Synthetic method of slow resilience foam polyether polyol

A polyether polyol and a synthesis method technology, applied in the chemical industry, can solve the problems of low resilience, volatilization, inability to fully suppress temperature changes and hardness changes, and achieve the effects of small hardness changes and easy technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

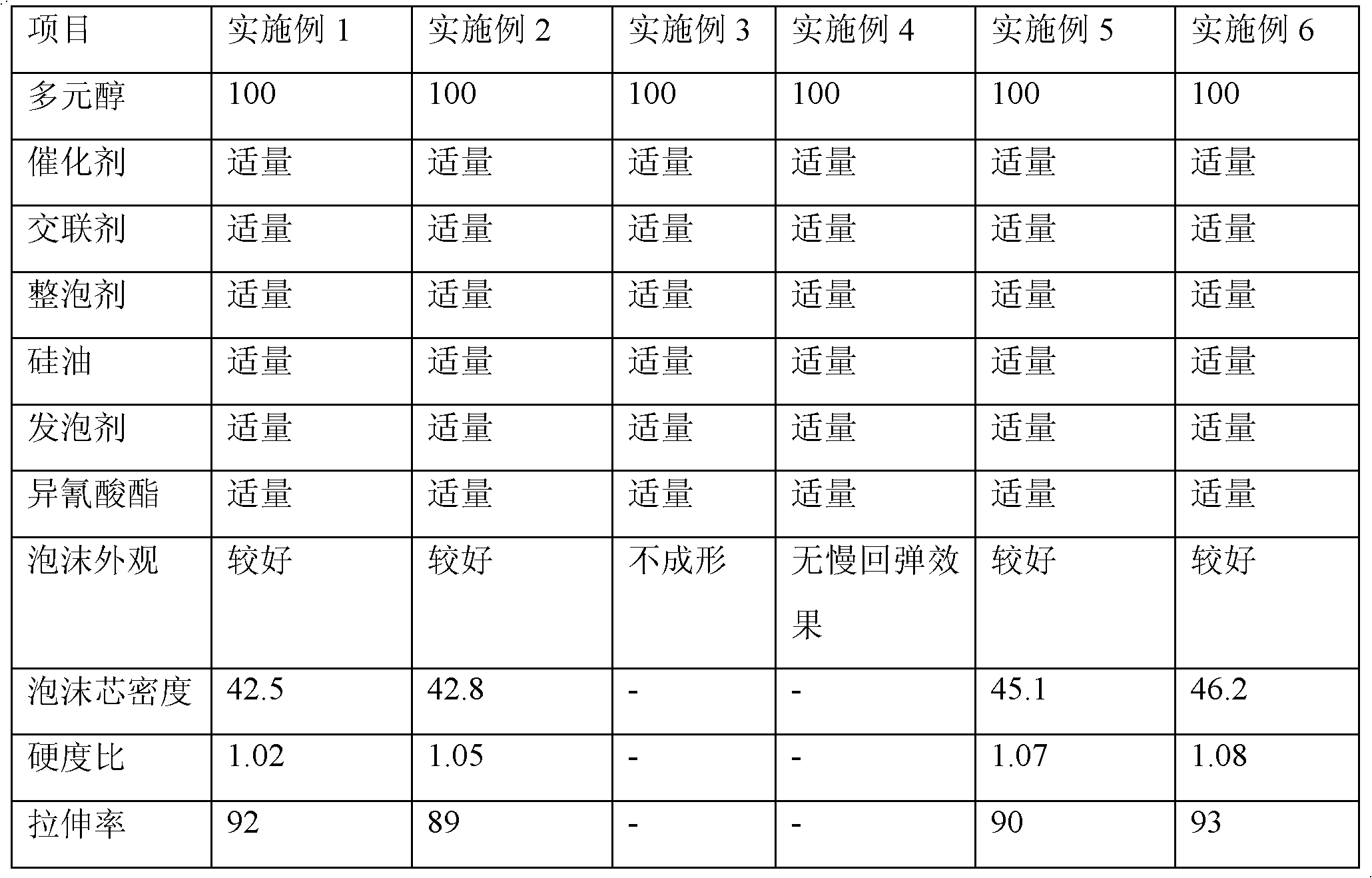

Examples

Embodiment 1

[0018] Add 82g of glycerin into a 5-liter stainless steel kettle for nitrogen replacement. After the oxygen content in the kettle is measured to be less than 100ppm, vacuumize to -0.098Mpa, draw in 12g of potassium hydroxide in a sealed manner, raise the temperature to 80°C, and start adding propylene oxide and ring Ethylene oxide, keep the temperature in the kettle at 50-60°C, and the pressure at 0-0.1Mpa, continuously add 3428g propylene oxide and 490g ethylene oxide, after the feeding is completed, react under internal pressure for 2 hours, and vacuum remove the unreacted Propylene oxide and ethylene oxide monomers, add 24g of phosphoric acid to neutralize, then use the Buchner funnel to filter the material, re-add the obtained filtrate in the reactor, and add 200g of deionized water and 8g of magnesium silicate to carry out Stir, then vacuum dehydrate for 2 hours, keep the temperature in the kettle at 103-107°C, then use a Buchner funnel to filter the material again, add th...

Embodiment 2

[0020] Add 40g glycerin and 42g diethylene glycol in a 5-liter stainless steel kettle, and carry out nitrogen replacement. After the oxygen content in the kettle is less than 100ppm, vacuumize to -0.098Mpa, and airtightly suck in 8g potassium hydroxide and 4g sodium ethylate, and heat up to 80°C, start to add propylene oxide and ethylene oxide, keep the temperature in the kettle at 70-80°C, and the pressure 0.1-0.2Mpa, continuously add 3428g propylene oxide and 490g ethylene oxide, after the feeding is completed, the internal pressure reaction For 2 hours, the unreacted propylene oxide and ethylene oxide monomers were removed in a vacuum, 24g of phosphoric acid was added for neutralization, and then the material was filtered using a Buchner funnel, and the obtained filtrate was re-added to the reactor, and added Stir 200g deionized water and 8g magnesium silicate, then vacuum dehydrate for 2 hours, keep the temperature in the kettle at 103-107°C, then filter the material again ...

Embodiment 3

[0022] Add 31g of propylene glycol and 20g of ethylene glycol into a 5-liter stainless steel kettle, and carry out nitrogen replacement. After the oxygen content in the kettle is less than 100ppm, vacuumize to -0.098Mpa, draw in 6g of potassium hydroxide and 6g of sodium methoxide, and heat up to 80 ℃, start to add propylene oxide and ethylene oxide, keep the temperature in the kettle 80-90 ℃, pressure 0.2-0.3Mpa, continuously add 3456g propylene oxide and 494g ethylene oxide, after the feeding is completed, the internal pressure reaction 2 hour, vacuum removed the unreacted propylene oxide and ethylene oxide monomers, added 24g of phosphoric acid for neutralization, then used the Buchner funnel to filter the material, re-added the obtained filtrate to the reactor, and added 200g Stir with deionized water and 8g of magnesium silicate, then vacuum dehydrate for 2 hours, keep the temperature in the kettle at 103-107°C, then use a Buchner funnel to filter the material again, add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com