Patents

Literature

102results about How to "Simple surface treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

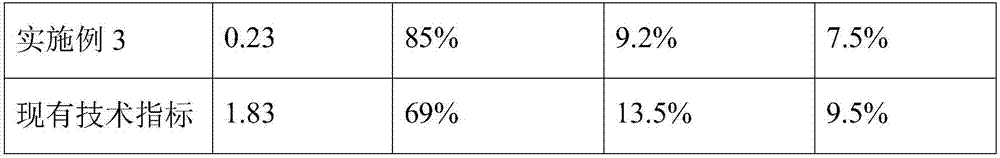

Method for preparing calcium sulphate crystal whisker from dolomite

InactiveCN101323974AHigh tensile strengthIncrease elasticityPolycrystalline material growthFrom normal temperature solutionsDolostoneNatural mineral

The invention discloses a method for preparing calcium sulphate crystal whiskers by dolostone, which takes the dolostone as a raw material, and prepares the calcium sulphate crystal whiskers through the steps of mineral acidification, microwave seed crystal synthesis and hydro-thermal crystal whisker synthesis, etc. The calcium sulphate crystal whiskers are a nemaline calcium sulphate crystal which has the slenderness ratio of 10 to 10000, the strength close to the theoretical strength of valence links between material atoms, and ultra-high tensile strength and elastic modulus; compared with other crystal whiskers, the calcium sulphate crystal whiskers further have the advantages of high temperature resistance, strong chemical corrosion resistance, good toughness, easier processing of surface modification, strong affinity with polymers and low toxicity, etc., and have wide application prospect in the fields of reinforced plastic, rubber, sizing agent, friction material and environmental engineering, etc. The method for preparing the calcium sulphate crystal whiskers disclosed by the invention uses the natural mineral of dolostone which has wide source and low price as the main raw material, has simple preparing process flow, less equipment investment and easier popularization.

Owner:ZHEJIANG UNIV

Flexible tapestry brick of external wall outer insulation system and production method thereof

The invention discloses a flexible decorated brick for exterior wall insulation system, mainly comprising main-body bricks or a composite surface coating of main-body bricks. The main-body brick formula contains major components of soil and acrylic emulsion, and further contains dispersant, softening agent, coloring agent, flame retardant, antifreeze and water according to different product performance requirements. The surface coating formula contains the main components of metal powder or a compound powder of more than two kinds of non-metallic powder or metal powder and acrylic emulsion and further contains dispersant, softening agent, coloring agent, flame retardant, antifreeze and water according to the needs of different product performances. The product of the invention is light-weighted, freeze-thaw resistance, anti-aging, high in bond strength, flexible and good in water-repellent and permeability, the pollution resistance of which is equivalent to that of polished tiles and the color of which is as rich as the paint and the appearance of which can be made into a decorative texture of metal curtain walls, stone walls, ceramic, wood, leather or cloth. Particularly, the inventive product has an excellent compatibility with the exterior insulation system, suitable for the decorated layer of the exterior insulation system. In addition, the inventive product avoids using the clay resource which is in shortage as the main production raw material and is a low-cost, environment-friendly flexible decorated material with high performance for exterior wall insulation system.

Owner:石磊

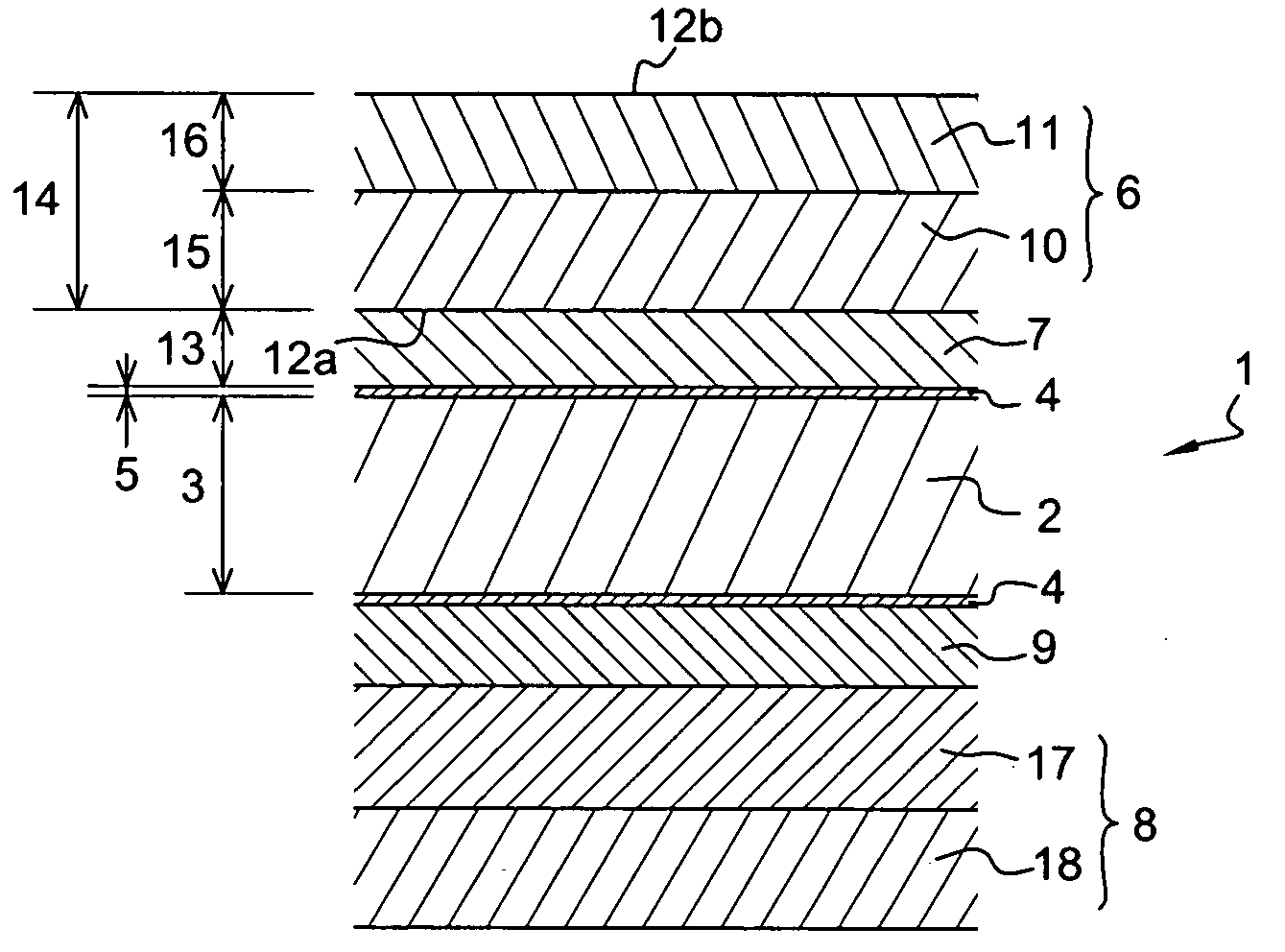

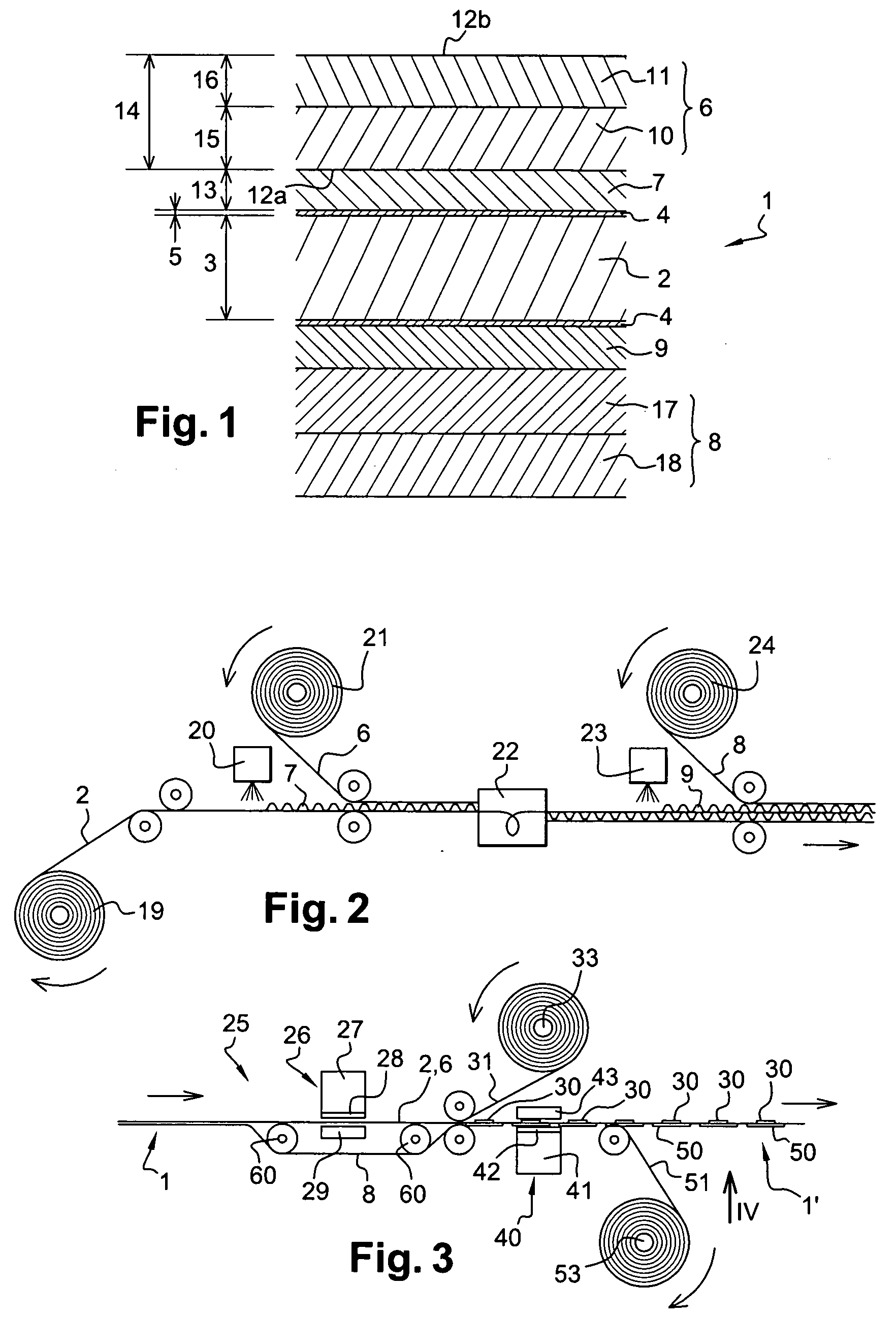

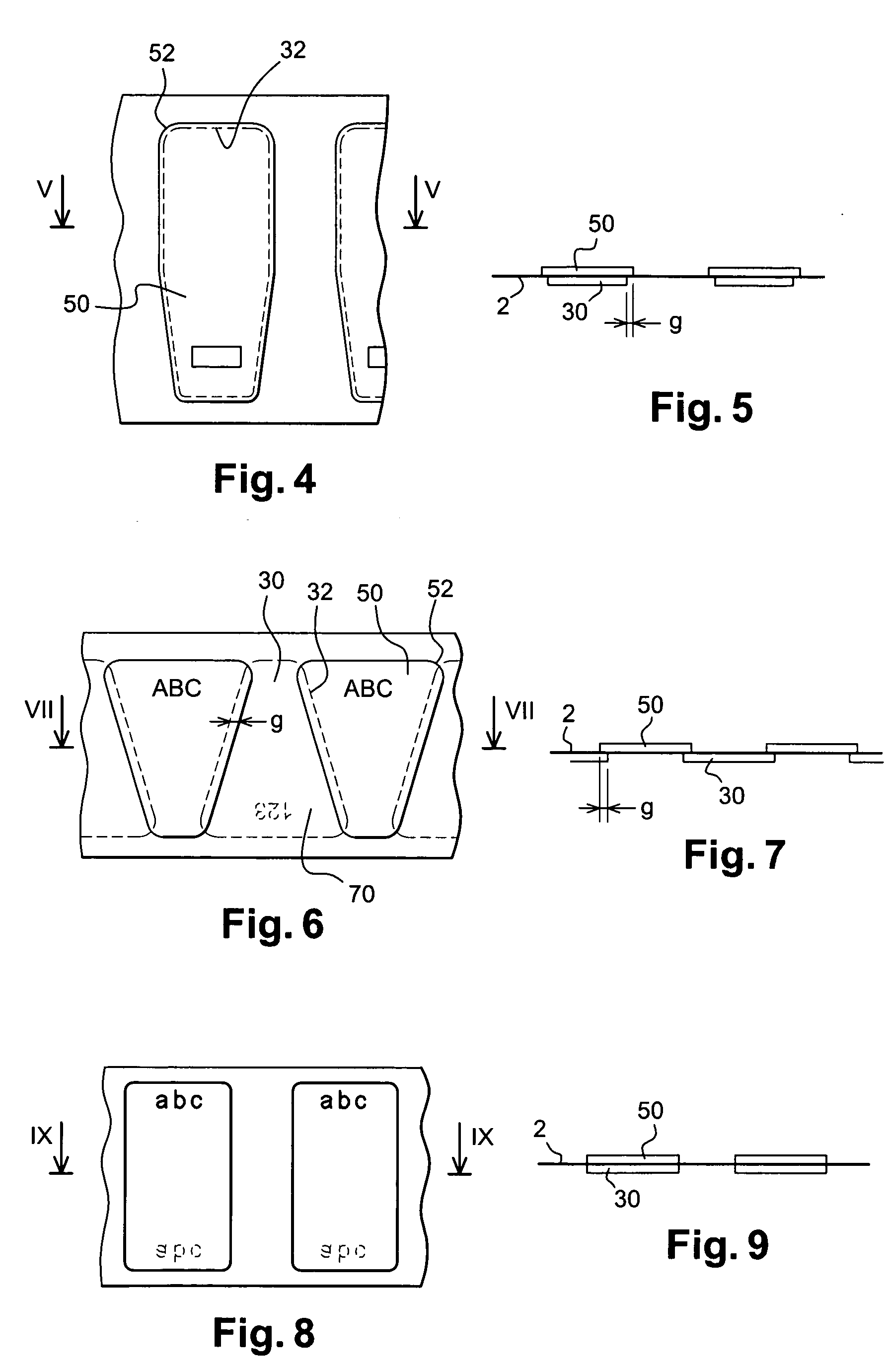

Support provided with two series of labels

InactiveUS20050255276A1Improve impermeabilityDurably printedStampsFlexible coversEngineeringElectrical and Electronics engineering

A support for labels includes a support tape provided on each of its two faces with first and second series of removable adhesive labels respectively. The labels of at least one of the first and second series include at least two layers of different coextruded materials. A method of forming the support is also provided, as well as a method of applying the labels.

Owner:LOREAL SA

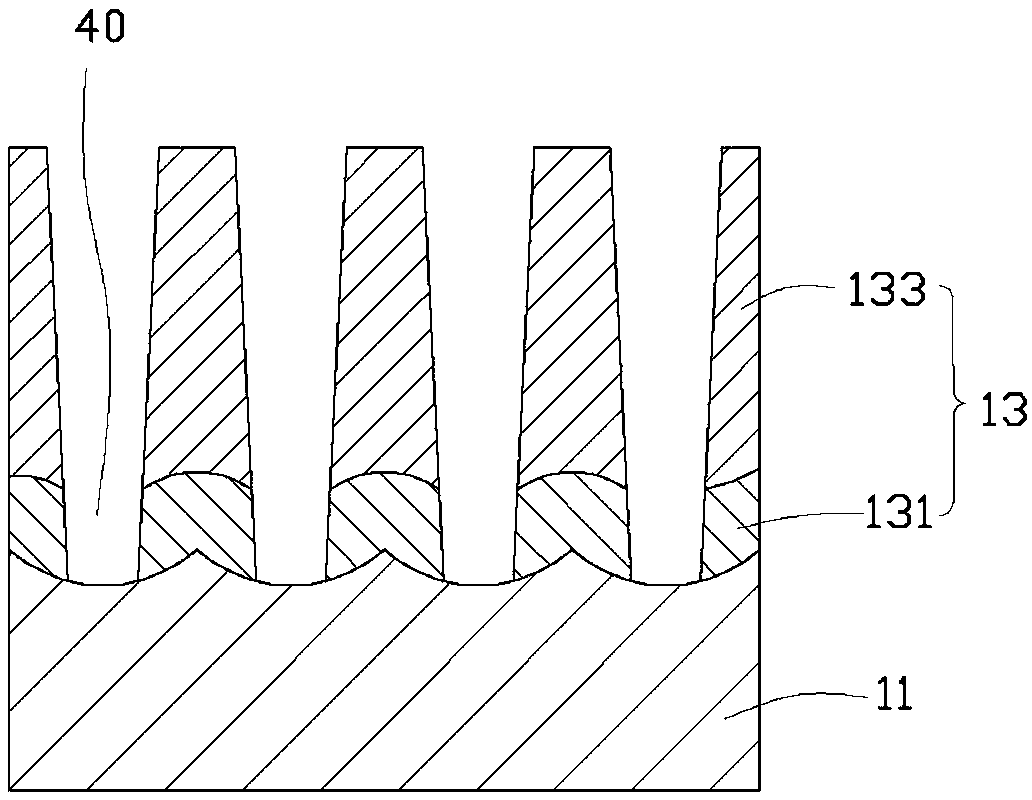

Surface treatment method of aluminum or aluminum alloy and product manufactured by adopting same

InactiveCN103173834ASimple surface treatmentShorten the production cycleAnodisationThin material handlingEthylene diaminePorous layer

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

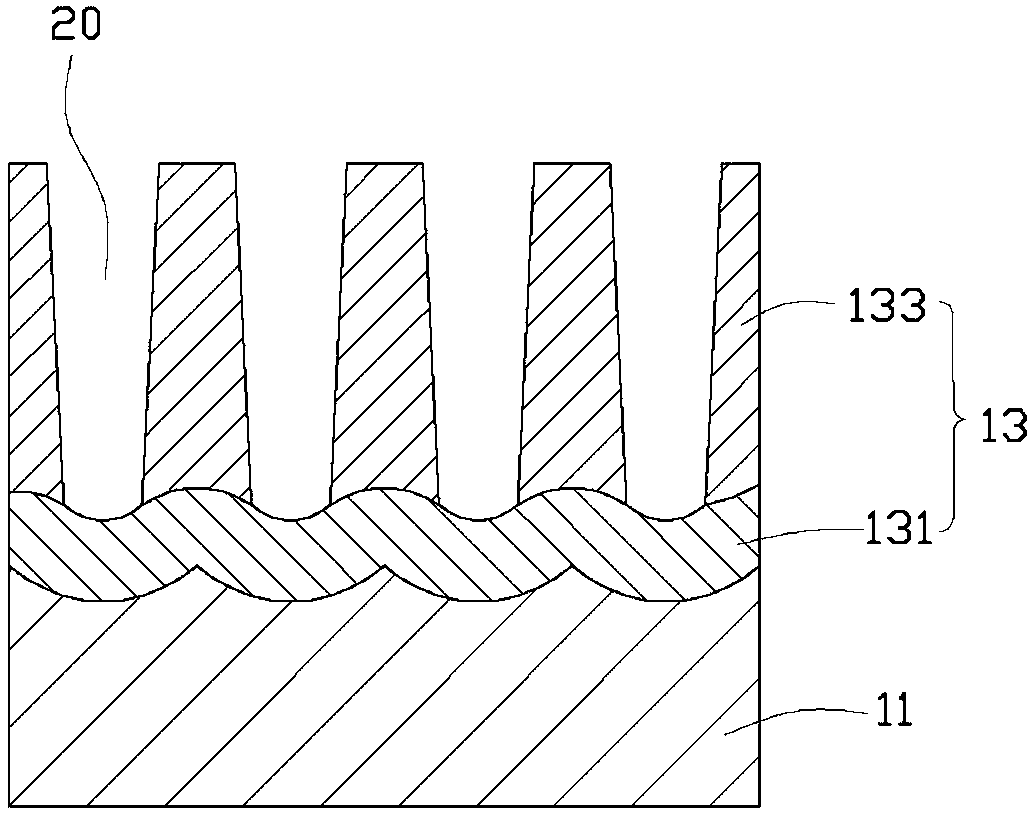

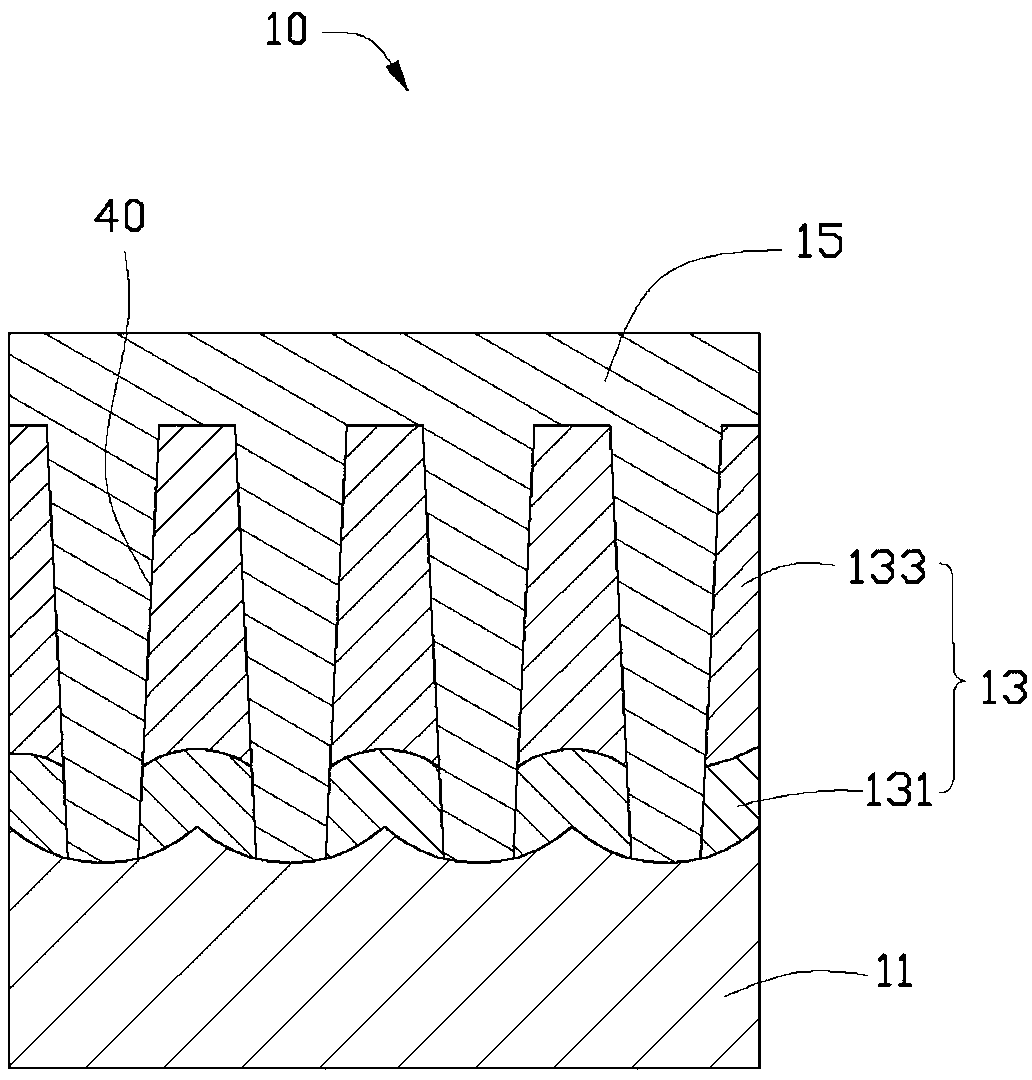

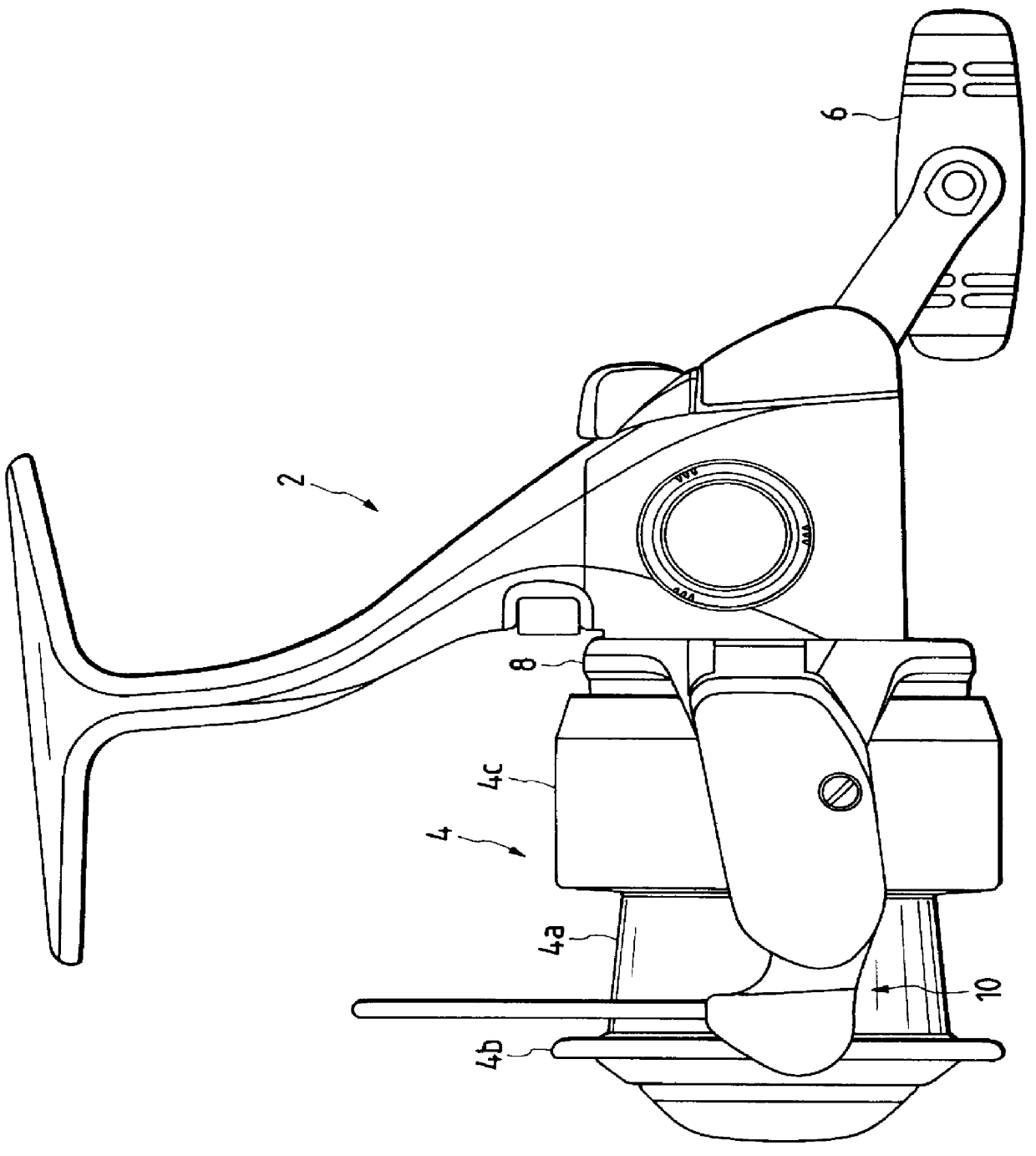

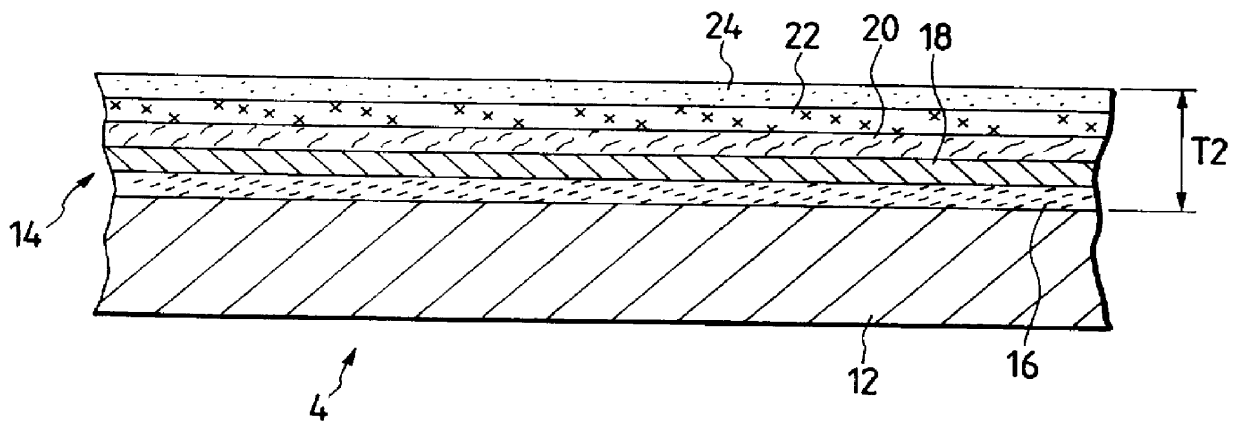

Spool having a surface treatment for use in a fishing reel

InactiveUS6164577AEnhanced in glossy appearanceImprove surface smoothnessReelsElectrolysisEngineering

A spool for use in a fishing reel, which is structured such that, by combining an electrolytic plating method, a non-electrolytic plating method, and a dry coating method properly and selectively, a metal film layer (14) having one of desired film thicknesses (T1, T2 and T3) is formed on the surface (outer peripheral surface) of the spool base material (12).

Owner:DAIWA SEIKO CORPORATION

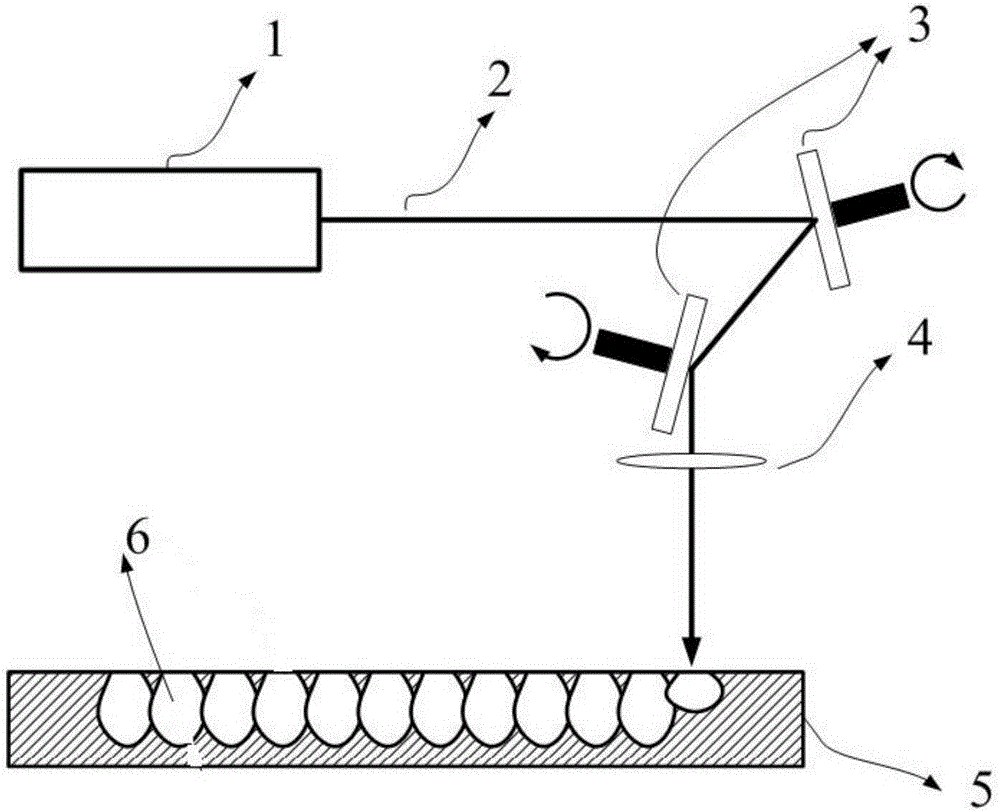

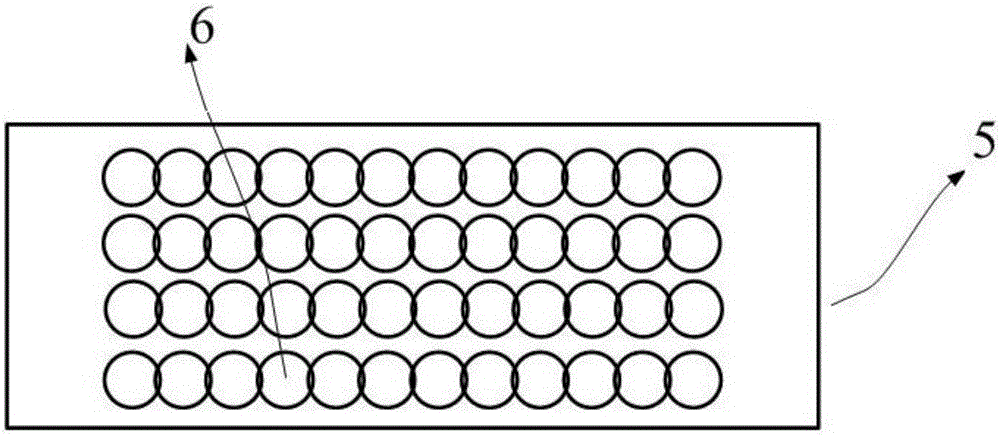

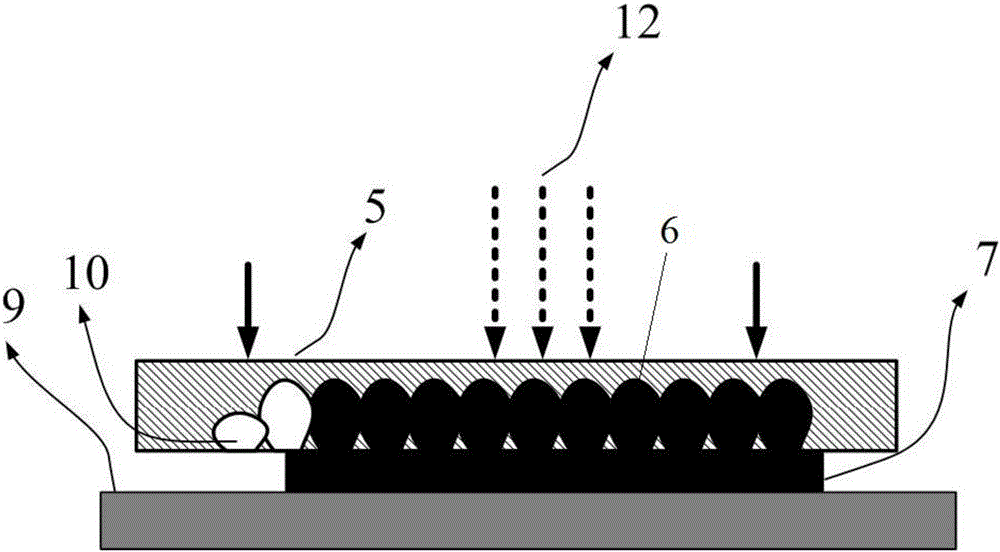

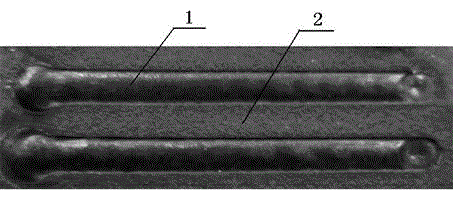

Plastic and metal permanent direct connection method

The invention relates to the technical field of metal and plastic welding, in particular to a plastic and metal permanent direct connection method. A plurality of connecting holes distributed in a cellular manner are ablated in the surface of a metal component by utilizing laser beams to irradiate at the surface of the metal component. A connecting surface of a plastic component is attached with the surface of the metal component, molten liquid plastic enters the connecting holes, and after the plastic entering the connecting holes is cooled, the welding connection of the metal component and the plastic component is fully realized. The welding method utilizes high-peak power, high beam quality and short-pulse laser beams to treat the metal surface and form the microstructural cellular holes in the surface, micro-hole diameter, depth and filling density can all be flexibly controlled, corresponding adjustment can be carried out according to actual requirements, and the adaptability is better.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

Coating anticorrosion method for connection part of steel structure

The invention discloses a coating anticorrosion method for connection parts of steel structures, which particularly comprises the following steps: (1) performing surface treatment to the connection part of a steel structure at a construction area to achieve a level of above St2 standard with no obvious bubbling or floating rust and no acute angle of surface protrusions; (2) uniformly smearing an anti-corrosion plaster on the surface of the connection part of the steel structure treated in step (1), wherein the amount of the anti-corrosion plaster is 10-1000 g / m2, and the smearing time is 1-10 times; (3) covering at least one layer of anti-corrosion strip outside the anti-corrosion plaster; (4) coating a protective cover at the surface of the anti-corrosion strip. The invention has excellent anticorrosion effect with an effective protection effect of above 20 years, has convenient construction and simple surface treatment, is operable with moisture and water, is applicable to structures with any shape, has good tightness and impact resistance, provides almost no additional load to structures, and has strong construction feasibility.

Owner:SHANGHAI XINHE BUSINESS CONSULTING

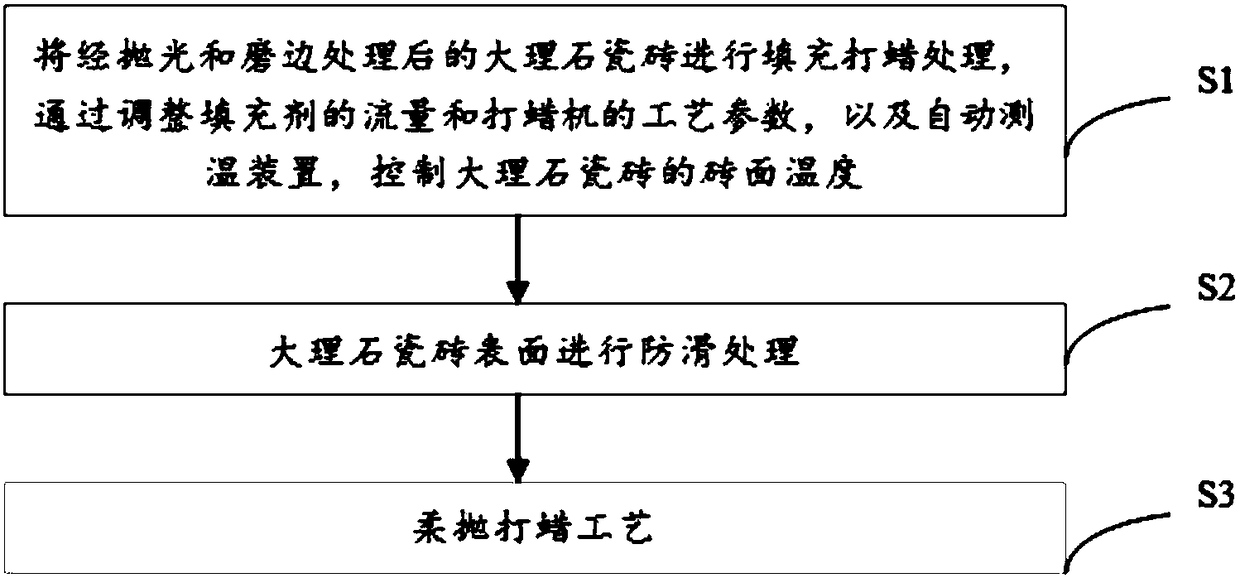

Marble ceramic tile surface treatment method

The invention discloses a marble ceramic tile surface treatment method. The marble ceramic tile surface treatment method comprises the following steps that (1), filling and waxing treatment is performed on marble ceramic tiles after polishing and edge grinding treatment; (2), anti-skid treatment is performed on the surfaces of the marble ceramic tiles after the filling and waxing treatment in thestep (1); (3), soft polishing and waxing are performed on the marble ceramic tiles after the anti-skid treatment in the step (2). The marble ceramic tile surface treatment method is simple, continuousoperations can be performed, industrialization can be achieved just by performing little improvement on existing production lines, the method adds little to the cost of production, but the anti-skidand anti-fouling comprehensive performance of the marble ceramic tiles can be significantly improved, all original performance indexes, such as texture, colour and lustre, permeability and texture arenot affected, the process is environment friendly, the environment is not affected, and the body health of workers is not damaged.

Owner:FOSHAN CITY GANI CERAMICS CO LTD +1

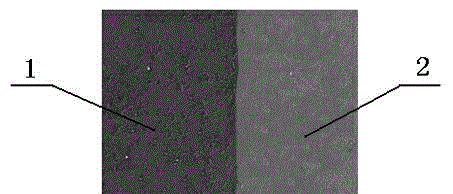

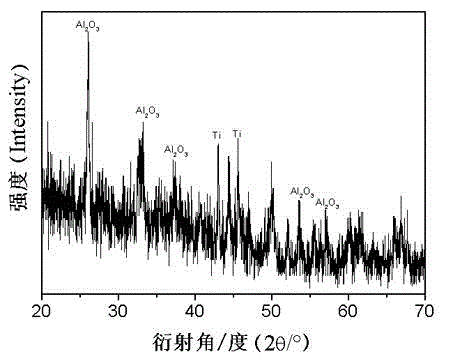

Method for laser cladding of metal ceramic powder on surface of austenitic stainless steel

The invention discloses a method for laser cladding of metal ceramic powder on the surface of austenitic stainless steel: A) carrying out oil removal and texturing treatment on the surface of an austenitic stainless steel base material to be cladded; B) mixing and grinding Al2O3 powder, Ti powder, Mo powder and B powder in accordance with weight percentage; C) coating the mixed powder after grinding on the surface of the austenitic stainless steel base material; and D) performing laser cladding on a surface coating layer of the austenitic stainless steel base material. The corrosion-resistant metal ceramic layer subjected to treatment by the method is highly combined with the austenitic stainless steel base material and has the advantageous of high liquid zinc corrosion resistance, high hardness, no environmental pollution and no generation of defects such as crack, air bubble and inclusion.

Owner:JIANGSU ZHAOLONG ELECTRIC

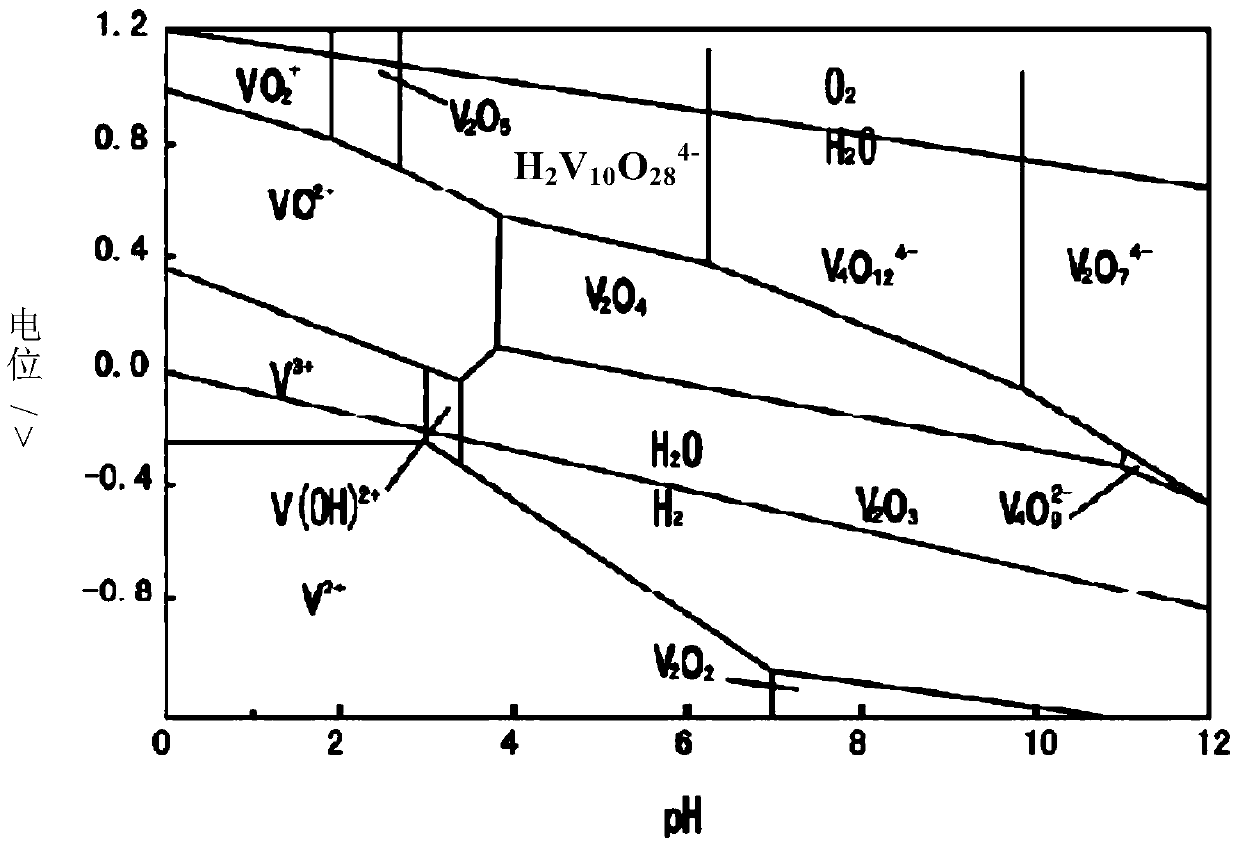

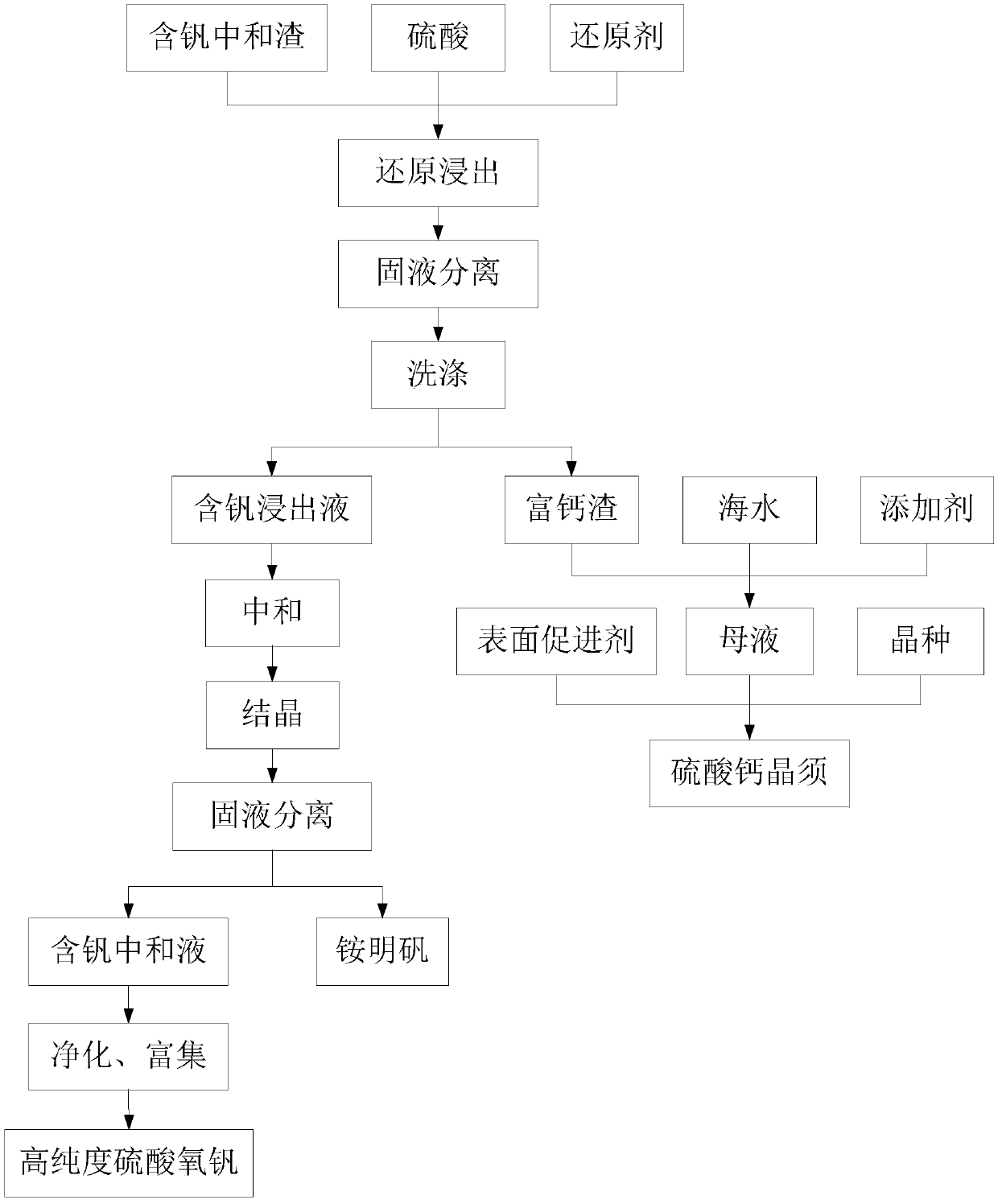

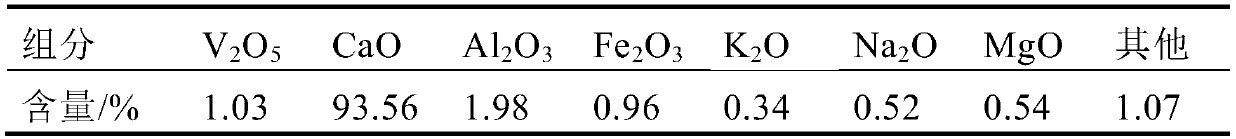

Recovery method of vanadium-containing neutralizing slag

ActiveCN109666796AHarmlessAchieve reductionPolycrystalline material growthFrom normal temperature solutionsRecovery methodSlag

The invention provides a recovery method of vanadium-containing neutralizing slag. The recovery method comprises the following steps of mixing the vanadium-containing neutralizing slag, concentrated sulfuric acid and water to obtain slurry; adding a reducing agent in the slurry, and performing reduction leaching; performing solid-liquid separation on the slurry obtained after reduction leaching, and cleaning filter residue with a sodium sulfate solution to obtain a vanadium-containing leaching solution and calcium-rich slag; adding ammonium sulfate in the vanadium-containing leaching solution,regulating the pH value of the leaching solution with ammonia water, performing cooling crystallization, and performing solid-liquid separation to obtain an ammonium alum crystal and a neutralizationsolution; and performing counter-current extraction, counter-current back extraction, upflow regeneration and counter-current washing on the neutralization solution, thereby obtaining a high-purity vanadyl sulfate solution. According to the recovery method, when the pollution of a vanadium element in the vanadium-containing neutralizing slag to environment is solved, the high value-added resourceutilization of the calcium-rich slag and the vanadium element in the vanadium-containing neutralizing slag is realized.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

Manufacturing method of aluminous plate for PS plate substrate for printing

InactiveCN1693992AEasy to processSimple surface treatmentPrinting pre-treatmentPhotosensitive materials for photomechanical apparatusHigh intensityIngot

A manufacturing method of aluminum board used for the PS plate aluminum board used for printing. The steps of the method are: a. according to the weight proportions of Al: 98, Si: < 1.0, Fe: 0.3 - 1.0, Cu: 0.03, Zn: 0.03, Mg: 0.03, Ti: 0.05, mix the said alloy components and smelt them in the temperature condition of 720 - 800 Deg. C; b. found them into alloy cast ingot in the temperature condition of 690 - 750 Deg. C; c. make the cast ingot equably anneal in the temperature condition of 500 - 610 Deg. C; d. have hot roll in the temperature condition of 400 - 540 Deg. C; e. cold roll them from 9.0 mm to 0.7 mm; f. have 11 hours' middle anneal, 1 hour's heat preservation, then cold roll them to 0.15 mm. The advantages are light weight, high intensity, good water-proof performance, good hydrophilic performance and easy to have surface process.

Owner:NORTHEAST LIGHT ALLOY CO LTD

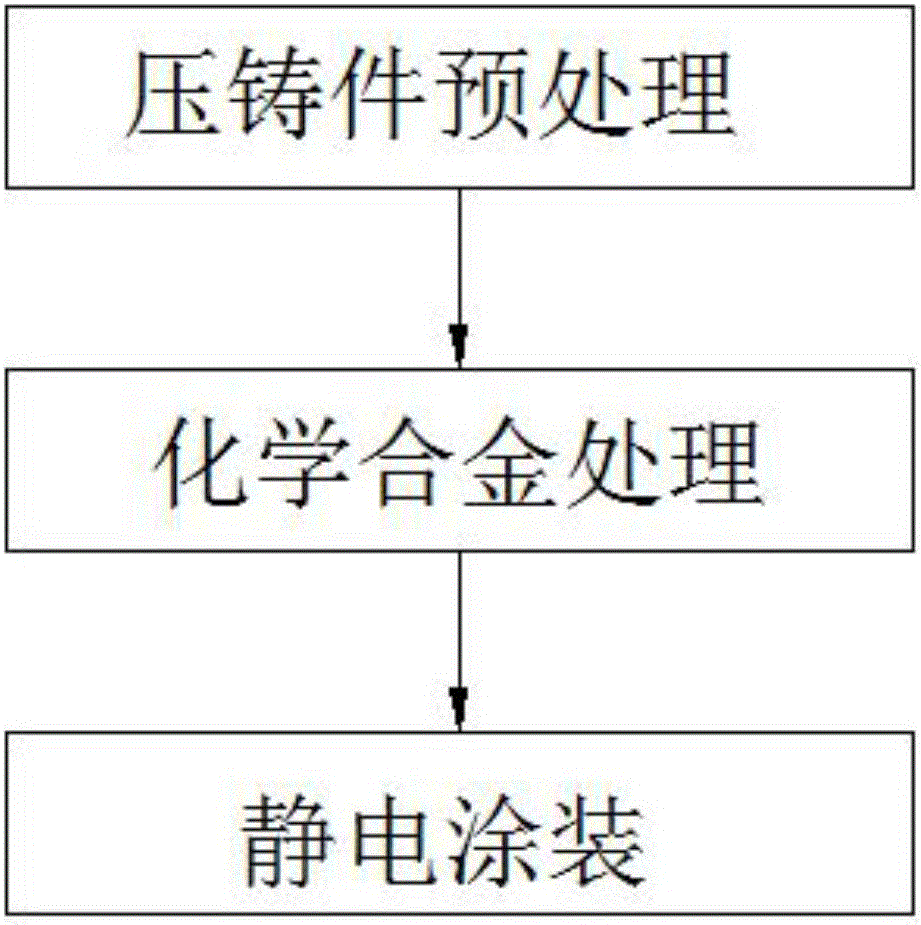

Surface treatment method for aluminum alloy die casting and product thereof

InactiveCN106048569AImprove work efficiencyEasy to handleLiquid surface applicatorsLiquid/solution decomposition chemical coatingSolution treatmentElectrostatic coating

The invention relates to the technical field of die casting production, in particular to a surface treatment method for an aluminum alloy die casting. The surface treatment method includes the three steps of die casting pretreatment, chemical alloy solution treatment and electrostatic coating. The step of die casting pretreatment includes the procedures of shot blasting treatment, wax removal, deoiling, grinding treatment, three times of washing and the like. The surface treatment method for the aluminum alloy die casting is high in work efficiency and good in treatment effect; and the obtained surface-treated die casting is uniform, fine and smooth in texture, high in strength and good in corrosion resistance.

Owner:HANSHAN ZHAOXIA CASTING

Amorphous alloy surface treatment method

ActiveCN105803458ASimple surface treatmentExquisite appearanceVacuum evaporation coatingFoundry mouldsWear resistanceAmorphous metal

The invention relates to an amorphous alloy surface treatment method. The amorphous alloy surface treatment method comprises hole sealing, curing and film plating; and an amorphous alloy has an air hole in the surface. The amorphous alloy surface treatment method is simple and efficient, and can enable the prepared amorphous alloy to have the advantage of delicate appearance; and the amorphous alloy treated by the method is high in corrosion resistance, compact in combination of a plating film and an amorphous alloy matrix and excellent in wear resistance.

Owner:南通斐腾新材料科技有限公司

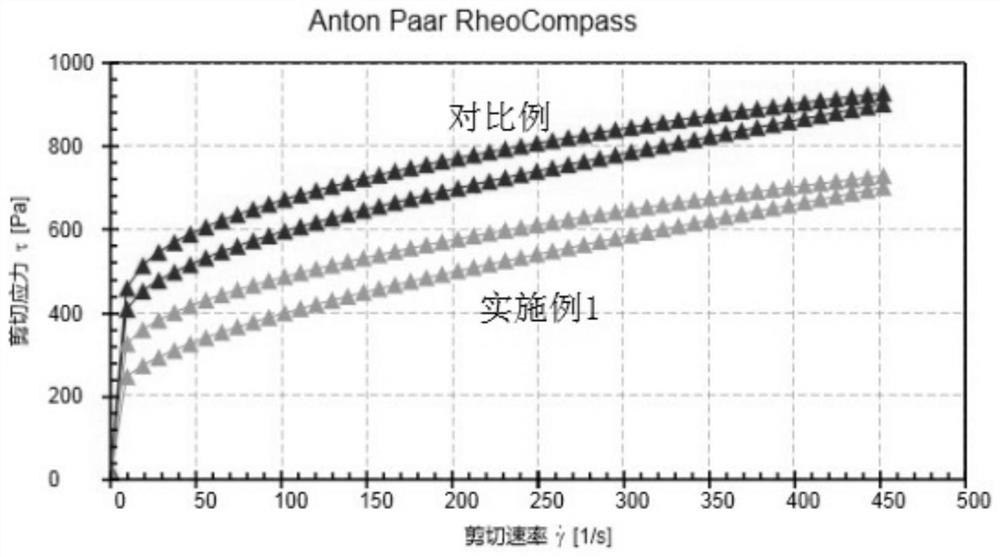

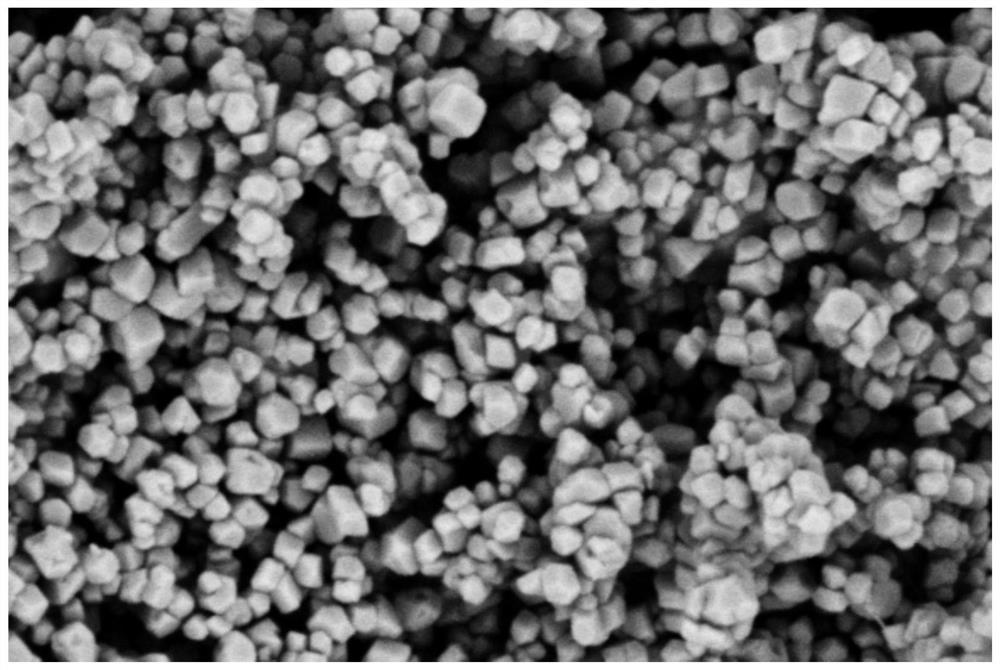

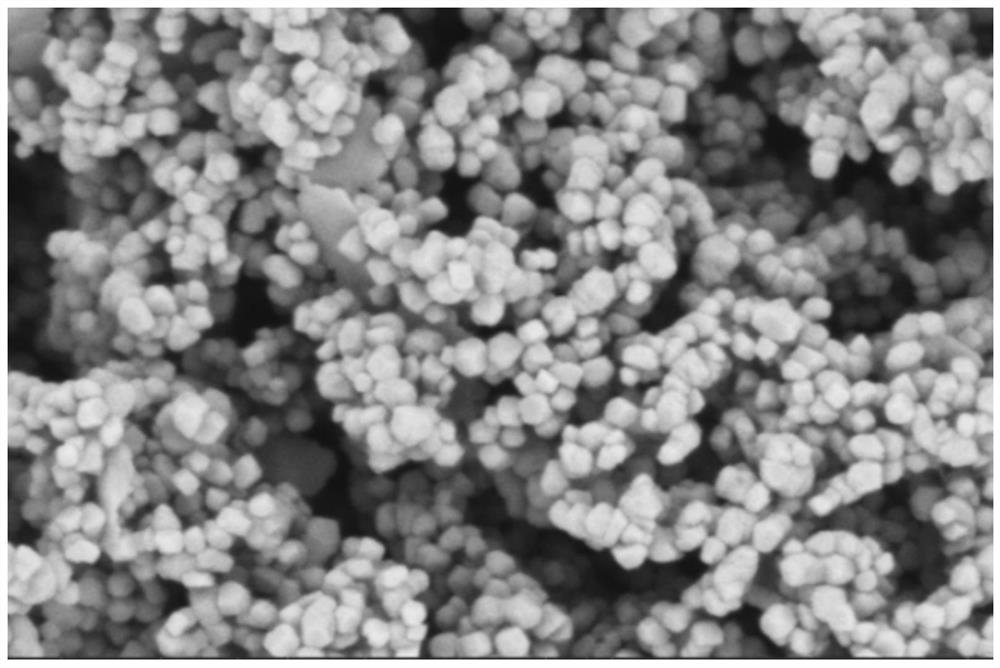

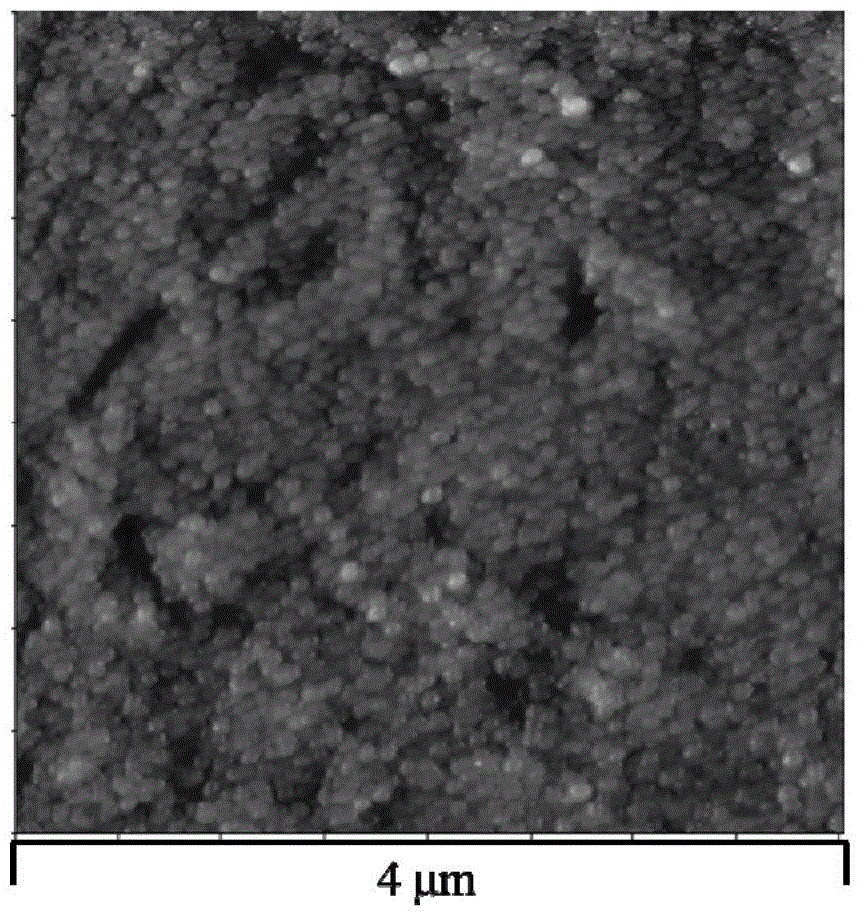

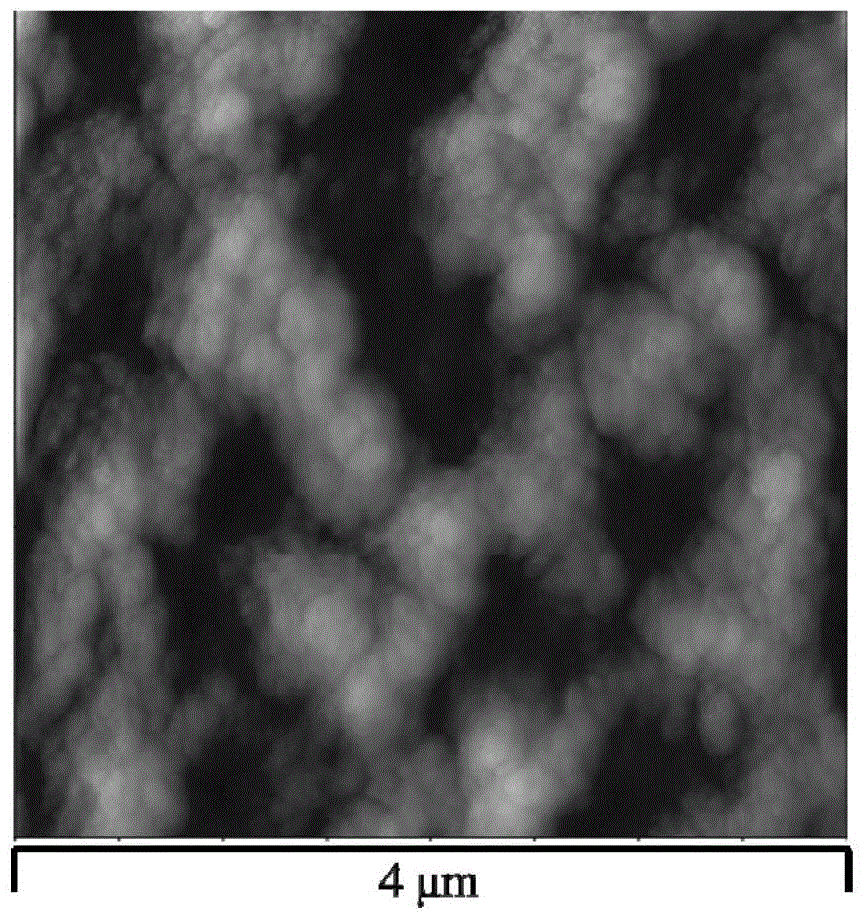

Surface treatment method of nano calcium carbonate for impact-resistant automobile chassis coating

ActiveCN112724708AHigh viscoelasticityImprove rheologyCalcium/strontium/barium carbonatesMaterial nanotechnologySodium stearateCarbonization

The invention discloses a surface treatment method of nano calcium carbonate for an impact-resistant automobile chassis coating, which comprises the following steps of diluting lime milk to obtain slurry, regulating the specific gravity, and carbonating the slurry in a carbonating tower, measuring conductivity through an instrument, adding a crystal form control agent at the lowest point of gelatinization conductivity at the initial stage of carbonization, and stirring to react until the pH value is less than or equal to 7 to obtain calcium carbonate suspension, carrying out oleophylic surface treatment on the calcium carbonate suspension, stirring, and adding a compound treatment agent consisting of a sodium stearate saponification solution and flaxseed gum, polyhexamethylene glycol, sodium dodecyl benzene sulfonate and isopropyl triisostearoyl titanate for surface treatment, and carrying out filter pressing, microwave vacuum drying and sieving to obtain the nano calcium carbonate. The nano calcium carbonate particles prepared through the method are regular in morphology, have the advantages of being good in stability, good in rheological property, high in impact resistance, low in moisture absorption capacity and the like, and can improve the impact resistance and sagging resistance of PVC paste when applied to filling of the automobile chassis coating PVC paste.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Self-brazing aluminum alloy laminar composite and preparation method and application thereof

InactiveCN111843280AImprove production environmentIncrease productivityWelding/cutting media/materialsSoldering mediaBraze alloyMaterials science

The invention relates to a self-brazing aluminum alloy laminar composite and a preparation method and application thereof. The self-brazing aluminum alloy laminar composite comprises at least one self-brazing aluminum alloy layer. The self-brazing aluminum alloy layer is formed by mixing and pressing Al-Si brazing alloy powder and brazing flux powder, wherein the mass percentage of the content ofthe brazing flux powder is 0.1%-10%, and the mass percentage of Si in the Al-Si brazing alloy powder is 4%-13%. The preparation method comprises a series of manufacturing steps of mixing and pressing,heating, hot rolling compounding, cold rolling, finished product annealing, finishing and packaging and the like, and then the self-brazing aluminum alloy laminar composite is manufactured. An appropriate amount of brazing flux is added and evenly distributed in the brazing alloy layer, so that the brazing quality of a brazed piece is stable and reliable, the yield of one-time brazing is high, the surface of the brazed piece is bright and smooth, and follow-up surface treatment is easy; and brazing flux spraying of a traditional brazing technology is omitted, and therefore pollution to a production environment is avoided.

Owner:上海萨新东台热传输材料有限公司

Surface treatment method for electric phosphorization of permanent magnet material

InactiveCN103806072AImprove adhesionSimple surface treatmentPhosphatisationSodium phosphatesAcid washing

The present invention provides a surface treatment method for electric phosphorization of a permanent magnet material. The surface treatment method comprises: (1) chamfering polishing: adopting a mechanical vibration mill and tumbling chamfer method to carry out conventional polishing on a neodymium-iron-boron permanent magnet material; (2) degreasing and deoiling: adding sodium phosphate, sodium carbonate or sodium hydroxide to carry out conventional defatting and deoiling; (3) acid washing rust removing: adding a nitric acid solution to carry out conventional acid washing rust removing and water washing; (4) an electric phosphorization treatment: adopting an electric phosphorization agent to carry out an electric phosphorization treatment; and (5) water washing and blow drying. According to the present invention, the surface treatment method has characteristics of simpleness, rapidness and environmental protection, and the high corrosion resistance is provided; the treatment process has characteristics of no sediment production, short treatment time and simple control; and the treatment steps are less, the surface conditioning step can be saved, the tank solution can be reused, and the adhesion of the paint on the substrate is effectively improved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

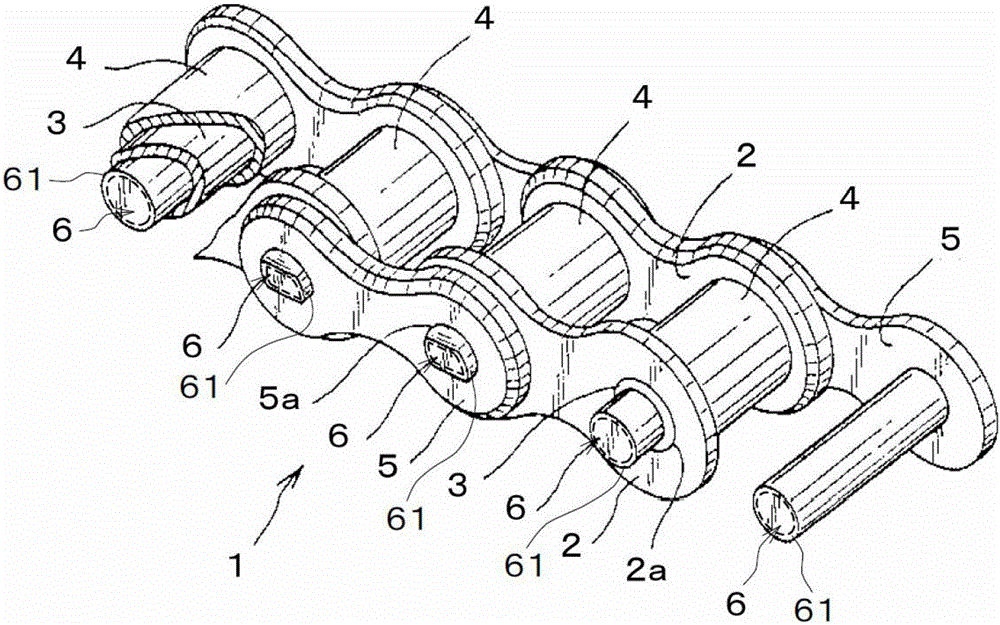

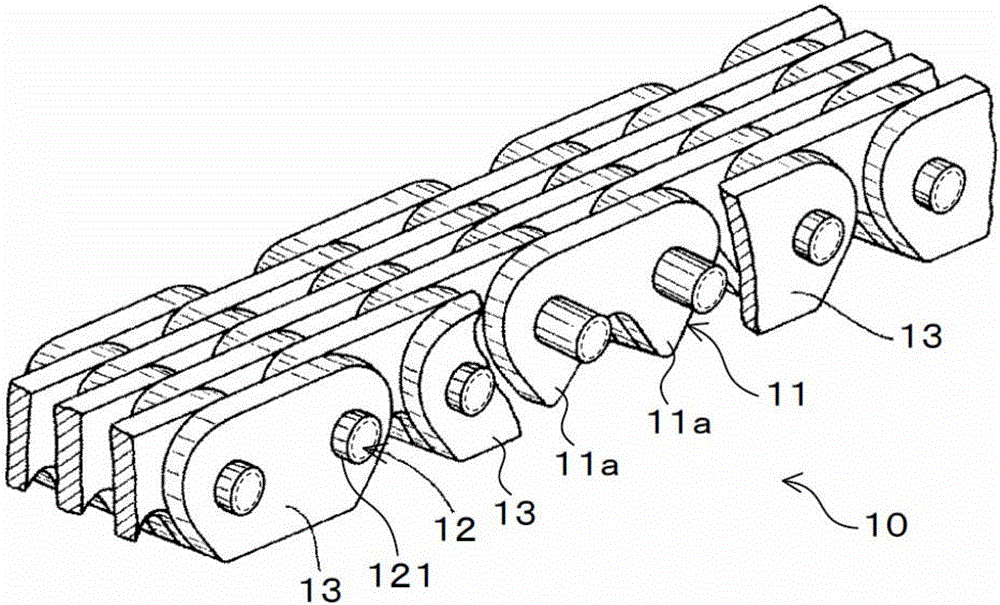

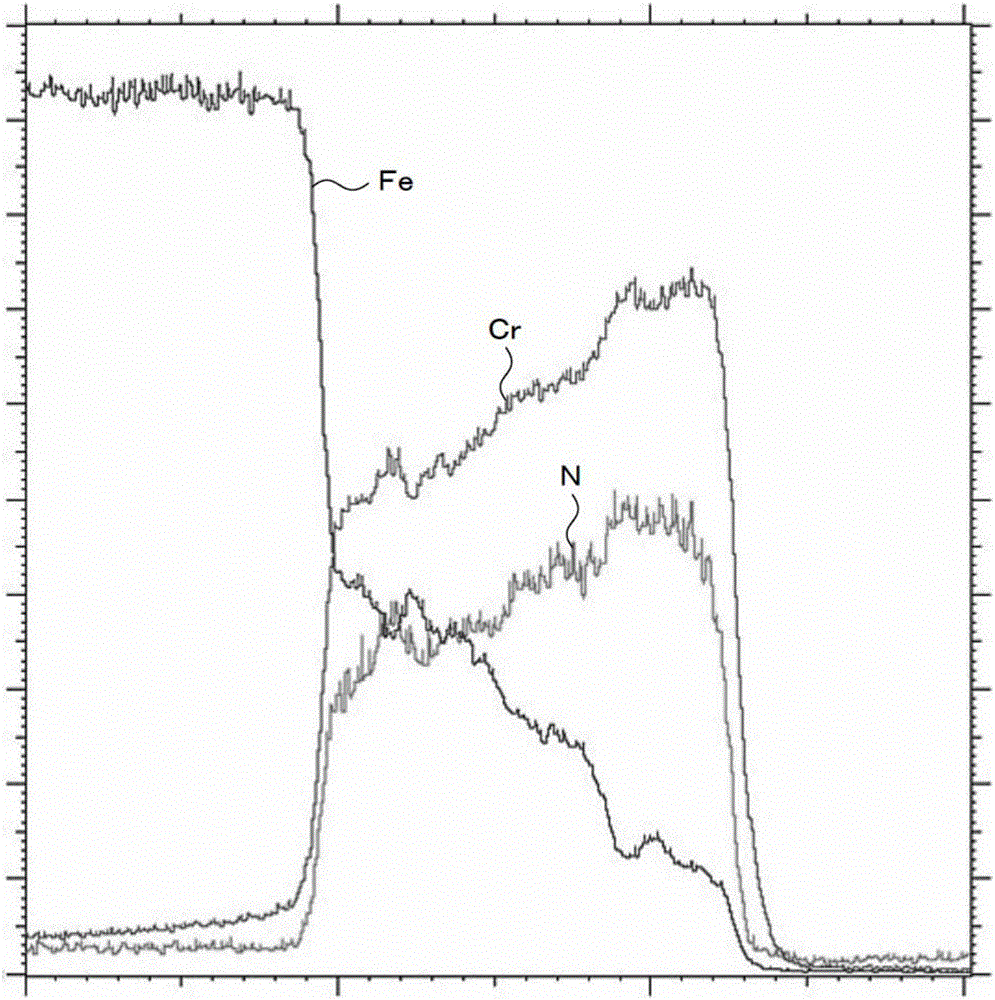

Chain Component And Chain

InactiveCN106480401ASimple surface treatmentReduce processSolid state diffusion coatingDriving chainsRoller chainEngineering

A chain component which has a simple surface treatment structure and in which satisfactory wear resistance is maintained for a long term; and a chain which employs this chain component so that a satisfactory wear elongation resistance is maintained are provided. A roller chain serving as an industrial chain for power transmission is constructed such that a pair of outer plates linked by two pins and a pair of inner plates linked together by two bushes onto each of which a roller is fit are alternately linked together in a plurality in a state that each pin is loosely fit in each bush. A chromium nitride layer is formed on the outer side of the steel-based substrate of the pin. The chromium nitride layer contains iron at a content higher than 0 mass % and lower than or equal to 55 mass %.

Owner:TSUBAKIMOTO CHAIN CO

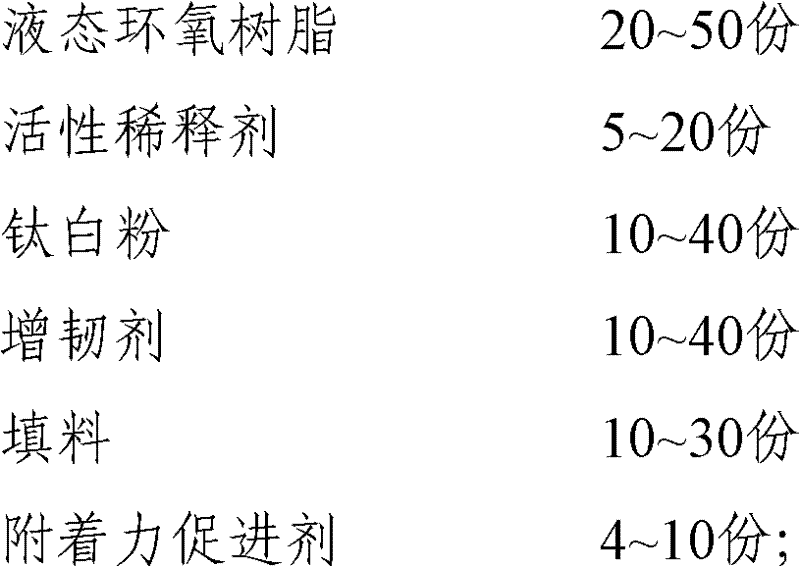

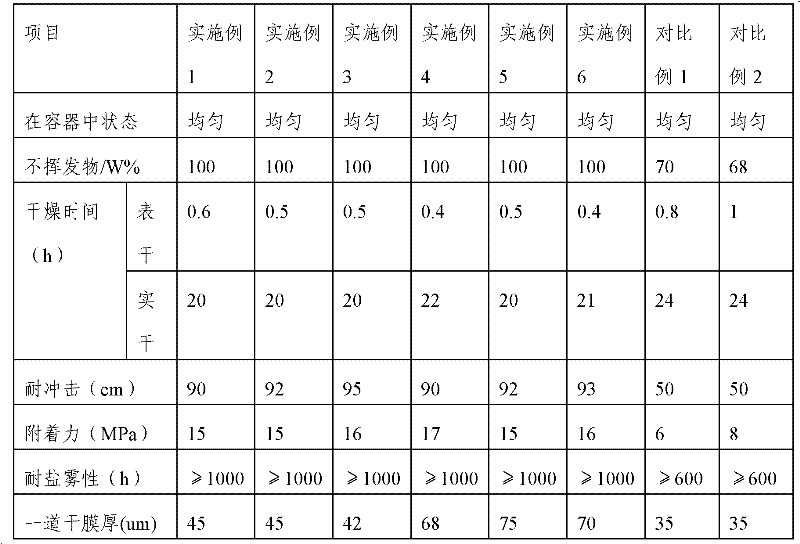

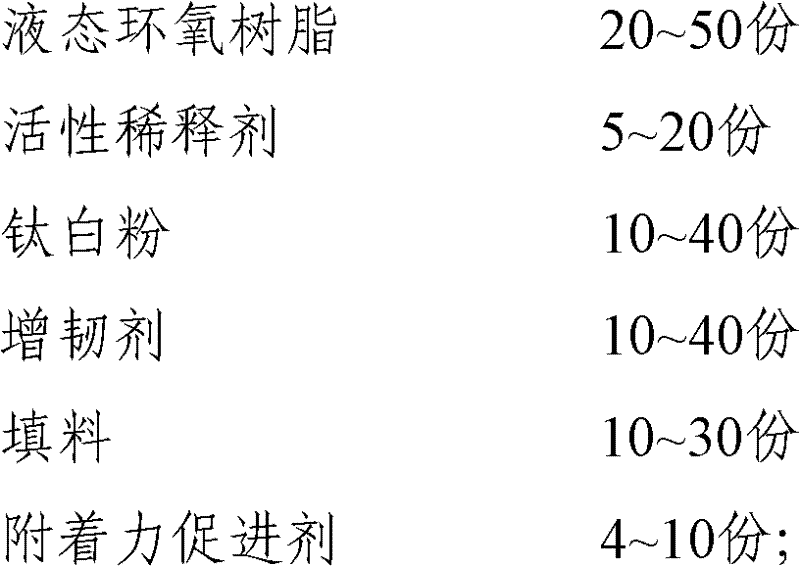

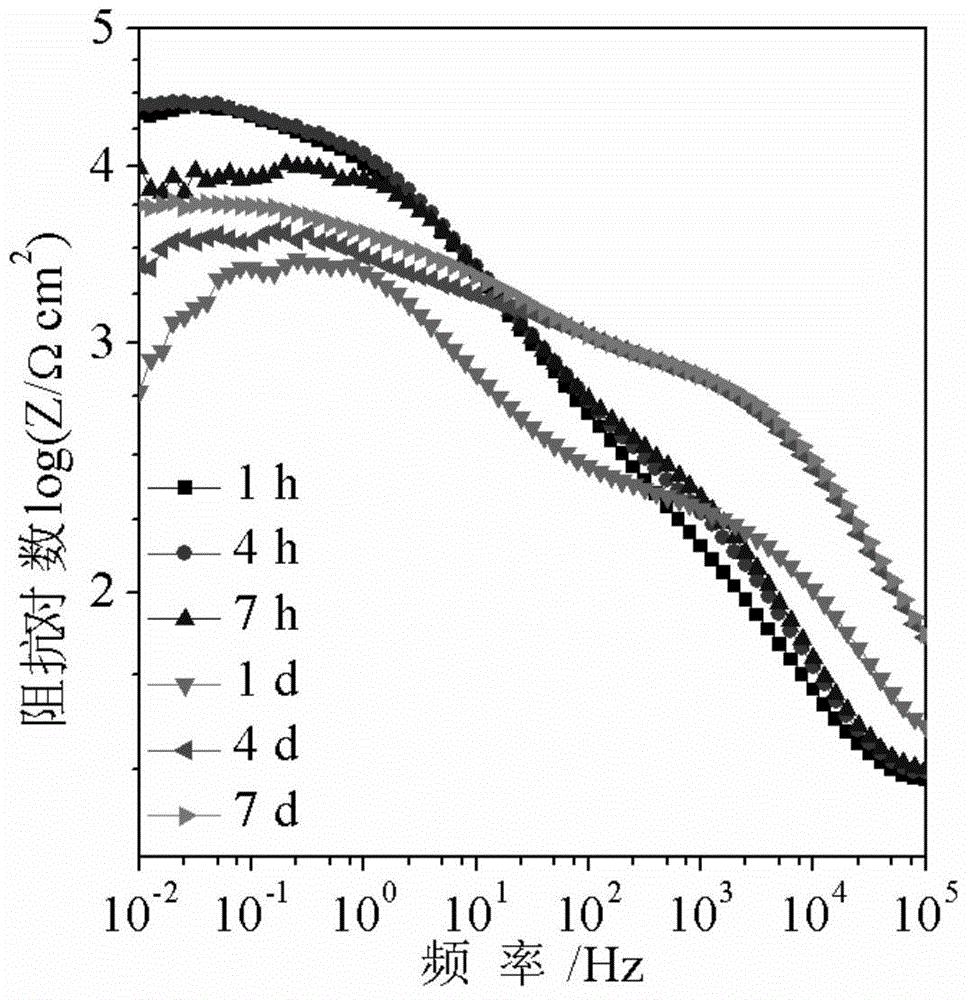

Solvent-free type fiber reinforced epoxy paint and preparation method thereof

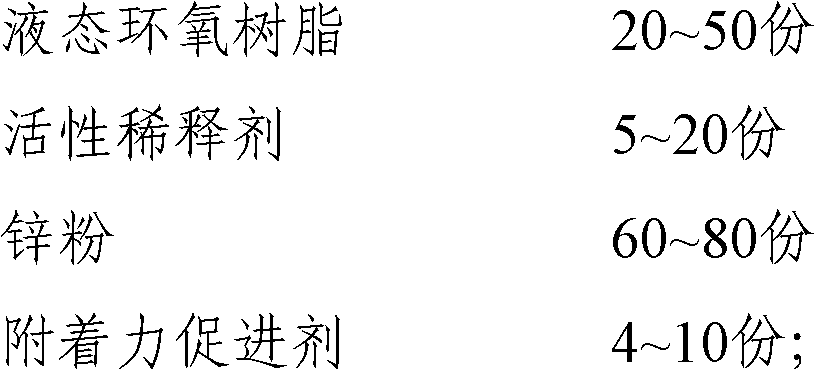

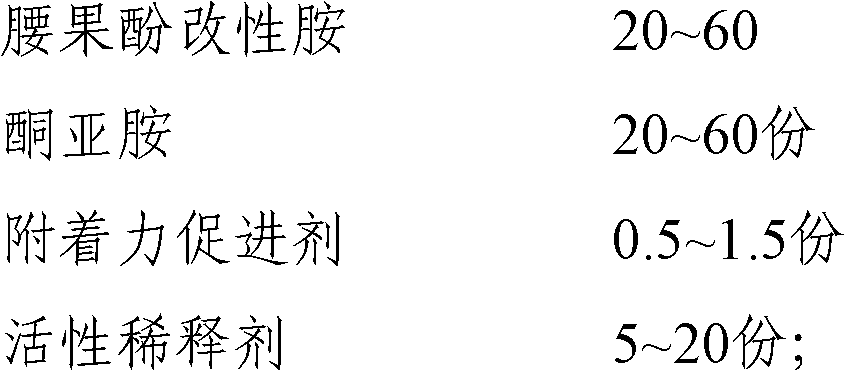

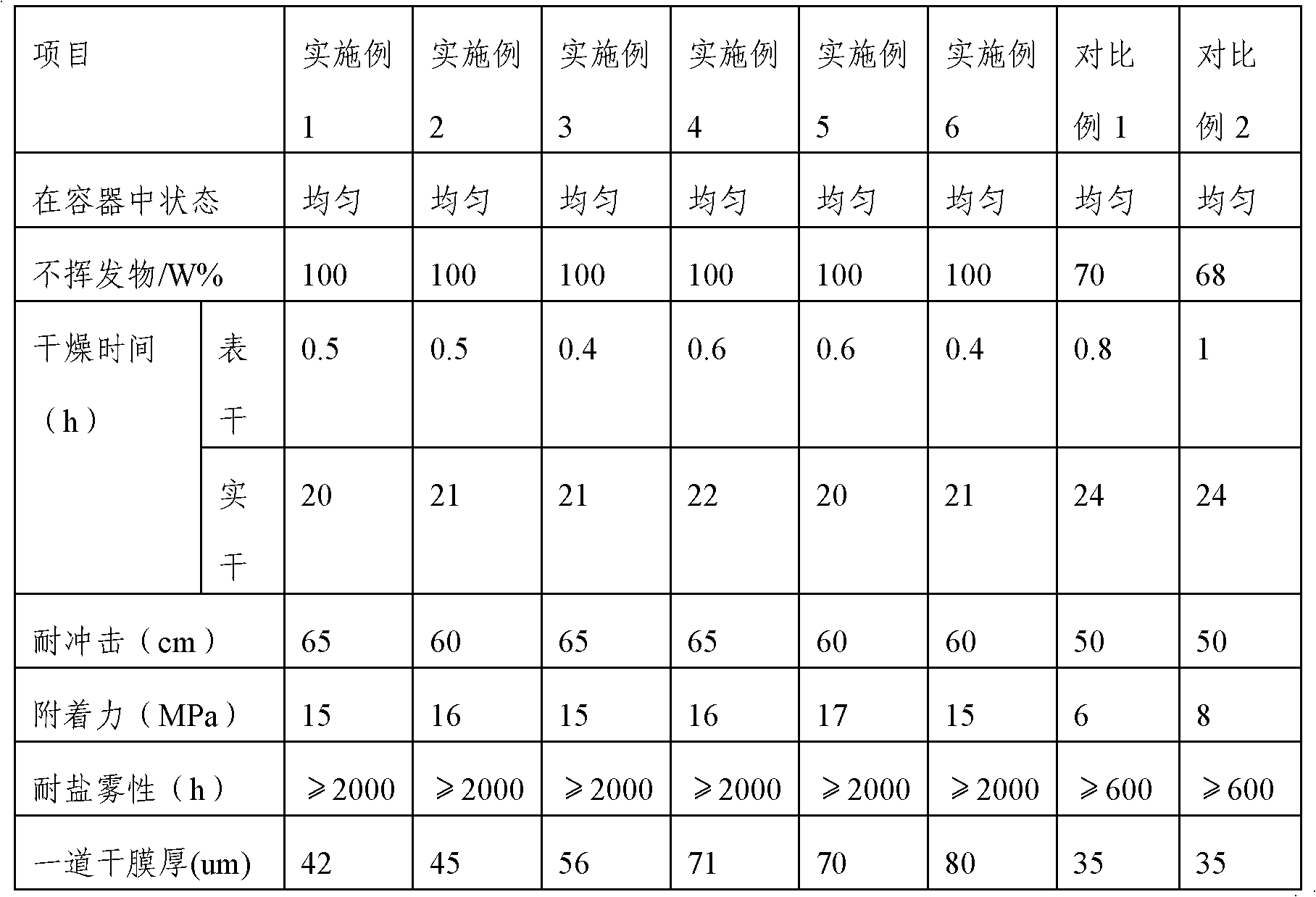

The invention relates to solvent-free type fiber reinforced epoxy paint and a preparation method of the solvent-free type fiber reinforced epoxy paint. The solvent-free type fiber reinforced epoxy paint comprises an ingredient A and an ingredient B, wherein the ingredient A mainly comprises the following ingredients in parts by weight: 20 to 50 parts of liquid epoxy resin, 5 to 20 parts of reactive diluents, 10 to 40 parts of titanium pigment, 10 to 40 parts of toughening agents, 10 to 30 parts of fillings and 4 to 10 parts of adhesion promoters, the ingredient B comprises the following ingredients in parts by weight: 20 to 60 parts of cashew modified amine, 20 to 60 parts of ketimine, 0.5 to 1.5 parts of adhesion promoters and 5 to 20 parts of active diluents, and the weight ratio of the ingredient A to the ingredient B is (4.5-5.5):1. The solvent-free type fiber reinforced epoxy paint is economic and environmental-friendly, the toughness is high, and wider industrial application prospects are realized.

Owner:JIANGSU DAZHONG NEW MATERIAL TECH CO LTD

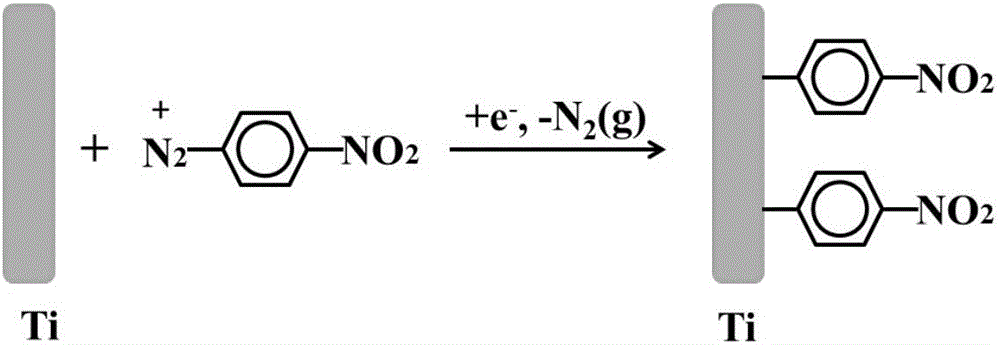

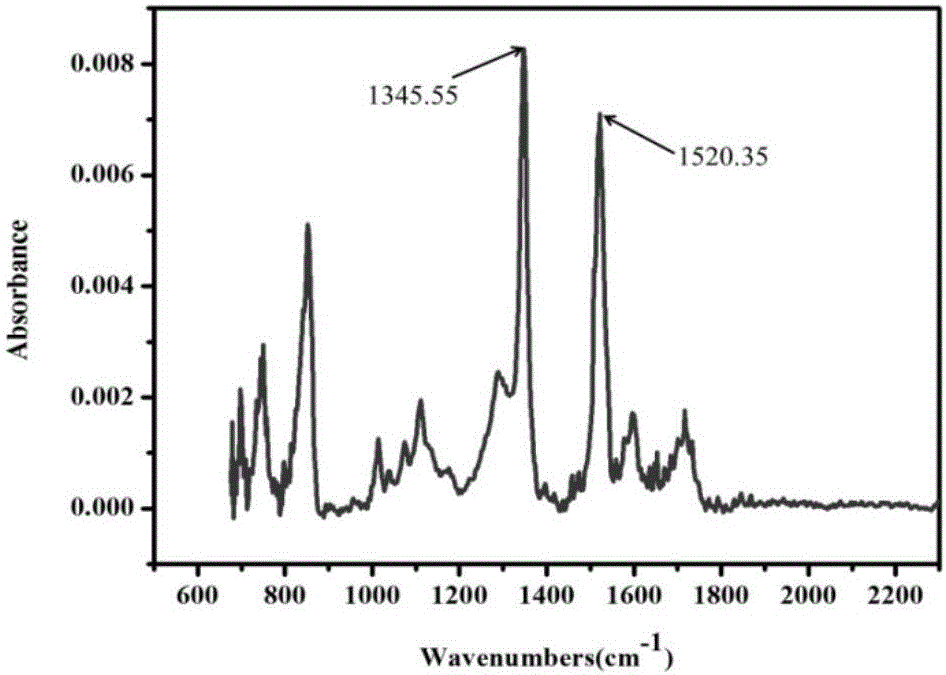

Method for modifying bonding surface of metal by virtue of electric grafting of aryl diazonium salts onto surface of metal

InactiveCN105803503AImprove interface performanceEnhanced interface bindingLamination ancillary operationsSurface reaction electrolytic coatingP-NitroanilineAnchoring - action

The invention belongs to the field of treatment of a bonding surface of metal and particularly relates to a method for modifying the bonding surface of metal by virtue of electric grafting of aryl diazonium salts onto the surface of metal. The method comprises the steps that a clean metal plate is subjected to surface treatment with an acid pickling method or / and an anodizing method and dried; p-nitroaniline is dissolved in an acidic aqueous solution, then a sodium nitrite solution is added dropwise to the p-nitroaniline-containing acidic aqueous solution under the condition of 0-5 DEG C, and an obtained mixture is stirred and subjected to cold storage; the pretreated metal plate is placed into an aryl diazonium salt solution prepared in the previous step, and an electric grafting reaction is carried out by cyclic voltammetry in a three-electrode system; and the metal plate is cleaned and dried finally. Active functional groups are produced on the metal surface with the electric grafting method, so that the properties of an interface between the metal and resin are improved under an anchoring action and a chemical bond action. The surface treatment method is simple and easy and suitable for mass production, and the cost is low.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Oxidative polymerization type rust-proof anti-corrosion adhesive paste

ActiveCN103289608AImprove corrosion resistanceSimple surface treatmentNon-macromolecular adhesive additivesAdhesiveBest fitting

The invention relates to a rust-proof anti-corrosion adhesive paste, and in particular relates to an oxidative polymerization type rust-proof anti-corrosion adhesive paste. The rust-proof anti-corrosion adhesive paste comprises the following ingredients in percentage by weight: 57-63% of polybutene, 10-14% of organic bentonite, 3-5% of an antirusting agent, 0.1-1% of titanium dioxide, 0.1-1% of graphite, 26-30% of talc and 0.1-0.24% of silicon dioxide. The oxidative polymerization type rust-proof anti-corrosion adhesive paste is coated on the surfaces of protected objects, has strong adherence and permeability, can permeate to a rusting layer to inhibit rust deterioration and has good fitting tightness and sealing performance, good rust-proof and anti-corrosion performances and long service life; the adhesive paste is simple in protected object surface treatment, can be used for filling and levelling pits, can be applied to original rusty coating construction and is convenient to apply, high in efficiency and labor cost-saving; and moreover, the rust-proof anti-corrosion adhesive paste has good flexibility, ageing resistance and high-strength impact resistance and further effectively and stably prevents steel structures from being corroded for a long time, so that the protected objects can be enabled to be safely produced.

Owner:侯保荣 +1

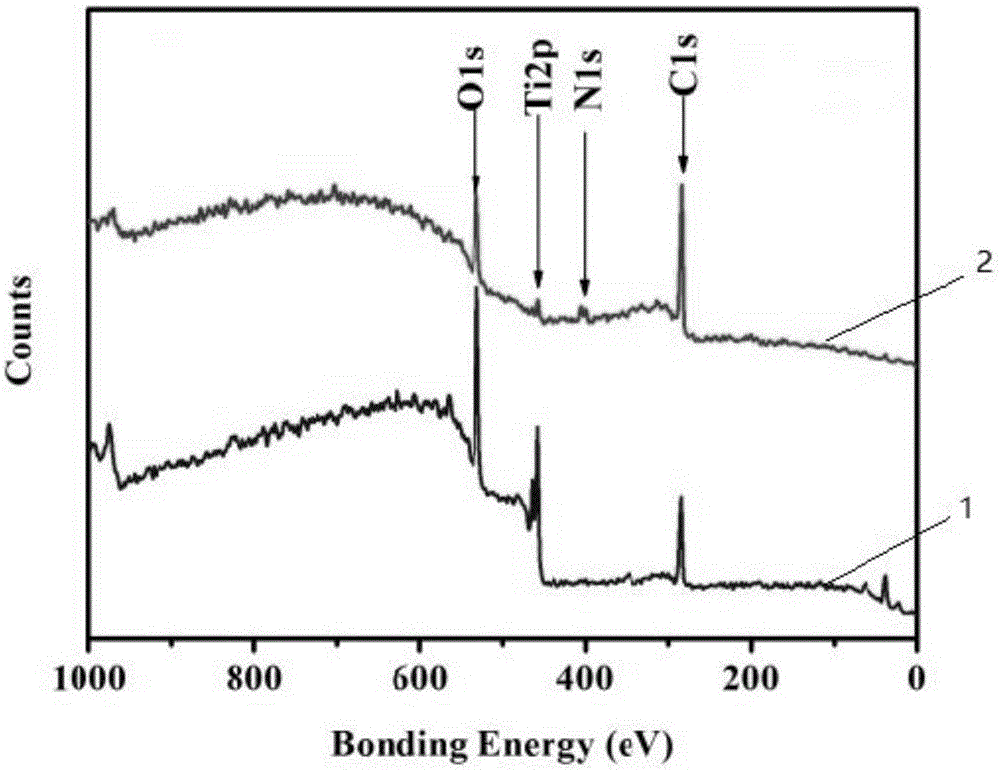

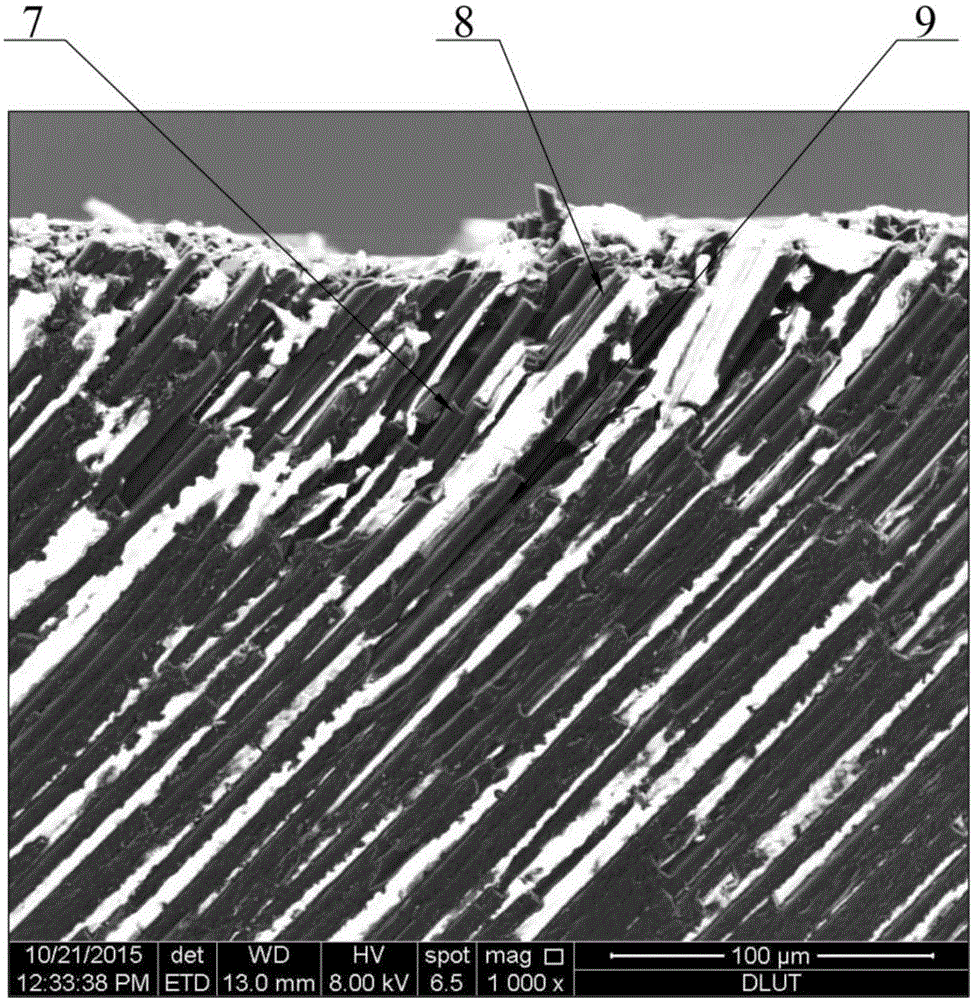

Surface treatment method of damage below machining face of carbon-fiber-reinforced composite material

ActiveCN105842265AThe surface treatment method is simple and easy to operateClean surfaceMaterial analysis by measuring secondary emissionSurface finishingCarbon fiber reinforced composite

The invention relates to a surface treatment method of damage below the machining face of carbon-fiber-reinforced composite material and belongs to the field of composite materials. The treatment method uses micro amount to remove the material layer by layer and includes: sampling; grinding, to be more specific, using a grinding machine to grinding the surface of a sample by using abrasive paper as the medium to expose the damaged surface, wherein the grinding includes coarse grinding, semi-finishing grinding and finishing grinding; cleaning, to be more specific, using an ultrasonic cleaning machine to clean the ground sample so as to remove the impurities on the surface of the material; airing; observing and evaluating. The surface treatment method has the advantages that the method is simple and easy to operate and unlimited by material shape; the surface damage of the obtained sample is clean and complete, and the problem that the damage of the machined observation sample, with the damage below the machining face, of the carbon-fiber-reinforced composite material easily expands to destroy the original shape during machining is solved.

Owner:DALIAN UNIV OF TECH

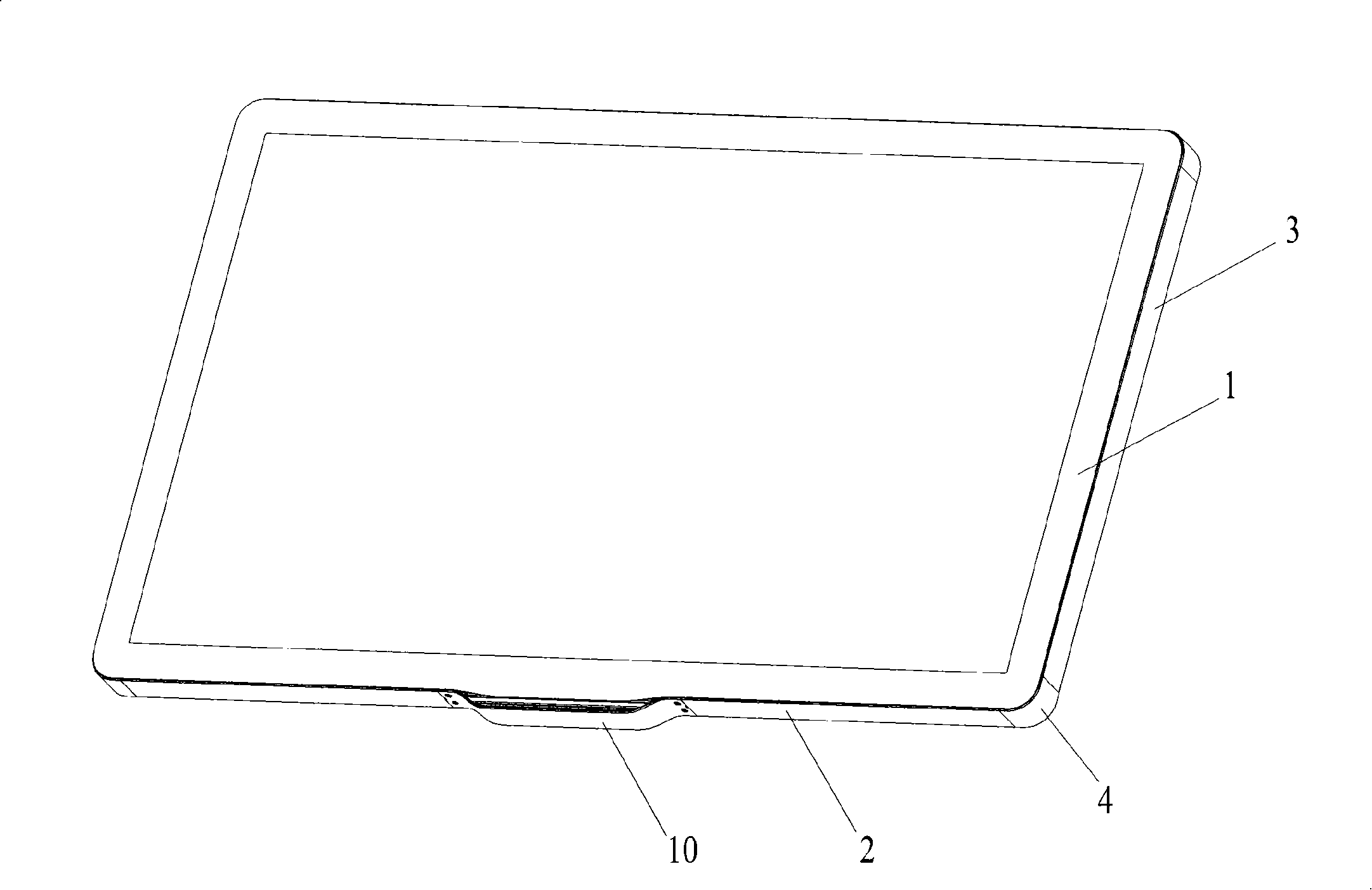

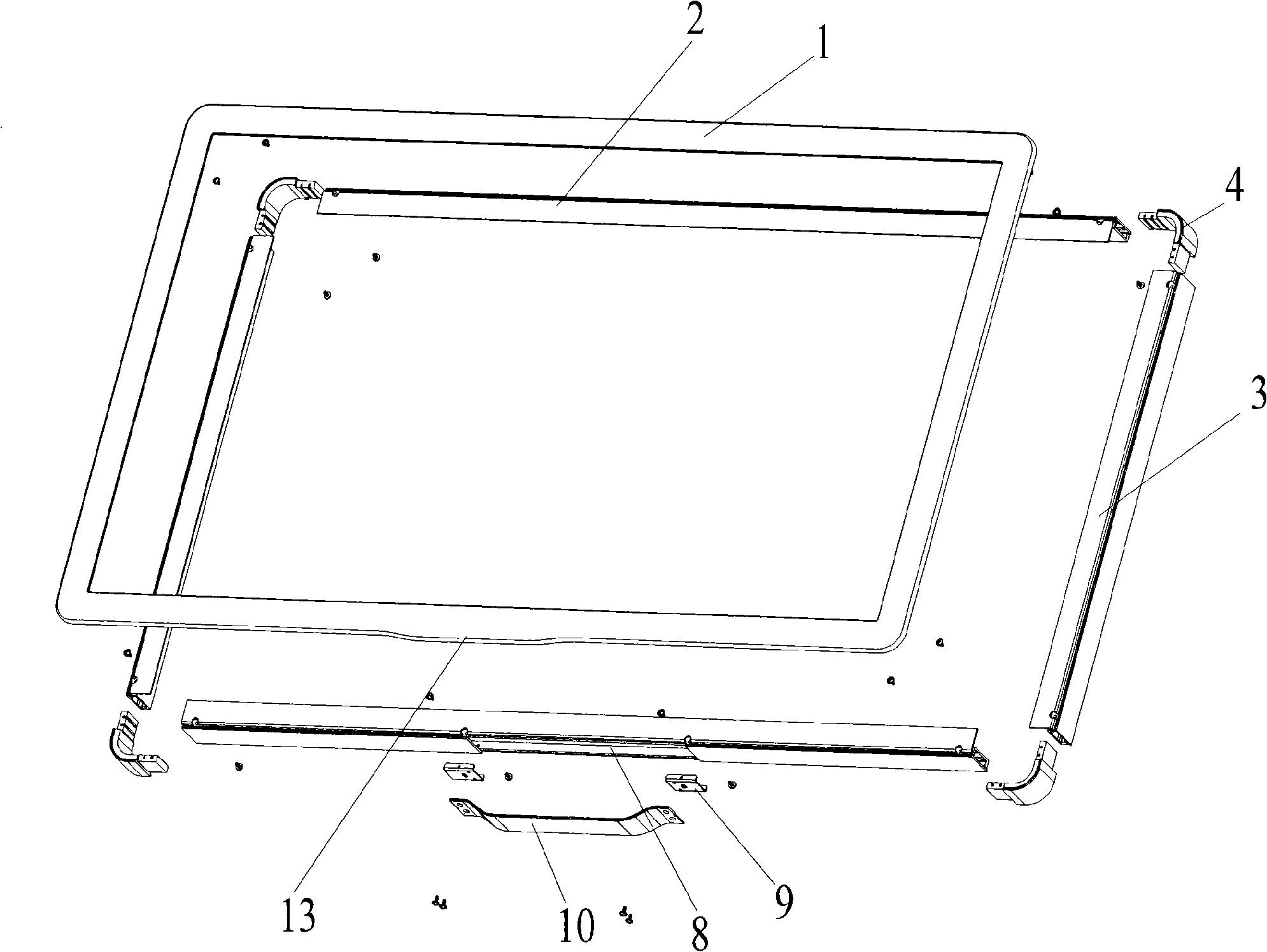

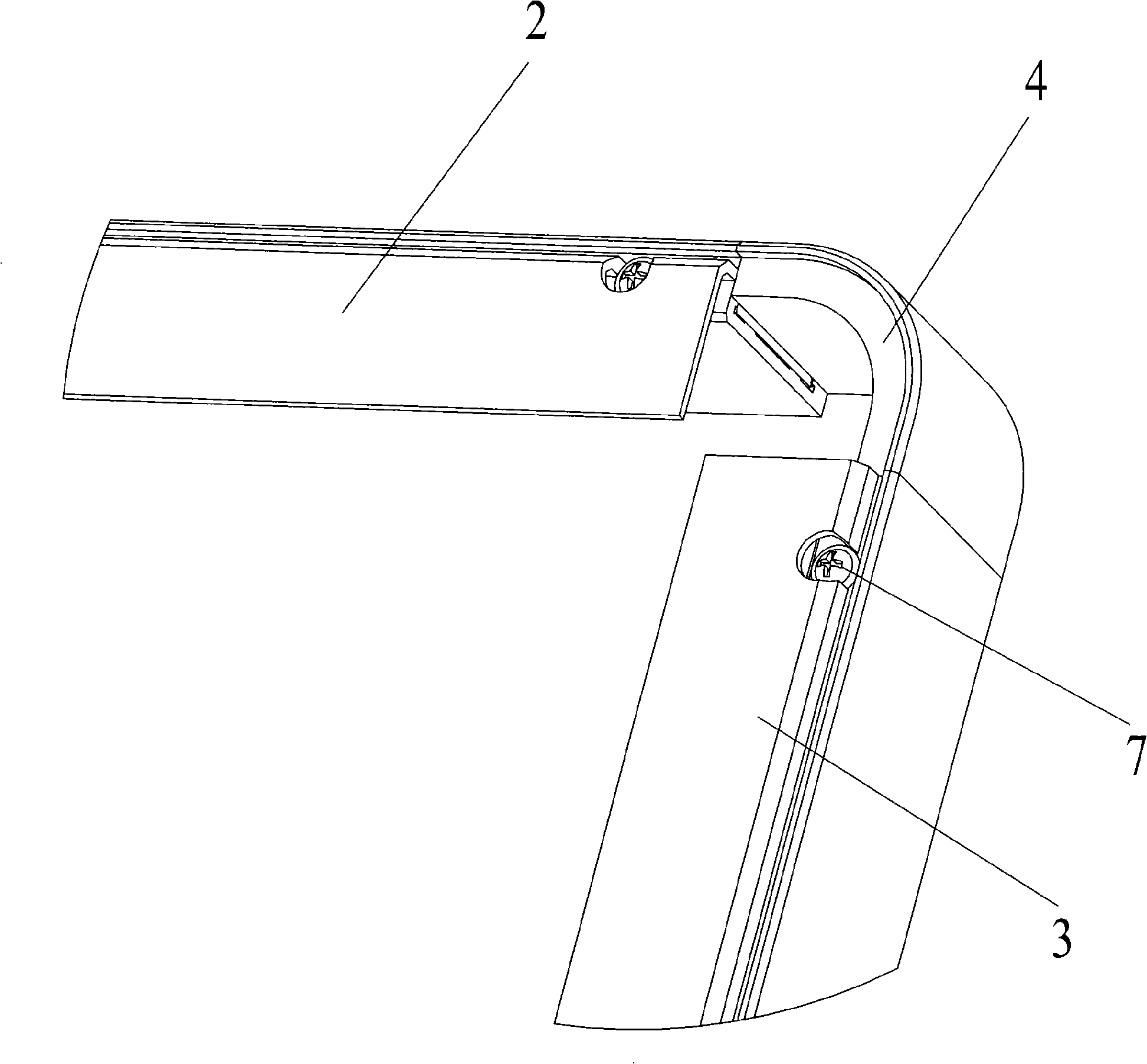

Metal frame of liquid crystal television

InactiveCN101291407ASteady metal textureGenerous metal textureTelevision system detailsColor television detailsMetallic materialsEngineering

The invention discloses an LCD TV metal frame, comprising a surface frame and a side frame, wherein the side frame comprises an upper horizontal bracket, a lower horizontal bracket, a left perpendicular bracket and a right perpendicular bracket; the upper horizontal bracket, the lower horizontal bracket, the left perpendicular bracket and the right perpendicular bracket comprise front parts parallel to the surface frame and side parts perpendicular to the surface frame; the horizontal brackets are fixed with end parts adjacent to the side parts of the perpendicular brackets through connection corners; four sides of the surface frame are respectively fixed on the front parts of the upper horizontal bracket, the lower horizontal bracket, the left perpendicular bracket and the right perpendicular bracket. The metal frame can allow a TV to have stable and graceful metal textural quality. The horizontal brackets and the perpendicular brackets of the metal frame can be identical in section structure and are convenient for mass production and popularization. Metal material can be recycled, which is beneficial to environmental protection.

Owner:SUZHOU VICTORY PRECISION MFG

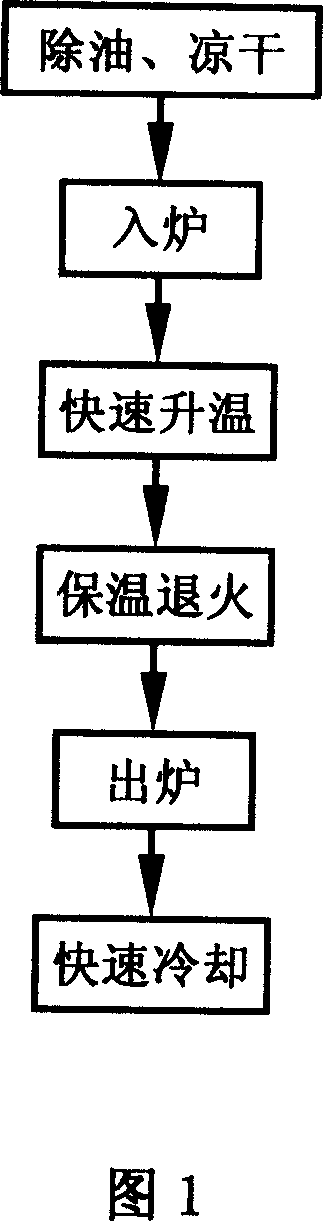

Quick annealing method for titanium seamless pipe

InactiveCN101086056AIncrease productivityReduce energy consumptionIncreasing energy efficiencyFurnace typesAutomatic controlIntermediate frequency

This invention discloses a method for annealing ti-seamless tubes. It comprises following steps: putting titanium tube into intermediate frequency induction annealing furnace orderly, heating to crystallization temperature rapidly when crossing intermediate frequency induction annealing furnace, restraining 'recovery' process, finishing recrystallization rapidly, cooling to room temperature fast, restraining ' grain growth' and high temperature oxidation. It only need several minutes for heating, thermal insulating and cooling for one titanium tube. It solves the technical problems of low production efficiency and high cost in background technology. The invention is characterized by automatic control, suitability for different length tubes annealing, mass or small production and excellent performance.

Owner:WESTERN TITANIUM TECH

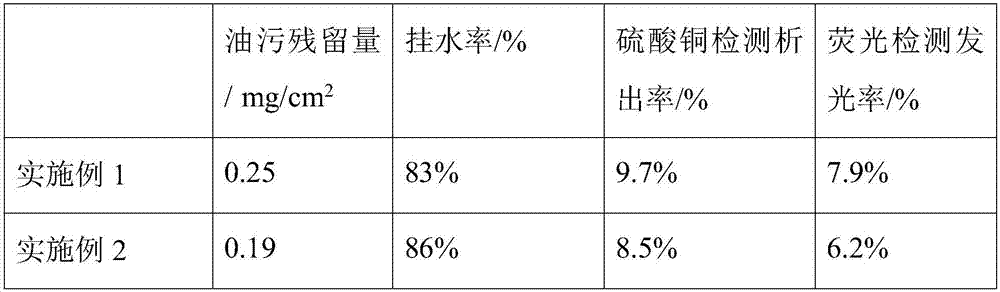

Oil-removing and cleaning process for automobile part

The invention discloses an oil-removing and cleaning process for an automobile part. The oil-removing and cleaning process comprises the following steps of: removing floating oil; performing acid pickling; performing water washing; removing oil of acid liquor; removing oil of alkali liquor; and performing water washing and drying. The oil-removing and cleaning process utilizes various oil-removing methods to perform deep oil-removing operation on the automobile part, so that the surface f the automobile part is smoother, follow-up surface treatment of the automobile part is convenient, and surface treated substance drop caused by residual oil on the surface of the automobile part is prevented.

Owner:ANHUI CAREMIC CONSULTING CO LTD

Oxidation polymerization type corrosion prevention method

The invention relates to a corrosion prevention technology, and in particular relates to an oxidation polymerization type corrosion prevention method which is suitable for iron and steel structures of electric power plants, stay cables of bridges, various storage tank edge plates, oil-gas pipelines, valves, flanges, H-section steel, spherical joints, screws, screw caps and mechanical equipment with various complex structures. According to the method, a corrosion prevention cream, a filling material and a corrosion prevention belt are arranged on the surface of a protected steel body in sequence, and then an adhesive is brushed on the outer surface layer of the corrosion prevention belt; the corrosion prevention cream can be used for filling corrosion hole parts, and can be used for construction with rust and original coatings, namely the surface of a protected object which is coated can be simply treated, so that the labor cost is saved, and the construction efficiency is high. The filling material is used at shaped parts of flanges, valves, storage tanks, spherical joints, screws, screw caps and the like, and is convenient in molding. The chemical compounds soaked on the corrosion prevention belt have good adhesive force, can obstruct the contact between metals and corrosive media including water, air and the like, and has good corrosion prevention performance; the corrosion prevention belt has good flexibility and structural displacement tracing ability and can be closely matched with the protected article.

Owner:侯保荣 +1

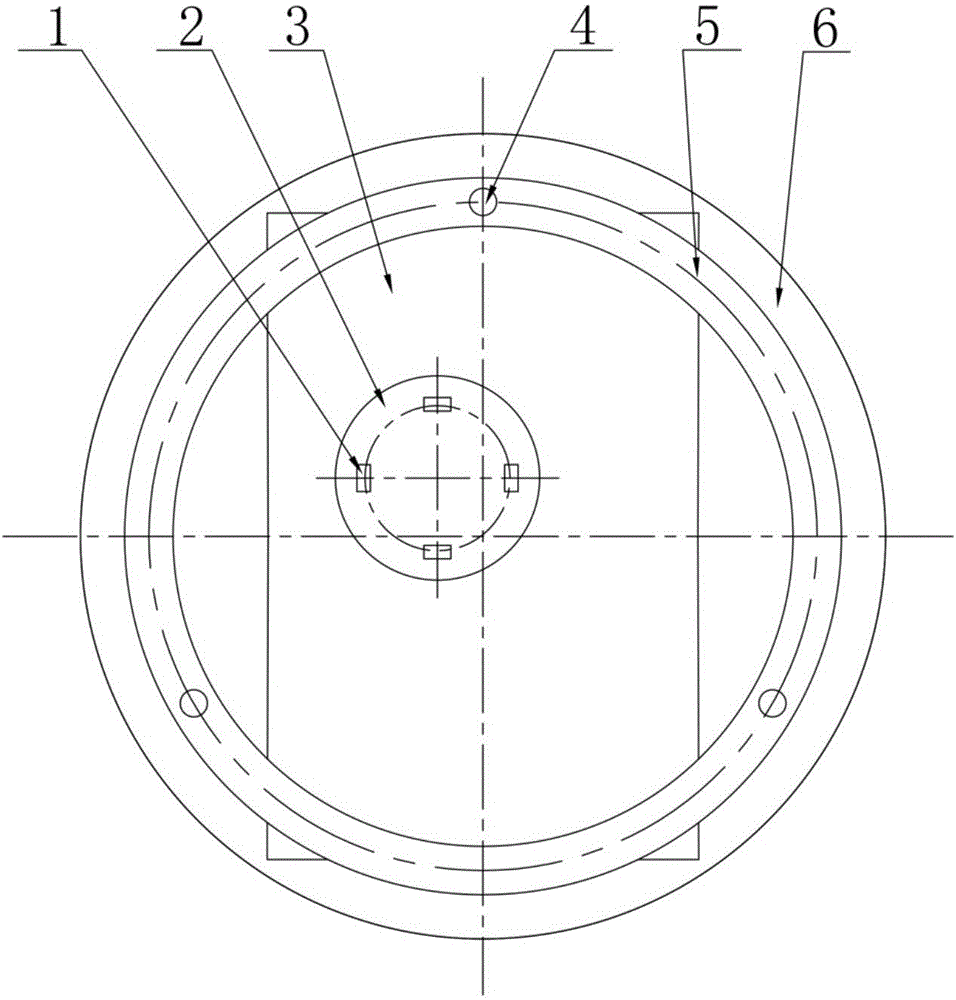

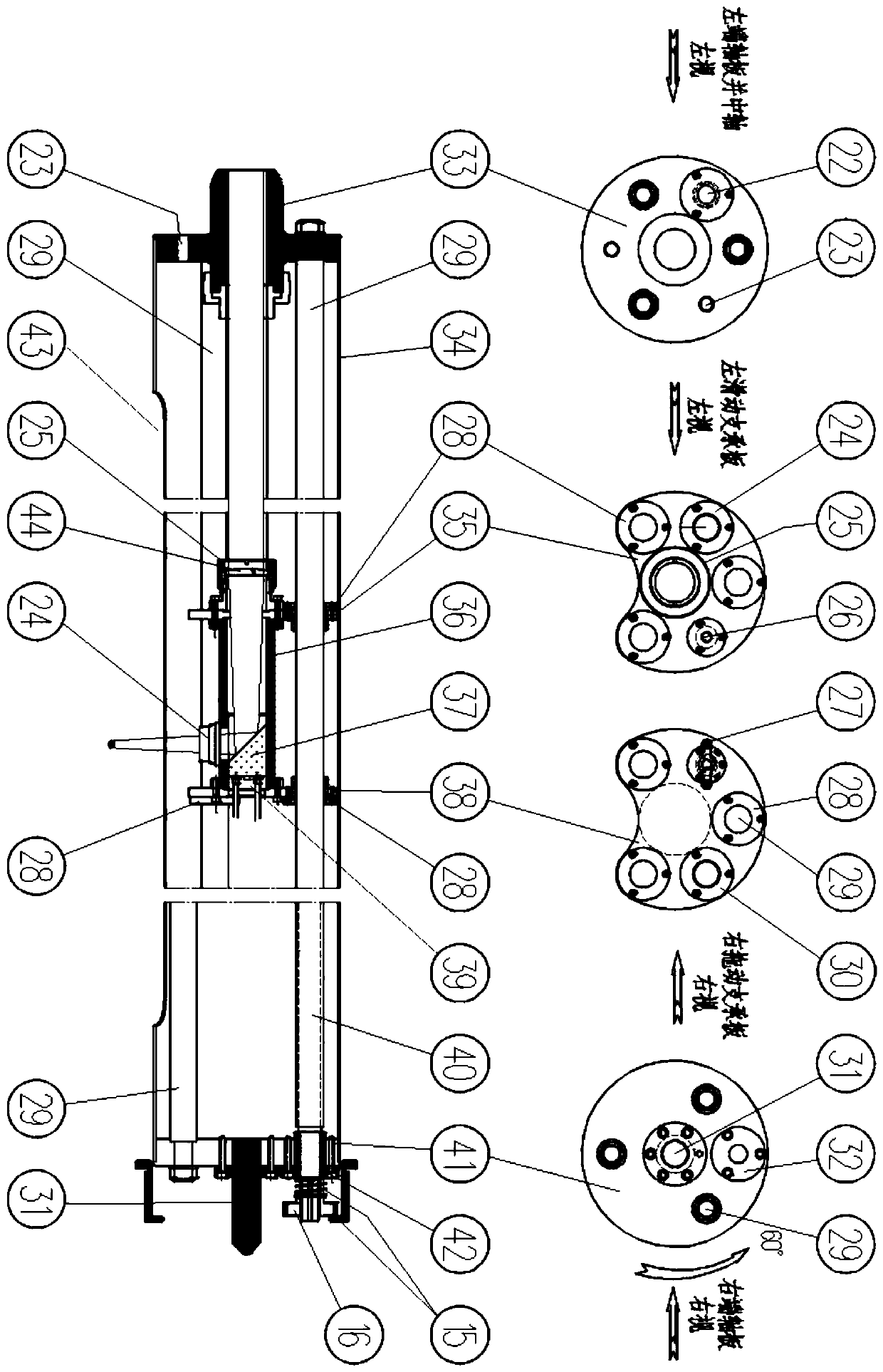

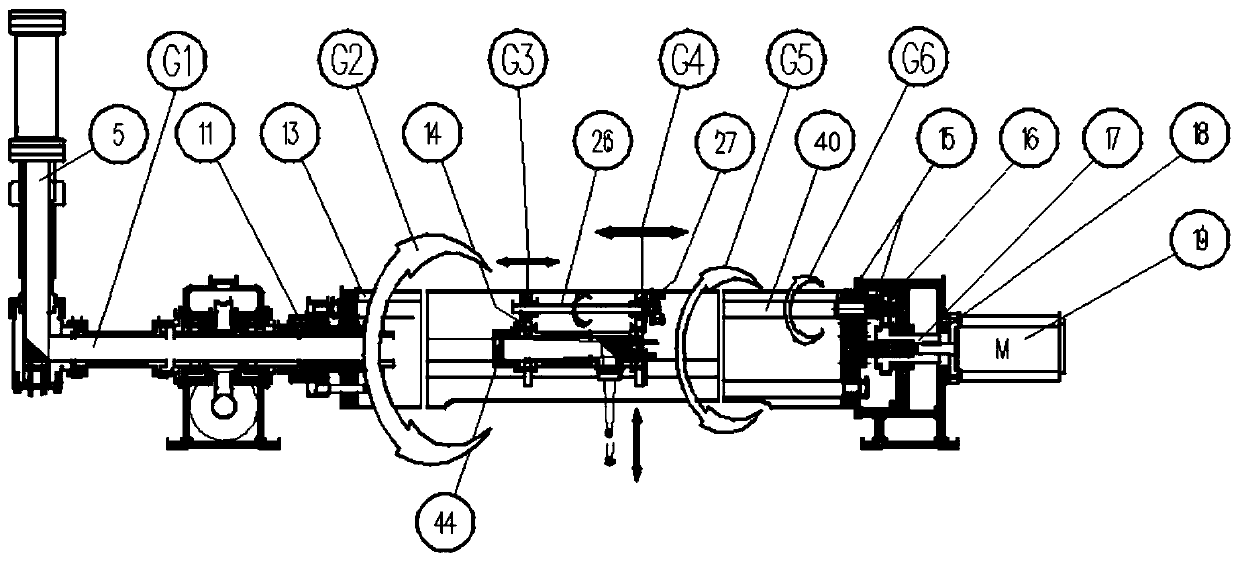

High-power semiconductor laser surface treatment device for inner walls of large long barrels

InactiveCN109739023ASolve the key problem of being too heavy to achieve rotationSimple surface treatmentMetallic material coating processesMountingsLaser processingPipe fitting

The invention discloses a high-power semiconductor laser surface treatment device for the inner walls of large long barrels. The device comprises a laser generation assembly, a laser beam expander anda laser processing beam type central rotating shaft, wherein the laser processing beam type central rotating shaft is arranged in a to-be-processed pipe fitting during use, and is provided with a shaft internal light guide channel; laser is transmitted through the shaft internal light guide channel after being shaped by the laser beam expander; a translation machine frame is further arranged in the laser processing beam type central rotating shaft, can rotate along with the rotation of the laser processing beam type central rotating shaft, and is used for driving a focusing assembly and a laser turning mirror to horizontally move in the laser processing beam type central rotating shaft; and the length of the to-be-processed pipe fitting is more than 10 meters. For the inner walls of largelong barrel workpieces such as ocean equipment, oil transportation pipelines, chemical equipment, tunneling equipment, coal mining equipment and the like, a high-power semiconductor laser cladding technology is used for enhancing the performances such as the wear resistance, the corrosion resistance and the like of the surfaces of the inner walls of the selected workpieces, so that the service lives of the workpieces are greatly prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

Metal surface treatment method based on chitosan and mussel adhesion protein composite membrane

ActiveCN104862757AGood biocompatibility and degradabilitySimple surface treatmentElectrolytic organic material coatingChemistryMetal

The invention discloses a metal surface treatment method based on a chitosan and mussel adhesion protein composite membrane, and relates to high-molecular compounds. The method comprises specific steps that step-by-step polishing, ultrasonic cleaning and drying are carried out on a metal material surface to be treated, and then an electro-deposition is adopted to enable chitosan and mussel adhesion protein to form a composite membrane layer on the metal material surface; and electro-deposition specifically comprises the steps that chitosan is added into a chitosan buffer solution to form a chitosan solution; the mussel adhesion protein is added into a mussel adhesion protein buffer solution to form a mussel adhesion protein solution; and the metal material to be treated is sequentially immersed into the chitosan solution and the mussel adhesion protein solution to be electrically deposited, and after drying, the composite membrane layer is formed on the metal material surface. The composite membrane layer is formed on the metal material surface, and the electro-deposition step can be repeatedly carried out to form multiple composite coatings. The method is simple, easy to implement and particularly suitable for corrosion prevention of metallic biomaterials.

Owner:XIAMEN UNIV

Solvent-free type epoxy zinc rich primer and preparation method thereof

Owner:JIANGSU DAZHONG NEW MATERIAL TECH CO LTD

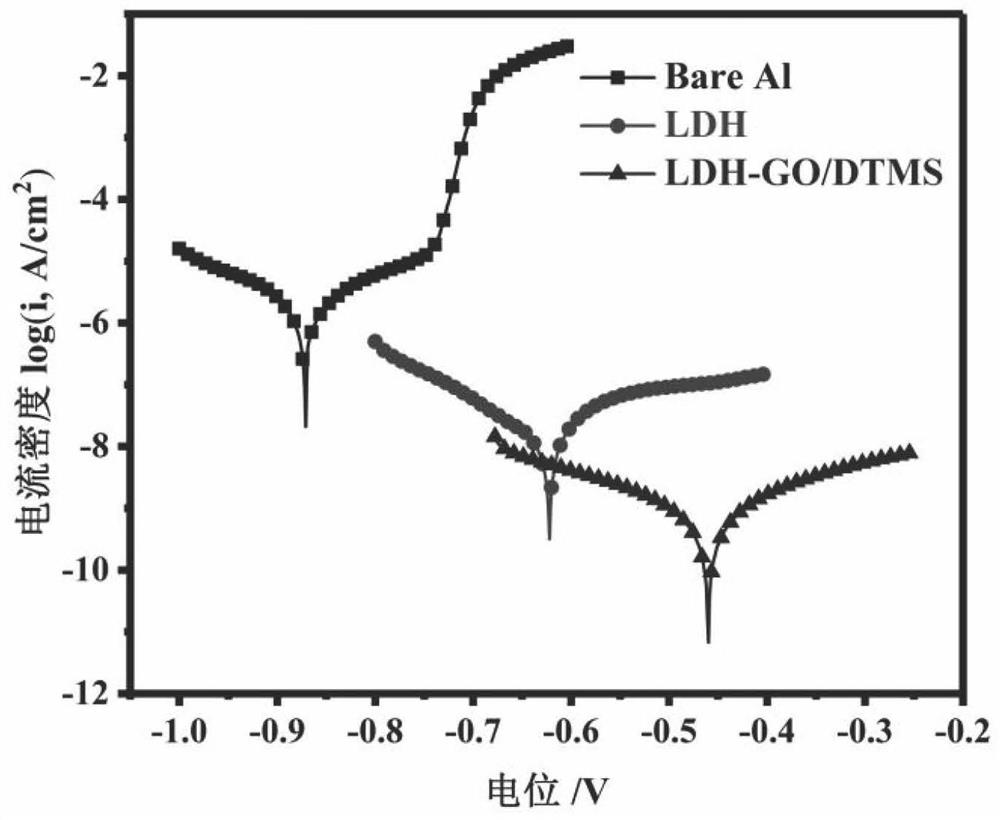

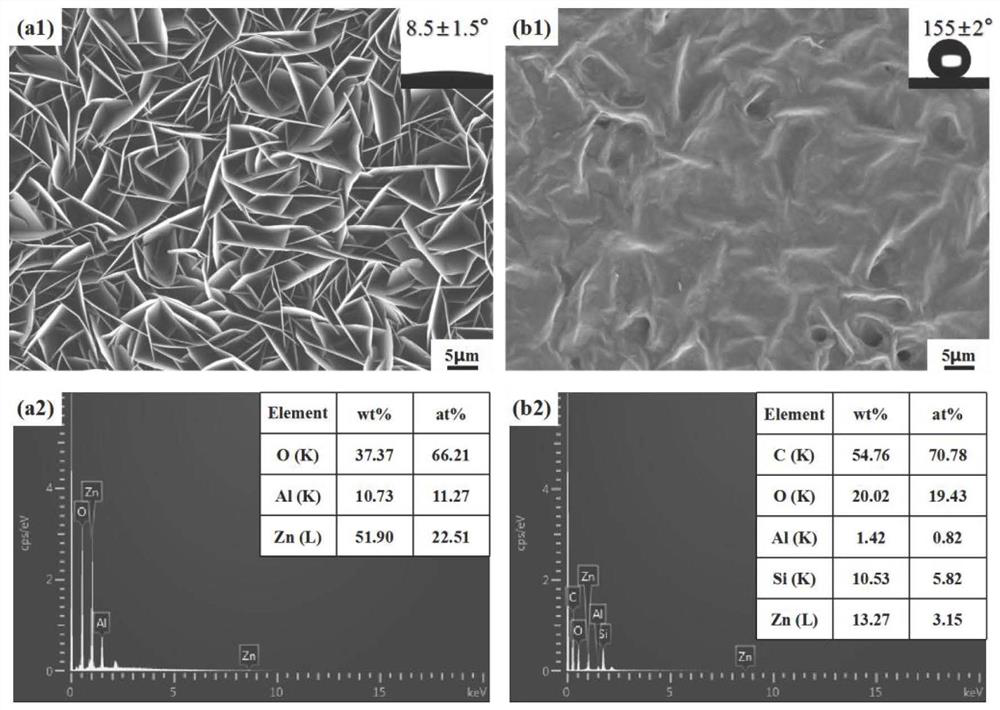

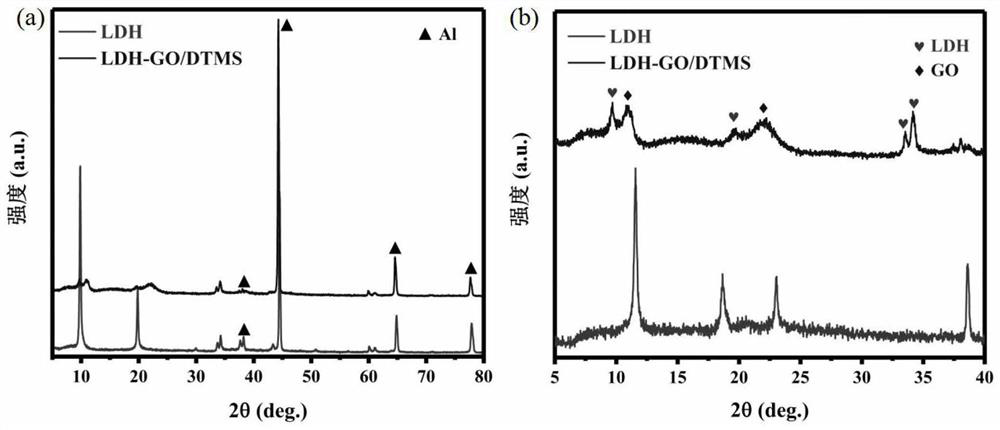

Aluminum alloy workpiece with layered double hydroxide-graphene oxide silane composite coating and preparation method of aluminum alloy workpiece

ActiveCN112553664ACompact structureStrong corrosion resistanceElectrolytic coatingsElectrolytic agentGraphite oxide

The invention belongs to the technical field of aluminum alloy surface treatment, and provides an aluminum alloy workpiece with a layered double hydroxide-graphene oxide silane composite coating and apreparation method of the aluminum alloy workpiece. The method comprises the following steps that S1, a mixed metal salt solution is prepared from aluminum salt and zinc salt, and the pH value of themixed metal salt solution is adjusted to 9-11; S2, the aluminum alloy workpiece is put into the mixed metal salt solution to be subjected to hydro-thermal treatment for a period of time, and the aluminum alloy workpiece subjected to thermal treatment is obtained; and S3, the aluminum alloy workpiece subjected to thermal treatment is put into a GO / DTMS ethanol solution, electro-deposition is conducted with the GO / DTMS ethanol solution as an electrolyte, a platinum electrode as an anode and the aluminum alloy workpiece as a cathode, and the layered double hydroxide-graphene oxide silane composite coating is deposited on the surface of the alloy workpiece. According to the aluminum alloy workpiece with the layered double hydroxide-graphene oxide silane composite coating and the preparation method of the aluminum alloy workpiece, the super-hydrophobic coating is prepared on the surface of the aluminum alloy, so that the corrosion resistance of the aluminum alloy in a saline solution is greatly improved; and in addition, the preparation method is simple, and large-scale preparation can be achieved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

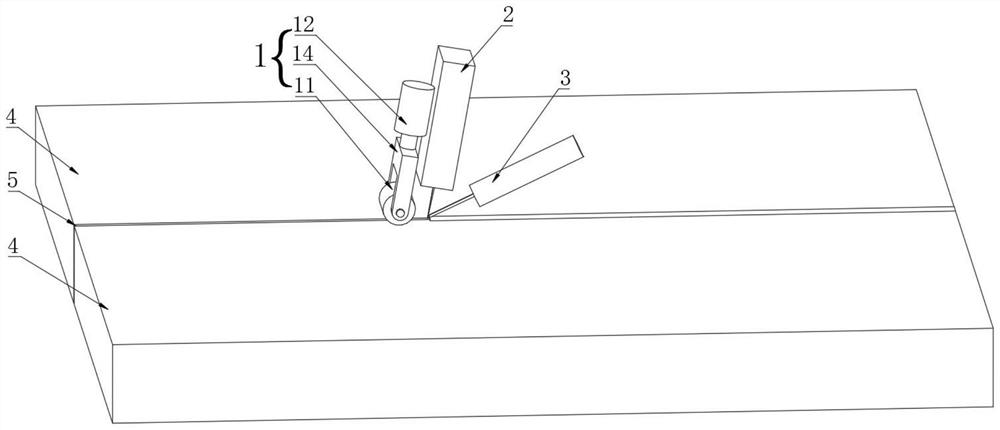

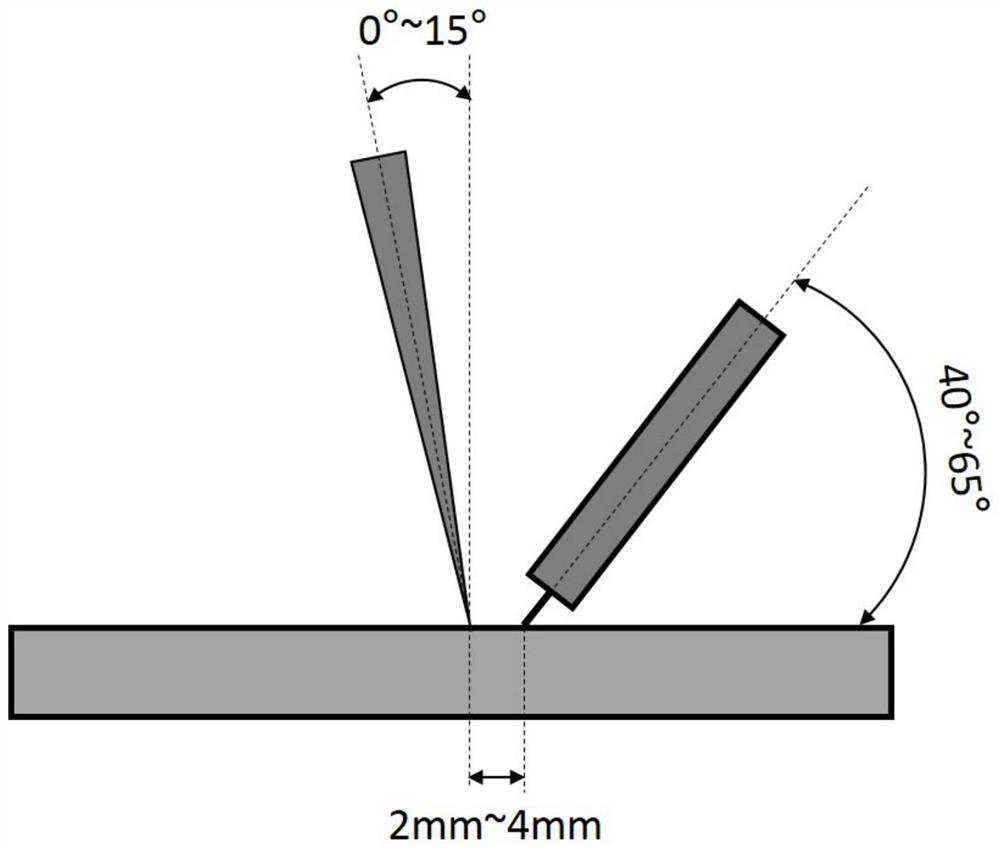

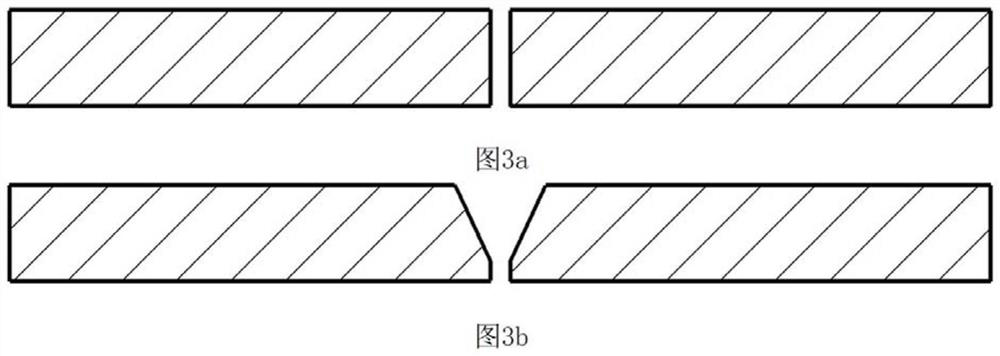

Welding system for aluminum alloy laser welding and surface treatment method

PendingCN113909678AReduce reflexesImprove welding qualityLaser beam welding apparatusSurface oxidationSurface roughness

The invention relates to the technical field of welding, in particular to a welding system for aluminum alloy laser welding. The welding system comprises a workbench, a surface machining device, a laser welding device and an electric arc welding device. A hard particle layer on a roller in the surface machining device is used for damaging a surface oxidation film of an aluminum alloy, so that the surface roughness of the aluminum alloy is improved, the reflection effect of the surface of the aluminum alloy on laser is effectively reduced, the welding process of the aluminum alloy is stabilized, and attractive and defect-free welding seams are obtained. Meanwhile, the invention further provides a surface treatment method of a to-be-welded part of the aluminum alloy by using the laser welding system, and a traditional surface treatment method used for laser or laser-arc welding hybrid welding of the aluminum alloy is changed, so that real-time treatment, namely surface treatment and the welding process of the surface of the be-welded part in the aluminum alloy welding process can be conducted synchronously, repeated treatment caused by the fact that the interval between surface pretreatment and the welding process is too long is avoided, the surface treatment method is simple and easy to operate, the welding pretreatment process is reduced, and the welding quality is improved.

Owner:HWI-NICHST WELDING & ENG INNOVATION CENT (QINGDAO) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com