Modified polyimide resin, adhesive composition containing modified polyimide resin and covering film containing adhesive composition

A polyimide resin and polyimide chain technology, applied in the direction of epoxy resin glue, adhesive additive, adhesive, etc., can solve the problem of dielectric properties and ion migration resistance, low dielectric properties , Ion migration resistance, poor flame retardancy, chemical resistance and heat aging resistance, etc., to achieve excellent room temperature storage, aging resistance, outstanding dielectric properties, and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

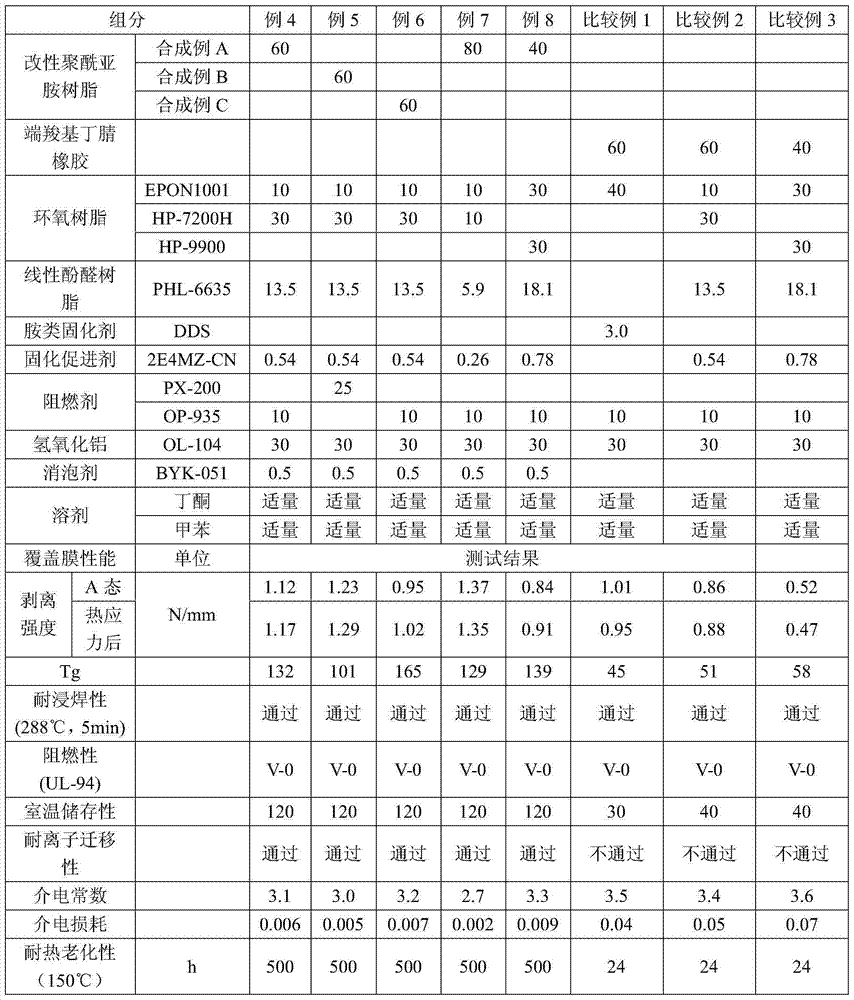

Examples

preparation example Construction

[0032] 1. Preparation of the modified polyimide resin

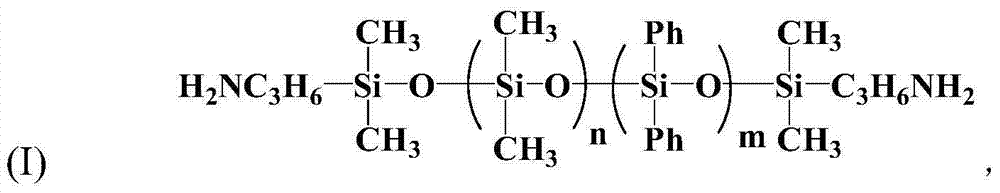

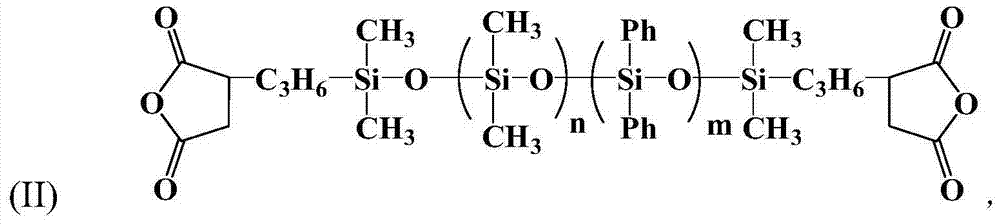

[0033] The raw materials used for the synthesis of the modified polyimide resin of the present invention and a brief expression are described as follows:

[0034] KF-8010: Silicone diamine monomer (manufactured by Shin-Etsu Chemical Co., Ltd., amino group equivalent: 450 g / mol)

[0035] X-2290: Silicone dianhydride monomer (manufactured by Shin-Etsu Chemical Co., Ltd., acid anhydride equivalent: 500 g / mol)

[0036] DACH: 1,4-cyclohexanediamine (molecular weight 114)

[0037] DDCM: 4,4'-Methylenebiscyclohexylamine (210)

[0038] CHDA: cyclohexane-1,2,4,5-tetraacid dianhydride (224)

[0039] CBDA: Cyclobutane-1,2,3,4-Tetraacid Dianhydride (196)

[0040] ODA: 4,4'-diaminodiphenyl ether (200)

[0041] BPDA: 3,3',4,4'-biphenyltetracarboxylic dianhydride (294)

Embodiment 1

[0043] A modified polyimide resin containing repeating units of a polysiloxane polyimide segment, an alicyclic polyimide segment and an aromatic polyimide segment in its molecular structure; and The molar ratio of the siloxane polyimide segment, the alicyclic polyimide segment and the aromatic polyimide segment in the chemical formula of the modified polyimide resin is 3:2:5.

[0044] Its preparation method is as follows:

[0045] In the reactor equipped with temperature control device, stirring device, reflux device and dehydration device, add 90Kg toluene and cyclohexanone weight ratio of 1:1 mixed solution, add liquid KF-801018Kg (20mol) and X-229010Kg (10mol) and stir until completely dissolved, add BPDA8.82Kg (30mol) and CHDA2.24Kg (10mol) under stirring, slowly add DACH1.14Kg (10mol) and ODA4Kg (20mol) after the system is evenly dispersed, and heat the reaction kettle to 80°C and continue stirring for 24 hours to generate a polyamic acid solution, then add 50Kg of a mix...

Embodiment 2

[0047] A modified polyimide resin containing repeating units of a polysiloxane polyimide segment, an alicyclic polyimide segment and an aromatic polyimide segment in its molecular structure; and The molar ratio of the siloxane polyimide segment, the alicyclic polyimide segment and the aromatic polyimide segment in the chemical formula of the modified polyimide resin is 4:3:3.

[0048] Its preparation method is as follows:

[0049] In the reactor equipped with temperature control device, stirring device, reflux device and dehydration device, add 110Kg mixed solution of ethylene glycol methyl ether and xylene with a weight ratio of 1:1, add liquid KF-801018Kg (20mol) and Liquid X-229020Kg (20mol) and stir until completely dissolved, add BPDA2.94Kg (10mol) and CHDA4.48Kg (20mol) under stirring, and slowly add DDCM2.1Kg (10mol) and ODA4Kg (20mol) after the system is uniformly dispersed , the reactor was heated to 80°C and stirred continuously for 24 hours to generate polyamic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com