Experimental device and experimental method for transformer oilpaper insulating thermal ageing

A technology of transformer oil and experimental device, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of inability to measure the dielectric parameters of oil-paper insulation samples in real time, difficulty in regular sampling, and changing the test environment by sampling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

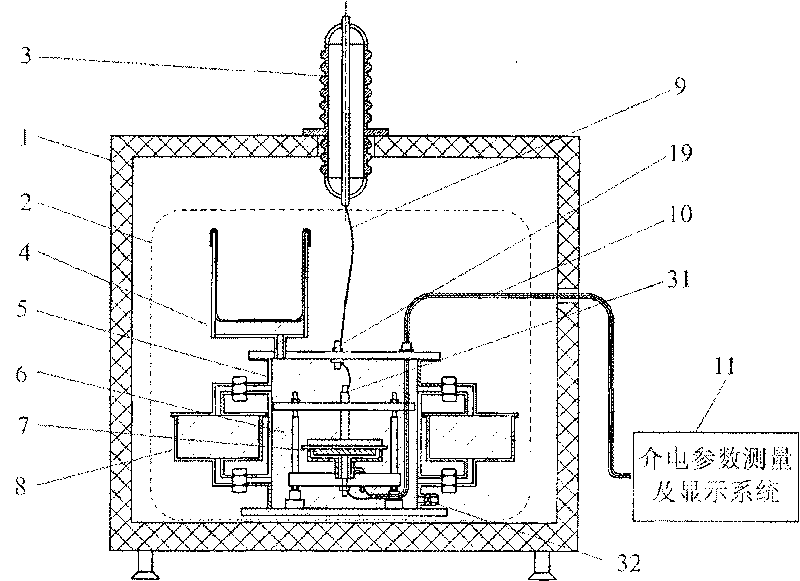

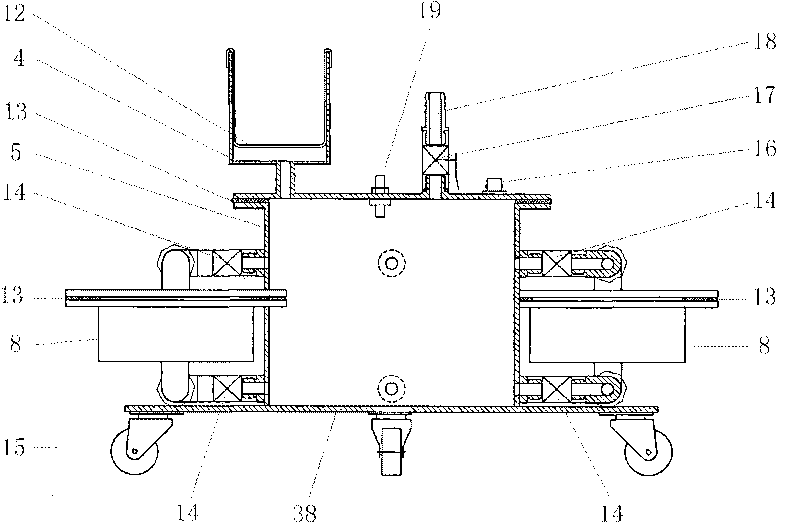

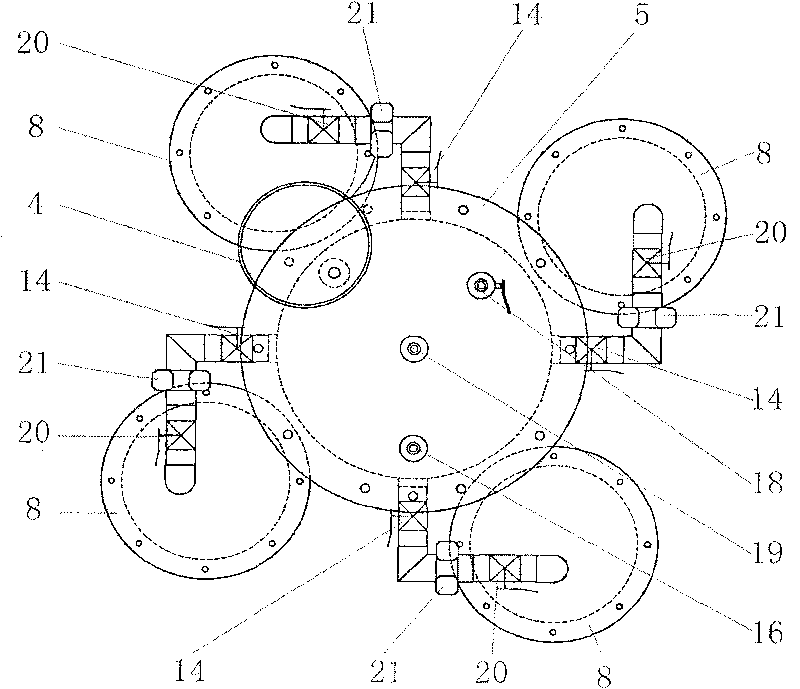

[0034] figure 1 It is the overall structure diagram of the experimental device of the present invention. It can be seen from the figure that the experimental device for thermal aging of oil-paper insulation includes an outer cavity 1, an inner cavity 2 arranged inside the outer cavity 1, and a measurement and display system 11. The inner cavity 2 consists of a cylinder The main chamber 5 of the cylindrical structure, the oil conservator 4 arranged on the main chamber 5 of the cylindrical structure, the electrode-sample test frame 7 arranged inside the main chamber 5 of the cylindrical structure and the centrally symmetrical shape arranged on the At least one secondary cavity 8 on the periphery of the main cavity 5 of the cylindrical structure is formed. The valve 20 of the secondary cavity 8 is connected to the valve 14 on the main cavity by disassembling the joint 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com