Patents

Literature

406 results about "Thermal ageing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal aging is used to test the ability of a product to withstand elevated temperatures for an extended period of time.

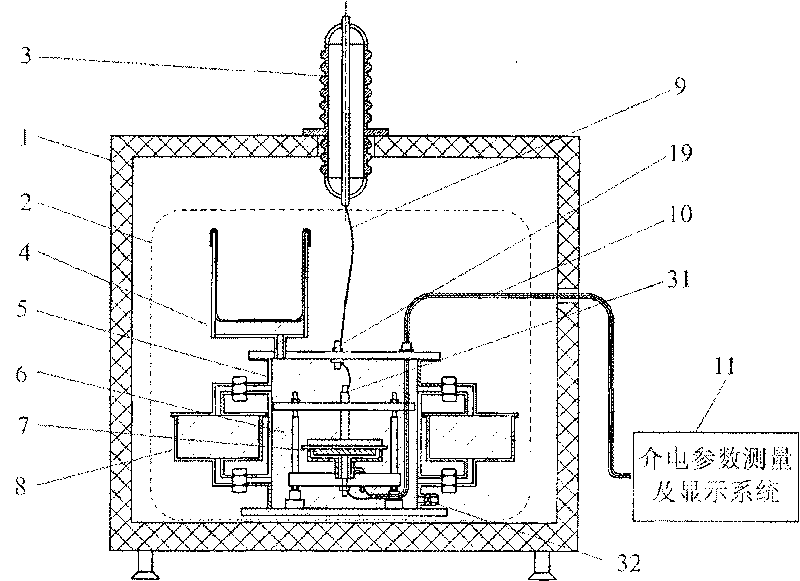

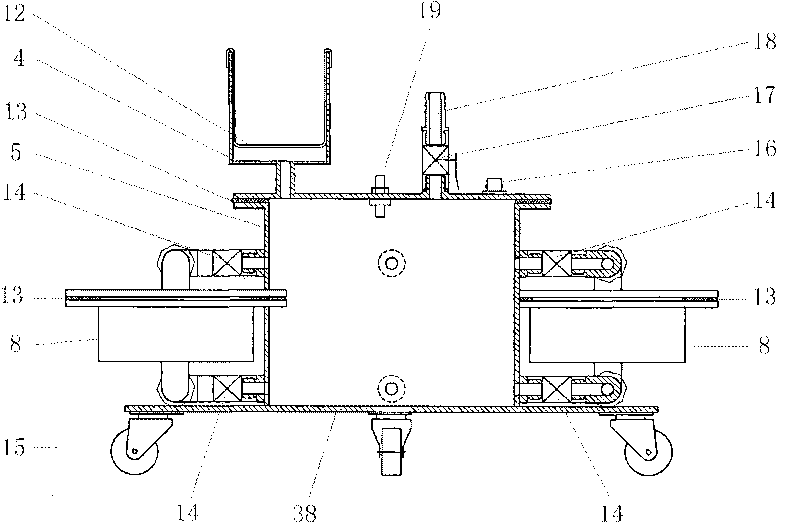

Experimental device and experimental method for transformer oilpaper insulating thermal ageing

InactiveCN101713721AWeighing by removing componentWeather/light/corrosion resistanceThermal ageingElectricity

Owner:XI AN JIAOTONG UNIV

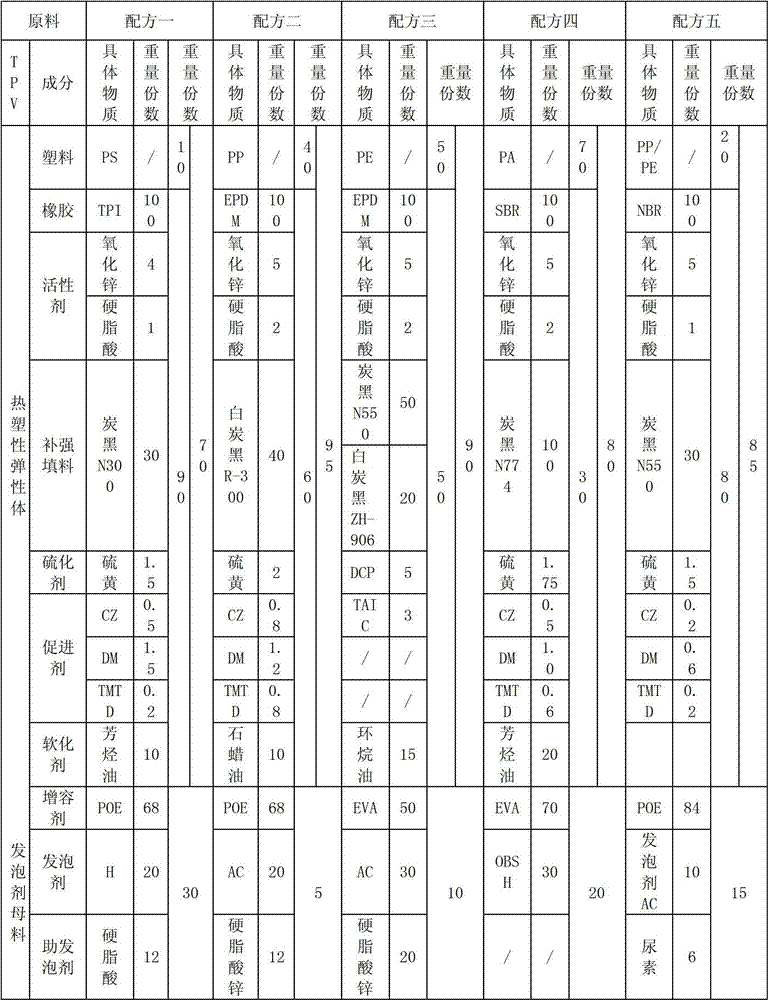

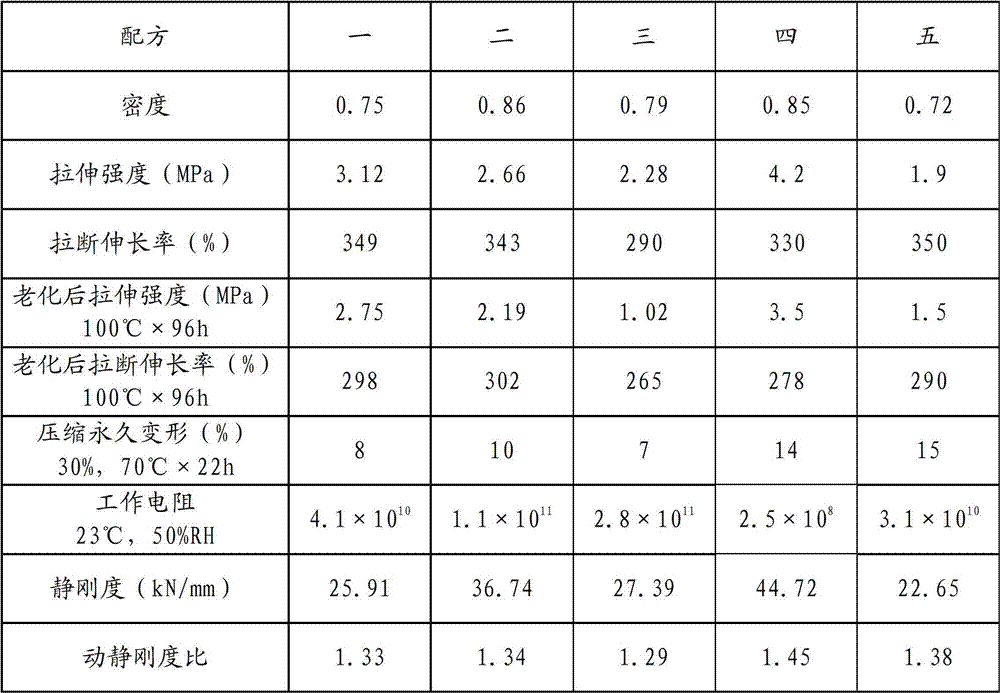

Thermoplastic elastomer micropore foaming material and preparation method thereof

The invention discloses a thermoplastic elastomer micropore foaming material and a preparation method thereof. The material comprises the following componnets in parts by weight: 70-95 parts of thermoplastic elastomer and 5-30 parts of foaming agent master batch. The preparation method comprises the following steps of: based on weight parts, placing 50-90 parts of compatibilizers, 6-30 parts of foaming agent and 4-20 parts of auxiliary foaming agents into a double-roller open mill for mixing to prepare foaming agent master batch; sequentially adding 100 parts of matrix rubber, 5-10 parts of active agent, 20-100 parts of reinforced fillers, 0-20 parts of softening agents, 0.5-5 parts of vulcanizing agents and 1-10 parts of accelerating agents into the open mill or an internal mixer for uniformly mixing to prepare a rubber compound; chopping the rubber compound and uniformly mixing the chopped rubber compound with 10-70 parts of plastics by a high-speed mixer; and extruding and pelleting the mixture to prepare thermoplastic vulcanizate (TPV) aggregates; and uniformly mixing the foaming agent master batch with the TPV aggregates to extrude and form again to prepare a high-performance micropore foaming material for vibration attenuation. The TPV foaming material is high in physical and mechanical properties and thermal ageing performance, is simple in process, can be widely popularized, and is suitable for being used in the field of rail transit.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

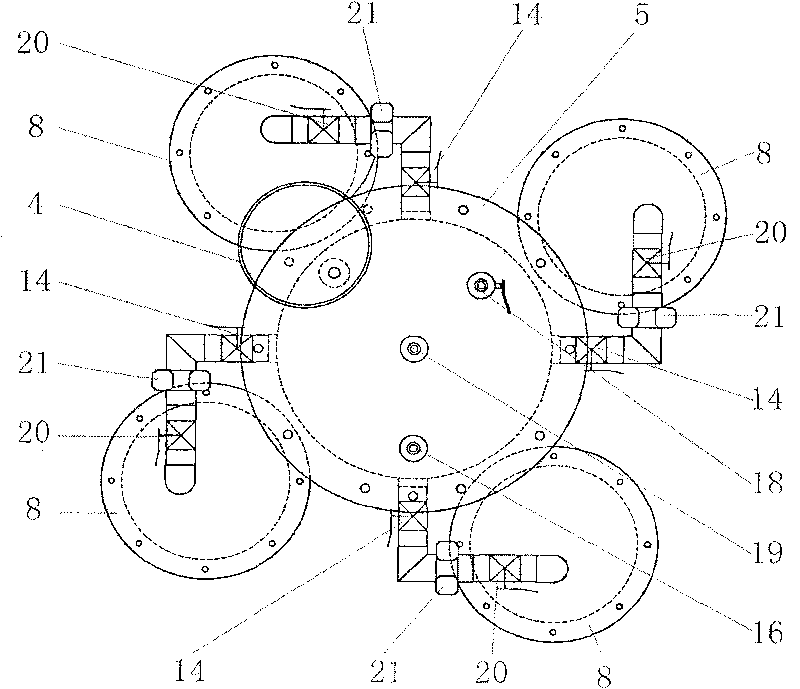

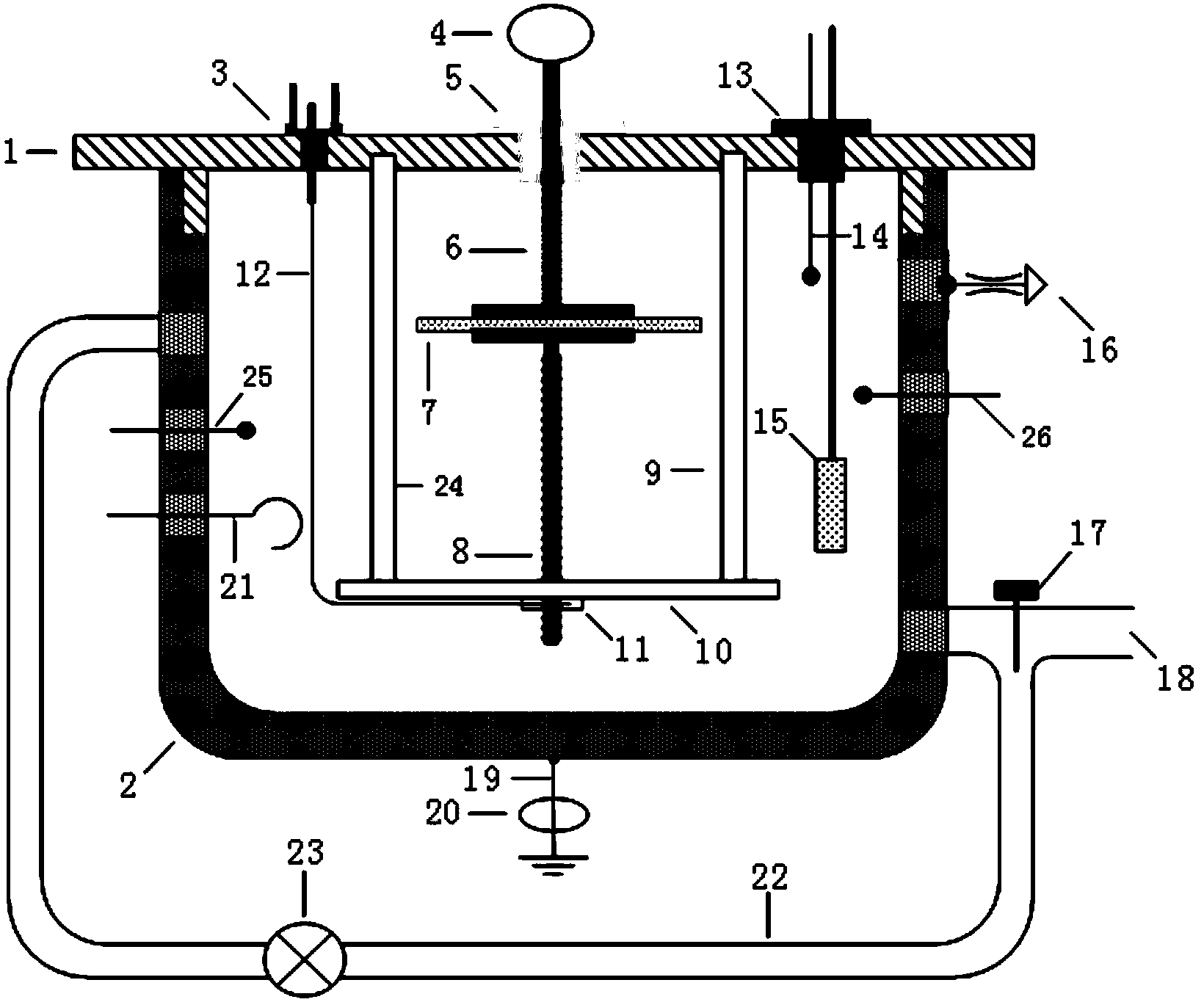

Transformer oil-paper insulation electricity-heating unite ageing test device

ActiveCN104076232AControllable aging conditionsReduce volumeElectrical testingThermal ageingLow voltage

The invention relates to a transformer oil-paper insulation electricity-heating unite ageing test device which comprises a sealing cavity and a test device body located in the sealing cavity. The test device body of the transformer oil-paper insulation electricity-heating unite ageing test device comprises a high voltage electrode, a low voltage electrode and an insulation paper sample, the insulation paper sample of the test device body is located between the high voltage electrode and the low voltage electrode, and electric ageing conditions of an oil-paper insulation test are controlled by controlling the voltage exerted to the insulation paper sample; the transformer oil-paper insulation electricity-heating unite ageing test device further comprises a heating device, and heat aging conditions of the oil-paper insulation test are controlled by controlling the heating temperature of the heating device; the transformer oil-paper insulation electricity-heating unite ageing test device further comprises a partial discharge detecting device, and high-frequency partial discharge detecting and low-frequency partial discharge detecting are achieved. By means of the transformer oil-paper insulation electricity-heating unite ageing test device, multi-state detection and fault diagnosis of a transformer can be achieved, an oil sample and gas in the sealing cavity after the aging test are directly taken out under the condition that the sealing cavity is not opened, the reliability of experimental analysis results is high, and the device is easy and convenient to operate, and the problem that an existing test device is low in reliability of the experimental analysis results and inconvenient to operate is solved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

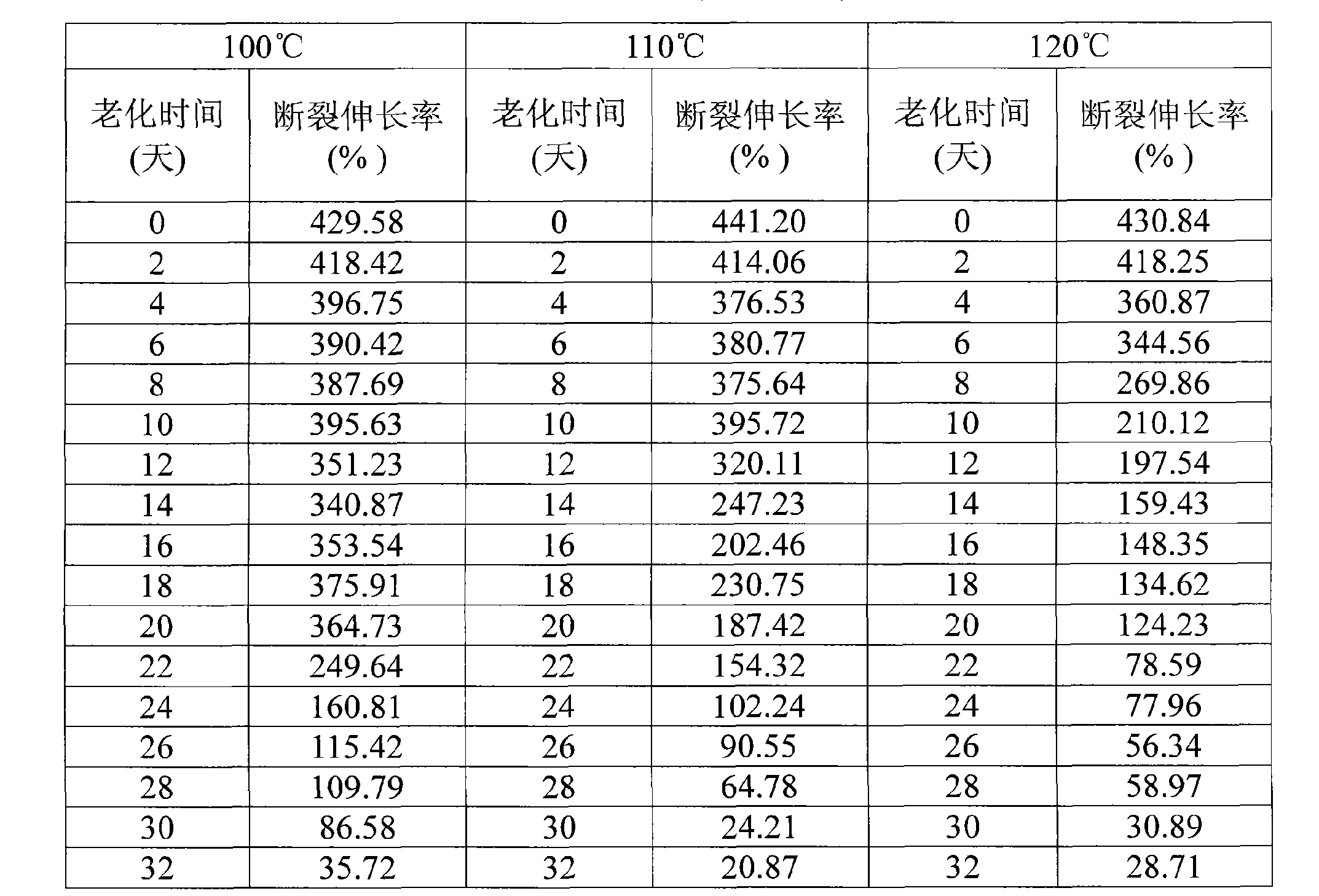

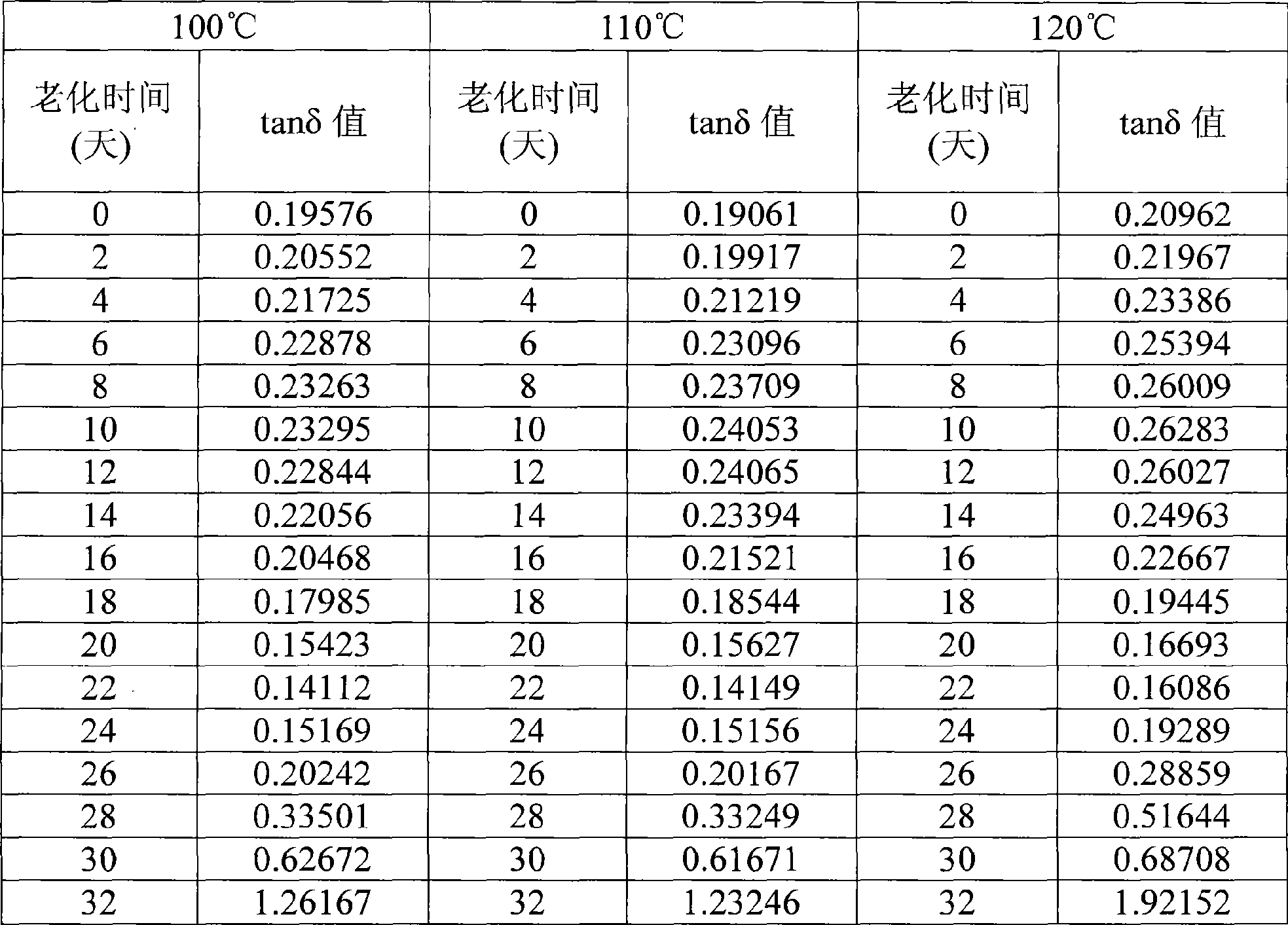

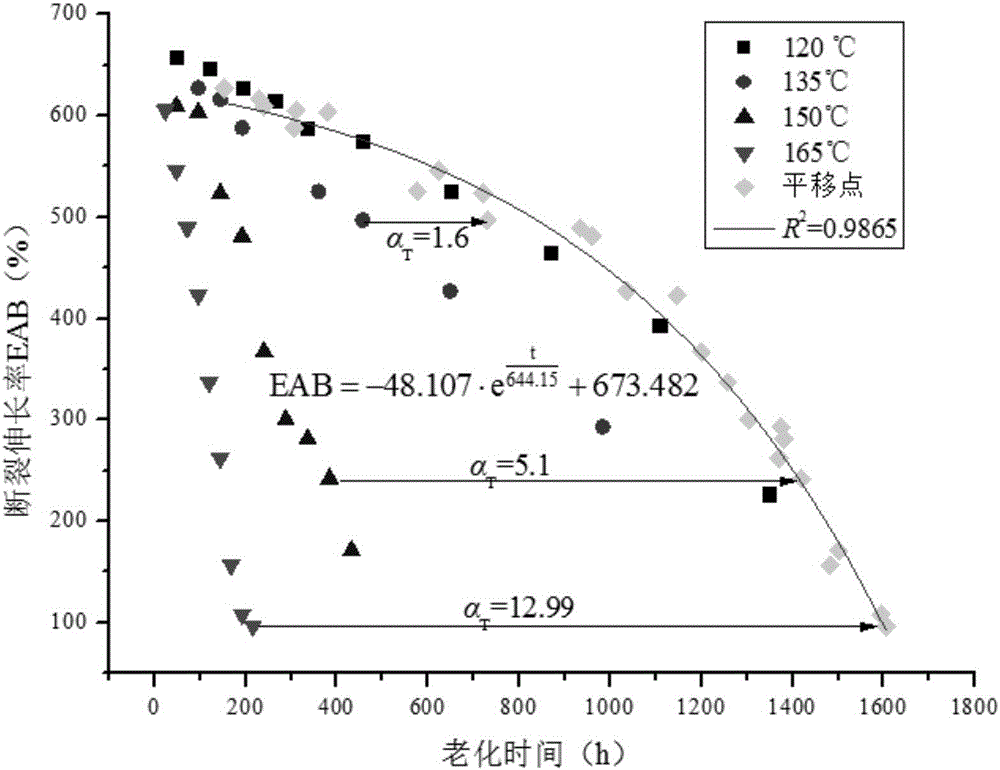

Method for evaluating residual service life of marine low-pressure rubber-insulated cable

InactiveCN101470058ADetermine working lifeFast and accurate assessmentMaterial testing goodsStrength propertiesThermal ageingLow voltage

The invention discloses a method for evaluating the residual life of low voltage rubber insulation cable used on ships, comprising: processing thermal accelerated aging test on the insulation material of a cable sample; quickly simulating the aging process of the cable; attaining a cable service life equation based on the breaking elongation of the cable insulation material; in each time node of the thermal accelerated aging test, measuring the tangent value of dielectric loss angle of the cable insulation material, to obtain a cable service life equation based on the tangent value of dielectric loss angle of the insulation material and a tangent critical value of the dielectric loss angle at the end of the cable life; evaluating the service life of a low voltage rubber insulation cable of one standard via the two service life equations; according to the tangent value of dielectric loss angle measured in site, using the cable service life equation based on the tangent value of dielectric loss angle to evaluate the residual life of the in-situ cable. The method can quickly and accurately evaluate the residual life of cable in-situ.

Owner:DALIAN UNIV OF TECH

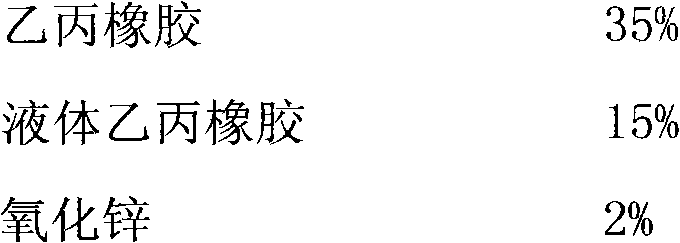

Adhesive coating rubber material for high temperature resistant canvas conveyer and use method thereof

ActiveCN102337092AImprove aging resistanceImprove adhesionConveyorsNon-macromolecular adhesive additivesThermal ageingRubber material

The invention relates to an adhesive coating rubber material for a high temperature resistant canvas conveyer and a use method thereof. In the adhesive coating rubber material, ethylene-propylene-diene rubber is used as a substrate and an unsaturated carboxylic metal salt filling material and a proper auxiliary are added, so that the adhesion property of rubber and a canvas conveyer core is improved; and at the same time, the thermal ageing resisting property of the adhesive coating rubber is also improved, so that the conveyer can endure the temperature of more than 175 DEG C for a long timewithout delaminating phenomenon, thereby prolonging the service life of the conveyer.

Owner:BEIJING UNIV OF CHEM TECH +1

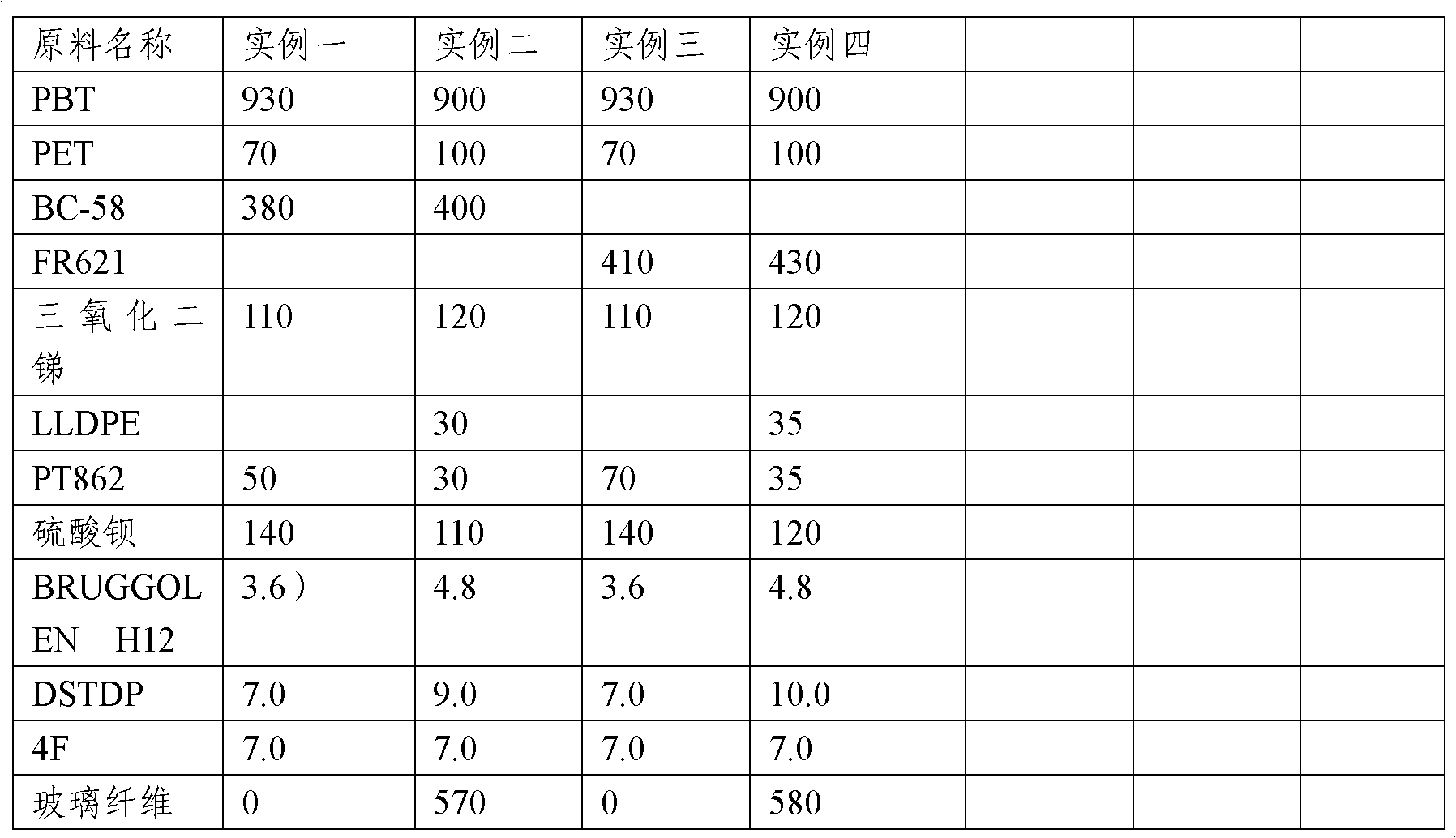

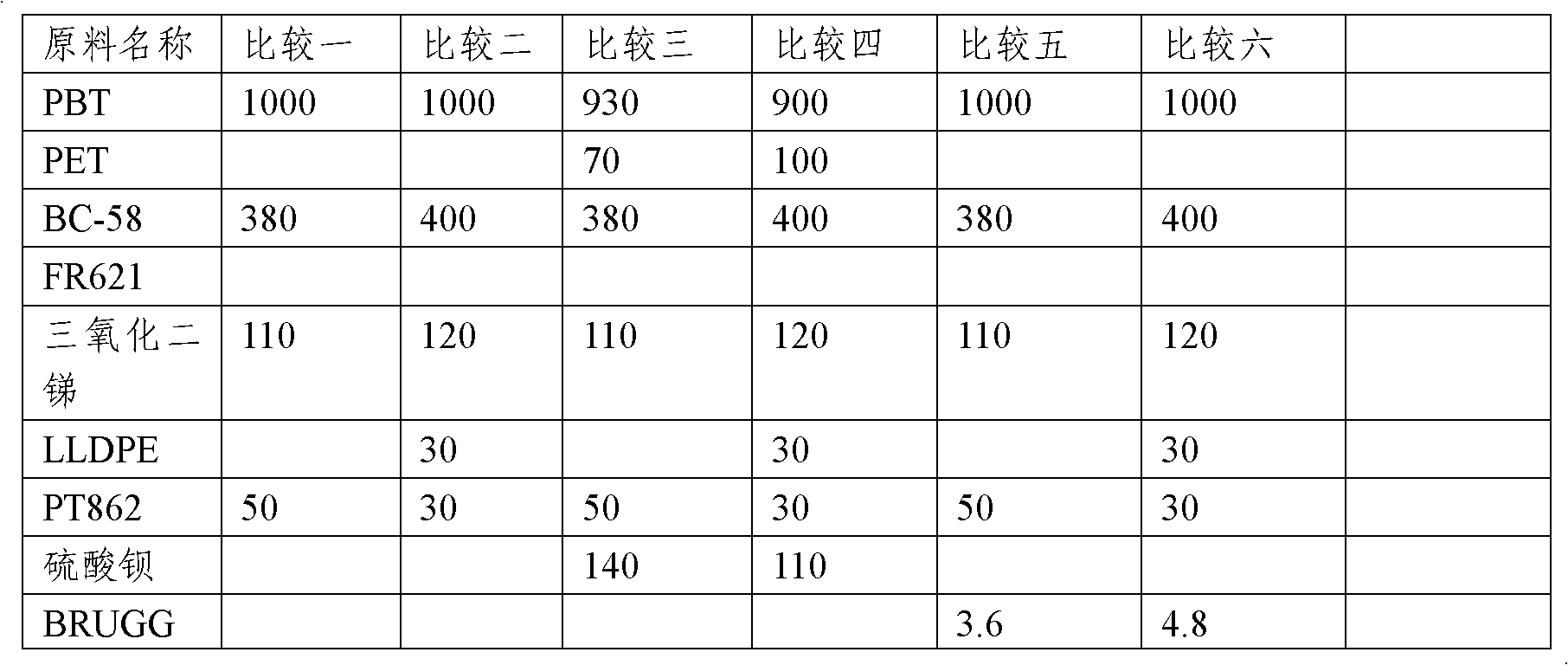

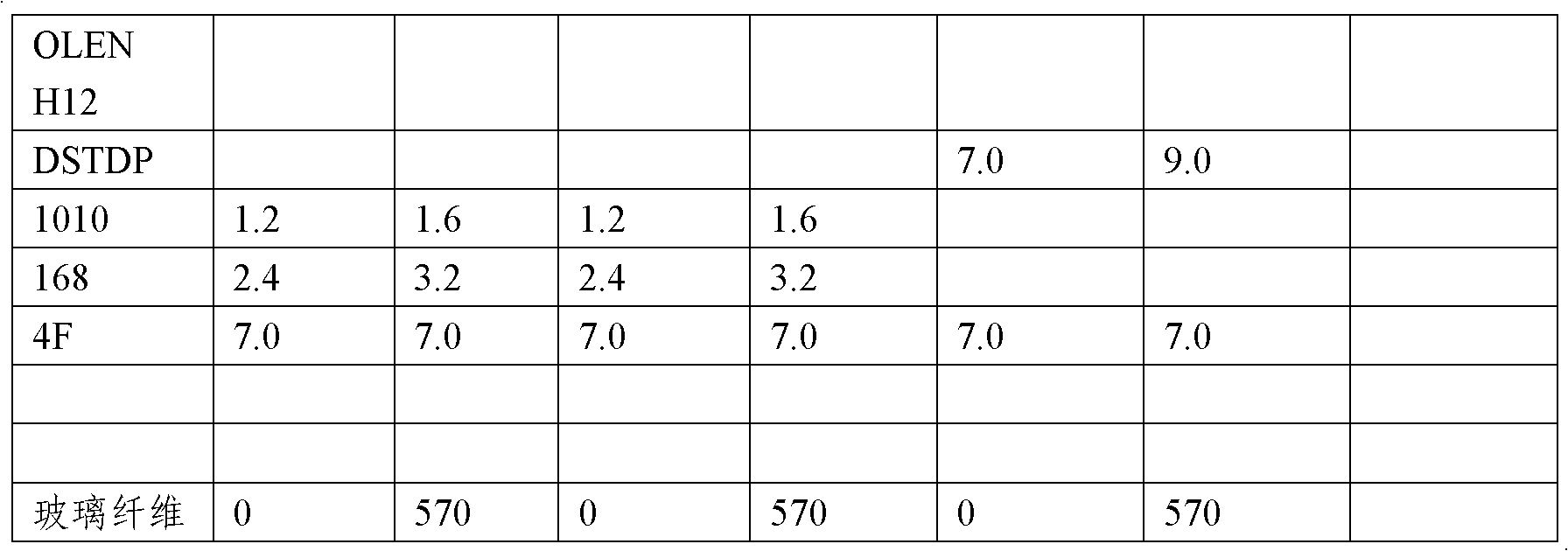

Polyester having thermal ageing resistant performance and production method thereof

The invention discloses polyester having thermal ageing resistant performance, which comprises a thermoplastic polyester, a flexibilizer, antioxygen, a heat stabilizer, a filler and other assistant. The product has high thermal ageing resistant performance and high flame-retarding performance.

Owner:东莞市东翔塑胶有限公司

Organic silicon material for power type LED encapsulation and synthetic method thereof

InactiveCN101654560AHigh refractive indexHigh transparencySemiconductor devicesThermal ageingHydrogen

The invention discloses an organic silicon material for power type LED encapsulation and a synthetic method thereof. The organic silicon material consists of vinyl silicone high polymer, curing catalyst, high polymer containing hydrogen-based silicon and inhibitor, wherein the vinyl silicone high polymer is composed of vinyl silicone resin and polysiloxane containing vinyl or is only composed of the polysiloxane containing vinyl or only composed of the vinyl silicone resin; the polysiloxane containing vinyl is vinyl-terminated polysiloxane; and the high polymer containing hydrogen-based silicon is composed of poly cyano-group siloxane and the vinyl silicone resin or is only composed of poly cyano-group siloxane. The organic silicon material has the advantages of higher refractive index, high transparency, good ultraviolet ageing resistant property, thermal ageing capacity and the like, and is an ideal encapsulation material for power type LED.

Owner:茂名市信翼化工有限公司

Glass fiber reinforced polypropylene material and preparation method thereof

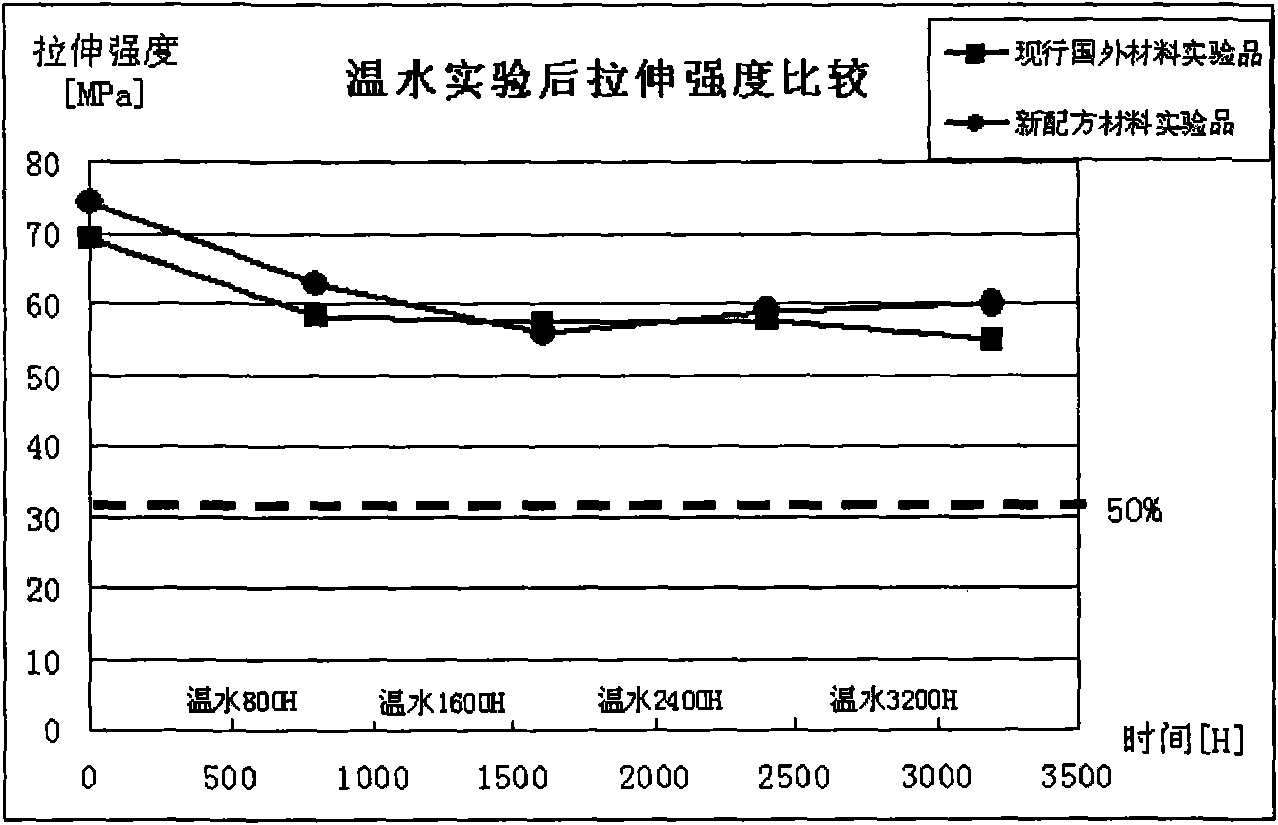

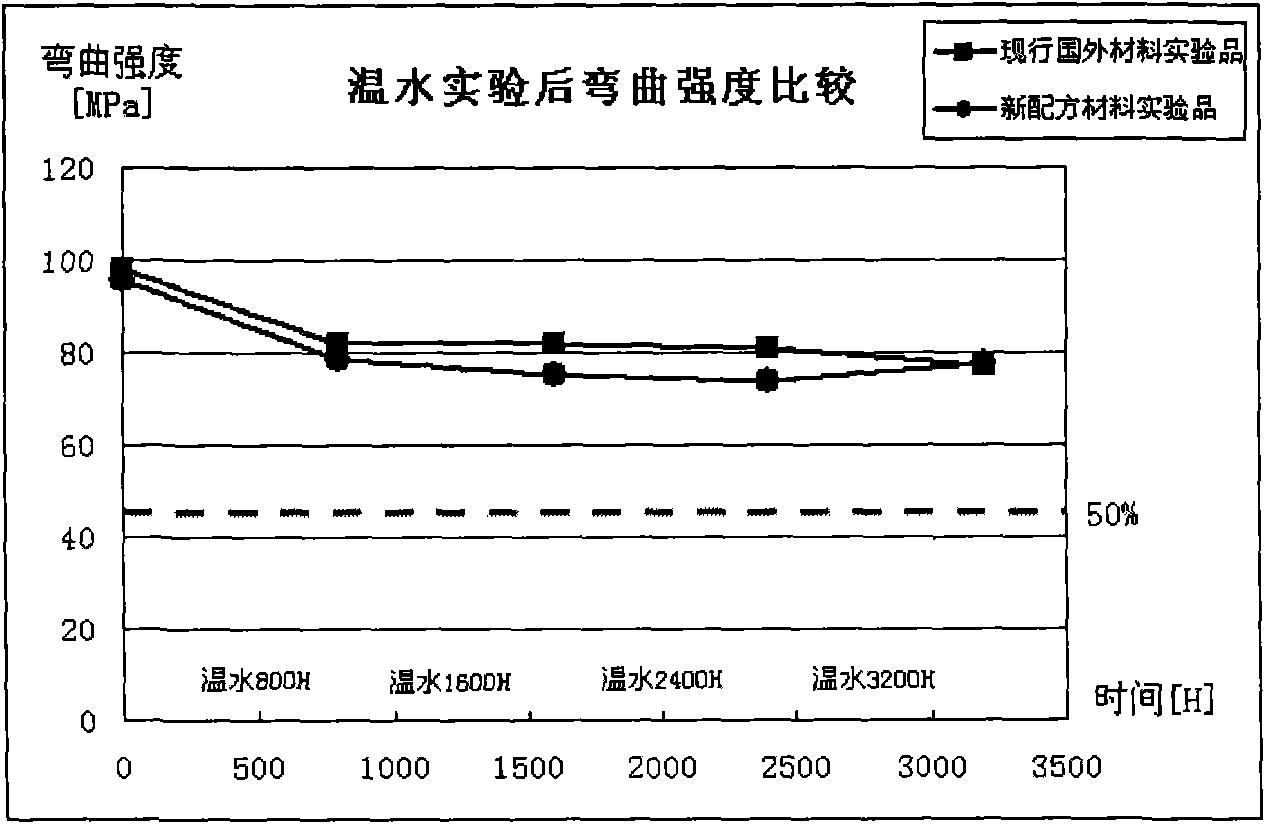

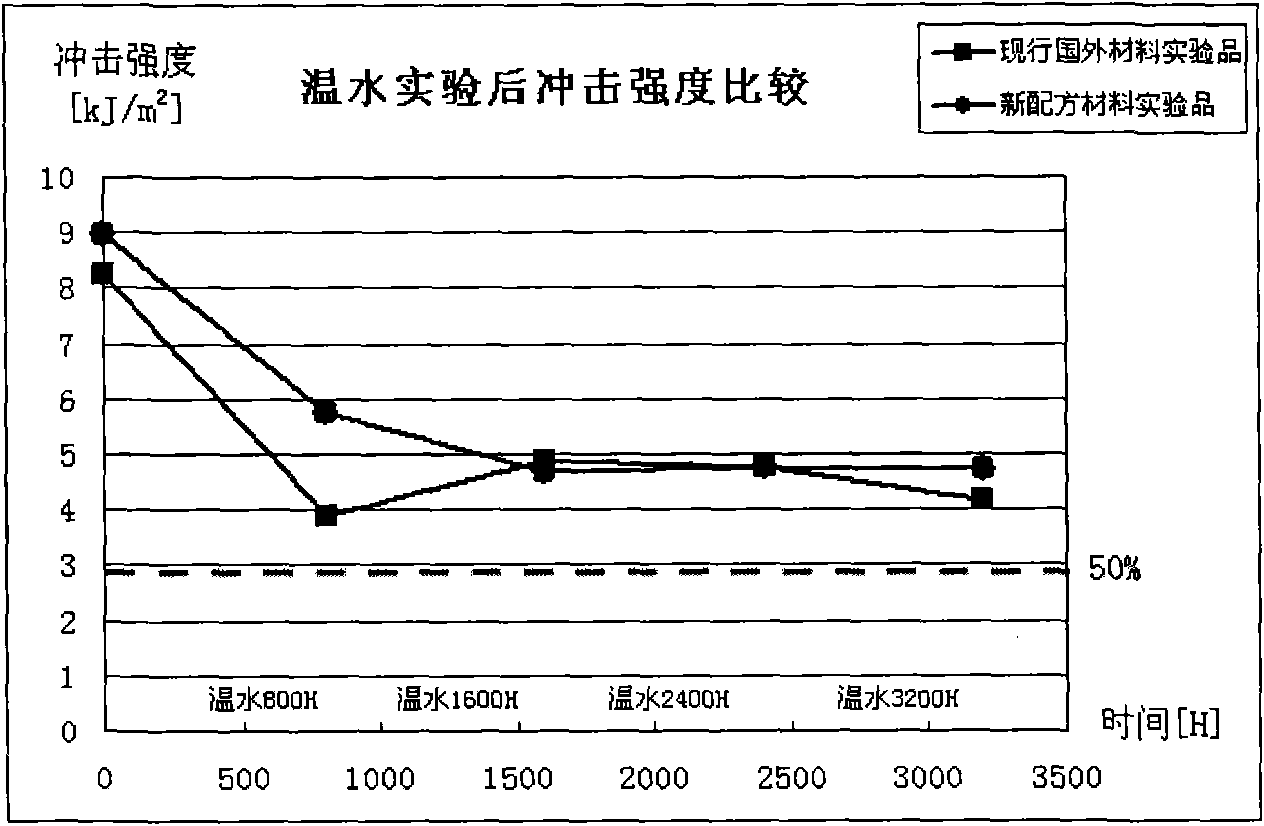

ActiveCN102181096AHigh thermal oxidation resistanceImprove hydrolysis resistanceThermal ageingWarm water

The invention discloses a glass fiber reinforced polypropylene material and a preparation method thereof, and belongs to the technical field of organic materials. The glass fiber reinforced polypropylene material comprises polypropylene copolymer and / or polypropylene homopolymer, compatilizer, glass fibers, antioxidant, light stabilizer and lubricating agent. The preparation method of the glass fiber reinforced polypropylene material comprises the following steps of: 1) weighing; 2) mixing; and 3) performing melt extrusion, drawing and granulating. The invention has the advantages that: 1) the prepared composite material has excellent hydrolysis resistance and high thermal oxidation resistance; 2) the prepared composite material has good mechanical property, and is suitable to be used as a drum washing machine material; 3) the preparation process is simple, and the glass fiber content is easily controlled; and 4) the anti-ageing time (warm water 800H + thermal ageing) of the prepared composite material meets the using requirement of a drum washing machine.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

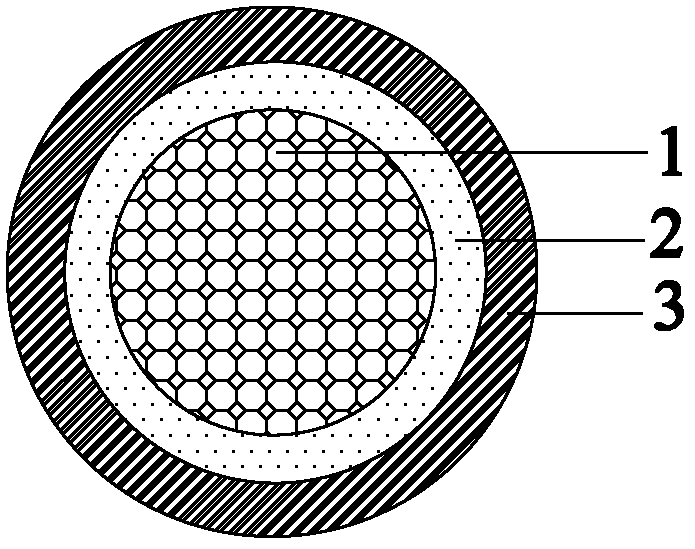

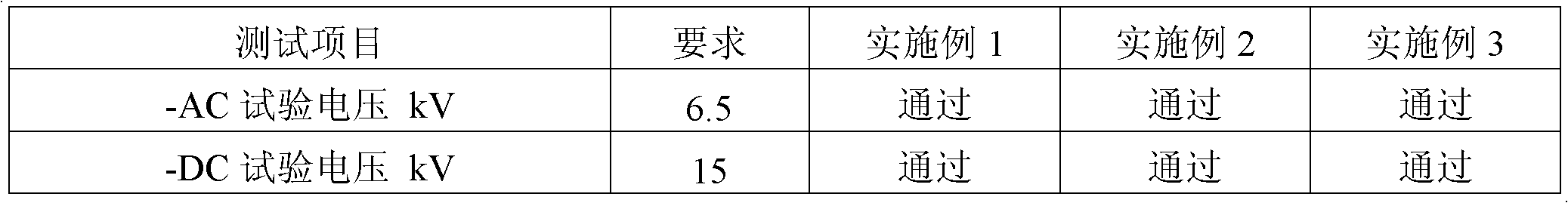

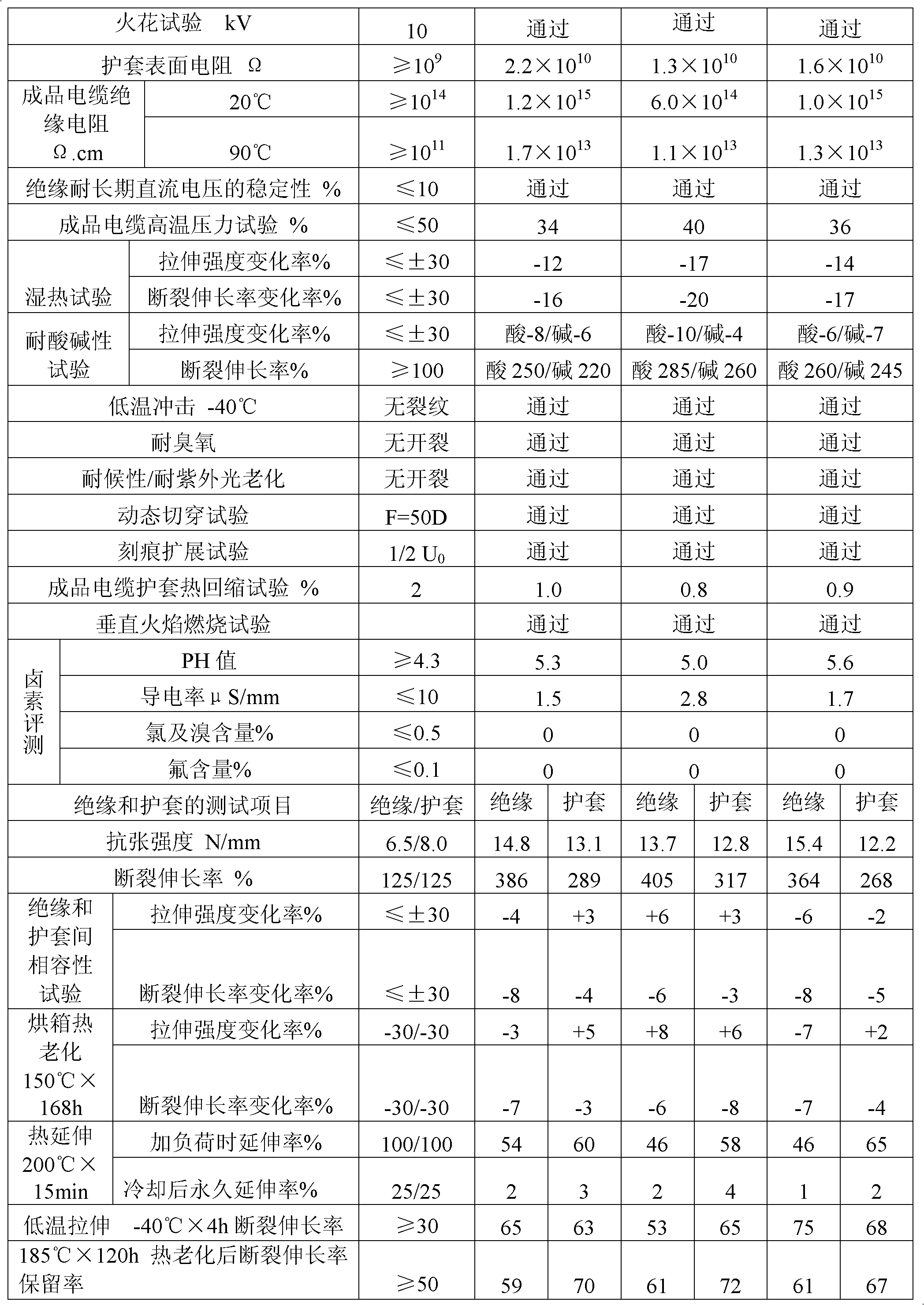

Photovoltaic cable and manufacturing method and application thereof

ActiveCN102610305AGood mechanical propertiesMeet environmental protection requirementsClimate change adaptationInsulated cablesThermal ageingCross-link

The invention discloses a photovoltaic cable and a manufacturing method and application thereof. The photovoltaic cable comprises an insulating layer and a jacket layer; the insulating layer comprises the following components: EVA (ethylene-vinyl acetate copolymer), LLDPE (linear low density polyethylene), EMA (ethylene-methyl acrylate), EVA-g-MAH (ethylene-vinyl acetate copolymer grafted maleic anhydride), magnesium hydrate, organic montmorillonoid, a cross-linked sensitizing agent, a lubricating agent, an antioxidant, a light stabilizer and a copper resisting agent; and the jacket comprisesthe following components: EVA, LLDPE, EMA, EVA-g-MAH, color masterbatch, magnesium hydrate, a phosphor series fire retardant, melamine chlorinated isocyanurates, zinc borate, a cross-linked sensitizing agent, a lubricating agent, an antioxidant, a light stabilizer and a copper resisting agent. According to the invention, the photovoltaic cable is manufactured by extruding insulating layer aggregates and jacket layer aggregates on a cable double-layer co-extrusion machine, wrapping the aggregates on the outer surface of a conductor in sequence and carrying out forming, air cooling, coiling andirradiation. The manufacturing method disclosed by the invention has the advantages of good machining property, favorable machining property and low cost and is suitable for industrial production; and the manufactured photovoltaic cable is environment-friendly and has excellent mechanical property, flame radiation resistance performance, thermal ageing property and weather fastness.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

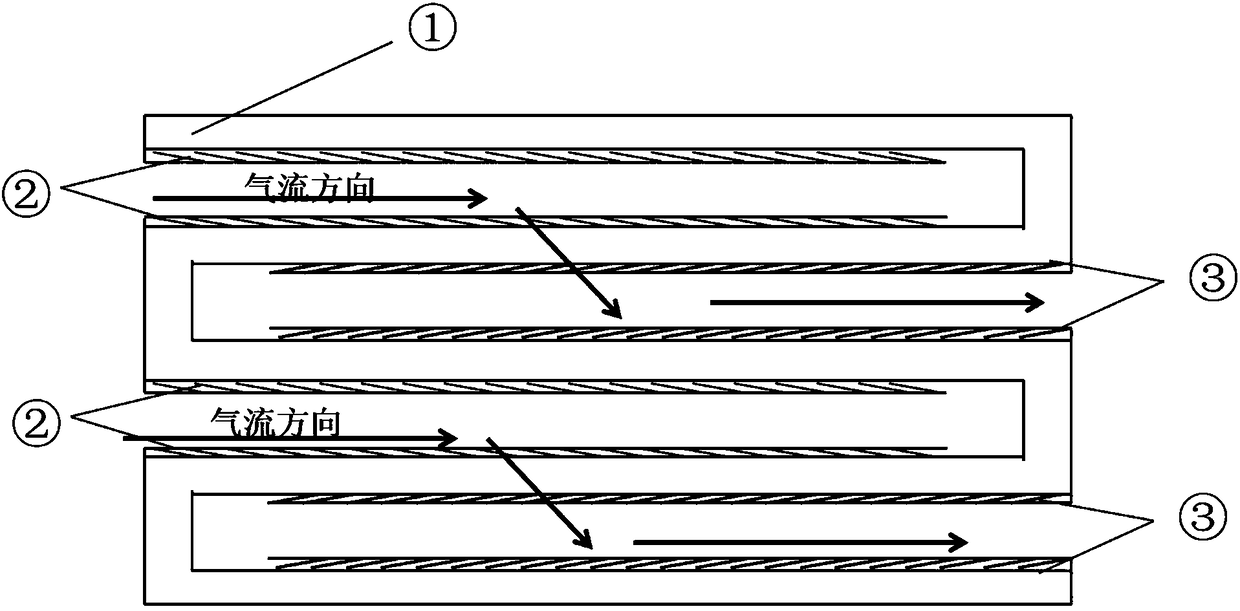

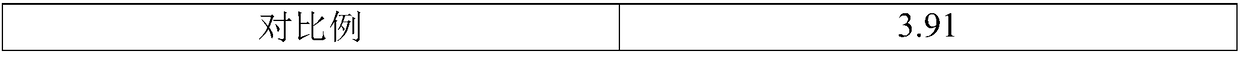

Catalyst for GPF (gasoline particulate filter) and preparation method of catalyst

ActiveCN108295851AGood dispersionHigh particle capture rateExhaust apparatusHeterogenous catalyst chemical elementsThermal ageingRare earth

The invention relates to a catalyst for a GPF (gasoline particulate filter) and a preparation method of the catalyst, and belongs to the technical field of catalyst preparation. Wall-flow cordierite honeycomb ceramic is taken as a support, pore channel walls inside a gas inlet end and a gas outlet end of the support are coated with a first coating and a second coating respectively, the first coating contains a Ce-Zr rare earth composite oxide and an La-Al composite oxide, and the second coating contains a Ce-Zr rare earth composite oxide, an La-Al composite oxide and an alkaline earth metal oxide. Coating quantities of the first coating and the second coating are 30-60 g / L, and axial height of each coating is 50%-90% of the support height. Precious metals Rh and Pd are supported on the first coating and the second coating respectively. The preparation method is simple and easy to operate. Exhaust back pressure of the catalyst is reduced remarkably by means of a coating regulator, dispersibility of the coatings is improved, the catalyst still keeps higher particulate filter efficiency and gaseous pollutant removal rate while the exhaust back pressure is reduced, besides, thermal stability of the precious metal Pd is improved by the alkaline earth metal oxide, and thermal ageing resistance of the catalyst is improved.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

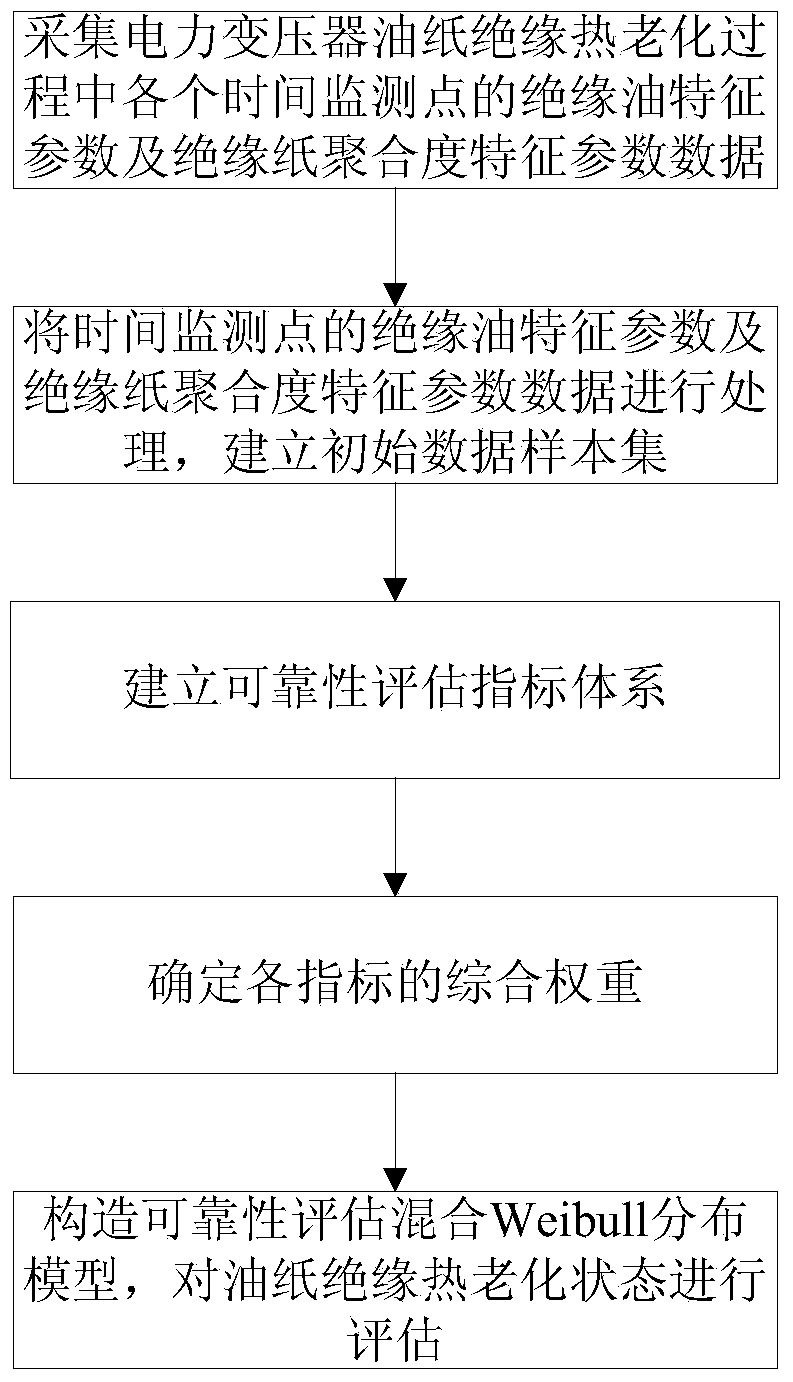

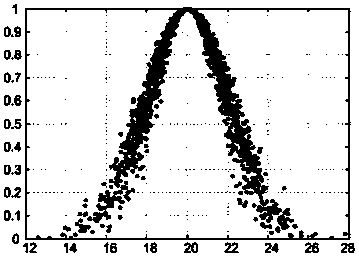

Transformer insulation thermal ageing state reliability evaluation method based on Weibull distribution

ActiveCN103983757AAccurate Aging Reliability ValuesMaterial testing goodsSpecial data processing applicationsThermal ageingTransformer

The invention discloses a transformer insulation thermal ageing state reliability evaluation method based on Weibull distribution. The transformer insulation thermal ageing state reliability evaluation method comprises the following steps: 1, collecting paper oil insulation thermal ageing characteristic data; 2, establishing a reliability evaluation index system; 3, determining comprehensive weights of all indexes; and 4, constructing a reliability evaluation hybrid Weibull distribution model, and evaluating a paper oil insulation thermal ageing state. According to the transformer insulation thermal ageing state reliability evaluation method, a reliability evaluation index system is established by analyzing the sensitivity of each paper oil insulation thermal ageing characteristic parameter to the thermal ageing state, and the paper oil insulation thermal ageing state reliability evaluation is performed by integrating the data and the weights of all the indexes. Compared with an existing paper oil insulation thermal ageing state evaluation method in the aspects of parameters such as the insulation paper polymerization degree and the content of furfuraldehyde in oil, the transformer insulation thermal ageing state reliability evaluation method has the advantages that the influence of the reliability of all the indexes to the overall reliability of paper oil insulation can be more sufficiently considered, and thus relatively accurate paper oil insulation thermal ageing reliability values can be obtained, and the accuracy rate of monitoring and evaluating the insulation ageing state of an oil immersible power transformer is effectively improved.

Owner:STATE GRID CORP OF CHINA +1

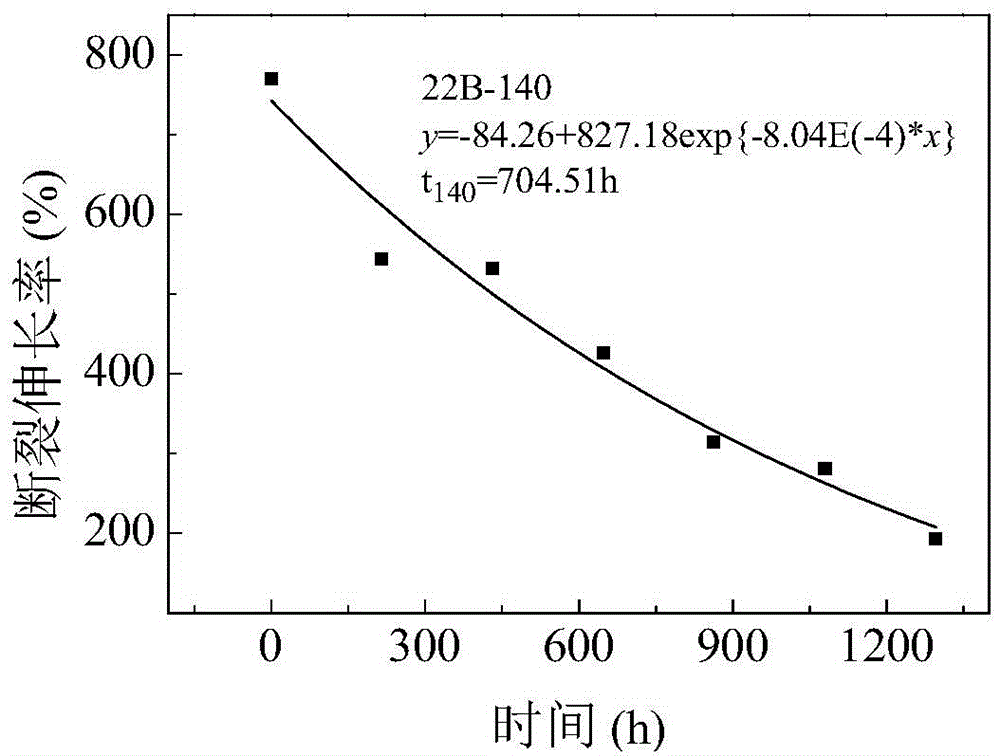

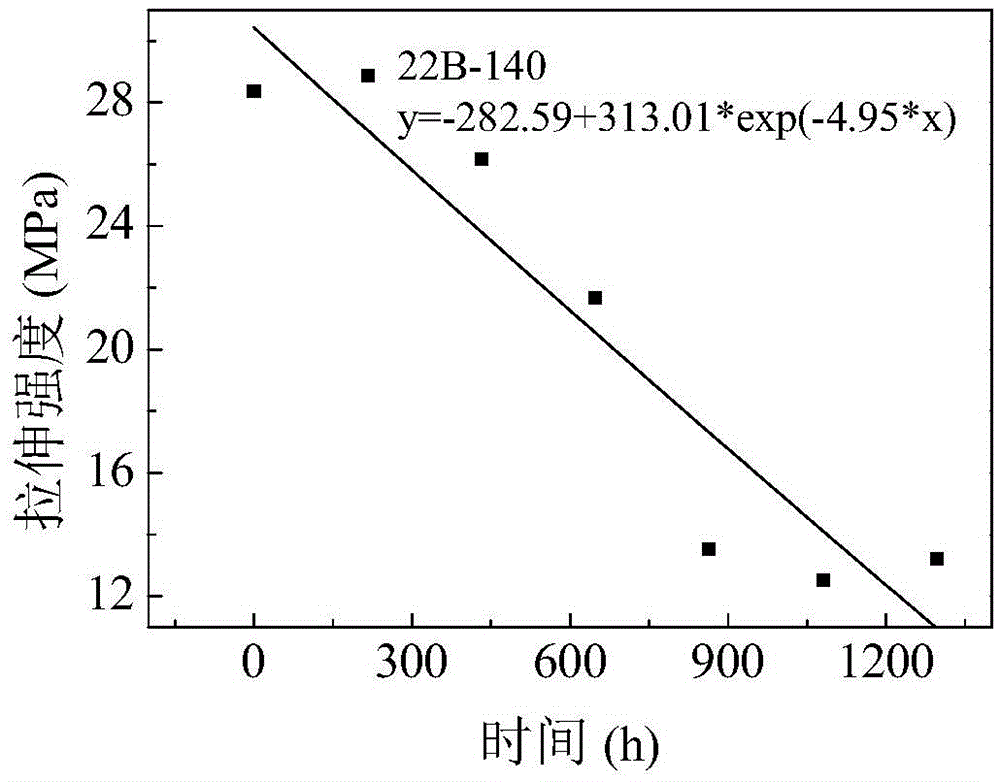

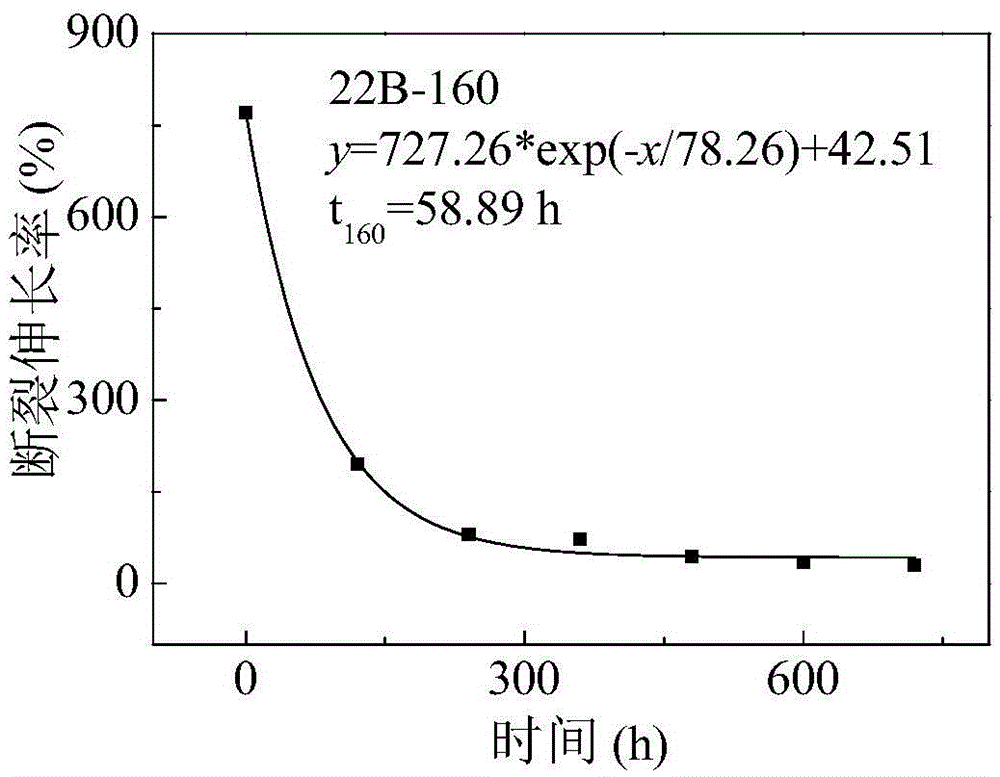

Method for assessing insulation aging state of cable

InactiveCN105486832AAvoid bias in resultsAccurate assessmentTesting metalsObservational errorThermal ageing

The invention discloses a method for assessing insulation aging state of a cable. The method comprises the following steps: slicing a cable sample, performing thermal ageing at two temperature points of 140 DEG C and 160 DEG C, taking out the sample after completely ageing and standing by for 24h at room temperature; performing tensile test, differential scanning calorimetry test, infrared spectroscopy test and thermal gravity test on the sample after ageing, and acquiring the related data parameters; and representing the insulation aging state of the cable according to the data parameters, so as to assess the insulation aging state of the cable. According to the method for assessing the insulation aging state of the cable, provided by the invention, the result deviation caused by measurement error can be avoided and the assessment for the aging state is more accurate.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

Bi-component room temperature vulcanizing silicone rubber for photovoltaic component

InactiveCN101717582AImprove the shortcomings of poor aging resistanceExcellent outdoor aging resistanceOther chemical processesAdhesivesThermal ageingNitrogen gas

The invention discloses a bi-component room temperature vulcanizing silicone rubber for a photovoltaic component, which comprises an A component and a B component. During use, the A component and the B component are uniformly coated on a work piece according to proportion through a bi-component glue spreader. The bi-component room temperature vulcanizing silicone rubber is characterized in that: the A component is prepared by grinding the following raw materials in part by weight: 100 parts of hydroxyl-terminated dimethyl silicone polymer, 20 to 50 parts of plasticizer, 60 to 100 parts of stuffing and 6 to 10 parts of thixotropic agent through a three-roll grinder; the B component is prepared by mixing the following raw materials in part by weight: 5 to 10 parts of cross-linking agent, 0.2 to 1.5 parts of compound catalyst, 1 to 2 parts of adhesion agent and 0.5 to 1.5 parts of catalyst carrier under the protection of nitrogen. The invention overcomes the shortcomings of poor aging resistance of the room temperature vulcanizing silicone rubber catalyzed by conventional organotin, and has characteristics of excellent outdoor aging resistance, good adhesiveness, fast curing speed, no reversion after the curing and no color change; the invention greatly improves the high temperature resistance and the damp-heat aging resistance, and can meet the requirement on the process procedure by controlling the curing speed.

Owner:YANTAI DARBOND TECH

Thermoplastic halogen-free few-smoke flame-proof cable sheath material and machining process

InactiveCN1763129AImprove securityImprove reliabilityInsulated cablesInsulated conductorsThermal ageingThermoplastic

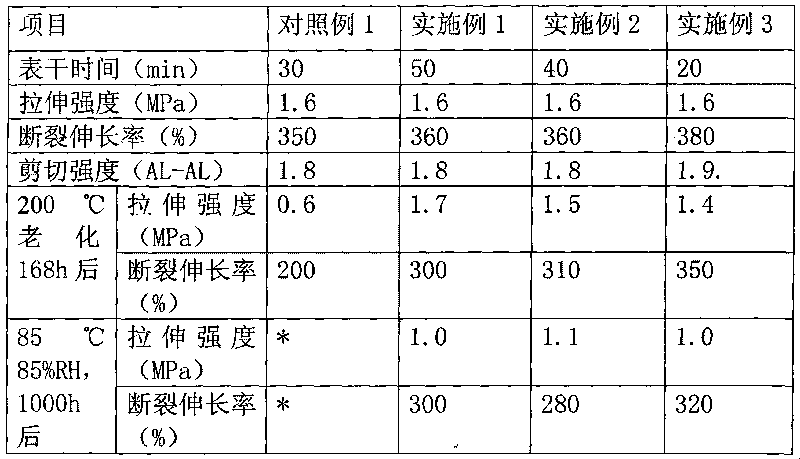

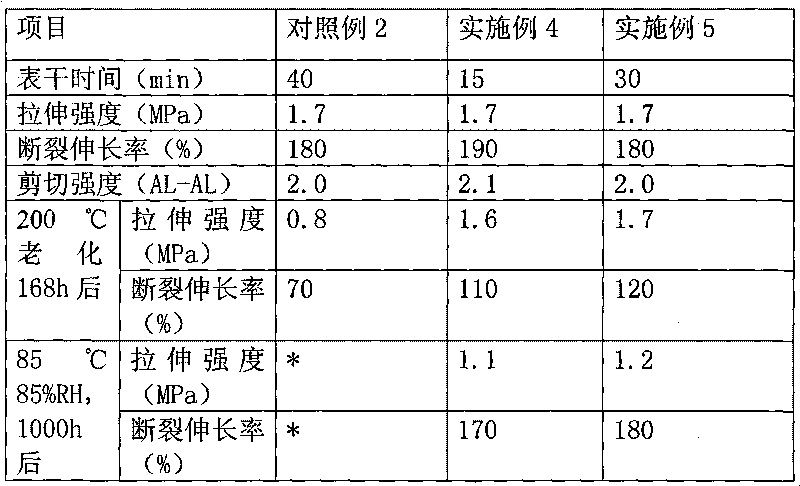

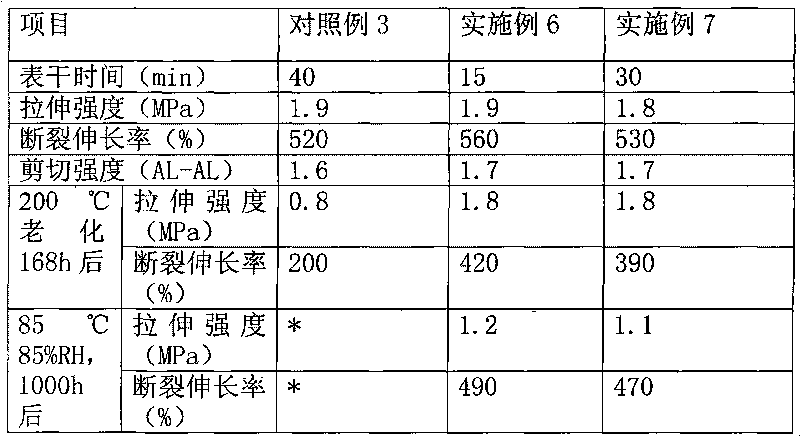

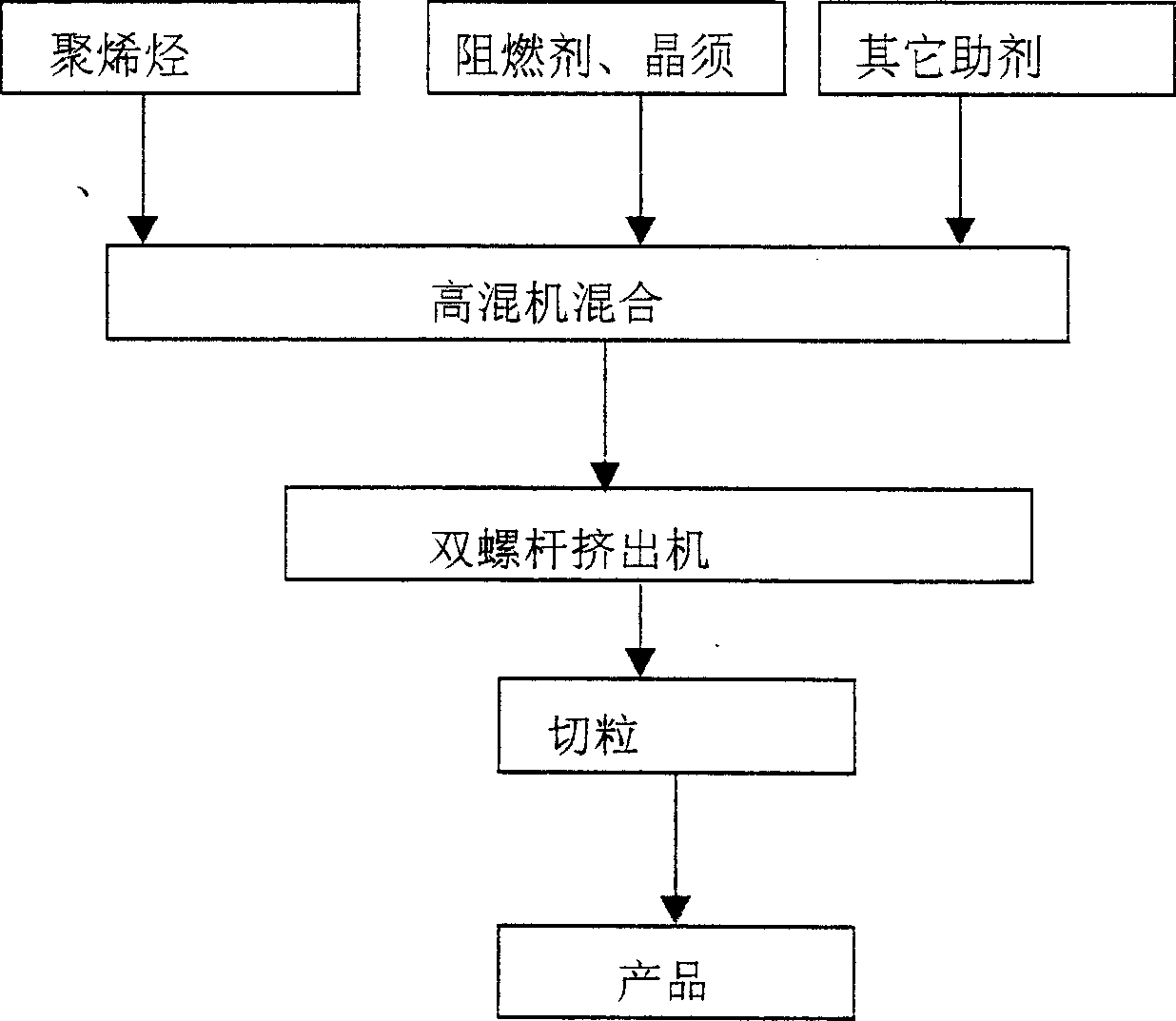

The present invention relates to the recipe design and making process of thermoplastic halogen-free low-smoke flame-retarding cable sheath material. Into polyolefin resin as base material, non-toxic halogen-free fire retardant, reinforcing inorganic whisker and proper assistant are added, and through compounding, mixing, plasticizing and pelletizing, the thermoplastic halogen-free low-smoke flame-retarding cable sheath material is prepared. Technologically, the present invention features no halogen, P, Pb and other heavy metal, excellent mechanical performance, machining performance and fire retarding performance, and excellent thermal deforming, thermal ageing and heat shock performance. The material may be used in making cable with high safety and high reliability.

Owner:大连圣迈化学有限公司 +1

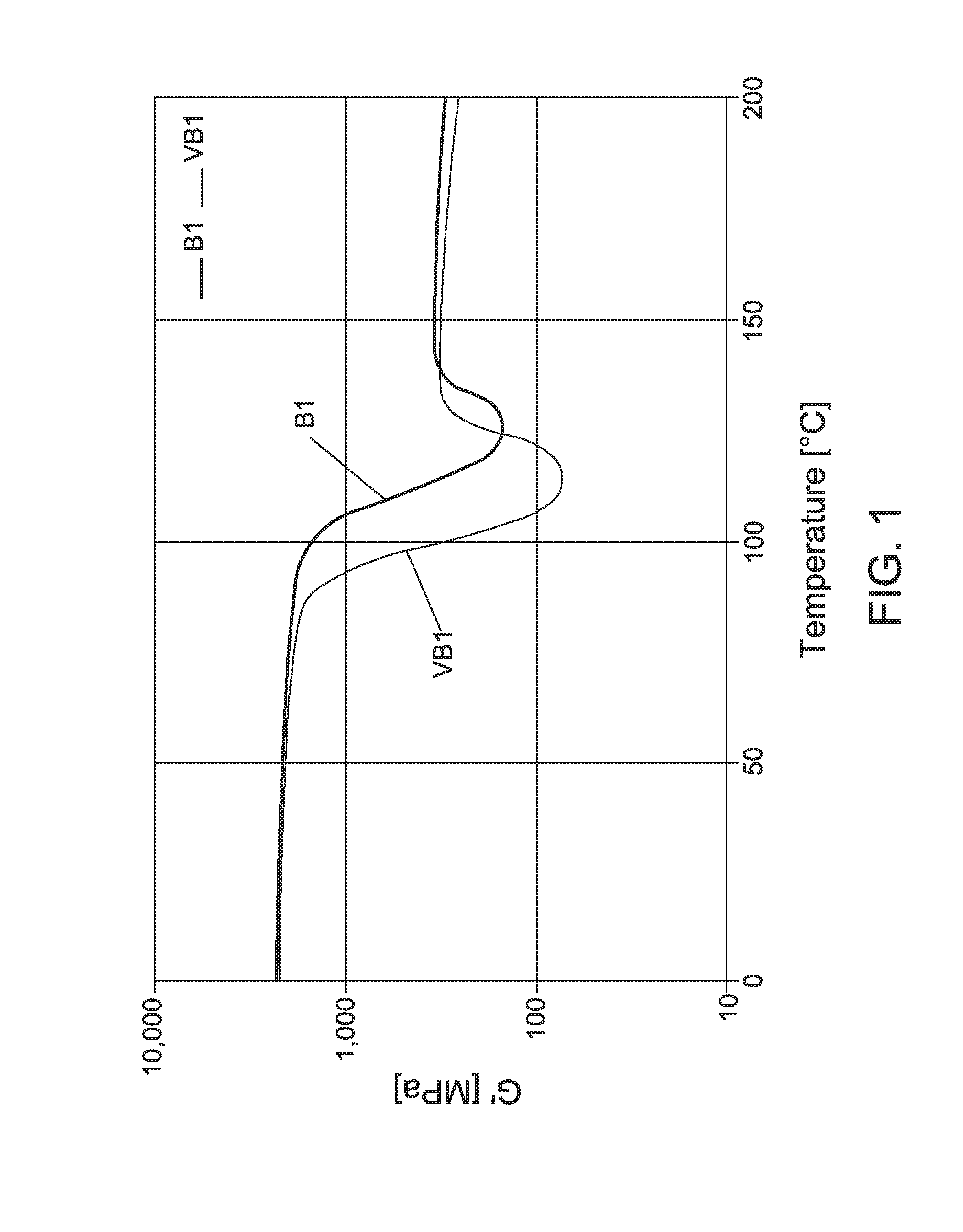

Polyamide molding material and moldings manufactured from same

ActiveUS20140171573A1Improve heat aging resistanceHigh melting pointSynthetic resin layered productsPolyamideCrystallization

The present invention relates to heat-aging resistant polyamide molding materials based on partially crystalline, partially aromatic polyamides as well as to moldings manufactured therefrom.

Owner:EMS PATENT AG

PVC cable material and preparation method thereof

ActiveCN103275427AHigh oxygen indexExcellent flexibility and electrical insulationPlastic/resin/waxes insulatorsThermal ageingPlasticizer

The invention discloses a PVC (polyvinyl chloride) cable material which comprises the following components by mass: 100 parts of PVC, 5-15 parts of heat stabilizer, 10-60 parts of plasticizer, 1-15 parts of lubricant, 0.1-1 part of antioxygen, 2-10 parts of fire retardant, 5-10 parts of calcined clay, 10-40 parts of calcium carbonate, and 0.1-0.5 part of UV-329; the oxygen index of the PVC cable material reaches up to be 33%, the dielectric constant is 4.2, the smoke density per the unit mass of smoke is 10-12 g, thermal ageing quality loss is 15-18 g / m<2>, the volume resistivity is 8*1015 omega / cm at the temperature of 20 DEG C, the volume resistivity is 6*1015 omega / cm at the temperature of 70 DEG C, the tensile strength is 18-19 MPa, the tensile strength retention rate is 99%, and the PVC cable material resists is heat-resistant and cold-resistant, is difficult to volatilize, is pumping-resistant and excellent in flexibility and electric insulation property, can be widely produced and can replace the conventional material continuously.

Owner:DAISHAN POWER SUPPLY CO STATE GRID ZHEJIANG ELECTRIC POWER CO +1

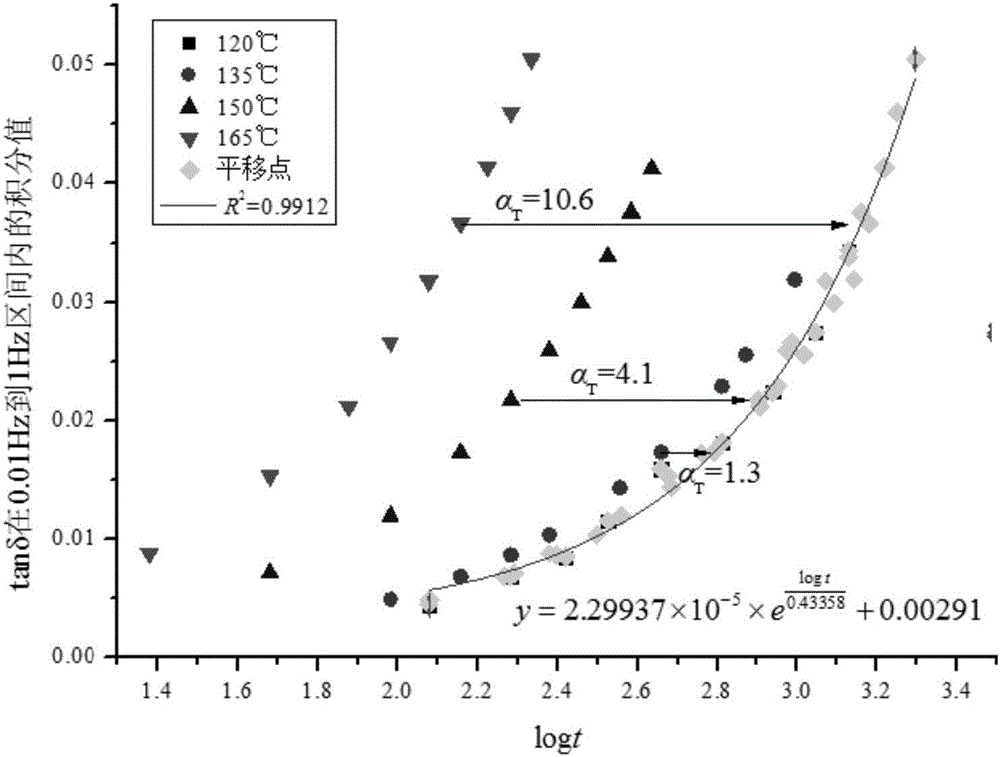

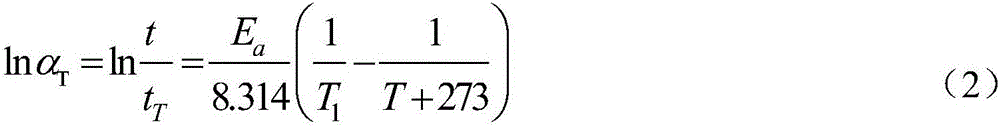

Method for evaluating ageing life of cable insulation material for ship

InactiveCN106644916AWeather/light/corrosion resistanceStrength propertiesThermal ageingActivation energy

The invention discloses a method for evaluating the ageing life of a cable insulation material for a ship. The method comprises the following steps: carrying out accelerated thermal ageing experiments on the cable insulation material under the conditions of different ageing temperatures and ageing time so as to rapidly simulate the ageing process of a cable, acquiring an equation of the life of the cable based on elongation at break, calculating activation energy by using a time-temperature shift algorithm and deducing the extrapolation equation of the life; meanwhile, measuring the values of dielectric loss tangent of the insulation material within temperature and time nodes of the accelerated thermal ageing, selecting a curve located in a frequency range of 0.01 to 1 Hz for integration, acquiring an equation of the cable life based on the integral value of the dielectric loss tangent values, and correlating the life equation based on elongation at break with the life equation based on the integral value; and for a cable of a same kind, substituting the integral value of dielectric loss tangent values measured on site into the correlated equations so as to calculate the value of corresponding elongation at break, and then evaluating the life of the cable by using the extrapolation equation. The method provided by the invention can accurately and rapidly evaluate the cable life on site.

Owner:DALIAN UNIV OF TECH

Method for preparing supercritical hydrotalcite grafted with flame retardant

ActiveCN103387757AGood dispersionImprove mechanical propertiesBulk chemical productionPigment treatment with organosilicon compoundsFiberPolyester

The invention belongs to the field of organic functional molecule modified hydrotalcite and particularly relates to hydrotalcite of which the surface is grafted with an organophosphorus heterocyclic compound, and a preparation method of hydrotalcite. According to the method disclosed by the invention, a silane coupling agent serves as a bridging linker in supercritical carbon dioxide, and the organophosphorus heterocyclic compound is chemically grafted to the surface of hydrotalcite, wherein the silane coupling agent accounts for 0.1-50 wt% of the total weight of hydrotalcite of which the surface is grafted with organic functional molecules, the organophosphorus heterocyclic compound accounts for 0.1-50 wt%, and the balance is hydrotalcite. The hydrotalcite of which the surface is grafted with the organic functional molecules, disclosed by the invention, can serve as a functional assistant, is added into macromolecular materials, such as polyolefins, polyesters, epoxy resin, binders, coating materials, rubber or fibers, and is used for improving the thermal ageing resistance, photo-aging resistance, heat resistance, transparency, flame retardance and the like of the prepared materials.

Owner:BEIJING ACAD OF BUILDING ENG

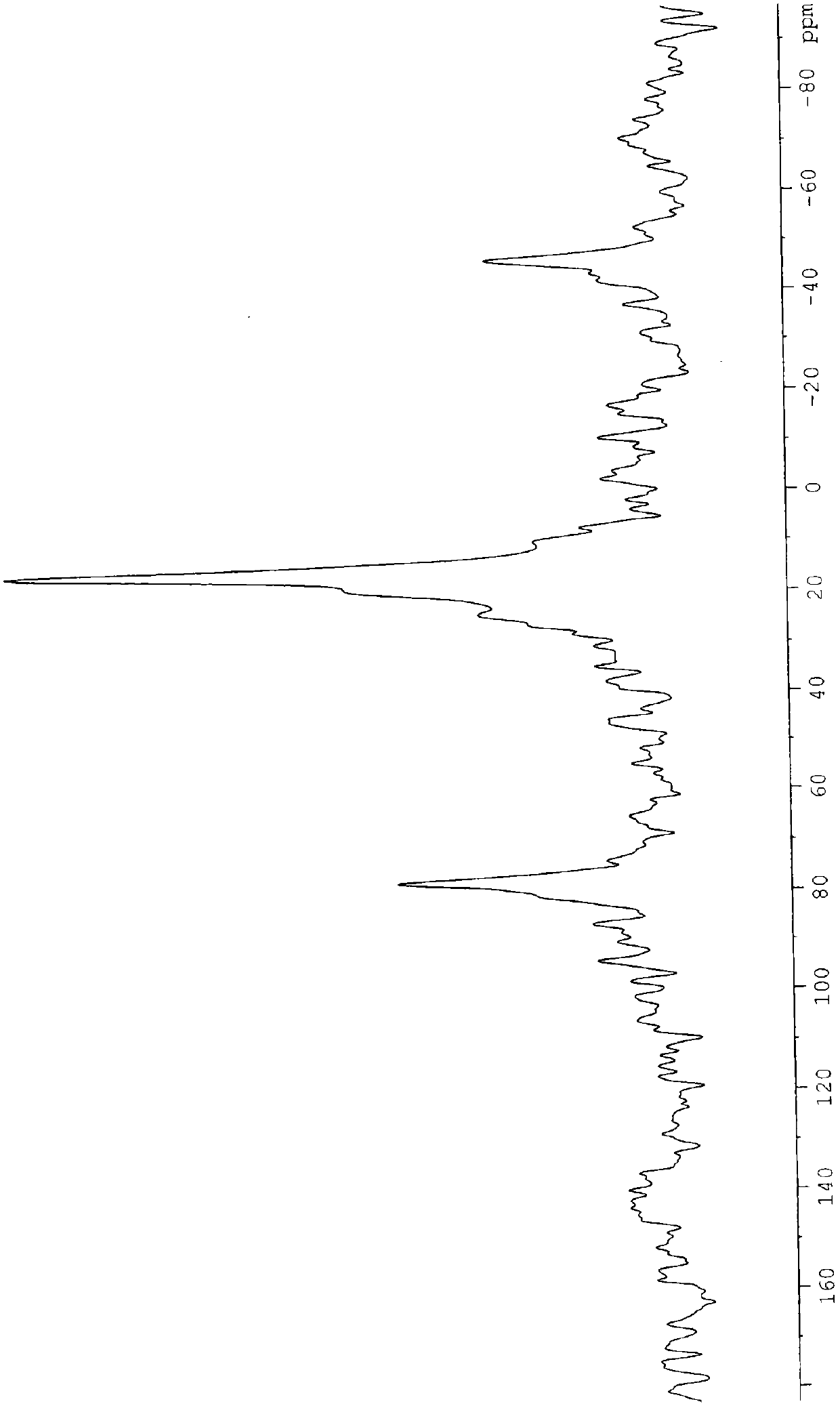

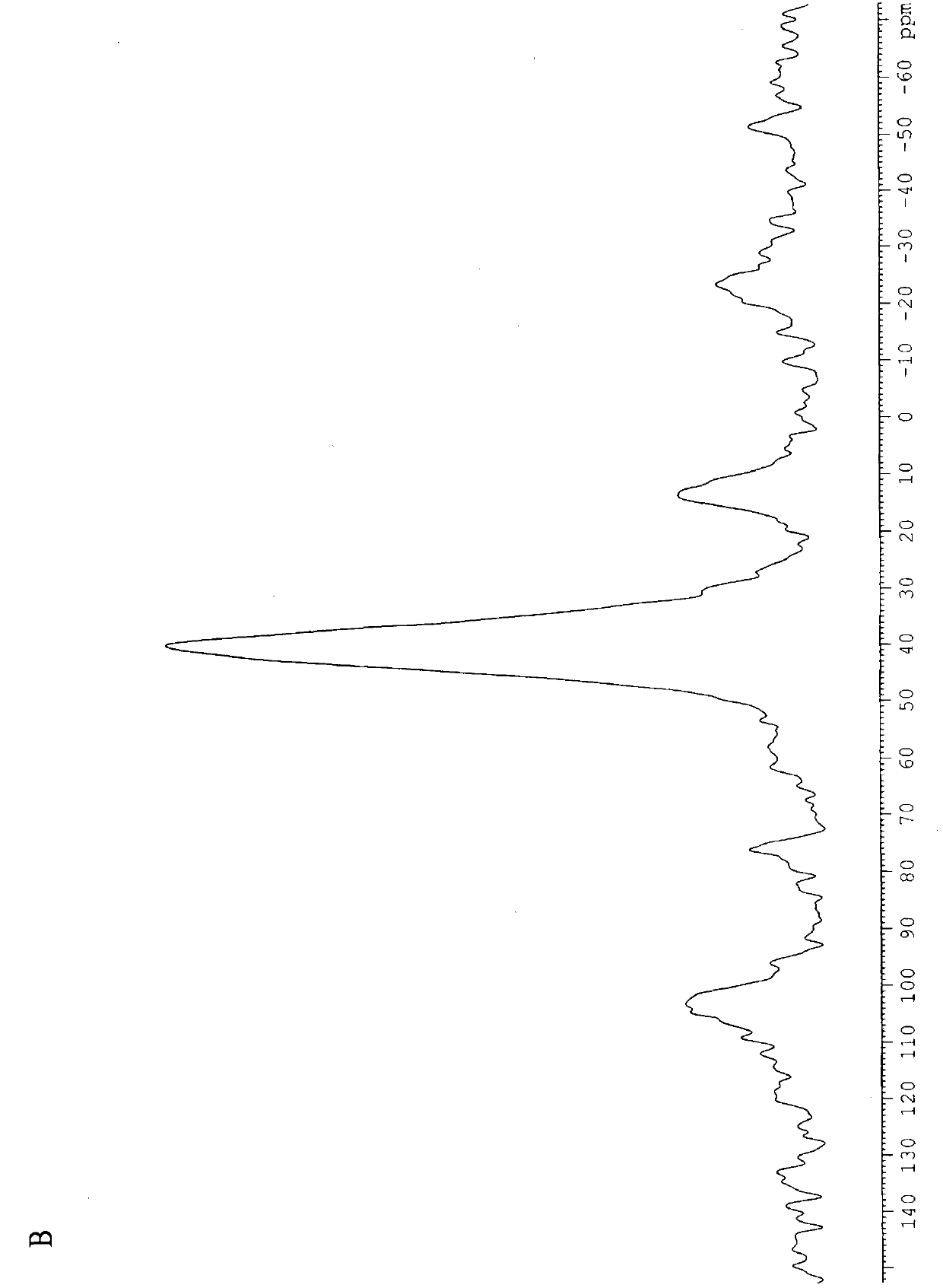

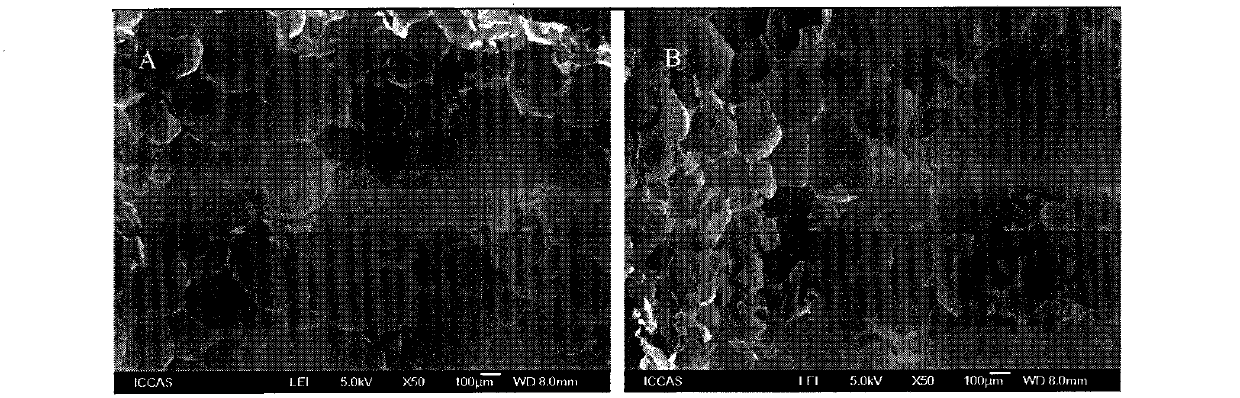

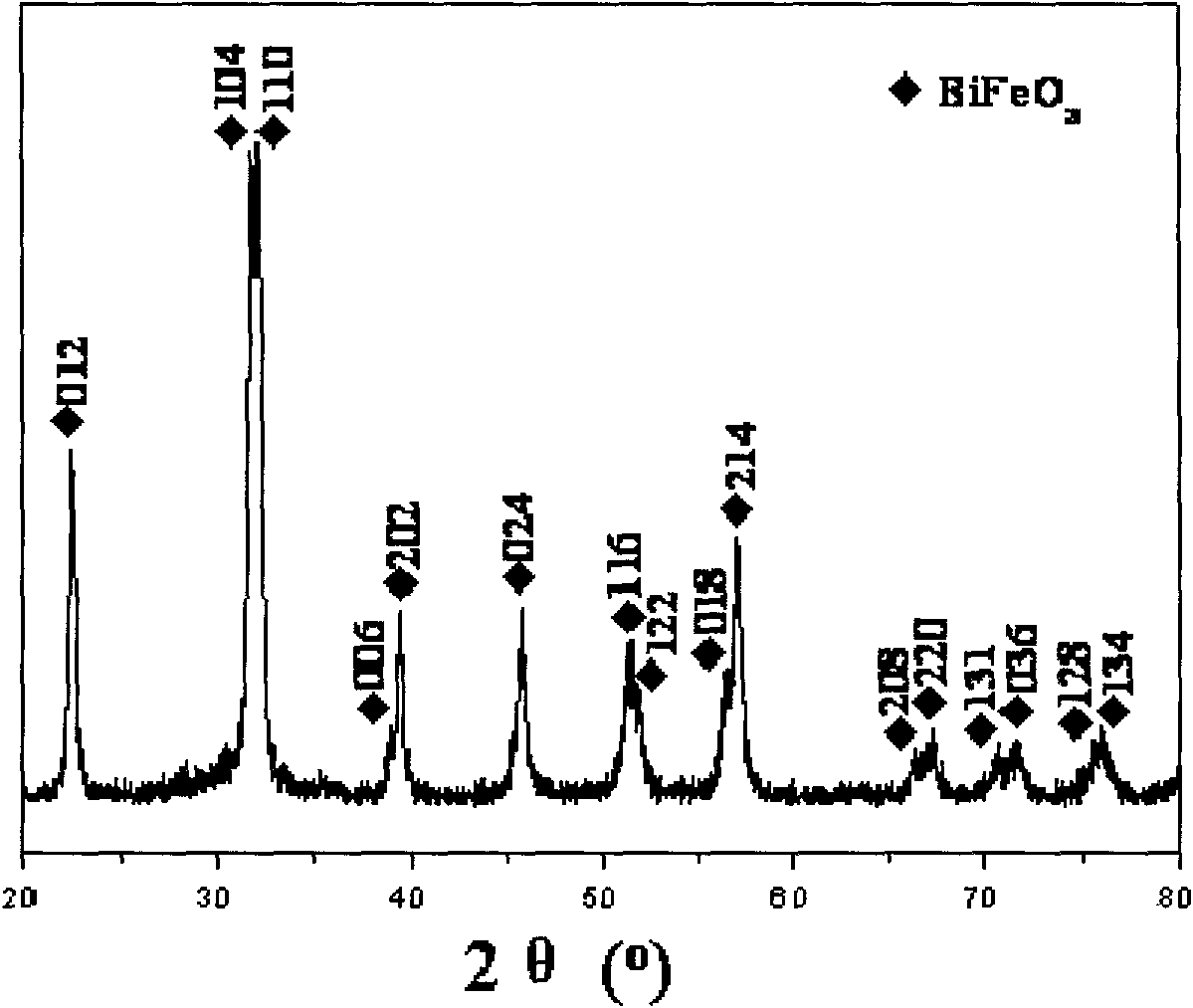

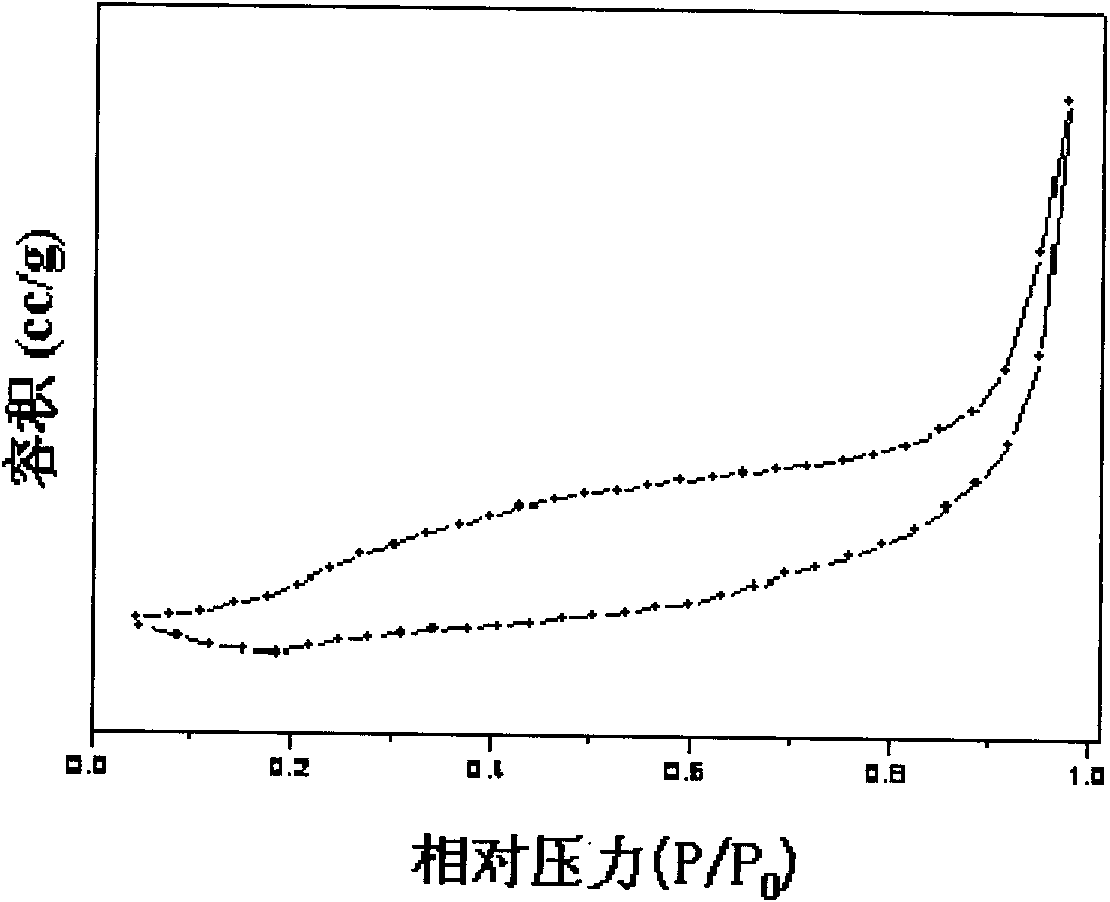

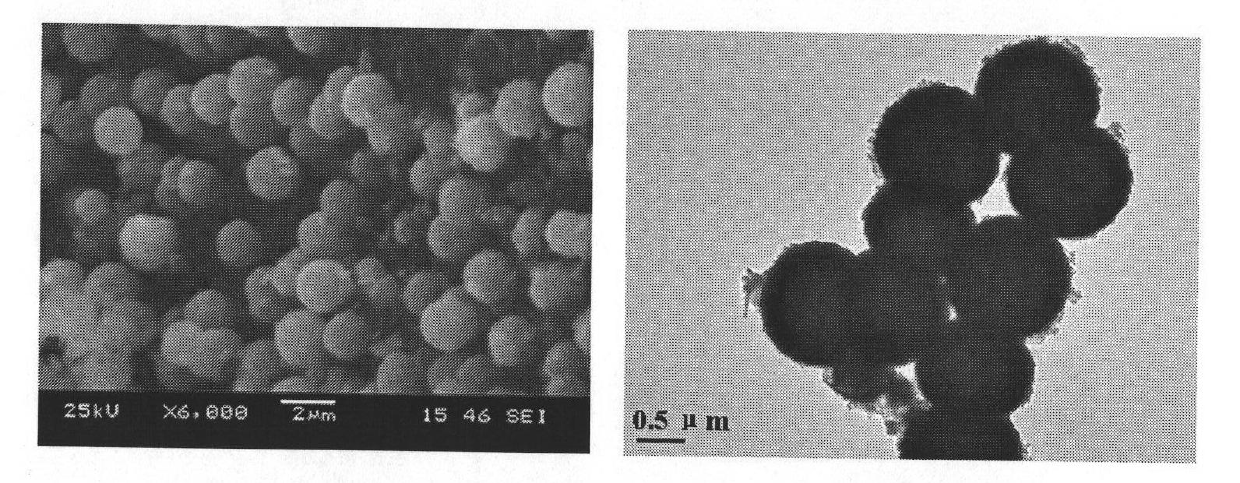

Bismuth ferrite microsphere photocatalyst with hollow structure and preparation method thereof

InactiveCN101791558ANo pollution in the processSimple preparation processMetal/metal-oxides/metal-hydroxide catalystsThermal ageingAlcohol

The invention belongs to a catalyst technology which relates to a bismuth ferrite microsphere photocatalyst with a hollow structure and a preparation method thereof. The defects of large grain diameter of a catalyst, small specific surface area, poor adsorption of the molecules of a pollutant and small photocatalytic activity exist in the prior art. The molecular formula of the bismuth ferrite microsphere photocatalyst with the hollow structure is BiFeO3, the grain diameter is 1.0 to 2.0mum, the thickness of the ball wall is 100 to 200nm, and the specific surface area is 7.2 to 28.1m2 / g. The preparation method comprises the following steps of: dissolving bismuth salt and ferric salt into a mixed alcohol solution of absolute ethyl alcohol and glycerol, adding citric acid and mixing evenly; dispersing by ultrasonic sound, putting into a stainless steel hydrothermal kettle and carrying out thermal ageing by a solvent; and drying an ageing product and calcining to prepare the bismuth ferrite microsphere photocatalyst with the hollow structure. The invention has the advantages that raw materials are cheap and are easy to obtain; the preparation process is simple; the bismuth ferrite microsphere photocatalyst has uniform grain diameter and large specific surface area; the photocatalytic activity is enhanced; and the catalyst can be repeatedly used.

Owner:SHANGHAI NORMAL UNIVERSITY

Bead wire coating compound for aircraft radial-ply tire

The invention discloses a bead wire coating compound for an aircraft radial-ply tire, which is prepared by mixing the following raw materials in part by weight: 50 to 100 parts of butadiene styrene rubber, 0 to 50 parts of natural rubber, 30 to 70 parts of powerful powder, 35 to 65 parts of general purpose furnace black N660, 3 to 10 parts of zinc oxide, 0 to 4 parts of stearic acid, 1 to 4 parts of p-Phenylenediamine antioxidant 4020 or 4010NA, 1 to 4 parts of acetone-amine condensation product antioxidant BLE or RD, 1 to 8 parts of insoluble sulfur IS-60 or IS-90, 1 to 3 parts of sulfenamide accelerator NOBS or DZ, 0.5 to 3.0 parts of adhesive AIR-101, 0.5 to 3.0 parts of cobalt boroacylate or cobalt decanoate and 0 to 2.0 parts of tackifying resin DHJH-B through a banbury. The compound has good elongation, elasticity and adhesiveness and particularly good bonding strength after thermal ageing, and can meet the requirement of a hexagonal steel ring production process.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

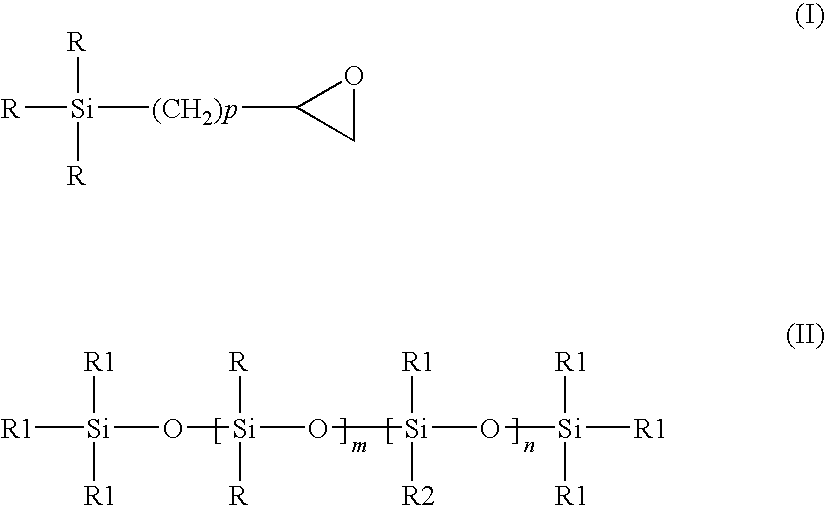

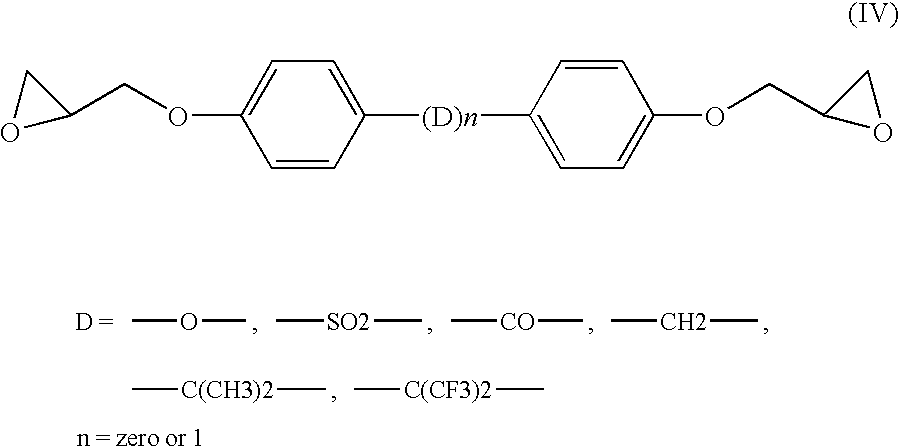

Hardenable epoxy resin composition

InactiveUS20090186975A1Improve thermal stabilityLow viscosityPlastic/resin/waxes insulatorsThermal ageingEpoxy

A hardenable epoxy resin composition which is suitable for the production of an electrical insulation with improved thermal ageing properties, wherein said hardenable epoxy resin composition comprises an epoxy resin, a hardener, an inorganic filler composition, and a coupling agent for improving the bonding between the polymer matrix and the filler, and optionally further additives. The filler composition comprises silica and aluminum trihydride (ATH). The composition can be used for the production of an electrical insulation, and electrical articles containing such an electrical insulation system.

Owner:ABB RES LTD

Glass fiber reinforced polypropylene material and hydrolysis resistance and oxidation resistance evaluation method thereof

InactiveCN102010548AReduce manufacturing costLow priceWeather/light/corrosion resistanceThermal ageingWater baths

The invention relates to a glass fiber reinforced polypropylene material and a hydrolysis resistance and oxidation resistance evaluation method thereof, belonging to the technical field of organic materials. The glass fiber reinforced polypropylene material comprises co-polypropylene and / or homo-polypropylene, a compatilizer, glass fiber, antioxygen, metal passivator and a processing agent. The evaluation method comprises the following steps of: soaking a sample in pure water; testing the performance of a sample wafer in 80-95 DEG C thermostatic water bath; naturally airing; hanging the sample wafer in 100-150 DEG C ventilation-type thermal ageing testing machine until the material reaches the service life; and then recording the testing time and the testing data. The glass fiber reinforced polypropylene material has good mechanical property, hydrolysis resistance and thermal oxidation resistance of resisting high-temperature detergents, and the performances exceed those of the prior home and abroad reinforced polypropylene materials, and moreover, the glass fiber reinforced polypropylene material has low production cost and low price.

Owner:PANASONIC HOME APPLIANCES R&D CENT HANGZHOU +1

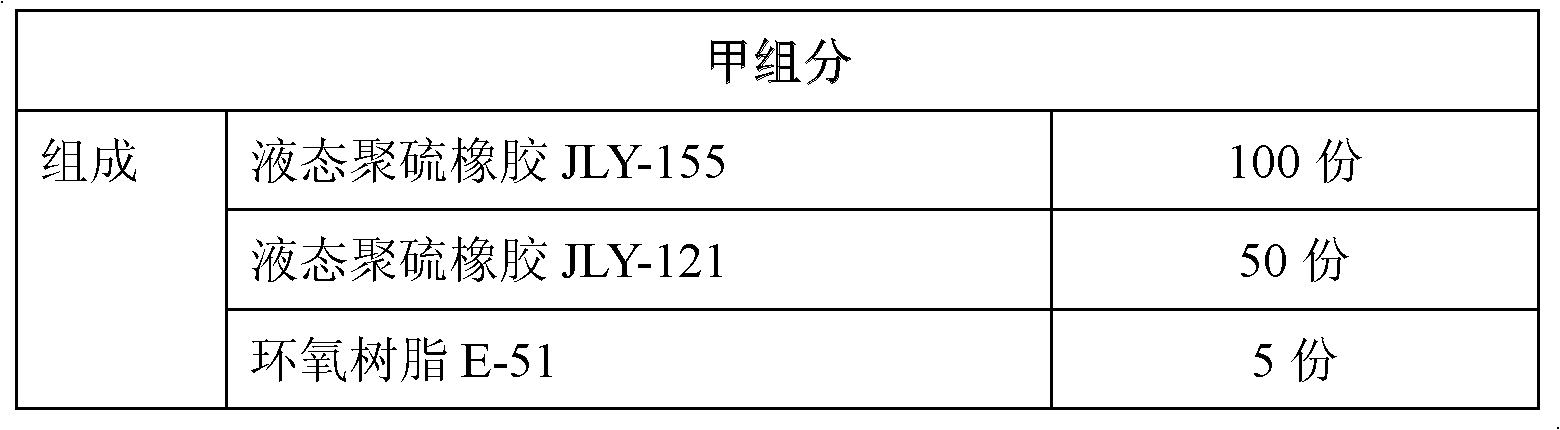

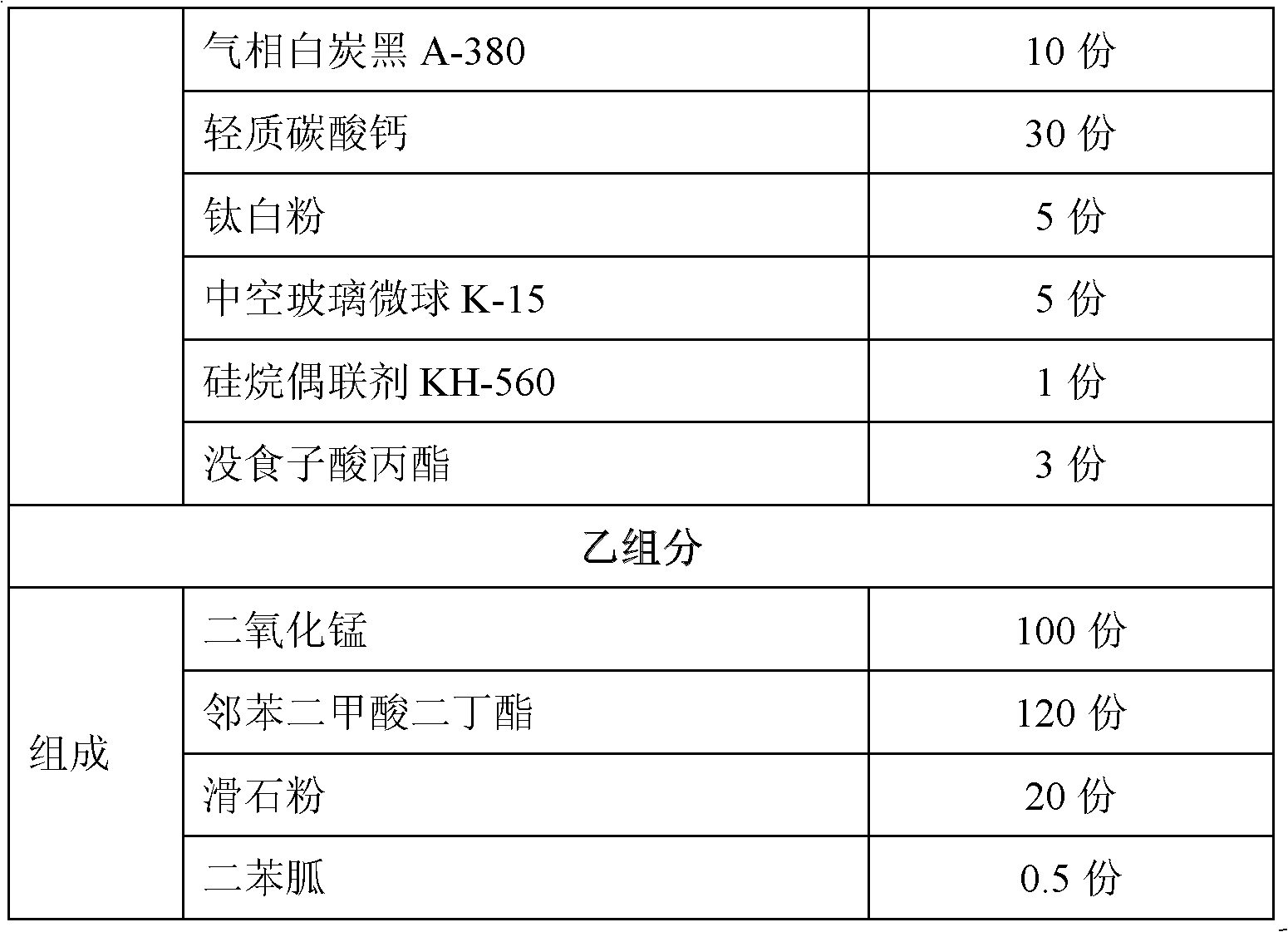

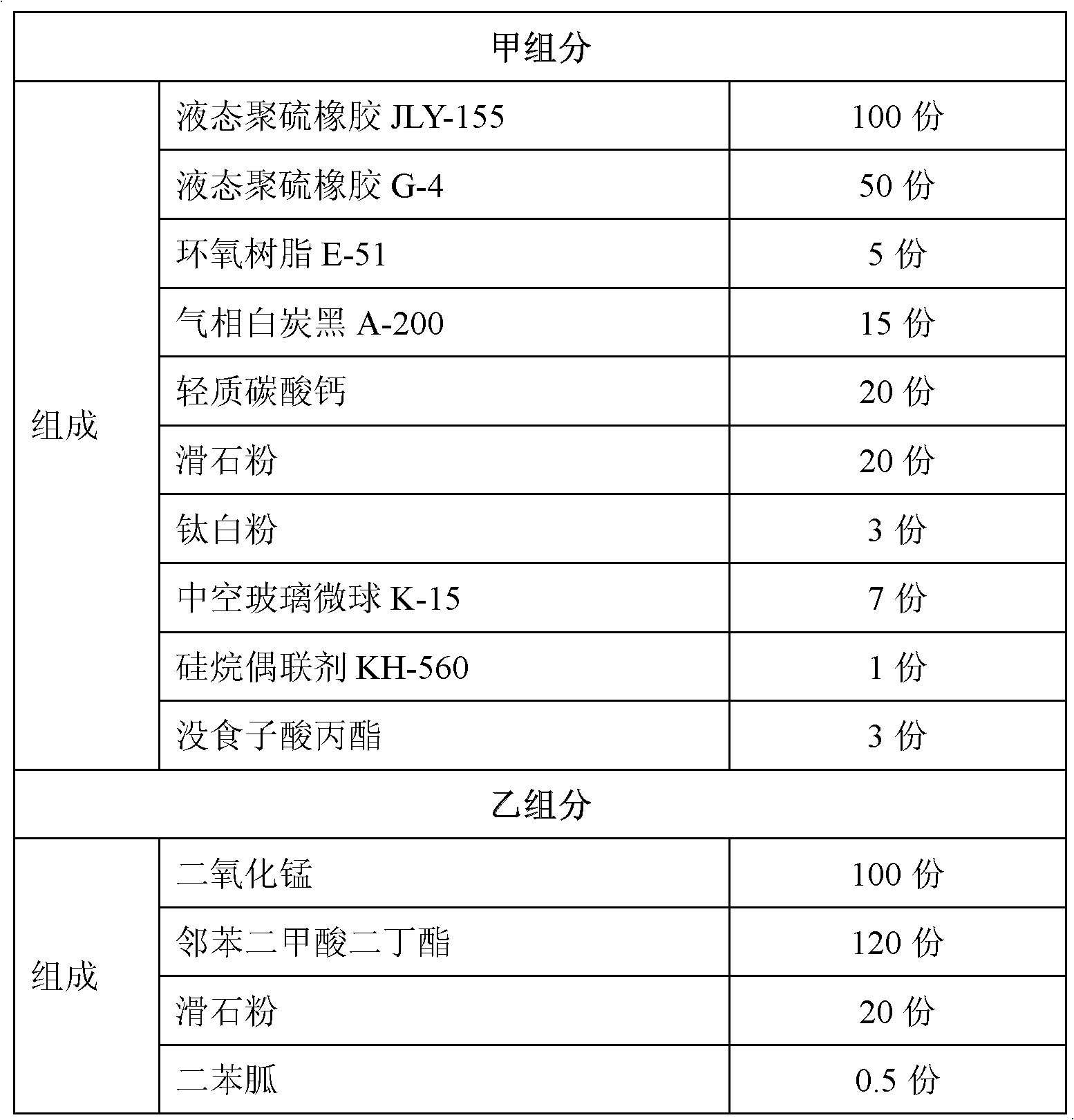

Bi-component polysulfide sealant and preparation method thereof

InactiveCN102618207AExcellent thermal degradation resistanceGood strength retentionNon-macromolecular adhesive additivesOther chemical processesThermal ageingPolymer science

Bi-component polysulfide sealant and a preparation method thereof relate to a high-polymer sealing material and a preparation method thereof and aim to solve the problems of high density and poor heatproof degradation performance of existing sealant after being sulfurized. A component includes liquid polysulfide rubber, epoxy resin, thixotropic agent, reinforcing filler, hollow glass microballs, titanium dioxide, silane coupler and antiager, B component includes manganese dioxide, plasticizer, talcum powder and melaniline. The preparation method includes: the A component is prepared by addingthe thixotropic agent, the titanium dioxide, the reinforcing filler and the antiager to grind after the liquid polysulfide rubber and the epoxy resin are pre-polymerized and then adding treated hollow glass microballs to grind; the B component is prepared by mixing and grinding the manganese dioxide, the plasticizer and the talcum powder and then adding the melaniline to grind. The bi-component polysulfide sealant with the density smaller than or equal to 1.3g / cm3 is not crispy and not viscous in flowing after thermal ageing at the temperature of 180 DEG C for 10 hours. The preparation methodis applicable to preparation of polysulfide sealant.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

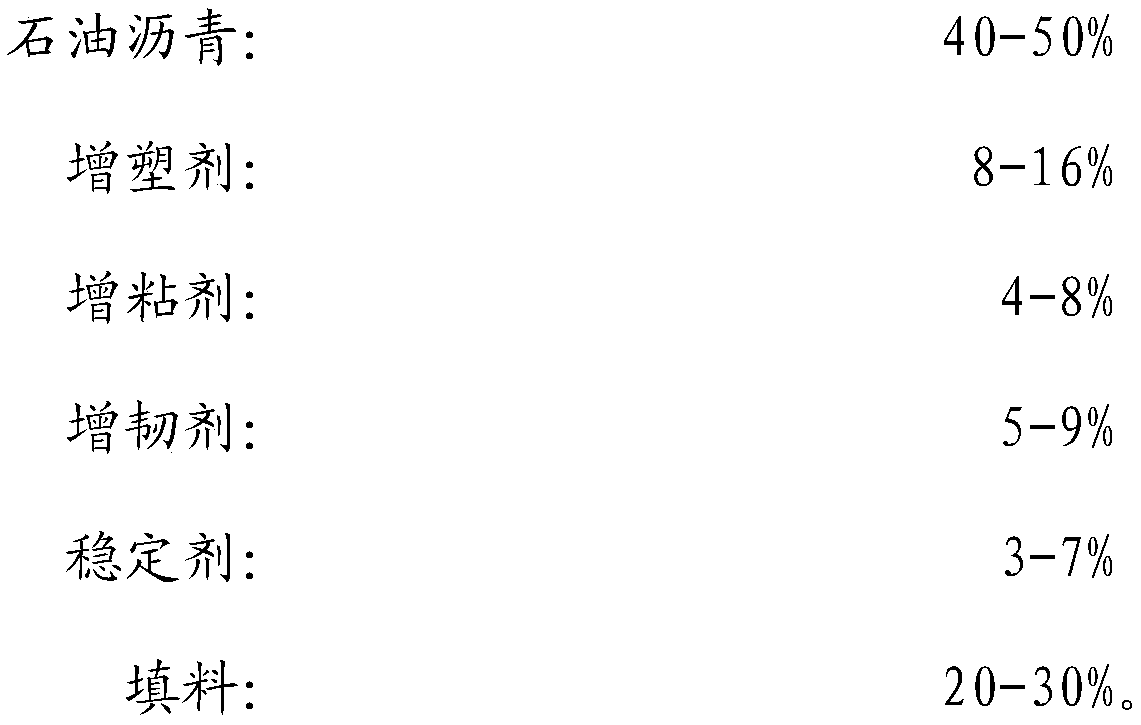

High temperature resistance self-adhesion 3D (Three Dimensional) multi-color waterproof roll and preparation method thereof

InactiveCN105500800AImprove the decorative effectColorfulNon-macromolecular adhesive additivesSynthetic resin layered productsThermal ageingHeat resistance

The invention discloses a high temperature resistance self-adhesion 3D (Three Dimensional) multi-color waterproof roll, and is mainly used for solving the problems of the existing self-adhesion glue that the heat resistance is low; the adhesive strength and peeling strength are low after the self-adhesion is soaked into water and suffers from thermal ageing, the self-adhesion glue can not be applied to waterproof construction of a building elevation, a highwall and an exposed roof of a building. The waterproof roll consists of an isolating layer, a high temperature resistance self-adhesion layer, a padding, a high temperature resistance self-adhesion layer and a 3D multi-color mineral grain layer. A preparation method of the waterproof roll comprises the following steps: the high temperature resistance self-adhesion layers respectively cover the two sides of the padding, an isolating film covers the surface of the high temperature resistance self-adhesion layer at one side, and the 3D multi-color mineral grain layer covers the high temperature resistance self-adhesion layer at the other side, so as to form the high temperature resistance self-adhesion 3D multi-color waterproof roll. The high temperature resistance self-adhesion 3D multi-color waterproof roll has the characteristics that the heat resistance is high, the adhesion property is super high, the smaller puncture damage can be automatically healed, the smaller base crackle can be automatically filled, the color is bright, patterns and shapes are various, and the waterproof roll has 3D stereoscopic vision effect from far view; in addition, the waterproof roll can be widely used in the technical fields of waterproof and decoration engineering of industrial and civil buildings.

Owner:盘锦亿丰防水材料有限公司

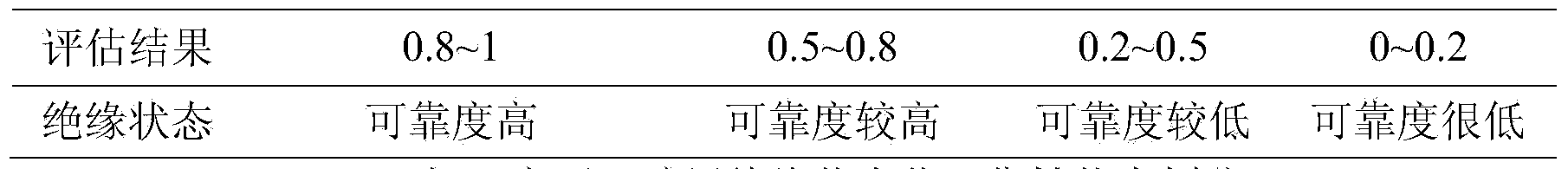

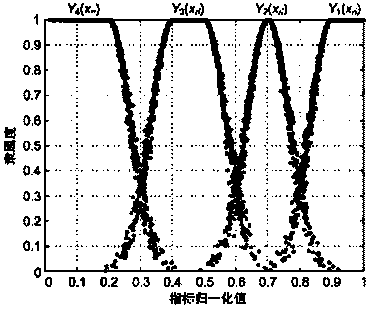

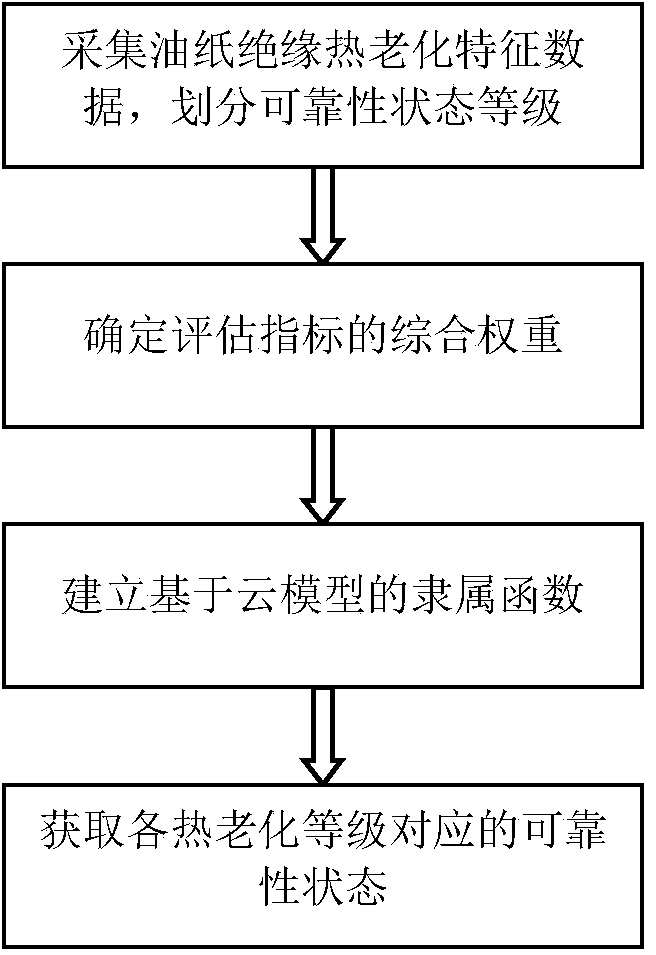

Cloud-model-theory-based method for evaluating insulation thermal ageing states of transformer

ActiveCN104020401AIncrease credibilityThe assessment conclusion is clearTesting dielectric strengthThermal ageingDependability

The invention provides a cloud-model-theory-based method for evaluating the insulation thermal ageing states of a transformer. The method comprises the steps that first, oil paper insulation thermal ageing characteristic data are collected, and oil paper insulation thermal ageing state grades are divided; second, the comprehensive weight of oil paper insulation evaluation indexes is determined according to the oil paper insulation thermal ageing characteristic data; third, a membership function model based on a cloud model is built according to the evaluation characteristics of the oil paper insulation thermal ageing states; fourth, the reliability states corresponding to the thermal ageing states are obtained according to the membership function model. The cloud-model-theory-based method for evaluating the insulation thermal ageing states of the transformer is high in credibility of the calculation result, and clear and accurate in evaluation conclusion, and the variation trend of the oil paper insulation ageing states of the transformer and the probability of the states of the transformer can be learnt about by calculating the degree of membership of oil paper insulation belonging to different state intervals.

Owner:STATE GRID CORP OF CHINA +1

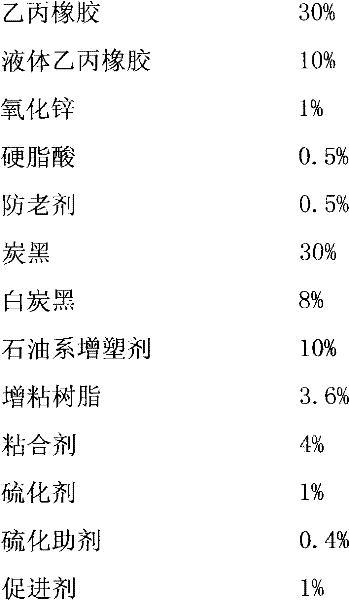

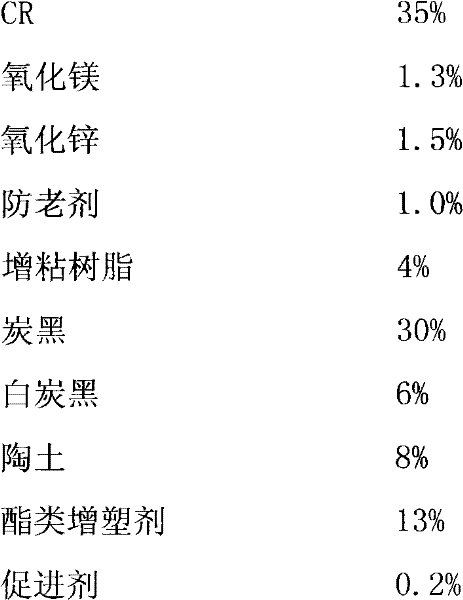

Hydraulic-controlled clutch pipe and production process thereof

ActiveCN102563237ALittle change in hardnessHigh elongationFlexible pipesTubular articlesFiberThermal ageing

The invention relates to an automobile clutch pipe with high temperature resisting, brake oil resisting, temperature change resisting, varying load pulse resisting performances and the like. A hydraulic-controlled clutch pipe comprises an inner rubber layer, a braiding layer and an outer rubber layer from inside to outside, the inner rubber layer uses ethylene propylene diene monomer as a main body material, the outer rubber layer uses chloroprene rubber as the main body material, and the braiding layer is made of a vinylon fiber material. The hydraulic-controlled clutch pipe and a production process thereof have the advantages that the design is optimized according to the formula, the ethylene propylene diene monomer and the chloroprene rubber respectively serve as the inner rubber layer and the outer rubber layer of the clutch pipe, the inner rubber layer has good brake oil resisting performance and high temperature thermal ageing resisting performance, the outer rubber layer has good machine oil resisting performance and high temperature thermal ageing resisting performance, and the rubber material has excellent physical and mechanical properties and good processing performance. The tensile strength and the hardness retention rate of the hose subjected to thermal ageing are high, no extraction is produced after the hose is soaked in DOT4 synthetic brake fluid, the standard requirements are met completely, and safety of a whole automobile is guaranteed.

Owner:QINGDAO SUNSONG CO LTD

Method for preparing molecular sieve SCR catalyst, and catalyst prepared therethrough

ActiveCN109174173AMaintain a wide active temperature windowImprove anti-aging propertiesNitrous oxide captureGas treatmentMolecular sieveThermal ageing

The invention discloses a method for preparing a molecular sieve SCR catalyst, and the catalyst prepared therethrough. Several molecular sieves are mixed, and then undergo ion exchange modification treatment by a transition metal or a rare earth metal, Fe is loaded through isopyknic impregnation, and Cu is loaded through one-stage or multistage liquid ion exchange. A technology for modifying the stable molecular sieve mixture with the transition and rare earth metals, a technology for loading Fe by the isopyknic impregnation process and a technology for loading Cu by the one-stage or multistage liquid ion exchange are combined, and a catalysis material obtained through stable and effective modification and loading control is applied to a carrier matrix after being blended to form a slurryin order to prepare the monolithic catalyst; results of fresh sample activity test and hydrothermal aging test show that the catalyst has a wide active temperature window and excellent hydrothermal aging resistance, and the N2O generation amount of the catalyst prepared in the invention is significantly lower than that of previous catalysts of the same type.

Owner:SINOCAT ENVIRONMENTAL TECH

In-situ polymerization method of graphene/vinyl chloride

ActiveCN104193864AGuaranteed decentralizationAvoid demulsificationThermal ageingIn situ polymerization

The invention discloses an in-situ polymerization method of graphene / vinyl chloride. By using a mechanical ultrasonic dispersion and microemulsion dispersant system, an in-situ polymerization grade graphene microemulsion is obtained; the graphene microemulsion is added into a vinyl chloride suspension polymerization system, and vinyl chloride monomers and graphene are subjected to in-situ polymerization, so that graphene / polyvinyl chloride resin subjected to in-situ polymerization is obtained. Observations implemented by using a transmission electron microscopy (TEM) show that graphene is arranged in a nanoscale monolayer dispersion mode in a polyvinyl chloride resin matrix, so that the thermal ageing properties and mechanical properties of the resin are significantly improved.

Owner:XINJIANG ZHONGTAI CHEM CO LTD +1

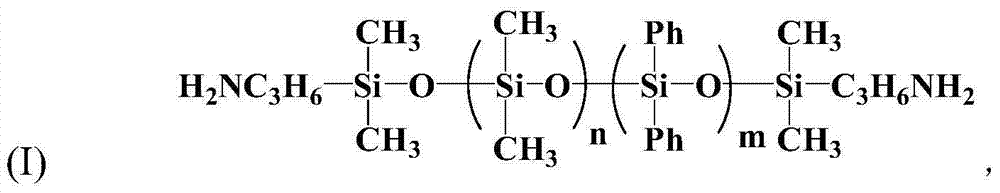

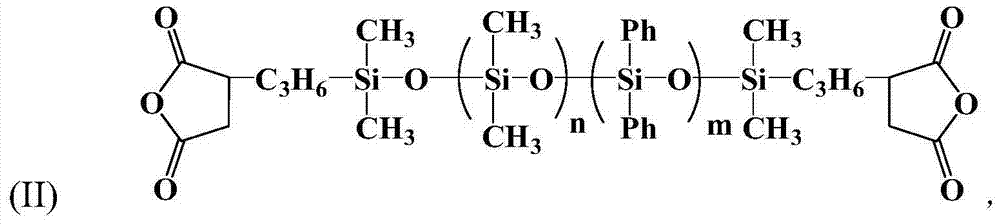

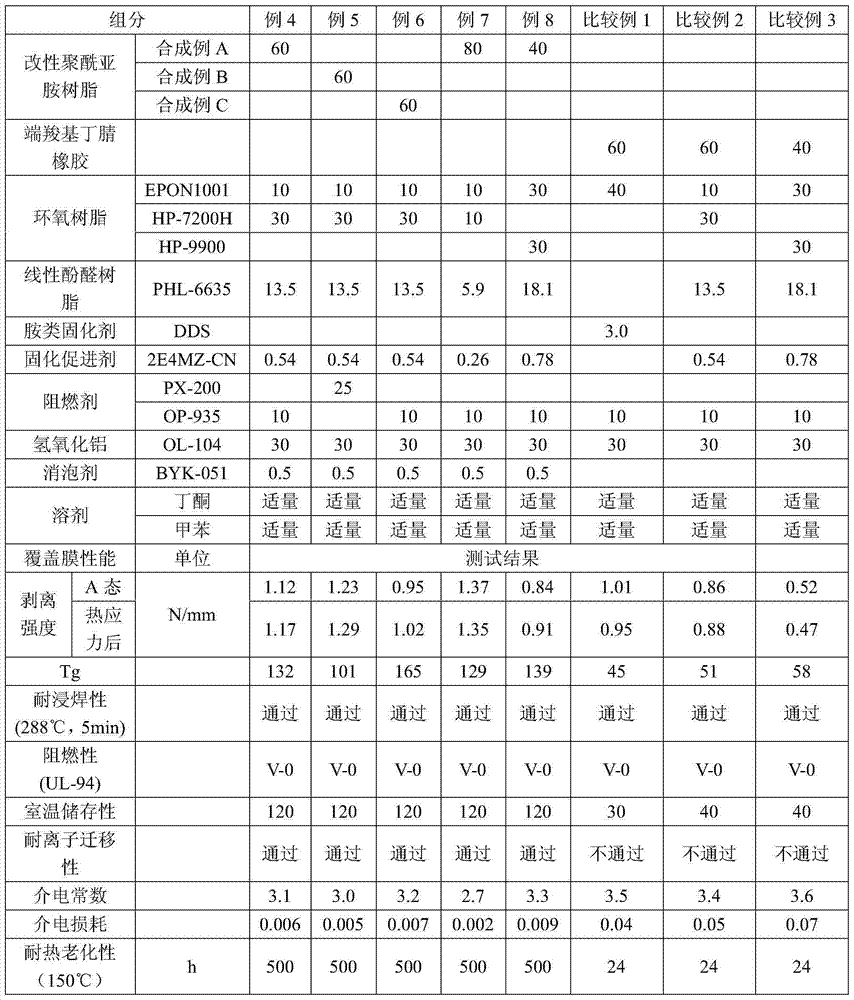

Modified polyimide resin, adhesive composition containing modified polyimide resin and covering film containing adhesive composition

ActiveCN103483586AImprove adhesionImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesThermal ageingVitrification

The invention provides modified polyimide resin. A molecular structure of the modified polyimide resin comprises the repeated units of the following chain segments: polysiloxane polyimide chain segments, cycloaliphatic polyimide chain segments and aromatic polyimide chain segments, wherein the molar contents of the polysiloxane polyimide chain segments, the cycloaliphatic polyimide chain segments and the aromatic polyimide chain segments in a chemical formula of the modified polyimide resin are 20-40%, 20-50% and 30-60% respectively. The modified polyimide resin can be used as a toughening agent of an epoxy resin adhesive and is more excellent in characteristics such as higher thermal ageing resistance, higher glass-transition temperature and the like in comparison with a buna-n rubber toughened epoxy adhesive agent.

Owner:GUANGDONG SHENGYI SCI TECH

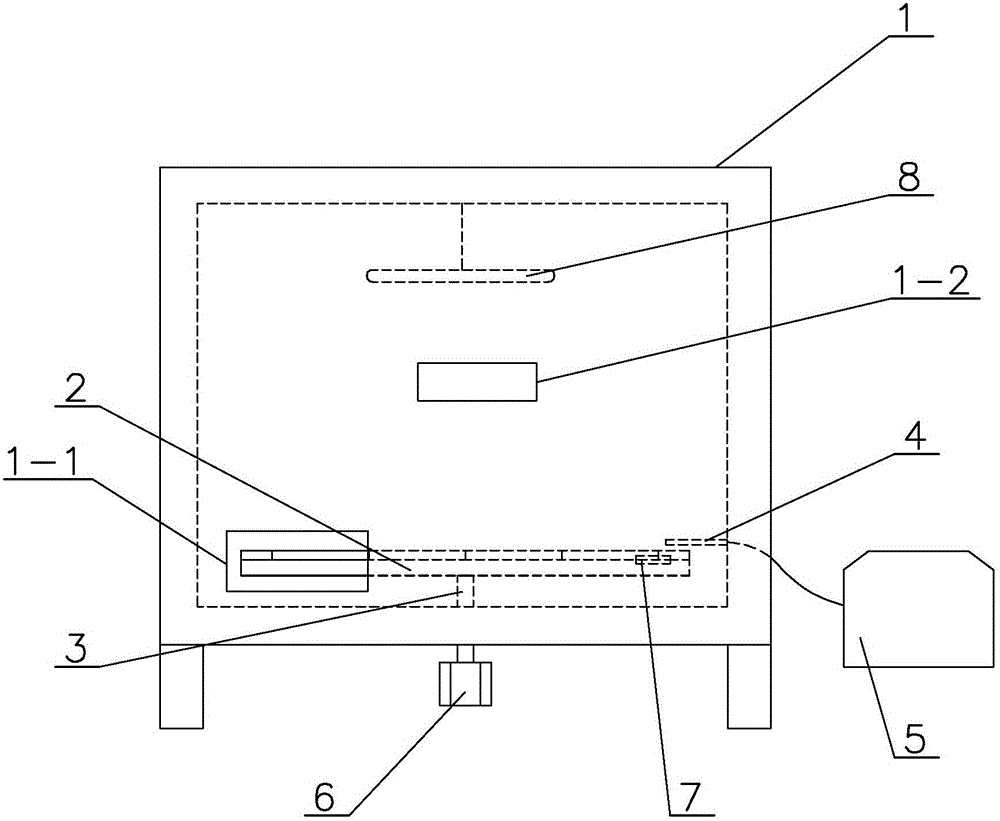

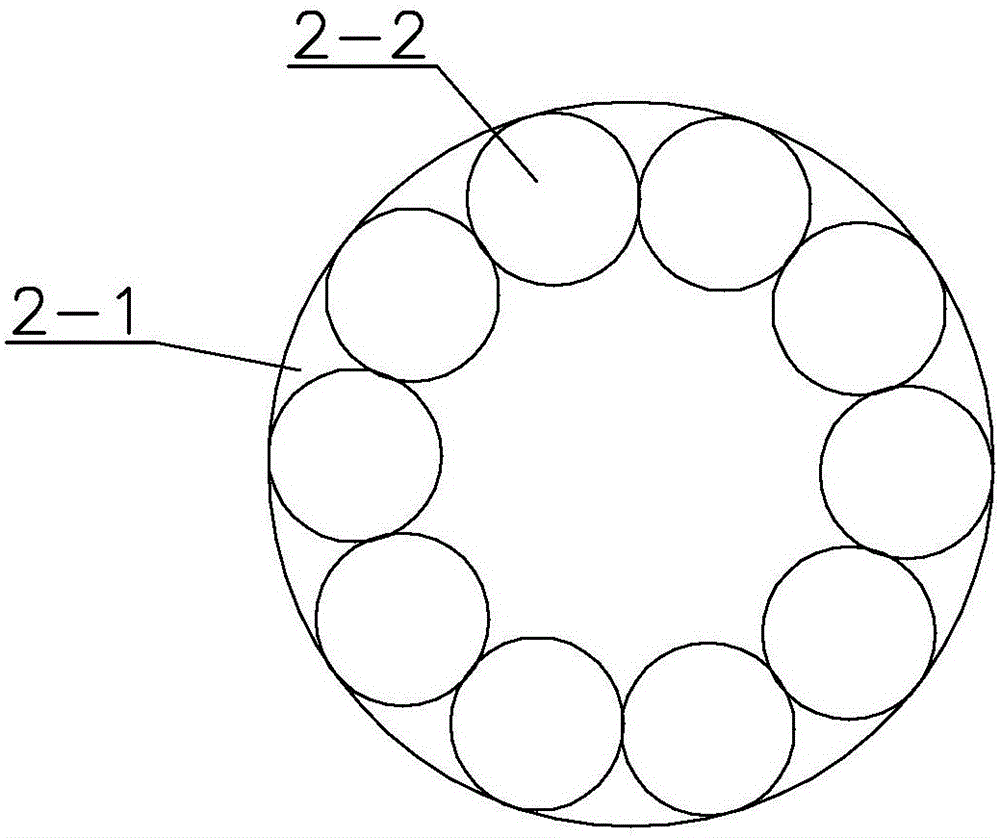

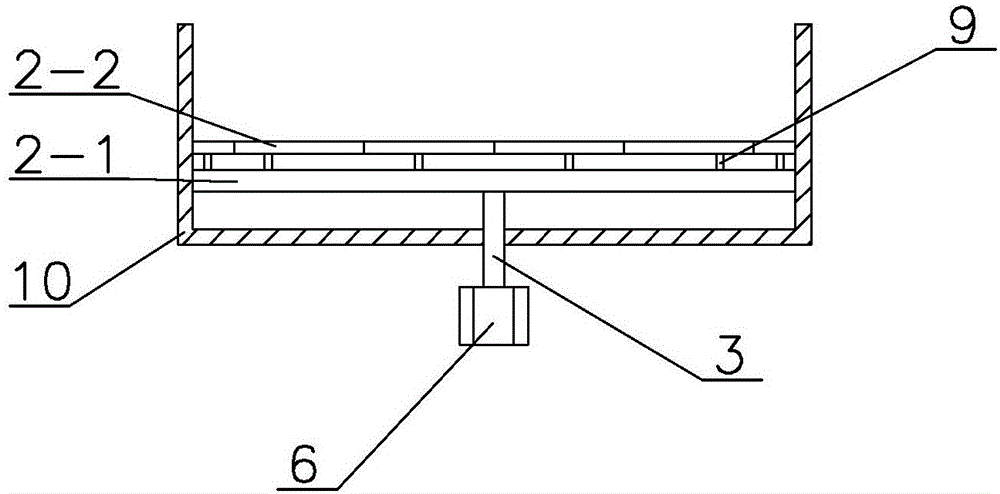

Test apparatus for ultraviolet aging acceleration of asphalt-based materials

ActiveCN105043964AAccurate temperature controlUniform photoagingWeather/light/corrosion resistanceThermal ageingUltraviolet lights

The invention provides a test apparatus for ultraviolet aging acceleration of asphalt-based materials and relates to a test apparatus. The invention solves the problems of tedious operation steps, uneven specimen aging, large thermal aging interference, failure in precise temperature control and accurate quantitative analysis of UV radiation energy in an asphalt specimen aging test. A complex rotating disk is set in an environment; complex rotating disk comprises a main rotating disk; at least one ultraviolet light source is disposed above the main rotating disk; the bottom of the main rotating disk is secured to one end of a drive shaft, and the other end drive shaft of the is connected to the output shaft of a drive motor; multiple asphalt specimens are placed on the main rotating disk; an ultraviolet probe of an ultraviolet radiation meter is arranged on the main rotating disk; the reading unit of the ultraviolet radiation meter is disposed outside the environment box; a temperature sensor is located in the environment and close to the main rotating disk; and a data acquisition and control system is set outside the environment box and is electrically connected to the temperature sensor. The invention is used for material ageing test.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com