Patents

Literature

88results about How to "Little change in hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low resilience flexible polyurethane foam and process for its production

To provide a flexible polyurethane foam which is excellent in low resiliency and durability without using a plasticizer and which shows little change in hardness against a change in temperature and at the same time, has high air permeability. A process for producing a flexible polyurethane foam, which comprises reacting a polyol mixture comprising polyol (A), polyol (B) and monool (D) with a polyisocyanate compound in the presence of a blowing agent etc. at an isocyanate index of at least 90. Polyol (A) is a polyether polyol having an average of 2-3 hydroxyl groups and a hydroxyl value of from 10 to 90 mgKOH / g, obtained by ring-opening addition polymerization of an alkylene oxide to an initiator using a double metal cyanide complex catalyst; Polyol (B) is a polyether polyol having an average of 2-3 hydroxyl groups and a hydroxyl value of from 15 to 250 mgKOH / g, other than the polyol (A); and Monool (D) is a polyether monool having a hydroxyl value of from 10 to 200 mgKOH / g.

Owner:ASAHI GLASS CO LTD

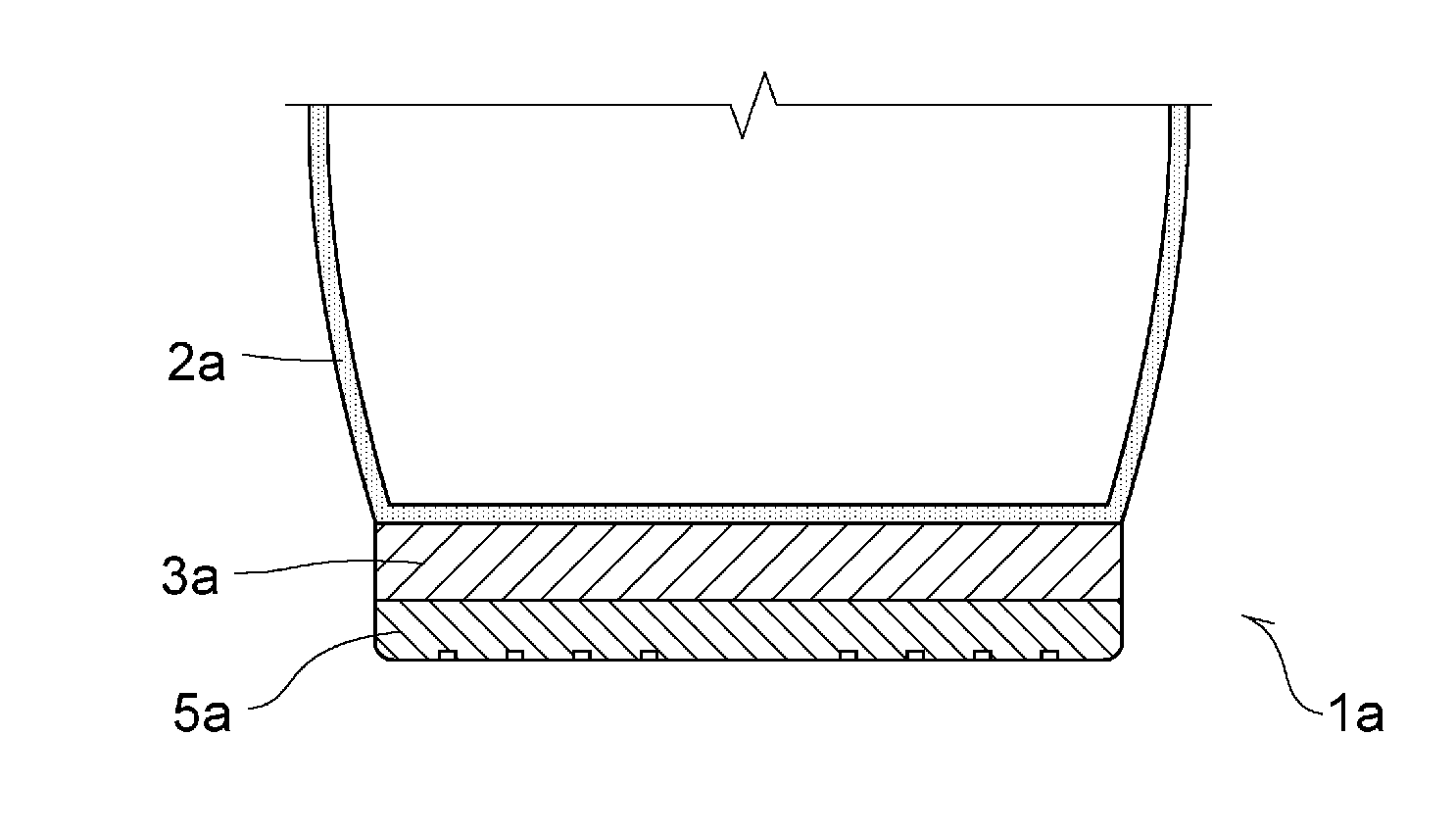

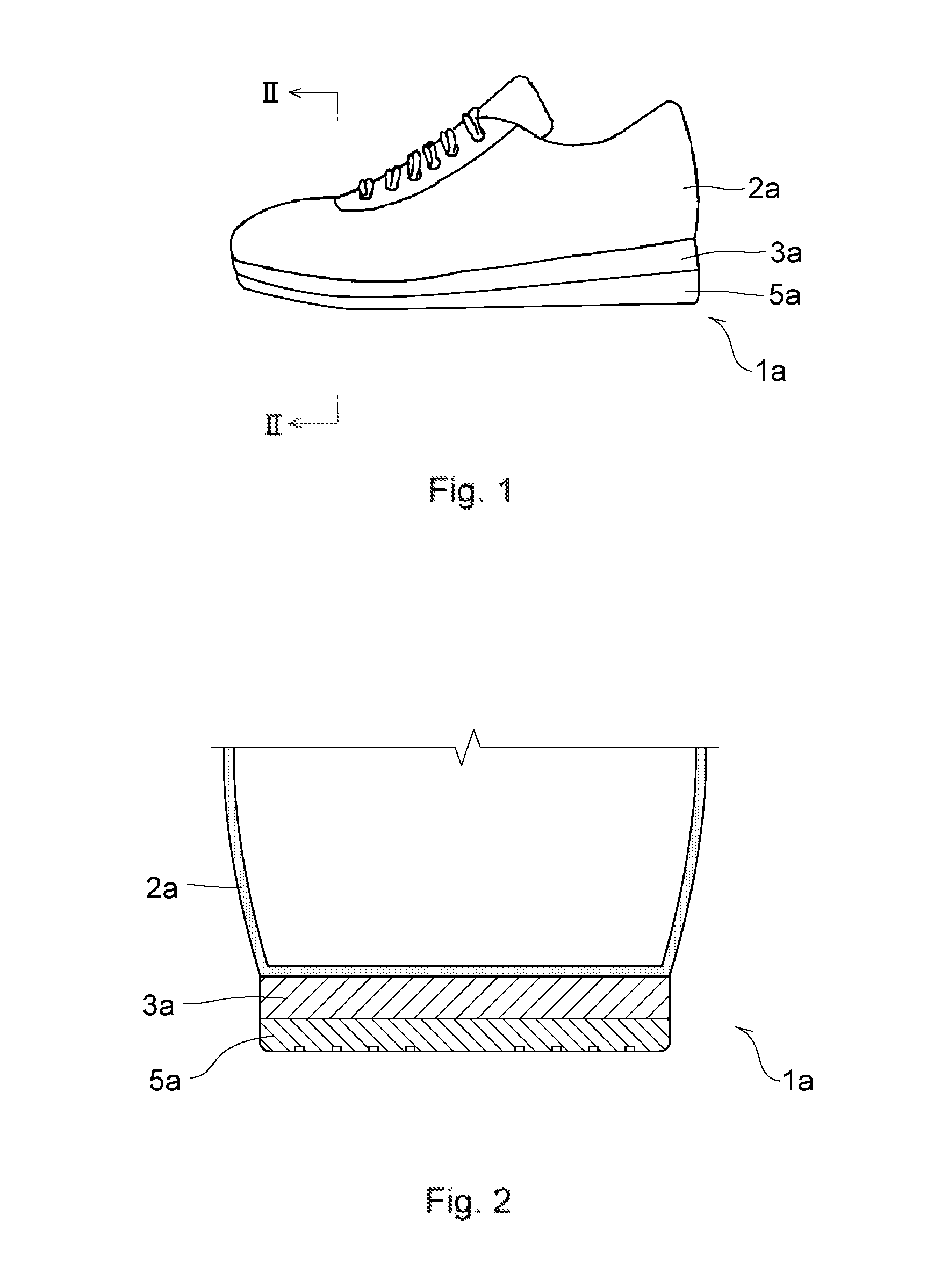

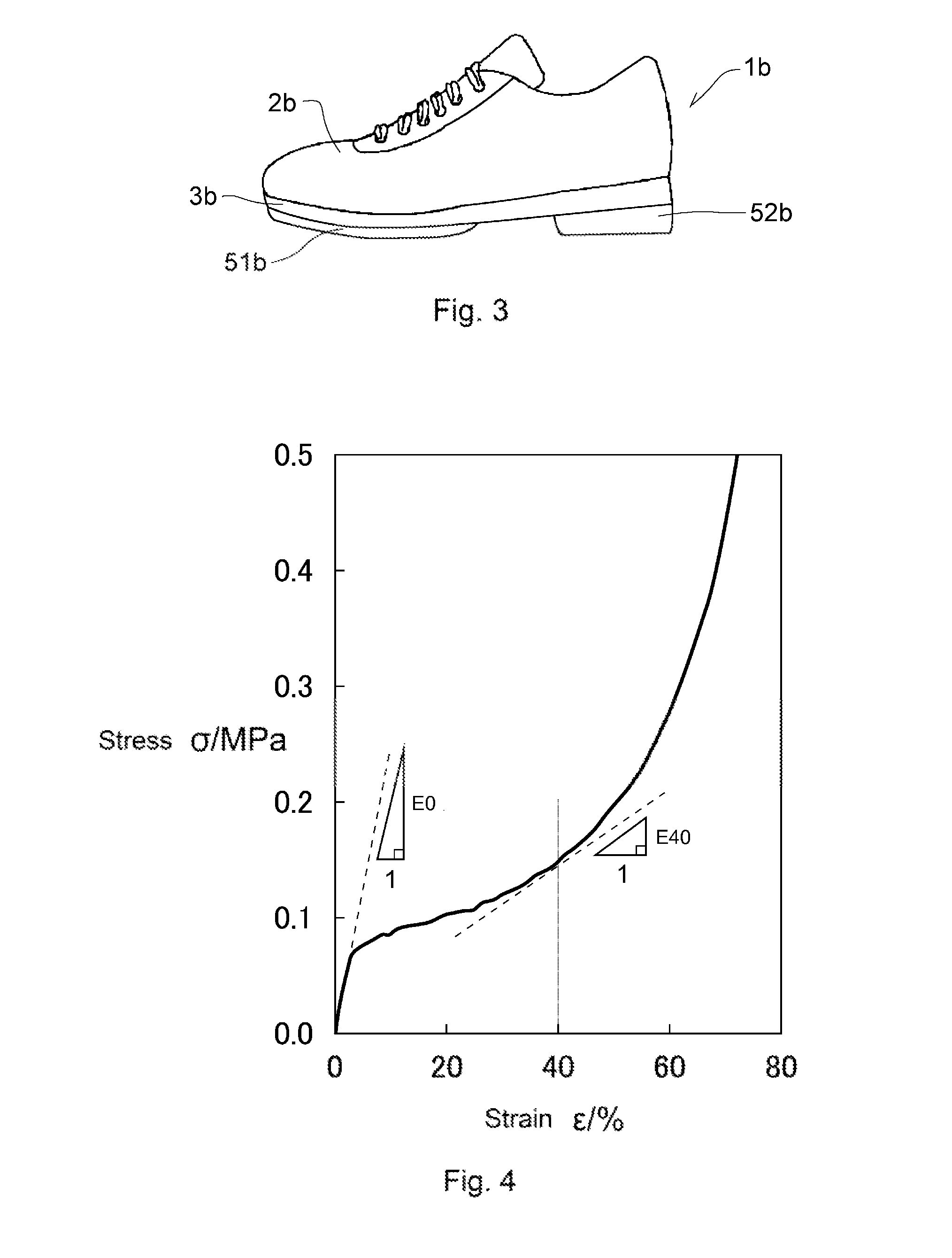

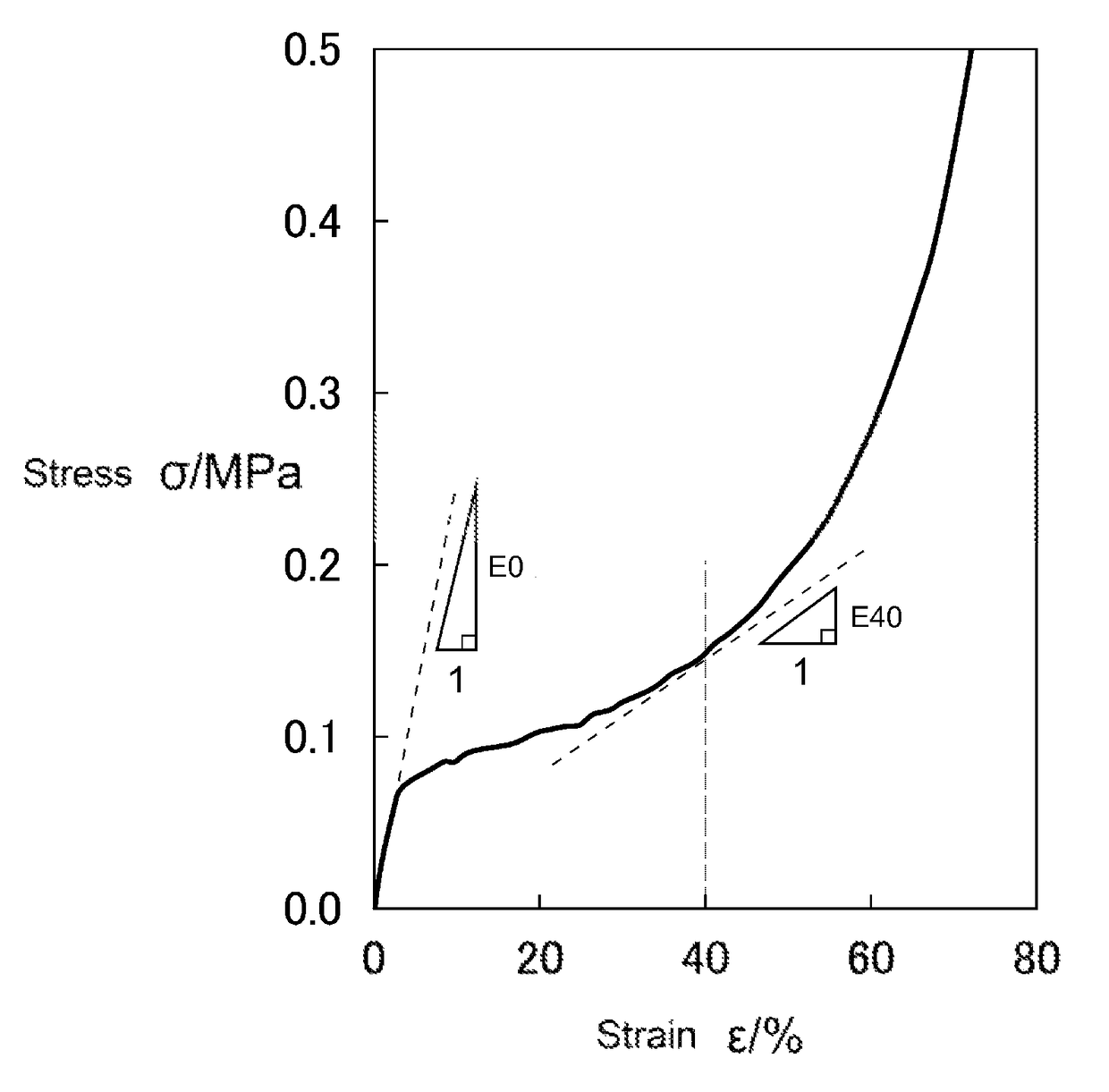

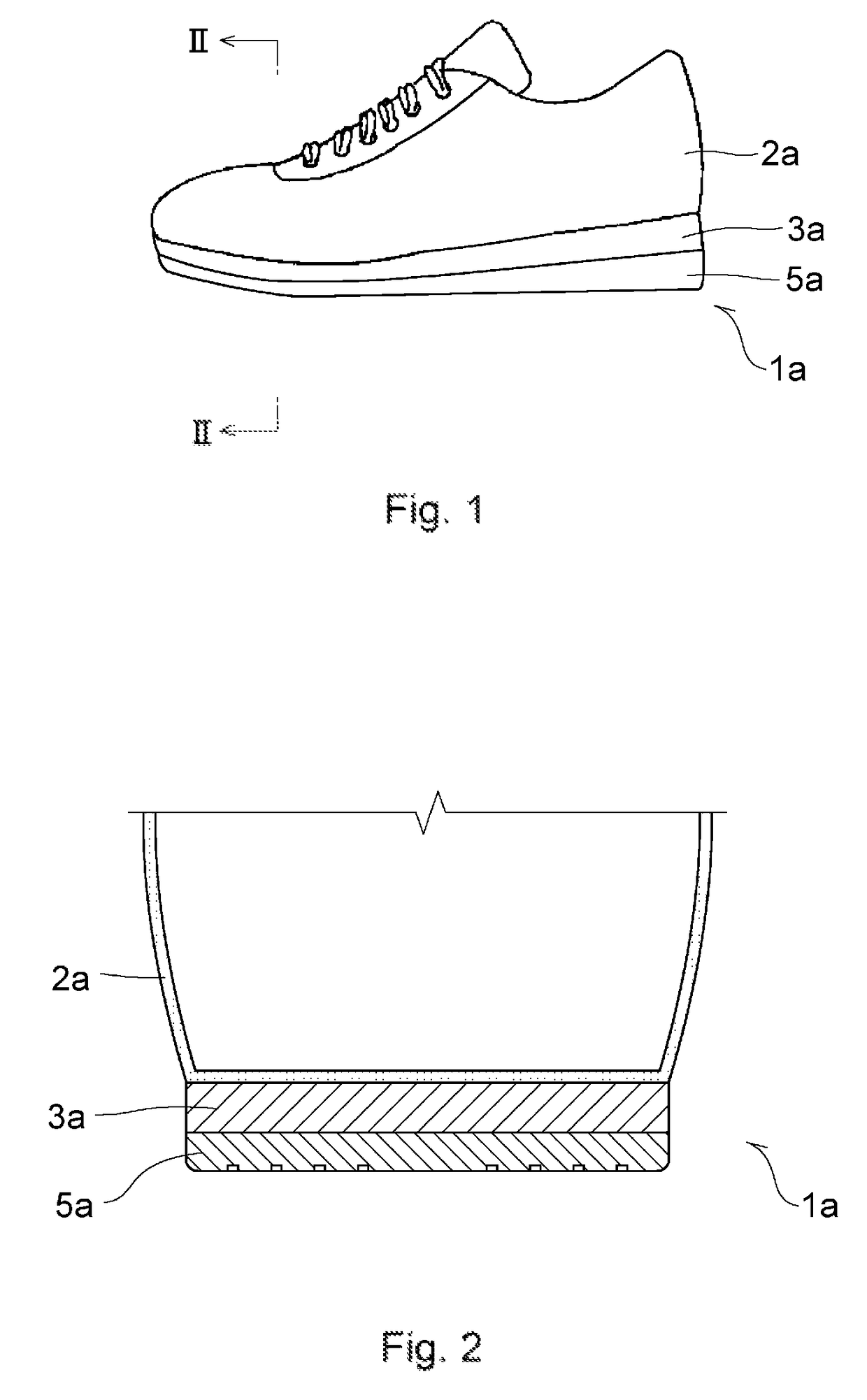

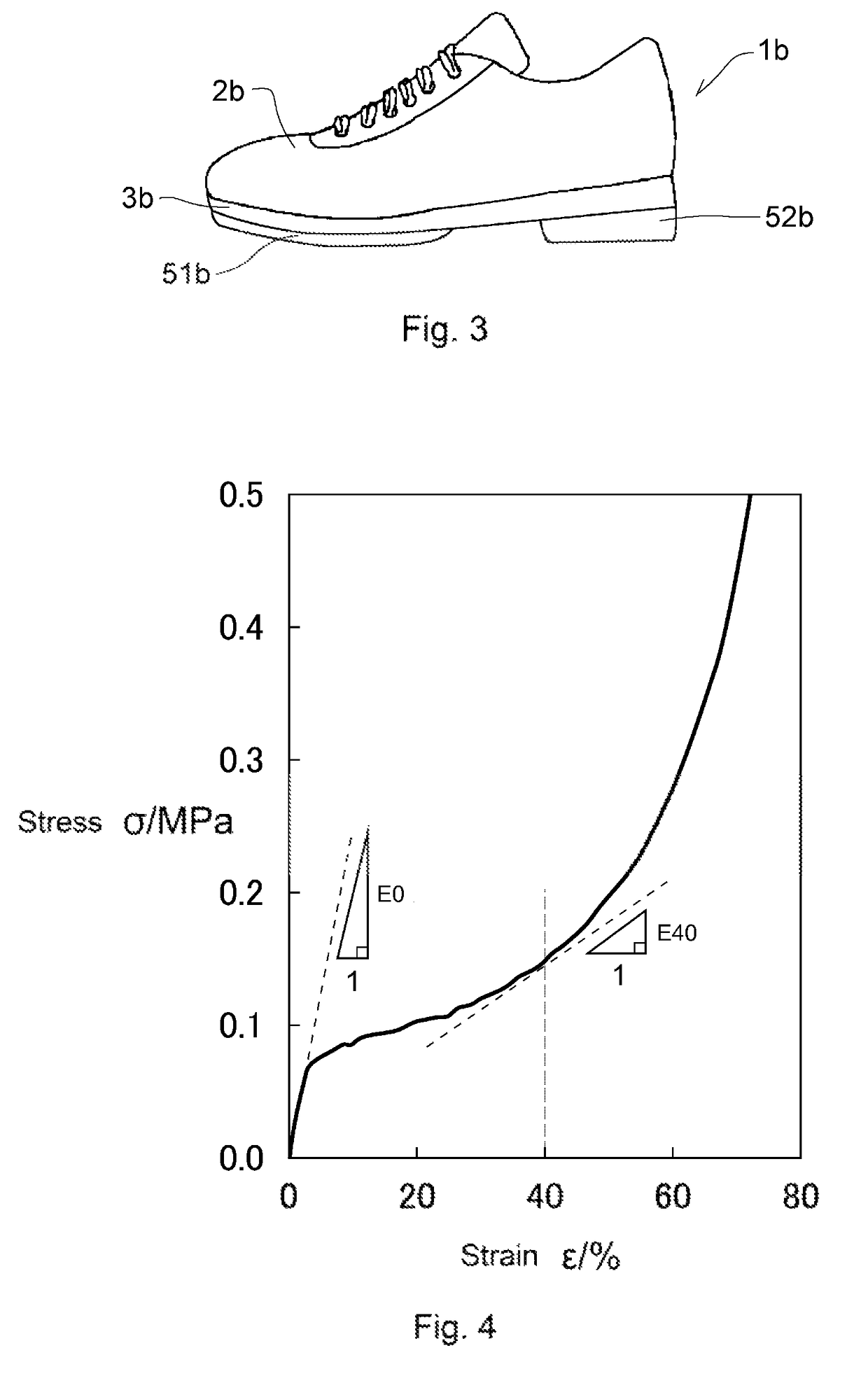

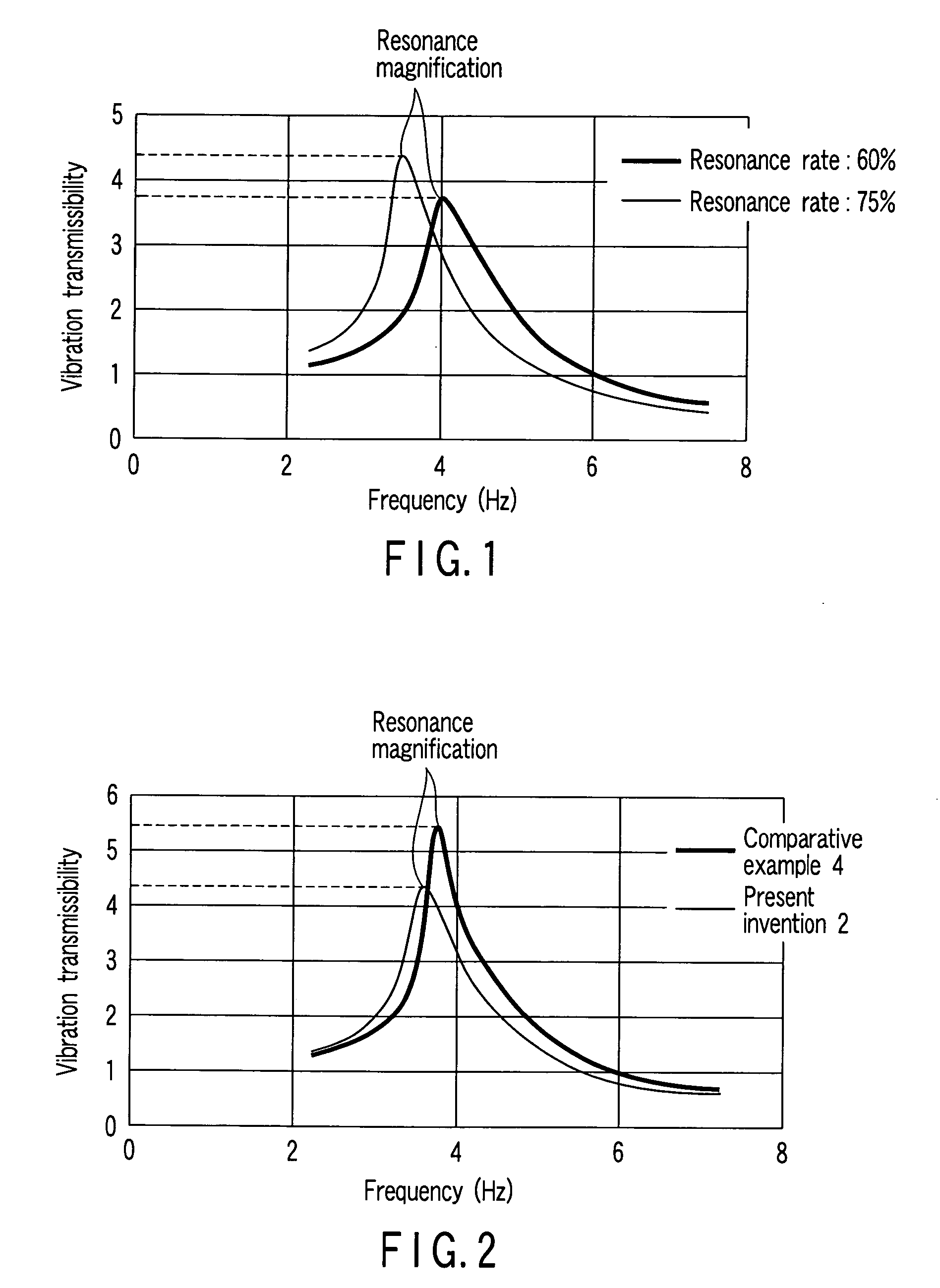

Molded Foam Article, Foamed Sole, and Shoe

ActiveUS20150143723A1Little change in hardnessKeep elasticSolesAbsorbent padsCompressive deformationComposite material

There is provided a molded foam article including a foam obtained by foaming a formation material wherein the formation material contains a resin component, an Asker C hardness of the foam is 10 degrees or more, and a ratio E40 / E0 of the foam is 0.5 or more, the ratio E40 / E0 being a ratio of an elastic coefficient E40 at a strain of 40% in relation to an elastic coefficient E0 at a strain of 0% of the foam.The molded foam article has appropriate softness with a small change in hardness under compressive deformation.

Owner:ASICS CORP

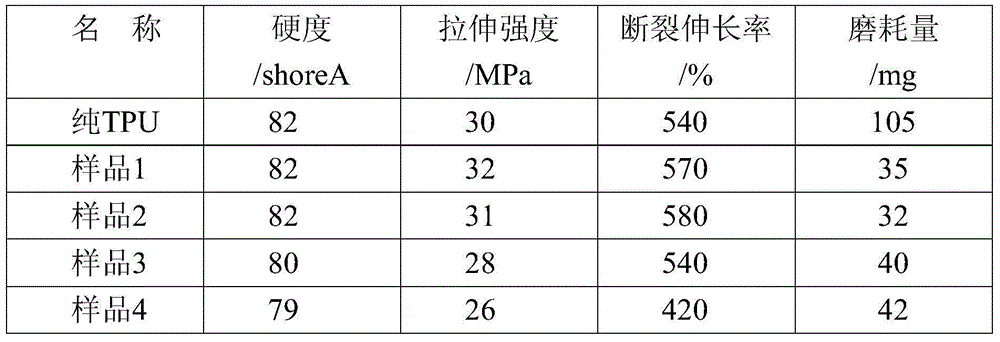

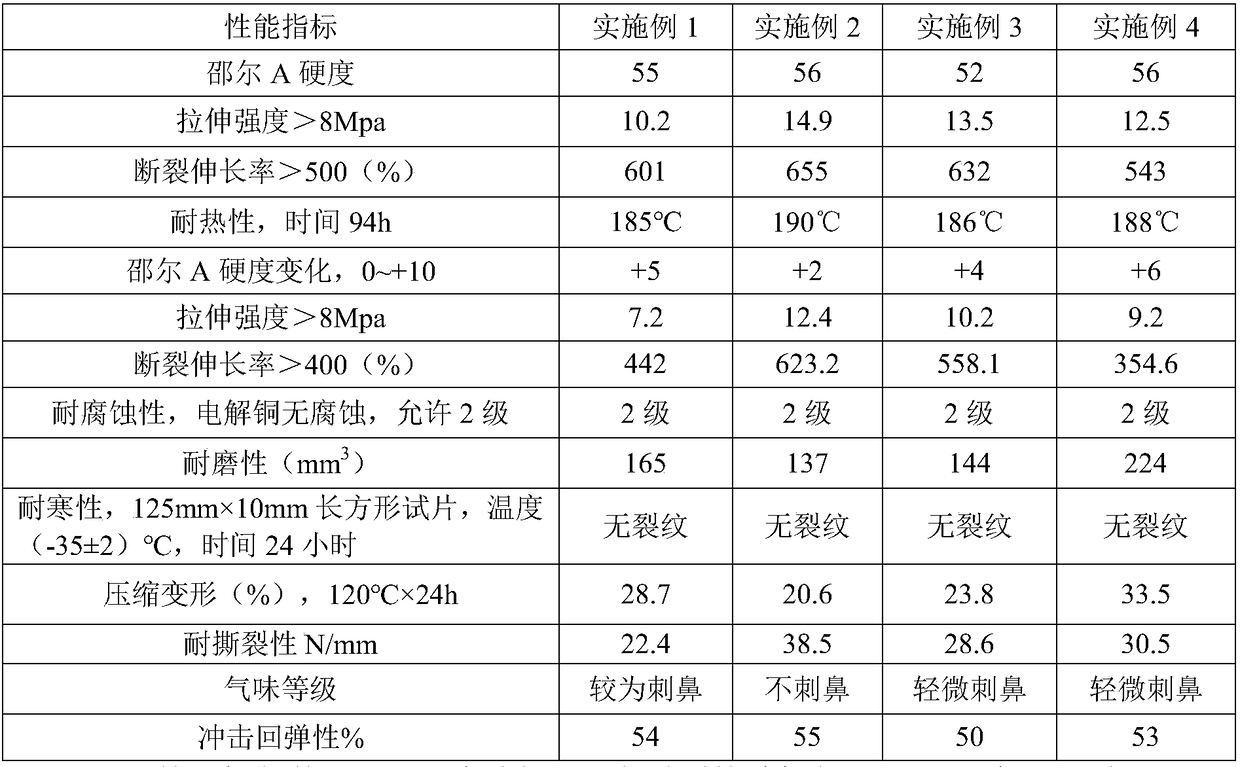

Wear resistant type thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN104151814AImprove wear resistanceImprove anti-scratch performanceFlexible pipesWear resistantUltraviolet

The invention discloses a wear resistant type thermoplastic polyurethane elastomer and a preparation method, the polyurethane elastomer comprises the following substances by mass percentage: 71-91.6% of thermoplastic polyurethane elastomer (TPU), 5-20% of terpolymer EP rubber (EPDM), 3-8% of carbon black master batch, 0.2-0.5% of anti-oxidant and 0.2-0.5% of ultraviolet ray absorber. The method employs a proper proportion of EPDM for physical modification on the thermoplastic polyurethane elastomer, the wear resistance of the thermoplastic polyurethane elastomer is increased by 2-3 times, rub-resistance performance of a TPU flexible pipe is improved, modified material hardness is little changed, the original extrusion moulding technology of the flexible pipe is satisfied, service life of the TPU flexible pipe is prolonged, and the cost is simultaneously reduced.

Owner:BEIJING UNIV OF CHEM TECH

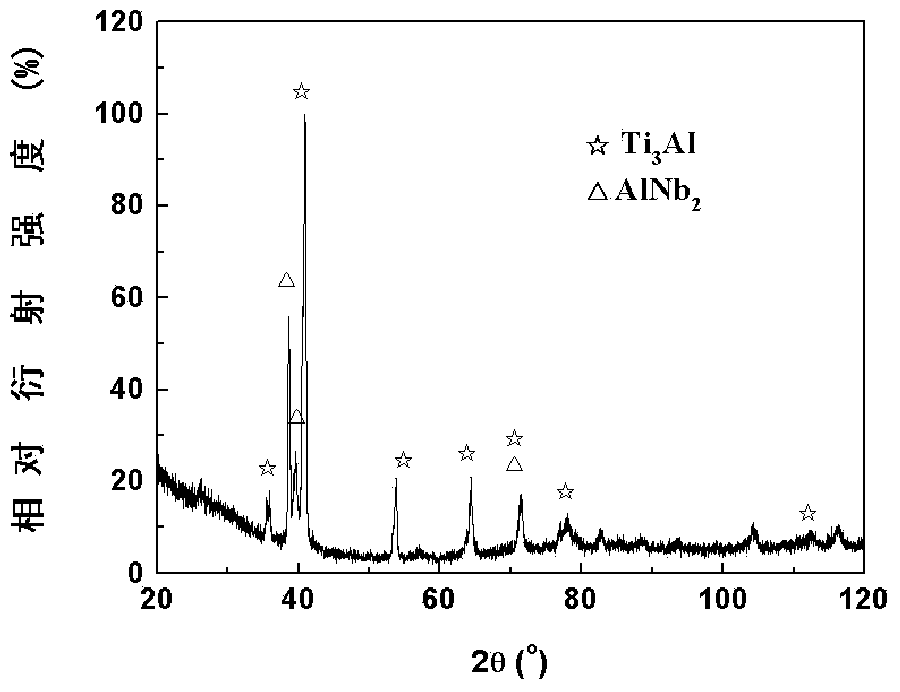

Method for preparing Ti-Al-Nb alloy coating on titanium metal surface

ActiveCN104005023AHigh hardnessImprove wear resistanceMetallic material coating processesAl powderTitanium metal

The invention provides a method for preparing a Ti-Al-Nb alloy coating on a titanium metal surface. The method is characterized by comprising the steps of prefabricating a pressed slice of mixed powder formed by Ti powder, Al powder, Nb powder and Y2O3 powder and carrying out laser cladding treatment, wherein the step of prefabricating the pressed slice of mixed powder comprises the processes of firstly mixing the Ti powder, Al powder, Nb powder and Y2O3 powder uniformly with a ball mill, secondly drying the mixture and finally pressing the mixture into a slice on a press machine; the step of carrying out laser cladding treatment comprises the processes of putting the pressed slice on the cleaned titanium metal surface and then carrying out laser cladding processing. The method has the beneficial effects that the cladding process has excellent properties; the coating has dense tissue and is good in interface bonding; the main composition phases of the coating are Ti3Al and AlNb2; the change of the hardness of the coating along the cross section is small; the average hardness is about HV530-600, and the wear resistance is about three times that of a matrix; the composition elements of the Ti-Al-Nb alloy coating are resistant to oxidation and corrosion, so that the Ti-Al-Nb alloy coating has extensive application fields.

Owner:JIANGSU UNIV

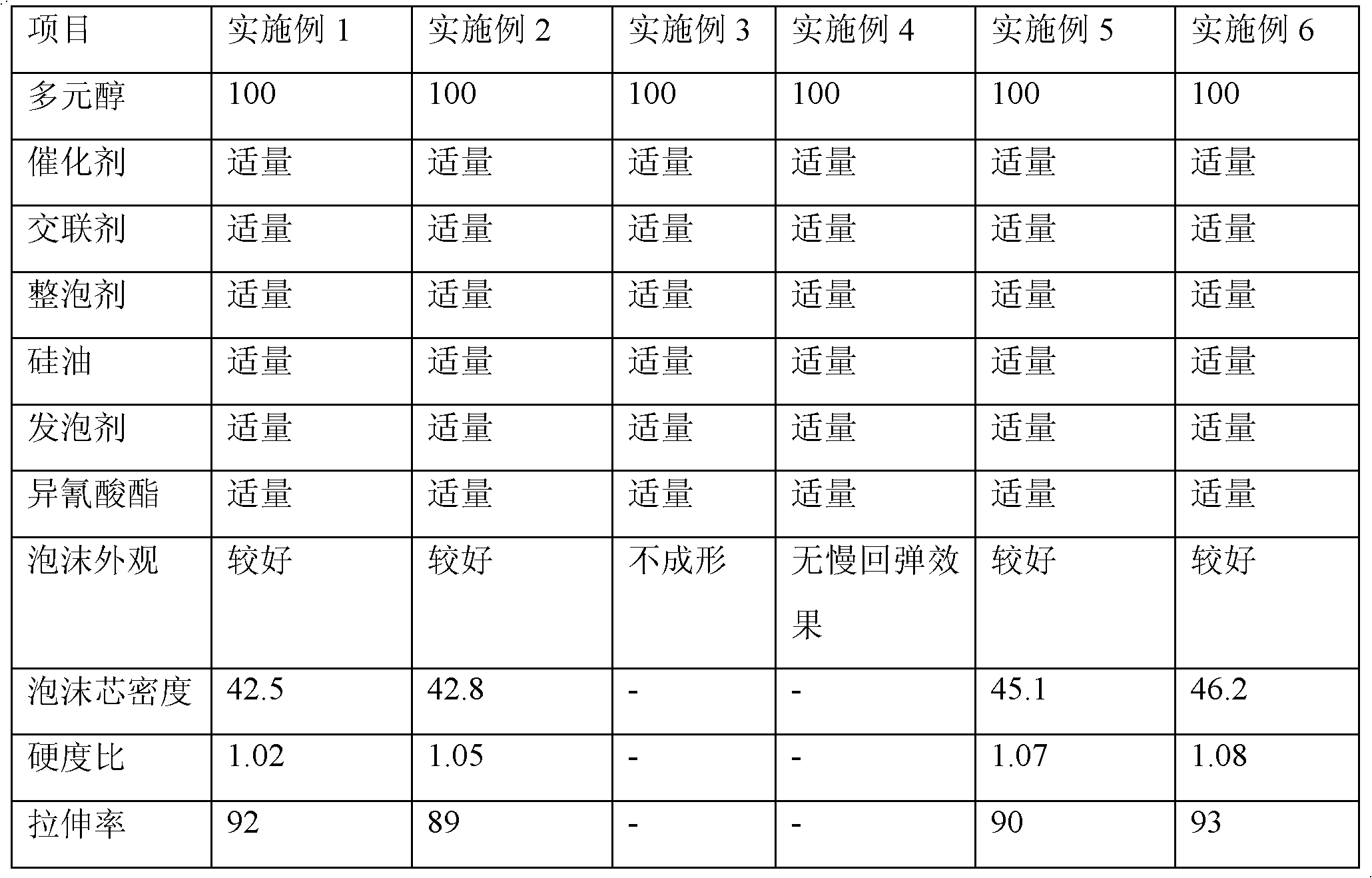

Synthetic method of slow resilience foam polyether polyol

The invention relates to a synthetic method of slow resilience foam polyether polyol, which is characterized by adopting a polyalcohol compound as an initiator, and taking alkali metal as a catalyst and acetic anhydride as an end sealing agent to polymerize with epoxy compound at the pressure of 0-0.5 Mpa and at the temperature of 50-150 DEG C to obtain the slow resilience foam polyether polyol. The process is convenient for workers to operate; the technical index is easy to control; and the prepared new-type slow resilience foam polyether polyol can be used for various slow resilience foam products, and has the characteristic of smaller hardness change at the condition of temperature change.

Owner:SHANDONG BLUSR DONGDA CHEM

Composition capable of forming yellowing-free, low-hardness polyurethane elastomer, and method for producing yellowing-free, low-hardness polyurethane elastomer using the same

The present invention provides a thermosetting polyurethane elastomer that is yellowing-free, has low hardness and does not give rise to bleeding without using any plasticizer, has little tack, and exhibits small changes in hardness with temperature.This is achieved by a composition forming a yellowing-free, low-hardness polyurethane elastomer, containing no plasticizer and having (A) an isocyanate-terminated prepolymer and (B) a polyester polyol, wherein the isocyanate-terminated prepolymer (A) is an isocyanate-terminated prepolymer obtained by reacting hexamethylene diisocyanate with a glycol having an alkyl group as a side chain and having a molecular weight no greater than 500, and the polyester polyol (B) is a polyester polyol obtained from trimethylolpropane, 3-methyl-1,5-pentanediol and adipic acid, and having an average number of functional groups of 2.5 to 3.5 and a number average molecular weight of 800 to 5,000.

Owner:NIPPON POLYURETHANE IND CO LTD

High-temperature abradable seal coating and preparation method thereof

InactiveCN108179371ASimple structureEase of mass productionMolten spray coatingWorking temperatureHardness

The invention provides a high-temperature abradable seal coating and a preparation method thereof. The MCrALY alloy powder is sprayed to the surface of a base body through a supersonic flame sprayingdevice to prepare a coating, multiple times of spraying are carried out on the surface of the base body, and the deposition thickness of the single spraying is smaller than or equal to 0.01mm; stressrelief and diffusion treatment are carried out on the sprayed coating with the thickness of 0.5-1.0mm by adopting vacuum heat treatment; and finally spraying is carried out to obtain a sealing coatingwith the thickness larger than or equal to 1.5mm. The sealing coating prepared by the preparation method has the advantages of oxidation resistance, high-temperature low hardness, abrasion resistance, high temperature stability, thermal shock resistance and high bonding strength, the working temperature can reach 1100 DEG C, the abrasion of a turbine rotor blade can be obviously reduced, the abrasion resistance and the reliability of the coating are improved, the service life of the coating is prolonged, the service life of the turbine rotor blade is obviously prolonged, the maintenance costof the engine is remarkably reduced, and the reliability of the engine is improved.

Owner:AECC AVIATION POWER CO LTD

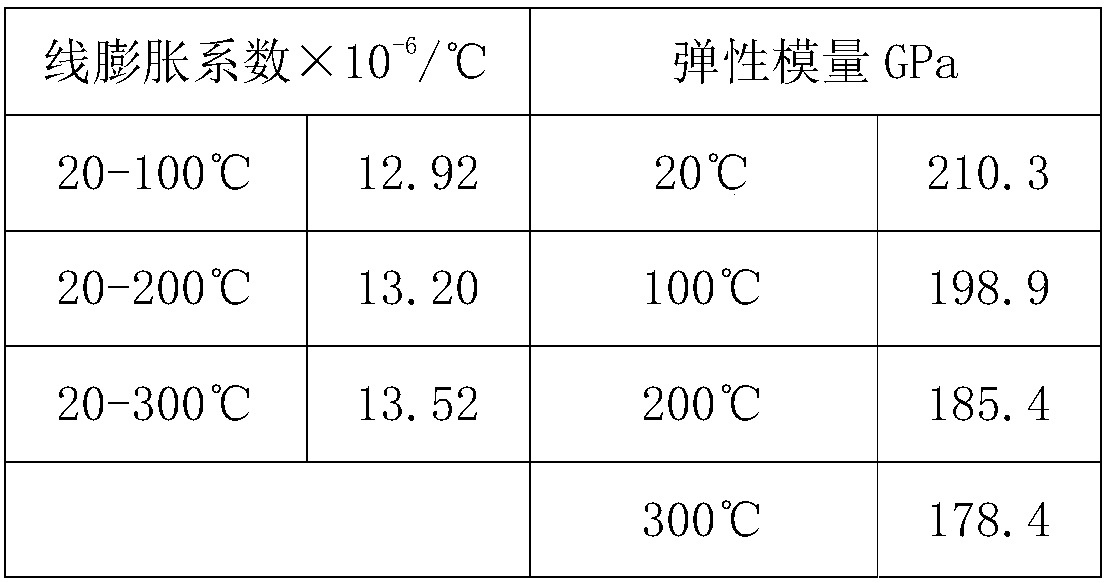

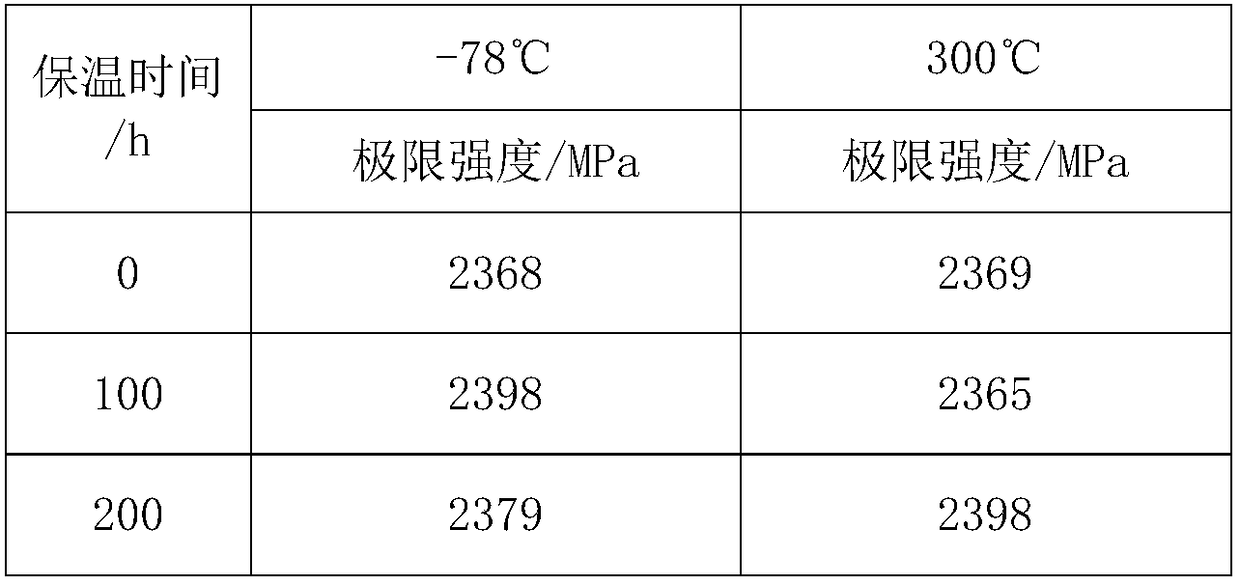

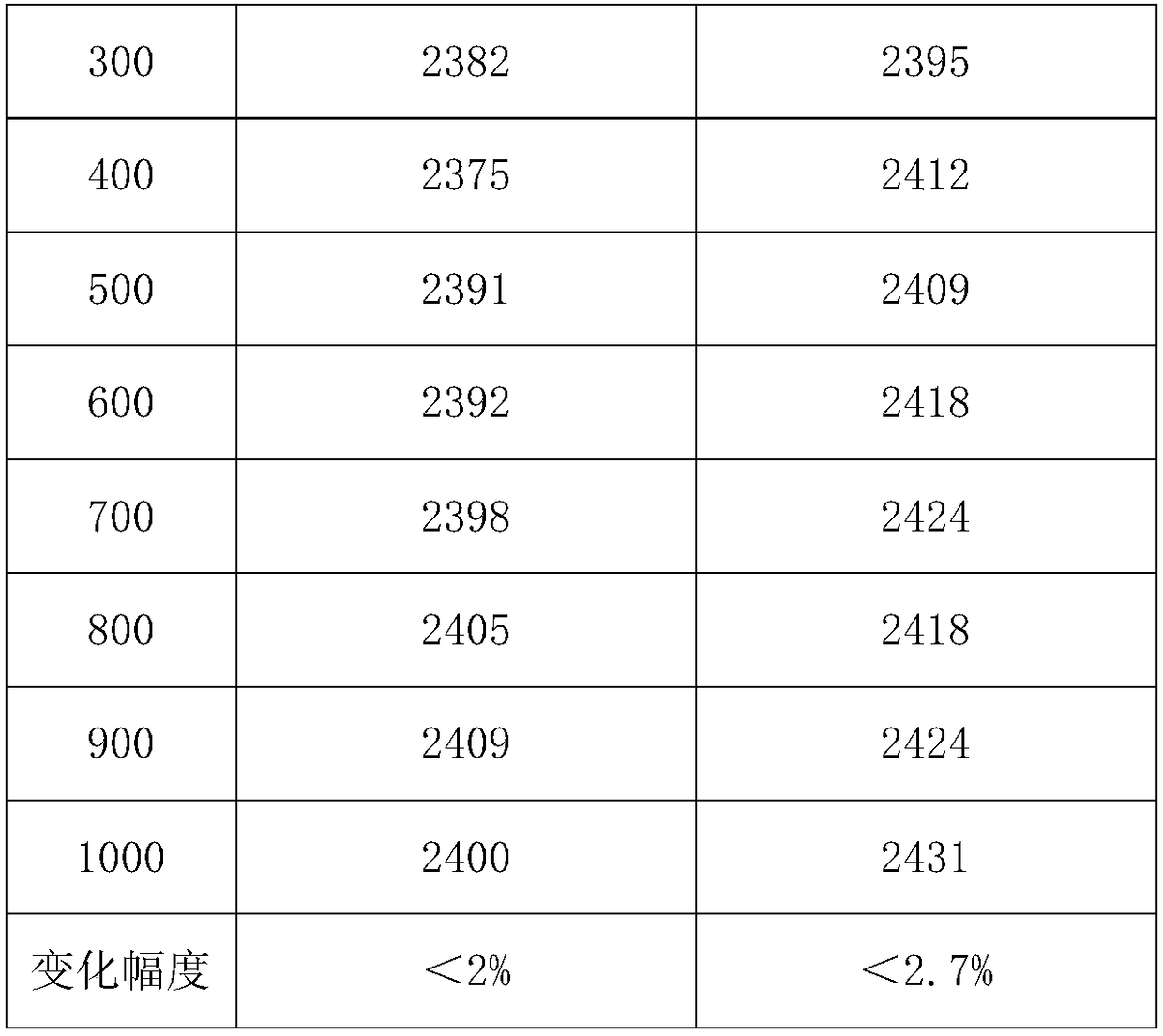

High-strength spring wire of high-elastic modulus and preparation method thereof

ActiveCN108193144ASimple preparation processLow costFurnace typesHeat treatment furnacesElastic modulusSelf consumption

The invention discloses a high-strength spring wire of a high-elastic modulus and a preparation method thereof, and belongs to the technical field of high-strength spring wire technologies. differentproportions are carried out through raw materials relatively and easily obtained, forging and hot rolling are carried out after vacuum smelting and self-consumption smelting, finished sizes are obtained through cold-drawing by different deformations and heat treatment process, and the spring after enwinding is subjected to heat treatment to obtain spring parts with excellent performance. The high-strength spring wire of the high-elastic modulus has the advantages that the operation is simple, the cost is low, the combination property is excellent, and the high-strength spring wire of the high-elastic modulus can be used for other spring parts with strict environmental requirements; and the preparation method is simple in operation, energy saving and environmental protection are achieved, and the preparation method is suitable for industrial mass production.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Ornaments or tag production process

InactiveCN1807091AImprove wear resistanceIncrease brightnessStampsSynthetic resin layered productsMetallic foilTectorial membrane

The invention relates the manufacturing technology used for ornaments and label, comprising the following steps: using the polychloroethylene or polyurethane film asbase material, spreading metallic foil on the base material, spreading protective film on the metallic foil, the base material, metallic foil and protective film composing the complex film, heat pressing and forming the complex film with high-frequency seal machine or ultrasonic seal machine. Due to adopt the polyethylene glycol terephthalate as protective film, the ornaments and label have the good abradability, high glossiness, good high temperature-resistant property and low temperature resistance, low hardness change and high tensile strength.

Owner:薛培荣

Chemical holding multilayer cladding compound protection method for fastener of transmission tower

ActiveCN104074281AImprove fastnessImprove anti-looseningNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementTransmission tower

The invention relates to fastening and anticorrosion technologies, in particular to a chemical holding multilayer cladding compound protection method applicable to a transmission tower with alternating loads in corrosion environment. Curing factice, non-curing factice, anti-corrosive tapes and adhesives are sequentially arranged on the surface of a protected structure. The curing factice is used for fastening and sealing the fastener, and the surface of a projected object to be coated needs to be subjected to treatment such as oil removal, rust removal and water removal. The non-curing factice is used for leveling a special-shaped structure; meanwhile, the curing factice is coated for building anaerobic environment; the chemical holding effect of the curing factice can be conveniently achieved; the alternating loads can be born; and the loosening is prevented. The adhesives are used for fast film forming; the adhesives and the anti-corrosive tapes are used for isolating the contact with corrosive media such as moisture and air in environment; the anticorrosion performance is good; and meanwhile, an effect of attractive appearance is achieved.

Owner:STATE GRID CORP OF CHINA +1

Rubber composition for outer tread and inflating tyre using said composition

InactiveCN1440883AImprove skid resistanceEasy to processSpecial tyresTyre tread bands/patternsPolymer scienceVolumetric Mass Density

A tread rubber composition improved both in grip performance on ice-covered and snow-covered road surfaces and in abrasion resistance is provided. The tread rubber composition contains aluminum hydroxide having an untamped density of not more than 0.60 g / cm<3>, a DOP oil absorption of at least 70 cm<3> / 100g and less than 250 cm<3> / 100g, and a BET specific surface area of at least 30 m<2> / g and not more than 350 m<2> / g in an amount of 5-60 parts by weight with respect to 100 parts by weight of a rubber component containing at least 50% by weight of at least one of polyisoprene rubber and polybutadiene rubber. The tread rubber composition has a tan delta peak temperature of not more than -45 DEG C and a type A durometer hardness at 0 DEG C of not more than 64.

Owner:SUMITOMO RUBBER IND LTD

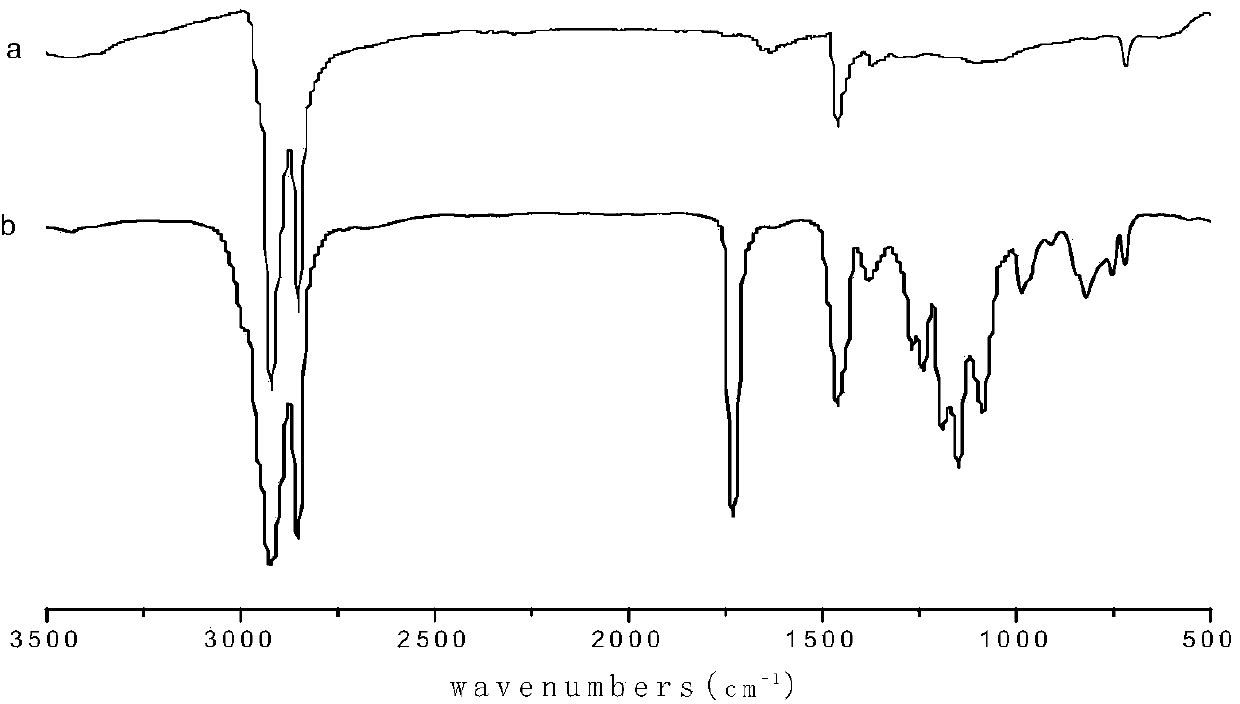

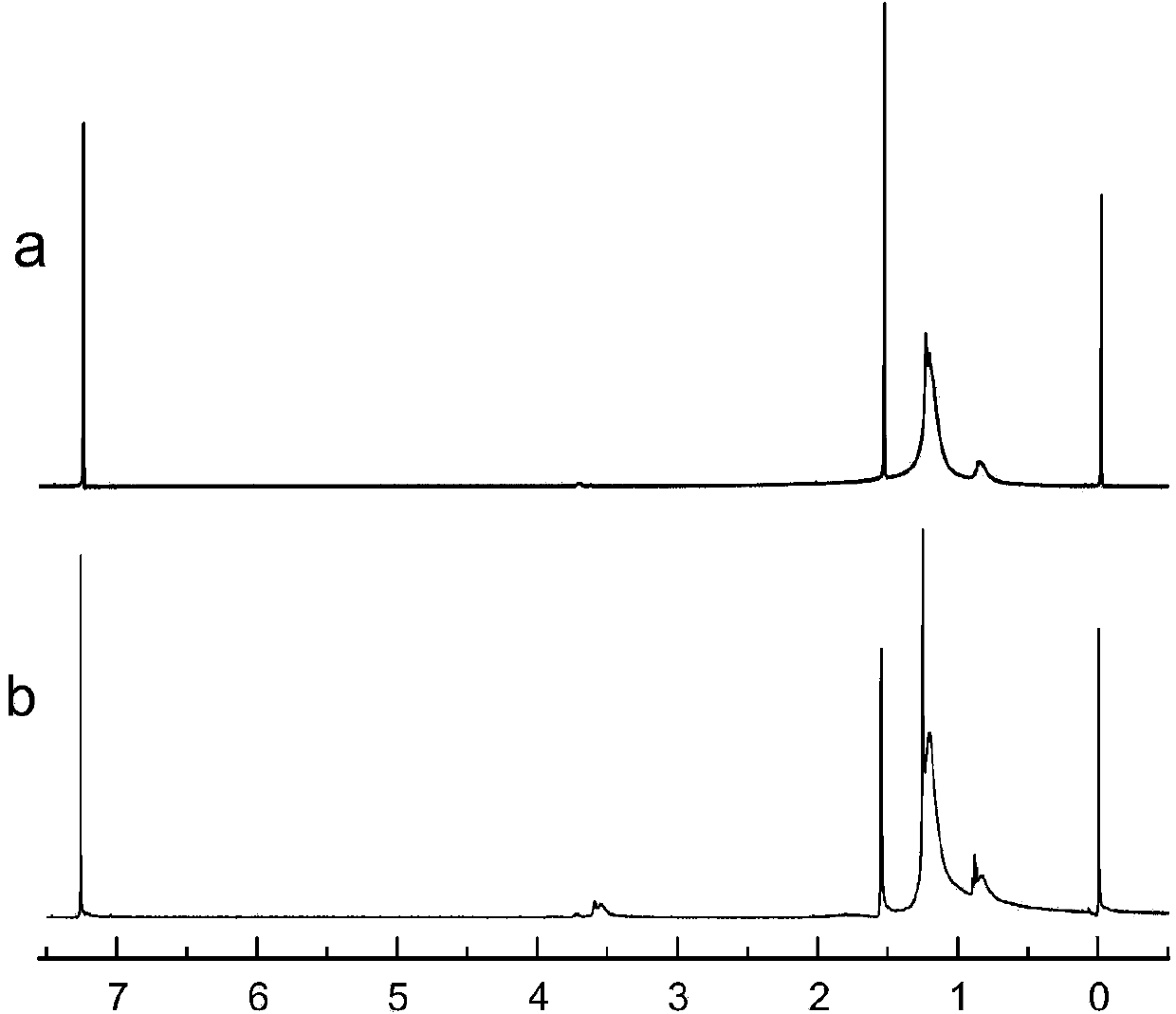

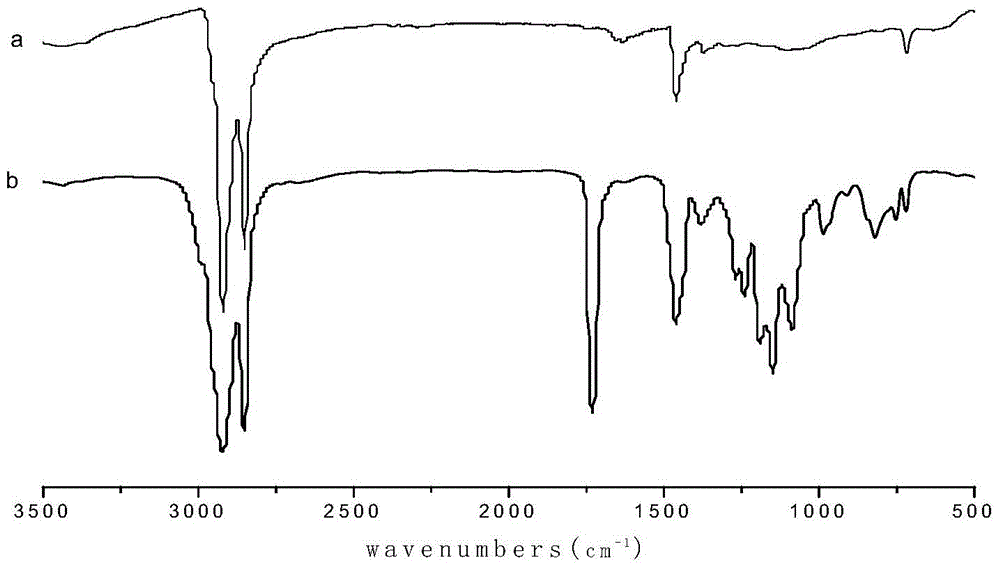

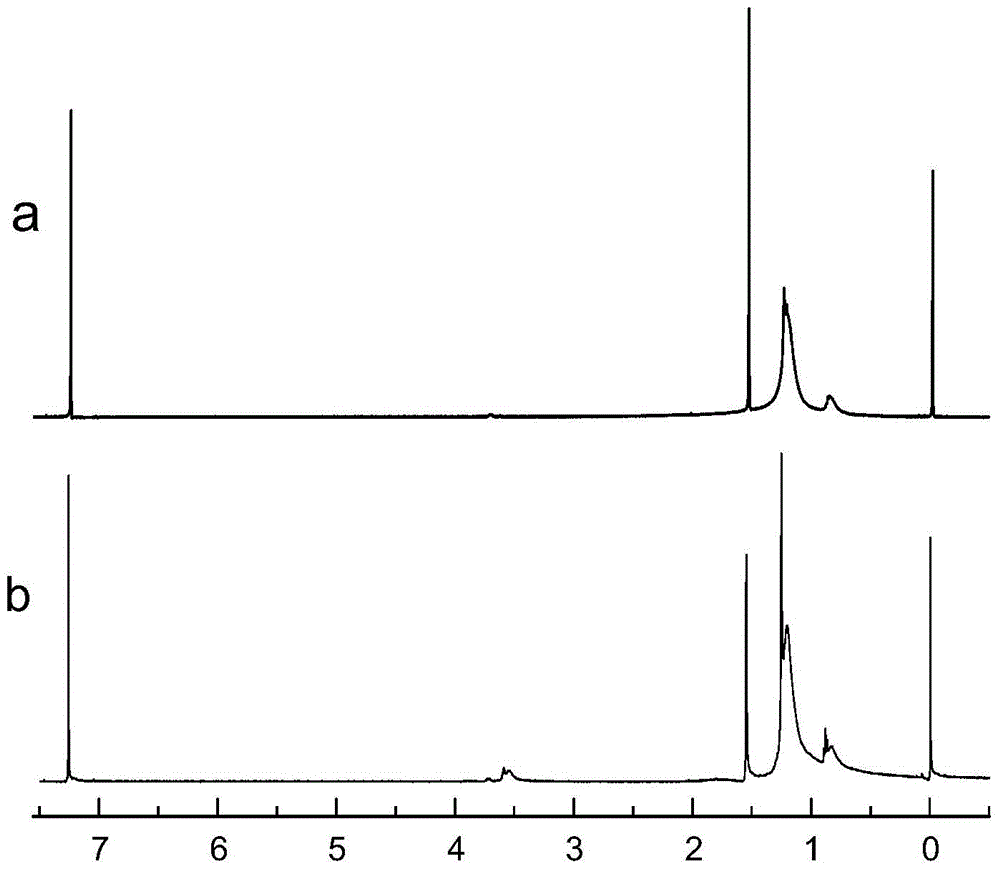

Preparation and application of macromolecular silane coupling agent used for ethylene propylene diene monomer rubber

The invention relates to preparation of a novel silane macromolecular coupling agent. The initiator benzoyl peroxide initiates graft polymerization reaction of ethylene propylene diene monomer rubber (EPDM), methyl methacrylate (MMA), and gamma-methacryloxy propyl trimethoxyl silane (KH-570). By controlling the reaction conditions, a series of macromolecular silane coupling agents with different grafting ratios can be prepared so as to reach the purpose of adjusting the strength and modulus of the system and realize control and optimization of the interface structure between an inorganic filler and a matrix material. The invention is conducive to optimizing design of macromolecular coupling agents, thus better improving the comprehensive properties of the composite material.

Owner:山东元禾新材料科技股份有限公司

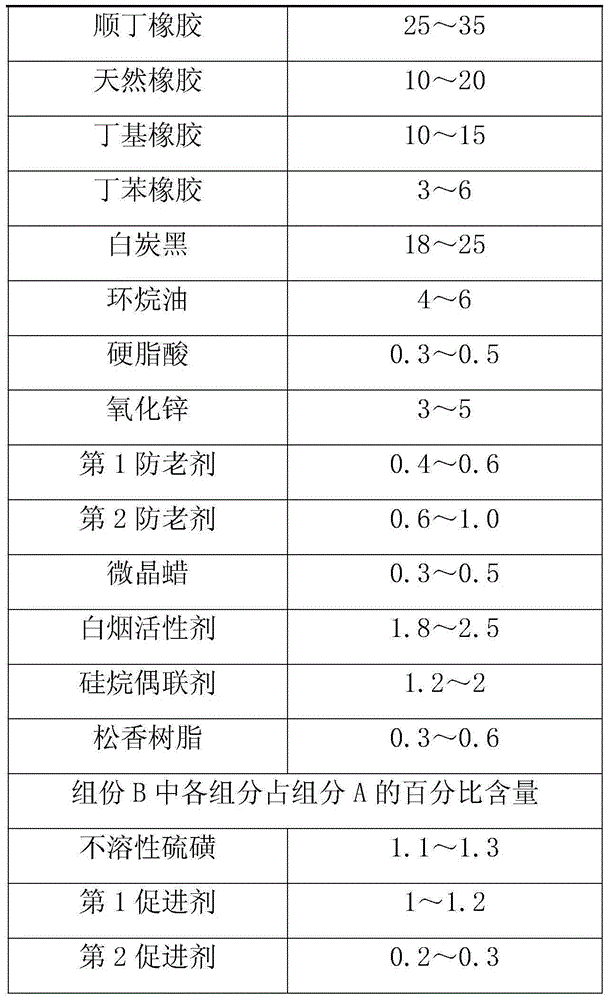

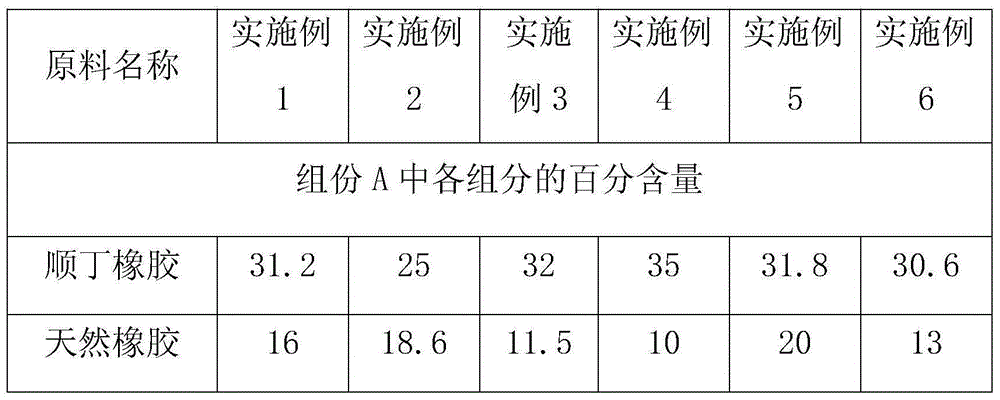

Cold-resistant non-slip rubber sports shoe material and manufacturing method thereof

InactiveCN104893027AAvoid the disadvantages of hardening and anti-slip declineImprove comfortFootwearVulcanizationMicrocrystalline wax

The invention discloses a cold-resistant non-slip rubber sports shoe material and a manufacturing method thereof. The cold-resistant non-slip rubber sports shoe material is made of raw materials comprising a composite A and a composite B, the composite A includes butadiene rubber, natural rubber, butyl rubber, butadiene styrene rubber, white carbon black, naphthenic oil, stearic acid, zinc oxide, a first antiager, a second antiager, microcrystalline wax, a white smoke surfactant, a silane coupling agent and rosin resin; the composite B includes insoluble sulfur, a first accelerator and a second accelerator. The invention further discloses a manufacturing method of the cold-resistant non-slip rubber sports shoe material. The method includes the steps of material weighing, closed mixing, open mixing, dosing, vulcanization curve measuring and hydraulic molding. The cold-resistant non-slip rubber sports shoe material has cold-resistance, weather-proof and non-slip performances.

Owner:XIAMEN MAITU NEW MATERIAL CO LTD

Suede simulation type superfine fiber synthetic leather and clean production method thereof

ActiveCN107177989AShorten the lengthReduce widthMechanical cleaningPressure cleaningProduction lineWater vapor permeability

The invention relates to suede simulation type superfine fiber synthetic leather and a clean production method thereof. The method comprises the steps of impregnating superfine fiber synthetic leather base cloth through an impregnating tank full of shrinking and kneading liquid, entering a continuous graining machine, drying the superfine fiber synthetic leather base cloth, and obtaining shrinking and kneading base cloth; adopting a flocking production line provided with PUR lattice roller coating equipment, coating PUR on the shrinking and kneading base cloth, sprinkling collagen fiber, adhering on the shrinking and kneading base cloth, cooling and winding, and placing to obtain flocking base cloth; adopting a brushing machine for removing the collagen fiber which is not firmly adhered onto the flocking base cloth, and obtaining the suede simulation type superfine fiber synthetic leather. According to the suede simulation type superfine fiber synthetic leather and the clean production method thereof provided by the invention, a shrinking and kneading technology is adopted, so that the softness, the air permeability and the water vapor permeability of the superfine fiber synthetic leather base cloth are greatly improved; a PUR lattice roller coating composite technology is adopted, so that the collagen fiber is compounded onto the superfine fiber synthetic leather base cloth, and the suede simulation type superfine fiber synthetic leather with the appearance being similar to the appearance of natural suede leather, and the mechanical property and the hygiene property being superior to the mechanical property and the hygiene property of the natural suede leather is obtained.

Owner:JIANGSU KEMEI NEW MATERIALS

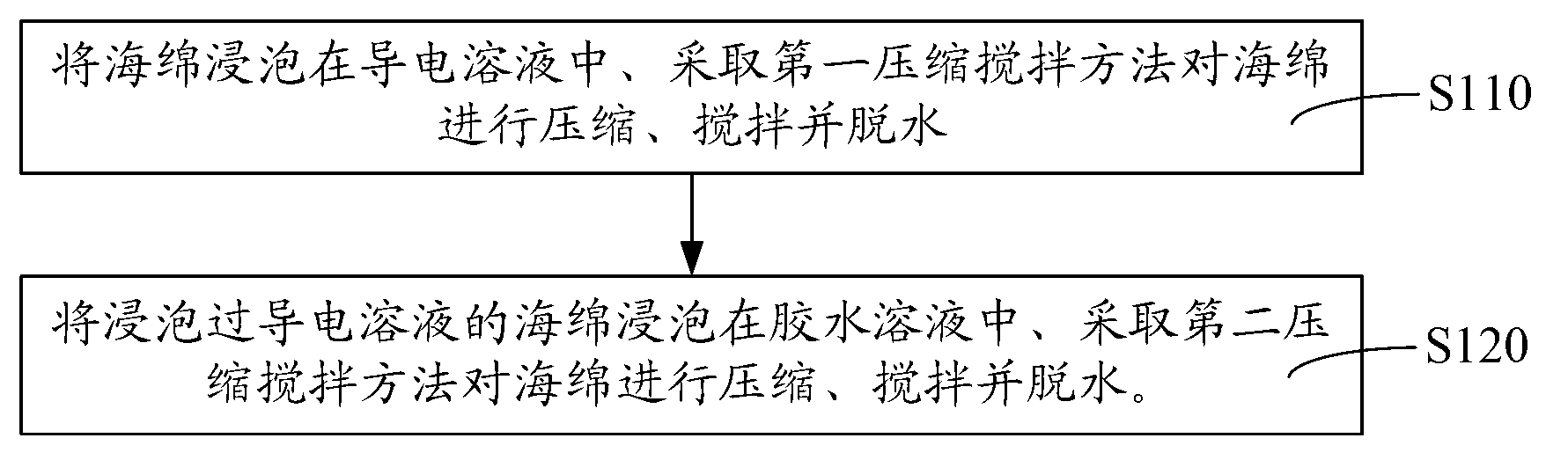

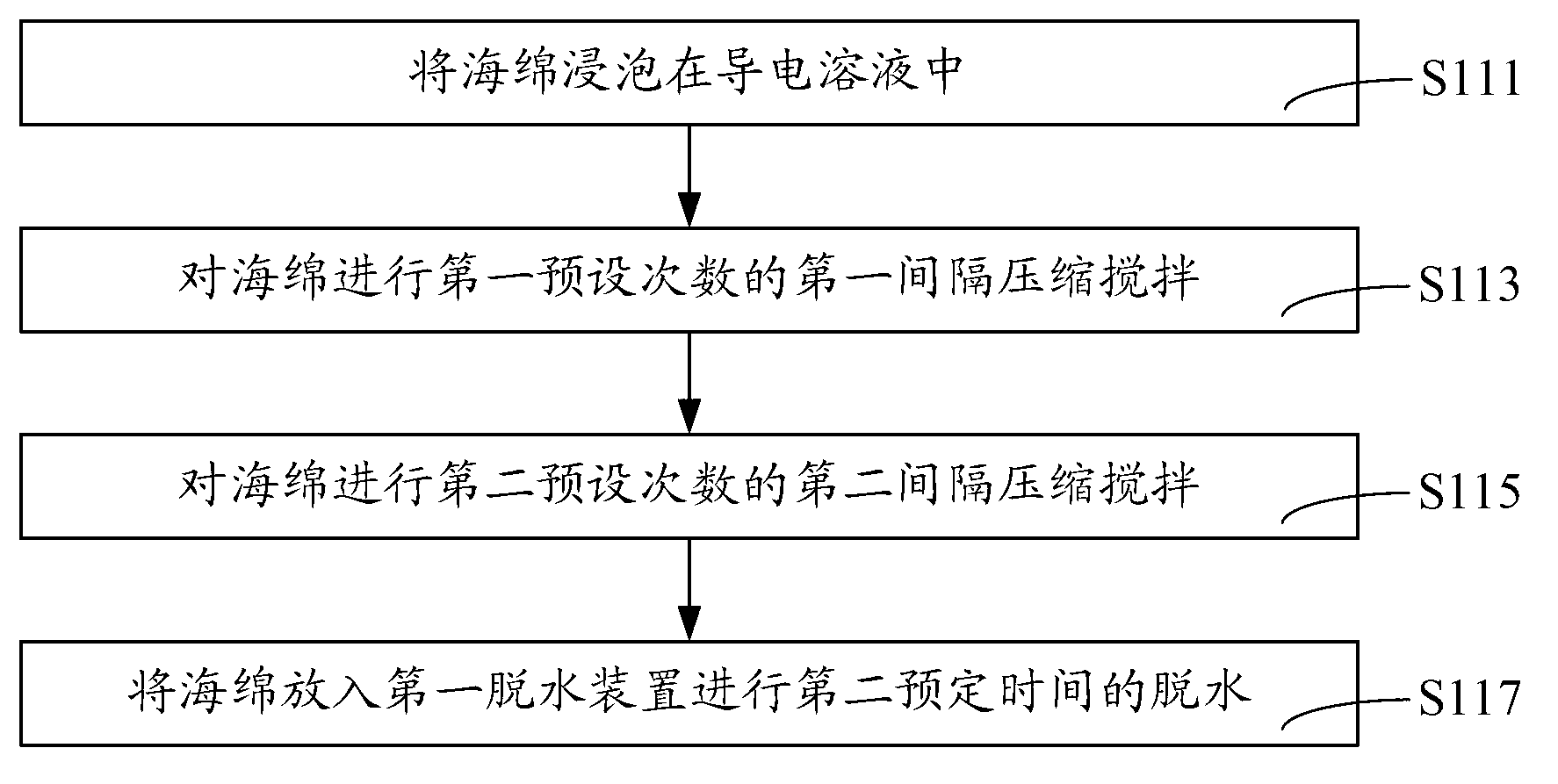

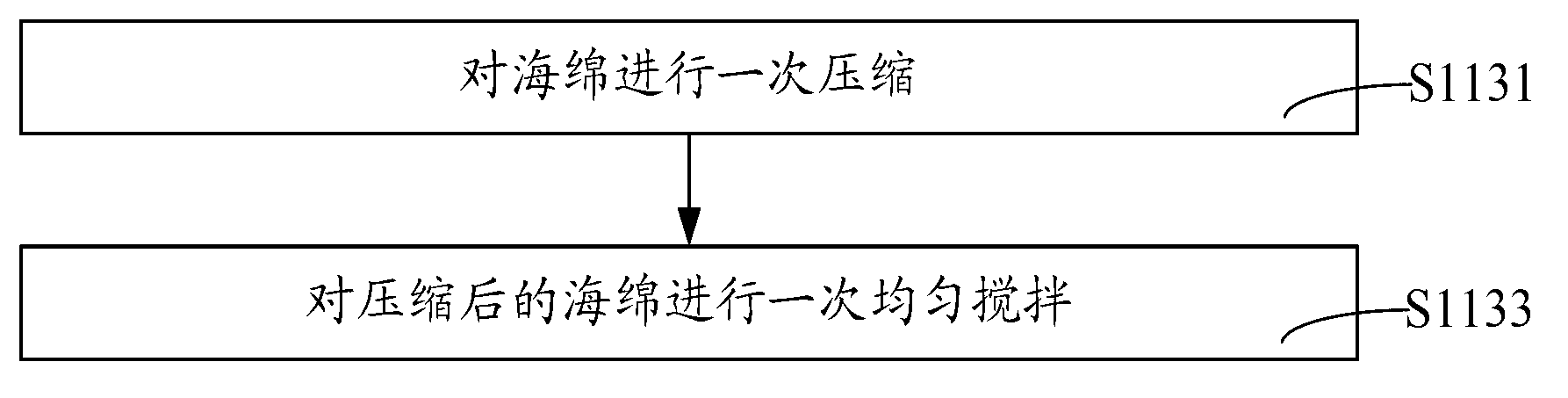

Preparation method of conductive sponge

ActiveCN103172900AReduce surface resistanceUniform volume resistance distributionHardnessNanotechnology

The invention discloses a preparation method of a conductive sponge. The preparation method has the beneficial effects that the sponge is compressed and stirred in conducting solution and glue solution respectively by adopting different compression and stirring methods in the preparation process of the conductive sponge, so that the prepared conductive sponge better adsorbs conductive particles and the glue better adheres to the conductive particles and the sponge, thus ensuring smaller surface resistance of the conductive sponge, more uniform distribution of volume resistance and smaller change of the hardness of the treated sponge.

Owner:中山市创怡兴实业有限公司

Oxidation polymerization type corrosion prevention method

The invention relates to a corrosion prevention technology, and in particular relates to an oxidation polymerization type corrosion prevention method which is suitable for iron and steel structures of electric power plants, stay cables of bridges, various storage tank edge plates, oil-gas pipelines, valves, flanges, H-section steel, spherical joints, screws, screw caps and mechanical equipment with various complex structures. According to the method, a corrosion prevention cream, a filling material and a corrosion prevention belt are arranged on the surface of a protected steel body in sequence, and then an adhesive is brushed on the outer surface layer of the corrosion prevention belt; the corrosion prevention cream can be used for filling corrosion hole parts, and can be used for construction with rust and original coatings, namely the surface of a protected object which is coated can be simply treated, so that the labor cost is saved, and the construction efficiency is high. The filling material is used at shaped parts of flanges, valves, storage tanks, spherical joints, screws, screw caps and the like, and is convenient in molding. The chemical compounds soaked on the corrosion prevention belt have good adhesive force, can obstruct the contact between metals and corrosive media including water, air and the like, and has good corrosion prevention performance; the corrosion prevention belt has good flexibility and structural displacement tracing ability and can be closely matched with the protected article.

Owner:侯保荣 +1

Polyester tangential belt with long service life, and manufacturing method thereof

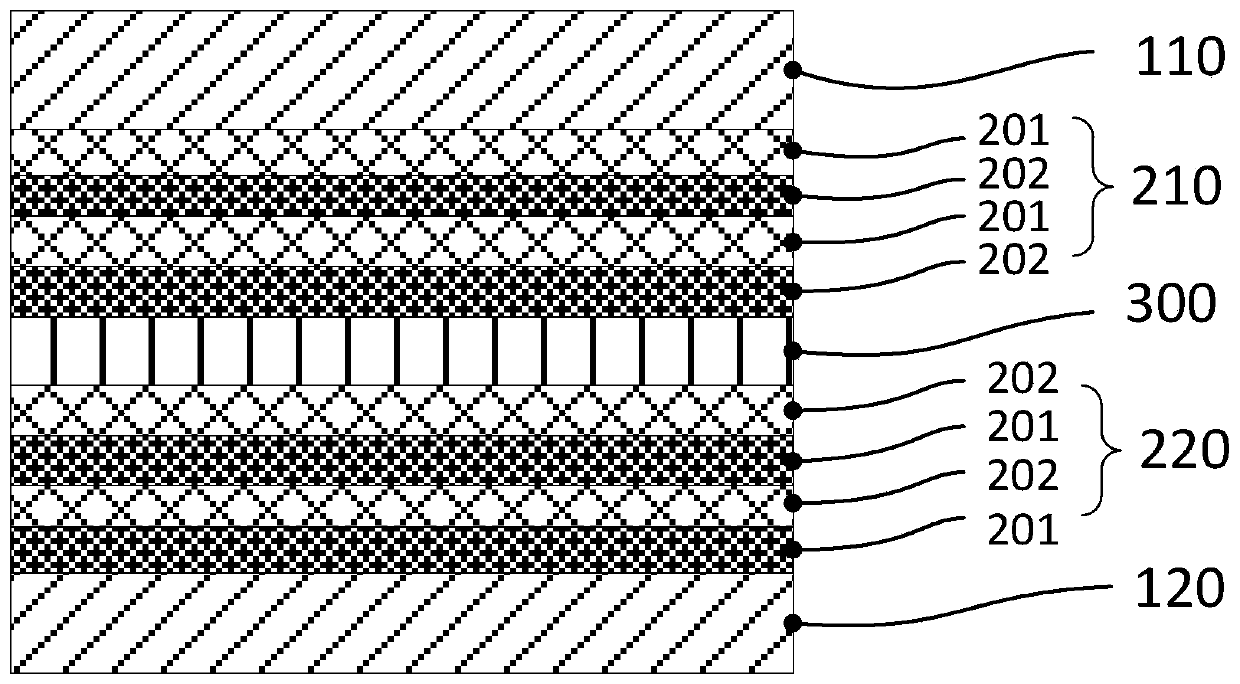

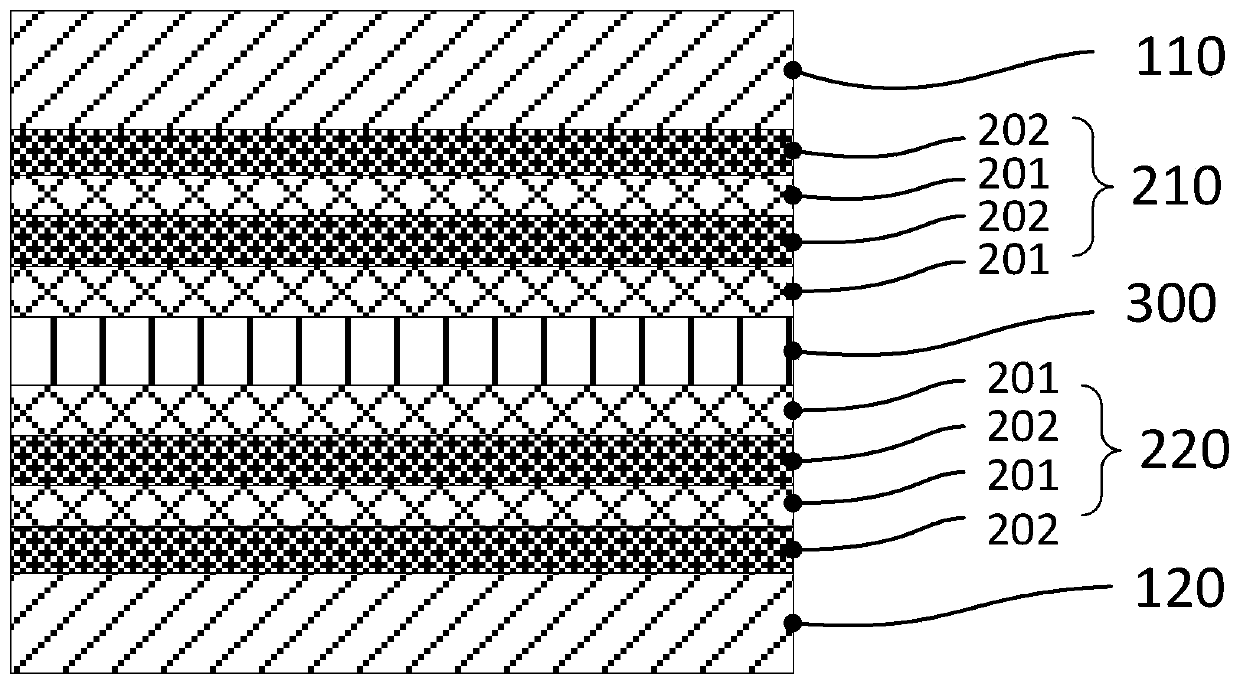

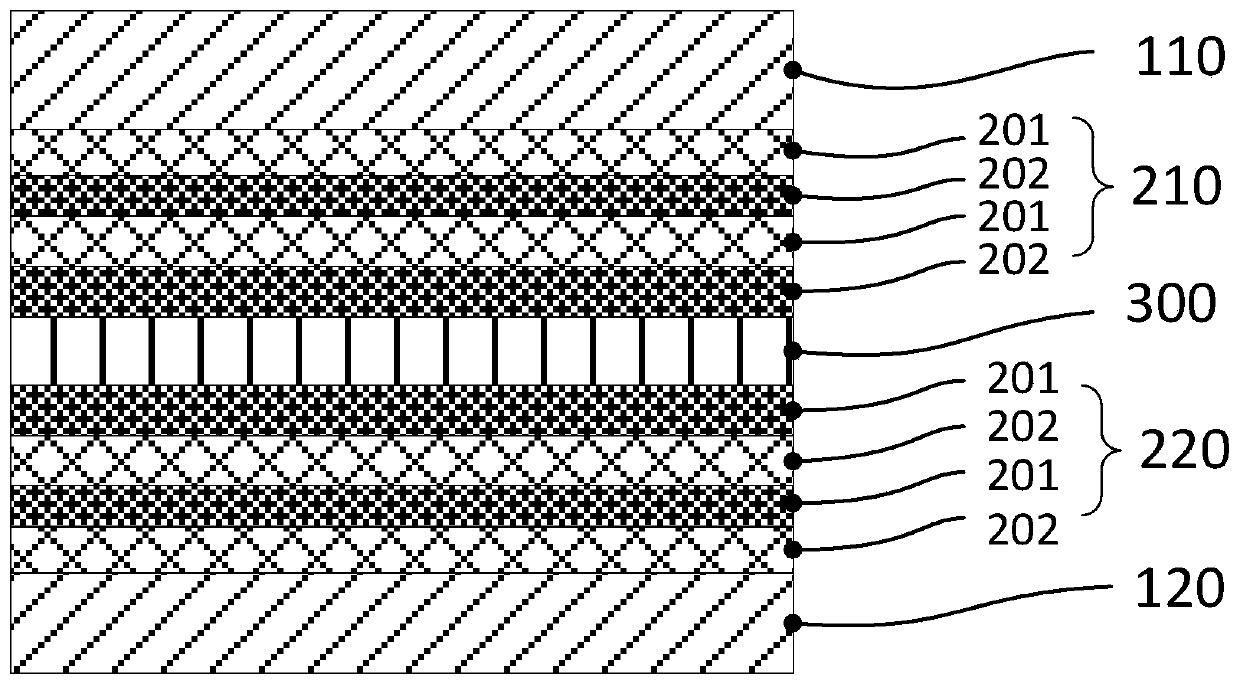

PendingCN109968764AChange a single structureHigh strengthConveyorsSynthetic resin layered productsPolyesterEngineering

The invention discloses a polyester tangential belt having a long service life, and a manufacturing method thereof. The polyester tangential belt comprises an upper rubber transmission layer, an upperbuffer layer, a skeleton layer, a lower buffer layer and a lower rubber friction layer which are sequentially adhered from top to bottom, the upper buffer layer includes at least one set of a first elastomer layer and a second elastomer layer which are sequentially adhered from top to bottom, or at least one set of the second elastomer layer and the first elastomer layer which are sequentially adhered from top to bottom; the lower buffer layer includes at least one set of the first elastomer layer and the second elastomer layer which are sequentially adhered from top to bottom, or at least one set of the second elastomer layer and the first elastomer layer which are sequentially adhered from top to bottom; and the first elastomer layer is a TPU sheet layer having a hardness of 95A, and the second elastomer layer is a TPU sheet layer having a hardness of 85A. The single structure of every buffer layer is changed, and the TPU sheets with different hardness values and different thicknesses are compounded, so the strength at the joint is increased, and the purpose of prolonging the service life is achieved.

Owner:江阴市斯强传动科技有限公司

High-temperature-resistant abrasion-resistant macromolecule shock-absorption rubber for vehicles, preparation method of high-temperature-resistant abrasion-resistant macromolecule shock-absorption rubber, and preparation method of automobile exhaust pipe lug

ActiveCN109054200AImprove high temperature resistanceReduce manufacturing costMicrocrystalline waxVulcanization

The invention discloses high-temperature-resistant abrasion-resistant macromolecule shock-absorption rubber for vehicles, a preparation method of the high-temperature-resistant abrasion-resistant macromolecule shock-absorption rubber, and a preparation method of an automobile exhaust pipe lug. The preparation method of the high-temperature-resistant abrasion-resistant macromolecule shock-absorption rubber comprises the following steps of conveying the following components in parts by mass of 60-70 parts of ethylene propylene diene monomer and 30-40 parts of silica gel into a banbury mixer, andperforming stirring and mixing; then adding 5-20 parts of zinc oxide, 1-3 parts of stearic acid, 0.1-0.5 part of essence, 3-8 parts of an abrasion-resistant agent, 1-4 parts of microcrystalline wax,0.2-1 part of an antioxidant, 2-4 parts of a common flow dispersing agent and 1-5 parts of Coumarone-indene resin, and then performing plastication for 50-70s; and then adding 30-50 parts of carbon black N550, 20-60 parts of carbon black N330 and 2-5 parts of paraffin oil, performing banbury warming, rubber discharging, roll mixing and cooling, then pouring milled glue into a banbury mixer, performing mixed warming, then adding 1-3 parts of insoluble sulfur, 1-5 parts of a vulcanizing agent and 1-3 parts of an accelerant, performing warming milling, and then performing rubber discharging and roll mixing once again. The obtained shock-absorption rubber and a metallic framework are subjected to vulcanization and shaping in a mold, so that the automobile exhaust pipe lug is prepared.

Owner:CHANGCHUN SHIFA AUTOMOTIVE COMPONENTS CO LTD

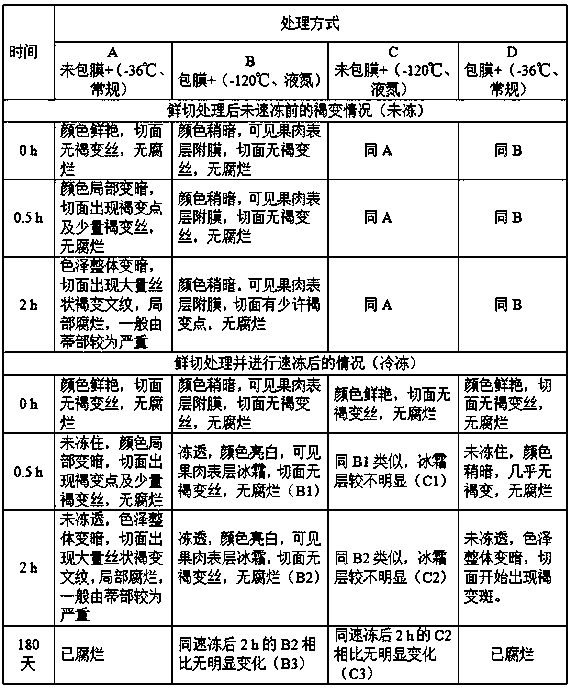

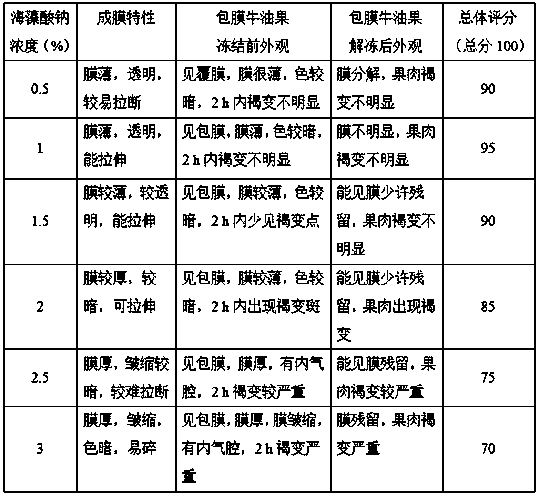

Preservation method of fresh-cut avocados based on film coating and liquid nitrogen quick-freezing

ActiveCN108522640ADelayed browningReduce mildewFood freezingFruit and vegetables preservationQuick FreezeFilm coating

The invention provides a preservation method of fresh-cut avocados based on film coating and liquid nitrogen quick-freezing. The method comprises the following steps: cleaning and disinfecting fresh avocados, and performing pit removing, peeling, dicing, color protection and film coating treatment; performing quick-freezing in a liquid nitrogen environment, wherein the quick-freezing temperature is -150 DEG C to -50 DEG C, the quick-freezing time is 5-30min and the heat insulation time is 2-30min; and then performing preserving in a condition not lower than -18 DEG C. The preservation method combines film coating treatment with the liquid nitrogen quick-freezing regulation and control technique, the preservation time of the quick-frozen avocados is as long as half a year, and the avocadosthawed at normal temperature have complete shapes, almost no brown stains and small variation in color and hardness. The preservation method maintains the nutrients, mouthfeel and flavor of the avocados, effectively prevents the avocados from browning, preserves the quality and freshness, prolongs the preservation time, is favorable for preparing avocado products with better mouthfeel, is safe, low-carbon and environmentally friendly and has broad application prospects.

Owner:SOUTH CHINA AGRI UNIV

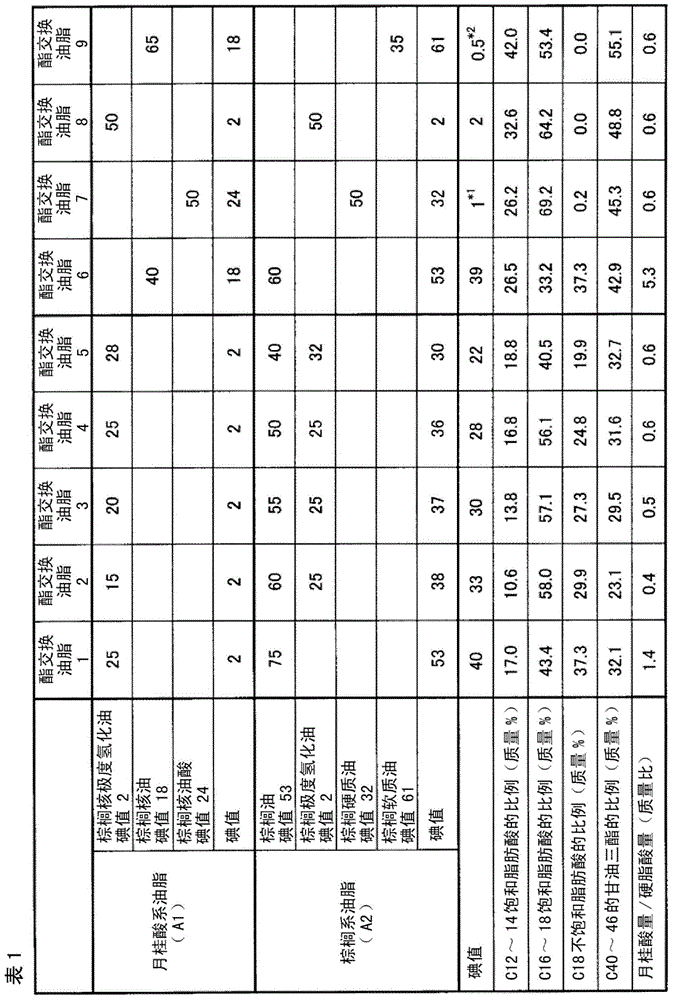

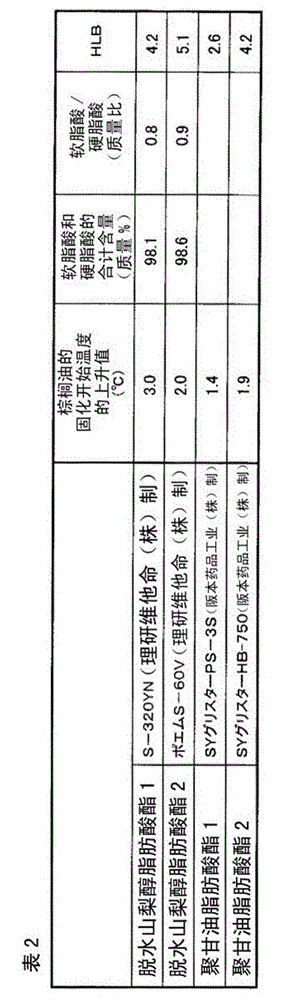

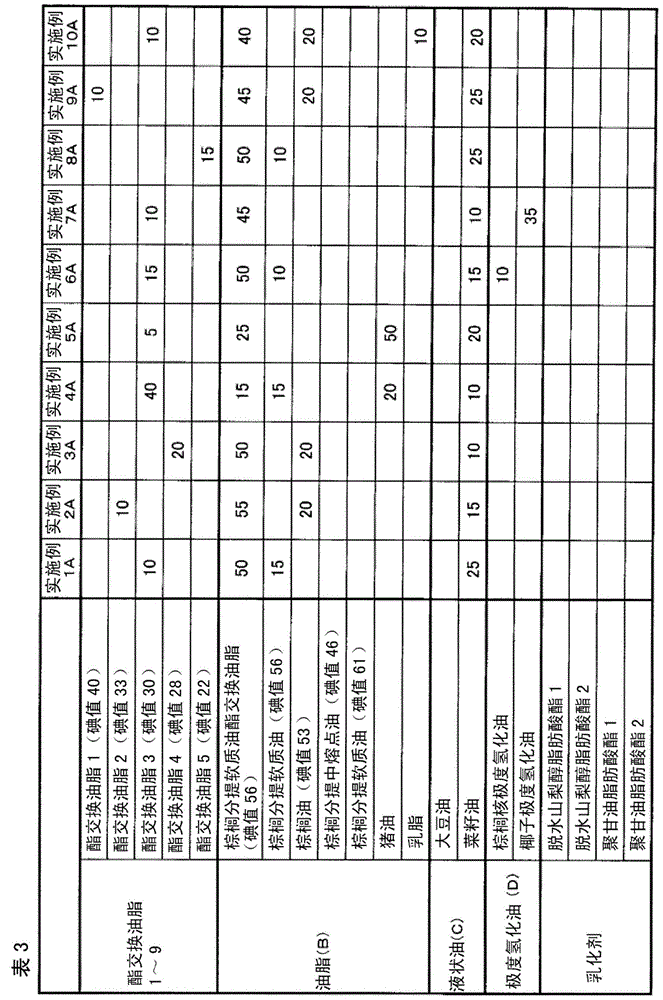

Oil/fat composition

ActiveCN105025728APromote exudationGood shape retentionEdible oils/fats with aqeous phaseOil and greaseCarbon number

Provided are an oil / fat composition for spreads, an oil / fat composition for butter cream, an oil / fat composition for kneading, and an oil / fat composition for layered food products, the oil / fat compositions being particularly improved in terms of shape retainability, change in hardness caused by long-term storage, and the seepage of liquid oil due to high temperature and / or the lapse of time, and also having satisfactory texture, flavor, and other required physical properties. This oil / fat composition includes a transesterified oil / fat (A) in which the contents of lauric oil / fat (A1) and palm oil / fat (A2) and the iodine value of the entire oil / fat are set within specific ranges. Further, in this oil / fat composition, the total percentage of disaturated triglycerides and trisaturated triglycerides, the mass ratio (SUS / SSU) between symmetrical triglycerides (SUS) and asymmetrical triglycerides (SSU) among disaturated triglycerides, the percentage of triglycerides in which the total carbon number of the constituent fatty acid is from 40 to 48, etc., are set within specific ranges.

Owner:MIYOSHI OIL & FAT

Coated transmission line net outdoor device and coating method thereof

ActiveCN105949890AEasy to fillGood adhesionFibre treatmentAnti-corrosive paintsGlass fiberEngineering

The invention provides a coated transmission line net outdoor device and a preparation method thereof. Directed at the special corrosion environment and corrosion factors of a transmission line net outdoor device, the invention adopts a comprehensive coating anticorrosion method, firstly an oxidative polymerization type anticorrosive paste is employed to form a first anticorrosive layer, then anticorrosion clay and an anticorrosion tape are used to cooperate with the first anticorrosive layer, the substances interpenetrate to form a second anticorrosive layer, and the two layers also compose a comprehensive anticorrosive structure. And the adopted anticorrosion tape, protective agent, winding non-woven fabric and resin, re-winding glass fiber product and roller coated resin form quadruple winding and multilayer comprehensive protection, the layers interpenetrate to form a another comprehensive stereo-network anticorrosion structure, thus giving full protection to a protected object-transmission line net outdoor device under a complex corrosion environment and corrosive factors, also the corrosion protection effect is good, and the anti-corrosion life is long.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

Molded foam article, foamed sole, and shoe

Owner:ASICS CORP

Preparation and application of a macromolecular silane coupling agent for EPDM rubber

The invention relates to preparation of a novel silane macromolecular coupling agent. The initiator benzoyl peroxide initiates graft polymerization reaction of ethylene propylene diene monomer rubber (EPDM), methyl methacrylate (MMA), and gamma-methacryloxy propyl trimethoxyl silane (KH-570). By controlling the reaction conditions, a series of macromolecular silane coupling agents with different grafting ratios can be prepared so as to reach the purpose of adjusting the strength and modulus of the system and realize control and optimization of the interface structure between an inorganic filler and a matrix material. The invention is conducive to optimizing design of macromolecular coupling agents, thus better improving the comprehensive properties of the composite material.

Owner:山东元禾新材料科技股份有限公司

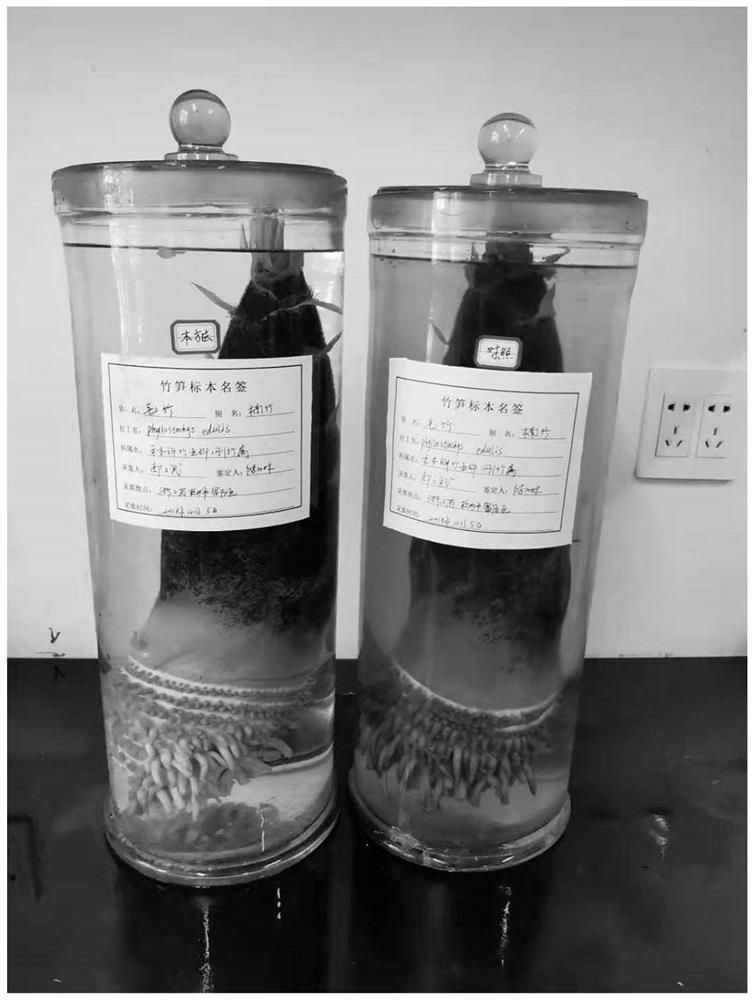

Preparation method of bamboo shoot infused specimen

ActiveCN113545339ANo turbidityObvious turbidityDead plant preservationClimate change adaptationAcetic acidSugar

The invention relates to the technical field of antiseptic preservation of plant materials and preparation of specimens, in particular to a preparation method of bamboo shoot specimens. According to the method disclosed by the invention, a mixed solution of glacial acetic acid, formalin and white granulated sugar is used as an infusion solution in the infusion process, and 45-55ml of glacial acetic acid, 15-25ml of formalin and 48-52g of white granulated sugar are added into every 1000ml of distilled water. The method has a very ideal preservation effect on the bamboo shoots, after long-time preservation, the bamboo shoot specimen preservation liquid is free of turbidity and extremely few in sediment, the bamboo shoot specimen is good in bamboo shoot body integrity, the sheath compactness and the bamboo shoot meat hardness change are not obvious, the distortion phenomenon is avoided, the problems of decoloration, sheath color gradual whitening and the like are avoided, and the fidelity effect is good.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

High-strength 7-series aluminum alloy for automobile anti-collision beam and automobile anti-collision beam

InactiveCN113388764AInhibition formationHigh hardnessExtrusion control devicesBumpersUltimate tensile strengthNatural aging

The invention discloses a high-strength 7-series aluminum alloy for an automobile anti-collision beam and the automobile anti-collision beam. The formation of ZnMg natural aging atomic clusters in the natural aging process of the 7-series aluminum alloy is effectively inhibited by adjusting aluminum bar alloy components and a heat treatment process. Natural aging clusters can hinder dislocation movement to cause strength increase, and meanwhile, part of strengthening phases can be slowly separated out to cause strength increase; and therefore, through inhibition, the hardness of the 7-series aluminum alloy in the natural aging process can be increased very slowly, the natural aging speed of the 7-series aluminum alloy is reduced, the parking effect is reduced, the situation that the hardness of the material is rapidly increased before aging is avoided, and meanwhile it can be guaranteed that the material reaches enough strength after aging. The formula of the adjusted alloy comprises less than or equal to 0.05% of Si, less than or equal to 0.15% of Fe, 0.2%-0.3% of Cu, 0.15%-0.20% of Mn, 1.4%-1.5% of Mg, less than or equal to 0.05% of Cr, 6.0%-6.3% of Zn, 0.15%-0.20% of Zr, 0.10%-0.15% of Sn, 0.05%-0.10% of In, 0.01%-0.03% of Ti, less than or equal to 0.05% of single impurities, less than or equal to 0.15% of total impurities and the balance Al.

Owner:FOSHAN AOMEI ALUMINUM IND

Flexible polyurethane foam

A flexible polyurethane foam for a cushioning material, the flexible polyurethane foam comprising a polyol and an isocyanate as main components, and a fluoride surfactant as a cell regulator, wherein the fluoride surfactant has the structure of a perfluoroalkyl group, exhibits a foaming height of 3 mm or more in a toluene solution containing thereof in a concentration of 0.1% by mass or an aqueous ethanol solution in a concentration of 60% by mass five minutes after the toluene solution of the aqueous ethanol solution is stirred.

Owner:NHK SPRING CO LTD

Tire vulcanizing capsule

The invention relates to a tire vulcanizing capsule which comprises the following components: 98-102 pats of butyl rubber, 4.96-5.04 parts of zinc oxide, 0.9996-1.0004 parts of stearic acid, 7.35-7.65 parts of vulcanizing resin, 44.1-45.9 parts of N220 carbon black, 29.4-30.6 parts of N550 carbon black, 4.96-5.04 parts of castor oil and 0.735-0.765 parts of stabilizer, wherein the vulcanizing resin is the alkyl phenol formaldehyde resin, and the stabilizer is the stannous chloride. Compared with the prior art, tire vulcanizing capsule can be used for more times, has longer service life and achieves obvious effect of improving the tire quality. The resin used for preparing the tire vulcanizing capsule can be vulcanized rapidly, and the vulcanized rubber has good physical and mechanical properties and changes less in hardness after being aged. The stannous chloride serving as the stabilizer can ensure that the service life of the capsule used for vulcanizing can be prolonged by over 65%. The product has the advantages of temperature resistance, high strength, high elongation and low permanent deformation at break, thereby having long service life.

Owner:SHENGFENG DAMPENER WUXI CITY

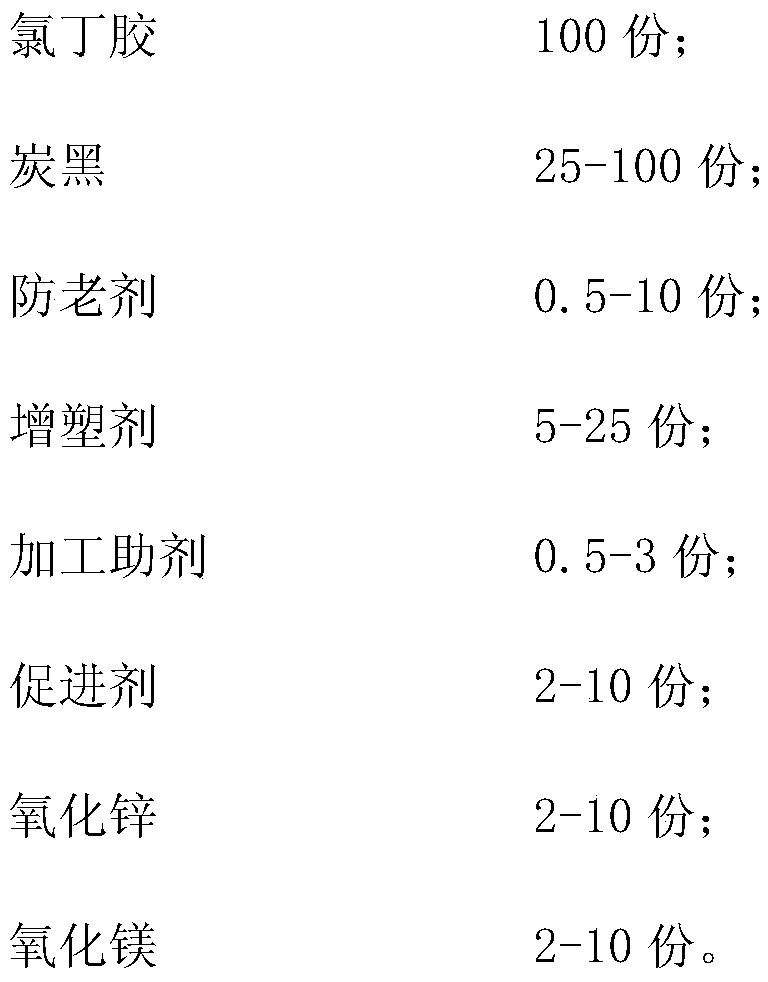

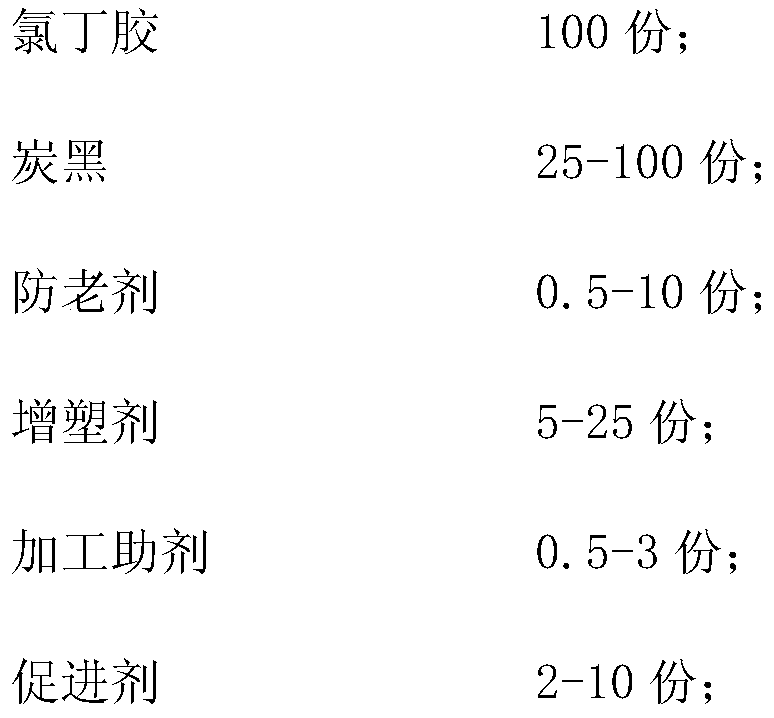

High-temperature-aging-resistant chloroprene rubber windshield wiper rubber strip and preparation method thereof

PendingCN111423642AImprove thermal stabilityImprove thermal characteristicsRubber materialPolymer science

The invention discloses a high-temperature-aging-resistant chloroprene rubber windshield wiper rubber strip and a preparation method thereof. The high-temperature-aging-resistant chloroprene rubber windshield wiper rubber strip comprises chloroprene rubber, carbon black, an anti-aging agent, a plasticizer, a processing aid, an accelerant, zinc oxide and magnesium oxide. The preparation method comprises the following steps: plastifying chloroprene rubber, pressurizing and banburying with the anti-aging agent and the plasticizer, adding carbon black, the processing aid and magnesium oxide, carrying out internal mixing, adding zinc oxide and the accelerant, carrying out internal mixing, discharging the rubber material when the temperature reaches 100-150 DEG C, carrying out re-mixing on an open mill for 3-6 minutes, pressing into a rubber sheet with an appropriate size by using a tablet press, standing for later use, putting the rubber sheet obtained in the step A into a special mold forthe windshield wiper rubber strip of a compression molding machine, molding for 3-10 minutes at the molding temperature of 150-180 DEG C to obtain a semi-finished product of the chloroprene rubber windshield wiper rubber strip, and performing post-treatment, cleaning, cutting, plasma treatment, spraying and other processes on the semi-finished windshield wiper rubber strip obtained in the step B to obtain the finished chloroprene rubber windshield wiper rubber strip.

Owner:JIANGSU YUNRUI AUTOMOBILE ELECTRIC SYST CO LTD

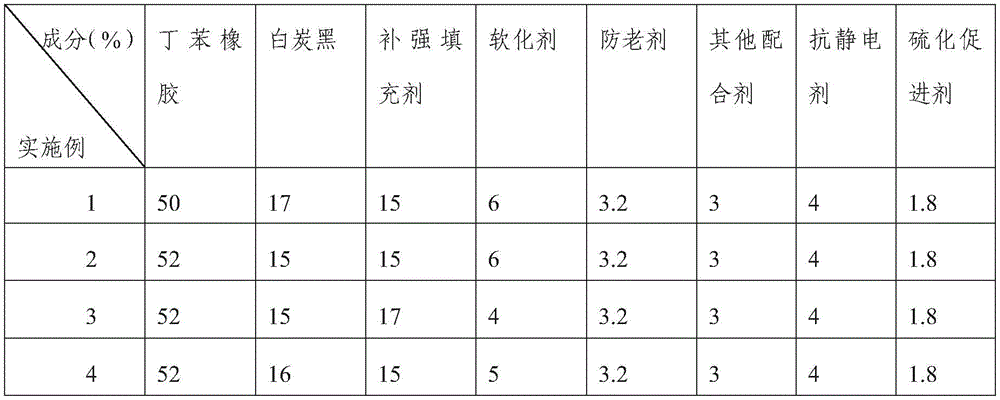

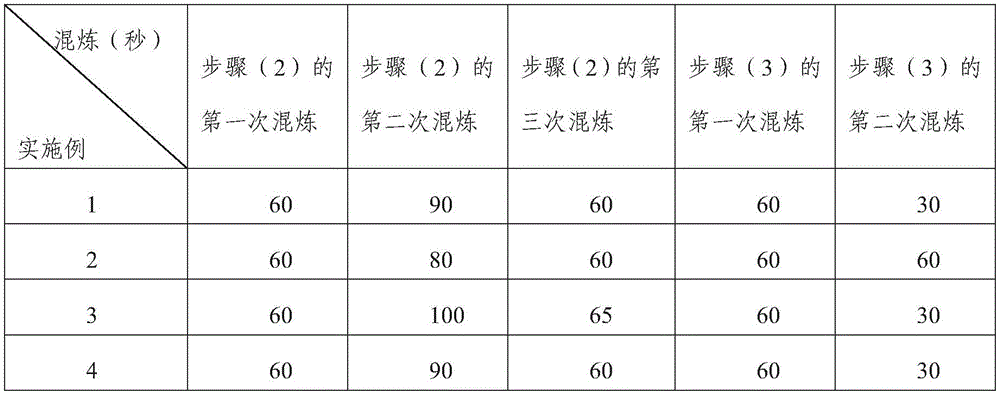

Special rubber compound for paper conveying rubber roll of printing paper and preparation method of special rubber compound

The invention discloses a special rubber compound for a paper conveying rubber roll of printing paper. The special rubber compound is prepared from the following components in percentage by weight: 46 percent to 55 percent of butadiene styrene rubber, 15 percent to 20 percent of white carbon black, 15 percent to 20 percent of reinforcing fillers, 4 percent to 9 percent of a softening agent, 2 percent to 5 percent of other compounding ingredients, 2 percent to 5 percent of an anti-ageing agent, 1.5 percent to 2.3 percent of a vulcanizing accelerator and 2 percent to 5 percent of an antistatic agent. The special rubber compound disclosed by the invention has the advantages of good ozone-resisting performance, small rigidity changes, high tensile strength, easiness of machining, good wearing resistance, antistatic property and stability, excellent comprehensive performances and low cost, and can meet the use requirements of current paper conveying rubber rolls of a printer.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

Printing ink for NFC antenna

The invention relates to printing ink for an NFC antenna. A preparation method of the printing ink comprises the following steps: firstly dissolving solid saturated polyester resin in liquid with a solvent; adding liquid unsaturated polyester resin and a dispersing agent in the solid saturated polyester resin liquid, and dispersing, so that dispersion liquid is obtained; adding carbon black to thedispersion liquid, and dispersing and uniformly stirring, so that a mixture is obtained; grinding a mixture dispersoid; taking out, adding extinction powder, PE wax liquor and polytetrafluoroethylenepowder, dispersing, and uniformly stirring; taking out, and grinding; and then adding a defoaming agent and a leveling agent, and dispersing, so that the printing ink used for the NFC antenna is obtained. The printing ink for the NFC antenna is simple in structure, harmony of all the components is good, and odor is small, thereby being more environment-friendly; and after the printing ink forms afilm, toughness of an ink layer is good, buckling performance is excellent, the system has good chemical properties, hardness of the ink layer is not obviously changed before and after test, viscosity of the printing ink is applicable to screen printing, and storability is good.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com