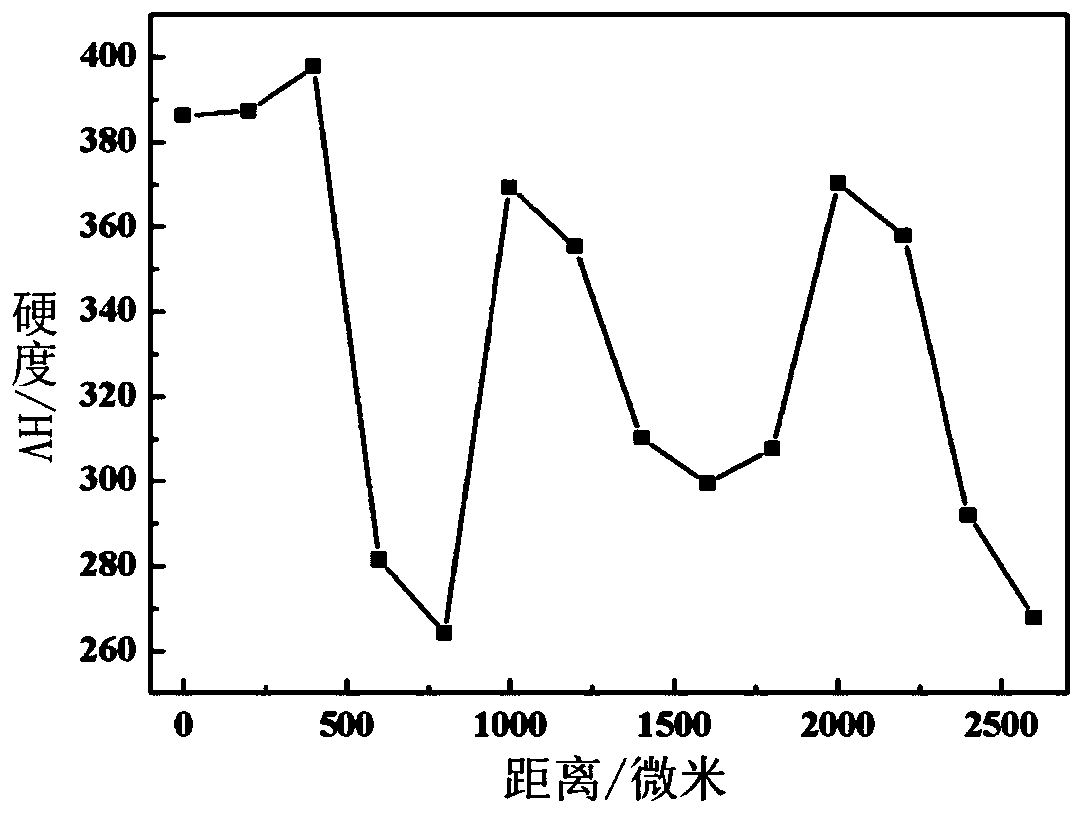

A Mechanical Heat Treatment Method for Obtaining Two-state Microstructure of Metastable β Titanium Alloy

The invention discloses a mechanical heat treatment method for obtaining duplex microstructures of metastable beta titanium alloys. The method comprises the following steps: the phase transformation temperature T beta of the metastable beta titanium alloys is measured; the alloys are homogenized at high temperature, and the cooling mode adopts furnace cooling; the ingot cogging and previous upsetting process of the alloys is performed in a beta single-phase area; the rest upsetting process is performed at a temperature below and near T beta; after heat heating number, the short-time recrystallization annealing is performed; and the two-phase region heat treatment is performed on deforming alloys. The heat deformation is performed in the beta single-phase area at the temperature below and near T beta, so that the deformation resistance is prominently reduced, and the forging defect is effectively controlled; the deformation resistance of beta single-phase regions of the alloys is low, the deformation is effectively controlled, and the structure uniformity is guaranteed; and the whole mechanical heat treatment method is convenient to operate, high in machining efficiency and low in energy loss, and prominently improves the mechanical performances of the structures.

Owner:NANJING UNIV OF SCI & TECH +1

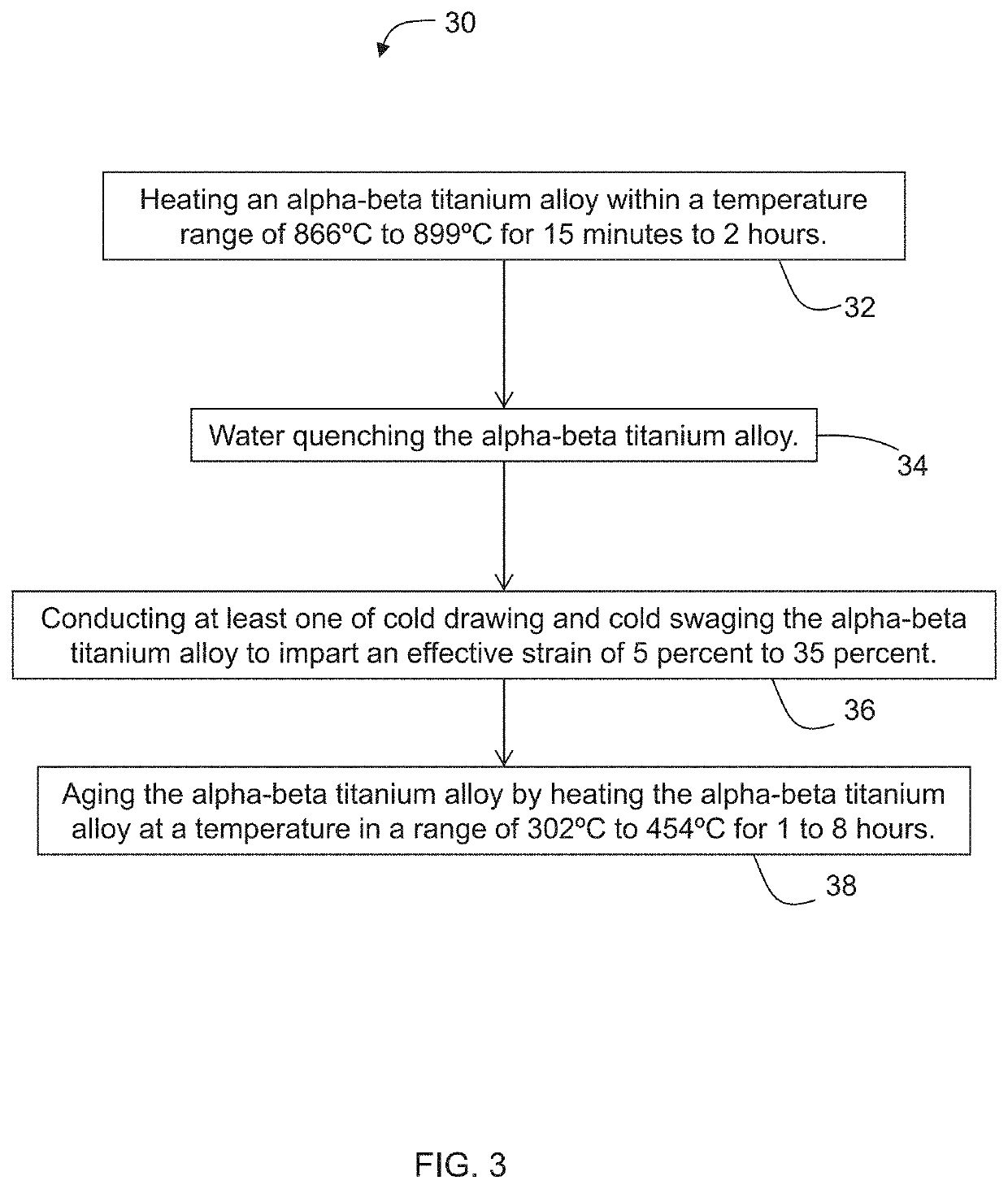

Processing of Alpha/Beta Titanium Alloys

The invention relates to processing of alpha / beta titanium alloys. Processes for forming an article from an [alpha]+[beta] titanium alloy are disclosed. The [alpha]+[beta] titanium alloy includes, in weight percentages, from 2.90 to 5.00 aluminum, from 2.00 to 3.00 vanadium, from 0.40 to 2.00 iron, and from 0.10 to 0.30 oxygen. The [alpha]+[beta] titanium alloy is cold worked at a temperature in the range of ambient temperature to 500 DEG F., and then aged at a temperature in the range of 700 DEG F. to 1200 DEG F.

Owner:ATI PROPERTIES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com