Online non-oxidation heat treatment method for beta titanium alloy wire

A technology of non-oxidative heat treatment, beta titanium alloy, applied in the field of beta titanium alloy heat treatment, can solve the problem that beta titanium alloy cannot fully achieve solid solution treatment, wire surface oxidation, affecting material properties, etc., and achieves good solution treatment effect. Low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

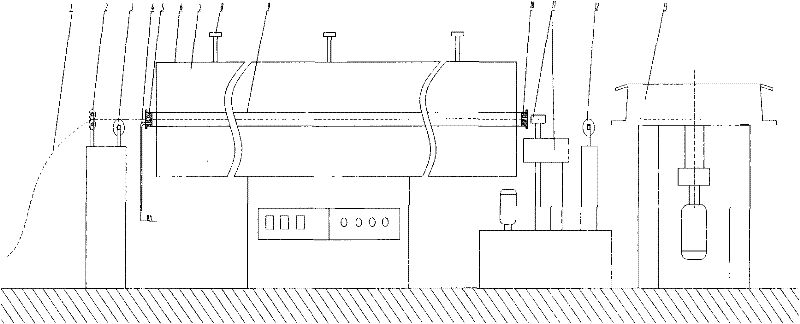

Image

Examples

Embodiment 1

[0027] A TB5 titanium alloy wire material with a diameter of Φ3.0mm is taken. This alloy contains (mass percentage): 15.1% vanadium, 3.2% chromium, 3.1% tin, 3.0% aluminum, and the balance is titanium. The wire is prepared from a TB5 titanium alloy wire with a diameter of Φ5.0 mm and cold stretched by a roll die, and the cold working deformation is 51%.

[0028] Surface pretreatment before annealing: Ultrasonic cleaning in a 60°C cleaning solution for 40 minutes to remove surface dirt on the titanium wire, drying surface moisture in a drying oven, the drying oven is controlled at 60°C, and the drying time is 40min.

[0029] The pretreated TB5 titanium alloy wire is sent into the tubular holding furnace through the damping pay-off device and the front guide for online annealing. The phase transition point of TB5 titanium alloy is about 750°C, so the furnace temperature is controlled at 780°C (slightly higher than the phase transition point). The take-up speed is set to 2 m / mi...

Embodiment 2

[0035] A Ti-20V-4Al-1Sn titanium alloy wire with a diameter of Φ4.0mm is taken. This alloy contains (mass percentage): 21.5% vanadium, 3.8% aluminum, 1.2% tin, and the balance is titanium. The wire is prepared by cold drawing the alloy wire with a diameter of Φ5.5mm through a roll die, and the cold working deformation is 49%.

[0036] Surface pretreatment before annealing: Ultrasonic cleaning for 30 minutes in a cleaning solution at 80°C to remove surface dirt on the titanium wire, and drying the surface moisture in a drying oven controlled at 50°C for a drying time of 30min.

[0037] The pretreated titanium alloy wire is sent into the tubular holding furnace through the damping pay-off device and the front guide for online annealing. The phase transition point of this titanium alloy is about 720°C, so the furnace temperature is controlled at 760°C (slightly higher than the phase transition point). The take-up speed is set to 3 m / min, the length of the annealing furnace is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com