Electronic synapse device and manufacturing method

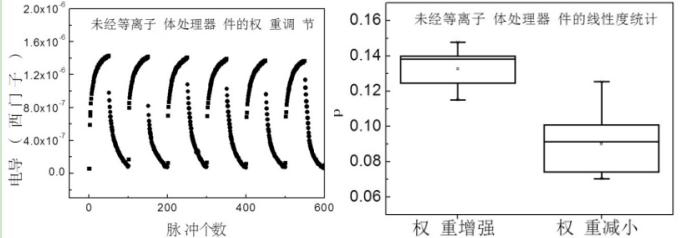

A technology of electronic synapse and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc. It can solve the problems of easy loss of weight and low linearity of resistance adjustment, so as to improve linearity and device synapse Performance, Simplification Predictable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

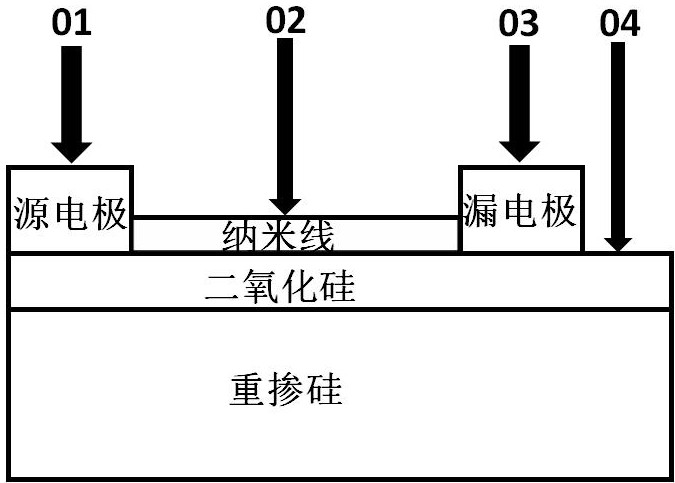

[0042] An electronic synaptic device has a structure such as figure 1 As shown, the heavily doped silicon / silicon dioxide substrate 04, the Ti with a thickness of 110 nm as the source electrode 01, the linear zinc oxide with a length of 10 μm and a diameter of 100 nm as the medium 02, and Ti with a thickness of 110 nm as the The drain electrode 03 constitutes.

[0043] The zinc oxide nanowires are subjected to plasma bombardment treatment, and the specific manufacturing steps are as follows:

[0044] First, 100 watts of argon plasma was used to treat the ZnO nanowires for 120 seconds, and then the plasma-treated ZnO nanowires were sprinkled on the heavily doped silicon / silicon dioxide substrate, and then the source and drain electrodes were sputtered by magnetron sputtering. fabricated on ZnO nanowires.

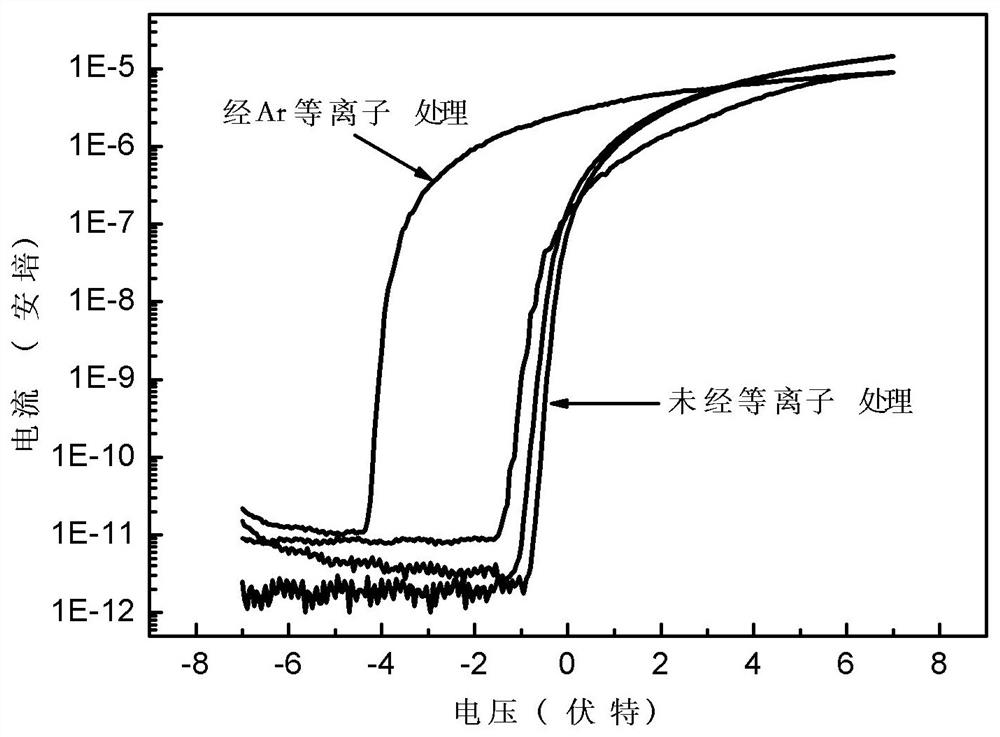

[0045] Perform an electrical test on the transistor in this embodiment, figure 2 It is the transfer characteristic curve of the transistor before and after plasma treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com