Method for preparing molecular sieve SCR catalyst, and catalyst prepared therethrough

A technology of SCR catalyst and molecular sieve, which is applied in the field of preparation of high-efficiency molecular sieve SCR catalyst and the prepared catalyst, can solve the problems of low selectivity and restriction, achieve high hydrothermal stability, reduce N2O generation, and high freshness/aging The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of carrier molecular sieve raw materials.

[0029] Take Beta molecular sieve and SSZ-13 molecular sieve, the mass ratio of the two is 3:1, mix them evenly, add deionized water to make slurry, and then spray dry to obtain the molecular sieve carrier material.

[0030] 2. Modification of carrier molecular sieve materials

[0031] Configure 1000mL lanthanum nitrate solution, the solution La 3+ The concentration is 0.5mol / L, heated to 70°C, and 50g of carrier molecular sieve powder is added while maintaining strong stirring, and ion exchange is carried out in a constant temperature reaction kettle at 70°C, and the exchange time is 10h. The obtained slurry was filtered, washed three times with deionized water, and the obtained molecular sieve mud was dried at a drying temperature of 105°C in an air atmosphere for 24 hours. The dried molecular sieve mud was twisted and passed through a 40-mesh sieve. The obtained powder is recorded as La-Zeolite.

[0032] 3....

Embodiment 2

[0043] Mix Beta molecular sieve and SSZ-13 molecular sieve evenly, the mass ratio of the two is 3:1, after mixing evenly, carry out pulping, spray drying, and then use a concentration of 0.2mol / L yttrium nitrate solution for modification treatment, and then carry out For equal volume impregnation loading Fe and ion exchange loading Cu, other catalyst preparation parameters and conditions are the same as in Example 1 except for the difference in the type of salt used for molecular sieve modification. The obtained sample is designated as S2.

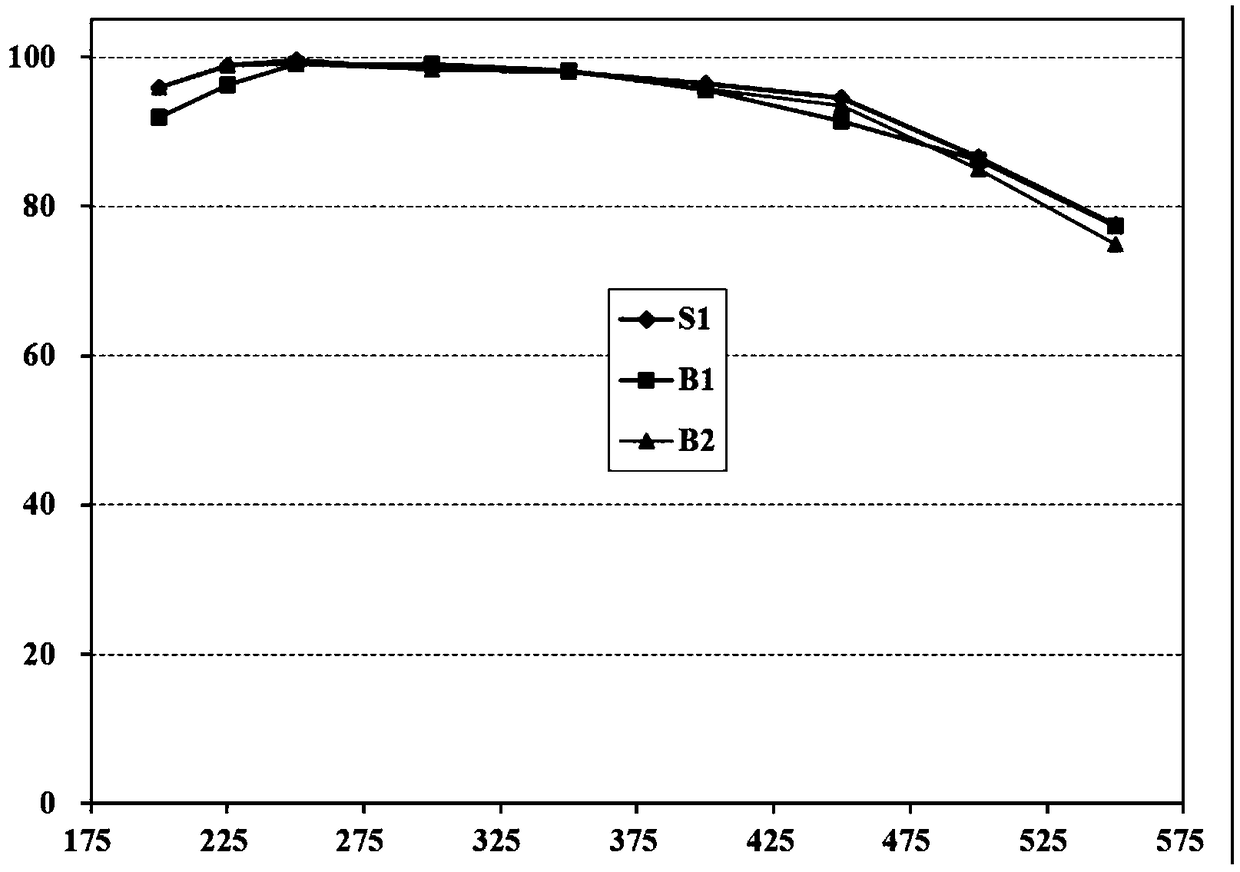

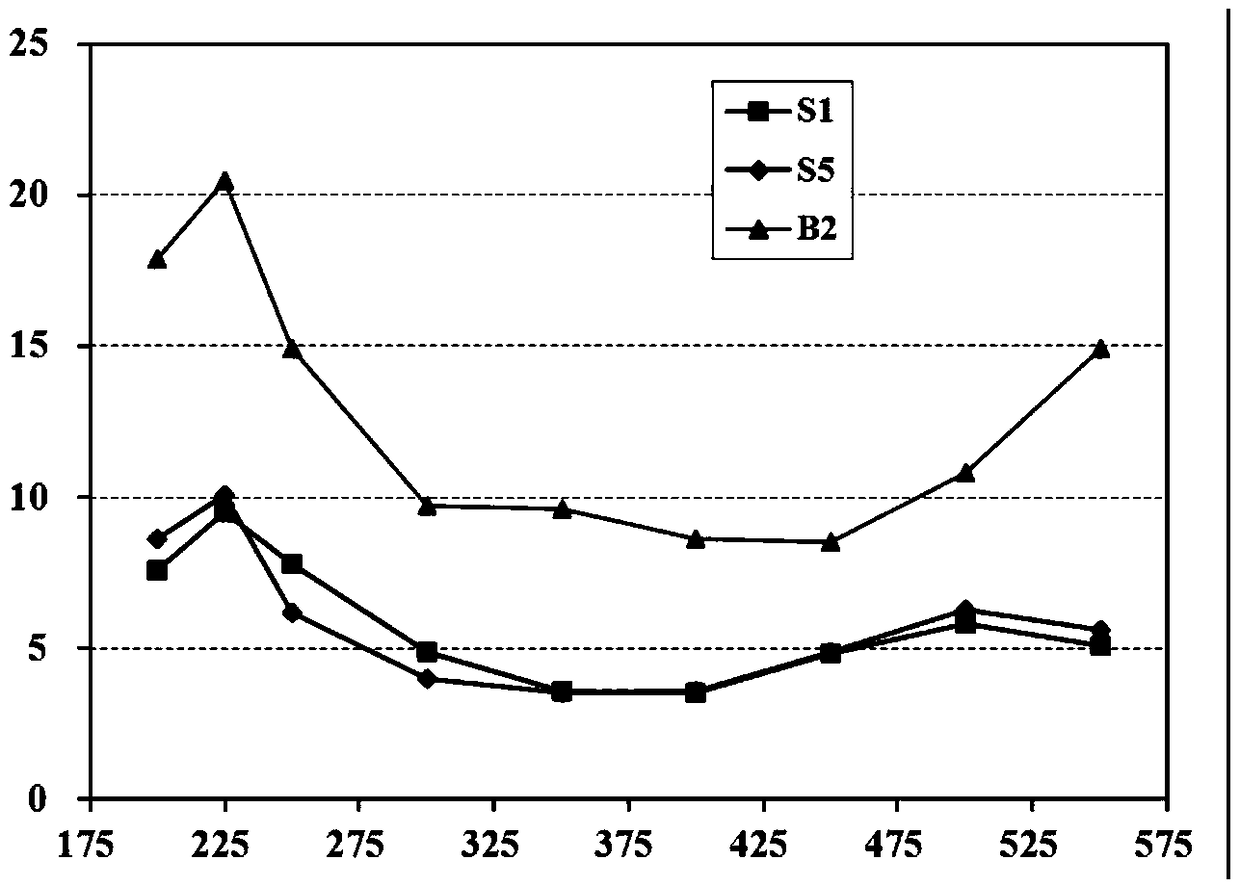

[0044] The amount of by-product N2O produced by comparing S1, S2 and B2 catalysts during the SCR reaction is as follows: figure 2 Shown, compare with B2, adopt the catalyst prepared by the present invention to produce N in catalytic reduction NOx process 2 The amount of O is reduced by nearly 50%, which obviously improves its N 2 selectivity, thus it can be seen that the N of the catalyst prepared by the catalyst preparation technology ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com