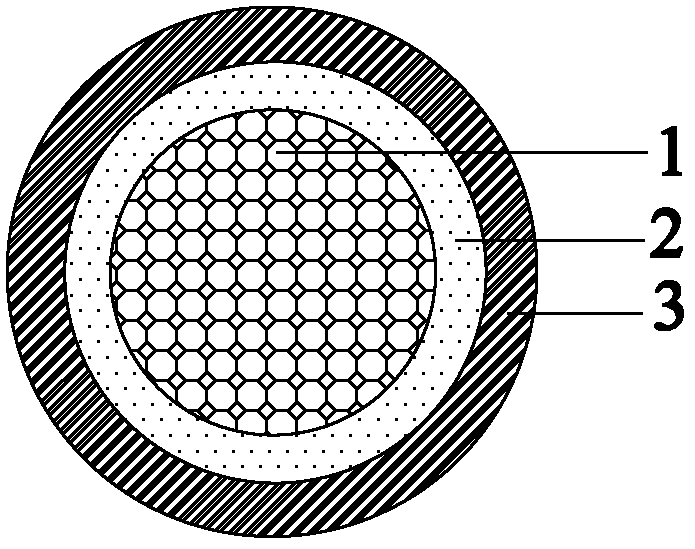

Photovoltaic cable and manufacturing method and application thereof

A technology of photovoltaic cables and copolymers, which is applied in the manufacture of cables/conductors, insulated cables, and insulation of conductors/cables. , complex photovoltaic cable production process and other issues, to achieve the effect of good processing performance, low cost, good processing performance and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

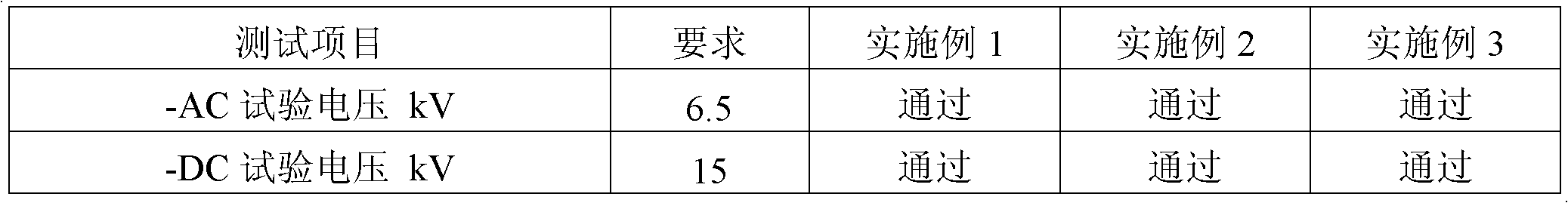

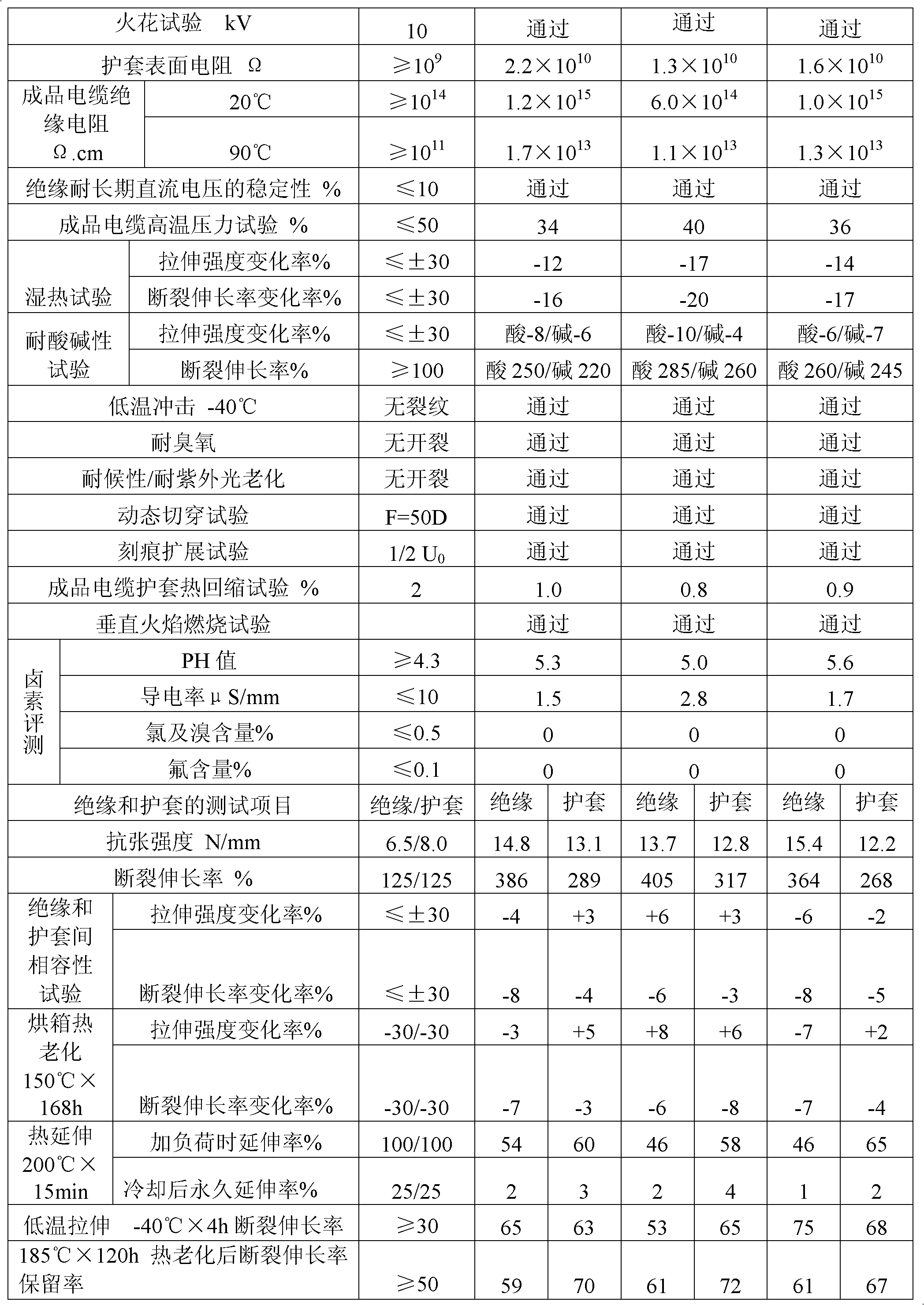

Embodiment 1

[0060] (1) Preparation of insulating layer pellets:

[0061] 20 parts by mass of ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 14% of the mass, and the melt index is 3.5g / 10min, Japan Mitsui Chemicals, the brand is EV560), 50 parts by mass of linear low-density polymer Ethylene (LLDPE, Saudi Basic Industries Corporation, brand 218-W, melt index is 2g / 10min, density is 0.918g / cm 3 ), 20 parts by mass of ethylene-methyl acrylate copolymer (AEM, Arkema Group, brand name is LOTRYL 24MA005, melt index is 0.4~0.6g / 10min), 10 parts by mass of maleic anhydride grafted ethylene-vinyl acetate Copolymer (grafting rate is 1.2%, melt index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., trade mark is JCP-851), 3 parts by mass of zinc stearate (ZnSt), 1 part by mass of compound Antioxidant (0.75 part of antioxidant 300 and 0.25 part of antioxidant 1010), 0.5 part by mass of composite light stabilizer (light stabilizer 944 and UV-531 are obtained...

Embodiment 2

[0066] (1) Preparation of insulating material:

[0067] 10 parts by mass of ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 14% of the mass, the melt index is 3.5g / 10min, Japan Mitsui Chemicals, the brand is EV560), 60 parts by mass of linear low-density polyethylene Ethylene (LLDPE, Saudi Basic Industries Corporation, brand 218-W, melt index is 2g / 10min, density is 0.918g / cm 3 ), 25 parts by mass of ethylene-methyl acrylate copolymer (AEM, Arkema Group, brand name is LOTRYL 24MA005, melt index is 0.4~0.6g / 10min), 5 parts by mass of maleic anhydride grafted ethylene-vinyl acetate Copolymer (graft rate 1.2%, melt index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., trade mark is JCP-851), 2 mass parts magnesium stearate (MgSt), 2 mass parts composite Antioxidant (1 mass part of antioxidant 300 and 1 mass part of antioxidant 1010), 0.2 mass part of composite light stabilizer (light stabilizer 944 and UV-531 are obtained in a mass rati...

Embodiment 3

[0072] (1) Preparation of insulating material:

[0073] 20 parts by mass of ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 14% of the mass, and the melt index is 3.5g / 10min, Japan Mitsui Chemicals, the brand is EV560), 40 parts by mass of linear low-density polymer Ethylene (LLDPE, Saudi Basic Industries Corporation, brand 218-W, melt index is 2g / 10min, density is 0.918g / cm 3 ), 30 parts by mass of ethylene-methyl acrylate copolymer (AEM, Arkema Group, brand name is LOTRYL 24MA005, melt index is 0.4~0.6g / 10min), 10 parts by mass of maleic anhydride grafted ethylene-vinyl acetate Copolymer (grafting rate is 1.2%, melt index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., trade mark is JCP-851), 1 mass part zinc stearate (ZnSt), 1.5 mass parts composite Antioxidant (1 mass part of antioxidant 300 and 0.5 mass part of antioxidant 1010), 0.4 mass part of composite light stabilizer (light stabilizer 944 and UV-531 are obtained in a mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com