Wear resistant type thermoplastic polyurethane elastomer and preparation method thereof

A technology of thermoplastic polyurethane and elastomer, which is applied in the direction of mechanical equipment, pipes, hoses, etc., can solve the problems such as the influence, loss, and scrapping of hose coils in the reel space, and achieve improved anti-scratch performance, low cost, and The effect of improving the wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

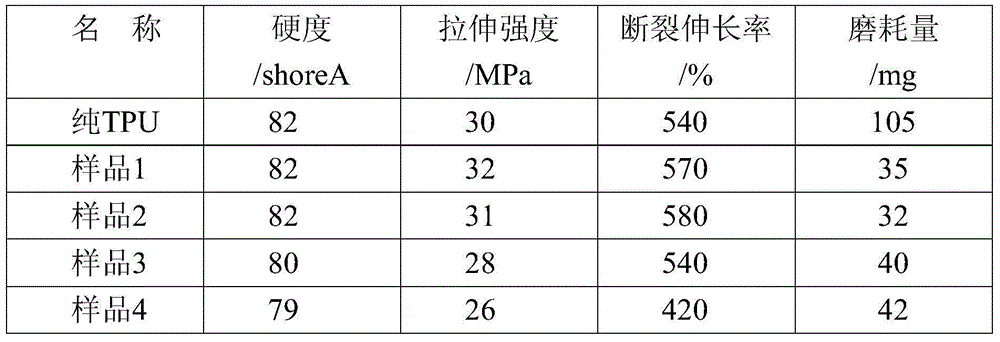

Embodiment 1

[0024] The wear-resistant thermoplastic polyurethane elastomer of the present invention is composed of the following mass percentages: thermoplastic polyurethane elastomer (TPU): 91.6%; EPDM: 5%; carbon black masterbatch: 3% ; Antioxidant: 0.2%; UV absorber: 0.2%. Among them, the density of EPDM is 0.88 g / cc (ASTM D 297), and the Mooney viscosity is 45 (ML 1+4125°C).

Embodiment 2

[0026] The wear-resistant thermoplastic polyurethane elastomer of the present invention is composed of the following mass percentages: Thermoplastic polyurethane elastomer (TPU): 87%; EPDM: 10%; carbon black masterbatch: 2.5% ; Antioxidant: 0.3%; UV absorber: 0.2%. Among them, the density of EPDM is 0.88 g / cc (ASTM D 297), and the Mooney viscosity is 45 (ML 1+4125°C).

Embodiment 3

[0028] The wear-resistant thermoplastic polyurethane elastomer of the present invention is composed of the following mass percentages: Thermoplastic polyurethane elastomer (TPU): 80.4%; EPDM: 15%; carbon black masterbatch: 4% ; Antioxidant: 0.4%; UV absorber: 0.2%. Among them, the density of EPDM is 0.88 g / cc (ASTM D 297), and the Mooney viscosity is 45 (ML 1+4125°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com