Bismuth ferrite microsphere photocatalyst with hollow structure and preparation method thereof

A photocatalyst, bismuth ferrite technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. problems such as small surface area, to achieve the effect of improving catalytic activity, simple preparation process and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] At 20°C, a mixture of bismuth nitrate, ferric nitrate and citric acid with a molar ratio of 1:1:1 was dissolved in a solution containing 10.0 mL glycerin and 30.0 mL ethanol, and a clear dark red solution could be obtained after 360 W ultrasound for 10 minutes . Move it into a 50ml hydrothermal kettle, then put it in an oven at 160°C for aging; take out the hydrothermal kettle after 24 hours, filter the precipitate; wash with absolute ethanol for 6 times, and put it in an oven at 80°C Dry for 12 hours; place the obtained product in a muffle furnace, raise the temperature to 500° C. at a rate of 2° C. / min, and keep it for 4 hours to obtain the target product of bismuth ferrite microspheres with uniform particle size and hollow structure.

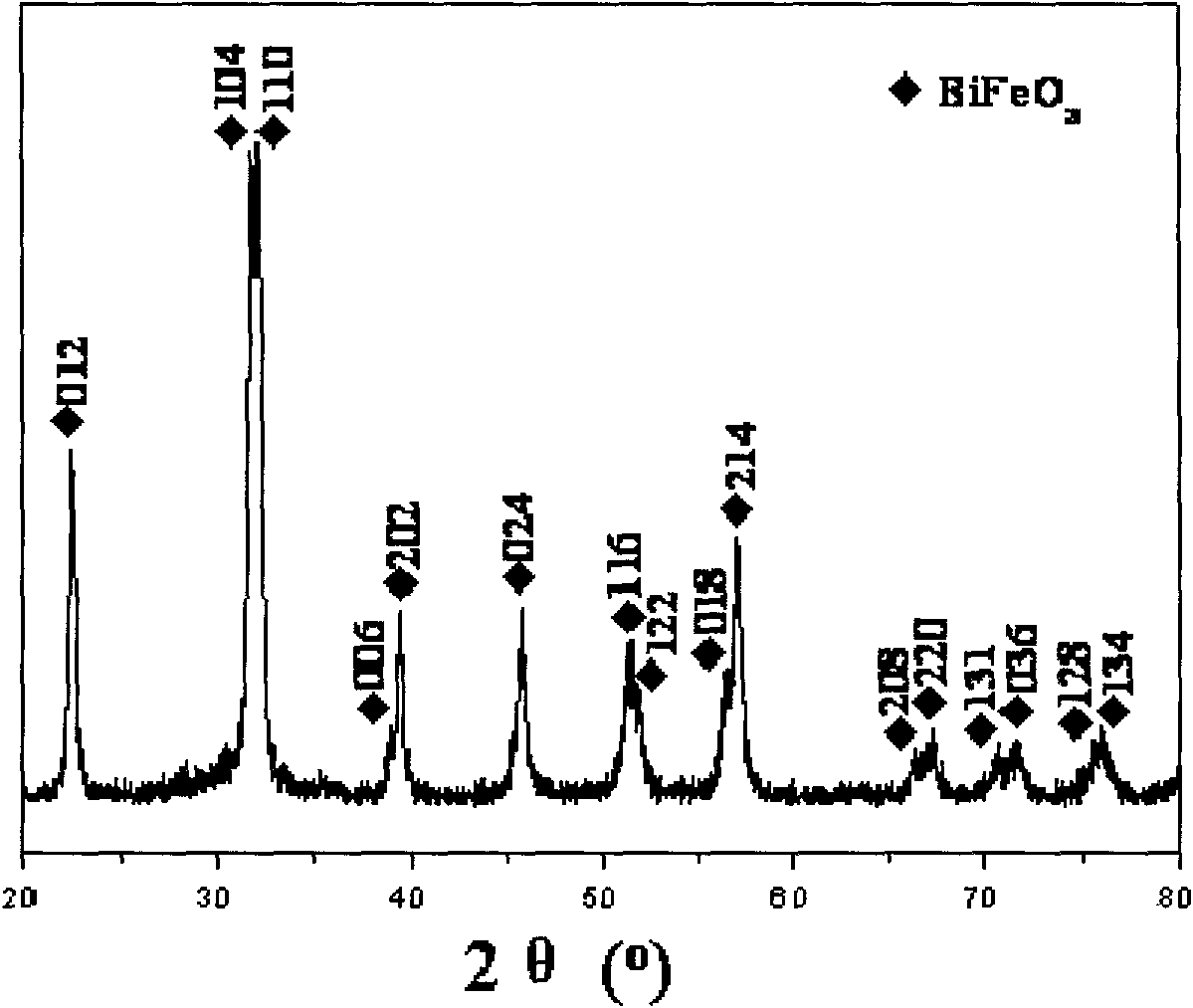

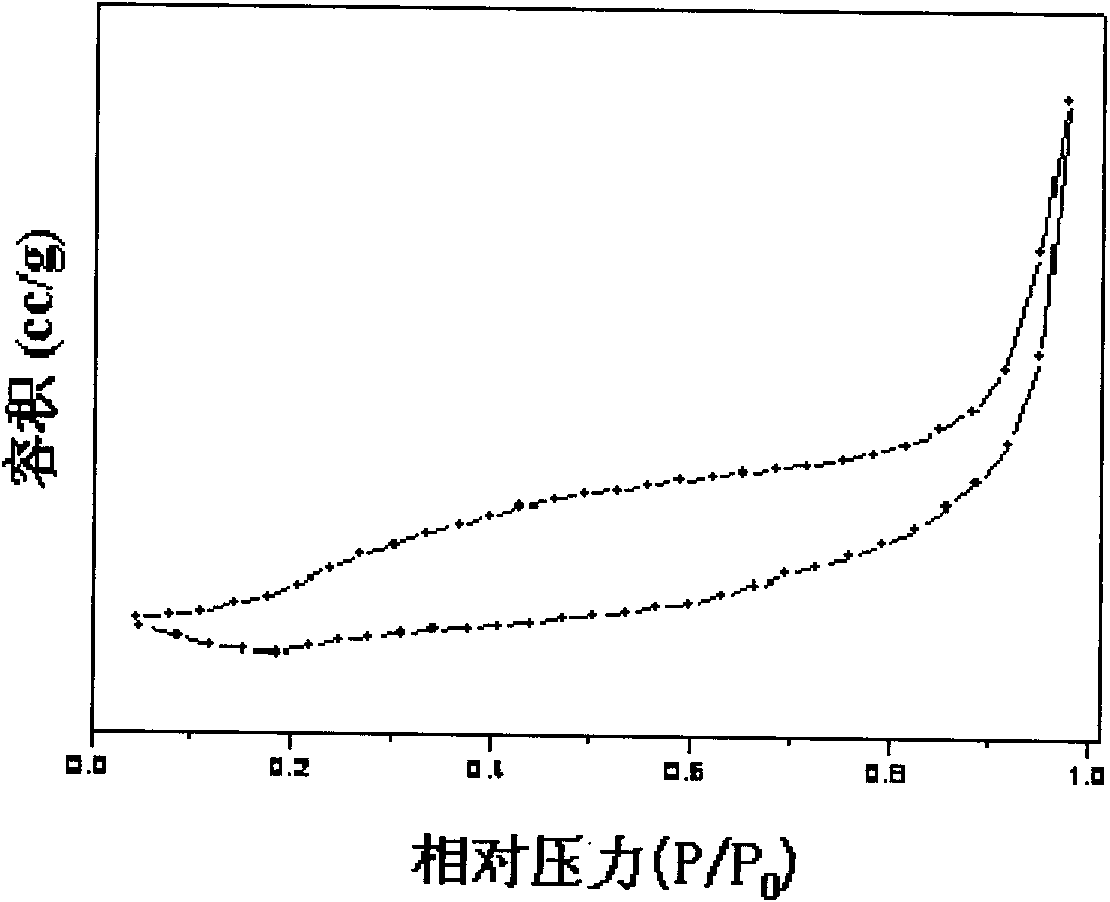

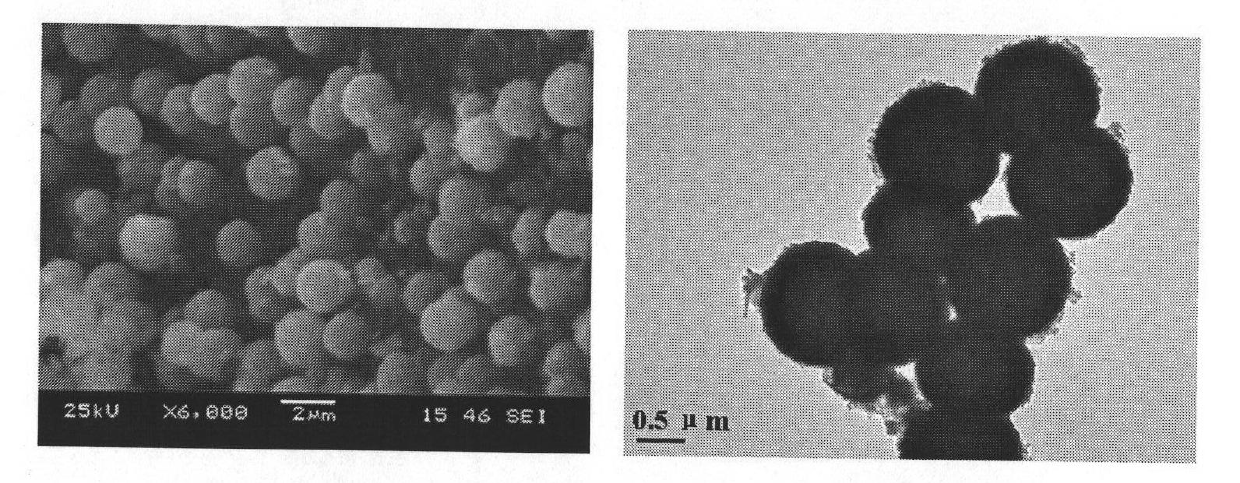

[0038] figure 1 For the X-ray diffraction spectrum of the preparation product of the present embodiment, can determine that gained product is BiFeO from the spectrum 3 . figure 2 Prepare the nitrogen absorption-desorption isotherm ...

Embodiment 2

[0040] At 20°C, a mixture of bismuth nitrate, ferric nitrate and citric acid with a molar ratio of 1:1:1 was dissolved in a solution containing 10.0 mL glycerin and 30.0 mL ethanol, and a clear dark red solution could be obtained after 360 W ultrasound for 10 minutes . Move it into a 50ml hydrothermal kettle, then put it in an oven at 160°C for aging; take out the hydrothermal kettle after 6 hours, filter the precipitate; wash with absolute ethanol for 6 times, and put it in an oven at 80°C Dry for 12 hours; place the obtained product in a muffle furnace, raise the temperature to 500° C. at a rate of 2° C. / min, and keep it for 4 hours to obtain the target product of bismuth ferrite microspheres with uniform particle size and hollow structure.

[0041] It can be confirmed that the obtained product is BiFeO by X-ray diffraction pattern 3 . Nitrogen absorption-desorption isotherm can determine the specific surface area of the product obtained is 16.4m 2 / g; The photo shows t...

Embodiment 3

[0043] At 20°C, a mixture of bismuth nitrate, ferric nitrate and citric acid with a molar ratio of 1:1:1 was dissolved in a solution containing 10.0 mL glycerin and 30.0 mL ethanol, and a clear dark red solution could be obtained after 360 W ultrasound for 10 minutes . Move it into a 50ml hydrothermal kettle, then put it in an oven at 160°C for aging; take out the hydrothermal kettle after 12 hours, filter the precipitate; wash with absolute ethanol for 6 times, and put it in an oven at 80°C Dry for 12 hours; place the obtained product in a muffle furnace, raise the temperature to 500° C. at a rate of 2° C. / min, and keep it for 4 hours to obtain the target product of bismuth ferrite microspheres with uniform particle size and hollow structure.

[0044] It can be confirmed that the obtained product is BiFeO by X-ray diffraction pattern 3 . From the nitrogen absorption-desorption isotherm, it can be determined that the specific surface area of the product obtained is 18.0m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com